A New Integration System for Natural Gas Combined Cycle Power Plants with CO2 Capture and Heat Supply

Abstract

:1. Introduction

2. Concept Design of a NGCC Power Plant with CO2 Capture and Heat Supply

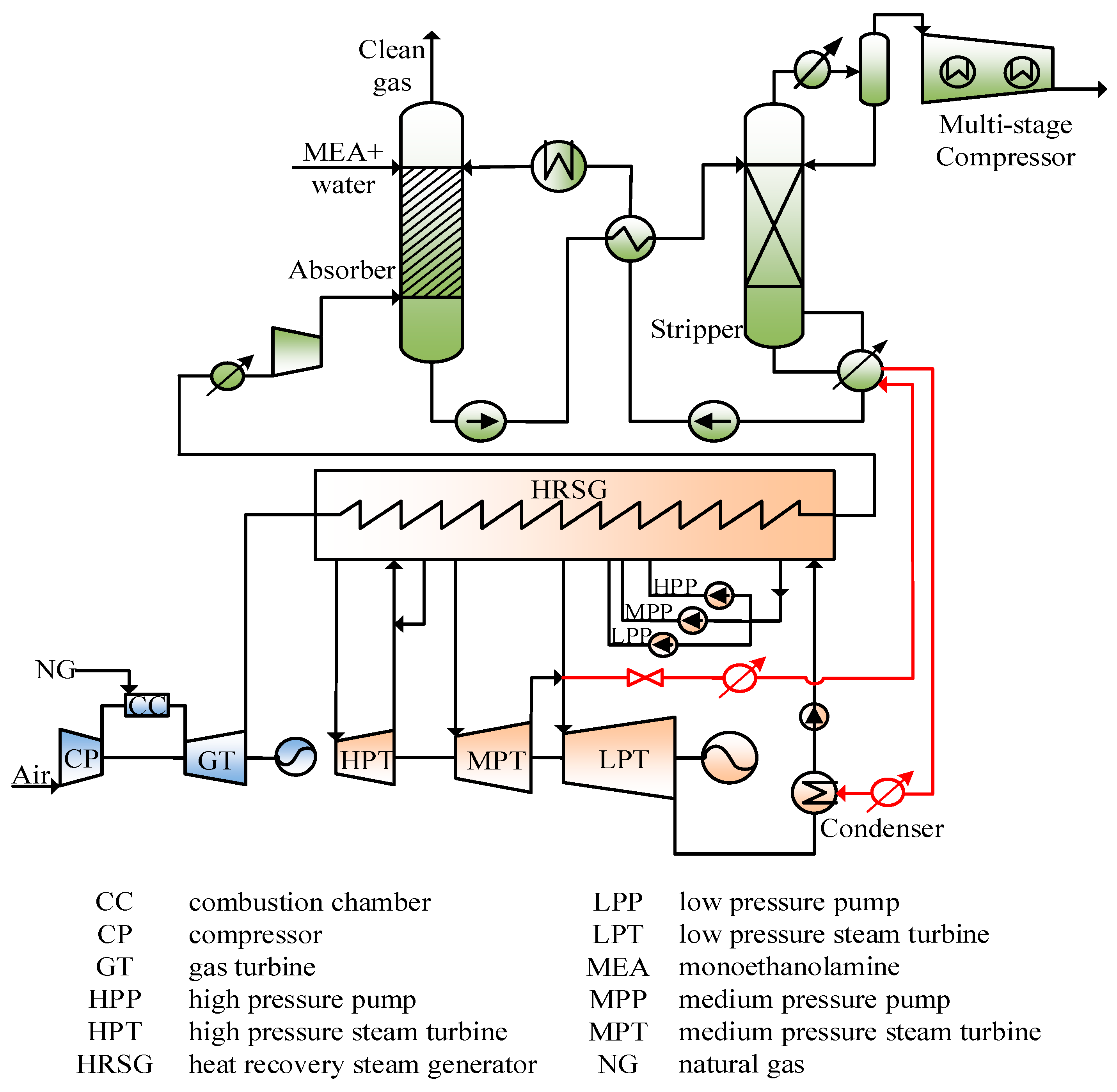

2.1. Typical Configuration of a NGCC Power Plant with MEA-Based CO2 Capture

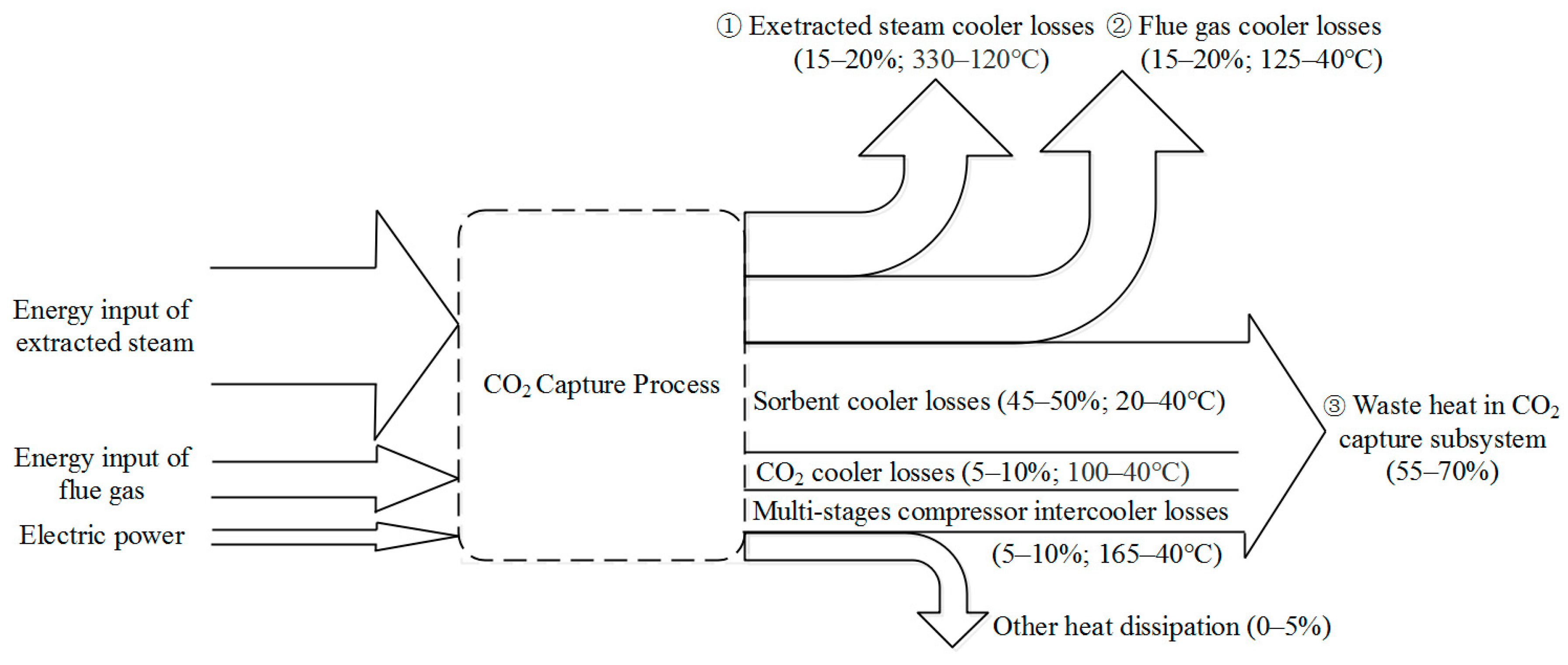

2.2. Energy Distribution Characteristics of the MEA-Based CO2 Capture Process

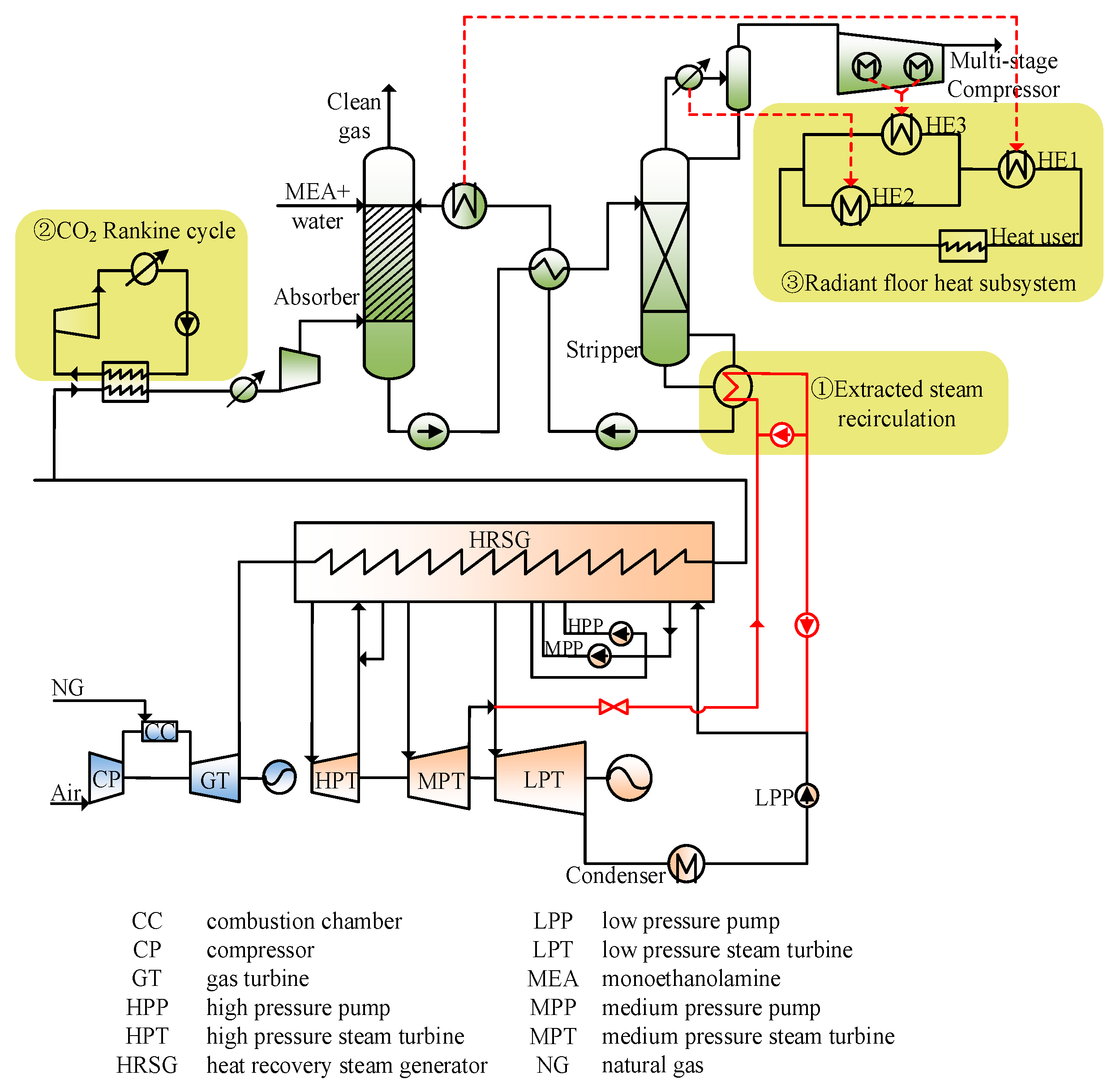

2.3. Description of the Improved De-Carbonization NGCC Power Plant Integrated with Heat Supply

3. Case Study

3.1. Main Assumptions and Case Description

