Development of a Multi-Architecture and Multi-Application Hybrid Vehicle Design and Management Tool

Abstract

1. Introduction

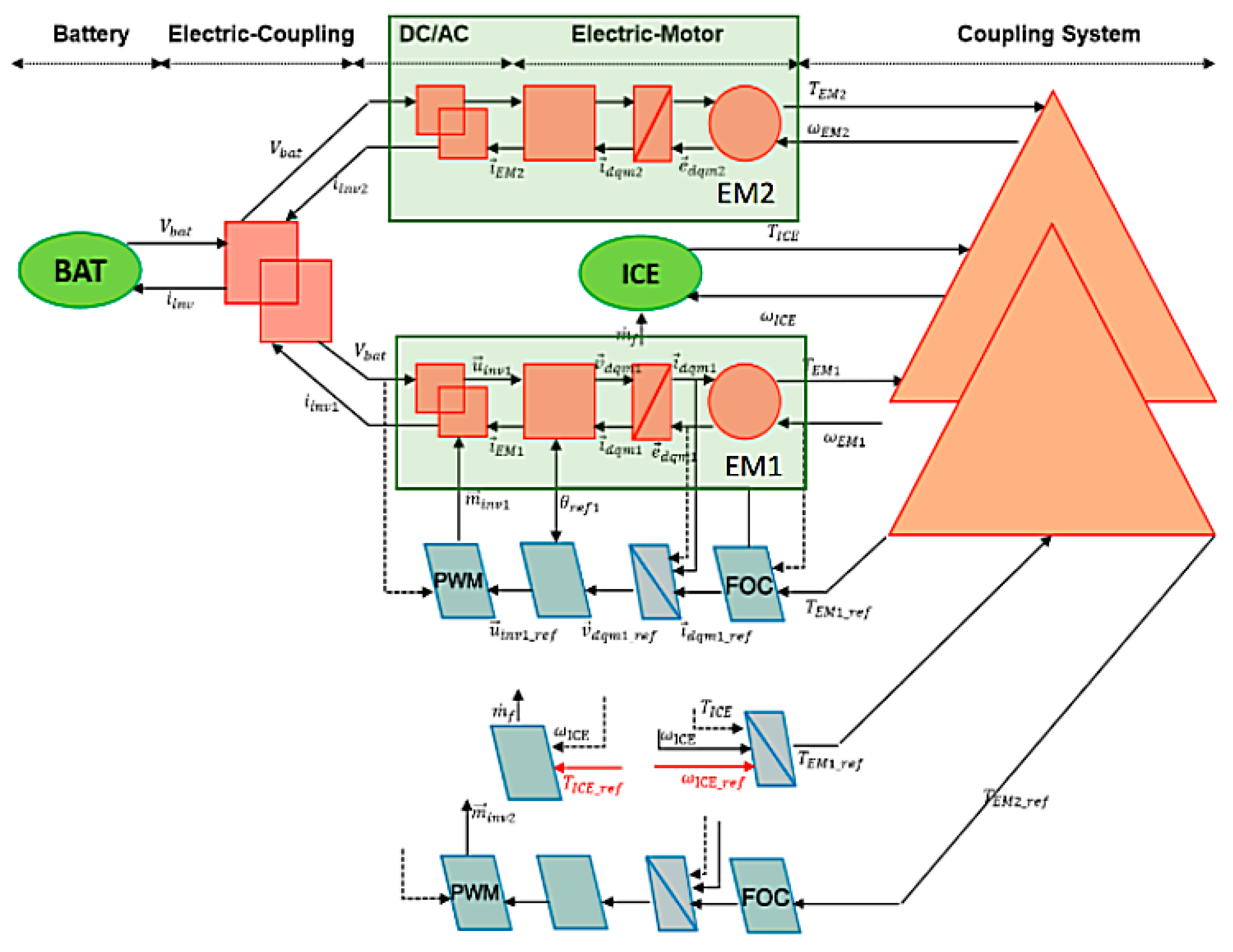

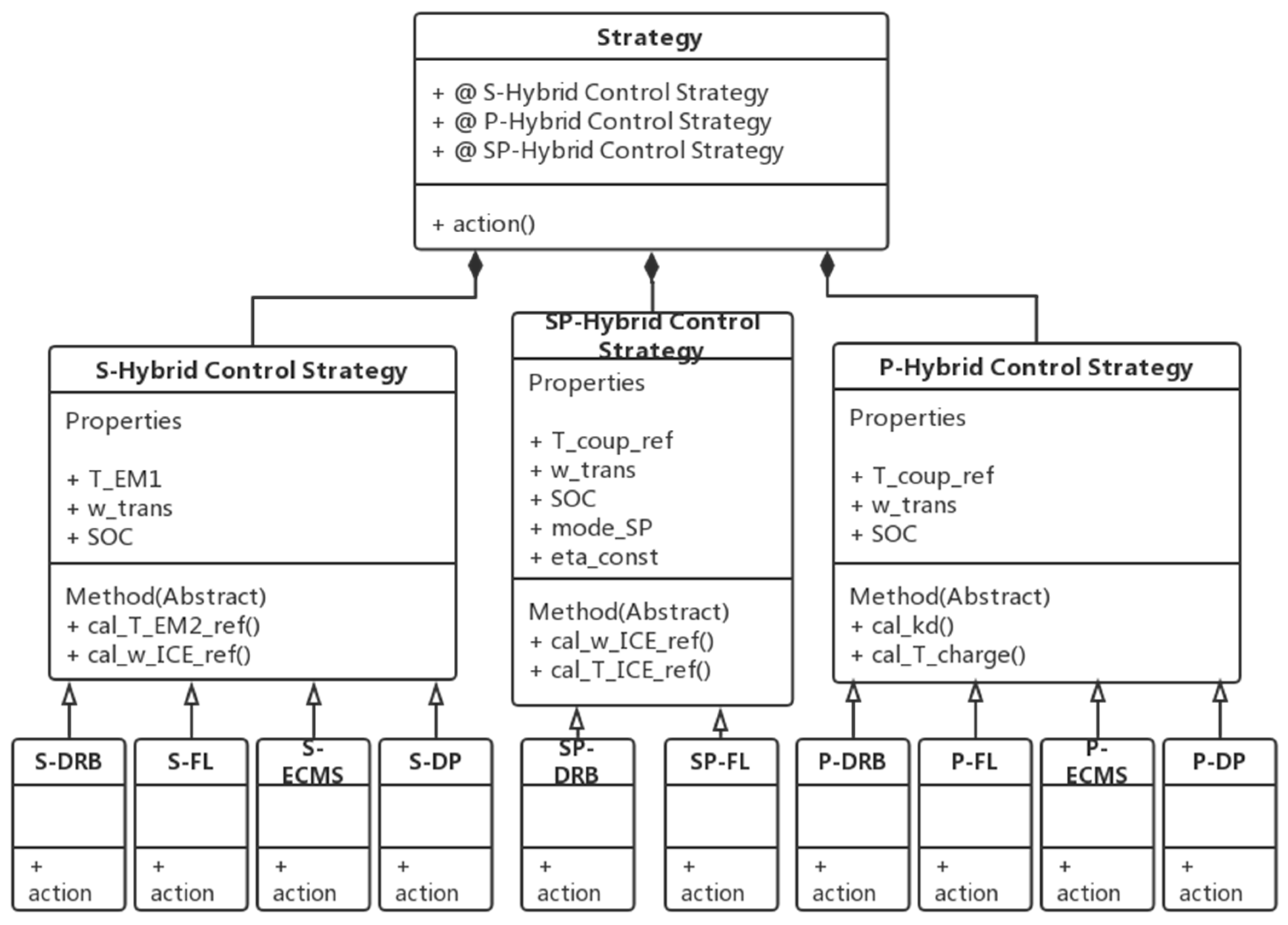

2. Hybrid Architecture & Energy Management

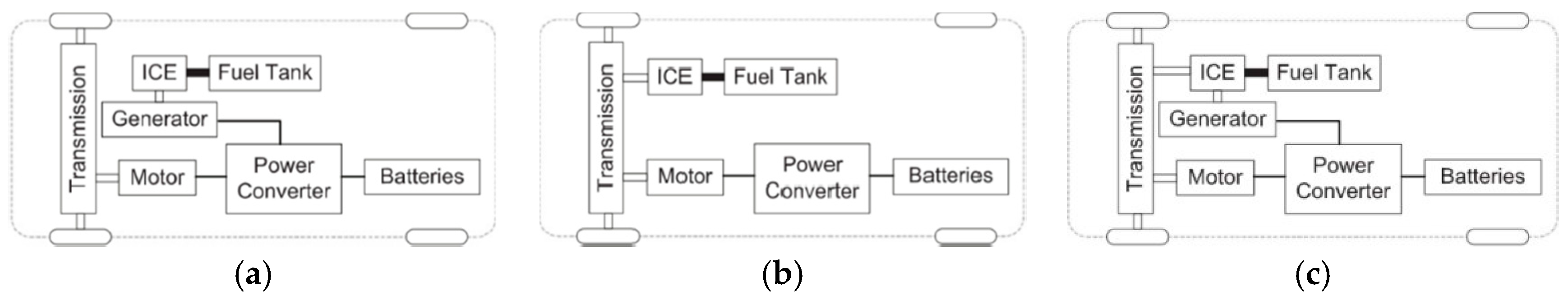

2.1. Hybrid Architecture

2.2. Energy Management

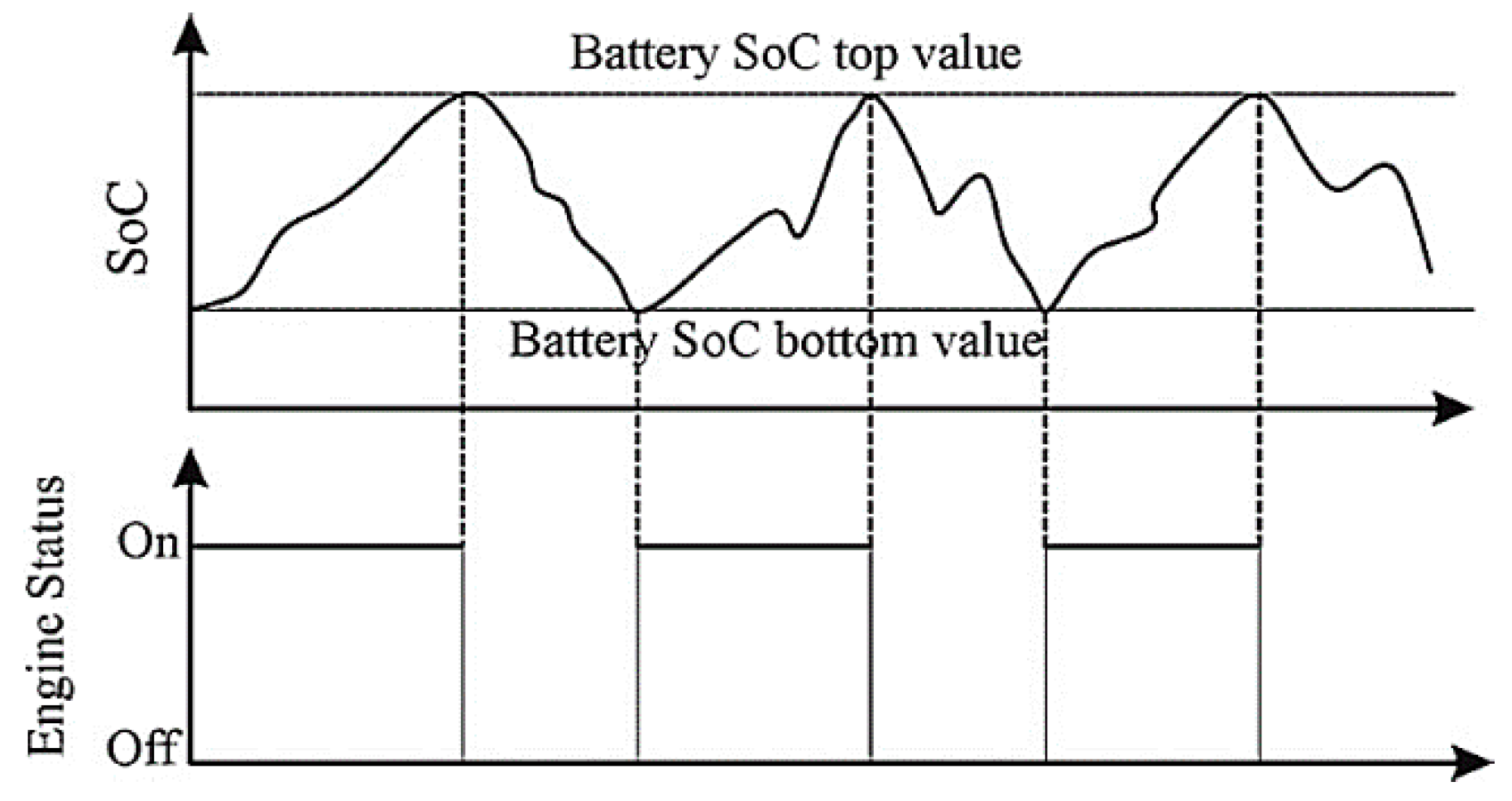

2.2.1. Deterministic Rule Based Control Strategy

- -

- If current SoC value is greater than predefined maximum SoC threshold value, ICE turns off;

- -

- If current SoC value is smaller than predefined minimum SoC threshold value, ICE turns on.

- -

- Only EM works when current velocity of HEV is lower than threshold value;

- -

- If HEV needed power is greater than the maximum threshold value, the EM will be used to assist ICE;

- -

- Battery is charged by recovery brake energy;

- -

- ICE turns off if the HEV needed power is smaller than the threshold value;

- -

- ICE provides energy to charge the battery when current SoC is smaller than the threshold value.

