HVDC Transmission Technology of Wind Power System with Multi-Phase PMSG

Abstract

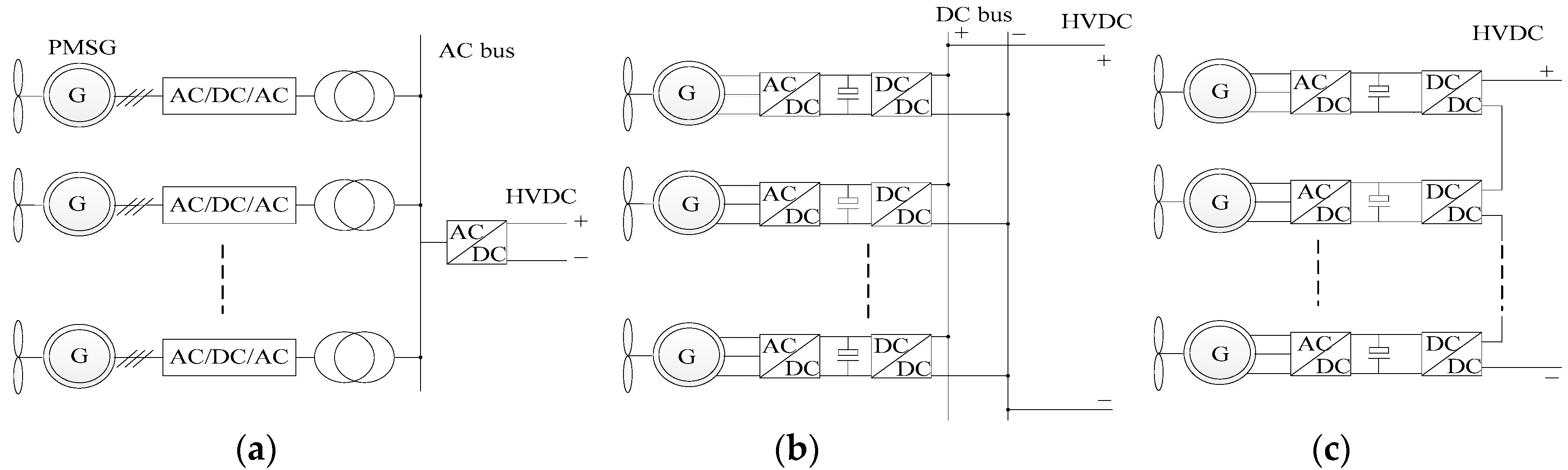

1. Introduction

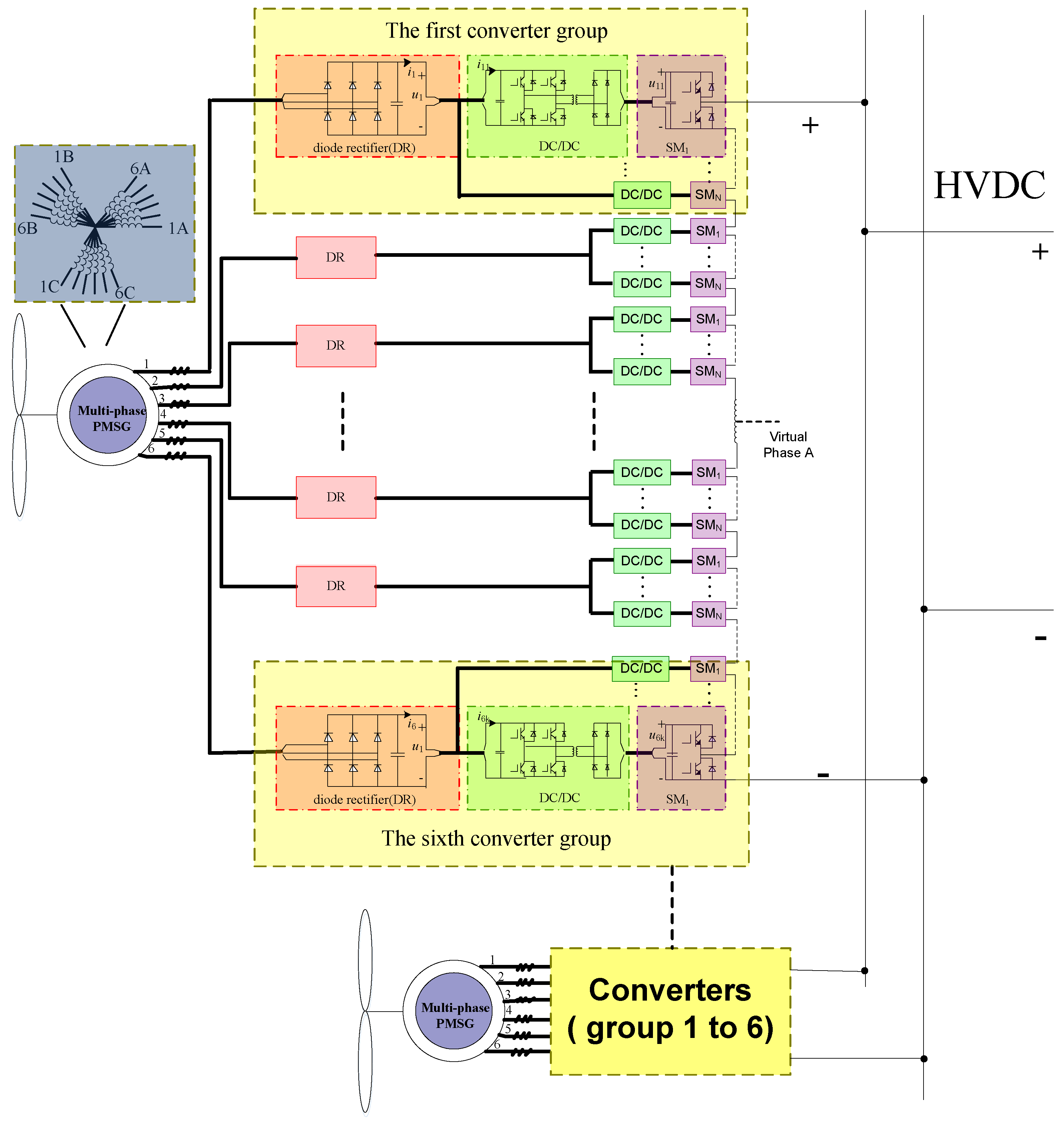

2. The System Topology and Working Principles

2.1. System Topology

2.2. Working Principles

2.3. Cost Analysis

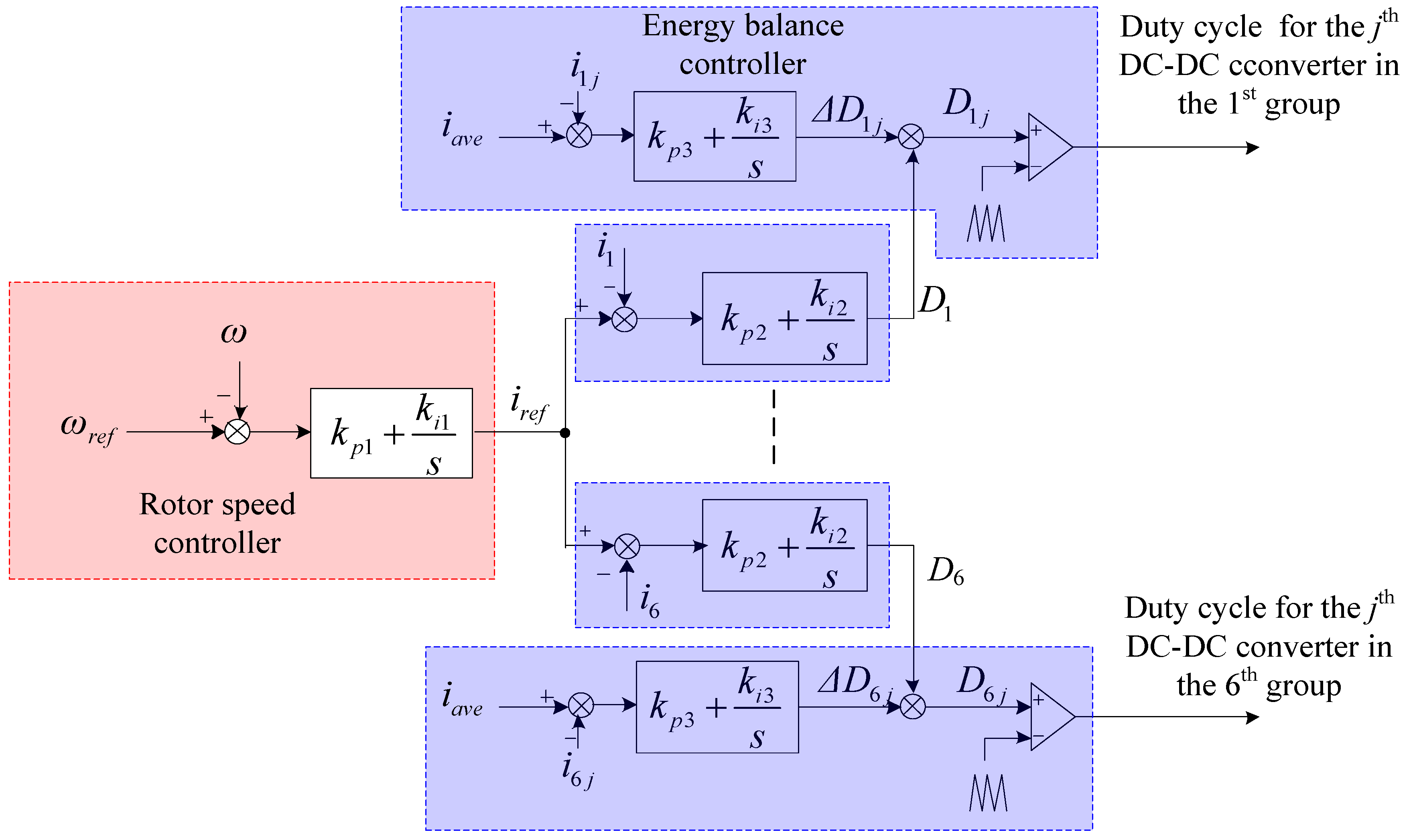

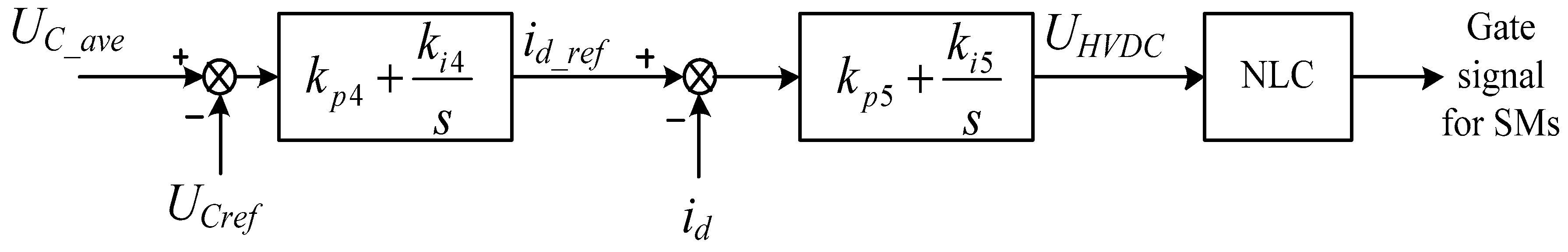

3. Control Method

