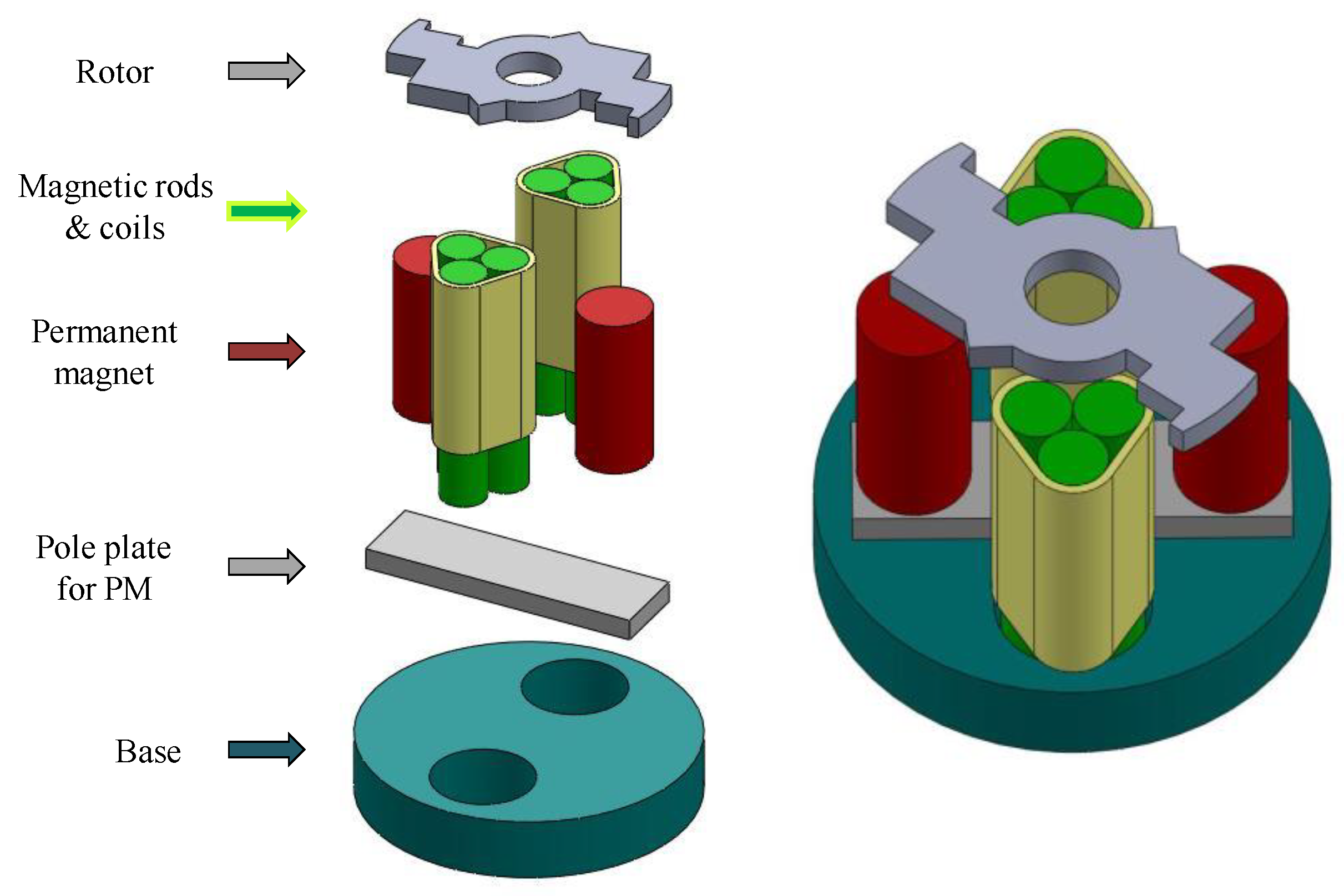

Figure 1.

Exploded view and assembly drawings of the micro, axial-flux, single-phase switched reluctance motor.

Figure 1.

Exploded view and assembly drawings of the micro, axial-flux, single-phase switched reluctance motor.

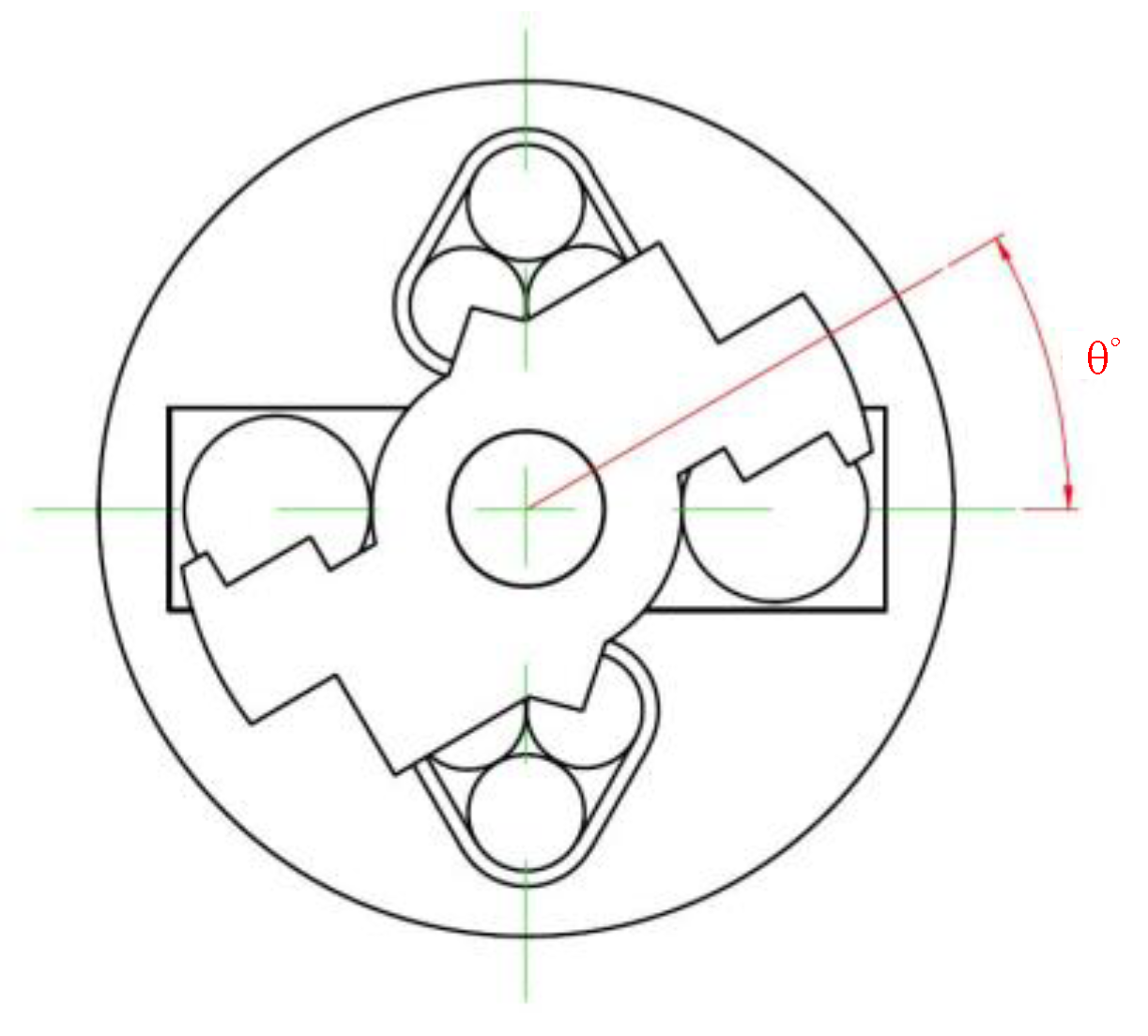

Figure 2.

Coordinate and rotating angle of the single-phase switched reluctance motor.

Figure 2.

Coordinate and rotating angle of the single-phase switched reluctance motor.

