Scavenging Ports’ Optimal Design of a Two-Stroke Small Aeroengine Based on the Benson/Bradham Model

Abstract

:1. Introduction

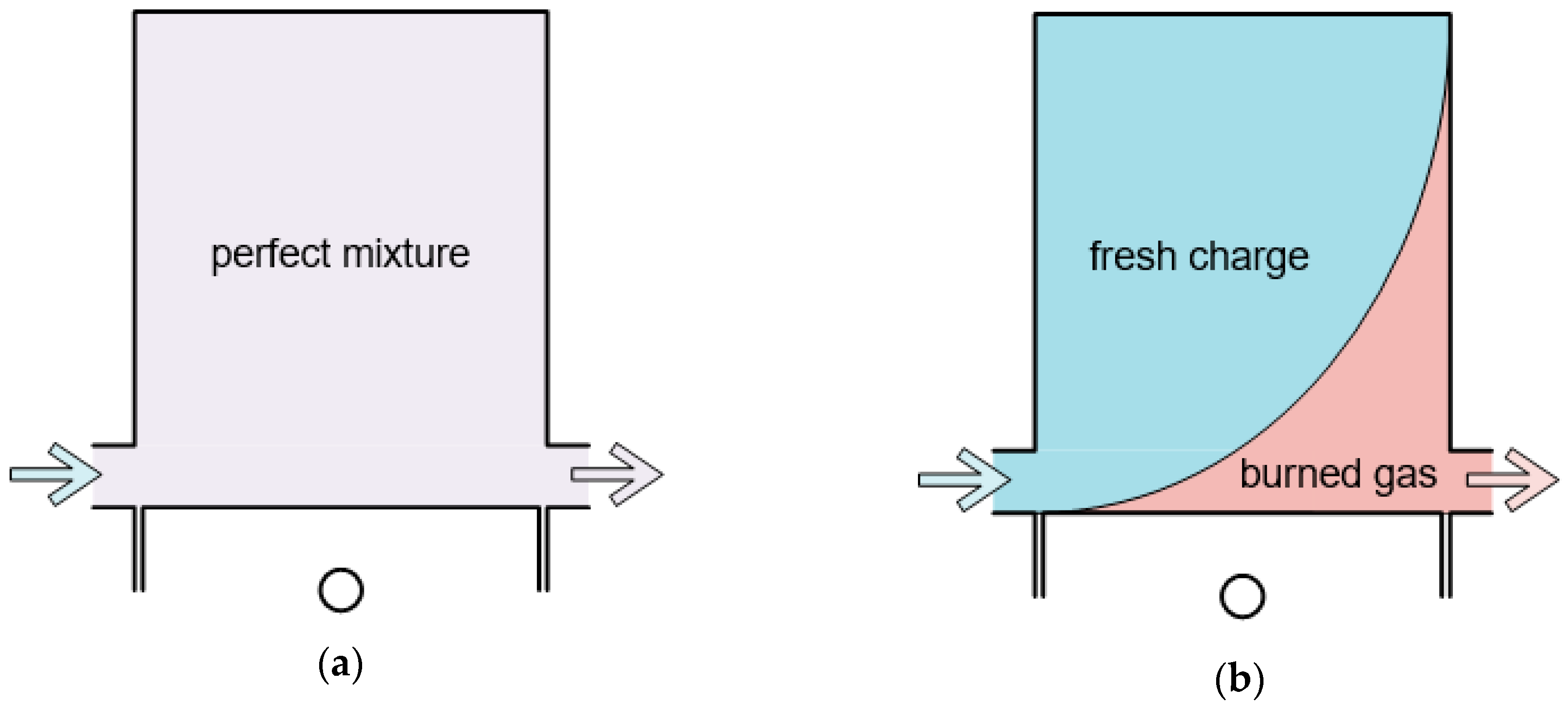

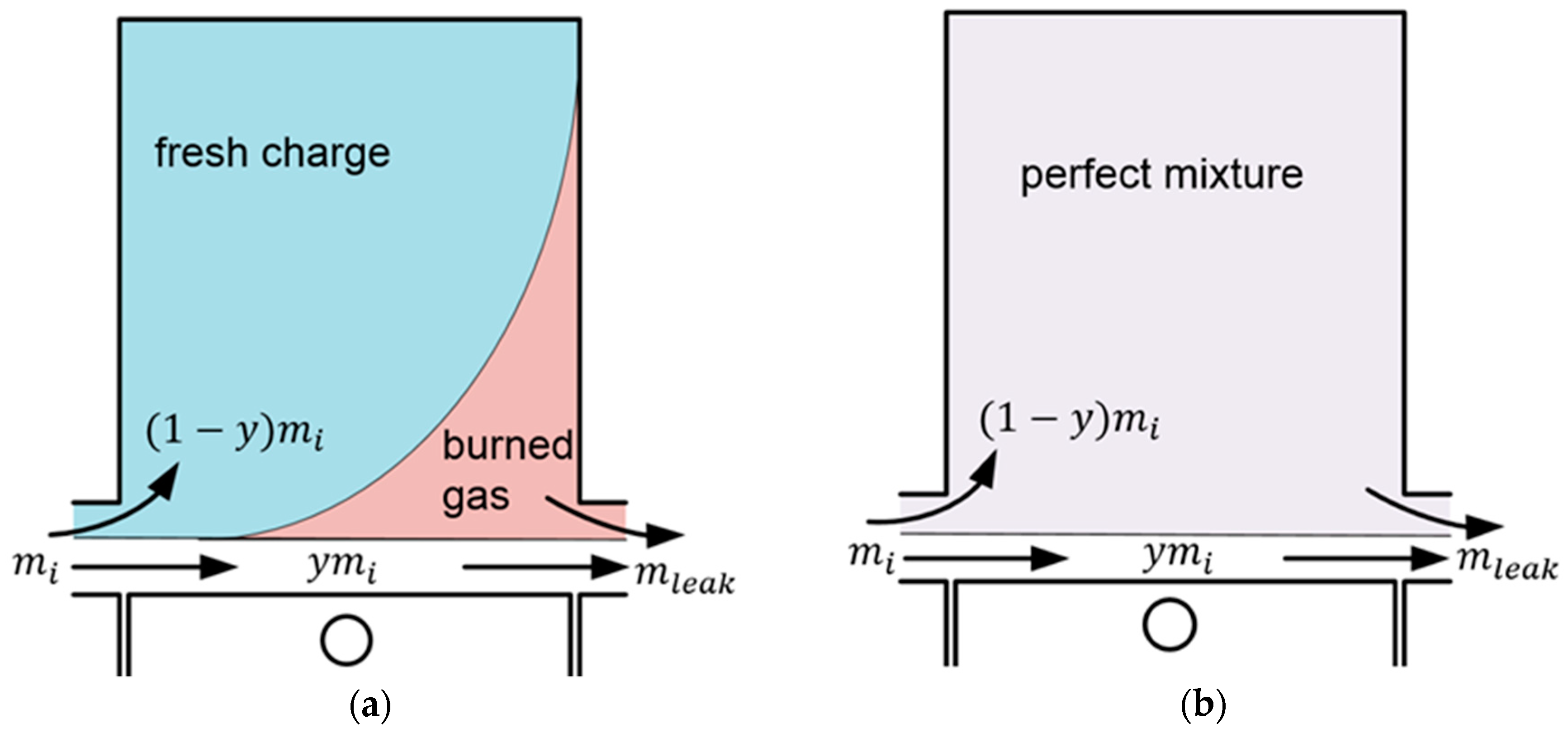

