A Reconfiguration Method for Extracting Maximum Power from Non-Uniform Aging Solar Panels

Abstract

1. Introduction

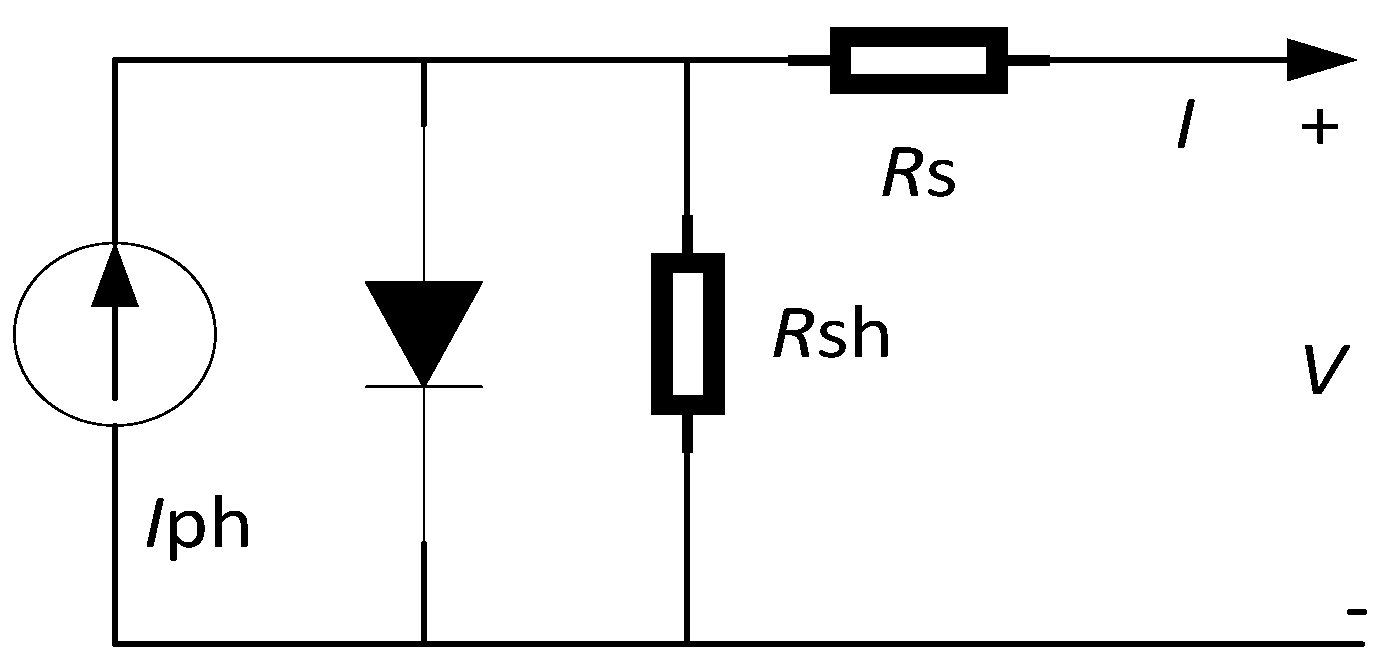

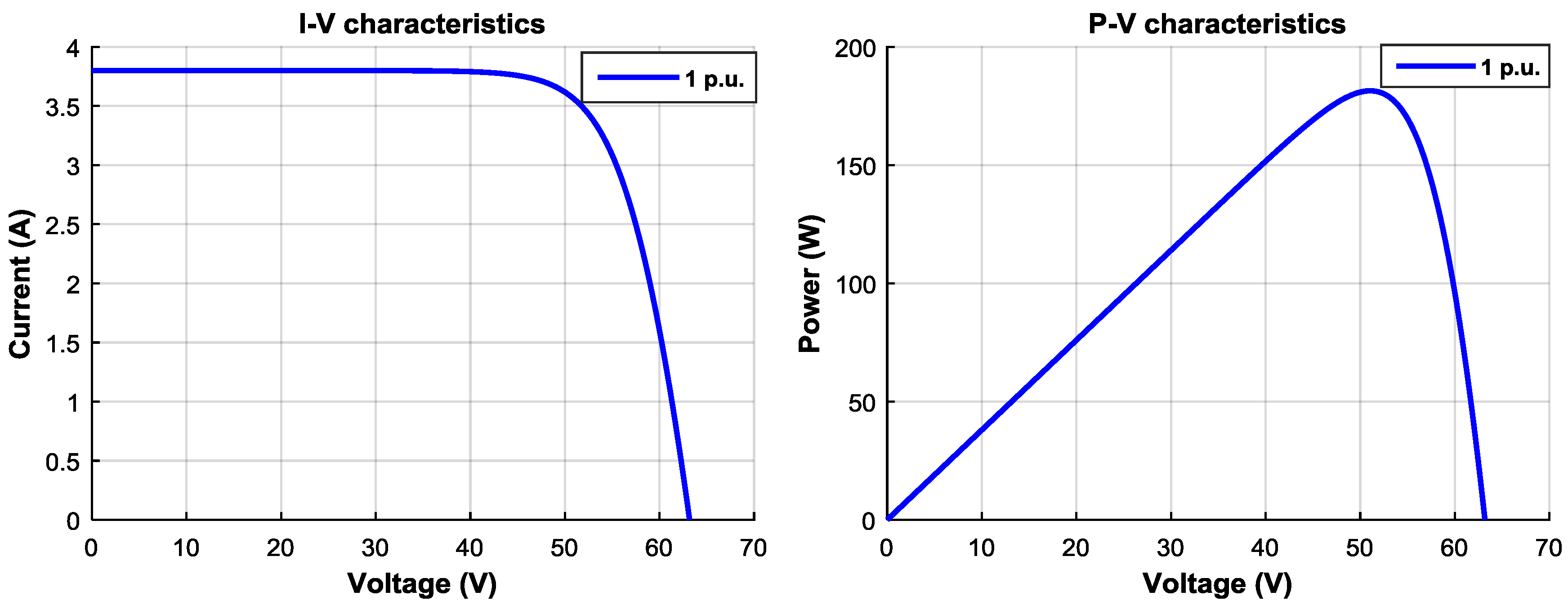

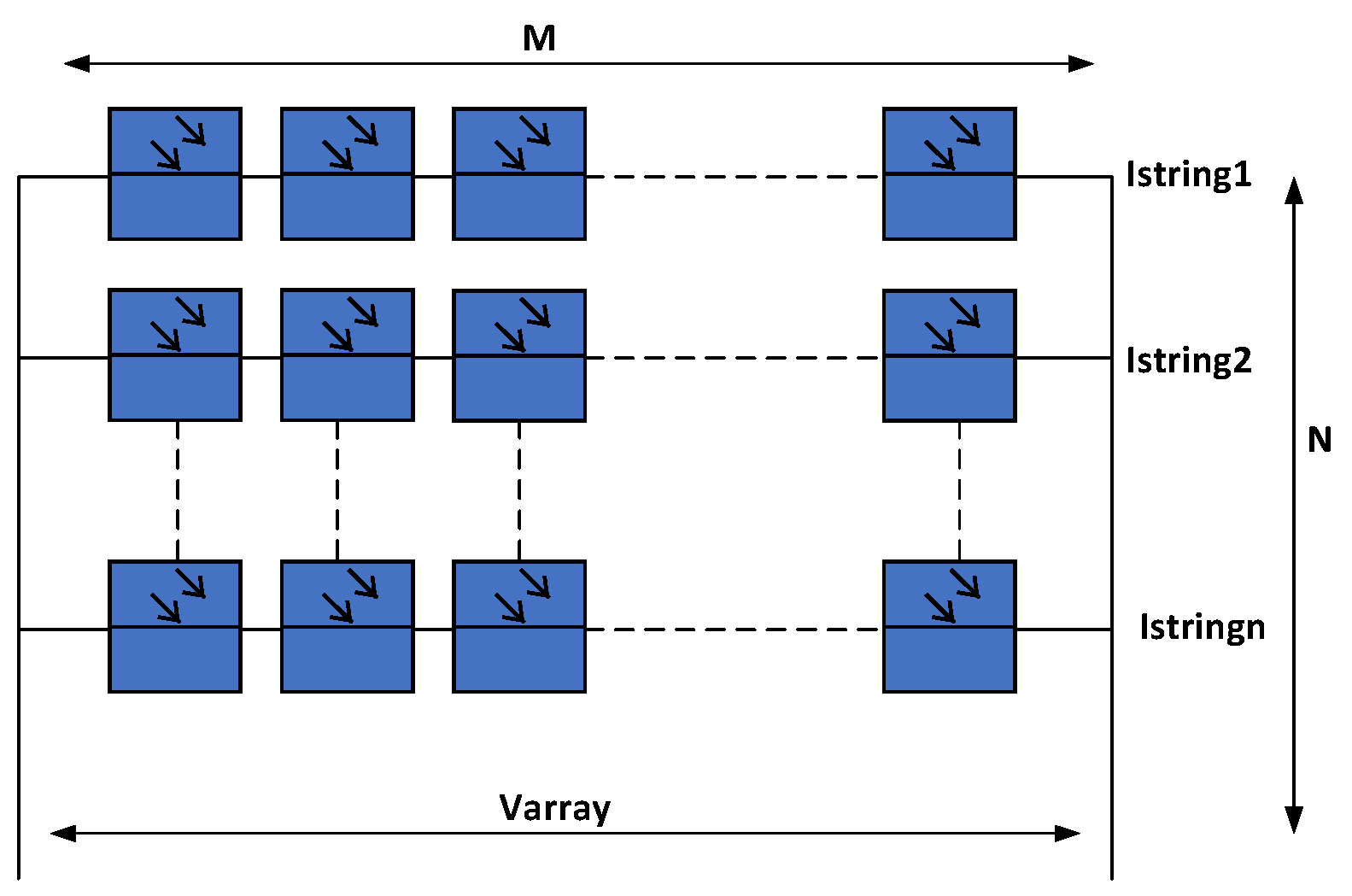

2. PV Modeling and Characteristics

2.1. Model of Good Quality PV Cells

- Short-circuit current is the maximum current that a PV cell can generate.

- Open-circuit voltage is the maximum voltage across a PV cell.

- Maximum power point (MPP) is the point on the I–V (voltage–current) characteristic curve where the product of voltage, , and current, , is the maximum [25].