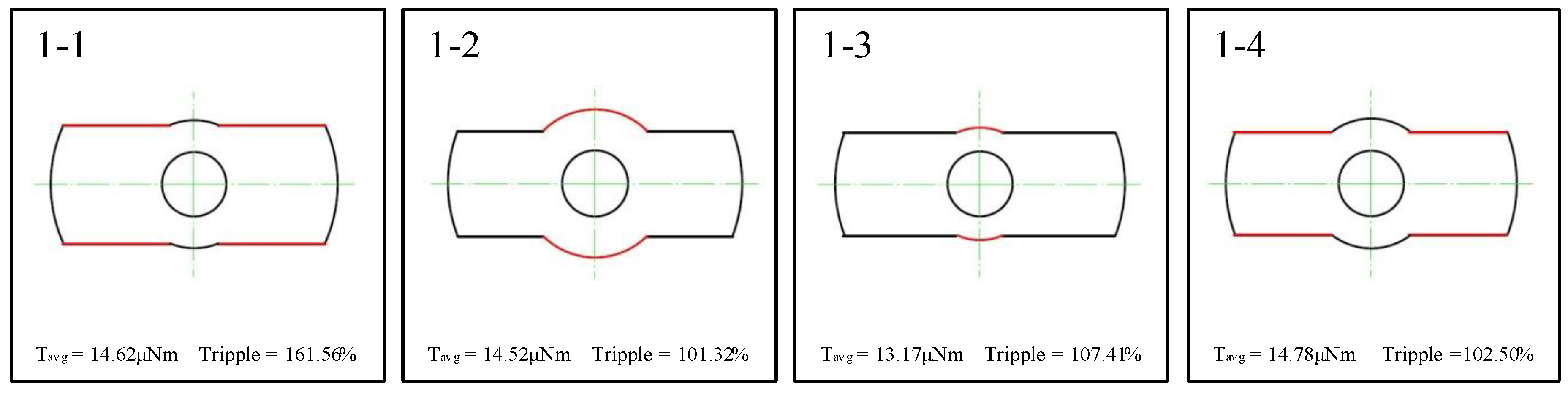

Figure 3.

Step 1: Design process of the rotor magnetic pole width and root diameter.

Figure 3.

Step 1: Design process of the rotor magnetic pole width and root diameter.

Figure 4.

Step 1: Torque-angle curve for each step.

Figure 4.

Step 1: Torque-angle curve for each step.

Figure 5.

Step 2: Design process of the rotor magnetic pole of quadrants 1 and 3.

Figure 5.

Step 2: Design process of the rotor magnetic pole of quadrants 1 and 3.

Figure 6.

Step 2: Torque-angle curve for each step.

Figure 6.

Step 2: Torque-angle curve for each step.

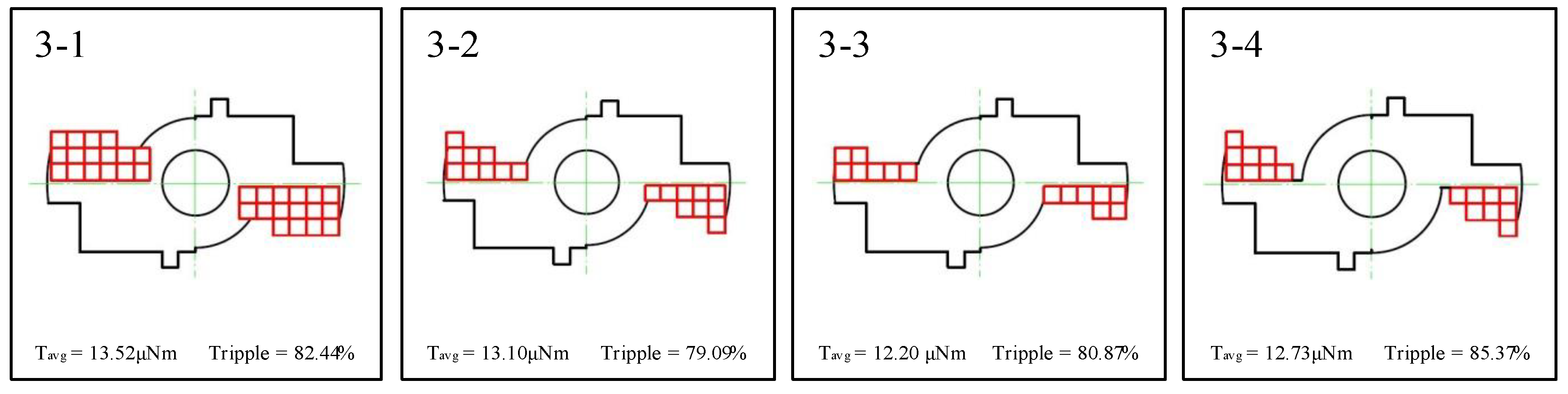

Figure 7.

Step 3: Design process of the rotor magnetic poles for quadrant 2 and 4.

Figure 7.

Step 3: Design process of the rotor magnetic poles for quadrant 2 and 4.

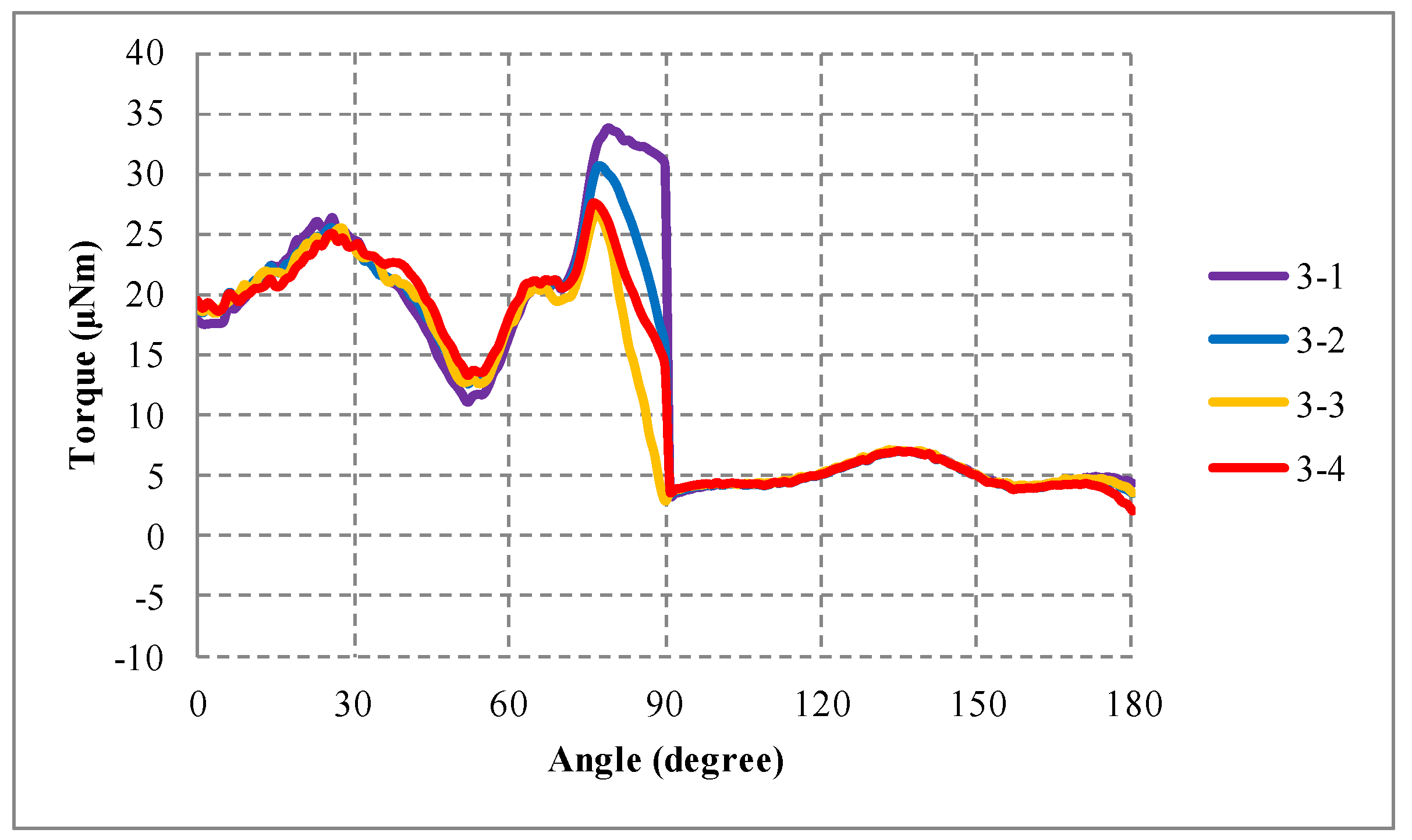

Figure 8.

Step 3: Torque-angle curve for each step.

Figure 8.

Step 3: Torque-angle curve for each step.