2.2.2. Fuzzy Logic Rule Based Control Strategy

2.2.3. Equivalent Consumption Minimization Strategy Optimization Based Control Strategy

2.2.4. Dynamic Programming Optimization Based Control Strategy

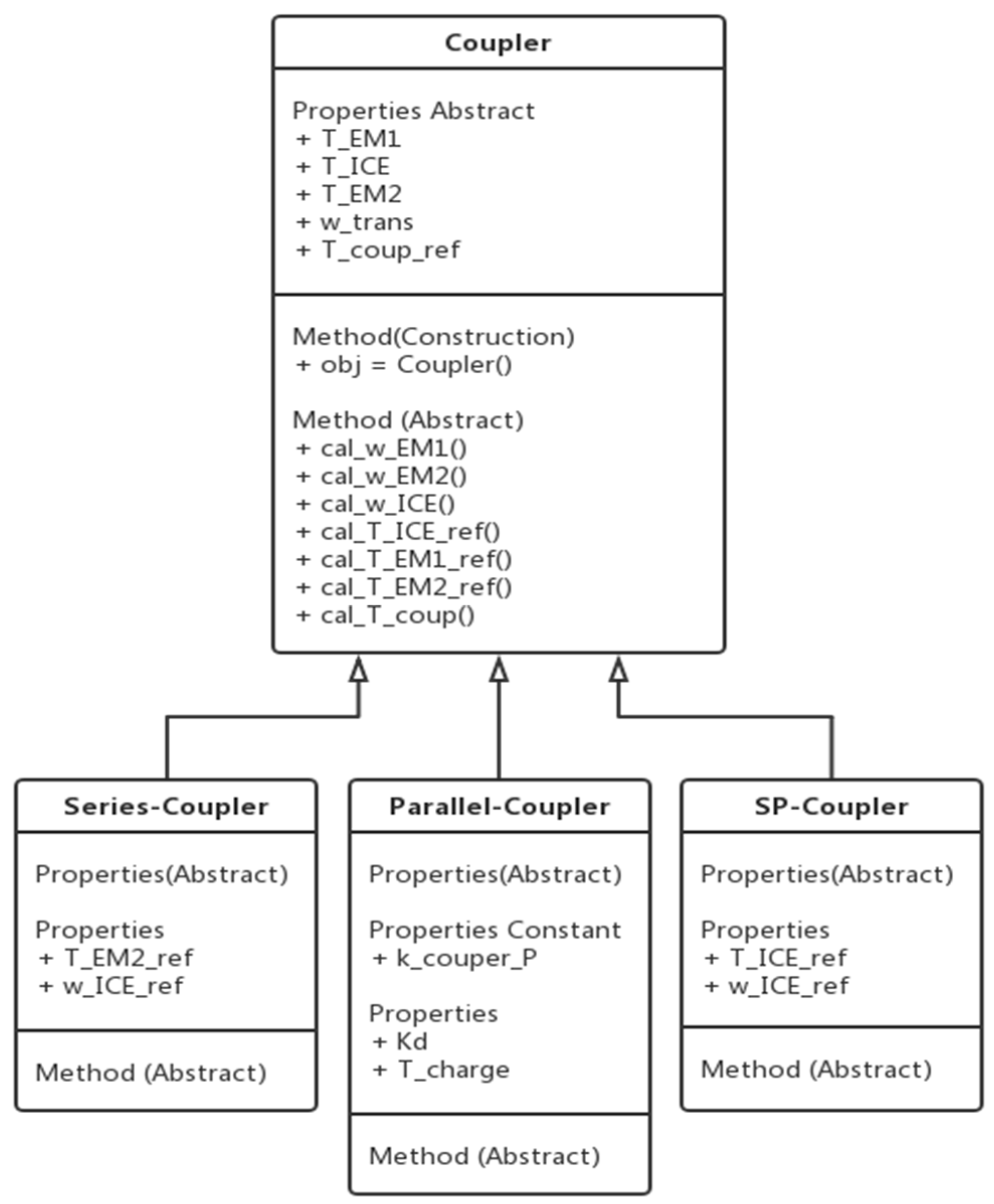

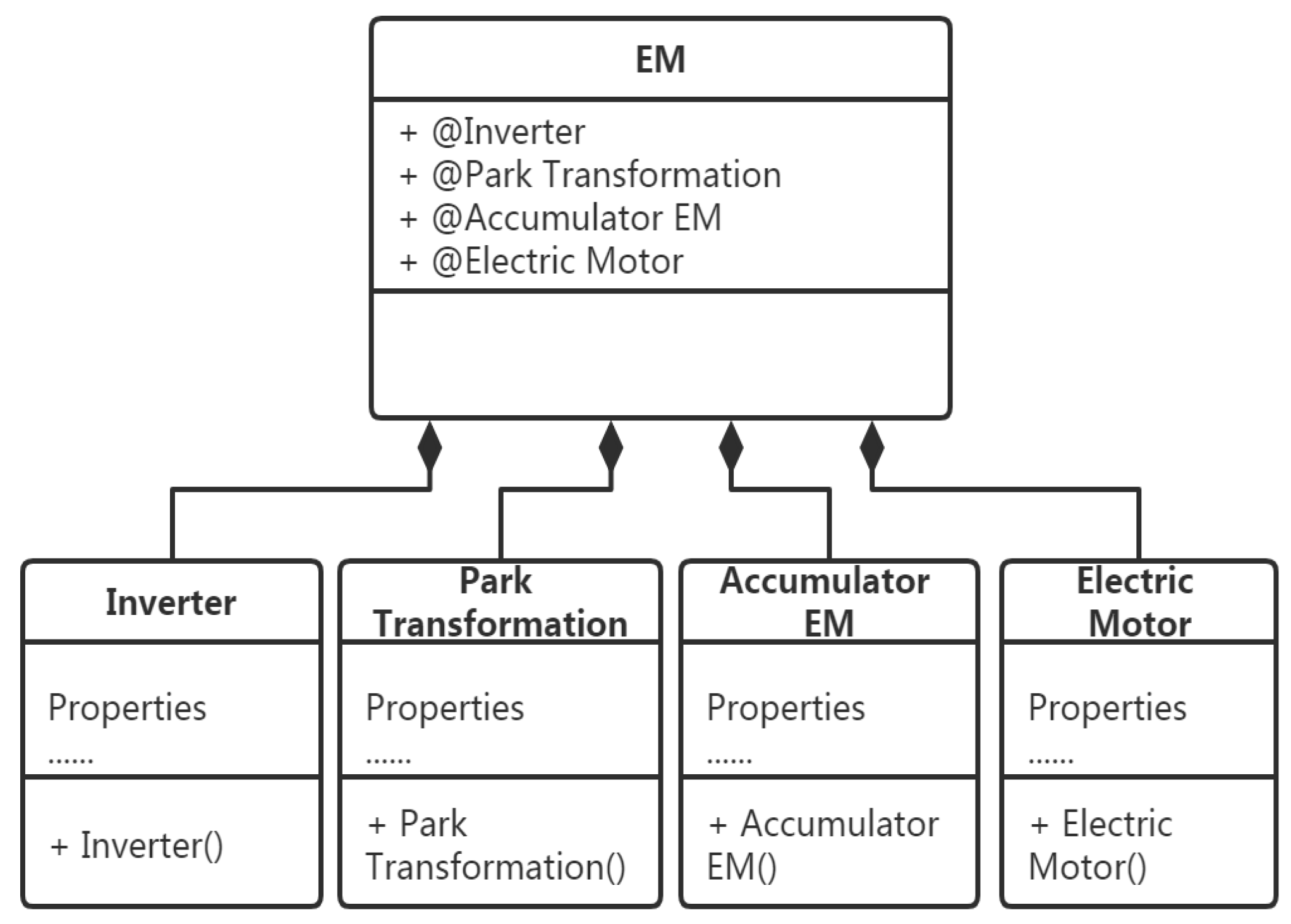

3. Modeling Principle and Approach

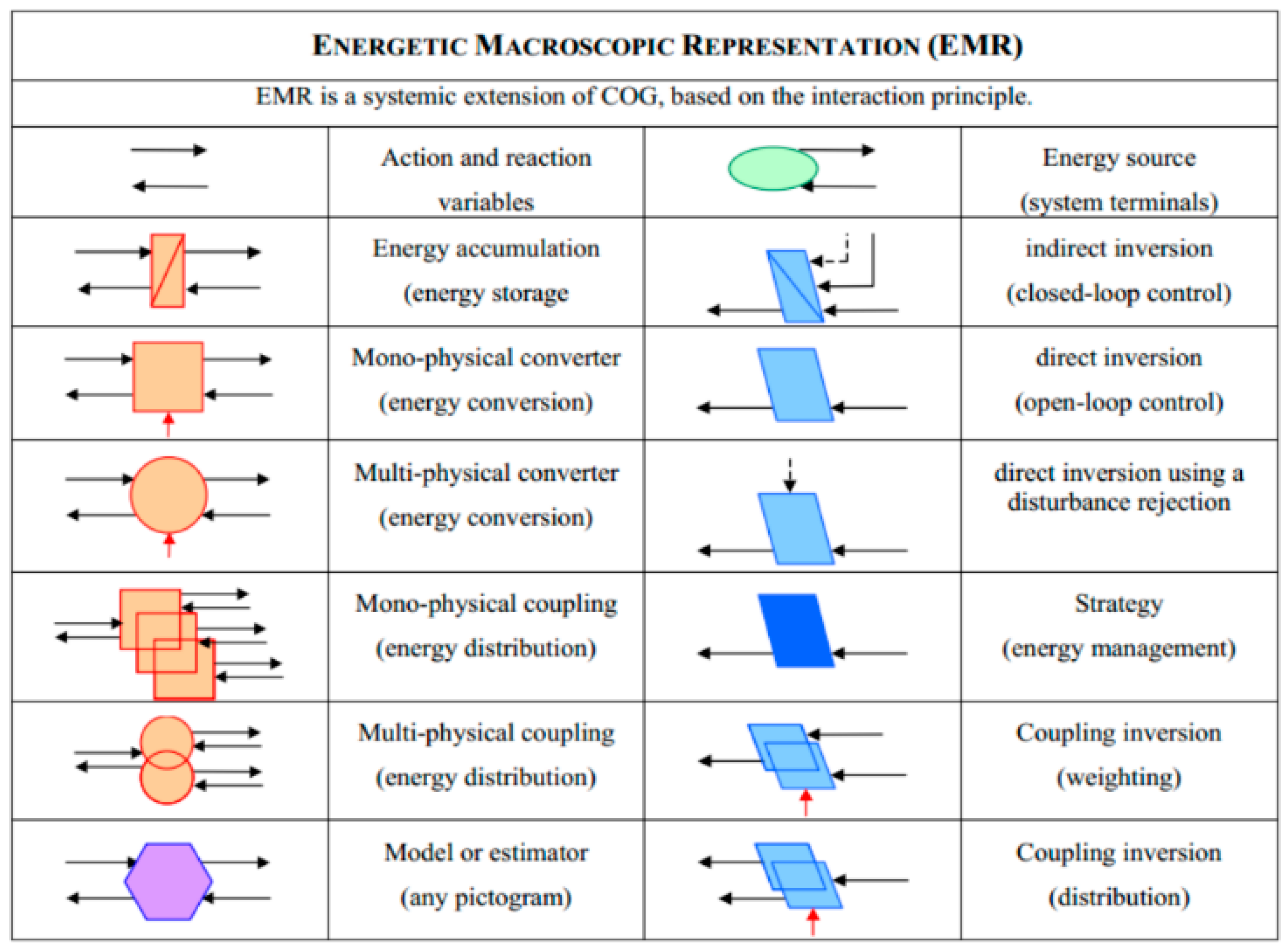

3.1. Overview of Energetic Macroscopic Representation

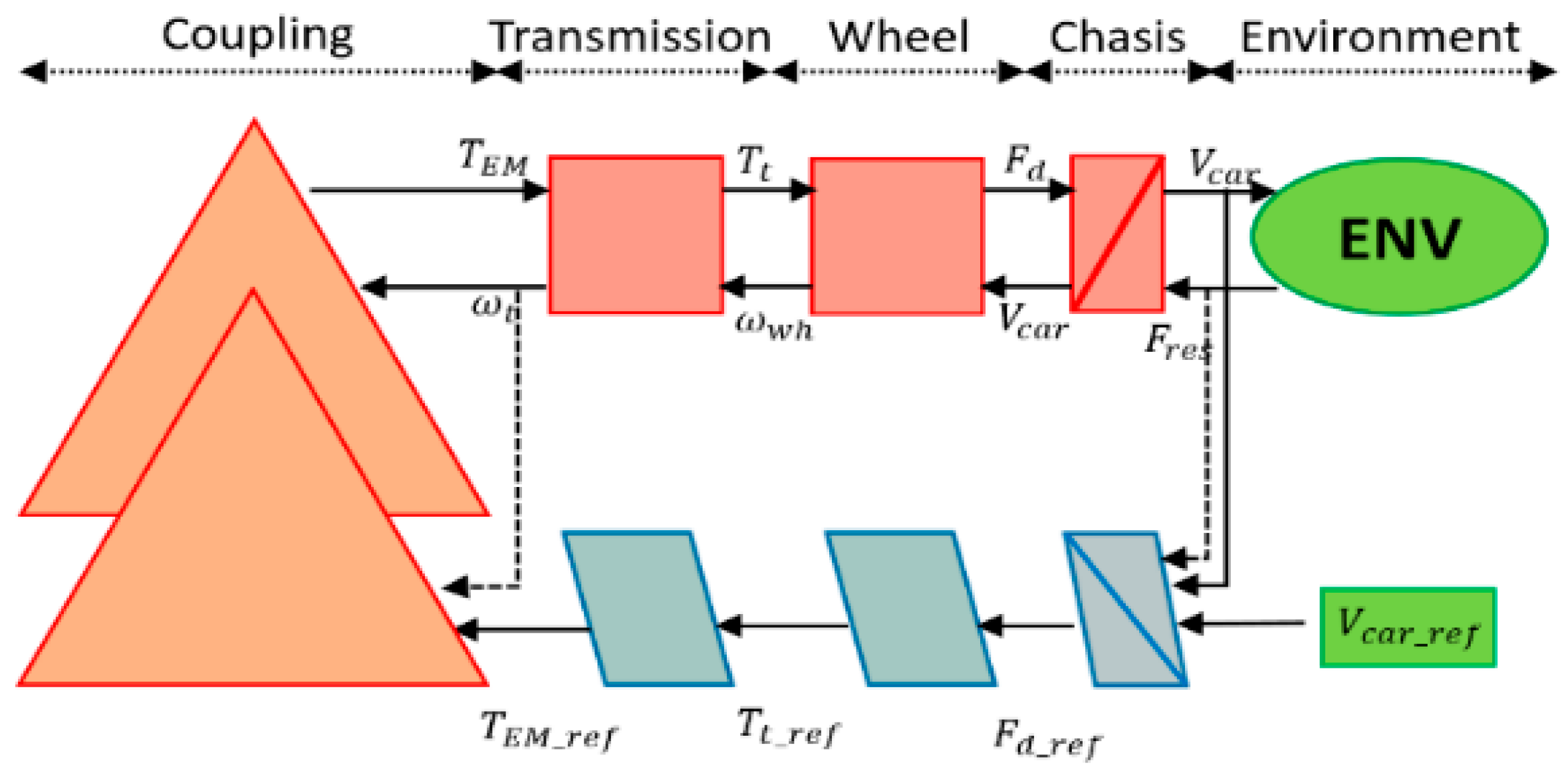

3.2. Multi-Architecture/Multi-Application Modeling Realization Using Energetic Macroscopic Representation

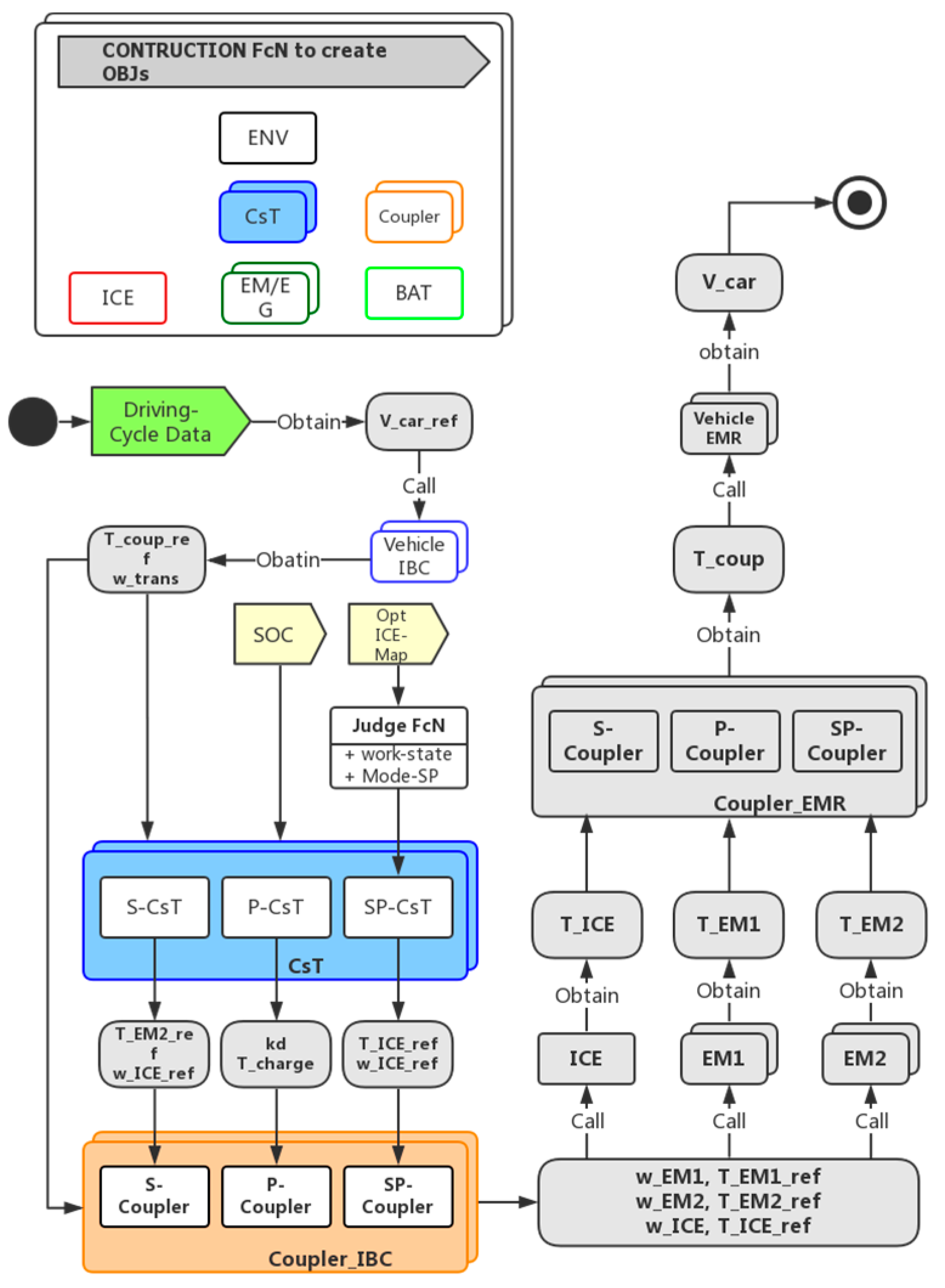

4. Improvement of Modeling Using Object Oriented Programming

4.1. Overview of Object Oriented Programming

4.2. Realization of Object Oriented Programming

5. Optimization for Power Source Resizing

5.1. Optimization Process

5.2. Optimization Results

6. Simulation for Different Control Strategies

6.1. Simulation Process

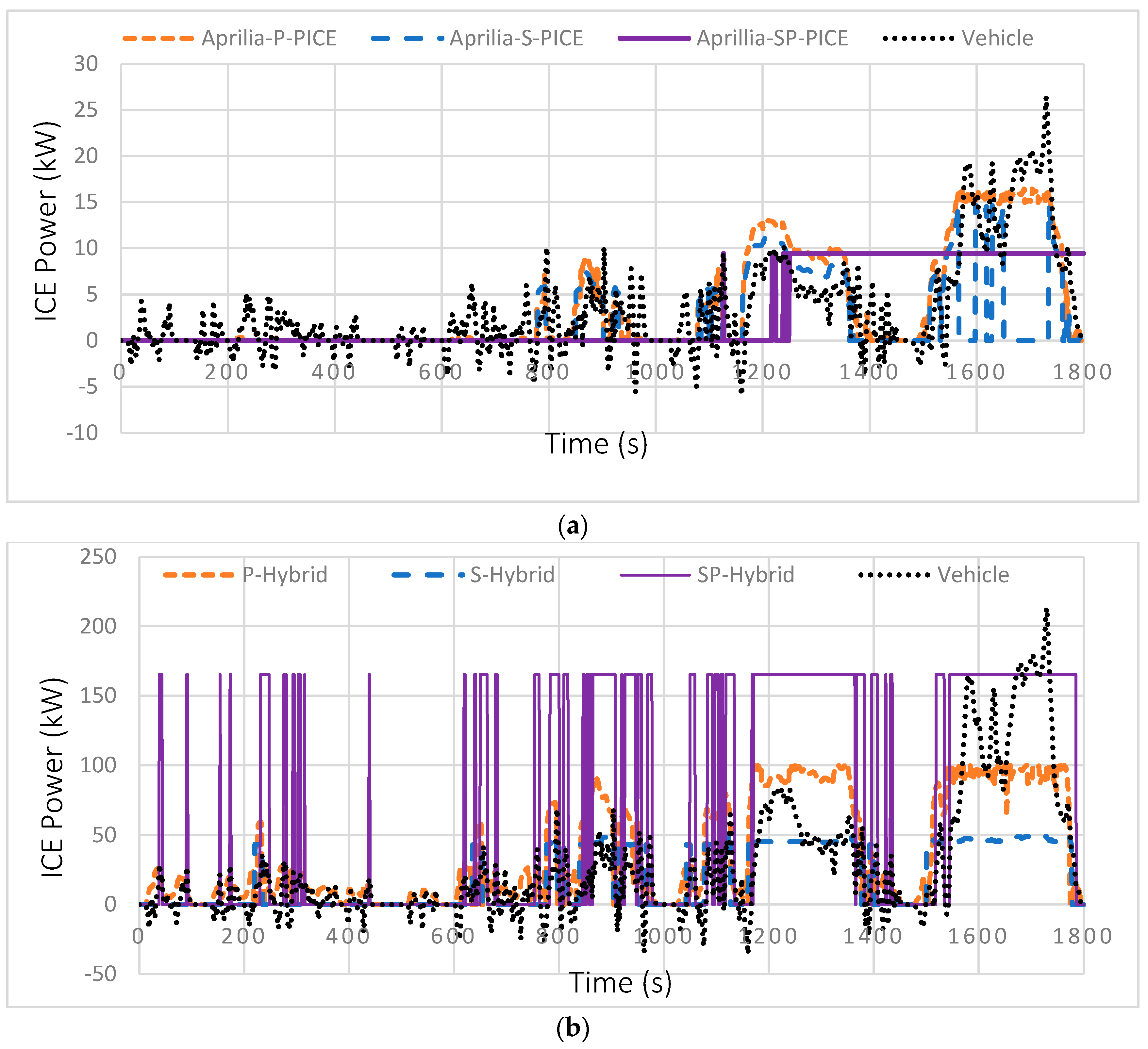