- Base case: NGCC power plant without CO2 capture

- Case 1: De-carbonization NGCC power plant without system integration

- Case 2: De-carbonization NGCC power plant with system integration

3.2. Simulation Basis

3.3. Evaluation Criteria

4. Results and Discussion

4.1. Thermodynamic Performance

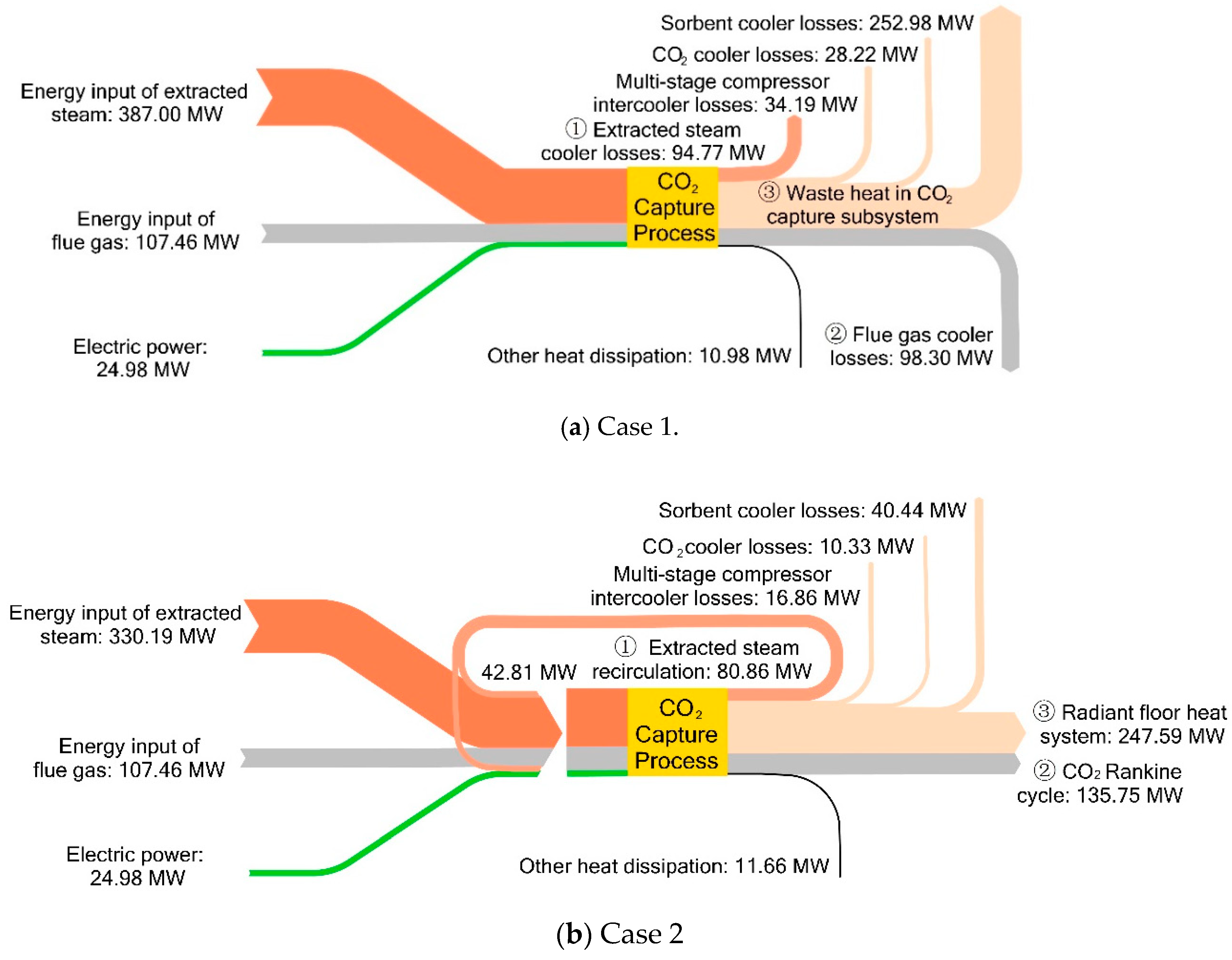

4.2. Energy Analysis for the CO2 Capture Process

4.3. Techno-Economic Analysis

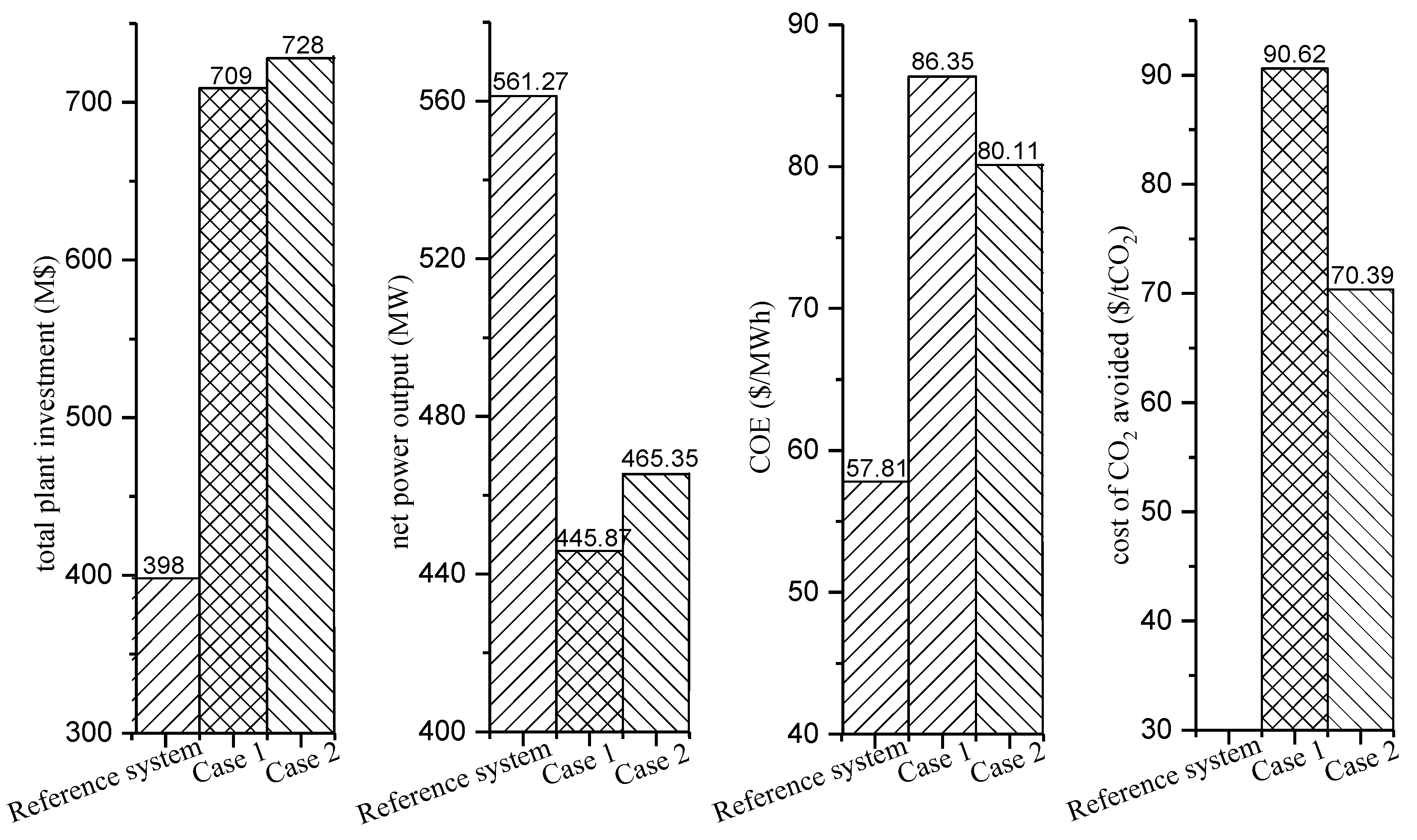

4.3.1. Techno-Economic Criteria

4.3.2. Techno-Economic Assumptions

4.3.3. Techno-Economic Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Climate Change 2007 Synthesis Report. Available online: http://www.ipcc.ch/pdf/assessment-report/ar4/syr/ar4_syr_full_report.pdf (accessed on 28 October 2018).