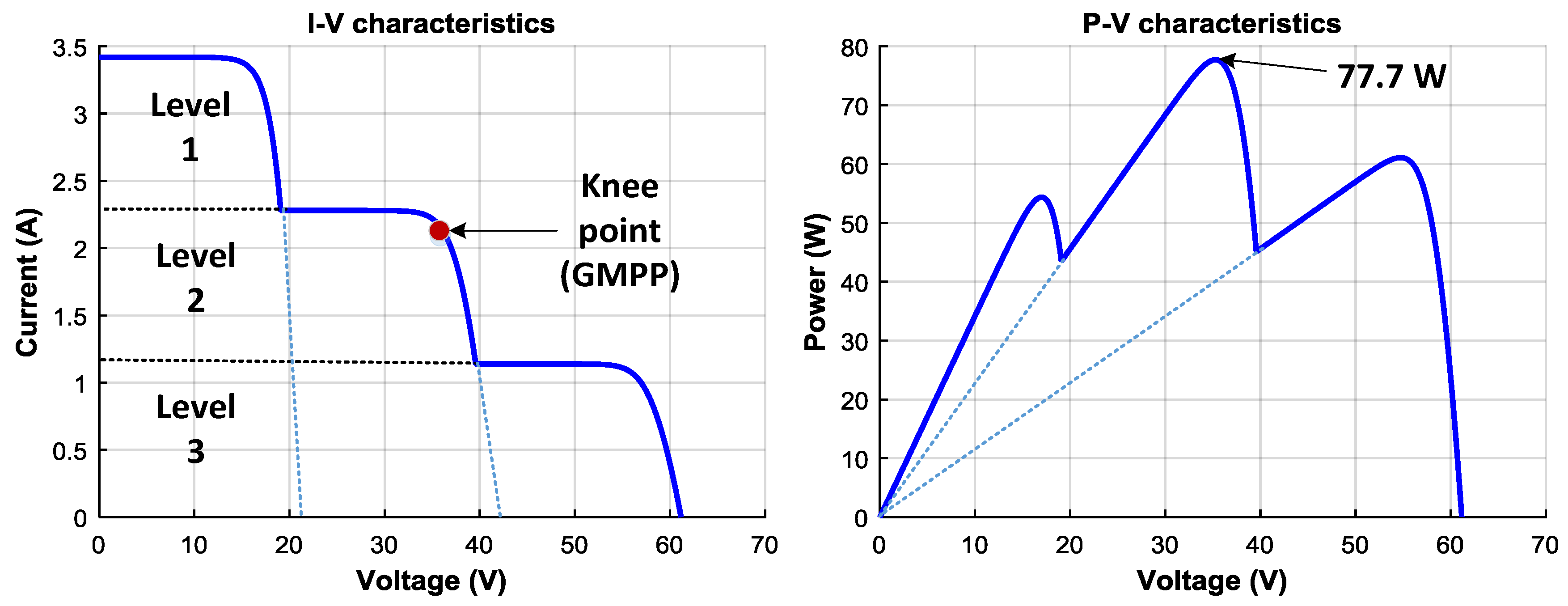

2.2. Mismatch Analysis Due to Non-Uniform Aging

3. PV Array Reconfiguration Scheme

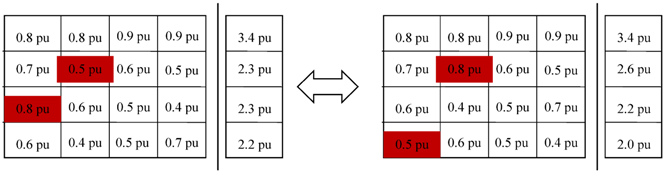

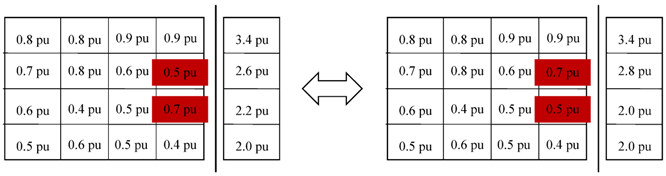

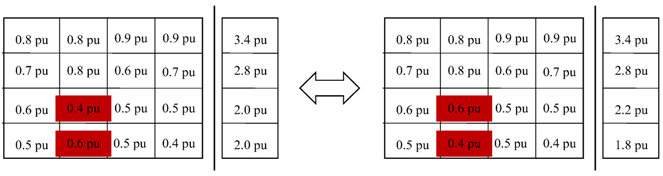

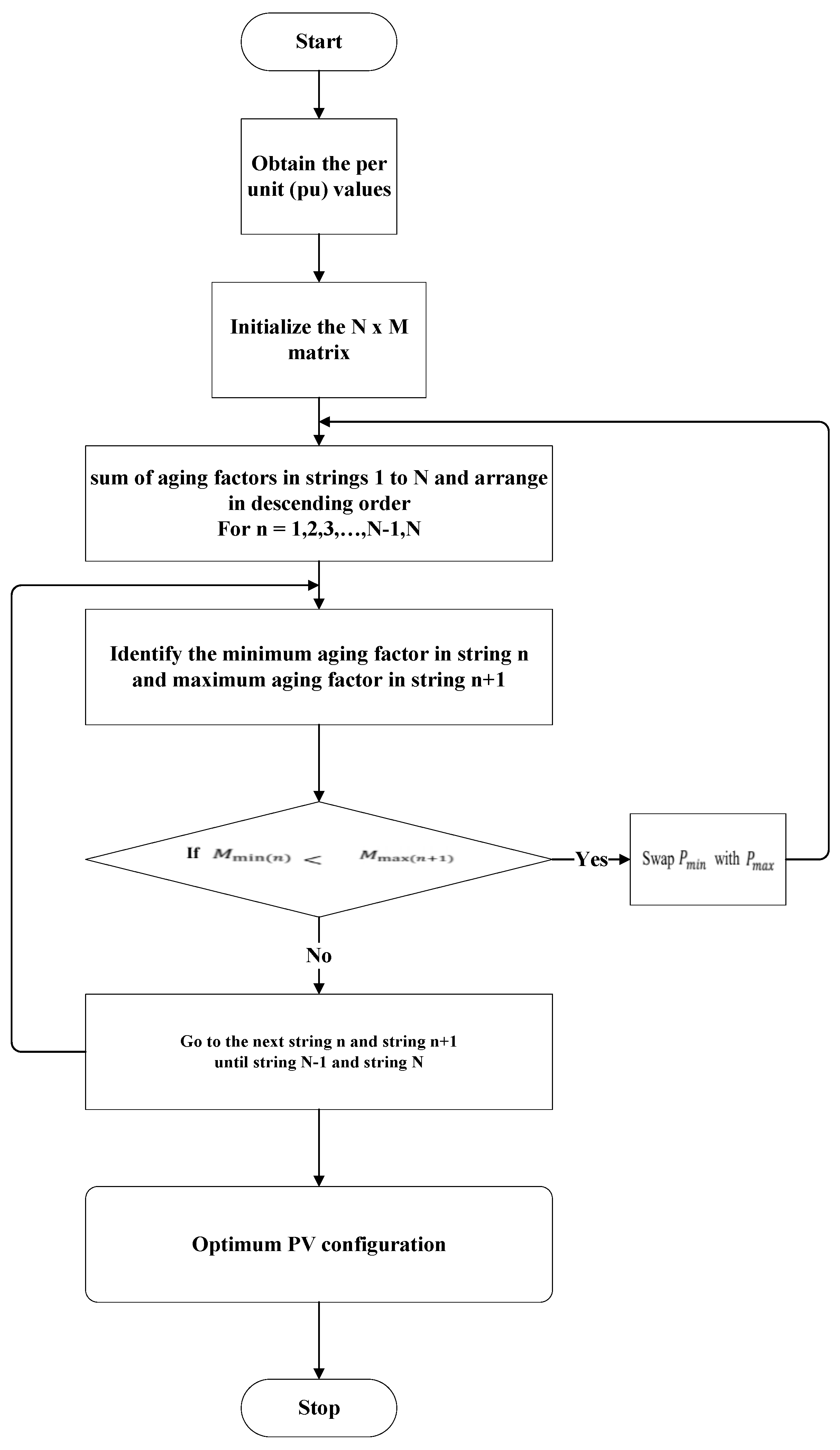

PV Reconfiguration Algorithm

4. Results and Discussions

4.1. Simulation Results

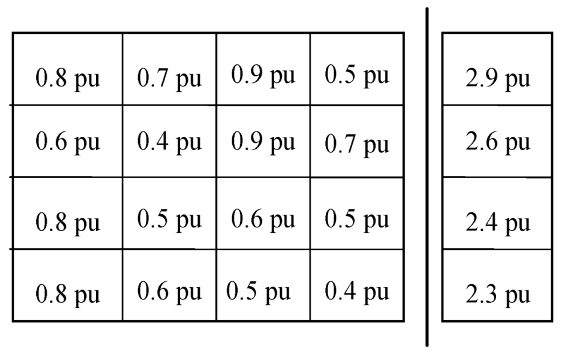

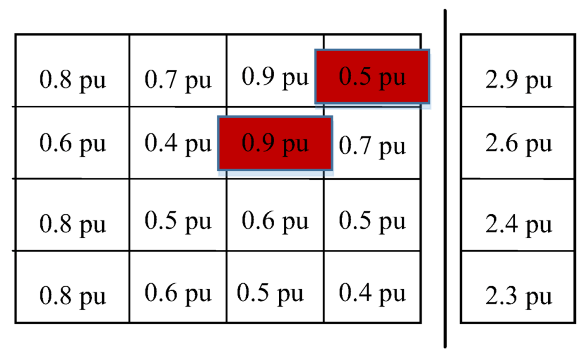