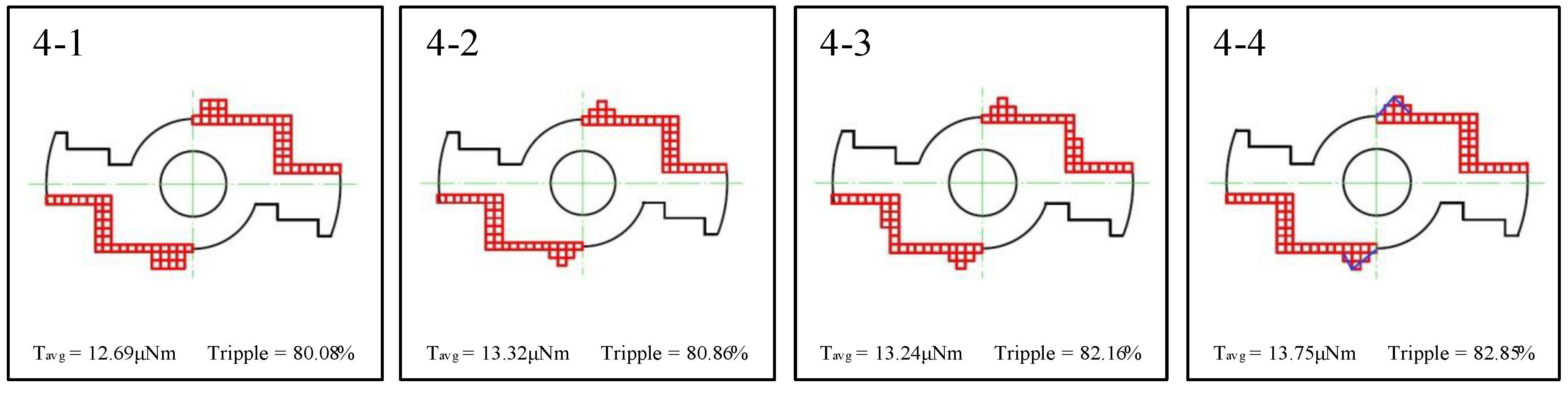

Figure 9.

Step 4: Detailed design process of the rotor magnetic pole.

Figure 9.

Step 4: Detailed design process of the rotor magnetic pole.

Figure 10.

Step 4: Torque-angle curve for each step.

Figure 10.

Step 4: Torque-angle curve for each step.

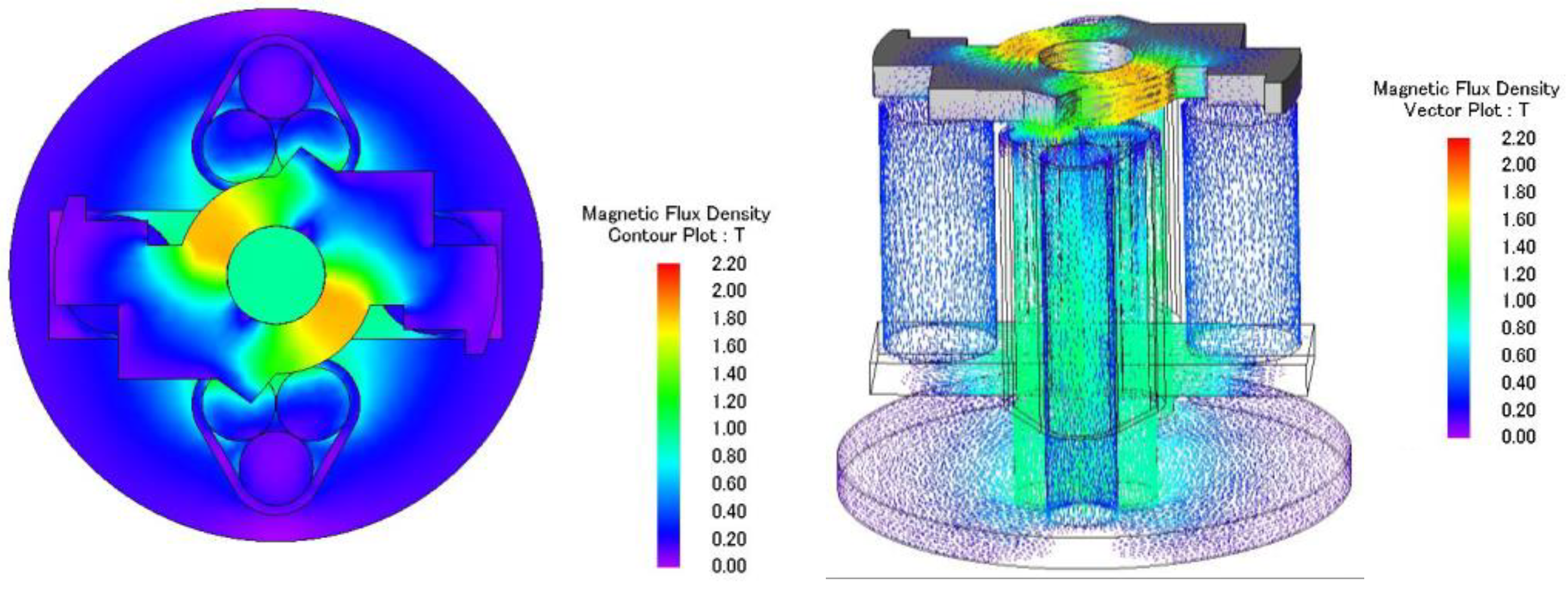

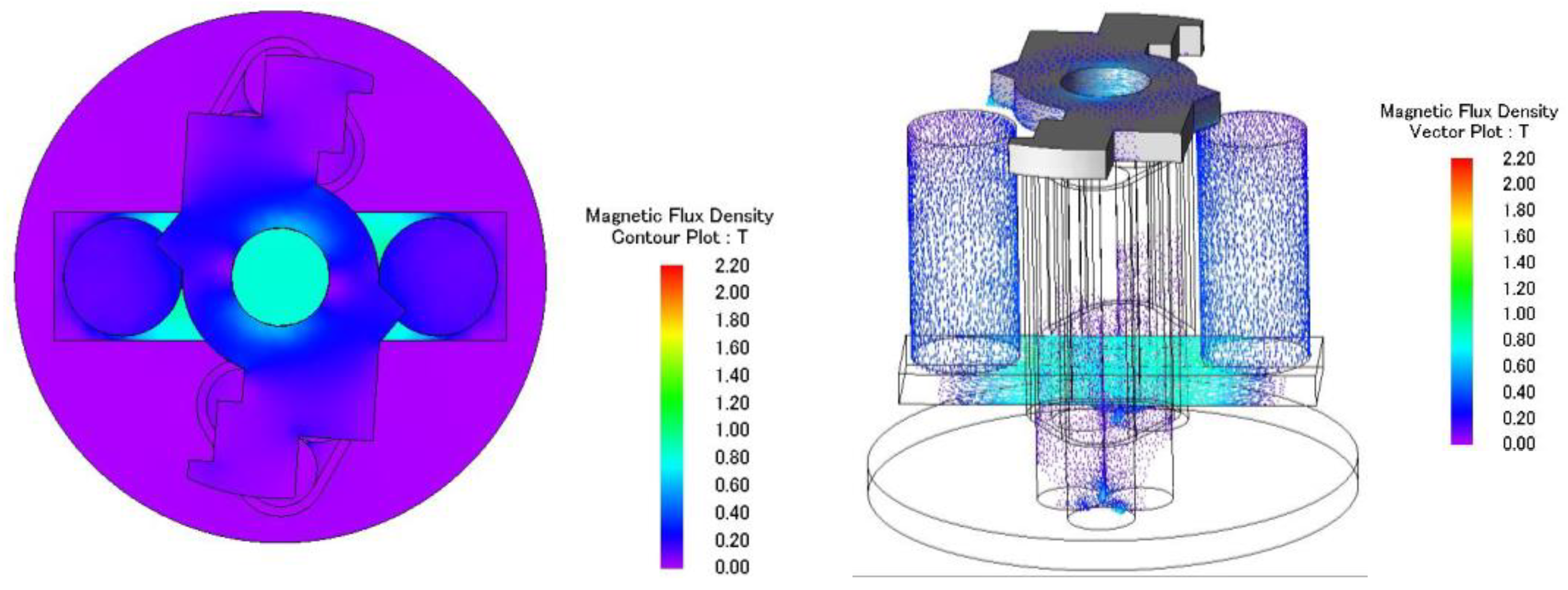

Figure 11.

Top view and 3D view of magnetic flux density plots of the motor at a rotating angle of 0°.

Figure 11.

Top view and 3D view of magnetic flux density plots of the motor at a rotating angle of 0°.