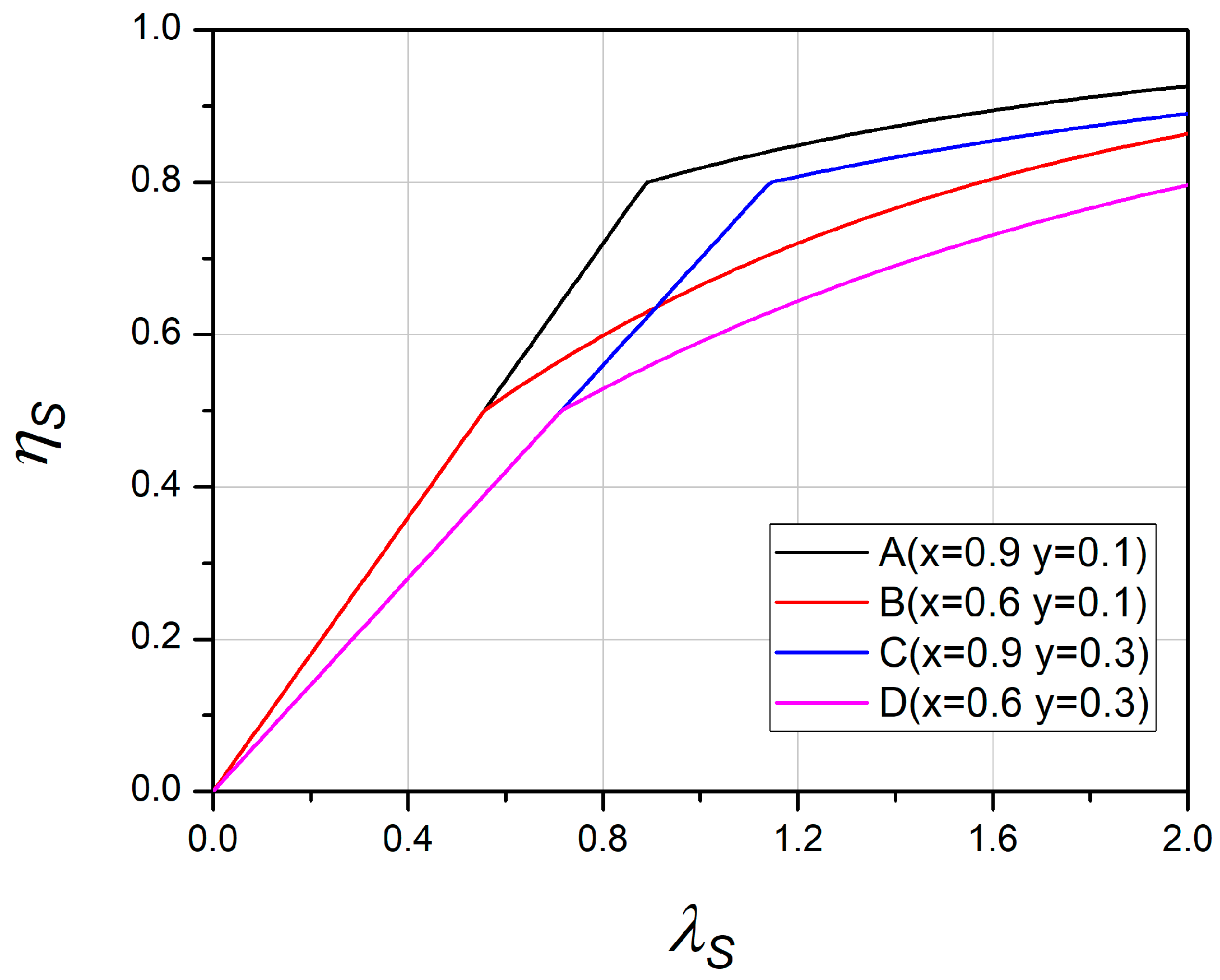

2. Scavenging System Modeling