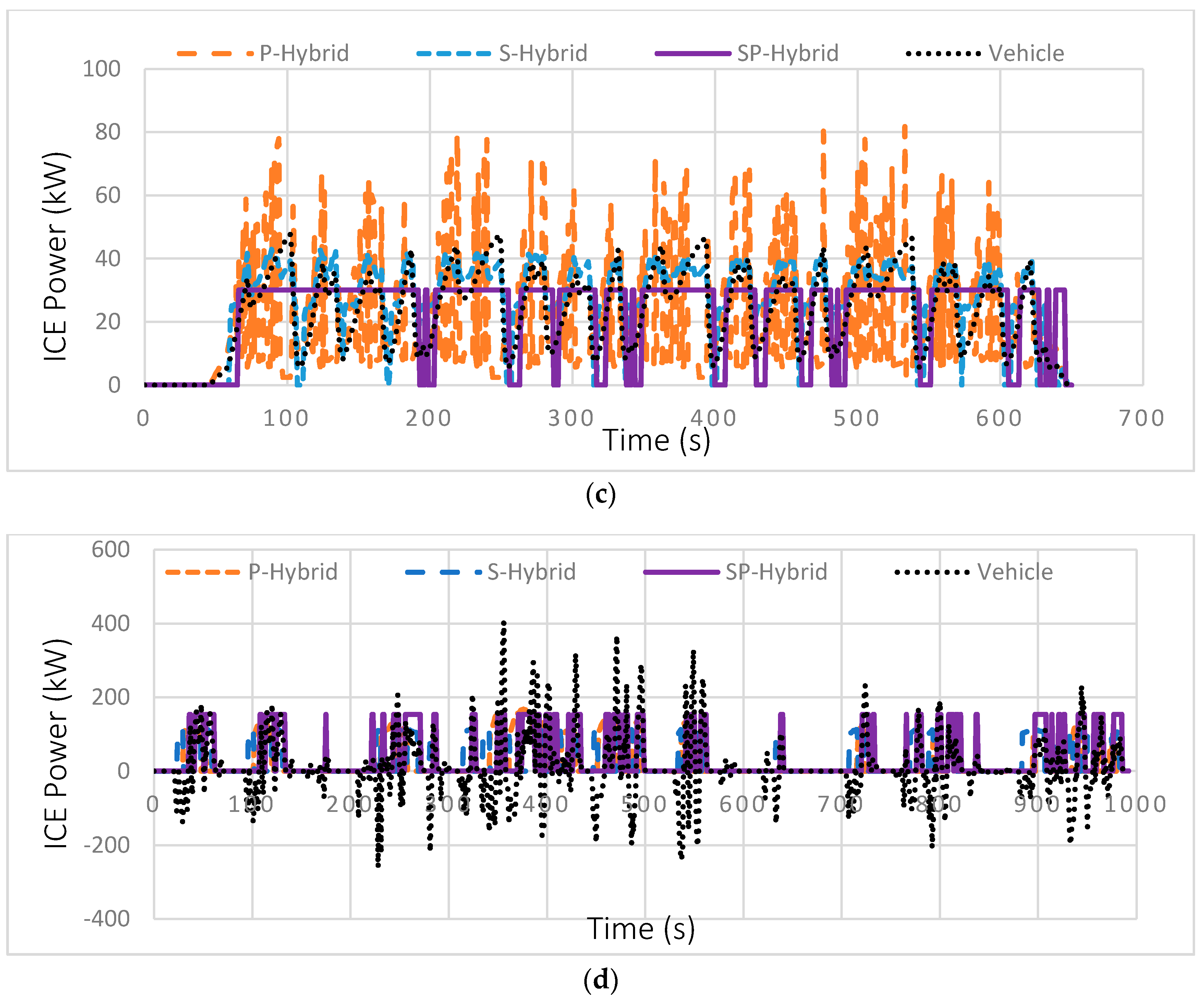

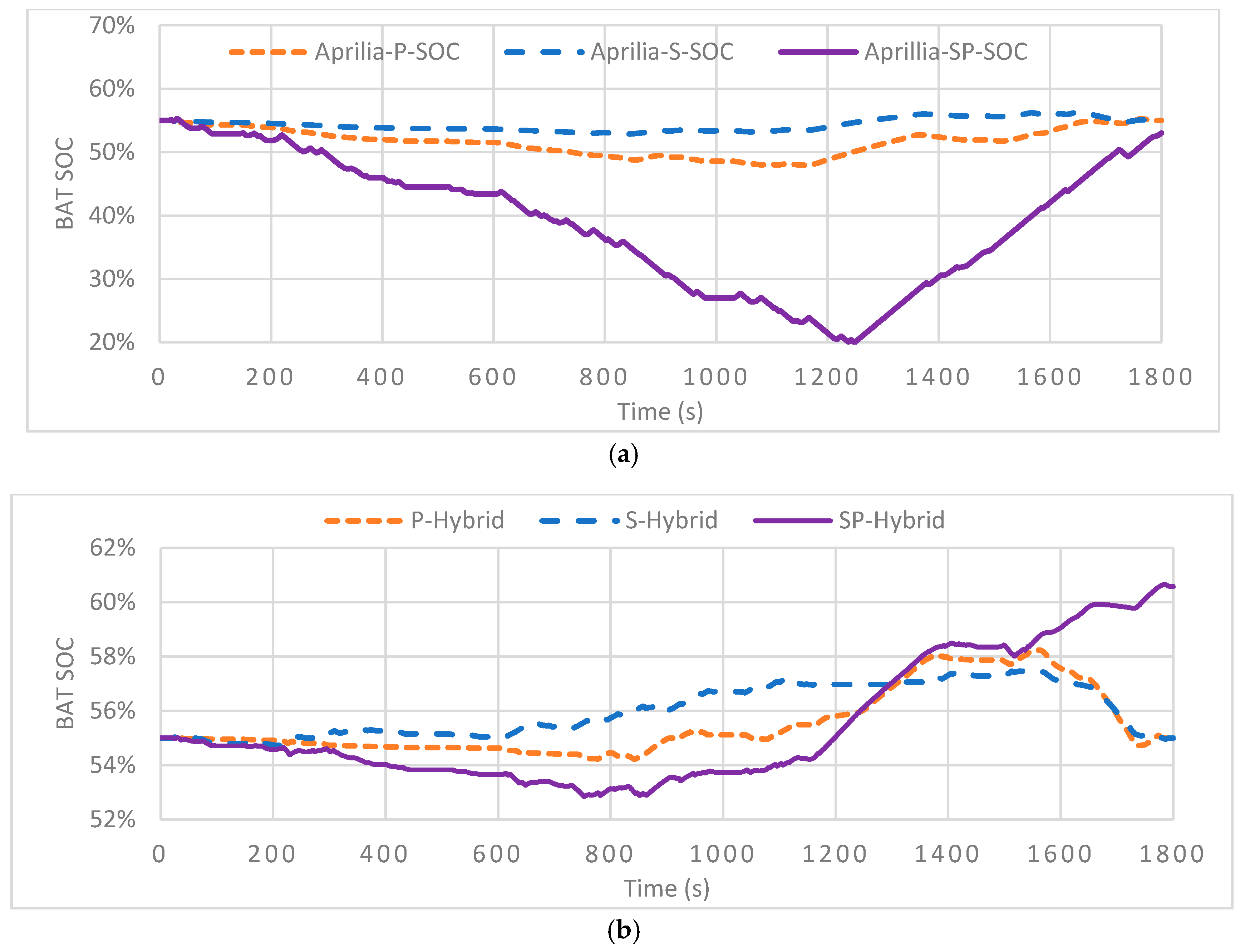

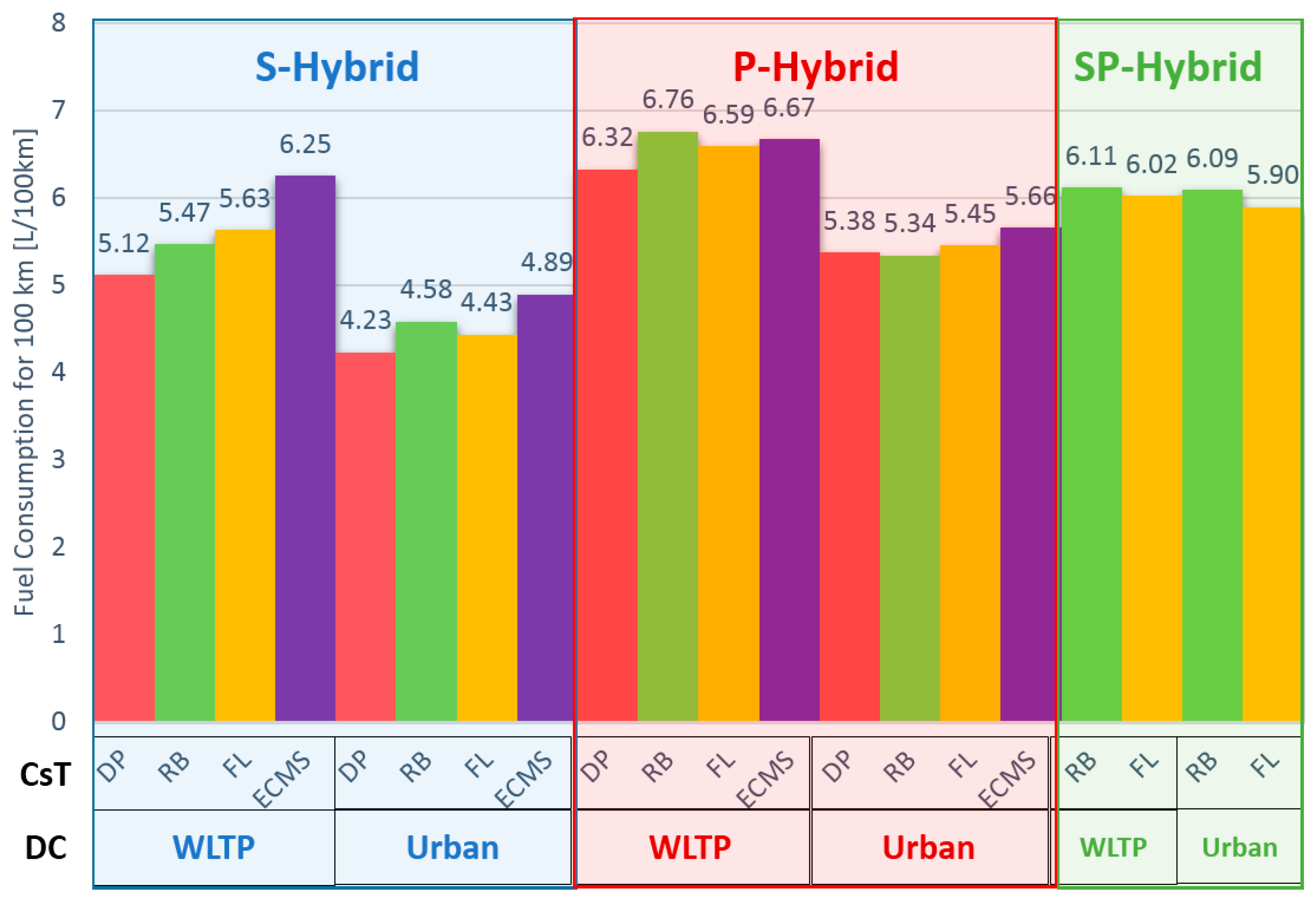

6.2. Simulation Results

- (1)

- (2)

- (3)

- (4)

7. Conclusions & Perspective

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Enerdata. Global Energy Statistical Yearbook 2017; Enerdata: Grenoble, France, 2017. [Google Scholar]

- International Energy Agency (IEA). Key World Energy Statistics; IEA: Paris, France, 2017. [Google Scholar]

- Rate, P.E. Fuel Consumption Modeling of Conventional and Advanced Technology Vehicles in the Physical Emission Rate Estimator (PERE) Draft; EPA: Washington, DC, USA, 2005. [Google Scholar]

- BP Statistical Review of World Energy; British Petroleun Company: London, UK, 2017.

- Kwon, J.; Wang, X.; Ahluwalia, R.K.; Rousseau, A. Impact of Fuel cell System Design Used in Series Fuel Cell HEV on Net Present Value (NPV). In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011. [Google Scholar]