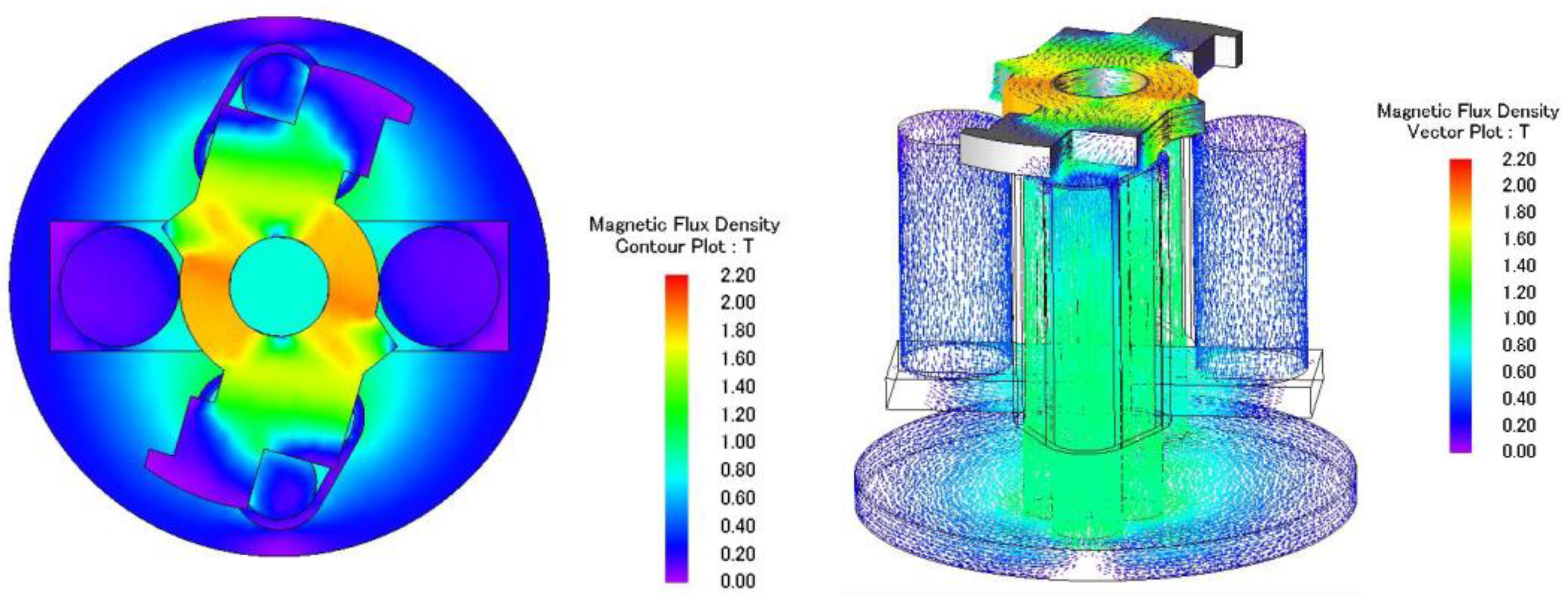

Figure 12.

Top view and 3D view of magnetic flux density plots of the motor at a rotating angle of 74°.

Figure 12.

Top view and 3D view of magnetic flux density plots of the motor at a rotating angle of 74°.

Figure 13.

Top view and 3D view of magnetic flux density plots of the motor at a rotating angle of 91°.

Figure 13.

Top view and 3D view of magnetic flux density plots of the motor at a rotating angle of 91°.

Figure 14.

Top view and 3D view of magnetic flux density plots of the motor at a rotating angle of 135°.

Figure 14.

Top view and 3D view of magnetic flux density plots of the motor at a rotating angle of 135°.

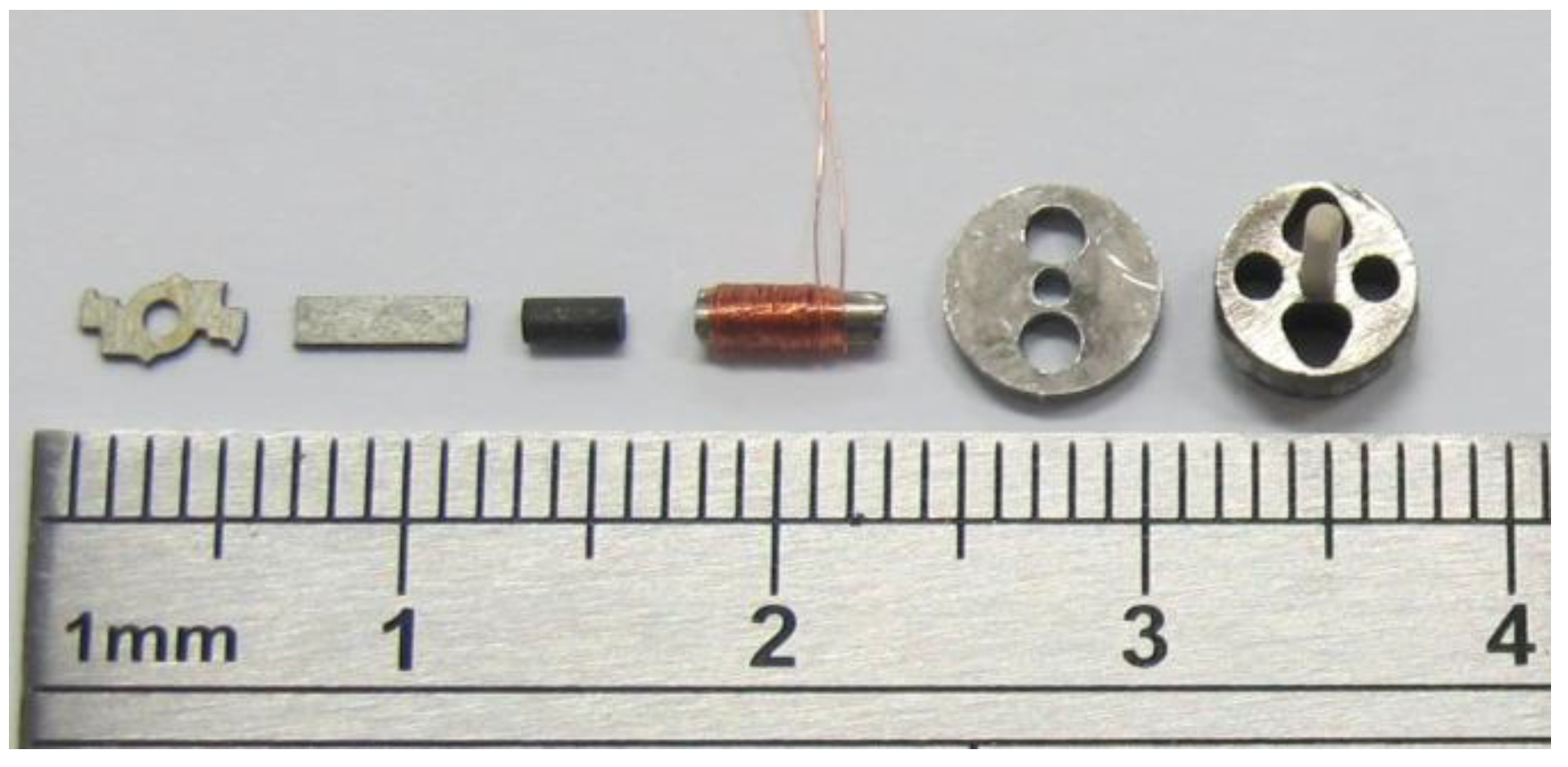

Figure 15.

Mechanical parts of the axial-flux, single-phase switched reluctance motor.

Figure 15.

Mechanical parts of the axial-flux, single-phase switched reluctance motor.

Figure 16.

Prototype of the axial-flux, single-phase switched reluctance motor.

Figure 16.

Prototype of the axial-flux, single-phase switched reluctance motor.

