Flashover Performance and Process of Suspension Insulator Strings Artificially Covered with Snow

Abstract

:1. Introduction

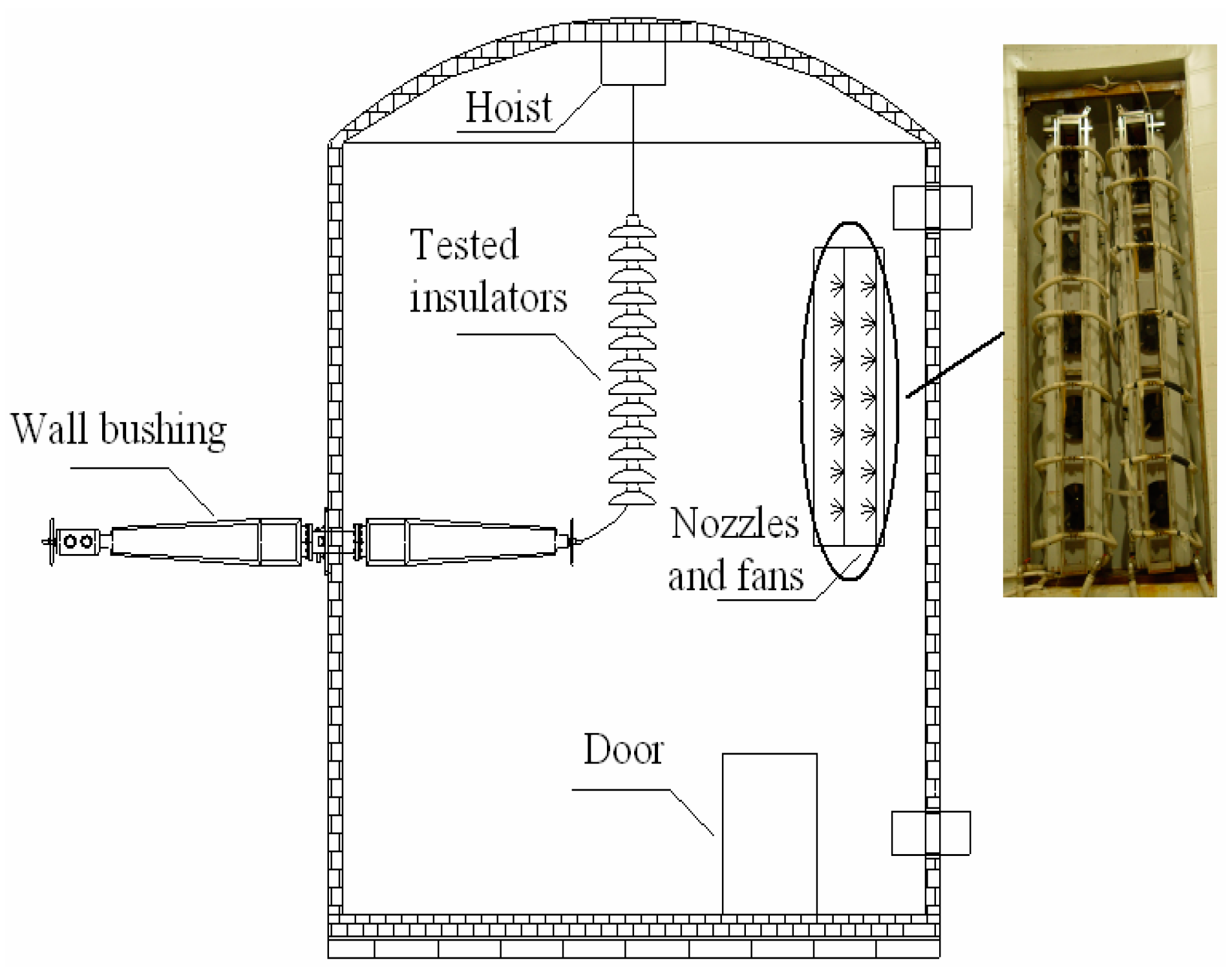

2. Test Equipment, Specimen, and Procedures

2.1. Test Equipment

2.2. Specimen

2.3. Test Procedures

- (1)

- Insulator contamination: The solid layer method recommended by the IEC standard was used to pollute insulators to simulate the contamination level before snow accretion [22,23]. Sodium chloride simulates conductive components and is characterized by equivalent salt deposit density (ESDD). Kaolin simulates inert components and is characterized by non-soluble deposit density (NSDD). ESDD is 0.05, 0.10, 0.15 mg/cm2 and 0.20 mg/cm2, respectively. The ratio of ESDD to NSDD is 1:4. The amount of sodium chloride and kaolin applied to the surface of the insulator was calculated according to ESDD, NSDD and the surface area of the specimen. The weighted sodium chloride and kaolin was added into deionized water with conductivity less than 10μS/cm. After fully stirring, the dirty liquid was evenly applied to the surface of the cleaned insulator for use. During the application process, special attention was given to applying the liquid evenly, avoiding spraying the contaminants on the steel foot and cap, and avoiding dirty liquid falling.

