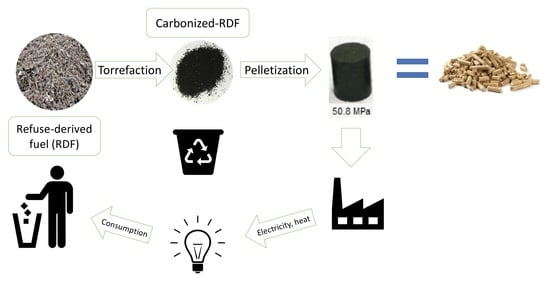

Waste to Carbon: Densification of Torrefied Refuse-Derived Fuel

Abstract

1. Introduction

- (a)

- the CS of CRDF pellets increases with the applied pressure during pelletization;

- (b)

- the CS of CRDF pellets increases with the addition of water glass as a binder and as a coating, and;

- (c)

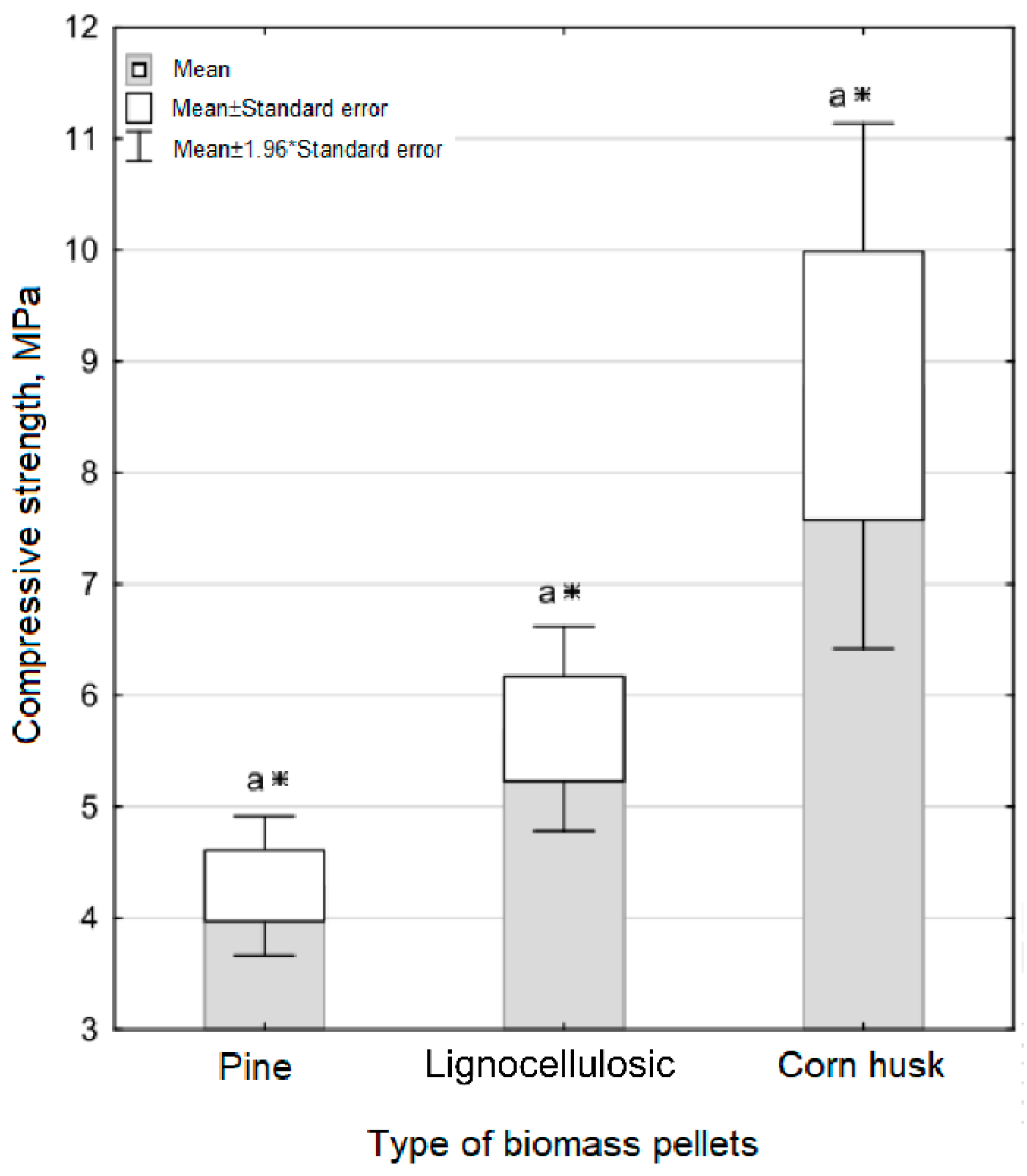

- the CS of CRDF pellets is comparable to conventional biomass pellets.

2. Materials and Methods

2.1. CRDF Used in Experiments

2.2. Biomass Pellets (Reference) Used in the Experiment

2.3. Experimental Design

- Modification of the CRDF structure by applying controlled pressure (i.e., densification via pelletizing).