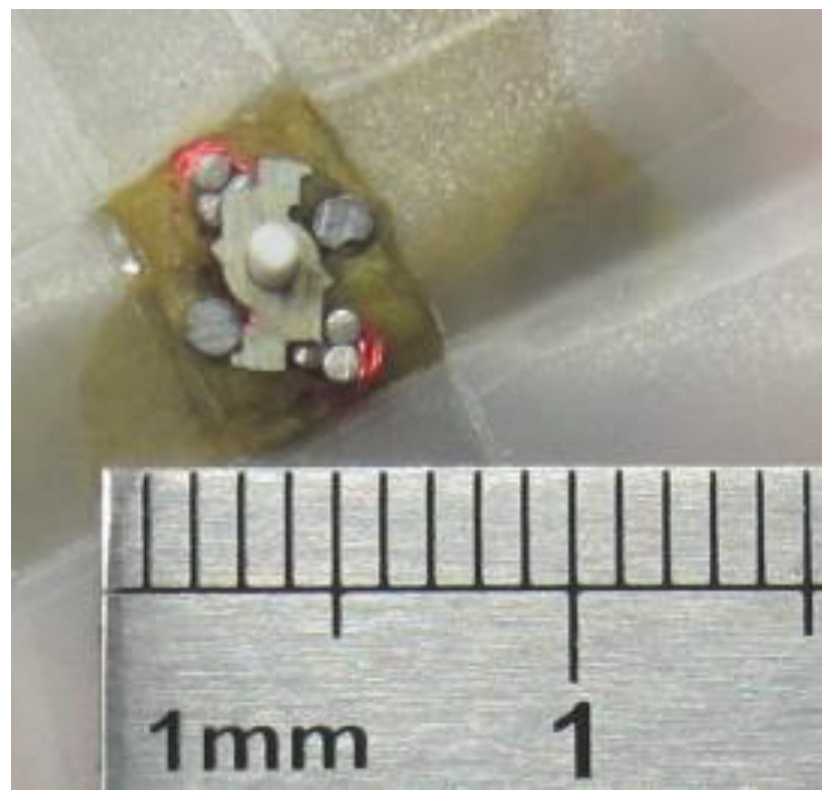

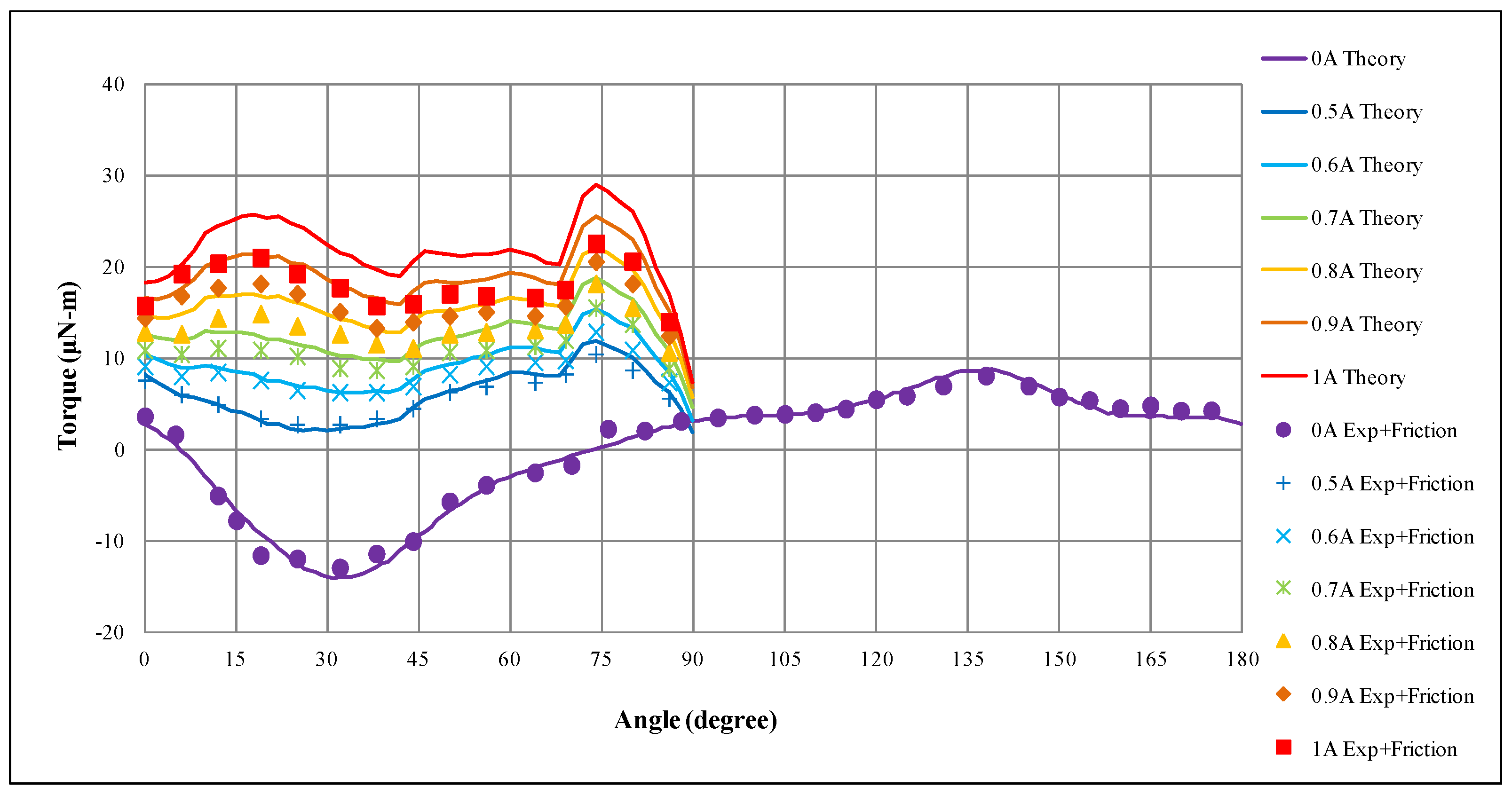

Figure 17.

Theoretical and experimental torque-angle curves of the single-phase switched reluctance motor.

Figure 17.

Theoretical and experimental torque-angle curves of the single-phase switched reluctance motor.

Figure 18.

Theoretical and experimental torque-angle curves of the motor with friction correction.

Figure 18.

Theoretical and experimental torque-angle curves of the motor with friction correction.

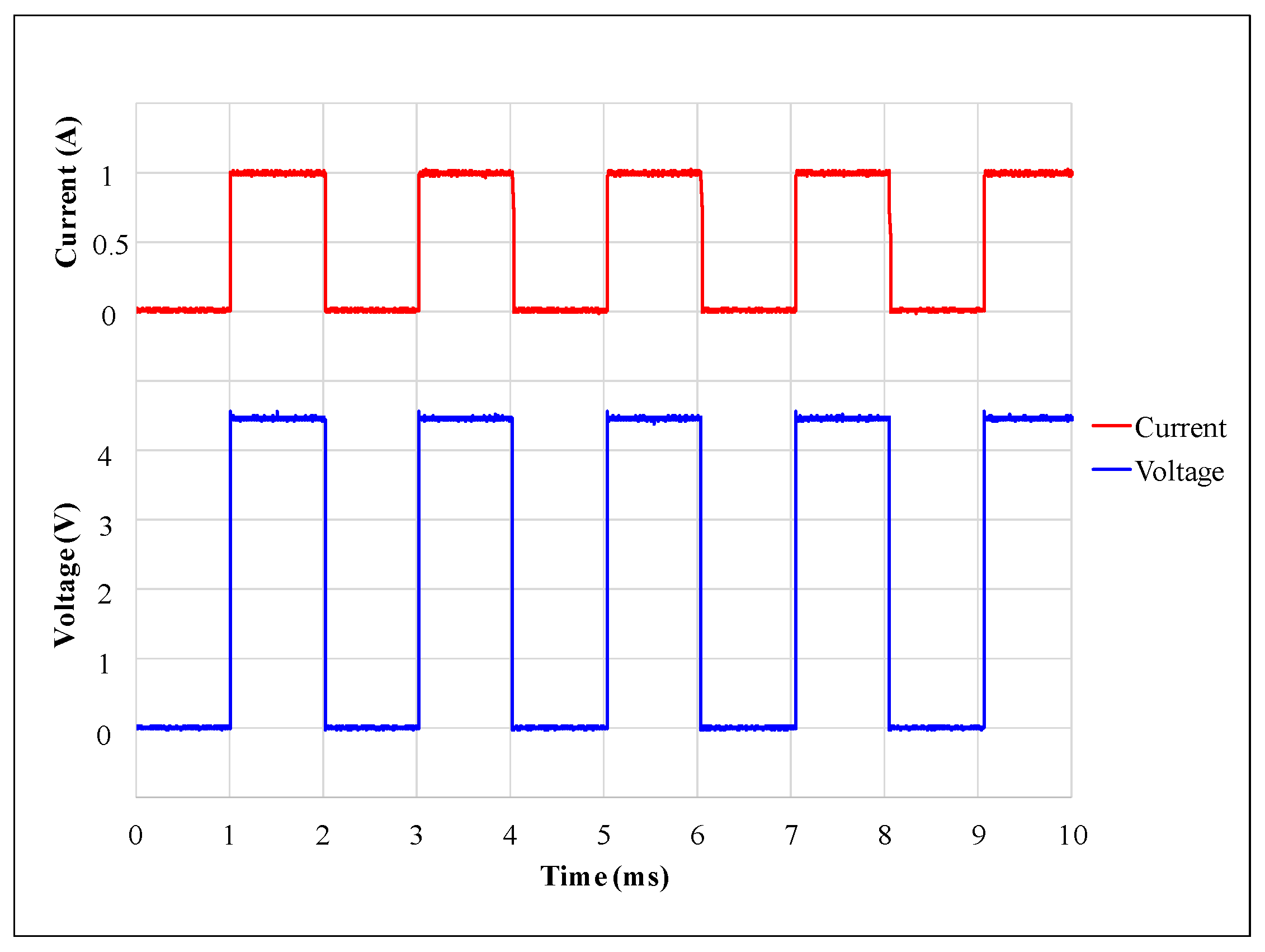

Figure 19.