- Climate Change 2014 Mitigation of Climate Change, Working Group III Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Available online: http://www.ipcc.ch/pdf/assessment-report/ar5/wg3/ipcc_wg3_ar5_full.pdf (accessed on 28 October 2018).

- Yamagata, Y. Global negative emission land use scenarios and their ecological implications. In Encyclopedia of Ecology, 2nd ed.; Fath, B., Ed.; Elsevier: New York, NY, USA, 2019; Volume 4, pp. 96–107. ISBN 978-0-444-64130-4. [Google Scholar]

- Budinis, S.; Krevor, S.; Mac Dowell, N.; Brandon, N.; Hawkes, A. An assessment of CCS costs barriers and potential. Energy Strategy Rev. 2018, 22, 61–81. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Y.F.; Zhang, W.X.; Wang, J.L.; Soltanian, M.R.; Olabi, A.G. Effectiveness of amino acid salt solutions in capturing CO2: A review. Renew. Sustain. Energy Rev. 2018, 98, 179–188. [Google Scholar] [CrossRef]

- Zareiekordshouli, F.; Lashanizadehgan, A.; Darvishi, P. Experimental and theoretical study of CO2 solubility under high pressure conditions in the ionic liquid 1-ethyl-3-methylimidazolium acetate. J. Supercrit. Fluid 2018, 133, 195–210. [Google Scholar] [CrossRef]

- Yu, H. Recent developments in aqueous ammonia-based post-combustion CO2 capture technologies. Chin. J. Chem. Eng. 2018, in press. [Google Scholar] [CrossRef]

- Mores, P.L.; Manassaldi, J.I.; Scenna, N.J.; Caballero, J.A.; Mussati, M.C.; Mussati, S.F. Optimization of the design operating conditions and coupling configuration of combined cycle power plants and CO2 capture processes by minimizing the mitigation cost. Chem. Eng. J. 2018, 331, 870–894. [Google Scholar] [CrossRef]

- Prentza, L.; Koronaki, I.P.; Papoutsis, E.G.; Papaefthimiou, V.D. Dynamic simulation and parametric sensitivity study in reactive CO2 capture systems—A solvent comparison study. Therm. Sci. Eng. Prog. 2018, 5, 555–567. [Google Scholar] [CrossRef]