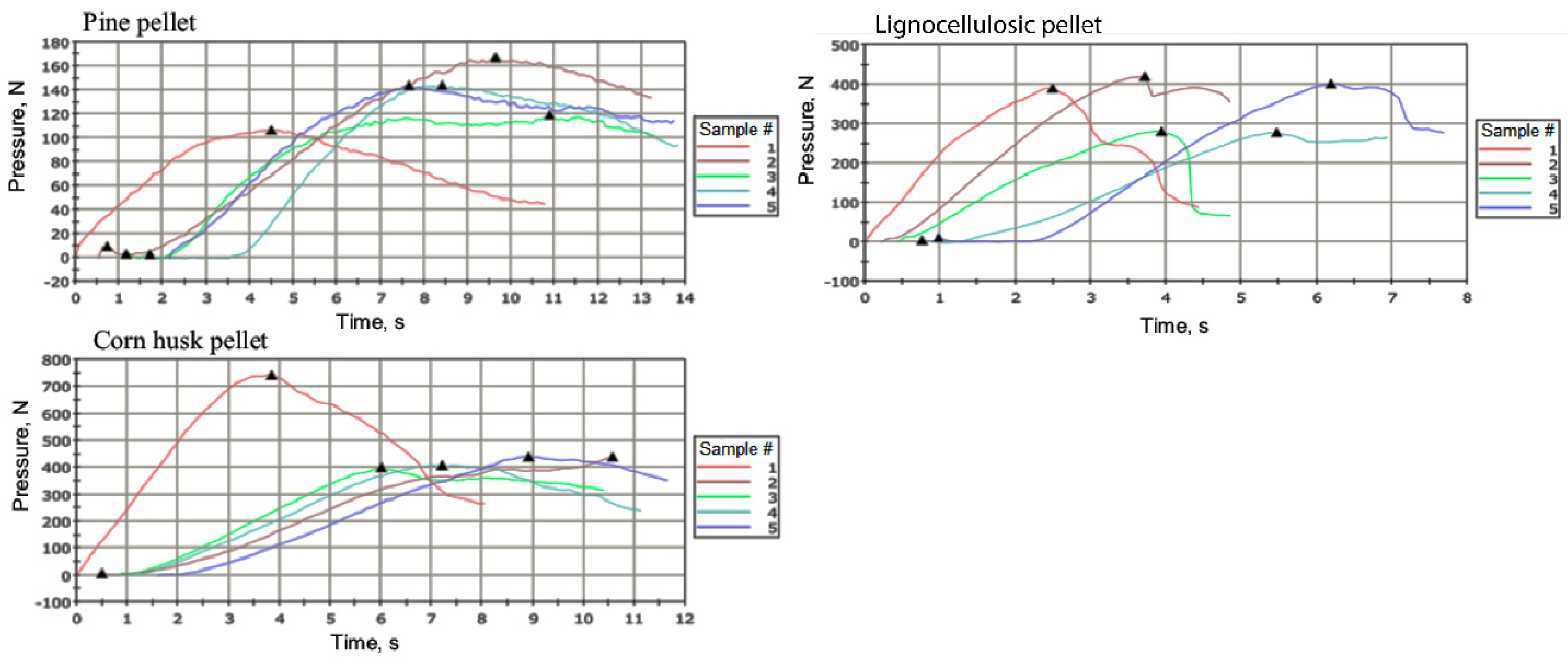

- Stress tests of produced CRDF pellets and conventional biomass pellets (pine, lignocellulosic, corn husks which were used as a reference, Figure A1—Appendix A) to determine CS.

- -

- combination I—CRDF using controlled pressure (from 8.5 MPa to 76.2 MPa with an interval of ~8.5 MPa)—checking the influence of just one factor—applied pressure—on CRDF pellet CS,

- -

- combination II—CRDF with water glass as a binder (from 10% to 50%, with an interval of 10%, produced using the pelletization pressure of 50.8 MPa)—checking the influence of just one factor—applied dose of water glass to one chosen type of CRDF pellet—on CRDF pellet CS,

- -

- combination III—CRDF pellets with water glass as a coating (produced using the pelletization pressure of 50.8 MPa)—checking the influence of just one factor—applied water glass as a coating agent of one chosen type of CRDF pellets—on CRDF pellet CS,

- -

- reference biomass pellets.