Voltage and current signals of the single-phase switched reluctance motor at a maximum speed of 1500 rpm.

Figure 19.

Voltage and current signals of the single-phase switched reluctance motor at a maximum speed of 1500 rpm.

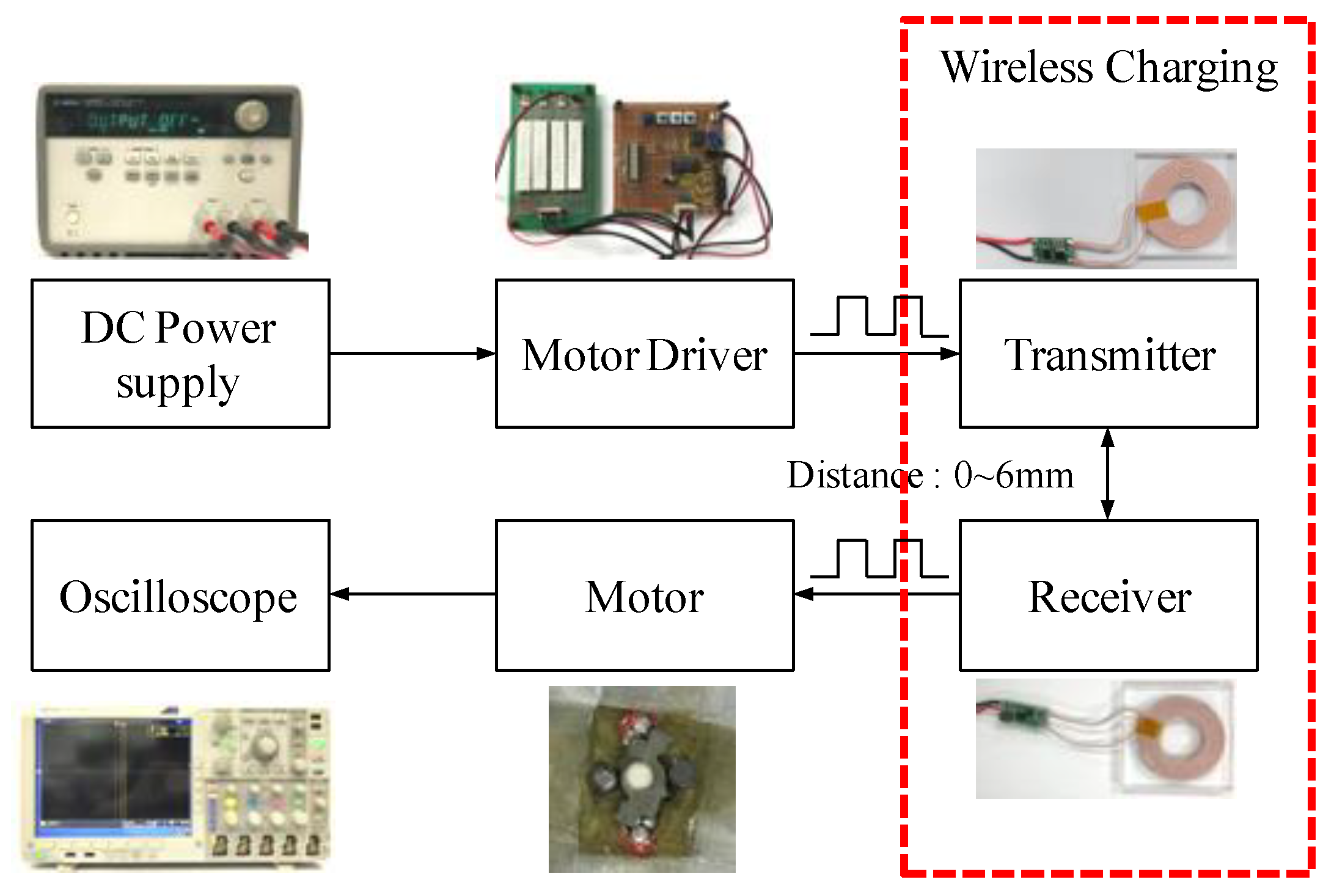

Figure 20.

Schematic diagram of the wireless-driven, single-phase switched reluctance motor system.

Figure 20.

Schematic diagram of the wireless-driven, single-phase switched reluctance motor system.

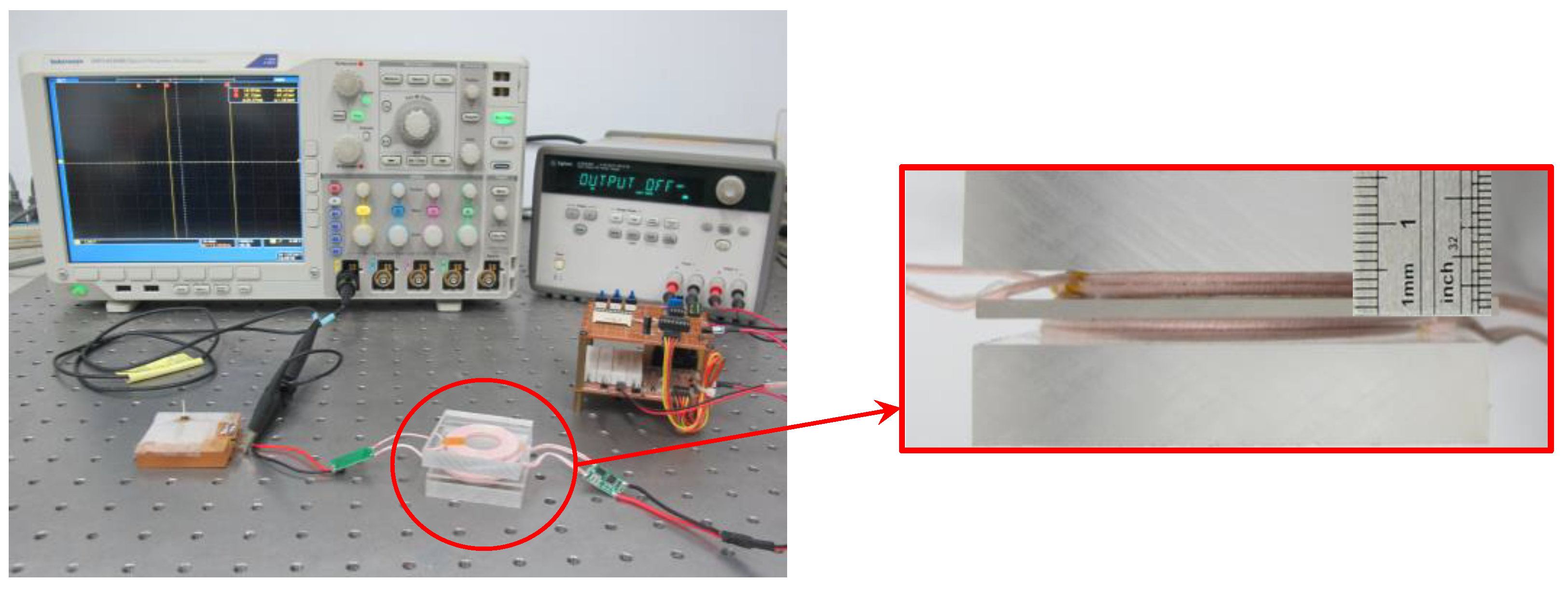

Figure 21.

Photograph of the actual wireless-driven, single-phase switched reluctance motor test system.

Figure 21.

Photograph of the actual wireless-driven, single-phase switched reluctance motor test system.