2.1. Scavenging Model Selection

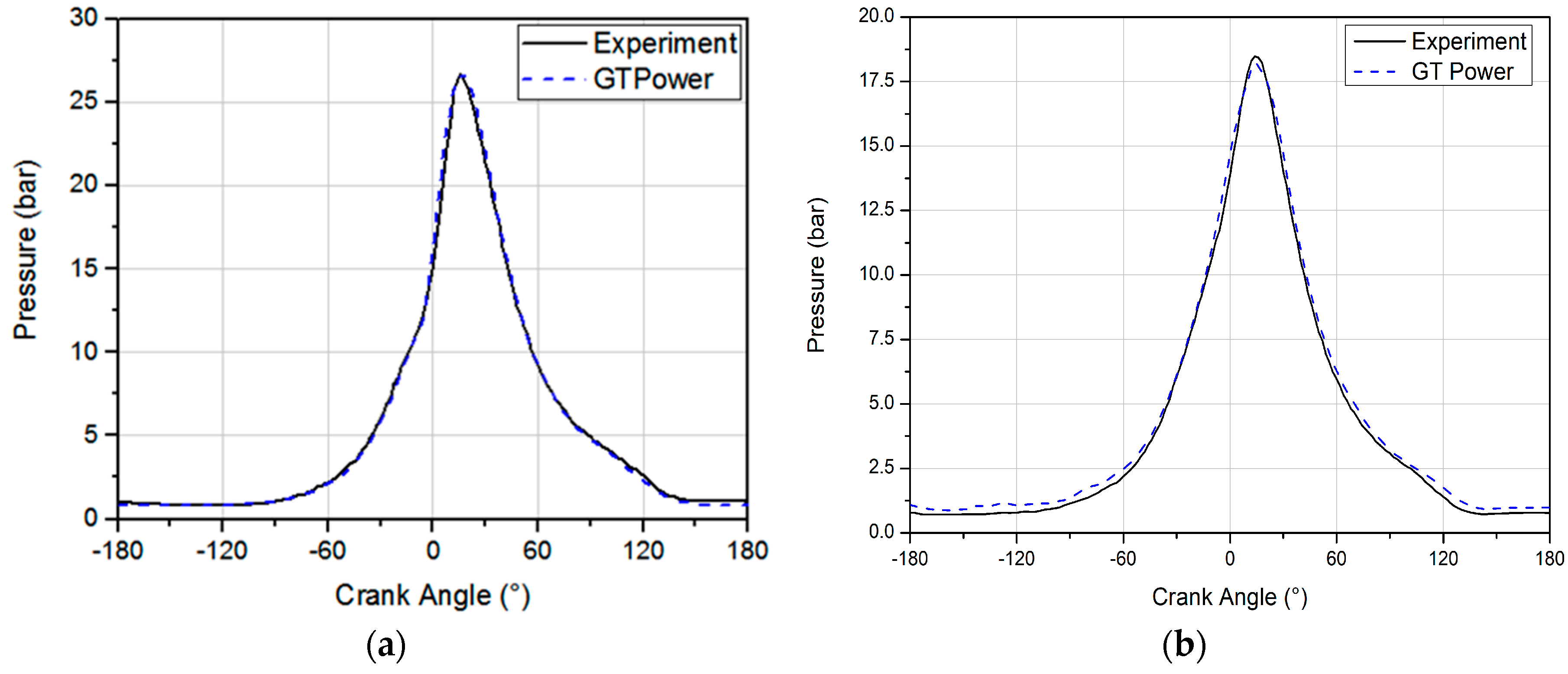

2.2. 1D GT Power Simulation Model