2.4. Structural Modification of CRDF

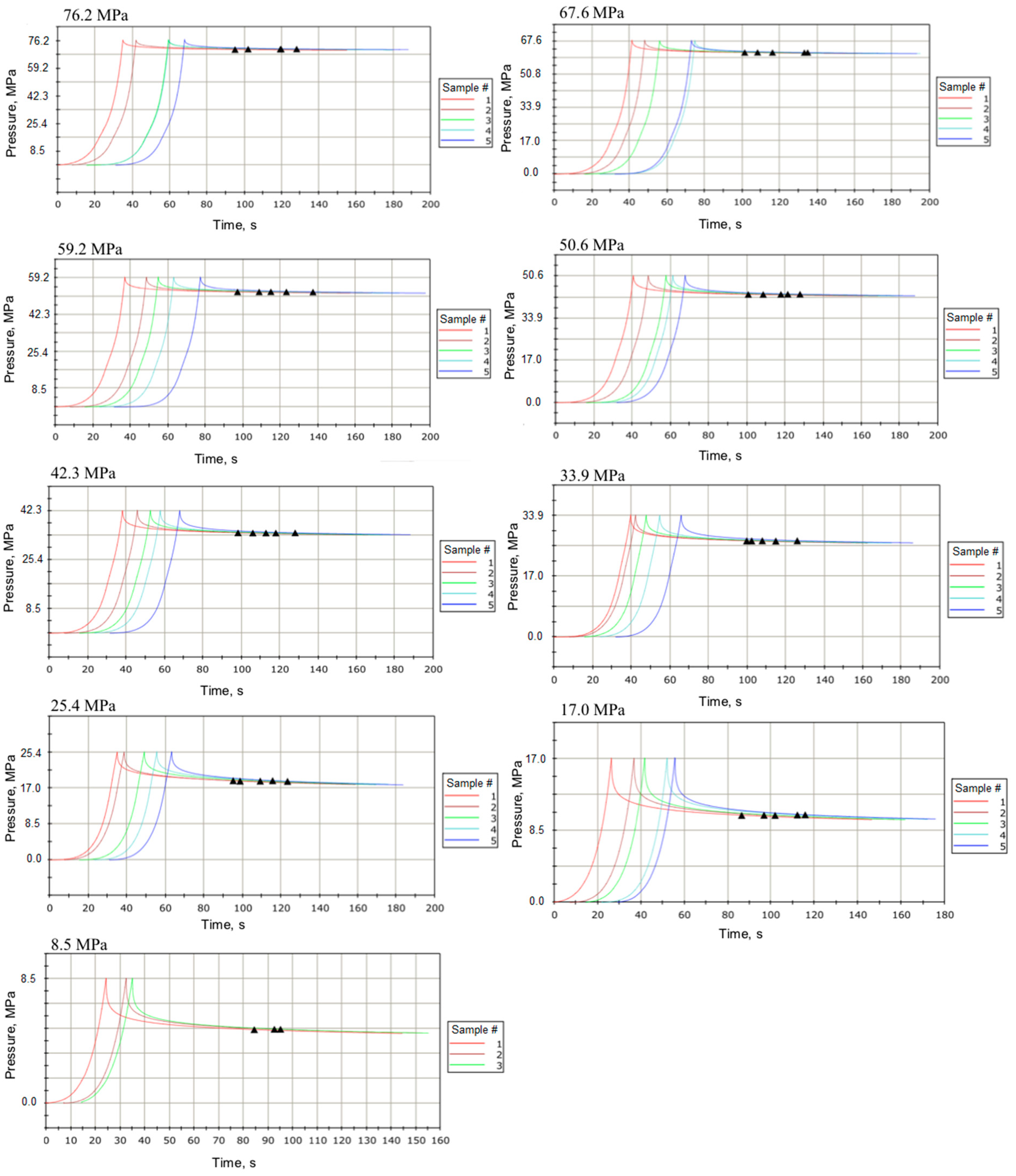

2.4.1. The Procedure of CRDF Structural Modification—Combination I

2.4.2. The Procedure of CRDF Structural Modification—Combination II

2.4.3. The Procedure of CRDF Structural Modification—Combination III

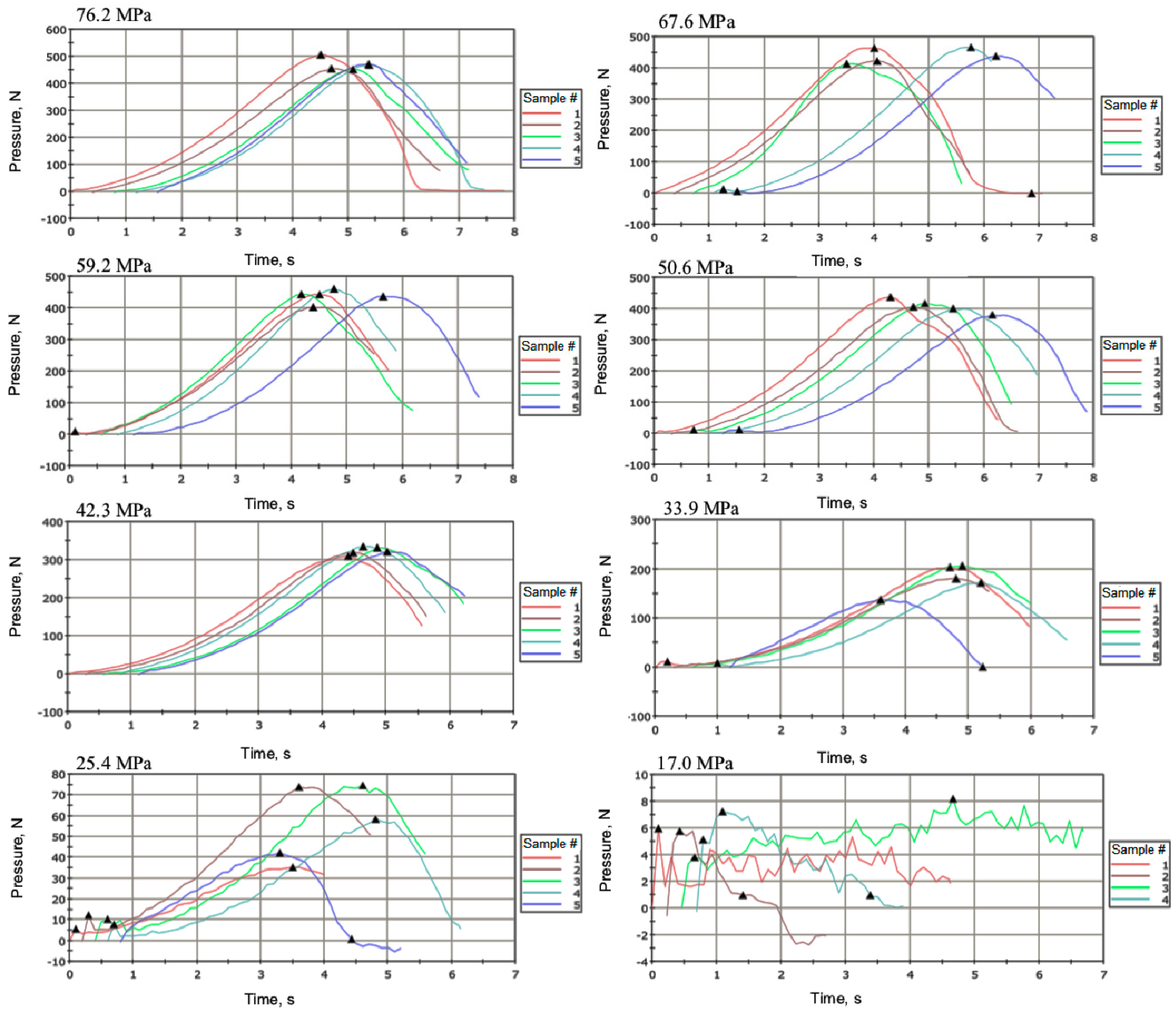

2.5. The Compressive Strength Test of Pellets

2.6. Statistical Analyses

3. Results

3.1. Structural Modification of CRDF

3.1.1. CRDF Pellets—Combination I

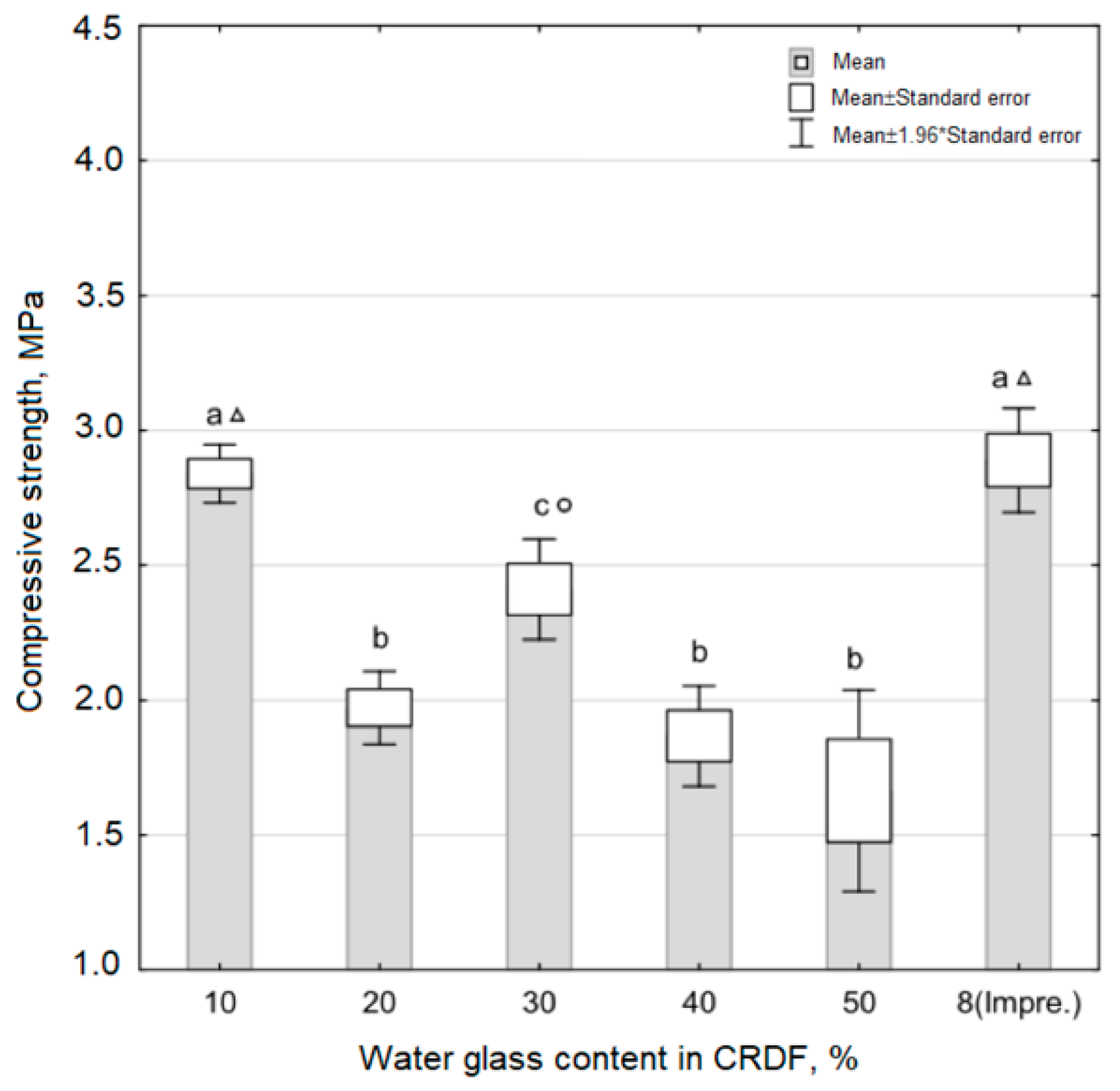

3.1.2. CRDF Pellets with Glass Water as a Binder—Combination II

3.1.3. CRDF Pellets Coated with Glass Water—Combination III

3.2. The Compressive Strength Tests

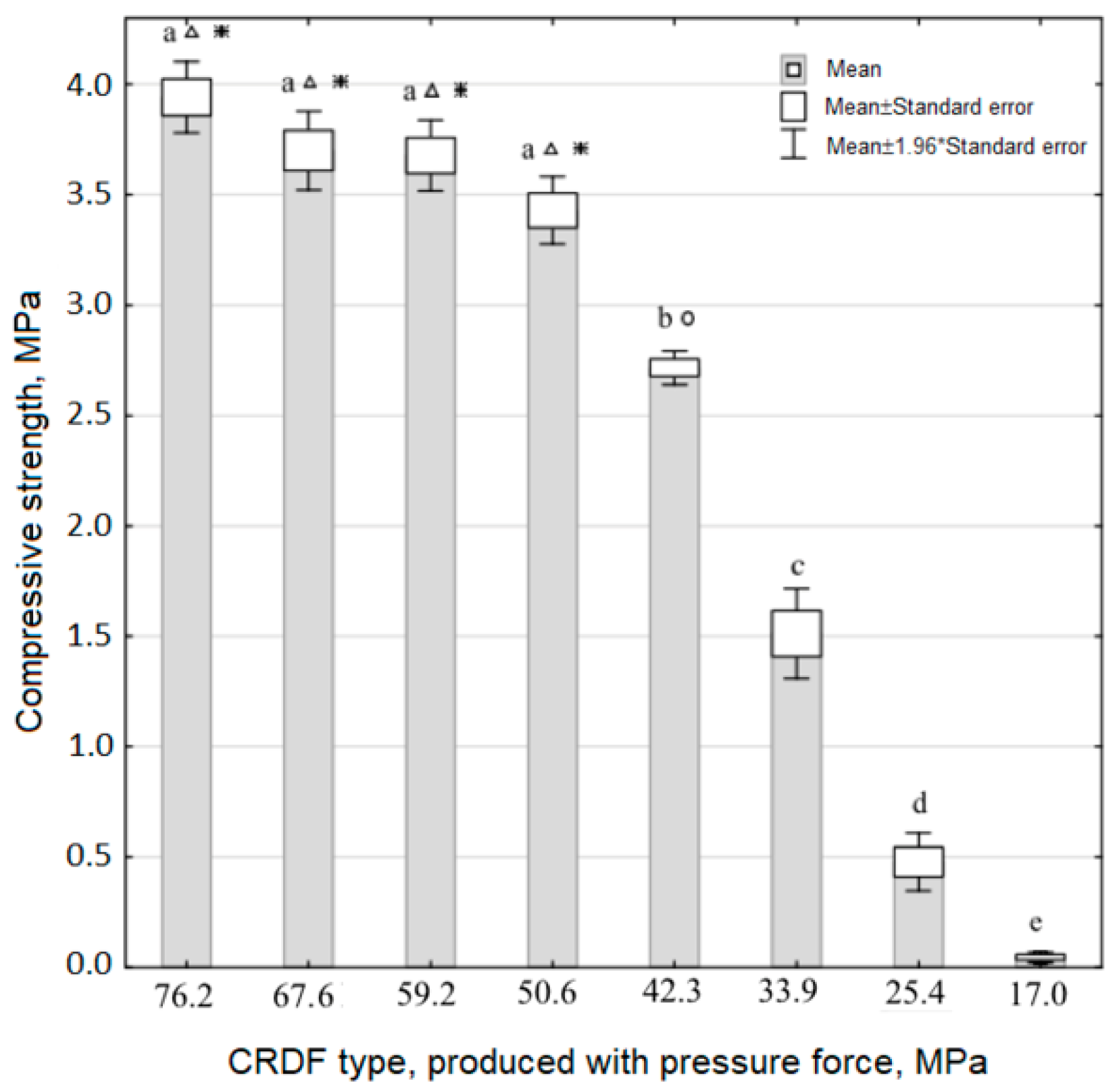

3.2.1. The Compressive Strength of CRDF Pellets—Combination I

3.2.2. The Compressive Strength of CRDF Pellets with the Addition of Water Glass as a Binder—Combination II

3.2.3. The Compressive Strength of CRDF Pellets Coated with Water Glass—Combination III

3.2.4. The Compressive Strength of (Reference) Plant Biomass Pellets

4. Discussion

5. Conclusions

- It is possible to produce durable pellets from CRDF. This, in turn, improves the feasibility of adopting this technology for municipal waste recycling and energy recovery due to lower volume and projected lower costs of storage, transportation, and utilization.