3.1. MPPT Control

3.2. DC Transmission Current Control

4. Results and Discussion

4.1. Simulation Results

4.1.1. Wind Speed Changes

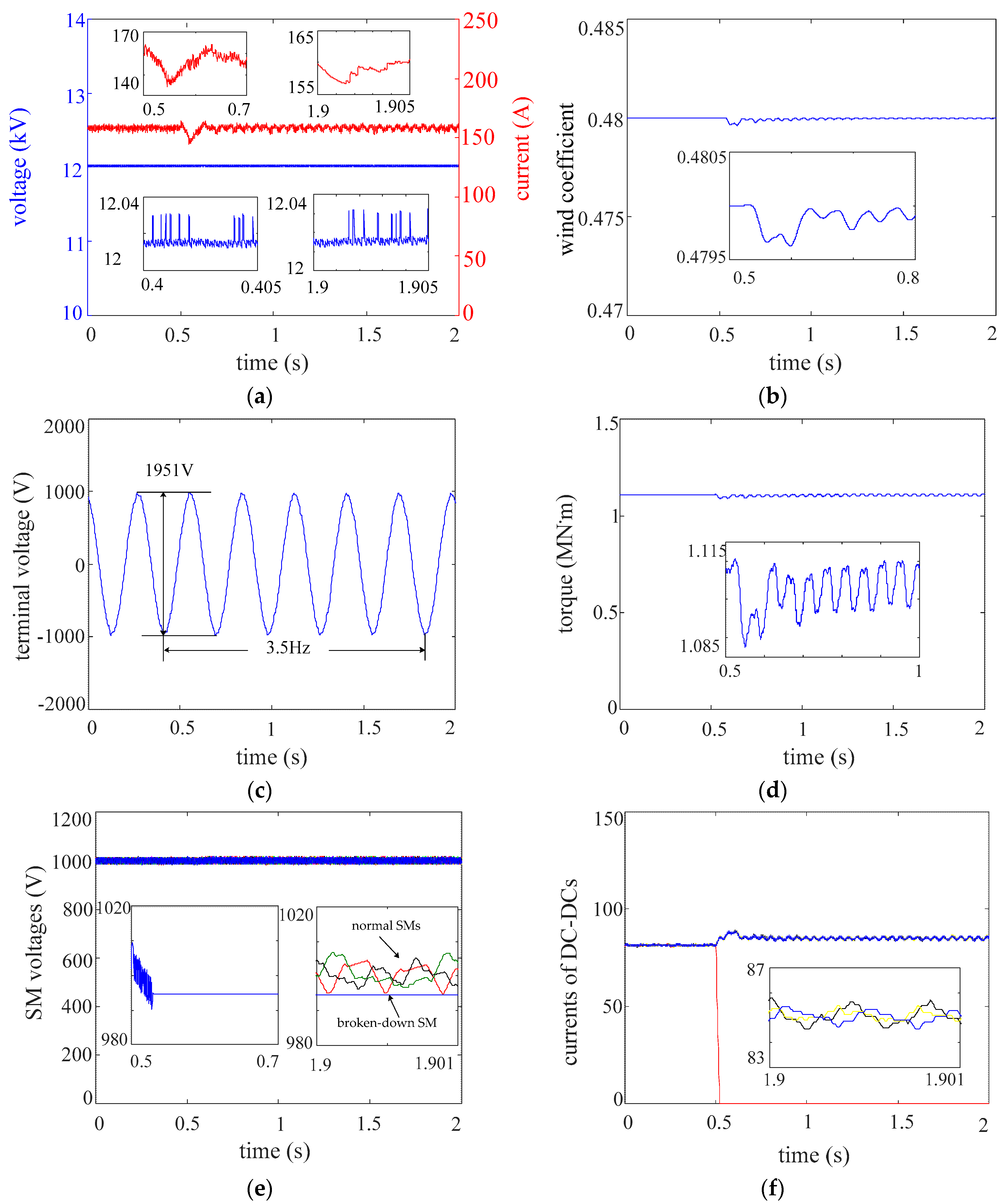

4.1.2. One DC–DC Converter Breaks Down

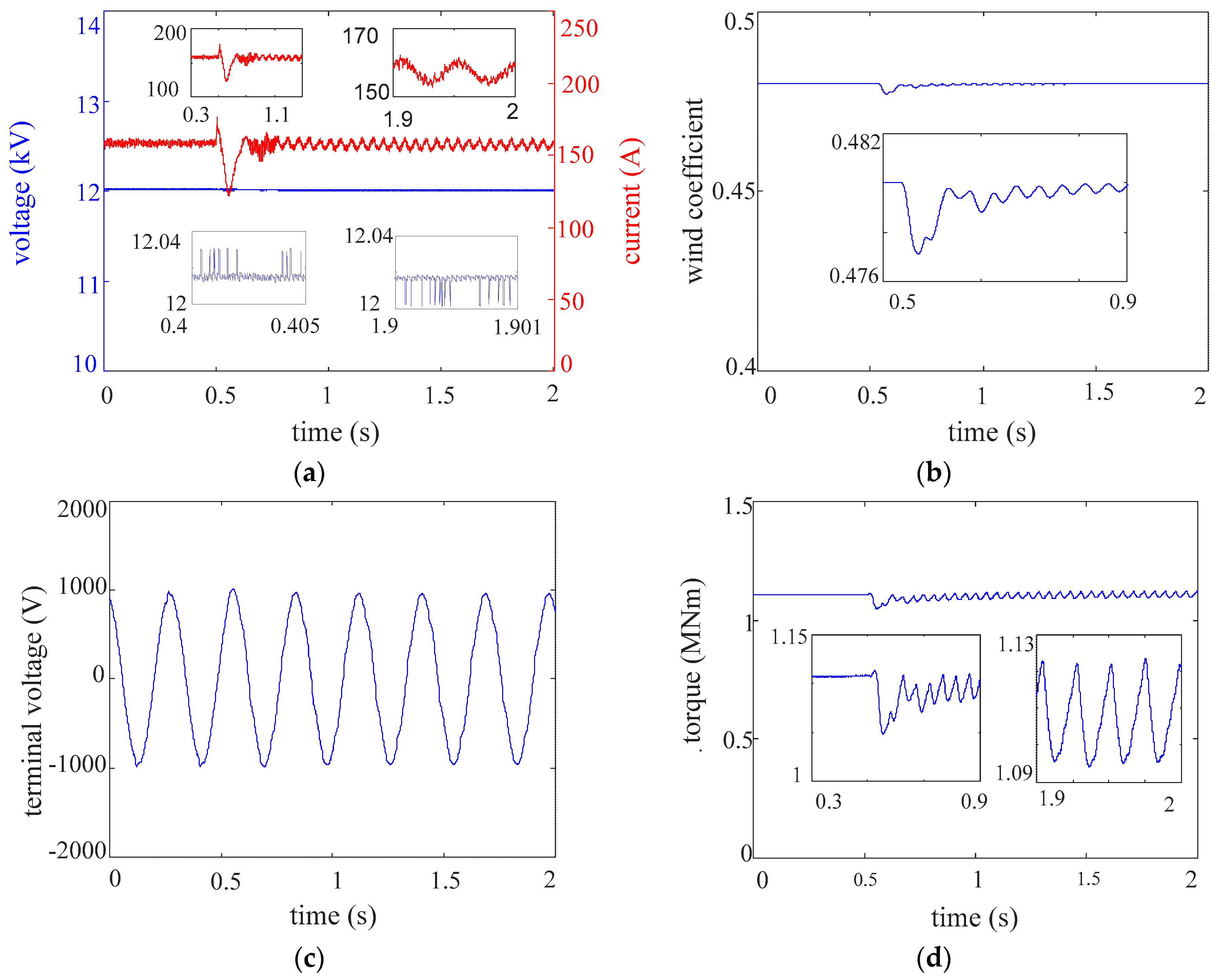

4.1.3. One Set of Three-Phase Winding Is Open Circuited

4.2. Experiment Results

4.2.1. Wind Speed Changes

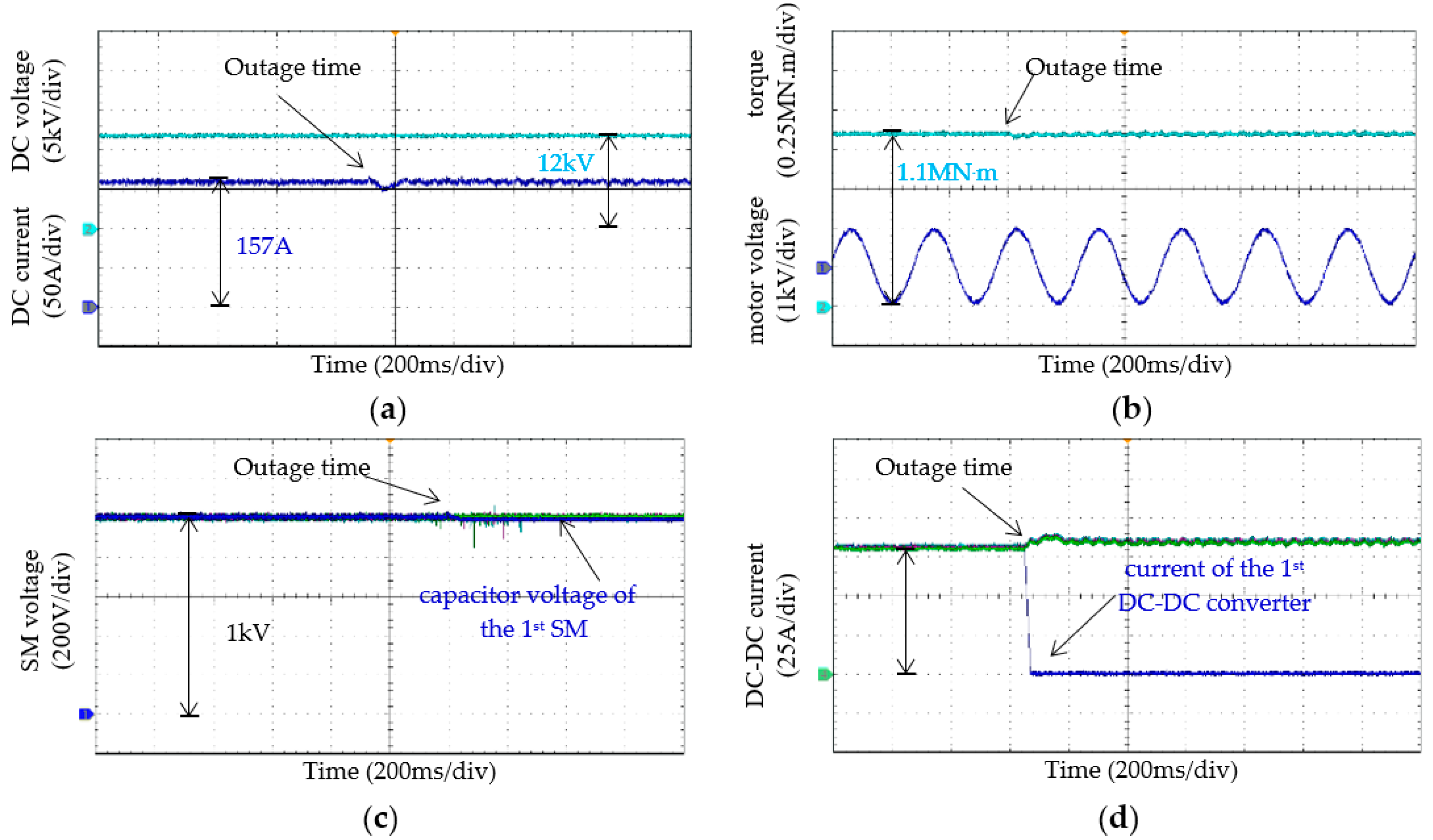