- Barré, A.; Suard, F.; Gérard, M.; Riu, D. Battery Capacity Estimation and Health Management of an Electric Vehicle Fleet. In Proceedings of the 2014 IEEE Vehicle Power and Propulsion Conference (VPPC), Coimbra, Portugal, 27–30 October 2014. [Google Scholar]

- Alexander, D.; Gartner, J. Electric Vehicles in Europe: Gearing Up for A New Phase; McKinsey & Company: New York, NY, USA, 2012. [Google Scholar]

- Hodkinson, R.; Fenton, J. Lightweight Electric/Hybrid Vehicle Design, 1st ed.; Hill, J., Ed.; Butterworth Heinemann: Oxford, UK, 2001. [Google Scholar]

- Maggetto, J.V.M.G. Electric and Electric Hybrid Vehicle Technology: A Survey. In Proceedings of the IEE Seminar Electric, Hybrid and Fuel Cell Vehicles (Ref. No. 2000/050), Durham, UK, 11 April 2000. [Google Scholar]

- Fuhs, A.E. Hybrid Vehicles and the Future of Personal Transportation; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Naumann, S.; Büchter, H.; Janecki, R.; Karon, G.; Sierpinski, G. Models and Methods for the Evaluation and the Optimal Application of Battery Charging and Switching Technologies for Electric Busses. 