- The 50.8 MPa pressure was the practical threshold value for CRDF densification. Further increases in pressure during pelletizing did not significantly increase the compressive strength (CS) of CRDF pellets.

- The CS of CRDF pellets is comparable to pine pellets.

- The addition of water glass binder reduces the CS of pellets. The water glass content should not exceed 10%.

- Coating CRDF pellets with water glass did not improve the CS.

- The use of other binders and coatings in general remains an open issue and research is warranted if practical durability issues arise with site-, waste-, and process-specific scale-up of the densification of CRDF.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References and Notes

- World Energy Outlook. International Energy Agency. 2017. Available online: http://www.iea.org/media/weowebsite/2017/Chap1_WEO2017.pdf (accessed on 21 September 2018).

- Mavropoulos, A. Waste management 2030+. 2010. Available online: https://waste-management-world.com/a/waste-management (accessed on 21 September 2018).

- Moya, D.; Aldas, C.; Lopez, G.; Kaparaju, P. Municipal Solid Waste as a Valuable Renewable Energy Resource: A Worldwide Opportunity of Energy Recovery by Using Waste-To-Energy Technologies. In Proceedings of the 9th International Conference on Sustainability in Energy and Buildings, Chania, Crete, Greece, 5–7 July 2017. [Google Scholar]