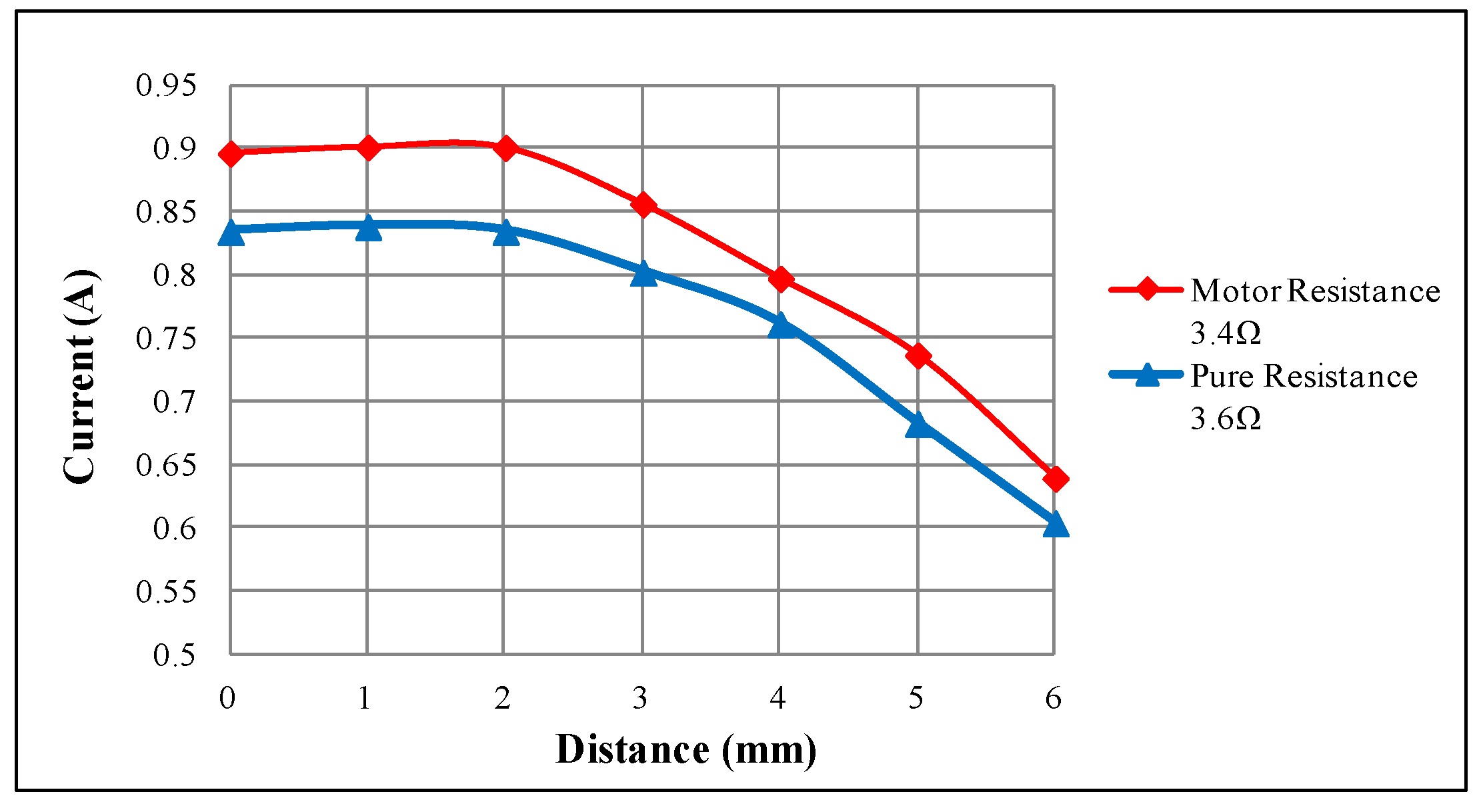

Figure 22.

Current-distance curves of the single-phase switched reluctance motor and pure resistance loads.

Figure 22.

Current-distance curves of the single-phase switched reluctance motor and pure resistance loads.

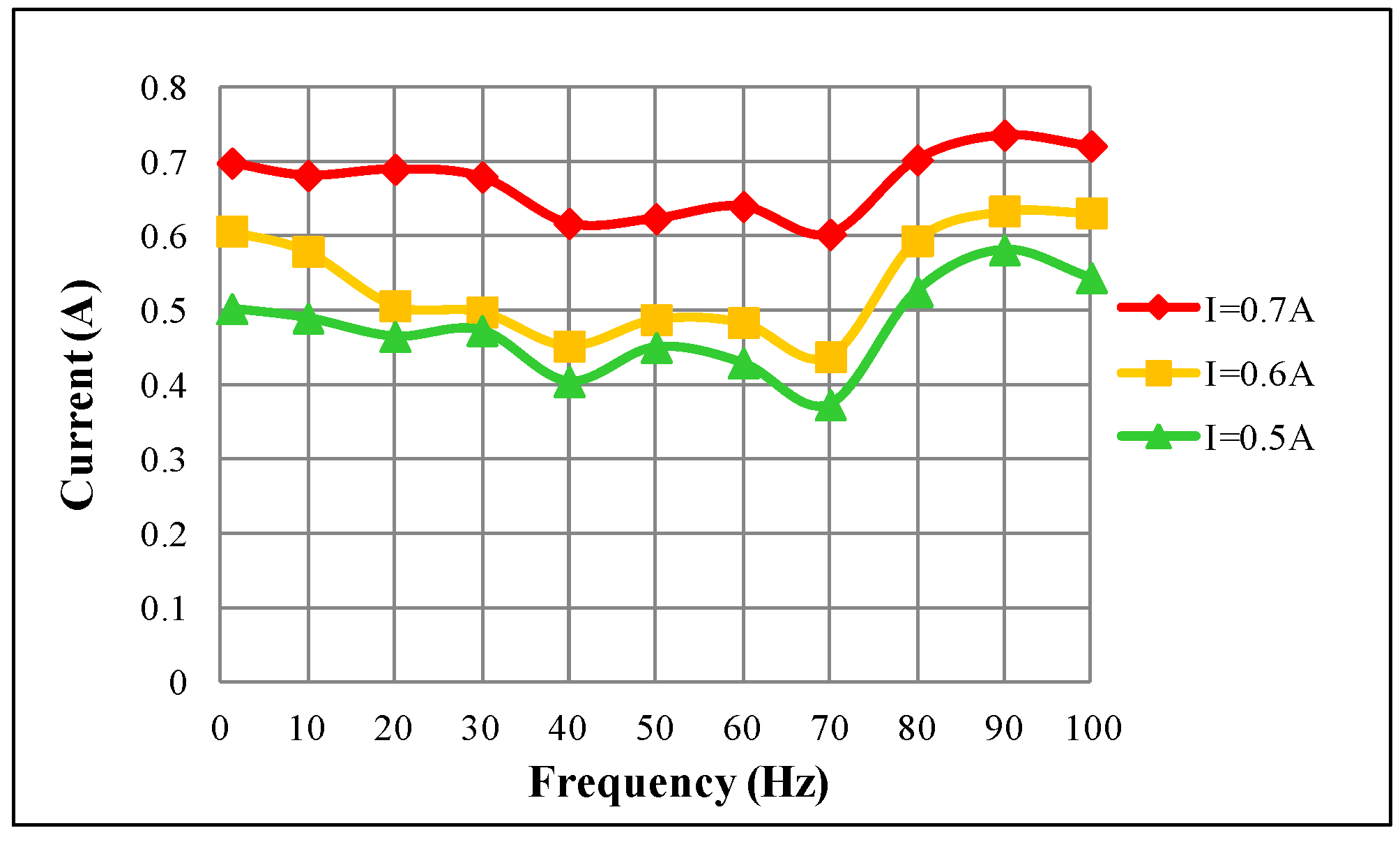

Figure 23.

Current-frequency curves of the wireless charging module with pure resistance loads at a 2 mm distance.

Figure 23.

Current-frequency curves of the wireless charging module with pure resistance loads at a 2 mm distance.