- (2)

- Snow accretion: As there are no relevant standards for snow accretion on insulator strings, reference [10] provides an experimental method for artificial snow accretion. The difference is that snow produced by nozzles directly accumulates on the insulator surface in this paper. Before icing, water conductivity was adjusted to 80 μS/cm and the water temperature dropped to 4 °C. Then the cooling system was turned on and the system was sprayed until the chamber temperature was between −9 and −13 °C, and the humidity was maintained between 89% and 95%, then the snow accretion test begun. The spraying system was not turned off until the snow thickness on the surface of the insulator met the requirement. The appearance of the snow-covered insulators was photographed and the snow density and thickness were measured.Because the porous structure of snow is easily destroyed and its density is affected, the drainage method applied to ice density measurement cannot accurately measure the density of snow. The following method was used to measure density in this paper. In the process of snow accretion, a flat plate with the surface area S and the weight m1 was placed in the chamber. After the snow accretion was over, the weight and thickness of the flat plate were measured, marked as m2 and h, respectively. Then, the density ρ was obtained by the following formula:

- (3)

- Flashover tests: In this paper, the U-type method is used to obtain the flashover voltage of the snow-covered insulator [24]. The procedure was as follows. The sealing door was opened to increase the temperature to about −2 °C in the climate chamber. Then, the temperature rise rate was controlled at 0.5 °C/5 min. The flashover tests were conducted on the snow-covered insulator by using the voltage boosting method. In order to prevent the influence of the snow layer melting on the results, the interval between adjacent flashover tests was 1~2 min. When multiple flashover voltage values Ufi were obtained, the relationship between Ufi and flashover time showed a U-shaped curve, and the lowest point was the lowest flashover voltage Umin:

3. Results and Analysis

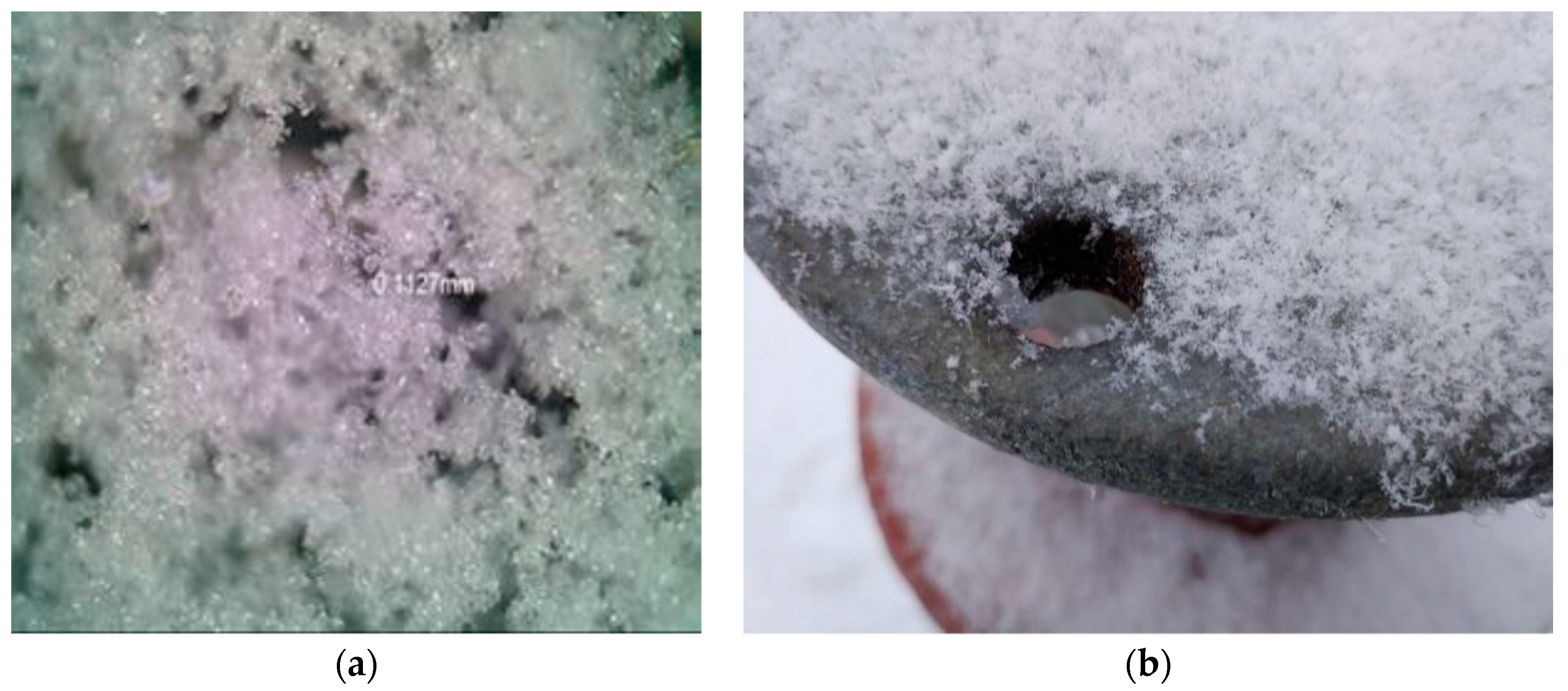

3.1. Comparison between Artificial Snow and Natural Snow

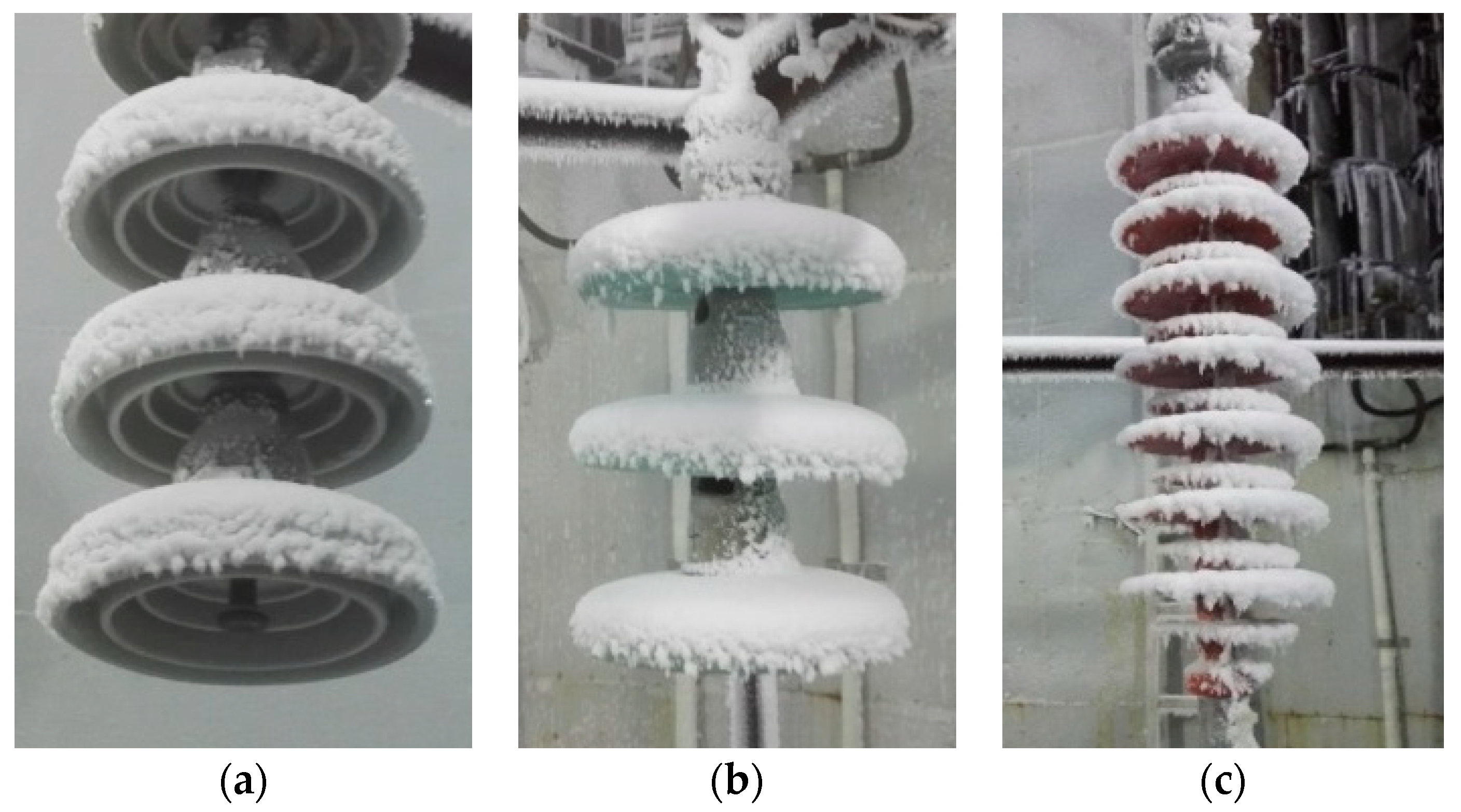