- Białowiec, A.; Pulka, J.; Stępień, P.; Manczarski, P.; Gołaszewski, J. The RDF/SRF torrefaction: An effect of temperature on characterization of the product–Carbonized Refuse Derived Fuel. Waste Manag. 2017, 70, 91–100. [Google Scholar] [CrossRef] [PubMed]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- EUROSTAT. Energy Statistics Manual; IEA PUBLICATIONS: Paris, France, 2004; p. 93. Available online: http://ec.europa.eu/eurostat/ramon/statmanuals/files/Energy_statistics_manual_2004_EN.pdf (accessed on 21 September 2018).

- Shi, H.; Mahinpey, N.; Aqsha, A.; Silbermann, R. Characterization, thermochemical conversion studies, and heating value modeling of municipal solid waste. Waste Manag. 2016, 48, 34–47. [Google Scholar] [CrossRef] [PubMed]

- Randolph, P.; Bansode, R.R.; Hassan, O.A.; Rehrah, D.; Ravella, R.; Reddy, M.R.; Watts, D.W.; Novak, J.M.; Ahmedna, M. Effect of biochars produced from solid organic municipal waste on soil quality parameters. J. Environ. Manag. 2017, 192, 271–280. [Google Scholar] [CrossRef] [PubMed]

- Rehrah, D.; Bansode, R.R.; Hassan, O.; Ahmedna, M. Physico-chemical characterization of biochars from solid municipal waste for use in soil amendment. J. Anal. Appl. Pyrolysis 2016, 118, 42–53. [Google Scholar] [CrossRef]

- Taherymoosavi, S.; Verheyen, V.; Munroe, P.; Joseph, S.; Reynolds, A. Characterization of organic compounds in biochars derived from municipal solid waste. Waste Manag. 2017, 67, 131–142. [Google Scholar] [CrossRef] [PubMed]