- Herraiz, L.; Fernández, E.S.; Palfi, E.; Lucquiaud, M. Selective exhaust gas recirculation in combined cycle gas turbine power plants with post-combustion CO2 capture. Int. J. Greenh. Gas Control 2018, 71, 303–321. [Google Scholar] [CrossRef]

- Wang, C.; Li, S.; Liu, F.; Gao, L.; Sui, J. Post combustion CO2 capture in power plant using low temperature steam upgraded by double absorption heat transformer. Appl. Energy 2018, 227, 603–612. [Google Scholar] [CrossRef]

- Cau, G.; Tola, V.; Ferrara, F.; Porcu, A.; Pettinau, A. CO2-free coal-fired power generation by partial oxy-fuel and post-combustion CO2 capture: Techno-economic analysis. Fuel 2018, 214, 423–435. [Google Scholar] [CrossRef]

- Oh, S.Y.; Yun, S.; Kin, J.K. Process integration and design for maximizing energy efficiency of a coal-fired power plant integrated with amine-based CO2 capture process. Appl. Energy 2018, 216, 311–322. [Google Scholar] [CrossRef]

- Rio, M.S.; Gibbins, J.; Lucquiaud, M. On the retrofitting and repowering of coal power plants with post-combustion carbon capture: An advanced integration option with a gas turbine windbox. Int. J. Greenh. Gas Control 2017, 58, 299–311. [Google Scholar] [CrossRef]

- Yu, Y.S.; Li, Y.; Li, Q.; Jiang, J.; Zhang, Z.X. An innovative process for simultaneous removal of CO2 and SO2 from flue gas of a power plant by energy integration. Energy Convers. Manag. 2009, 50, 2885–2892. [Google Scholar] [CrossRef]

- Ystad, P.A.M.; Lakew, A.A.; Bolland, O. Integration of low-temperature transcritical CO2 Rankine cycle in natural gas-fired combined cycle (NGCC) with post-combustion CO2 capture. Int. J. Greenh. Gas Control 2013, 12, 213–219. [Google Scholar] [CrossRef]

- Kurtulus, K.; Coskun, A.; Ameen, S.; Yilmaz, C.; Bolatturk, A. Thermoeconomic analysis of a CO2 compression system using waste heat into the regenerative organic Rankine cycle. Energy Convers. Manag. 2018, 168, 588–598. [Google Scholar] [CrossRef]

- Zhai, R.R.; Yu, H.; Chen, Y.; Li, K.K.; Yang, Y.P. Integration of the 660MW supercritical steam cycle with the NH3-based CO2 capture process: System integration mechanism and general correlation of energy penalty. Int. J. Greenh. Gas Control 2018, 72, 117–129. [Google Scholar] [CrossRef]

- Alie, C.; Backham, L.; Croiset, E.; Douglas, P.L. Simulation of CO2 capture using MEA scrubbing: A flowsheet decomposition method. Energy Convers. Manag. 2005, 46, 475–487. [Google Scholar] [CrossRef]

- Bonaventura, D.; Chacartegui, R.; Valverde, J.M.; Becerra, J.A.; Ortiz, C.; Lizana, J. Dry carbonate process for CO2 capture and storage: Integration with solar thermal power. Renew. Sustain. Energy Rev. 2018, 82, 1796–1812. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, Q.; Yang, Z.P.; Li, X.S.; Xu, G.; Yang, Y.P. An improved supercritical coal-fired power generation system incorporating a supplementary supercritical CO2 cycle. Appl. Energy 2018, in press. [Google Scholar] [CrossRef]

- Adams, T.; Mac Dowell, N. Off-design point modelling of a 420 MW CCGT power plant integrated with an amine-based post-combustion CO2 capture and compression process. Appl. Energy 2016, 178, 681–702. [Google Scholar] [CrossRef]

- Luo, X.; Wang, M.; Chen, J. Heat integration of natural gas combined cycle power plant integrated with post-combustion CO2 capture and compression. Fuel 2015, 151, 110–117. [Google Scholar] [CrossRef]

- Rezazadeh, F.; Gale, W.F.; Akram, M.; Hughes, K.J.; Pourkashanian, M. Performance evaluation and optimisation of post combustion CO2, capture processes for natural gas applications at pilot scale via a verified rate-based model. Int. J. Greenh. Gas Control 2016, 53, 243–253. [Google Scholar] [CrossRef]