2014. Available online: http://www.cactus-emobility.eu/CACTUS_Deliverable_3.1_Methods.pdf (accessed on 16 November 2018).

- Zhang, P.; Yan, F.; Du, C. A comprehensive Analysis of Energy Management Strategies for Hybrid Electric Vehicles Based on Bibliometrics. Renew. Sustain. Energy Rev. 2015, 48, 88–104. [Google Scholar] [CrossRef]

- Zhang, M. HEV Powertrain Fundamentals. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011. [Google Scholar]

- Chrenko, D.; Gan, S.; Gutenkunst, C.; Kriesten, R.; Moyne, L.L.E. Novel Classification of Control Strategies for Hybrid Electric Vehicles. In Proceedings of the 2015 IEEE Vehicle Power and Propulsion Conference (VPPC), Montreal, QC, Canada, 19–22 October 2015. [Google Scholar]

- Asus, Z.; Chrenko, D.; Aglzim, E.H.; Kéromnès, A.; Le Moyne, L. Simple Method of Estimating Consumption of Internal Combustion Engine for Hybrid Application. In Proceedings of the 2012 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 18–20 June 2012. [Google Scholar]

- Tribioli, L.; Barbieri, M.; Capata, R.; Sciubba, E.; Jannelli, E.; Bella, G. A Real Time Energy Management Strategy for Plug-in Hybrid Electric Vehicles based on Optimal Control Theory. Energy Procedia 2014, 45, 949–958. [Google Scholar] [CrossRef]

- Zheng, C.; Shin, C.W.; Seo, H.; Park, Y.; Cha, S.W. Strategies and Evaluation of Fuel Economy in Fuel Cell Hybrid Vehicles. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011. [Google Scholar]

- Cipek, M.; Pavković, D.; Petrić, J. A Control-Oriented Simulation Model of A Power-Split Hybrid Electric Vehicle. Appl. Energy 2013, 101, 121–133. [Google Scholar] [CrossRef]

- Lajunen, A. Evaluation of The Benefits of Using Dual-Source Energy Storage in Hybrid Electric Vehicles. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar]