- Stępień, P.; Mysior, M.; Białowiec, A. Technical and technological problems and application potential of waste torrefaction. In Innovations in Waste Management: Selected Issues; Białowiec, A., Ed.; Monografie–Uniwersytet Przyrodniczy we Wrocławiu 210; Wydawnictwo Uniwersytetu Przyrodniczego we Wrocławiu: Wrocław, Poland, 2018; pp. 47–58. ISBN 978-83-7717-278-0. [Google Scholar] [CrossRef]

- Aleluia, J.; Ferrão, P. Assessing the costs of municipal solid waste treatment technologies in developing Asian countries. Waste Manag. 2017, 69, 592–608. [Google Scholar] [CrossRef] [PubMed]

- De Medina-Salas, L.; Castillo-González, E.; Giraldi-Díaz, M.R.; Guzmán-González, V. Analysis of economic and environmental costs for the selection of municipal solid waste treatment and disposal scenarios through multicriteria analysis (ELECTRE Method). Sustainability 2017, 9, 1758. [Google Scholar] [CrossRef]

- KPGO2022. National waste management plan 2022. Warszawa, Poland, 2016. (Dz. U. Nr 88 poz. 784).

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefing 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Gaitán-Alvarez, J.; Moya, R.; Puente-Urbina, A.; Rodriguez-Zuñiga, A. Physical and compression properties of pellets manufactured with the biomass of five woody tropical species of Costa rica torrefied at different temperatures and times. Energies 2017, 10, 1205. [Google Scholar] [CrossRef]

- Szufa, S. Ways to Convert Biomass to Improve Its Fuel Properties; Centrum Badań i Innowacji Pro-Akademia: Łódzki, Poland, 2015. [Google Scholar]

- Pietrzakowski, M. Materials Durability; Politechnika Warszawska: Warszawa, Poland, 2010; Volume 10–18, pp. 28–34. ISBN 83-89703-50-5. [Google Scholar]

- Jakubiak, M.; Kordylewski, W. Biomass torrefaction. Pol. Inst. Spal. 2010, 10, 11–25. [Google Scholar]

- Szufa, S. Methods of initial biomass preparation for co-firing with coal in power boilers. Part 2. Technika Chłodnicza i Klimatyzacyjna. 2011, 9, 433–436. [Google Scholar]

- Garcia-Maraver, A.; Carpio, M. Biomass Pelletization Process. In WIT Transactions on State of the Art in Science and Engineering, 85; WIT Press: Southampton, UK, 2015; pp. 53–66. [Google Scholar] [CrossRef]

- EN14961-2, Solid Biofuels. Fuel Specification and Classes. Part 2: Wood Pellets for Non-Industrial Use; International Organization for Standardization: Geneva, Switzerland, 2011.

- EN14961-6, Solid Biofuels. Fuel Specifications and Classes. Part 6: Nonwoody Pellets for Non-Industrial Use; International Organization for Standardization: Geneva, Switzerland, 2012.

- Garcia-Maraver, A.; Salvachúa, D.; Martínez, M.J.; Diaz, L.F.; Zamorano, M. Analysis of the relation between the cellulose, hemicellulose and lignin content and the thermal behavior of residual biomass from olive trees. Waste Manag. 2013, 33, 2245–2249. [Google Scholar] [CrossRef] [PubMed]

- Tarasov, D.; Shahi, C.; Leitch, M. Effect of additives on wood pellet physical and thermal characteristics: A review. ISRN For. 2013, 2013. [Google Scholar] [CrossRef]

- Altun, N.E.; Hiçyılmaz, C.; Kök, M.V. Effect of different binders on the combustion properties of lignite. Part 1. Effect on thermal properties. J. Therm. Anal. Calorim. 2001, 65, 787–795. [Google Scholar] [CrossRef]

- Chinmayananda, D.; Jeevan, S.; Akash, P.; Gajanan, A. Development and investigation of briquettes using organic and inorganic binders. Int. J. Sci. Eng. Res. 2018, 9, 254–257. [Google Scholar]

- Singh, A.; Singh, Y. Briquetting of paddy straw. AMA-Agric. Mech. Asia Afr. 1982, 13, 42–44. [Google Scholar]

- Hiçyılmaz, C.; Altun, N.E. Focusing on the combustion properties of binder added coal. In Mineral Processing on the Verge of the 21st Century; Özbayoğlu, G., Hosten, C., Atalay, M.U., Arol, A.I., Eds.; A. A. Balkema Publishers: Leiden, The Netherlands, 2000; pp. 441–445. [Google Scholar]

- Snell, F.D.; Kimbal, C.S. Briquetting coal with sodium silicate. Ind. Eng. Chem. 1937, 29, 724–726. [Google Scholar] [CrossRef]

- Young, W. Using Binders to Briquette Carbonaceous Materials and Steel Waste. 2015. Available online: https://www.powderbulk.com/enews/2015/editorial/story_pdf/pbe_05_20_15RIHF.pdf (accessed on 21 September 2018).

- PN-EN ISO 18134-1:2015-11: Solid Biofuels–Determination of Moisture Content–Drying Method–Part 1: Total Moisture–Reference Method; International Organization for Standardization: Geneva, Switzerland, 2015.

- PN-G-04516:1998: Determination of Volatile Matter Content by Gravimetric Method; International Organization for Standardization: Geneva, Switzerland, 1998.

- PN-EN ISO 16948:2015-07: Solid Biofuels–Determination of The Total Carbon, Hydrogen and Nitrogen Content; International Organization for Standardization: Geneva, Switzerland, 2015.

- PN-EN ISO 16994:2016-10: Solid Biofuels–Determination of Total Sulfur and Chlorine Content; International Organization for Standardization: Geneva, Switzerland, 2016.

- PN-EN ISO 18125:2017-07: Solid Biofuels–Determination of Calorific Value; International Organization for Standardization: Geneva, Switzerland, 2017.

- PN-EN ISO 18122:2016-01: Solid Biofuels–Determination of Ash Content; International Organization for Standardization: Geneva, Switzerland, 2016.