- Liu, X.; Chen, J.; Luo, X.; Wang, M.; Meng, H. Study on heat integration of supercritical coal-fired power plant with post-combustion CO2, capture process through process simulation. Fuel 2015, 158, 625–633. [Google Scholar] [CrossRef]

- Xu, G.; Wu, Y.; Yang, Y.; Zhang, K.; Song, X. A novel integrated system with power generation CO2 capture and heat supply. Appl. Therm. Eng. 2013, 61, 110–120. [Google Scholar] [CrossRef]

- Reddick, C.; Sorin, M.; Rheault, F. Energy savings in CO2, (carbon dioxide) capture using ejectors for waste heat upgrading. Energy 2014, 65, 200–208. [Google Scholar] [CrossRef]

- Cost and Performance Baseline for Fossil Energy Power Plants, Volume 1, Bituminous Coal and Natural Gas to Electricity. Available online: http://www.netl.doe.gov/File%20Library/Research/Energy%20Analysis/OE/BitBase_FinRep_Rev2a-3_20130919_1.pdf (accessed on 25 September 2018).

- Ozcan, D.C.; Ahn, H.; Brandani, S. Process integration of a Ca-looping carbon capture process in a cement plant. Int. J. Greenh. Gas Control 2013, 19, 530–540. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Nord, N.; Ertesvåg, I.S.; Ge, Z.; Yang, Z.; Yang, Y. Integrated multiscale simulation of combined heat and power based district heating system. Energy Convers. Manag. 2015, 106, 337–354. [Google Scholar] [CrossRef]

- Solli, C.; Anantharaman, R.; Strømman, A.H.; Zhang, X.; Hertwich, E.G. Evaluation of different CHP options for refinery integration in the context of a low carbon future. Int. J. Greenh. Gas Control 2009, 3, 152–160. [Google Scholar] [CrossRef]

- Kuramochi, T.; Ramírez, A.; Faaij, A.; Turkenburg, W. Post-combustion CO2 capture from part-load industrial NGCCCHPs, selected results. Energy Procedia 2009, 1, 1395–1402. [Google Scholar] [CrossRef]

- Kreutz, T.; Williams, R.; Consonni, S.; Chiesa, P. Co-production of hydrogen, electricity and CO2 from coal with commercially ready technology. Part B: Economic analysis. Int. J. Hydrogen Energy 2005, 30, 769–784. [Google Scholar] [CrossRef]

- Frey, H.C.; Zhu, Y. 11–Techno-economic analysis of combined cycle systems. Comb. Cycle Syst. Near-Zero Emiss. Power Gener. 2012, 306–328. [Google Scholar] [CrossRef]

- Tianjin Development and Reform Commission, Heat Price. Available online: http://fzgg.tj.gov.cn/gzcx/syjgcx/gr/201307/t20130705_30045.shtml (accessed on 25 September 2018).

- Campanari, S.; Chiesa, P.; Manzolini, G.; Bedogni, S. Economic analysis of CO2 capture from natural gas combined cycles using molten carbonate fuel cells. Appl. Energy 2014, 130, 562–573. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, Q.; Fang, M.; Luo, Z.; Cen, K. Thermodynamic and economic analysis of polygeneration system integrating atmospheric pressure coal pyrolysis technology with circulating fluidized bed power plant. Appl. Energy 2014, 113, 1301–1314. [Google Scholar] [CrossRef]