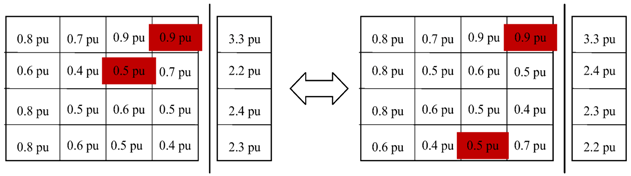

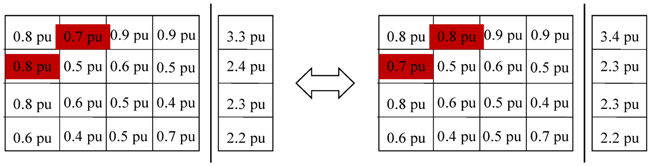

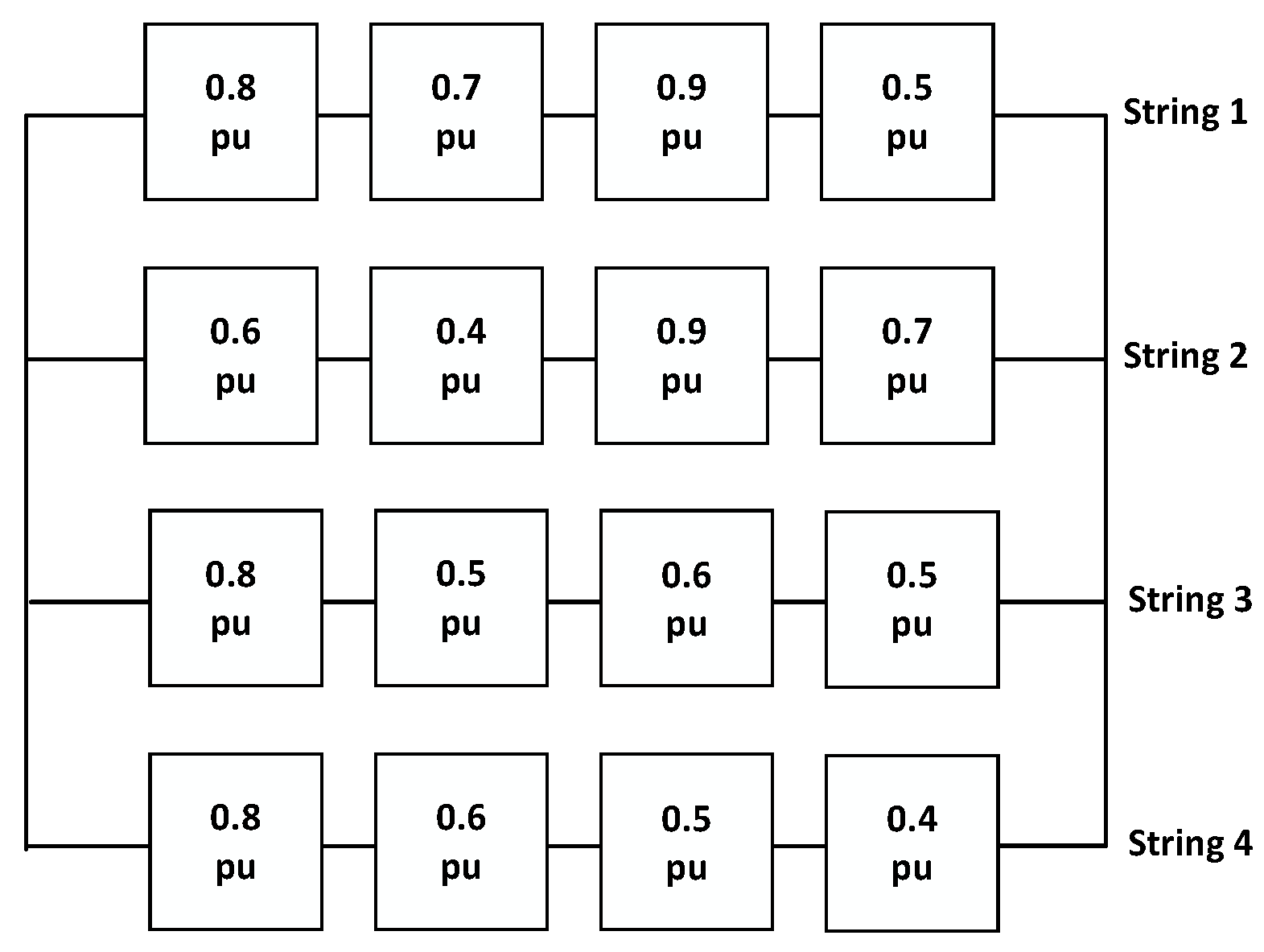

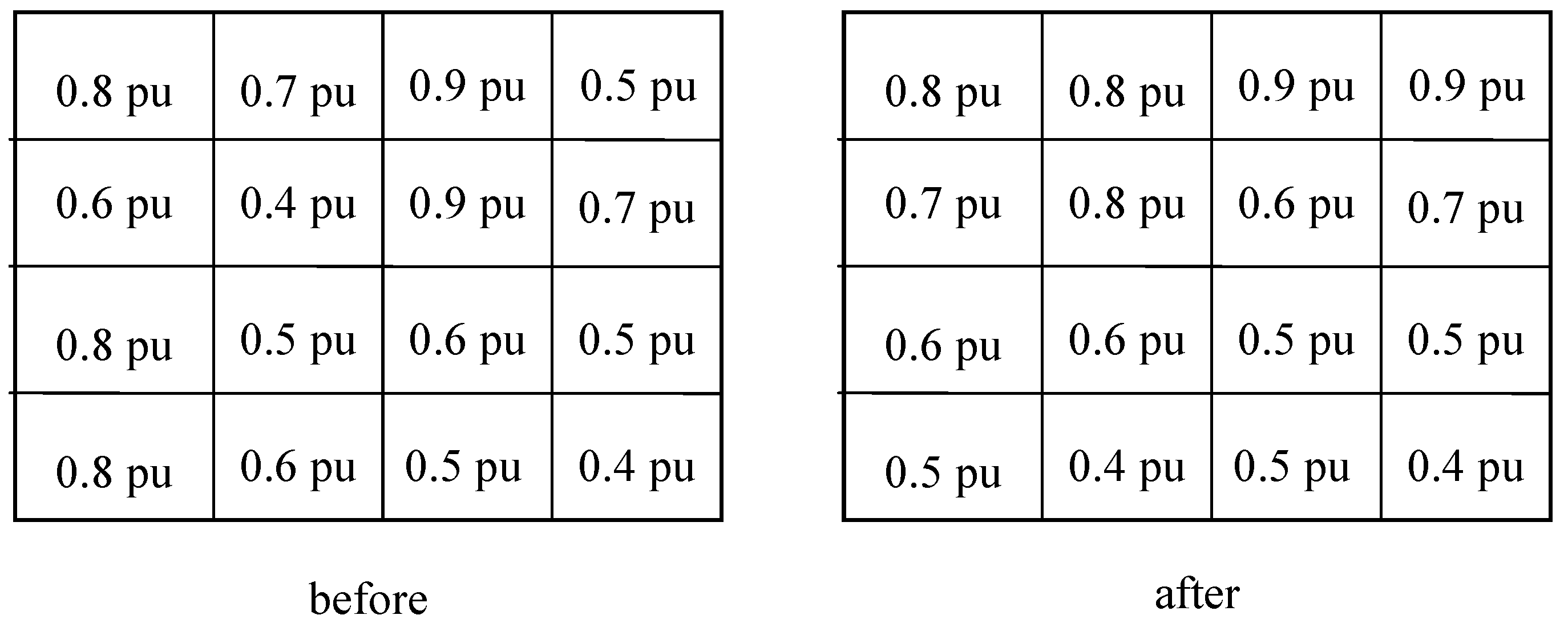

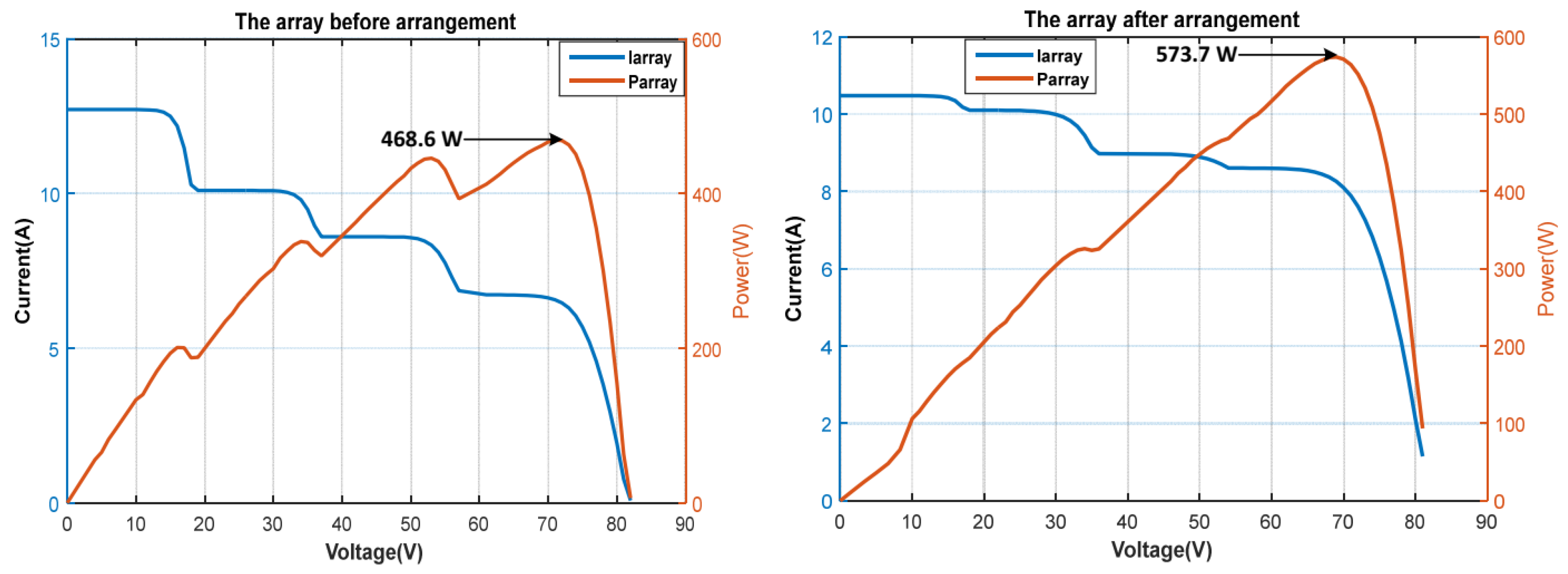

4.2. Case 1: 4 × 4 PV Array

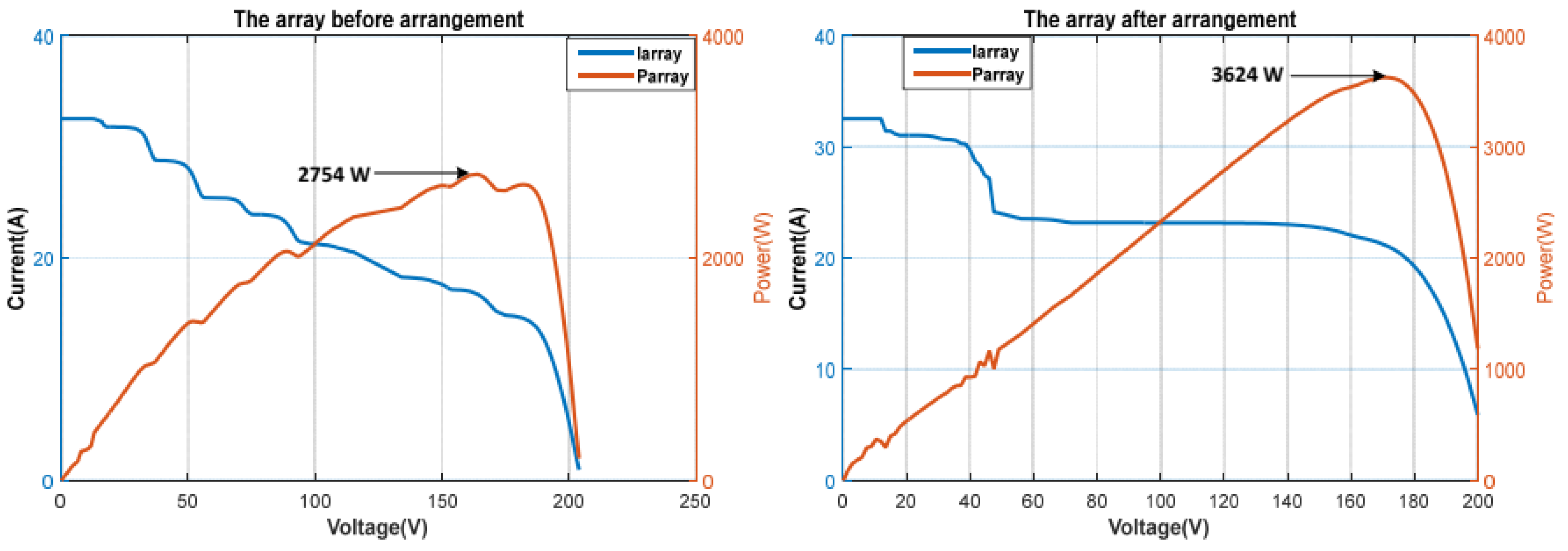

4.3. Case 2: 10 × 10 PV Array

4.4. Case 3: 100 × 10 PV Array

4.5. Discussions

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sanseverino, E.R.; Ngoc, T.N.; Cardinale, M.; Vigni, V.L.; Musso, D.; Romano, P.; Viola, F. Dynamic programming and munkres algorithm for optimal pv arrays reconfiguration. Sol. Energy 2015, 122, 347–358. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA), Renewable Power Generation Costs in 2017. Available online: https://www.irena.org//media/Files/IRENA/Agency/Publication/2018/Jan/IRENA_2017_Power_Costs_2018.pdf (accessed on 12 September 2018).

- Banavar, M.; Braun, H.; Buddha, S.T.; Krishnan, V.; Spanias, A.; Takada, S.; Takehara, T.; Tepedelenlioglu, C.; Yeider, T. Signal processing for solar array monitoring, fault detection, and optimization. Ynth. Lect. Power Electron. 2012, 7, 1–95. [Google Scholar] [CrossRef]

- Photovoltaics Report, Fraunhofer ISE and Werner Warmuth, PSE Conferences & Consulting GmbH, 27 August 2018. Available online: hhtps://www.ise.fraunhofer.de (accessed on 12 September 2018).