- PN-EN ISO 17828:2016-02: Solid Biofuels–Determination of Bulk Density; International Organization for Standardization: Geneva, Switzerland, 2016.

- PN-EN ISO 17831-1:2016-02–Solid Biofuels–Determination of Mechanical Strength of Pellets and Briquettes–Part 1: Wood Pellets; International Organization for Standardization: Geneva, Switzerland, 2016.

- Emmerich, F.G.; Luengo, C.A. Babassu charcoal: A sulfurless renewable thermo- reducing feedstock for steelmaking. Biomass Bioenergy 1996, 10, 41–44. [Google Scholar] [CrossRef]

- Kumar, M.; Verma, B.B.; Gupta, R.C. Mechanical properties of acacia and Eucalyptus wood chars. Energy Source 2010, 21, 675–685. [Google Scholar] [CrossRef]

- Noumi, E.S.; Blin, J.; Rousset, P. Optimization of Quality of Charcoal for Steelmaking Using Statistical Analysis Approach. In Proceedings of the 5th International Conference on Engineering for Waste and Biomass Valorisation, Rio de Janeiro, Brazil, 25–28 August 2014; pp. 1–14. [Google Scholar]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.J.; Poulsen, T.; Felby, C. Importance of temperature, moisture content, and species for the conversion process of wood residues into fuel pellets. Wood Fibre Sci. 2009, 41, 414–425. [Google Scholar]

- Ahn, B.J.; Chang, H.S.; Lee, S.M.; Choi, D.H.; Cho, S.T.; Han, G.S.; Yang, I. Effect of binders on the durability of wood pellets fabricated from Larix kaemferi C. and Liriodendron tulipifera L. sawdust. Renew. Energy 2014, 62, 18–23. [Google Scholar] [CrossRef]

- Lee, S.M.; Ahn, B.J.; Choi, D.H.; Han, G-S.; Jeong, H.-S.; Ahn, S.H.; Yang, I. Effects of densification variables on the durability of wood pellets fabricated with Larix kaempferi C. and Liriodendron tulipifera L. sawdust. Biomass Bioenergy 2013, 48, 1–9. [CrossRef]

- Adapa, P.; Tabil, L.; Shoenau, G.; Opoku, A. Pelleting characteristics of selected biomass with and without steam explosion pretreatment. Int. J. Agric. Biol. Eng. 2010, 3, 62–79. [Google Scholar] [CrossRef]

- Adapa, P.; Tabil, L.; Schoenau, G. Grinding performance and physical properties of non-treated and steam exploded barley, canola, oat and wheat straw. Biomass Bioenergy 2011, 35, 549–561. [Google Scholar] [CrossRef]

- Carone, M.T.; Pantaleo, A.; Pellerano, A. Influence of process parameters and biomass characteristics on the durability of pellets from the pruning residues of Olea europaea L. Biomass Bioenergy 2011, 35, 402–410. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: the importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Alakangas, E.; Paju, P. Wood Pellets in Finland–Technology, Economy and Market; OPET Report 5; VTT Processes: Jyvaskyla, Finland, 2002. [Google Scholar]

- Williams, O.; Taylor, S.; Lester, E.; Kingman, S.; Giddings, D.; Eastwick, C. Applicability of mechanical tests for biomass pellet characterisation for bioenergy applications. Materials 2018, 11, 1329. [Google Scholar] [CrossRef] [PubMed]

- Lisowski, A.; Kostrubiec, M.; Dąbrowska-Salwin, M.; Świętochowski, A. Features of pellets from plant biomass in the aspect of supply logistics. Logistyka 2015, 5, 351–356. [Google Scholar]

| Parameter | Standard Method | Unit | Mean ± SD |

|---|---|---|---|

| Moisture | [32] | % | 1.54 ± 0.36 |

| Loss on ignition | [33] | % d.m. | 79.9 ± 1.24 |

| C | [34] | % d.m. | 59.7 ± 1.63 |

| H | [34] | % d.m. | 6.07 ± 0.53 |

| N | [34] | % d.m. | 0.68 ± 0.02 |

| S | [35] | % d.m. | 0.17 ± 0.01 |

| O | [34] | % d.m. | 13.24 ± 0.92 |

| Cl | [35] | % d.m. | 0.80 ± 0.13 |

| Higher Heating Value | [36] | MJ∙kg−1 | 27.315 ± 1.183 |

| Lower Heating Value | [36] | MJ∙kg−1 | 25.953 ± 1.306 |

| Ash | [37] | % d.m. | 20.14 ± 1.24 |

| Bulk density | [38] | kg∙m−3 | 424.4 ± 150.2 |

| Type of Biomass Pellet | Diameter, d | Height, h |

|---|---|---|

| mm | mm | |

| Pine pellet | 6.354 ± 0.054 | 16.654 ± 1.718 |

| Lignocellulosic pellet | 8.888 ± 0.081 | 16.206 ± 1.687 |

| Corn husk pellet | 8.410 ± 0.062 | 14.704 ± 1.410 |

| Experimental Combination | Pelletizing Pressure Applied, MPa | The Ratio of Water Glass in Pellet, % |

|---|---|---|

| I | 76.2 | 0.0 |

| 67.6 | ||

| 59.2 | ||

| 50.8 | ||

| 42.3 | ||

| 33.9 | ||

| 25.4 | ||

| 17.0 | ||

| 8.5 | ||

| II | 50.8 | 10.0 |

| 20.0 | ||

| 30.0 | ||

| 40.0 | ||

| 50.0 | ||

| III | 50.8 | 8.1 |

| Pine pellets * | - | 0.0 |

| Lignocellulosic pellets * | - | 0.0 |

| Corn husk pellets * | - | 0.0 |

| Pellets Produced with Applied Pelletizing Pressure, MPa | The Ratio of Water Glass in Pellet | Diameter, d | Height, h | Weight, m | Volume, V | Density, ρ |

