A Novel Energy-Efficient Wobble Plate Hydraulic Joint for Mobile Robotic Manipulators

Abstract

:1. Introduction

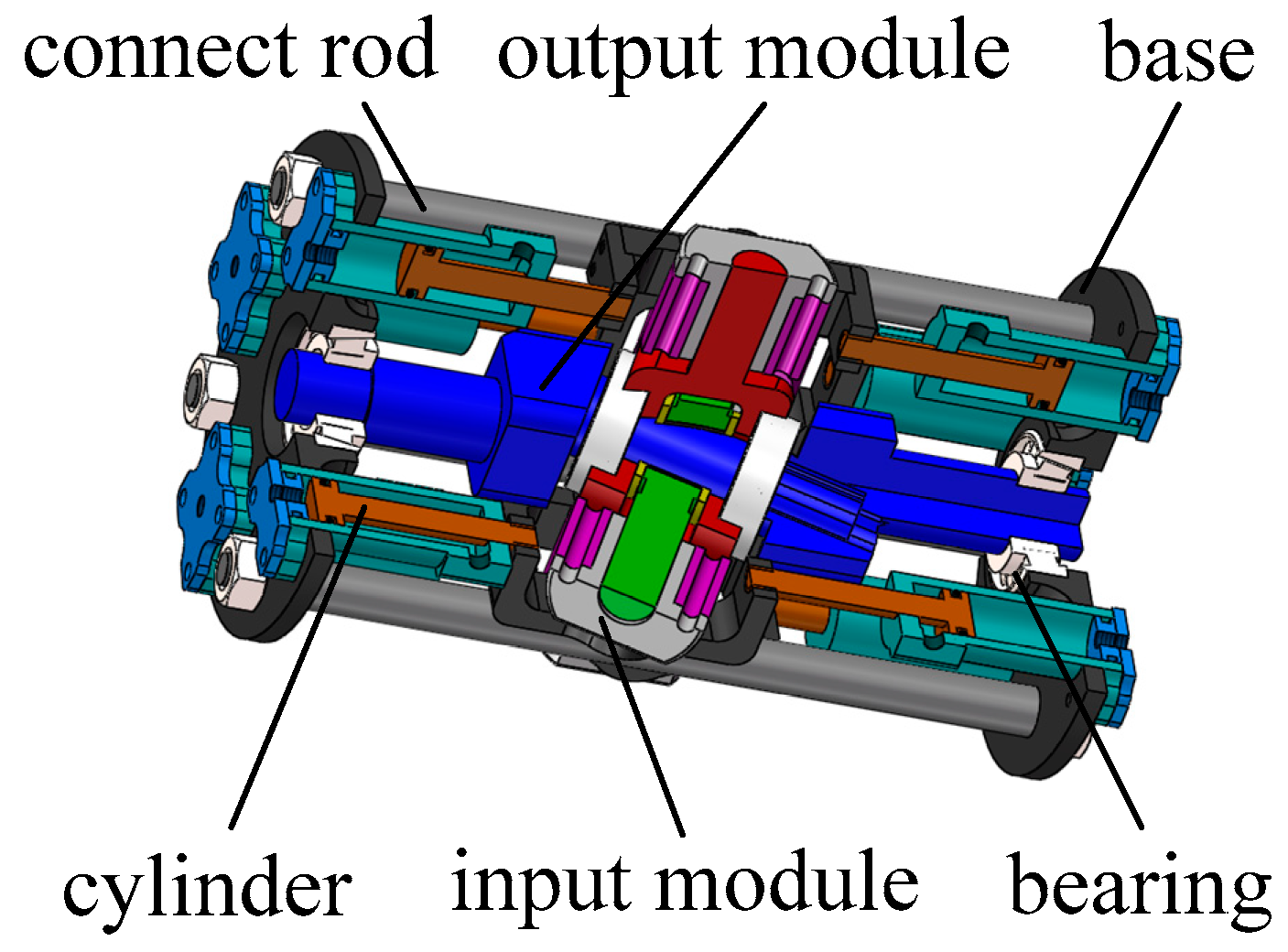

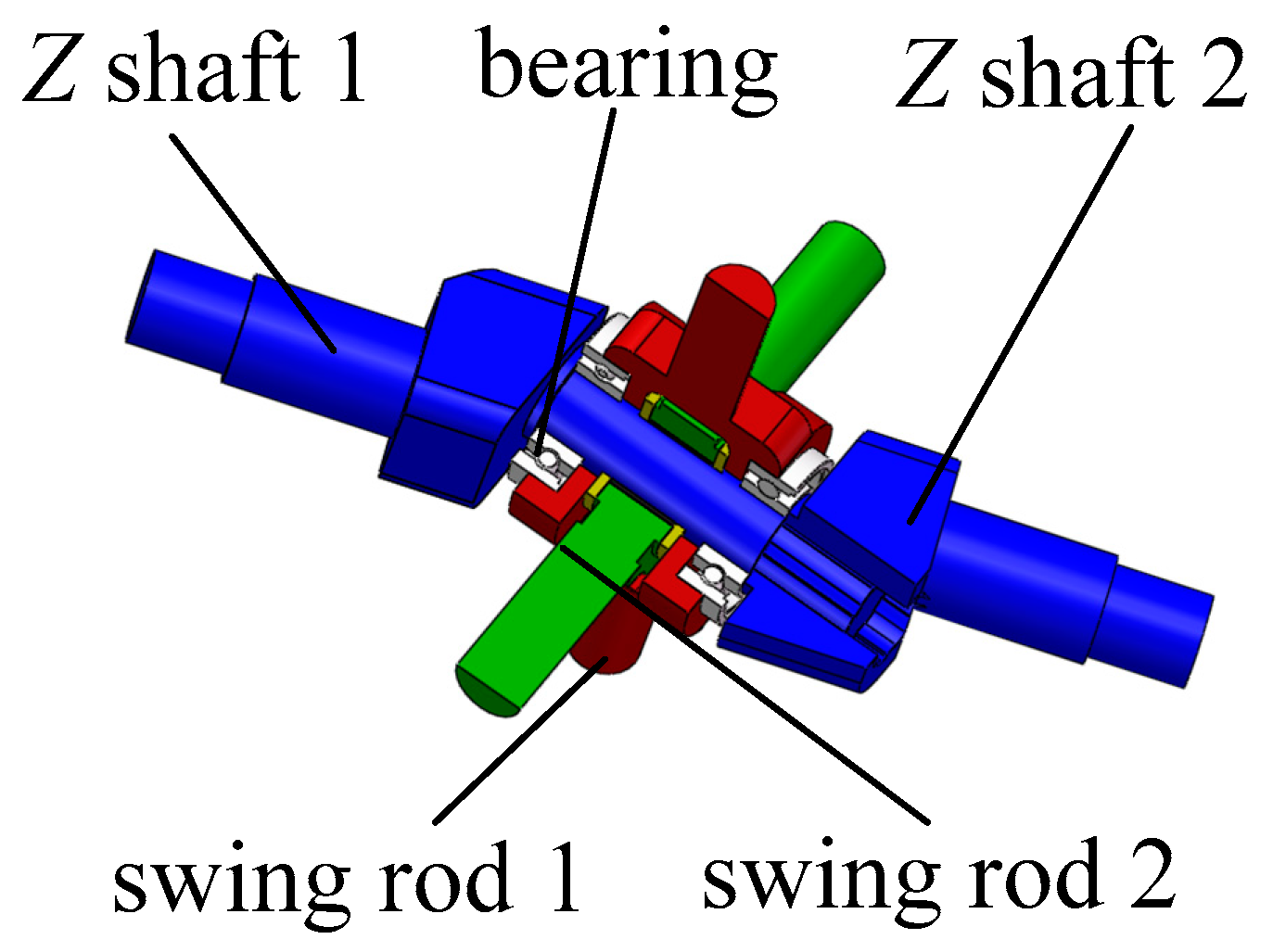

2. Design of Wobble Plate Hydraulic Joint

2.1. Efficiency Analysis of Mobile Manipulators

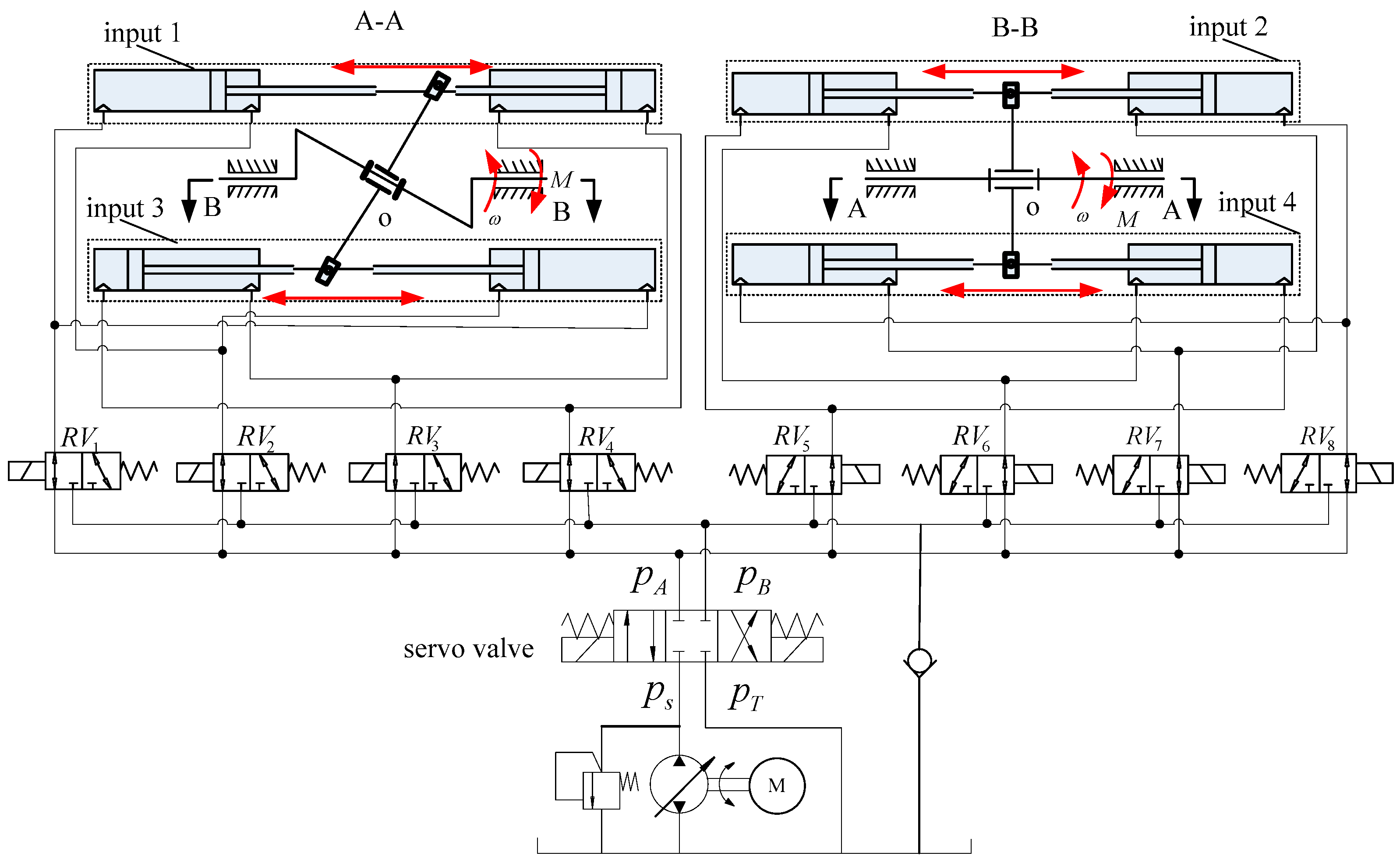

2.2. Structure Description

3. Analysis of Mechanical Characteristic

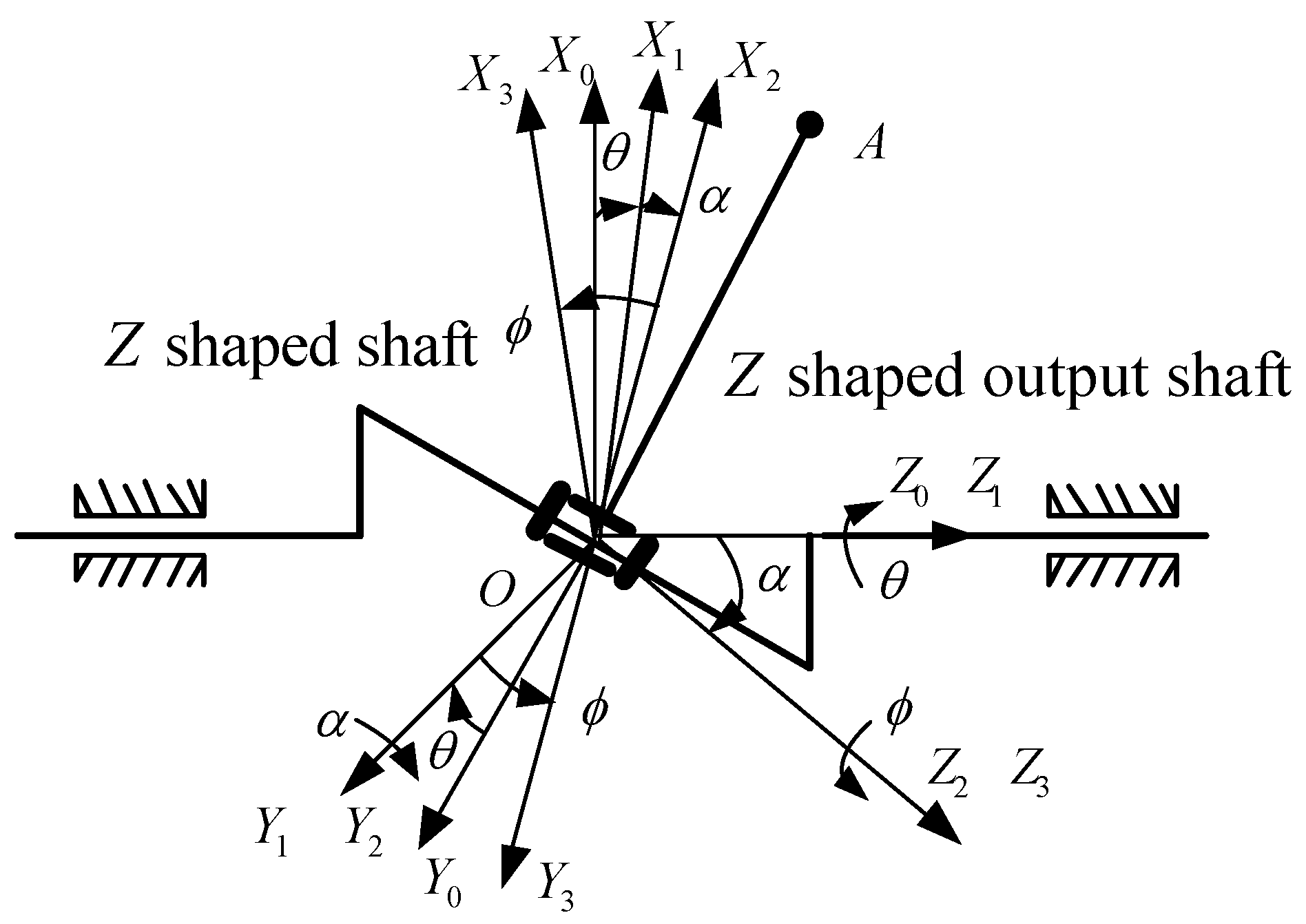

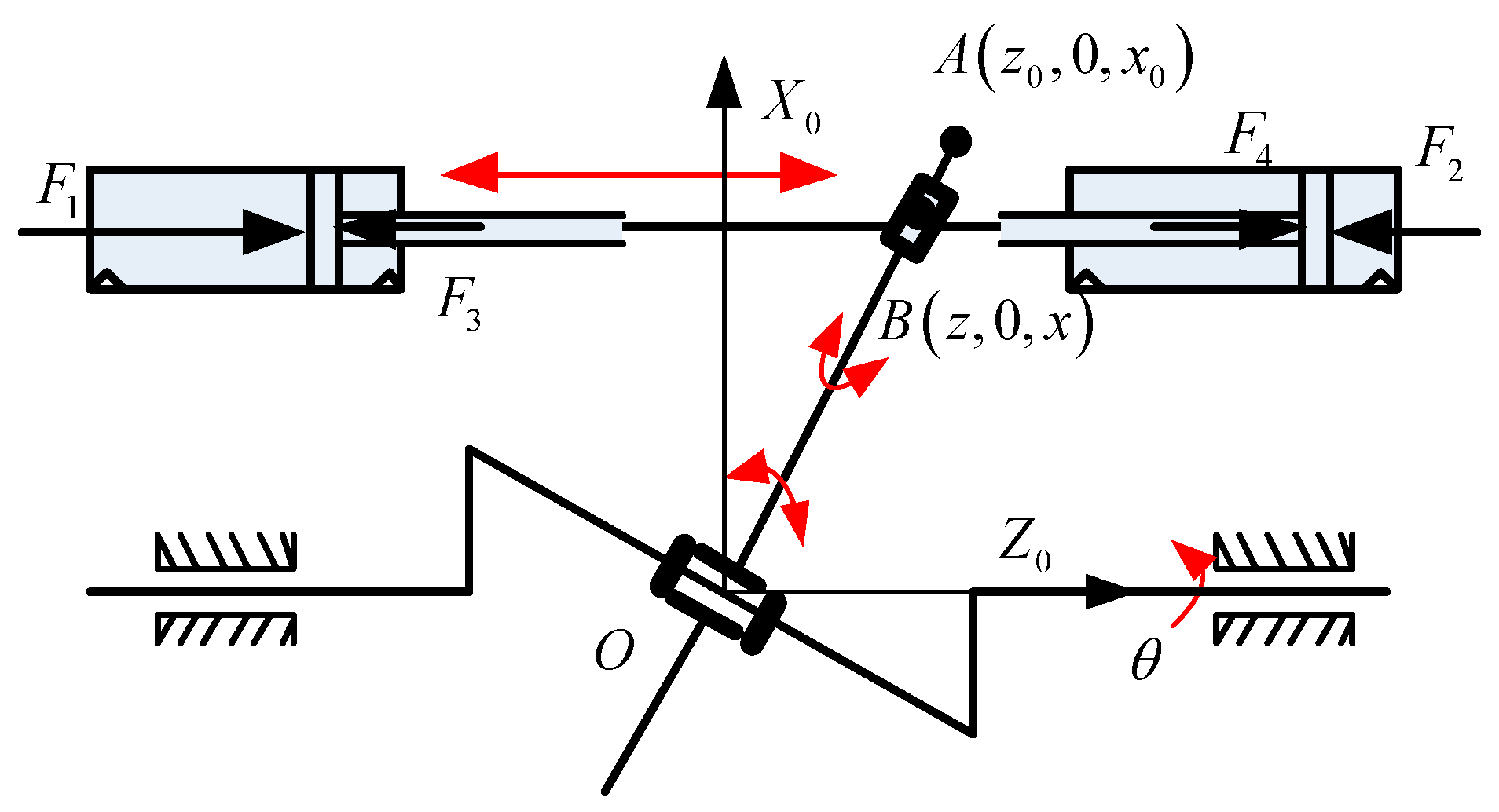

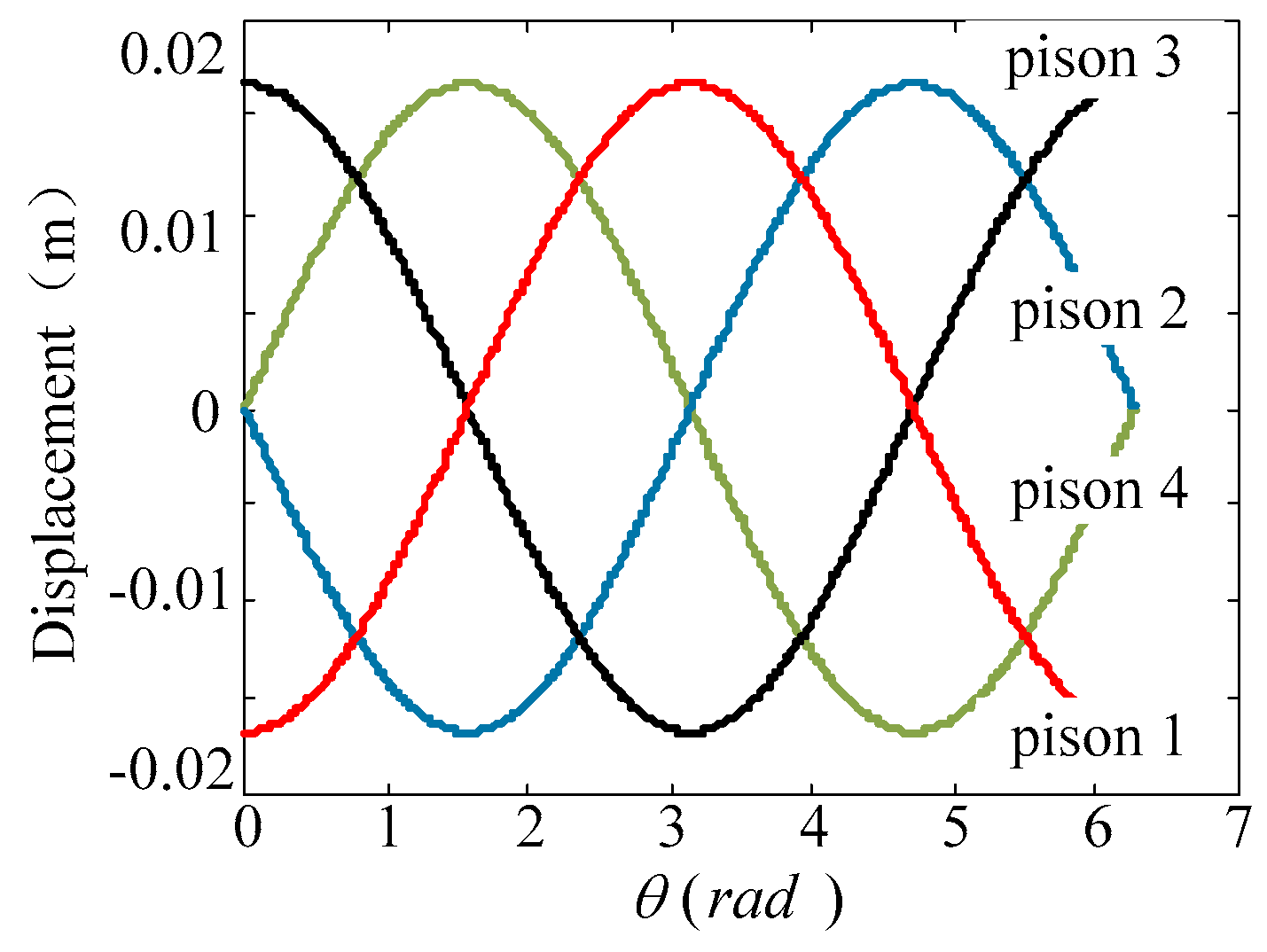

3.1. Kinematic Analysis

3.2. Dynamic Analysis

4. Design of Load Matching Control

4.1. Analysis of Control Principle

4.2. Design of the Load Matching Controller

- (1)

- Determine the combination of the reversing valves, which can output the torque that is closest to the load torque. To meet the requirements of joint angle tracking and ensure sufficient driving force, the output torque selected initially is usually slightly larger than the actual load torque.

- (2)

- Predict the trend of the angle tracking error and adjust the mode of the valves’ combination. At a sampling point, if the absolute value of joint angle error is less than the allowable value, the existing combination remains unchanged, otherwise, the characteristics of the error need to be further determined. When the error is positive, it indicates that the output torque is insufficient, so it should be increased. When the error is negative, it indicates that the output torque is sufficient, so it should be reduced.

- Step 1:

- Use the torque sensor to measure the load torque .

- Step 2:

- Calculate all the output torques at the current rotating angle according to all the reversing valve position combinations.

- Step 3:

- Calculate all the generalized torques, which would be sorted from small to large, to form a sequence of generalized torques with the number of regulating grade .

- Step 4:

- In the generalized torque series, select the optimal generalized torque which is closest to the last torque and the initial grade is selected.

- Step 5:

- Compare the angle tracking error with the allowable value . If , it indicates that the optimal generalized torque selected is appropriate, and grade is maintained; otherwise, Step 6 is performed.

- Step 6:

- Compare the derivative of the angle tracking error with the corresponding allowable value .

- Step 7:

- The optimal generalized torque is applied to the hydraulic joint and the instant angular displacement is fed back to step 5.

- Step 8:

- Go back to step 2 and perform the following steps in turn until the ending.