3.2. Appearance of Snow-Covered Insulator Strings

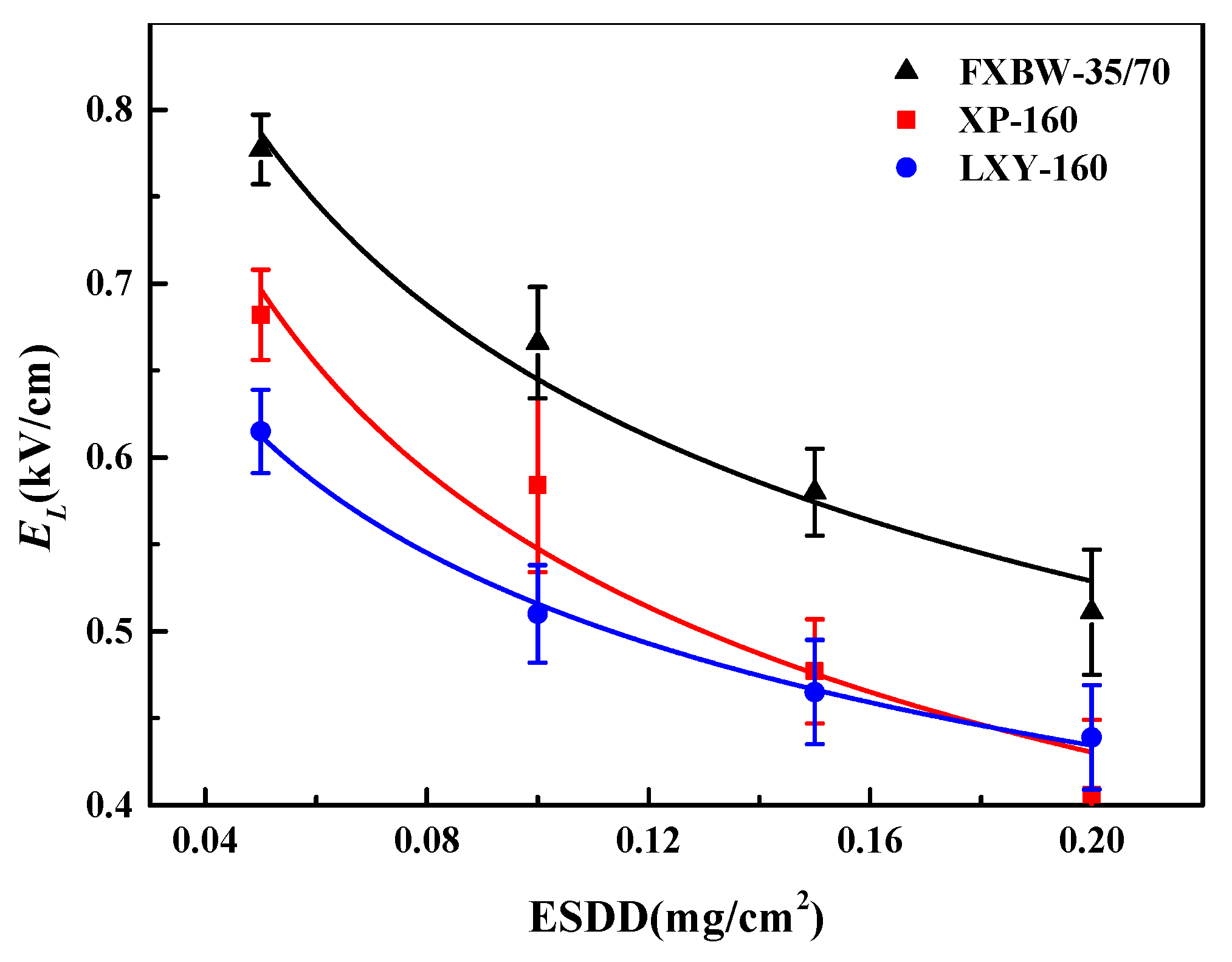

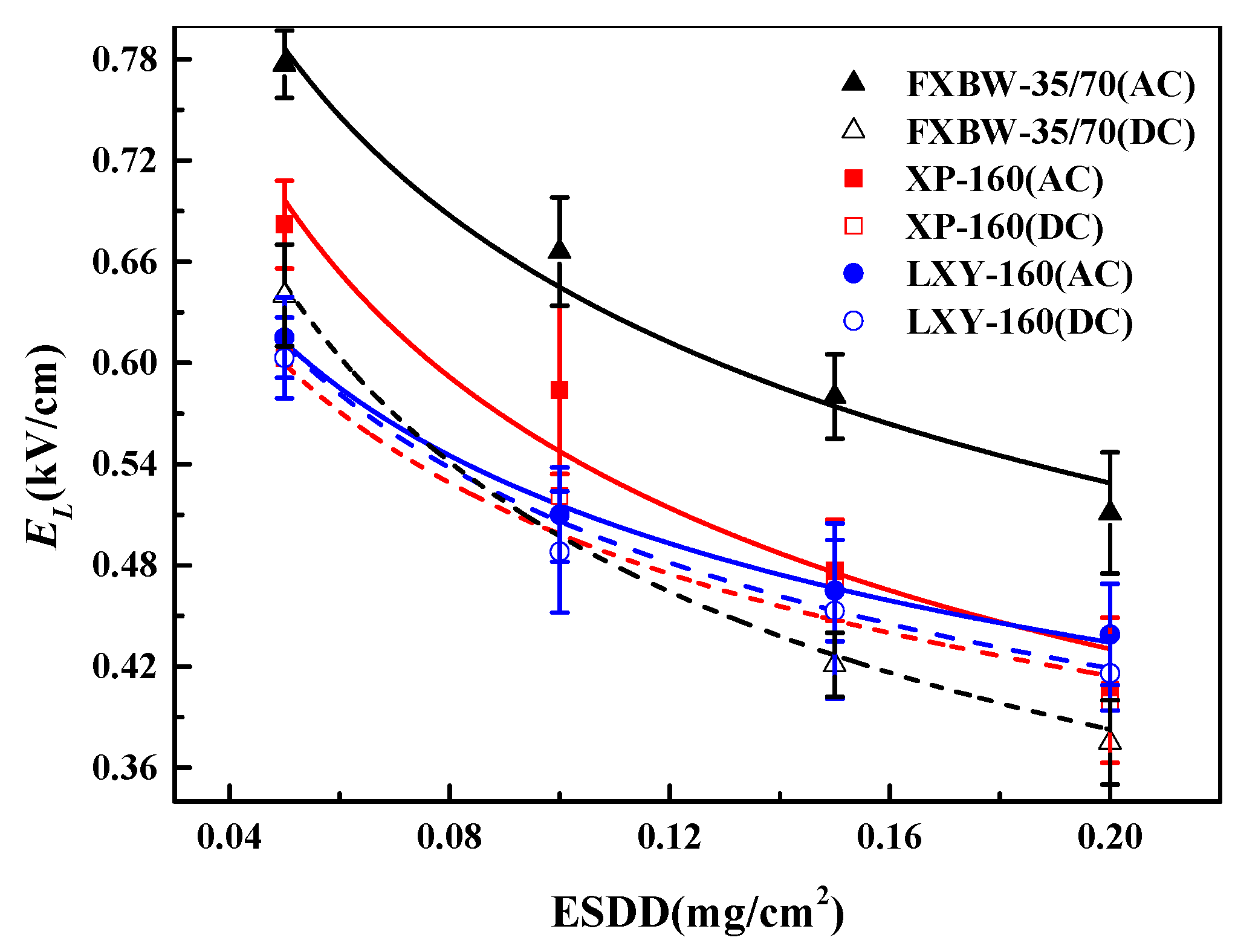

3.3. Effect of ESDD on EL

- (1)