- Chrenko, D.; Gan, S.; Daud, Z.H.C.; Asus, Z.; Aglzim, E.L.; le Moyne, L. Sizing of ICE and Lithium-Ion Battery for Hybrid Vehicles over Life Cycle with Battery Aging. In Proceedings of the 2013 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 16–19 June 2013. [Google Scholar]

- Finesso, R.; Spessa, E.; Venditti, M. Layout Design and Energetic Analysis of a Complex Diesel Parallel Hybrid Electric Vehicle. Appl. Energy 2014, 134, 573–588. [Google Scholar] [CrossRef]

- Lajunen, A. Development of Energy Management Strategy for Plug-in Hybrid City Bus. In Proceedings of the 2012 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 18–20 June 2012. [Google Scholar]

- Hartavi, A.E.; Uygan, I.M.C.; Yildirim, A.M.; Güvenç, L. Development and Use of Hybrid Electric Vehicle Hardware-in-The-Loop Simulator for Power Management Controller Design and Testing. In Proceedings of the 7th Kongresi Otomotiv Teknolojileri, Bursa, Turkey, 26–27 May 2014. [Google Scholar]

- Erdinc, I.O.; Vural, B.; Uzunoglu, M. A Dynamic Lithium-Ion Battery Model Considering The Effects of Temperature and Capacity Fading. In Proceedings of the 2009 International Conference on Clean Electrical Power, Capri, Italy, 9–11 June 2009. [Google Scholar]

- Chen, M.; Rincon-Mora, G.A. Accurate Electrical Battery Model Capable of Predicting Runtime and I–V Performance. IEEE Power Energy Soc. 2006, 21, 504–511. [Google Scholar] [CrossRef]

- Amiri, M.; Esfahanian, M.; Hairi-Yazdi, M.R.; Esfahanian, V. Minimization of Power Losses in Hybrid Electric Vehicles in View of the Prolonging of Battery Life. J. Power Sources 2009, 190, 372–379. [Google Scholar] [CrossRef]

- Poursamad, A.; Montazeri, M. Design of Genetic-Fuzzy Control Strategy for Parallel Hybrid Electric Vehicles. Control Eng. Pract. 2008, 16, 861–873. [Google Scholar] [CrossRef]

- Chaoui, H.; Sicard, P. Fuzzy Logic Based Supervisory Energy Management for Multisource Electric Vehicles. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011. [Google Scholar]

- Alipour, H.; Asaei, B.; Farivar, G. Fuzzy Logic Based Power Management Strategy for Plug-in Hybrid Electric Vehicles with Parallel Configuration. In Proceedings of the International Conference on Renewable Energies and Power Quality (ICREPQ’12), Santiago de Compostela, Spain, 28–30 March 2012. [Google Scholar]

- Lee, H.D.; Sul, S.K. Fuzzy-Logic-Based Torque Control Strategy for Parallel-Type Hybrid Electric Vehicle. IEEE Trans. Ind. Electron. 1998, 45, 625–632. [Google Scholar]

- Musardo, C.; Rizzoni, G.; Guezennec, Y.; Staccia, B. A-ECMS: An Adaptive Algorithm for Hybrid Electric Vehicle Energy Management. Eur. J. Control 2005, 11, 509–524. [Google Scholar] [CrossRef]

- Liu, J.; Peng, H. Modeling and Control of a Power-Split Hybrid Vehicle. IEEE Trans. Control Syst. Technol. 2008, 16, 1242–1251. [Google Scholar]

- Chasse, A.; Corde, G.; del Mastro, A.; Bois-Préau, D. Online Optimal Control of A Parallel Hybrid with After-Treatment Constraint Integration. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar]

- Fröberg, A.; Åslund, J.; Nielsen, L. Optimal Transient Control of Power Generation in Hybrid Construction Equipment. In Proceedings of the Vehicle Power and Propulsion Conference (VPPC), 2011 IEEE, Chicago, IL, USA, 6–9 September 2011; pp. 2–7. [Google Scholar]

- Lescot, J.; Sciarretta, A.; Chamaillard, Y.; Charlet, A. On The Integration of Optimal Energy Management and Thermal Management of Hybrid Electric Vehicles. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar]

- Alnajjar, M.; Gerling, D. Minimization of Energy Losses in the Traction Drive of HEV using Optimized Adaptive Control. In Proceedings of the 2014 IEEE Vehicle Power and Propulsion Conference (VPPC), Coimbra, Portugal, 27–30 October 2014. [Google Scholar]

- Gurkaynak, Y.; Member, S.; Khaligh, A.; Member, S.; Emadi, A. Neural Adaptive Control Strategy for Hybrid Electric Vehicles with Parallel Powertrain. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010. [Google Scholar]

- Lhomme, W.; Bouscayrol, A.; Barrade, P. Simulation of a Series Hybrid Electric Vehicle based on Energetic Macroscopic Representation. In Proceedings of the 2004 IEEE International Symposium on Industrial Electronics, Ajaccio, France, 4–7 May 2004. [Google Scholar]

| Basic-Vehicle | Hybrid | Prated-EM (kW) | n-Cell | Vd (cc) | Gear-Ratio |

|---|---|---|---|---|---|

| Aprilia-RSV4-RF-2017 | S | 110 | 24 | 2778 | 7.2 |

| P | 174 | 29 | 1380 | ||

| SP | 196 | 20 | 1220 | ||

| CT6-2017 | S | 71 | 137 | 1440 | 14.88 |

| P | 115 | 156 | 1500 | ||

| SP | 71 | 230 | 2550 | ||

| Noao | S | 76 | 144 | 1200 | 10.8 |

| P | 121 | 211 | 1200 | ||

| SP | 278 | 120 | 1660 | ||

| BYD K9 | S | 77 | 969 | 2960 | 21.65 |

| P | 100 | 813 | 3500 | ||

| SP | 166.5 | 942 | 1780 |

| Vehicle | Driving-Cycle | Architecture | CsT | mf (L/100 km) |

|---|---|---|---|---|

| Aprilia-RSV4-RF-2017 | WLTP | S | DP | 1.81 |

| P | DP | 3.43 | ||

| SP | RB | 2.22 | ||

| CT6-2017 | WLTP | S | DP | 5.12 |

| P | DP | 6.32 | ||

| SP | RB | 6.11 | ||

| NOAO | RACE-WAY | S | DP | 7.03 |

| P | DP | 7.20 | ||

| SP | RB | 5.48 | ||

| BYD K9 | ARTEMIS-URBAN | S | DP | 22.00 |

| P | DP | 15.28 | ||

| SP | RB | 13.94 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, S.; Chrenko, D.; Kéromnès, A.; Le Moyne, L. Development of a Multi-Architecture and Multi-Application Hybrid Vehicle Design and Management Tool. Energies 2018, 11, 3185. https://doi.org/10.3390/en11113185

Gan S, Chrenko D, Kéromnès A, Le Moyne L. Development of a Multi-Architecture and Multi-Application Hybrid Vehicle Design and Management Tool. Energies. 2018; 11(11):3185. https://doi.org/10.3390/en11113185

Chicago/Turabian StyleGan, Shiyu, Daniela Chrenko, Alan Kéromnès, and Luis Le Moyne. 2018. "Development of a Multi-Architecture and Multi-Application Hybrid Vehicle Design and Management Tool" Energies 11, no. 11: 3185. https://doi.org/10.3390/en11113185

APA StyleGan, S., Chrenko, D., Kéromnès, A., & Le Moyne, L. (2018). Development of a Multi-Architecture and Multi-Application Hybrid Vehicle Design and Management Tool. Energies, 11(11), 3185. https://doi.org/10.3390/en11113185