4.2.2. One DC–DC Converter Breaks Down

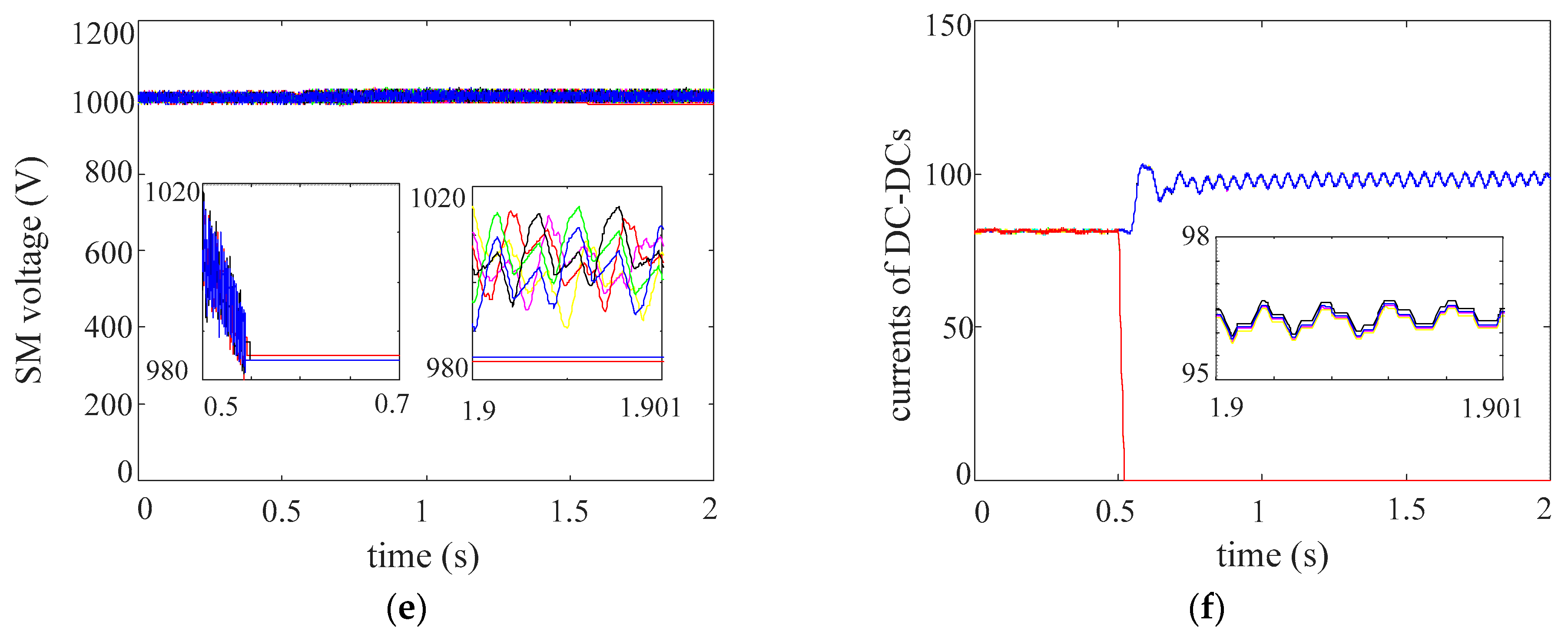

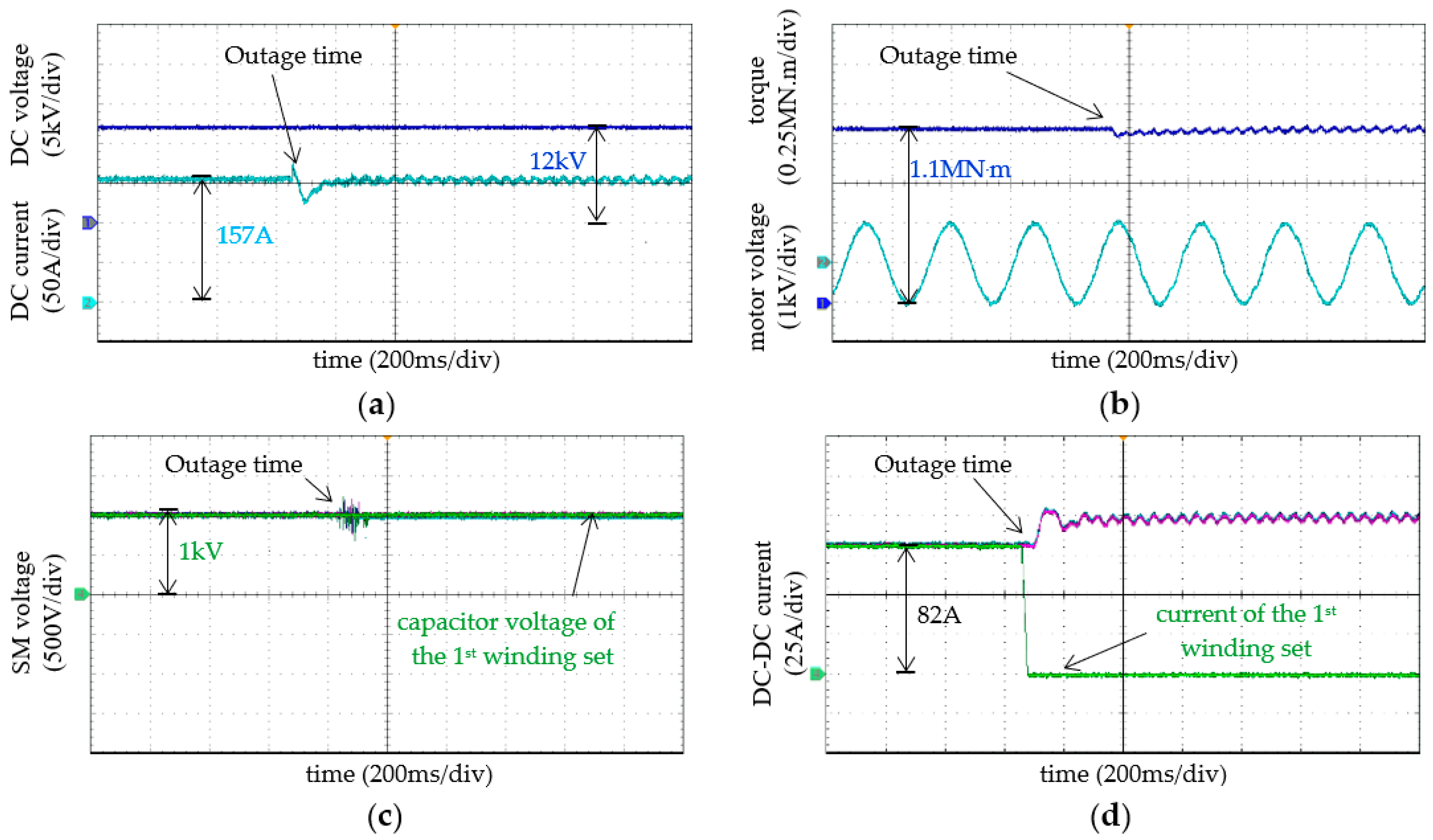

4.2.3. One Set of Three-Phase Winding Is Open Circuited

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| UHVDC | Voltage of high voltage DC grid (V) |

| N | Number of SMs |

| UDR | Voltage of the DC converter (V) |

| Kboost | Ratio of DC-DC converter |

| Nphase | Phase number of PMSG |