- Goodrich, A.; James, T.; Woodhouse, M. Residential, commercial and utility-scale PV system prices in the US: Current drivers and cost-reduction opportunities. Natl. Renew. Energy Lab. 2012. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, J.; Wu, J.; Cao, W.; Tian, G.Y.; Kirtley, J.L. Efficiency of non-uniformly aged PV array. IEEE Trans. Power Electron. 2017, 32, 1124–1137. [Google Scholar] [CrossRef]

- Ndiaye, A.; Kébé, C.M.; Ndiaye, P.A.; Charki, A.; Kobi, A.; Sambou, V. A novel method for investigating photovoltaic module degradation. Energy Procedia 2013, 36, 1222–1231. [Google Scholar] [CrossRef]

- Mekhilefa, S.; Saidurb, R.; Kamalisarvestanib, M. Effect of dust, humidity and air velocity on efficiency of photovoltaic cells. Renew. Sustain. Energy Rev. 2012, 16, 2920–2925. [Google Scholar] [CrossRef]

- Cristaldi, L.; Faifer, M.; Rossi, M.; Toscani, S.; Catelani, M.; Ciani, L.; Lazzaroni, M. Simplified method for evaluating the effects of dust and aging on photovoltaic panels. Measurement 2014, 54, 207–214. [Google Scholar] [CrossRef]

- Femia, N.; Petrone, G.; Spagnuolo, G.; Vitelli, M. Power Electronics and Control Techniques for Maximum Energy Harvesting in Photovoltaic Systems; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Balato, M.; Costanzo, L.; Vitelli, M. Reconfiguration of PV modules: A tool to get the best compromise between maximization of the extracted power and minimization of localized heating phenomena. Sol. Energy 2016, 138, 105–118. [Google Scholar] [CrossRef]

- Kaplanis, S.; Kaplani, E. Energy performance and degradation over 20 years performance of BP c-Si PV modules. Simul. Model. Pract. Theory 2011, 19, 1201–1211. [Google Scholar] [CrossRef]

- Shirzadi, S.; Hizam, H.; Wahab, N.I.A. Mismatch losses minimization in photovoltaic arrays by arranging modules applying a genetic algorithm. Sol. Energy 2014, 108, 467–478. [Google Scholar] [CrossRef]

- Manganiello, P.; Balato, M.; Vitelli, M. A survey on mismatching and aging of PV Modules: The closed loop. IEEE Trans. Ind. Electron. 2015, 62, 7276–7286. [Google Scholar] [CrossRef]

- La Manna, D.; Vigni, V.L.; Sanseverino, E.R.; Di Dio, V.; Romano, P. Reconfigurable electrical interconnection strategies for photovoltaic arrays: A review. Renew. Sustain. Energy Rev. 2014, 33, 412–426. [Google Scholar] [CrossRef]

- Malathy, S.; Ramaprabha, R. Comprehensive analysis on the role of array size and configuration on energy yield of photovoltaic systems under shaded conditions. Renew. Sustain. Energy Rev. 2015, 49, 672–679. [Google Scholar] [CrossRef]

- Camarillo-Peñaranda, J.R.; Ramírez-Quiroz, F.A.; González-Montoya, D.; Bolaños-Martínez, F.; Ramos-Paja, C.A. Reconfiguration of photovoltaic arrays based on genetic algorithm. Rev. Fac. Ing. Univ. Antioq. 2015, 95–107. [Google Scholar] [CrossRef]

- Auttawaitkul, Y.; Pungsiri, B.; Chammongthai, K.; Okuda, M. A method of appropriate electrical array reconfiguration management for photovoltaic powered car. In Proceedings of the 1998 IEEE Asia-Pacific Conference on Circuits and Systems. Microelectronics and Integrating Systems (Cat. No.98EX242), Chiangmai, Thailand, 24–27 November 1998; pp. 201–204. [Google Scholar]

- Chang, C. Solar Cell Array Having Lattice or Matrix Structure and Method of Arranging Solar Cells and Panels. U.S. Patent 6635817 B2, 21 October 2003. [Google Scholar]

- Sherif, R.A.; Boutros, K.S. Solar Module Array with Reconfigurable Tile. U.S. Patent 6350944 B1, 26 February 2002. [Google Scholar]

- Nguyen, D.; Lehman, B. An adaptive solar photovoltaic array using model-based reconfiguration algorithm. IEEE Trans. Ind. Electron. 2008, 55, 2644–2654. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, J.; Li, P.; Yu, D.; Jiang, L. Non-Uniform Aged Modules Reconfiguration for Large-Scale PV Array. IEEE Trans. Device Mater. Reliab. 2017, 17, 560–569. [Google Scholar] [CrossRef]

- Walker, G. Evaluating MPPT converter topologies using a Matlab PV Model. J. Electr. Electron. Eng. Aust. 2001, 21, 49–56. [Google Scholar]

- Castaner, L.; Silvestre, S. Modelling Photovoltaic Systems Using PSpice; John Wiley and Sons Ltd.: Hoboken, NJ, USA, 2002. [Google Scholar]

- Mahmoud, Y.A.; Xiao, W.; Zeineldin, H.H. A parameterization approach for enhancing PV model accuracy. IEEE Trans. Ind. Electron. 2013, 60, 5708–5716. [Google Scholar] [CrossRef]