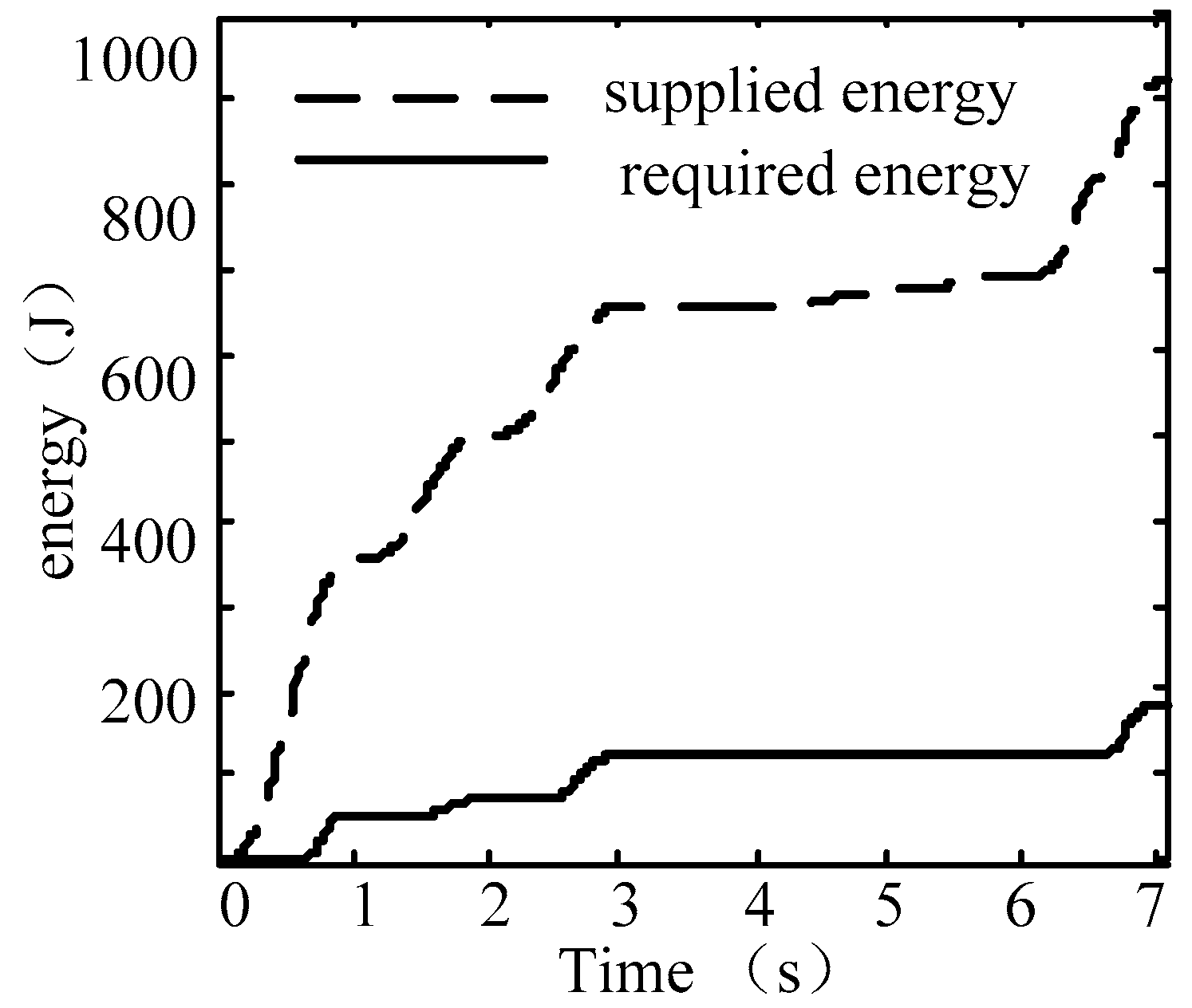

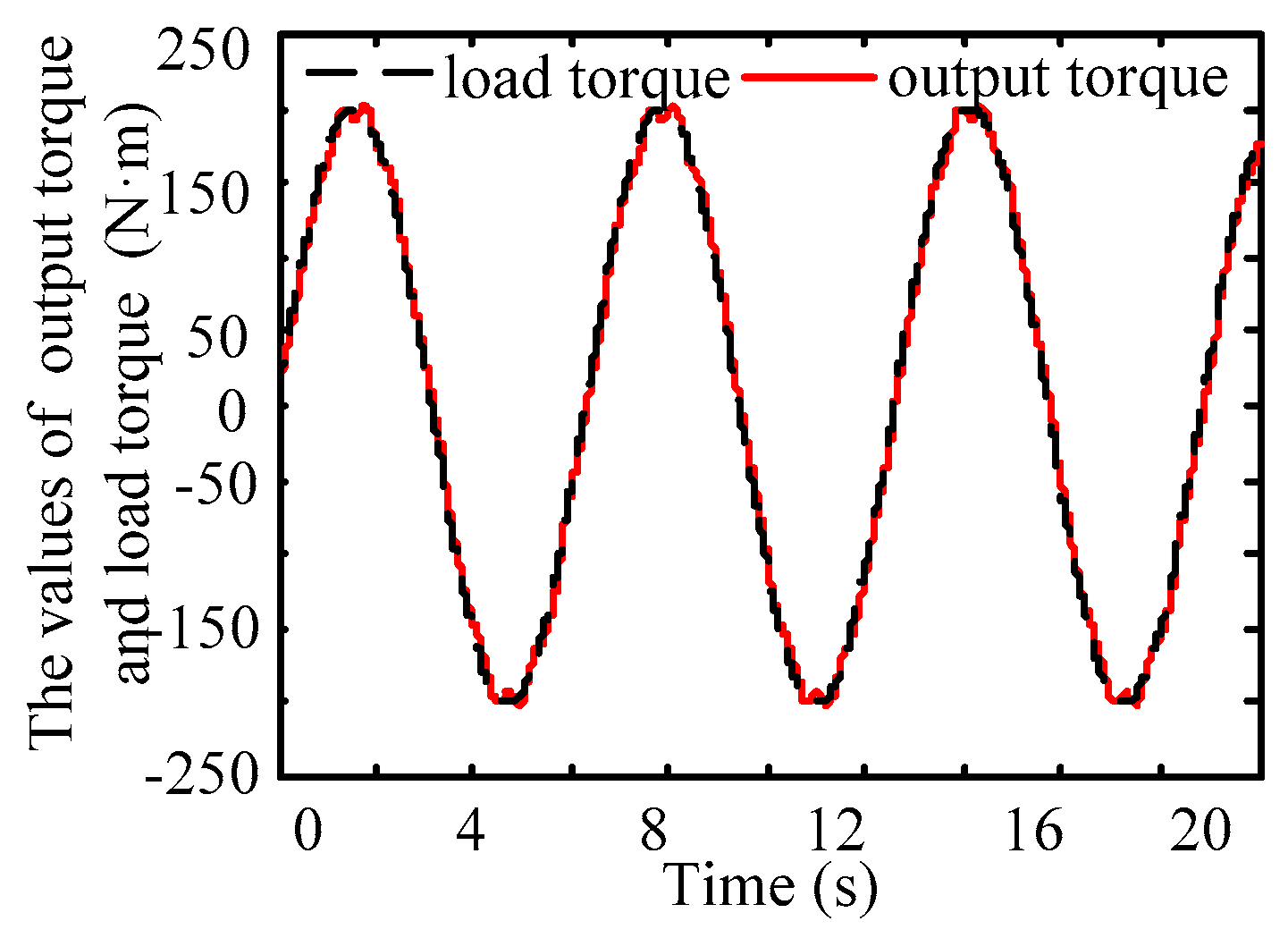

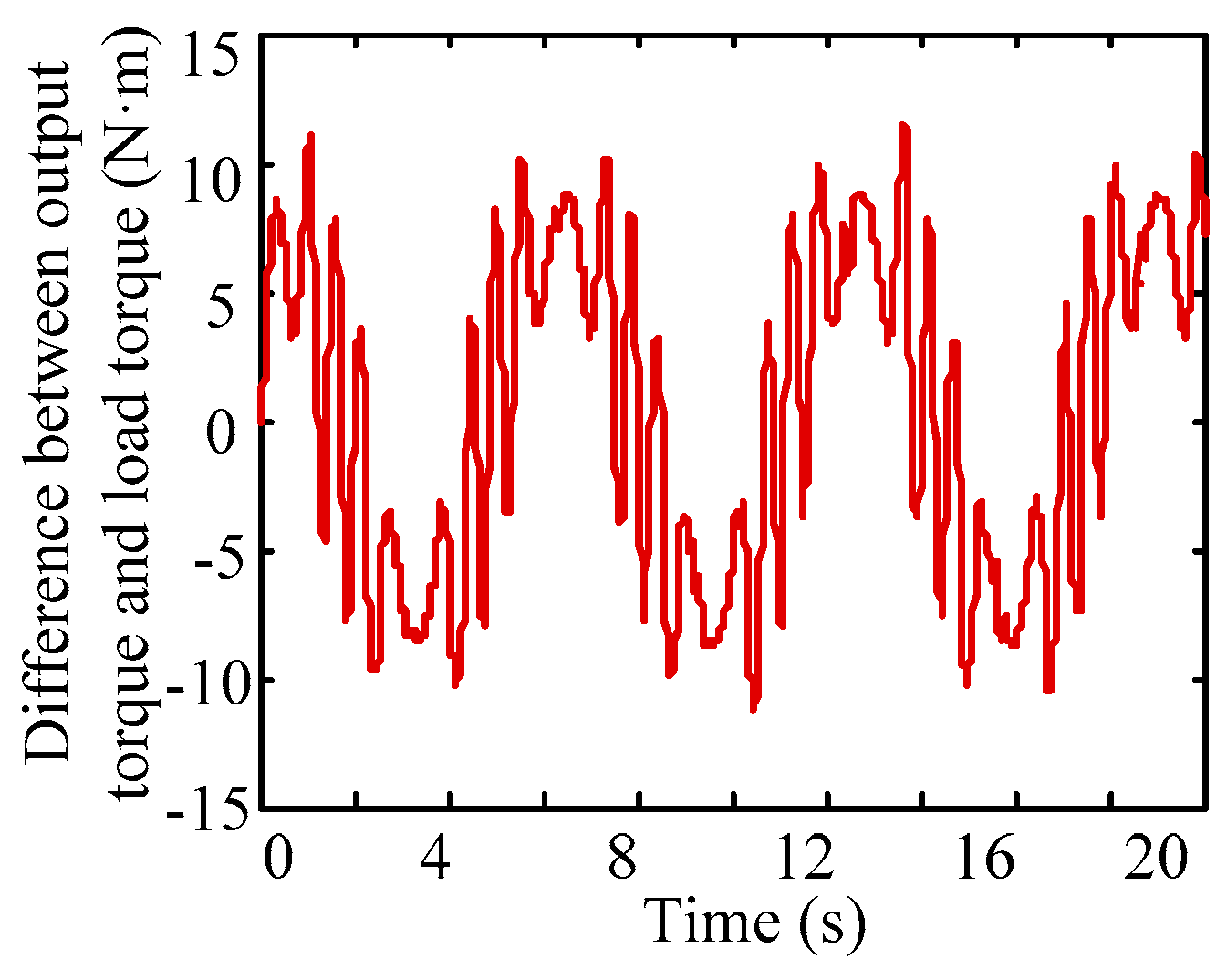

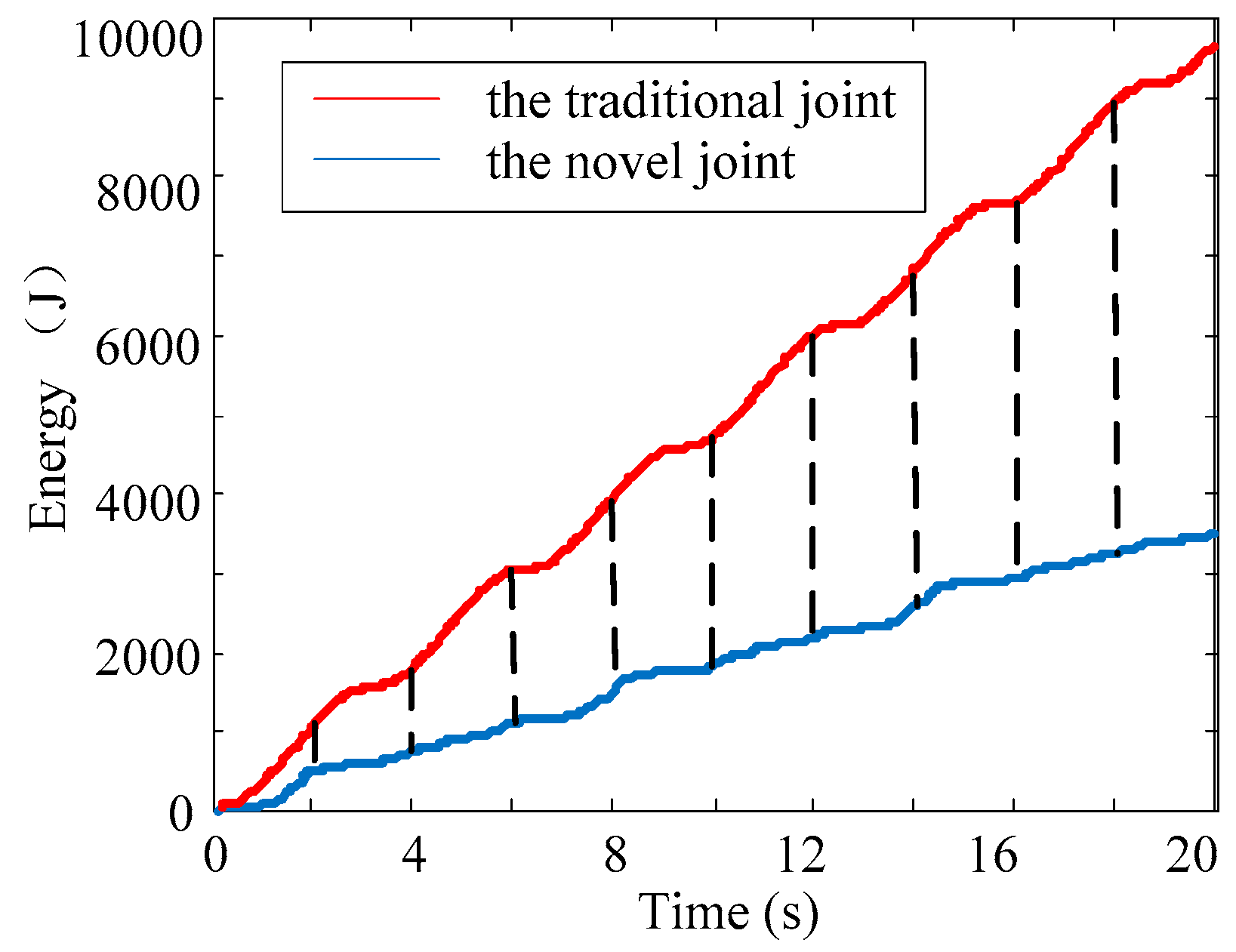

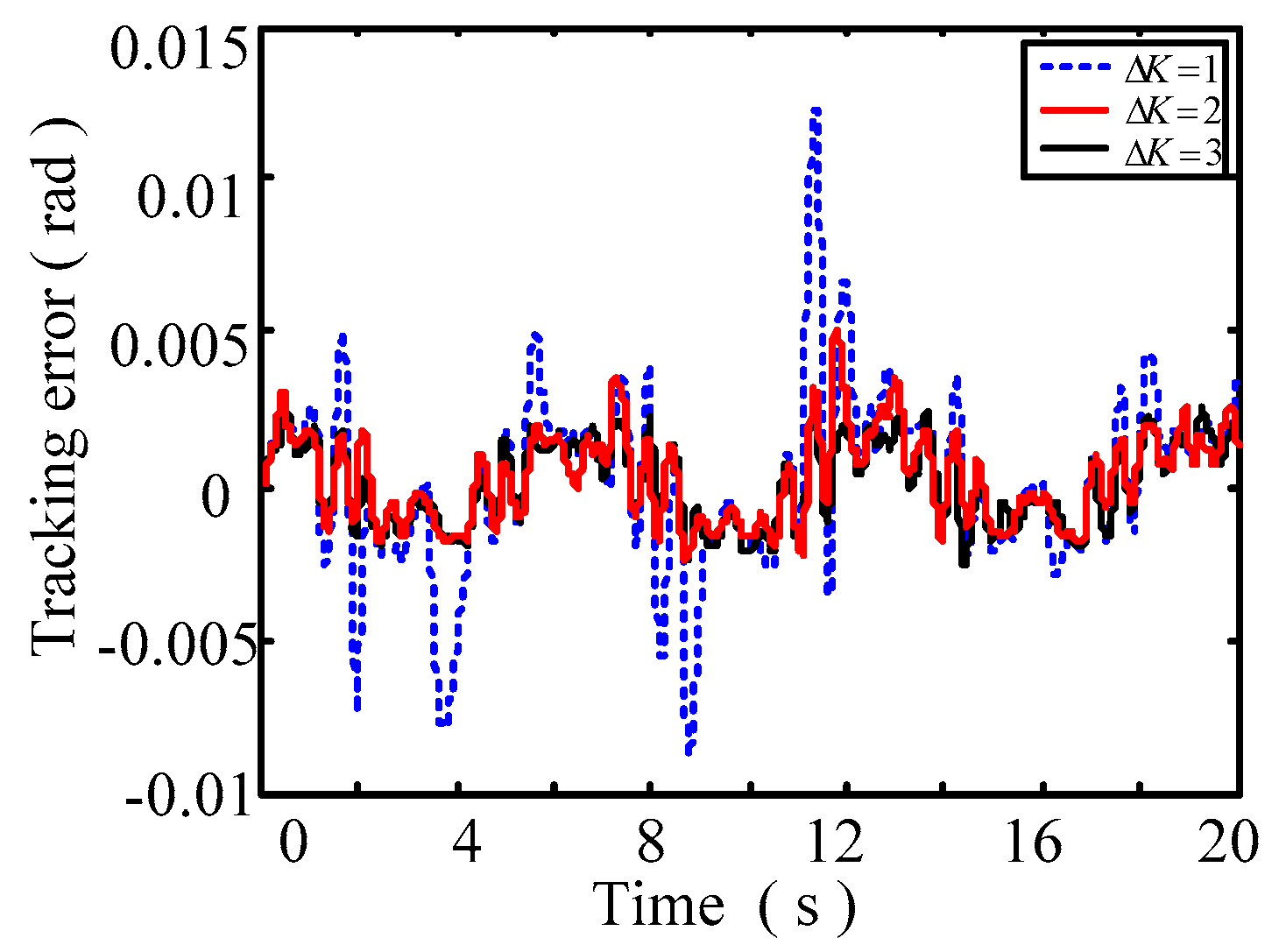

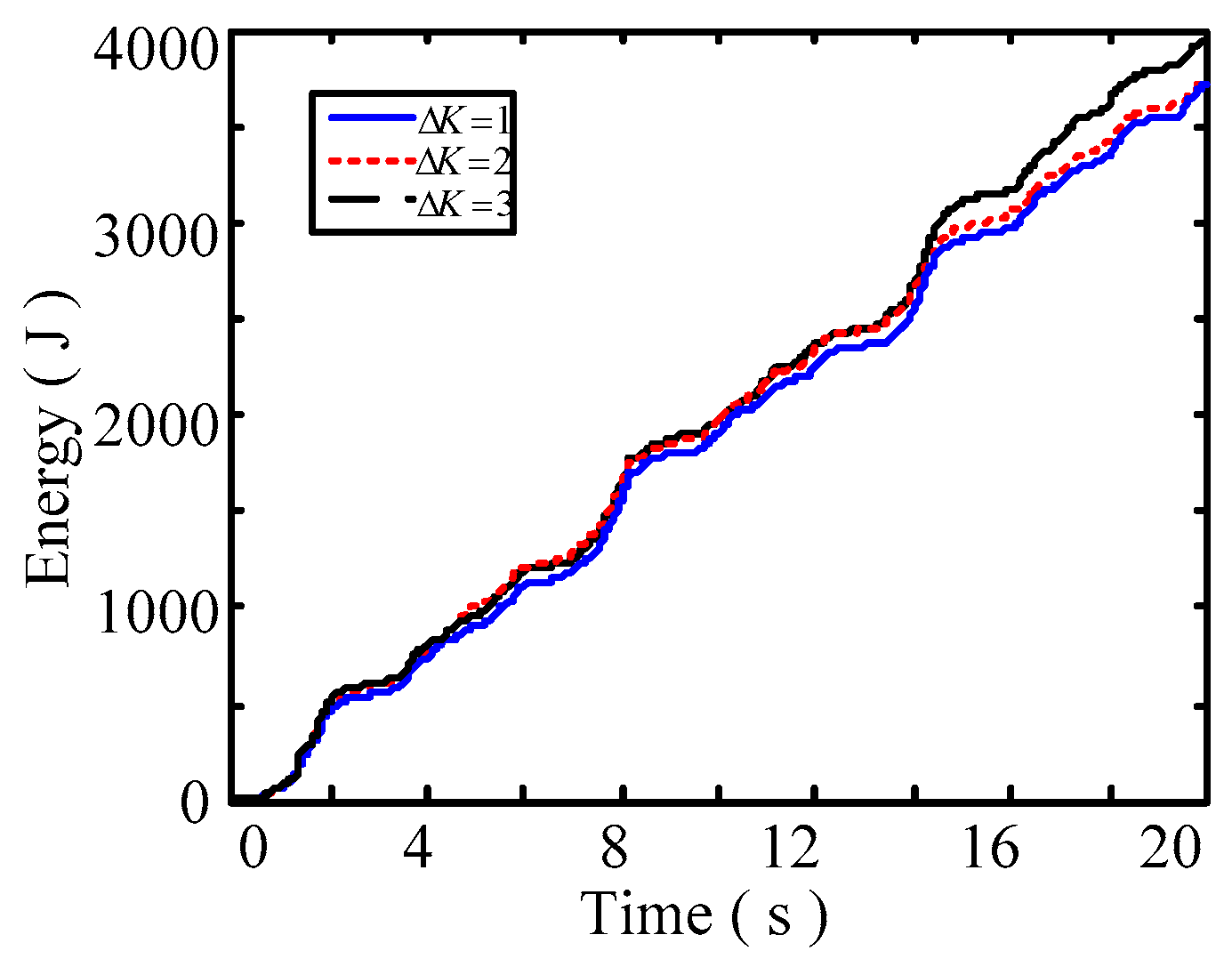

5. Simulation and Discussion

6. Conclusions

- (1)

- Based on an efficiency analysis of the traditional hydraulic system in the mobile robotic manipulator, an energy-efficient hydraulic joint with wobble plate structure was proposed. By analyzing its working principle, the reason for the high efficiency in the novel joint was explained.

- (2)

- With the method of coordinate transformation, a kinematics model was established. By using the Lagrange Method, a dynamic model was established. Based on a numerical simulation, the functional relationship between the input angle and output torque of the novel joint was deduced.