| Rotor speed and its reference (rad/s) | |

| Optimal tip speed ratio | |

| v | Wind speed (m/s) |

| iref | Diode rectifier output current reference |

| kp1, ki1, kp2, ki2, kp3, ki3, kp4, ki4 | Proportional and integral coefficients |

| ik | Output current of the kth diode rectifier (A) |

| ikj | Input current of the jth DC-DC converter in the kth converter group (A) |

| Dk | Duty cycle of the DC-DC converter in the kth converter group |

| iave | Average current of the parallel DC-DC converters (A) |

| UCref | Rated capacitor voltage of SM (V) |

| UCkj | Capacitor voltage of the jth SM in the kth converter group (V) |

| UC_ave | Average value of all SM capacitor voltages (V) |

| id, idref | DC transmission current and its reference (A) |

References

- Wu, Y.K.; Su, P.E. Economics- and Reliability-Based Design for an Offshore Wind Farm. IEEE Trans. Ind. Appl. 2017, 53, 5139–5149. [Google Scholar] [CrossRef]

- Verde, A.; Lastres, O.; Hernández, G.; Ibañez, G.; Verea, L.; Sebastiana, P.J. A new method for characterization of small capacity wind turbines with permanent magnet synchronous generator: An experimental study. Heliyon 2018, 4, 732. [Google Scholar] [CrossRef] [PubMed]