|---|---|---|---|---|---|---|

| MPa | % | mm | mm | g | mm−3 | kg·m−3 |

| 76.2 | 0.0 | 12,266 ± 0.022 | 14.266 ± 0.080 | 1.998 ± 0.004 | 1685.8 ± 15.2 | 1185.5 ± 11.6 |

| 67.6 | 12.276 ± 0.030 | 14.354 ± 0.090 | 2.000 ± 0.002 | 1698.9 ± 9.4 | 1177.0 ± 6.8 | |

| 59.2 | 12.274 ± 0.017 | 14.332 ± 0.140 | 1.999 ± 0.001 | 1695.8 ± 17.6 | 1178.7 ± 13.0 | |

| 50.8 | 12.264 ± 0.009 | 14.513 ± 0.052 | 2.001 ± 0.002 | 1714.4 ± 4.5 | 1167.1 ± 2.7 | |

| 42.3 | 12.264 ± 0.017 | 14.717 ± 0.040 | 1.997 ± 0.003 | 1738.5 ± 7.7 | 1149.0 ± 6.7 | |

| 33.9 | 12.266 ± 0.015 | 15.174 ± 0.089 | 1.999 ± 0.003 | 1793.1 ± 8.2 | 1114.8 ± 5.3 | |

| 25.4 | 12.272 ± 0.018 | 15.970 ± 0.110 | 1.999 ± 0.003 | 1889.0 ± 12.2 | 1058.1 ± 7.6 | |

| 17.0 | 12.240 ± 0.021 | 16.953 ± 0.130 | 1.991 ± 0.003 | 1994.8 ± 15.7 | 997.9 ± 8.6 | |

| 8.5 | - | - | - | - | - | |

| 50.8 | 10 | 12.346 ± 0.021 | 14.474 ± 0.187 | 1.960 ± 0.015 | 1732.7 ± 19,2 | 1131.1 ± 19.6 |

| 20 | 12.436 ± 0.035 | 14.288 ± 0.171 | 1.909 ± 0.012 | 1735.4 ± 16,9 | 1100.1 ± 92.0 | |

| 30 | 12.399 ± 0.025 | 13.931 ± 0.111 | 1.900 ± 0.012 | 1682.1 ± 16,8 | 1129.4 ± 12.7 | |

| 40 | 12.305 ± 0.058 | 13.465 ± 0.225 | 1.881 ± 0.040 | 1601.2 ± 34,1 | 1175.1 ± 22.9 | |

| 50 | 12.180 ± 0.118 | 12.905 ± 0.386 | 1.820 ± 0.090 | 1503.1 ± 26.3 | 1210.4 ± 51.9 |

| Type of Pellets | Diameter, d | Height, h | Weight, m | Volume, V | Density, ρ |

|---|---|---|---|---|---|

| mm | mm | g | mm3 | kg·m−3 | |

| Before coating | 12.262 ± 0.008 | 14.525 ± 0.020 | 2.000 ± 0.000 | 1715.294 ± 2.993 | 1160.9 ± 1.9 |

| After coating | 12.356 ± 0.058 | 15.080 ± 0.142 | 2.176 ± 0.043 | 1808.122 ± 8.303 | 1203.7 ± 22.5 |

| Increase, % | 0.77 | 3.61 | 8.80 | 5.41 | 3.69 |

| Feedstock for Biochar Production | Pyrolysis Conditions, °C; min | Additives for Pelletization | Compressive Strength, MPa (kN) | Source |

|---|---|---|---|---|

| Biochar Pellets | ||||

| RDF | 260; 50 | - | 3.43 (0.405)–3.94 (0.465) | Present Study |

| Water glass (10%) | 2.84 (0.340) | |||

| Water glass coating (8.09) | 2.89 (0.346) | |||

| White cedar | 200–250; 8–12 | - | (0.323–0.929) | Gaitán-Alvarez et al. [16] |

| Almendro | - | 0.342–0.841) | ||

| Beechwood | - | (0.165–0.583) | ||

| Teak | - | (0.251–0.620) | ||

| Yemeri wood | - | (0.624–1.469) | ||

| Biomass Pellets | ||||

| Pine sawdust | - | - | 4.29 (0.136) | Present Study |

| Lignocellulosic | - | - | 4.84 (0.300) | |

| Corn husk | - | - | 8.85 (0.491) | |

| Eucalyptus pellets | - | - | 5 | Williams et al. [52] |

| Mixed wood pellets | - | - | 7 | |

| Miscanthus pellets | - | - | 7 | |

| Sunflower pellets | - | - | 8 | |

| Steam exploded pellets | - | - | 15 | |

| Microwave pellets | - | - | 3 | |

| Hay | - | - | 3.29 | Lisowski et al. [53] |

| Straw | - | - | 4.21 | |

| Hay:Straw (1:1) | - | - | 3.74 | |

| Hay:Straw (1:1) | - | CaCO3 (10%) | 4.76 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Białowiec, A.; Micuda, M.; Koziel, J.A. Waste to Carbon: Densification of Torrefied Refuse-Derived Fuel. Energies 2018, 11, 3233. https://doi.org/10.3390/en11113233

Białowiec A, Micuda M, Koziel JA. Waste to Carbon: Densification of Torrefied Refuse-Derived Fuel. Energies. 2018; 11(11):3233. https://doi.org/10.3390/en11113233

Chicago/Turabian StyleBiałowiec, Andrzej, Monika Micuda, and Jacek A. Koziel. 2018. "Waste to Carbon: Densification of Torrefied Refuse-Derived Fuel" Energies 11, no. 11: 3233. https://doi.org/10.3390/en11113233

APA StyleBiałowiec, A., Micuda, M., & Koziel, J. A. (2018). Waste to Carbon: Densification of Torrefied Refuse-Derived Fuel. Energies, 11(11), 3233. https://doi.org/10.3390/en11113233