- (3)

- Based on the structural characteristics and control principle, the load matching controller of the wobble plate hydraulic joint was designed, and the specific control processes were formulated.

- (4)

- Combined with the strategy of load matching control, the servo control system was established, and simulation was carried out to verify the energy-saving effect of the novel wobble plate hydraulic joint.

Author Contributions

Funding

Conflicts of Interest

References

- Florek-JasińSka, M.; WimböCk, T.; Ott, C. Humanoid compliant whole arm dexterous manipulation: Control design and experiments. IEEE Trans. Robot. Autom. 2014, 1616–1621. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Bai, G.C. Extremum response surface method of reliability analysis on two-link flexible robot manipulator. J. Cent. South Univ. 2012, 19, 101–107. [Google Scholar] [CrossRef]

- Marca, R.; Rucińskia, M.; Coatesa, A.; Allouisa, E.; Garlanda, M.; Lachata, D.; Doncheva, A.; Tubbyb, W.; Hamptonb, J.; Kisdib, Á.; et al. Design Concepts and Implementation of the Lightweight Advanced Robotic Arm Demonstrator (LARAD). In Proceedings of the 67th International Astronautical Congress (IAC), Guadalajara, Mexico, 26–30 September 2016. [Google Scholar]

- Feng, F.; Liu, Y.; Liu, H.; Cai, H. Design Schemes and Comparison Research of the End-effector of Large Space Manipulator. Chin. J. Mech. Eng. 2012, 25, 674–687. [Google Scholar] [CrossRef]

- Li, Y.; Hou, J.; Yuan, J.; Zhao, X.; Liu, X.; Zhang, L. Experiment and vibration suppression algorithm for high-branch pruning manipulator based on fuzzy PID with improved PSO. Trans. Chin. Soc. Agric. Eng. 2017, 33, 49–58. [Google Scholar]

- Albu-Schäffer, A.; Haddadin, S.; Ott, C.; Stemmer, A.; Wimböck, T.; Hirzinger, G. The DLR lightweight robot: Design and control concepts for robots in human environments. Ind. Robot 2007, 34, 376–385. [Google Scholar] [CrossRef]

- Zoss, A.B.; Kazerooni, H.; Chu, A. Biomechanical Design of the Berkeley Lower Extremity Exoskeleton (BLEEX). IEEE/ASME Trans. Mechatron. 2006, 11, 128–138. [Google Scholar] [CrossRef]

- Albers, A.; Ottnad, J. Integrated Structural and Controller Optimization in Dynamic Mechatronic Systems. J. Mech. Des. 2010, 132, 041008. [Google Scholar] [CrossRef]