- The relationship between Umin, EL and ESDD is a power function with a negative exponent. The values of n for the three insulators are 0.368, 0.244, and 0.296, respectively. Among them, the porcelain insulator has the largest n, which indicates that the snow flashover voltage is affected more by ESDD than that of the glass and composite insulators.

- (2)

- For the same contamination level, the inequality is established as follows: EL (FXBW-35/70) > EL (XP-160) > EL (LXY-160). That is, the insulation performance of FXBW-35/70 among three kinds of snow-covered insulators is the best, and that of LXY-160 is the worst. This phenomenon is related to the creepage distance. According to Figure 4, when snow thickness reaches 10 mm, the three types of insulators are not bridged by accumulated snow, and the creepage distance can still be effectively utilized.

3.4. Effect of Voltage Type on EL

- (1)

- The relationship between Umin, EL and ESDD meets the power function with a negative exponent. n is 0.263~0.390. The value of n for the composite insulator is the largest. It is indicated that ESDD has a larger impact on the snow flashover voltage of the composite insulator than that of the porcelain and glass insulators.

- (2)

- The DC flashover voltage is lower than AC flashover voltage for the same type of snow-covered insulator. For example, when ESDD is 0.10 mg/cm2, the AC arc flashover gradient of porcelain, glass, and composite insulators are 0.584 kV/cm, 0.510 kV/cm and 0.666 kV/cm, respectively, and the DC arc flashover gradients are 0.521 kV/cm, 0.488 kV/cm and 0.517 kV/cm, respectively, which decrease by 10.8%, 4.31% and 22.4%, respectively.