- Pedram, A.; Ramon, B.; Barzegaran, M.R.; Lapthorn, A.; Mewes, D. Load identification of different Halbach-array topologies on permanent magnet synchronous generators using the coupled field-circuit FE methodology. Electr. Power Syst. Res. 2018, 154, 484–492. [Google Scholar] [CrossRef]

- Wei, Q.; Liyan, Q.; Ronald, G.H. Control of IPM Synchronous Generator for Maximum Wind Power Generation Considering Magnetic Saturation. IEEE Trans. Ind. Appl. 2009, 45, 1095–1105. [Google Scholar] [CrossRef]

- Nasiri, M.; Milimonfared, J.; Fathi, S.H. A review of low-voltage ride-through enhancement methods for permanent magnet synchronous generator based wind turbines. Renew. Sustain. Energy Rev. 2015, 47, 399–415. [Google Scholar] [CrossRef]

- Yang, Z.; Chai, Y.; Yin, H.; Tao, S. LPV Model Based Sensor Fault Diagnosis and Isolation for Permanent Magnet Synchronous Generator in Wind Energy Conversion Systems. Appl. Sci. 2018, 8, 1816. [Google Scholar] [CrossRef]

- Ma, K.; Blaabjerg, F. Modulation Methods for Neutral-Point-Clamped Wind Power Converter Achieving Loss and Thermal Redistribution Under Low-Voltage Ride-Through. IEEE Trans. Ind. Electron. 2014, 61, 835–845. [Google Scholar] [CrossRef]

- Montilla-DJesus, M.E.; Santos-Martin, D.; Arnaltes, S. Optimal Operation of Offshore Wind Farms with Line-Commutated HVDC Link Connection. IEEE Trans. Energy Convers. 2010, 25, 504–513. [Google Scholar] [CrossRef]

- Mehdi, T.; Edris, P.; Jafar, A.; Radu, G. Load-frequency control in a multi-source power system connected to wind farms through multi terminal HVDC systems. Comput. Oper. Res. 2018, 96, 305–315. [Google Scholar] [CrossRef]

- Prada, M.D.; Igualada, L.; Corchero, C. Hybrid AC-DC Offshore Wind Power Plant Topology: Optimal Design. IEEE Trans. Power Syst. 2015, 30, 1868–1876. [Google Scholar] [CrossRef]

- Liu, H.; Chen, Z. Contribution of VSC-HVDC to Frequency Regulation of Power Systems with Offshore Wind Generation. IEEE Trans. Energy Convers. 2015, 30, 918–926. [Google Scholar] [CrossRef]

- Muyeen, S.M.; Takahashi, R.; Tamura, J. Operation and Control of HVDC-Connected Offshore Wind Farm. IEEE Trans. Sustain. Energy 2010, 1, 30–37. [Google Scholar] [CrossRef]

- Wang, X.; Wei, X.; Meng, Y. Experiment on Grid-Connection Process of Wind Turbines in Fractional Frequency Wind Power System. IEEE Trans. Energy Convers. 2015, 30, 22–31. [Google Scholar] [CrossRef]

- Egea-Alvarez, A.; Bianchi, F.; Junyent-Ferre, A. Voltage Control of Multiterminal VSC-HVDC Transmission Systems for Offshore Wind Power Plants: Design and Implementation in a Scaled Platform. IEEE Trans. Ind. Electron. 2013, 60, 2381–2391. [Google Scholar] [CrossRef]

- Beik, O.; Schofield, N. An Offshore Wind Generation Scheme with a High-Voltage Hybrid Generator, HVDC Interconnections, and Transmission. IEEE Trans. Power Deliv. 2016, 31, 867–877. [Google Scholar] [CrossRef]

- Gandomkar, A.; Parastar, A.; Seok, J.K. High-Power Multilevel Step-Up DC/DC Converter for Offshore Wind Energy Systems. IEEE Trans. Ind. Electron. 2016, 63, 7574–7585. [Google Scholar] [CrossRef]

- Adam, G.P.; Gowaid, I.A.; Finney, S.J. Review of dc–dc converters for multi-terminal HVDC transmission networks. IET Power Electron. 2016, 9, 281–296. [Google Scholar] [CrossRef]

- Dey, S.; Samajdar, D.; Bhattacharya, T. A modular DC-DC converter topology for HVDC applications. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017. [Google Scholar]

- Barrenetxea, M.; Baraia, I.; Larrazabal, I. Analysis, comparison and selection of DC-DC converters for a novel modular energy conversion scheme for DC offshore wind farms. In Proceedings of the IEEE EUROCON 2015—International Conference on Computer as a Tool (EUROCON), Salamanca, Spain, 8–11 September 2015. [Google Scholar]

- Chuangpishit, S.; Tabesh, A.; Moradi-Shahrbabak, Z. Topology Design for Collector Systems of Offshore Wind Farms with Pure DC Power Systems. IEEE Trans. Ind. Electron. 2014, 61, 320–328. [Google Scholar] [CrossRef]

- Sakamuri, J.N.; Rather, Z.H.; Rimez, J. Coordinated Voltage Control in Offshore HVDC Connected Cluster of Wind Power Plants. IEEE Trans. Sustain. Energy 2016, 7, 1592–1601. [Google Scholar] [CrossRef]

- Veilleux, E.; Lehn, P.W. Interconnection of Direct-Drive Wind Turbines Using a Series-Connected DC Grid. IEEE Trans. Sustain. Energy 2014, 5, 139–147. [Google Scholar] [CrossRef]