- Shumei, Y.U. Development of an Amphibious Snake-like Robot and Its Gaits on Ground and in Water. J. Mech. Eng. 2012, 48, 18–25. [Google Scholar]

- Lin, J.; Jie, Z.; Wenchao, W.; Xianbao, X.; Xinyuan, C.; Hui, Z.; Liangcai, Z. Easy control hydraulic rotary self-servo reconfigurable decoupling hydraulic joint. In Proceedings of the International Conference on Mechatronics and Automation, Chengdu, China, 5–8 August 2012; pp. 2361–2365. [Google Scholar]

- Niguchi, N.; Hirata, K. Magnetic-geared motors with high transmission torque density. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2015, 34, 428–438. [Google Scholar] [CrossRef]

- Huang, S.N.; Tan, K.K.; Lee, T.H. Adaptive friction compensation using neural network approximations. IEEE Trans. Syst. Man Cybern. Part C 2000, 30, 551–557. [Google Scholar] [CrossRef]

- Tan, K.K.; Huang, S.N.; Jiang, X. Adaptive control of ram velocity for the injection moulding machine. IEEE Trans. Control Syst. Technol. 2001, 9, 663–671. [Google Scholar] [CrossRef]

- Seok, S.; Wang, A.; Otten, D.; Kim, S. Actuator design for high force proprioceptive control in fast legged locomotion. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura, Portugal, 7–12 October 2012; pp. 1970–1975. [Google Scholar]

- Liyanage, M.H.; Krouglicof, N.; Gosine, R. Design and control of a high performance SCARA type robotic arm with rotary hydraulic actuators. In Proceedings of the Canadian Conference on Electrical and Computer Engineering (CCECE 2009), St. John’s, NL, Canada, 3–6 May 2009; pp. 827–832. [Google Scholar]

- Liang, X.C.; Wang, G.J.; Zheng, X.G. Research on Rotary Actuator Based on Screw Device. Acta Aeronautica et Astronautica Sinica 2003, 24, 282–285. [Google Scholar]

- Deng, M.J.; Wang, Z.; He, H.H.; Xue, Y. Design and Weight Lifting Analysis of a Strengthen Upper Limb Exoskeleton Robot. Appl. Mech. Mater. 2013, 437, 695–699. [Google Scholar] [CrossRef]

- Bhounsule, P.A.; Cortell, J.; Ruina, A. Design and control of ranger: An energy-efficient, dynamic walking robot. In Proceedings of the Fifteenth International Conference on Climbing and Walking Robots and the Support Technologies for Mobile Machines (CLAWAR 2012), Baltimore, MD, USA, 23–26 July 2012; pp. 441–448. [Google Scholar]

- Seok, S.; Wang, A.; Chuah, M.Y.; Otten, D.; Lang, J.; Kim, S. Design principles for highly efficient quadrupeds and implementation on the MIT Cheetah robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 3307–3312. [Google Scholar]

- Ho, T.H.; Ahn, K.K. Design and control of a closed-loop hydraulic energy-regenerative system. Autom. Constr. 2012, 22, 444–458. [Google Scholar] [CrossRef]

- Ho, T.H.; Ahn, K.K. Modeling and simulation of hydrostatic transmission system with energy regeneration using hydraulic accumulator. J. Mech. Sci. Technol. 2010, 24, 1163–1175. [Google Scholar] [CrossRef]

- Du, C.; Plummer, A.R.; Johnston, D.N. Performance analysis of an energy-efficient variable supply pressure electro-hydraulic motion control system. Control Eng. Pract. 2016, 48, 10–21. [Google Scholar] [CrossRef]

- Zimmerman, J.; Ivantysynova, M. Hybrid displacement controlled multi actuator hydraulic systems. In Proceedings of the Twelfth Scandinavian International Conference on Fluid Power (SICFP11), Tampere, Finland, 18–20 May 2011. [Google Scholar]

- Hippalgaonkar, R.; Ivantysynova, M. A Series-Parallel Hydraulic Hybrid Mini-Excavator with Displacement Controlled Actuators. In Proceedings of the 13th Scandinavian International Conference on Fluid Power (SICFP2013), Linköping, Sweden, 3–5 June 2013. [Google Scholar]

- Daher, N.; Ivantysynova, M. Energy analysis of an original steering technology that saves fuel and boosts efficiency. Energy Convers. Manag. 2014, 86, 1059–1068. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| piston diameter (mm) | D | 18 |

| rod diameter (mm) | d | 8 |

| length of Z shaped shaft (mm) | H | 48 |

| arrangement diameter of input module (mm) | R | 10 |

| bulge diameter of Z shaped shaft (mm) | r | 40 |

| mass of piston rods (kg) | 0.25 | |

| moment of inertia of axis (kg·mm2) | 420 | |

| moment of inertia of axis (kg·mm2) | 161 | |

| moment of inertia of the output shaft (kg·mm2) | 965 |

| Serial Number | Control Signals [x1 x2 x3 x4] | Serial Number | Control Signals [x5 x6 x7 x8] |

|---|---|---|---|

| 1 | [0 0 0 0] | 1 | [0 0 0 0] |

| 2 | [1 0 0 0] | 2 | [1 0 0 0] |

| 3 | [0 1 0 0] | 3 | [0 1 0 0] |

| 4 | [0 0 1 0] | 4 | [0 0 1 0] |

| 5 | [0 0 0 1] | 5 | [0 0 0 1] |

| 6 | [1 1 0 0] | 6 | [1 1 0 0] |

| 7 | [1 0 1 0] | 7 | [1 0 1 0] |

| 8 | [0 1 0 1] | 8 | [0 1 0 1] |

| 9 | [0 0 1 1] | 9 | [0 0 1 1] |

| Parameters | Symbol | Value |

|---|---|---|

| proportionality coefficient | Kp | 0.086 |

| integration coefficient | Ki | 0.02 |

| differential coefficient | Kd | 0.02 |

| frequency of reversing valve (Hz) | f | 100 |

| allowable value of error 1 (rad) | δ11 | 0.002 |

| allowable value of error 2 (rad) | δ12 | 0.001 |

| allowable velocity value of error (rad/s) | δ2 | 0.8 |

| step size of grade adjustment | 2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, D.; Yang, J.; Shang, J.; Wang, Z.; Feng, Y. A Novel Energy-Efficient Wobble Plate Hydraulic Joint for Mobile Robotic Manipulators. Energies 2018, 11, 2915. https://doi.org/10.3390/en11112915

Fang D, Yang J, Shang J, Wang Z, Feng Y. A Novel Energy-Efficient Wobble Plate Hydraulic Joint for Mobile Robotic Manipulators. Energies. 2018; 11(11):2915. https://doi.org/10.3390/en11112915

Chicago/Turabian StyleFang, Delei, Junhong Yang, Jianzhong Shang, Zhuo Wang, and Yong Feng. 2018. "A Novel Energy-Efficient Wobble Plate Hydraulic Joint for Mobile Robotic Manipulators" Energies 11, no. 11: 2915. https://doi.org/10.3390/en11112915

APA StyleFang, D., Yang, J., Shang, J., Wang, Z., & Feng, Y. (2018). A Novel Energy-Efficient Wobble Plate Hydraulic Joint for Mobile Robotic Manipulators. Energies, 11(11), 2915. https://doi.org/10.3390/en11112915