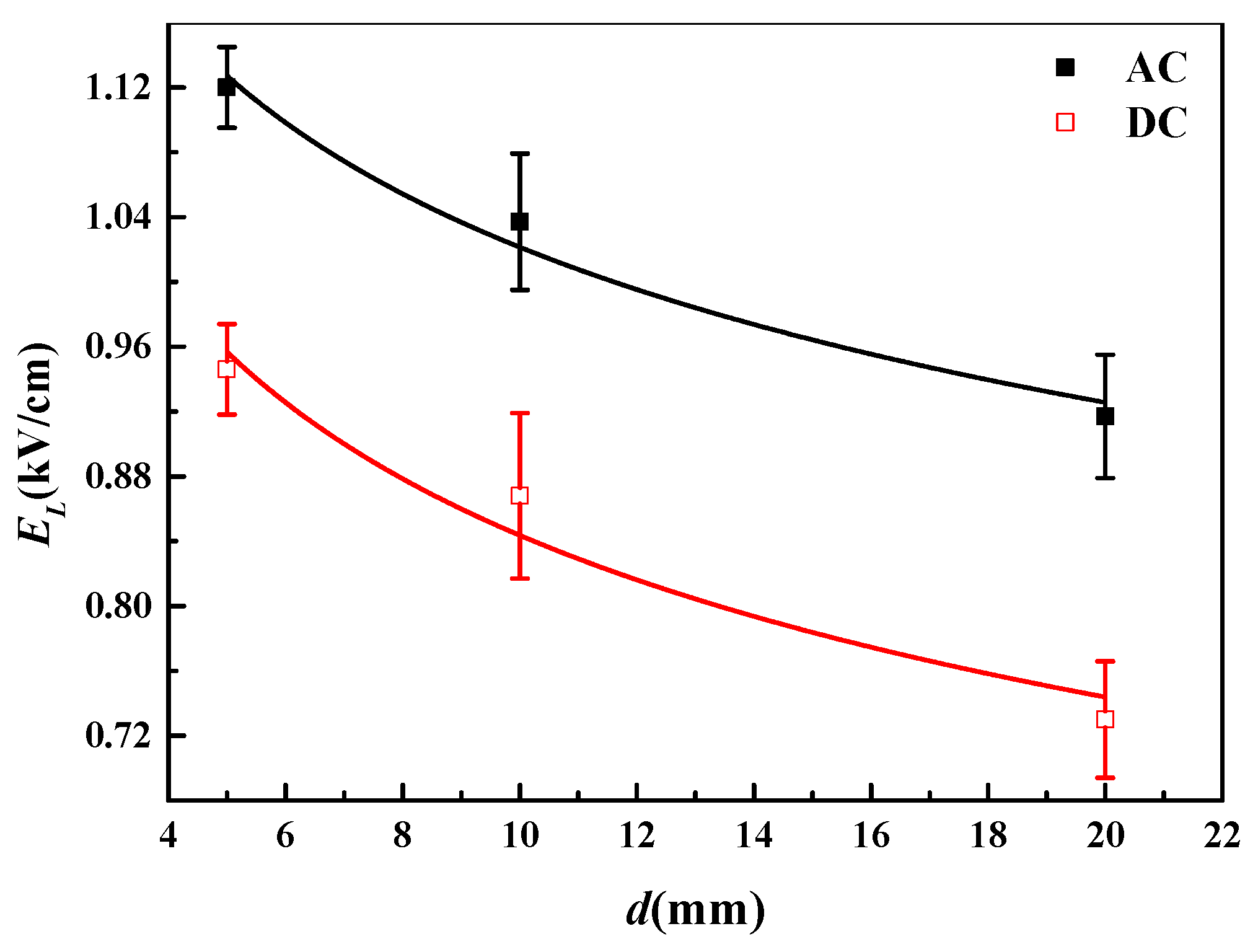

3.5. Effect of d on EL

- (1)

- With the increase of snow thickness d, the flashover voltage Umin and arc flashover gradient EL decline. Furthermore, the relationship between EL and d is a power function with a negative exponent.

- (2)

- The AC arc flashover gradient of the composite insulators is greater than the DC arc flashover gradient, and the gap between them increases with the increase of snow thickness. For example, when ESDD is 0.02 mg/cm2 and d is 5 mm,10 mm and 20 mm, the AC arc flashover gradients are 1.120 kV/cm, 1.037 kV/cm and 0.917 kV/cm, respectively. The DC arc flashover gradients are 0.946 kV/cm, 0.868 kV/cm and 0.730 kV/cm, which decreased by 15.5%, 16.3% and 20.4%, respectively.

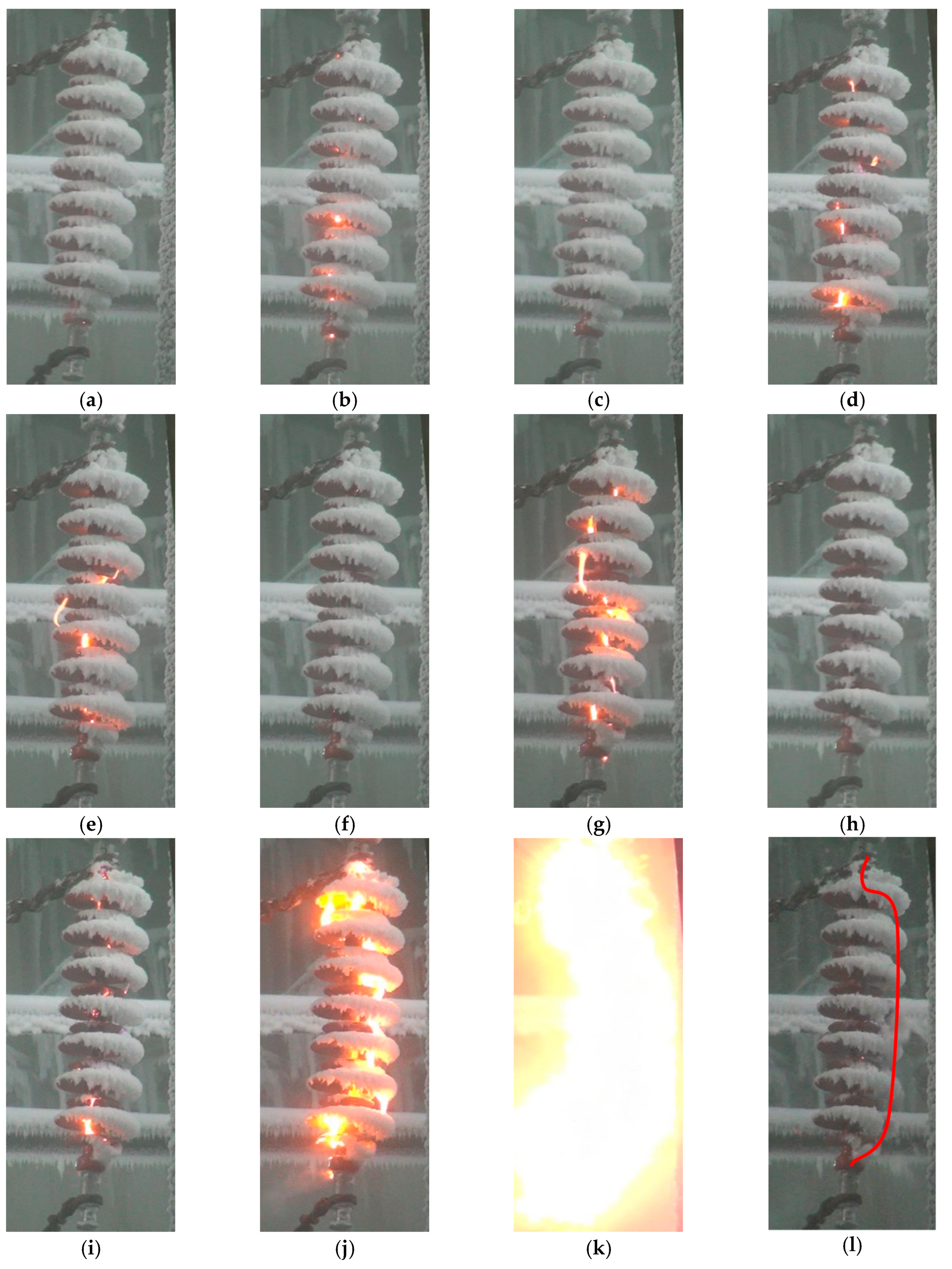

4. Arc Discharge Development Process of the Snow-Covered Insulator

5. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, Z. Ultra-High Voltage AC and DC Grid; China Electric Power Press: Beijing, China, 2002. [Google Scholar]