- Shi, G.; Zhang, J.; Cai, X. Improved variable speed control of series-connected DC wind turbines for offshore wind power collection to high-voltage direct current system. IET Renew. Power Gener. 2016, 10, 843–851. [Google Scholar] [CrossRef]

- Abdeltawab, H.H.; Mohamed, Y.A.R.I. Robust Energy Management of a Hybrid Wind and Flywheel Energy Storage System Considering Flywheel Power Losses Minimization and Grid-Code Constraints. IEEE Trans. Ind. Electron. 2016, 63, 4242–4254. [Google Scholar] [CrossRef]

- Lu, S.Y.; Wang, L.; Lo, T.M. Integration of Wind Power and Wave Power Generation Systems Using a DC Microgrid. IEEE Trans. Ind. Appl. 2015, 51, 2753–2761. [Google Scholar] [CrossRef]

- Gonzalez-Prieto, I.; Duran, M.J.; Che, H.S. Fault-Tolerant Operation of Six-Phase Energy Conversion Systems with Parallel Machine-Side Converters. IEEE Trans. Power Electron. 2016, 31, 3068–3079. [Google Scholar] [CrossRef]

- Shao, L.; Hua, W.; Dai, N. Mathematical Modeling of a 12-Phase Flux-Switching Permanent-Magnet Machine for Wind Power Generation. IEEE Trans. Ind. Electron. 2016, 63, 504–516. [Google Scholar] [CrossRef]

- Elserougi, A.A.; Daoud, M.I.; Abdel-Khalik, A.S. Series-connected multi-half-bridge modules converter for integrating multi-megawatt wind multi-phase permanent magnet synchronous generator with dc grid. IET Electr. Power Appl. 2017, 11, 981–990. [Google Scholar] [CrossRef]

- Chiniforoosh, S. Dynamic Average Modeling of Front-End Diode Rectifier Loads Considering Discontinuous Conduction Mode and Unbalanced Operation. IEEE Trans. Power Deliv. 2012, 27, 421–429. [Google Scholar] [CrossRef]

- Prafullachandra, M.M.; Vijay, B.B. A Simplified Nearest Level Control (NLC) Voltage Balancing Method for Modular Multilevel Converter (MMC). IEEE Trans. Power Electron. 2015, 30, 450–462. [Google Scholar] [CrossRef]

- Wang, H.; Yang, J.; Chen, Z.; Ge, W.; Hu, S.; Ma, Y.; Li, Y.; Zhang, G.; Yang, L. Gain Scheduled Torque Compensation of PMSG-Based Wind Turbine for Frequency Regulation in an Isolated Grid. Energies 2018, 11, 1623. [Google Scholar] [CrossRef]

- Xia, Y.; Ahmed, K.H.; Williams, B.W. Wind Turbine Power Coefficient Analysis of a New Maximum Power Point Tracking Technique. IEEE Trans. Ind. Electron. 2013, 60, 1122–1132. [Google Scholar] [CrossRef]

| Items | Proposed Topology | Topology 1 Figure 1a | Topology 2 Figure 1b | Topology 3 Figure 1c |

|---|---|---|---|---|

| IGBT | 6S | 14S | 15.5S | 7.5S |

| diode | 7.5S | - | - | 4S |

| transformer frequency | high | low | high | high |

| transformer ratio | low | high | high | low |

| ESS | no | no | no | need |

| Items | Parameter | Value |

|---|---|---|

| PMSG | phase number | 18 |

| structure | Asymmetrical, six neutral points | |

| rated power | 2 MW | |

| rated voltage | 690 V | |

| rated speed | 17.5 rpm | |

| pole pairs | 12 | |

| stator resistance | 2 mΩ | |

| leakage inductance | 0.1 mH | |

| PM flux linkage | 5.1 Wb | |

| HVDC | rated voltage of SM | 1000 V |

| capacitance of SM | 4 mF/each | |

| Inductance | 10 mH | |

| rated DC transmission voltage | 12 kV | |

| number of SMs in each bridge arm | 12 | |

| controller | control frequency | 5 kHz |

| kp1, ki1 | 70, 250 | |

| kp2, ki2 | 0.1, 10 | |

| kp3, ki3 | 1, 10 | |

| kp4, ki4 | 5, 201 | |

| kp5, ki5 | 1.3, 100 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Rong, F.; Yin, Z.; Huang, S.; Zhou, Y. HVDC Transmission Technology of Wind Power System with Multi-Phase PMSG. Energies 2018, 11, 3294. https://doi.org/10.3390/en11123294

Zhou S, Rong F, Yin Z, Huang S, Zhou Y. HVDC Transmission Technology of Wind Power System with Multi-Phase PMSG. Energies. 2018; 11(12):3294. https://doi.org/10.3390/en11123294

Chicago/Turabian StyleZhou, Shijia, Fei Rong, Zhangtao Yin, Shoudao Huang, and Yuebin Zhou. 2018. "HVDC Transmission Technology of Wind Power System with Multi-Phase PMSG" Energies 11, no. 12: 3294. https://doi.org/10.3390/en11123294

APA StyleZhou, S., Rong, F., Yin, Z., Huang, S., & Zhou, Y. (2018). HVDC Transmission Technology of Wind Power System with Multi-Phase PMSG. Energies, 11(12), 3294. https://doi.org/10.3390/en11123294