| Gas Turbine Cycle | |||

| Gas turbine type | Advanced F Class | ||

| Air mass flowrate (t/h) | 3143.00 | ||

| Nature gas flowrate (kmol/h) | 4380.00 | ||

| Low heat value (LHV) of NG (kJ/kmol) | 817,955.00 | ||

| Steam Turbine Cycle | |||

| Temperature (°C) | Pressure (MPa) | Flowrate (t/h) | |

| HPT inlet steam | 560.0 | 16.65 | 392.50 |

| MPT inlet steam | 560.0 | 2.48 | 467.20 |

| LPT inlet steam | 329.7 | 0.52 | 509.30 |

| HPT exhaust steam | 304.1 | 2.69 | 392.50 |

| MPT exhaust steam | 334.2 | 0.52 | 467.20 |

| Condensate water | 38.8 | 0.90 | 514.20 |

| CO2 Capture Subsystem | |||

| CO2 recovery ratio (%) | 90 | ||

| Absorber pressure (MPa) | 0.10 | ||

| Reboiler pressure (MPa) | 0.22 | ||

| Pressure drop in column (MPa) | 0.01 | ||

| Multi-stage compressor | |||

| 1st stage outlet pressure (MPa) | 0.60 | ||

| 2nd stage outlet pressure (MPa) | 1.70 | ||

| 3rd stage outlet pressure (MPa) | 5.10 | ||

| 4th stage outlet pressure (MPa) | 15.00 | ||

| Classified Performance | Base Case | Case 1 | Case 2 |

|---|---|---|---|

| Power consumed by air compressor (MW) | 449.31 | 449.31 | 449.31 |

| GT power output (MW) | 823.26 | 823.26 | 823.26 |

| HPT power output (MW) | 48.33 | 48.33 | 48.33 |

| MPT power output (MW) | 59.76 | 59.76 | 59.76 |

| LPT power output (MW) | 95.15 | 3.72 | 14.15 |

| Auxiliary power (MW) | 9.57 | 34.55 | 39.08 |

| Net power output (MW) | 561.27 | 445.87 | 465.35 |

| Fuel molar LHV (kJ/kmol) | 817,955 | 817,955 | 817,955 |

| Flowrate of NG (kmol/h) | 4380 | 4380 | 4380 |

| Flue gas outlet temperature of HRSG (°C) | 122.4 | 122.3 | 161.1 |

| CO2 flowrate entering CO2 capture subsystem (kg/s) | 56.20 | 56.20 | 56.20 |

| Specific regeneration heat (GJ/tCO2) | —— | 5.18 | 5.18 |

| Flowrate of extracted steam (kg/s) | —— | 130.56 | 111.94 |

| Heat recovery in absorbent cooler (MW) | —— | —— | 212.58 |

| Heat recovery in extracted stream (MW) | —— | —— | 23.65 |

| Heat recovery in captured CO2 (MW) | —— | —— | 11.36 |

| Power generated by CO2 Rankin cycle (MW) | —— | —— | 13.69 |

| Pump power in CO2 Rankin cycle (MW) | —— | —— | 4.61 |

| Heat recovery by CO2 Rankin cycle (MW) | —— | —— | 135.94 |

| Net efficiency (%) | 56.4 | 44.80 | 46.76 |

| Overall energy efficiency (%) | 56.4 | 44.80 | 71.64 |

| Component | Scaling Parameter | CB (M$) | QB | M | Q |

|---|---|---|---|---|---|

| Heat exchanger | |||||

| HE1 | Heat transferred (MW) | 1.64 a | 57.20 a | 0.90 a | 212.58 |

| HE2 | Heat transferred (MW) | 1.64 a | 57.20 a | 0.90 a | 23.65 |

| HE3 | Heat transferred (MW) | 1.64 a | 57.20 a | 0.90 a | 7.93 |

| CO2 Rankine cycle | |||||

| Turbine | Power output (MW) | 30.77 a | 200.00 a | 0.67 a | 13.69 |

| Pump | Volume flow (m3/h) | 0.02 b | 250.00 b | 0.14 b | 2487.10 |

| HE | Heat transferred (MW) | 1.64 a | 57.20 a | 0.90 a | 135.94 |

| Condenser | Heat transferred (MW) | 1.64 a | 57.20 a | 0.90 a | 126.85 |

| Extracted stem pretreatment | |||||

| Pump | Volume flow (m3/h) | 0.02 b | 250 b | 0.140 b | 74.26 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Gao, Y.; Lv, H.; Xu, G.; Dong, S. A New Integration System for Natural Gas Combined Cycle Power Plants with CO2 Capture and Heat Supply. Energies 2018, 11, 3055. https://doi.org/10.3390/en11113055

Hu Y, Gao Y, Lv H, Xu G, Dong S. A New Integration System for Natural Gas Combined Cycle Power Plants with CO2 Capture and Heat Supply. Energies. 2018; 11(11):3055. https://doi.org/10.3390/en11113055

Chicago/Turabian StyleHu, Yue, Yachi Gao, Hui Lv, Gang Xu, and Shijie Dong. 2018. "A New Integration System for Natural Gas Combined Cycle Power Plants with CO2 Capture and Heat Supply" Energies 11, no. 11: 3055. https://doi.org/10.3390/en11113055

APA StyleHu, Y., Gao, Y., Lv, H., Xu, G., & Dong, S. (2018). A New Integration System for Natural Gas Combined Cycle Power Plants with CO2 Capture and Heat Supply. Energies, 11(11), 3055. https://doi.org/10.3390/en11113055