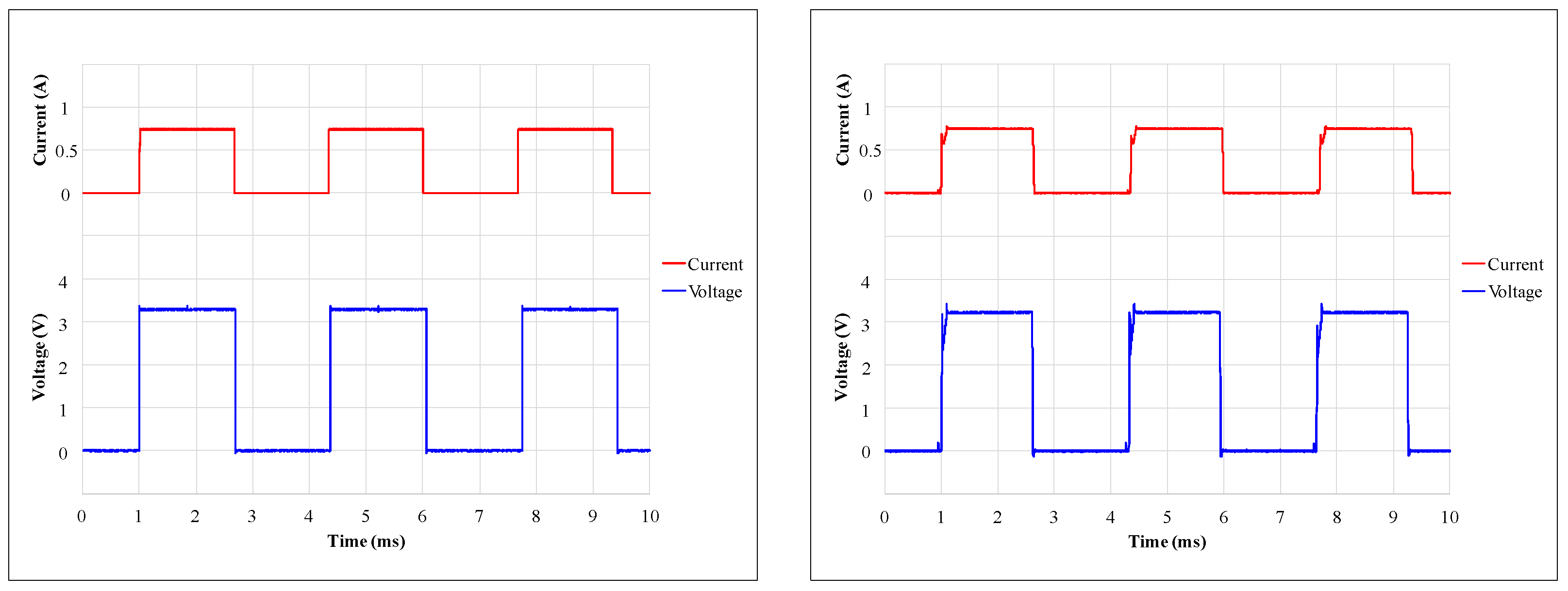

Figure 24.

Voltage and current signals of the motor at 900 rpm with wire-driven (left) and wireless-driven (right) conditions.

Figure 24.

Voltage and current signals of the motor at 900 rpm with wire-driven (left) and wireless-driven (right) conditions.

Table 1.

Specifications of the micro, axial-flux, single-phase switched reluctance motor.

Table 1.

Specifications of the micro, axial-flux, single-phase switched reluctance motor.

| Mechanical Specifications |

|---|

| Stator | Poles | 2 | Rotor | Poles | 2 |

| Number of permanent magnets | 2 | External diameter | 4.5 mm |

| External diameter | 5.5 mm | Root diameter | 2 mm |

| Diameter of magnetic rods | 0.75 mm × 3 | Internal diameter | 1 mm |

| Diameter of permanent magnets | 1.2 mm | Length | 0.35 mm |

| Length of magnetic rods | 4 mm | Air gap between rotor and stator pole | 0.06 mm |

| Length of permanent magnets | 2.65 mm | Air gap between rotor and permanent magnet | 0.2 mm |

| Electrical Specifications |

| Phase | 1 | Step angle | 90° |

| Number of turns of coil | 120 | Diameter of coil | 0.07 mm |

| Maximum current | 1 A | Resistance of coil | 3.4 Ω |

Table 2.

Step 1: Comparison of the torque characteristics of each step.

Table 2.

Step 1: Comparison of the torque characteristics of each step.

| Step | 1-1 | 1-2 | 1-3 | 1-4 |

|---|

| Maximum torque (μN·m) | 34.52 | 47.07 | 29.37 | 38.11 |

| Minimum torque (μN·m) | −8.12 | −0.31 | −1.05 | −0.47 |

| Average torque (μN·m) | 14.62 | 14.52 | 13.17 | 14.78 |

| Relative ripple torque (%) | 161.56 | 101.32 | 107.41 | 102.50 |

Table 3.

Step 2: Comparison table of the torque characteristic of each step.

Table 3.

Step 2: Comparison table of the torque characteristic of each step.

| Step | 2-1 | 2-2 | 2-3 | 2-4 |

|---|

| Maximum torque (μN·m) | 28.07 | 29.50 | 28.14 | 34.21 |

| Minimum torque (μN·m) | −0.13 | 0.18 | 0.90 | 3.03 |

| Average torque (μN·m) | 13.01 | 13.61 | 13.62 | 13.38 |

| Relative ripple torque (%) | 100.92 | 98.82 | 93.80 | 83.75 |

Table 4.

Step 3: Comparison of the torque characteristics of each step.

Table 4.

Step 3: Comparison of the torque characteristics of each step.

| Step | 3-1 | 3-2 | 3-3 | 3-4 |

|---|

| Maximum torque (μN·m) | 33.87 | 30.68 | 26.77 | 27.40 |

| Minimum torque (μN·m) | 3.26 | 3.58 | 2.83 | 2.16 |

| Average torque (μN·m) | 13.52 | 13.10 | 12.20 | 12.73 |

| Relative ripple torque (%) | 82.44 | 79.09 | 80.87 | 85.37 |

Table 5.

Step 4: Comparison of the torque characteristics of each step.

Table 5.

Step 4: Comparison of the torque characteristics of each step.

| Step | 4-1 | 4-2 | 4-3 | 4-4 |

|---|

| Maximum torque (μN·m) | 33.26 | 31.53 | 33.90 | 29.04 |

| Minimum torque (μN·m) | 3.68 | 3.34 | 3.32 | 2.72 |

| Average torque (μN·m) | 12.67 | 13.32 | 13.24 | 13.75 |

| Relative ripple torque (%) | 80.08 | 80.86 | 82.16 | 82.85 |

Table 6.

Comparisons of theoretical and experimental torque characteristics of the single-phase switched reluctance motor.

Table 6.

Comparisons of theoretical and experimental torque characteristics of the single-phase switched reluctance motor.

| Current (A) | Max. Torque (μN·m) | Min. Torque (μN·m) | Average Torque (μN·m) | Relative Ripple Torque (%) |

|---|

| Theory | Experiment | Theory | Experiment | Theory | Experiment | Theory | Experiment |

|---|

| 0.5 | 12.03 | 9.26 | 1.98 | 1.54 | 5.65 | 4.29 | 71.77 | 71.43 |

| 0.6 | 15.37 | 11.69 | 2.72 | 1.92 | 7.33 | 5.56 | 69.89 | 67.23 |

| 0.7 | 18.75 | 14.33 | 2.72 | 1.92 | 8.99 | 6.77 | 74.64 | 72.45 |

| 0.8 | 22.20 | 16.98 | 2.72 | 1.92 | 10.62 | 8.01 | 78.15 | 76.23 |

| 0.9 | 25.61 | 19.40 | 2.72 | 1.92 | 12.21 | 9.26 | 80.78 | 78.89 |

| 1 | 29.04 | 21.39 | 2.72 | 1.92 | 13.75 | 10.34 | 82.85 | 80.66 |

Table 7.

Torque characteristics of the single-phase switched reluctance motor with and without friction correction.

Table 7.

Torque characteristics of the single-phase switched reluctance motor with and without friction correction.

| Current (A) | Maximum Torque (μN·m) | Average Torque (μN·m) |

|---|

| Theory | Experiment without Correction | Experiment with Correction | Theory | Experiment without Correction | Experiment with Correction |

|---|

| 0.5 | 12.03 | 9.26 | 10.45 | 5.65 | 4.29 | 5.48 |

| 0.6 | 15.37 | 11.69 | 12.88 | 7.33 | 5.56 | 6.75 |

| 0.7 | 18.75 | 14.33 | 15.52 | 8.99 | 6.77 | 7.96 |

| 0.8 | 22.20 | 16.98 | 18.17 | 10.62 | 8.01 | 9.20 |

| 0.9 | 25.61 | 19.40 | 20.59 | 12.21 | 9.26 | 10.45 |

| 1 | 29.04 | 21.39 | 21.58 | 13.75 | 10.34 | 11.53 |

Table 8.

Time response comparisons of the wire- and wireless-driven, single-phase switched reluctance motors.

Table 8.

Time response comparisons of the wire- and wireless-driven, single-phase switched reluctance motors.

| Speed (rpm) | Driven Method | Stable Time (ms) | Rise Time (ms) | Lag Time (ms) |

|---|

| 900 | Wire-driven | 0.10 | 0.08 | 0.05 |

| Wireless-driven | 1.26 | 0.86 | 0.54 |