- Jiang, X.; Zhang, Z.; Hu, Q.; Hu, J.; Shu, L. Thinkings on the restrike of ice and snow disaster to the power grid. High Volt. Eng. 2018, 44, 463–469. [Google Scholar]

- Lu, J.; Xie, P.; Jiang, Z.; Fang, Z.; Wu, W. Voltage distribution and flashover performance of 220kV composite insulators under different icing conditions. Energies 2018, 11, 632. [Google Scholar] [CrossRef]

- Jiang, X.; Hu, Y.; Shu, L.; Zhang, Z.; Hu, J.; Hu, Q.; Wang, Q. Crystallisation effect of conductive ions in freezing water during phase transition and its effect on ice flashover voltage. IET Gener. Transm. Distrib. 2016, 10, 2147–2154. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, Q.; Zhang, Z.; Hu, J.; Hu, Q.; Zhu, C. Ion migration in the process of water freezing under alternating electric field and its impact on insulator flashover. Energies 2017, 10, 61. [Google Scholar] [CrossRef]

- Hu, Y.; Jiang, X.; Shu, L.; Zhang, Z.; Hu, Q.; Hu, J. DC flashover performance of ice-covered insulators under complex ambient conditions. IET Gener. Transm. Distrib. 2016, 10, 2504–2511. [Google Scholar] [CrossRef]

- Farzaneh, M.; Chisholm, W. Insulators for Icing and Polluted Environments; John Wiley & Sons Inc.: New York, NY, USA, 2009. [Google Scholar]

- Yaji, K.; Homma, H.; Sakata, G.; Watanabe, M. Evaluation on flashover voltage property of snow accreted insulators for overhead transmission lines, Part I—Field observation and laboratory tests to evaluate snow accretion properties. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2549–2558. [Google Scholar] [CrossRef]

- Yaji, K.; Homma, H.; Aso, T.; Watanabe, M. Evaluation on flashover voltage property of snow accreted insulators for overhead transimission lines. Part II—Flashover characteristics under salt contaminated snowstorm. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2559–2567. [Google Scholar]

- Homma, H.; Yaji, K.; Aso, T.; Watanabe, M.; Sakata, G.; Demfalk, A. Evaluation on flashover voltage property of snow accreted insulators for overhead transimission lines, Part III—154kV full-scale flashover voltage test of snow accreted insulators. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 2568–2575. [Google Scholar] [CrossRef]

- Hemmatjou, H.; Farzaneh, M.; Fofana, I. Modeling of the AC arc discharge on snow-covered insulators. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 1390–1400. [Google Scholar] [CrossRef]

- Pappas, S.S.; Ekonomou, L. Comparison of adaptive techniques for the prediction of the equivalent salt deposit density of medium voltage insulators. WSEAS Trans. Power. Syst. 2017, 12, 220–224. [Google Scholar]

- Liu, Y.; Farzaneh, M.; Du, B. Investigation on shed icicle characteristeics and induced surface discharges along a suspension insulator string during ice accretion. IET Gener. Transm. Distrib. 2017, 11, 1265–1269. [Google Scholar] [CrossRef]

- Ale-Emran, S.M.; Farzaneh, M. Flashover performance of ice-covered post insulator with booster sheds using experiments and partial arc modeling. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 979–986. [Google Scholar] [CrossRef]

- Jiang, X.; Han, X.; Hu, Y.; Yang, Z. Model for ice wet growth on composite insulator and its experimental validation. IET Gener. Transm. Distrib. 2018, 12, 556–563. [Google Scholar] [CrossRef]

- Vita, V.; Ekomomou, L.; Chatzarakis, G.E. Design of artificial neural network models for the estimation of distribution system voltage insulators’ contamination. In Proceedings of the 12th WSEAS International Conference on Mathematical Methods, Computational Techniques and Intelligent Systems, Kantaoui, Sousse, Tunisia, 3–6 May 2010; pp. 227–231. [Google Scholar]

- Oikonomou, D.S.; Maris, T.I.; Ekonomou, L. Artificial intelligence assessment of sea salt contamination of medium voltage insulators. In Proceedings of the 8th WSEAS International Conference on Systems Theory and Scientific Computation, Rhodes, Greece, 26–28 October 2008; pp. 319–323. [Google Scholar]

- Yasui, M.; Naito, K.; Hasegawa, Y. AC withstand voltage characteristics of insulator string covered with snow. IEEE Trans. Power Deliv. 1988, 3, 828–838. [Google Scholar] [CrossRef]

- Wang, Y.; Ouyang, B.; Lian, S.; Pan, B. Study on electric field distribution along the surface of snowed composite insulator in high altitude area. High Volt. Apprais. 2016, 52, 115–123. [Google Scholar]

- Xiang, Z.; Jiang, X.; Zhang, Z.; Hu, J.; Jin, X.; Guo, Y. AC flashover performance of glass insulators covered with ice or snow at natural station. High Volt. Eng. 2014, 40, 1345–1350. [Google Scholar]

- Farzaneh, M.; Baker, T.; Bernstorf, A.; Brown, K. Insulator icing test methods and procedures: A position paper prepared by the IEEE task force on insulator icing test methods. IEEE Trans. Power Deliv. 2003, 18, 1503–1515. [Google Scholar] [CrossRef]

- IEC Std. 61245-2015, Artificial Pollution Tests on High-Voltage Insulators to Be Used on DC Systems; International Electrotechnical Commission: Geneva, Switzerland, 2015.