- Braun, H.; Buddha, S.T.; Krishnan, V.; Tepedelenlioglu, C.; Spanias, A.; Banavar, M.; Srinivasan, D. Topology reconfiguration for optimization of photovoltaic array output. Sustain. Energy Grids Netw. 2016, 6, 58–69. [Google Scholar] [CrossRef]

| At Temperature T = 25 °C | ||

|---|---|---|

| Open circuit voltage | 21.0 V | |

| Short circuit current | 3.74 A | |

| Voltage at max. power | 17.1 V | |

| Current at max. power | 3.5 A | |

| Maximum power | 59.9 W | |

| Steps | Maximum Power (W) | Voltage at MPP (V) | String Currents (A) | |||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 1 | 468.6 | 71 | 1.863 | 1.492 | 1.757 | 1.482 |

| 2 | 515.6 | 70 | 2.587 | 1.793 | 1.490 | 1.488 |

| 3 | 530.7 | 70 | 2.818 | 1.779 | 1.490 | 1.488 |

| 4 | 535.3 | 70 | 2.818 | 1.859 | 1.488 | 1.475 |

| 5 | 558.6 | 70 | 2.818 | 2.206 | 1.475 | 1.475 |

| 6 | 573.7 | 69 | 2.867 | 2.260 | 1.790 | 1.428 |

| Before Arrangement | After Arrangement | ||||||

|---|---|---|---|---|---|---|---|

| 0.8 pu | 0.7 pu | 0.9 pu | 0.5 pu | 0.8 pu | 0.8 pu | 0.9 pu | 0.9 pu |

| 0.6 pu | 0.4 pu | 0.9 pu | 0.7 pu | 0.7 pu | 0.8 pu | 0.6 pu | 0.7 pu |

| 0.8 pu | 0.5 pu | 0.6 pu | 0.5 pu | 0.6 pu | 0.6 pu | 0.5 pu | 0.5 pu |

| 0.8 pu | 0.6 pu | 0.5 pu | 0.4 pu | 0.5 pu | 0.4 pu | 0.5 pu | 0.4 pu |

| Parameter | Before | After | Computing Time (s) | Power Improvement (Percentage) |

|---|---|---|---|---|

| 0.01 | 22.4% | |||

| Before Arrangement | |||||||||

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| After Arrangement | |||||||||

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

| pu | pu | pu | pu | pu | pu | pu | pu | pu | pu |

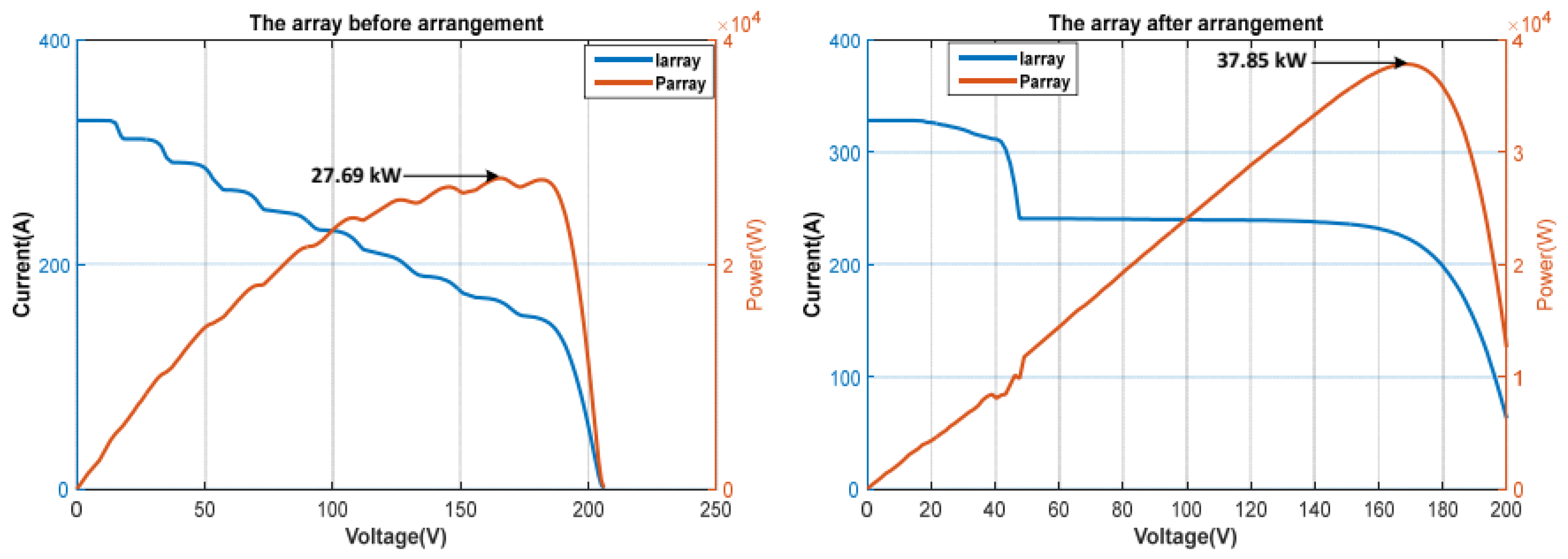

| Parameter | Before | After | Computing Time (s) | Power Improvement (Percentage) |

|---|---|---|---|---|

| 0.035 | 31.6% | |||

| Parameter | Before | After | Computing Time (s) | Power Improvement (Percentage) |

|---|---|---|---|---|

| 2.746 | 36.7% | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Udenze, P.; Hu, Y.; Wen, H.; Ye, X.; Ni, K. A Reconfiguration Method for Extracting Maximum Power from Non-Uniform Aging Solar Panels. Energies 2018, 11, 2743. https://doi.org/10.3390/en11102743

Udenze P, Hu Y, Wen H, Ye X, Ni K. A Reconfiguration Method for Extracting Maximum Power from Non-Uniform Aging Solar Panels. Energies. 2018; 11(10):2743. https://doi.org/10.3390/en11102743

Chicago/Turabian StyleUdenze, Peter, Yihua Hu, Huiqing Wen, Xianming Ye, and Kai Ni. 2018. "A Reconfiguration Method for Extracting Maximum Power from Non-Uniform Aging Solar Panels" Energies 11, no. 10: 2743. https://doi.org/10.3390/en11102743

APA StyleUdenze, P., Hu, Y., Wen, H., Ye, X., & Ni, K. (2018). A Reconfiguration Method for Extracting Maximum Power from Non-Uniform Aging Solar Panels. Energies, 11(10), 2743. https://doi.org/10.3390/en11102743