- IEC Std. 60507-2013, Artificial Pollution Tests on High-Voltage Insulators to Be Used on AC Systems; International Electrotechnical Commission: Geneva, Switzerland, 2013.

- Jiang, X.; Shu, L.; Sun, C. Insulation of Electric Power System under Pollution and Icing Conditions; China Electric Power Press: Beijing, China, 2009. [Google Scholar]

- Jiang, X.; Yi, H. Ice Accretion on Transmission Lines and Protection; China Electric Power Press: Beijing, China, 2002. [Google Scholar]

- Zhang, Z.; Huang, H.; Jiang, X.; Hu, J.; Sun, C. Analysis of ice growth on different type insulators based on fluid dynamics. Trans. China Electr. Soc. 2012, 27, 35–43. [Google Scholar]

| Insulator | D/mm | H/mm | L/mm |

|---|---|---|---|

| XP-160 | 291 | 162 | 420 |

| LXY-160 | 280 | 170 | 410 |

| FXBW-35/70 | 110/80 | 615 | 1375 |

| ESDD (mg/cm2) | XP-160 | LXY-160 | FXBW-35/70 | |||

|---|---|---|---|---|---|---|

| Umin (kV) | EL (kV/cm) | Umin (kV) | EL (kV/cm) | Umin (kV) | EL (kV/cm) | |

| 0.05 | 85.9 | 0.682 | 75.6 | 0.615 | 106.8 | 0.777 |

| 0.10 | 73.6 | 0.584 | 62.7 | 0.510 | 91.6 | 0.666 |

| 0.15 | 60.1 | 0.477 | 57.2 | 0.465 | 79.8 | 0.580 |

| 0.20 | 51.2 | 0.406 | 54.0 | 0.439 | 70.3 | 0.511 |

| Parameters | XP-160 | LXY-160 | FXBW-35/70 |

|---|---|---|---|

| AS | 0.234 | 0.294 | 0.327 |

| n | 0.368 | 0.244 | 0.296 |

| R2 | 0.952 | 0.996 | 0.976 |

| ESDD (mg/cm2) | XP-160 | LXY-160 | FXBW-35/70 | |||

|---|---|---|---|---|---|---|

| Umin (kV) | EL (kV/cm) | Umin (kV) | EL (kV/cm) | Umin (kV) | EL (kV/cm) | |

| 0.05 | 76.0 | 0.603 | 74.2 | 0.603 | 88.0 | 0.640 |

| 0.10 | 65.7 | 0.521 | 60.0 | 0.488 | 71.1 | 0.517 |

| 0.15 | 58.8 | 0.467 | 55.7 | 0.453 | 57.9 | 0.421 |

| 0.20 | 50.2 | 0.398 | 51.2 | 0.416 | 51.5 | 0.375 |

| Parameters | XP-160 | LXY-160 | FXBW-35/70 |

|---|---|---|---|

| AS | 0.263 | 0.272 | 0.203 |

| n | 0.285 | 0.263 | 0.390 |

| R2 | 0.953 | 0.991 | 0.988 |

| d (mm) | AC | DC | ||

|---|---|---|---|---|

| Umin (kV) | EL (kV/cm) | Umin (kV) | EL (kV/cm) | |

| 5 | 154.0 | 1.120 | 130.1 | 0.946 |

| 10 | 142.6 | 1.037 | 119.4 | 0.868 |

| 20 | 126.1 | 0.917 | 100.7 | 0.730 |

| FXBW-35/70 | Ad | m | R2 |

|---|---|---|---|

| AC | 1.417 | 0.142 | 0.965 |

| DC | 1.282 | 0.182 | 0.925 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Guo, S.; Xian, R.; Han, X.; Yang, Z.; Wu, Y. Flashover Performance and Process of Suspension Insulator Strings Artificially Covered with Snow. Energies 2018, 11, 2916. https://doi.org/10.3390/en11112916

Hu Y, Guo S, Xian R, Han X, Yang Z, Wu Y. Flashover Performance and Process of Suspension Insulator Strings Artificially Covered with Snow. Energies. 2018; 11(11):2916. https://doi.org/10.3390/en11112916

Chicago/Turabian StyleHu, Yuyao, Sihua Guo, Richang Xian, Xingbo Han, Zhongyi Yang, and Ying Wu. 2018. "Flashover Performance and Process of Suspension Insulator Strings Artificially Covered with Snow" Energies 11, no. 11: 2916. https://doi.org/10.3390/en11112916

APA StyleHu, Y., Guo, S., Xian, R., Han, X., Yang, Z., & Wu, Y. (2018). Flashover Performance and Process of Suspension Insulator Strings Artificially Covered with Snow. Energies, 11(11), 2916. https://doi.org/10.3390/en11112916