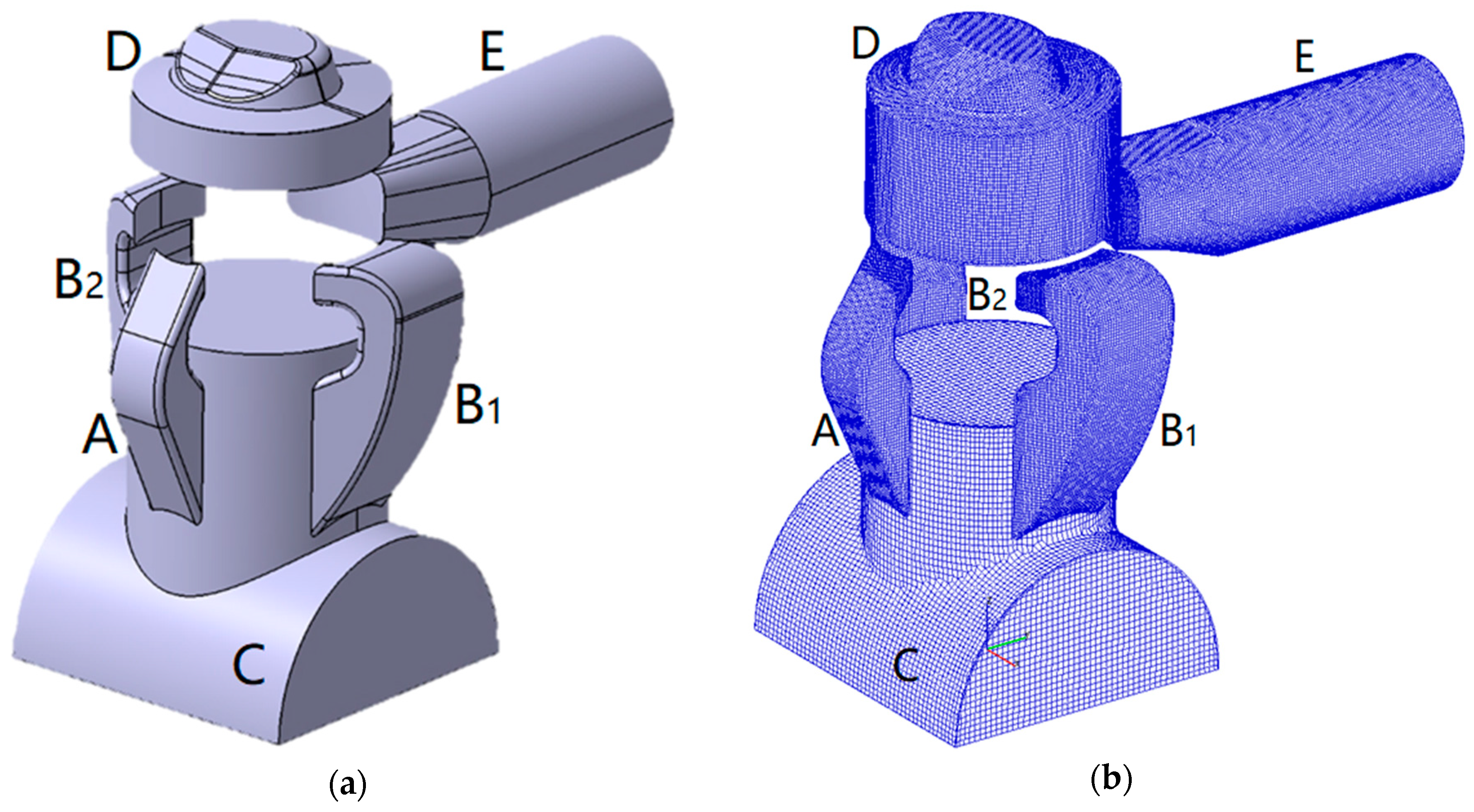

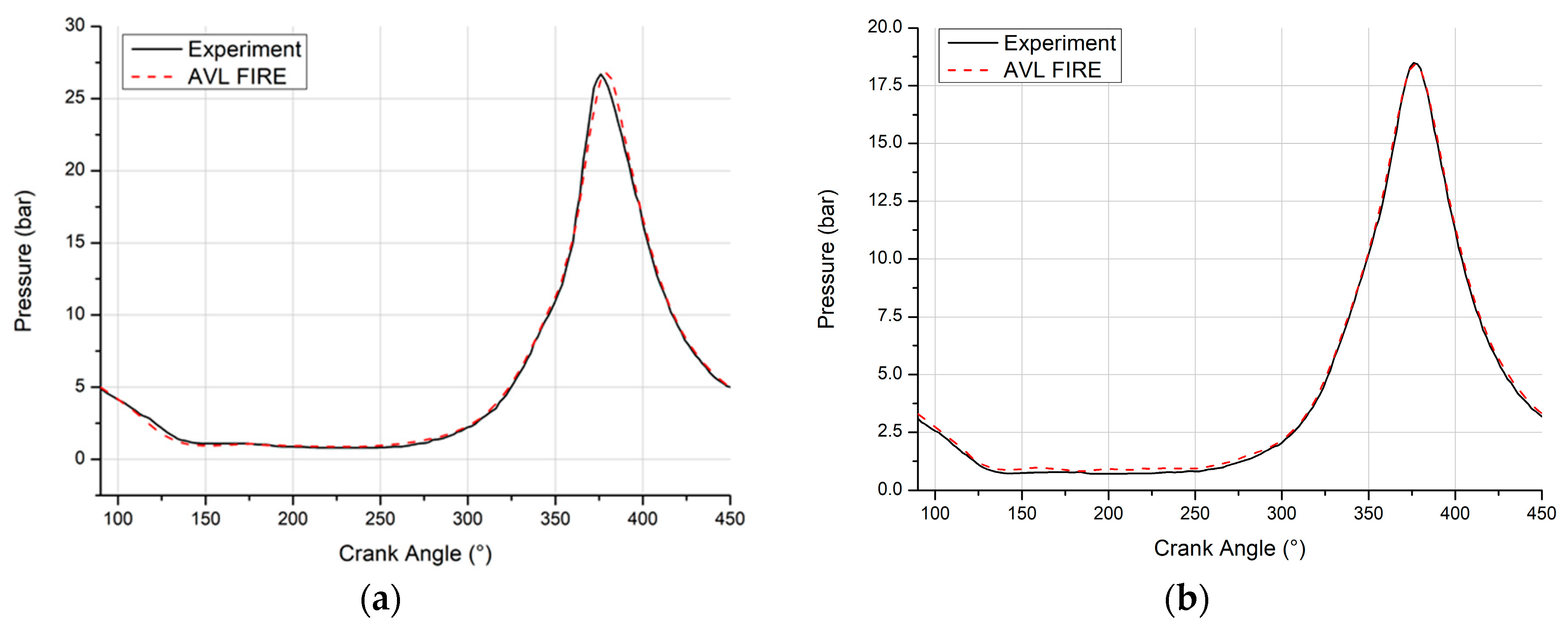

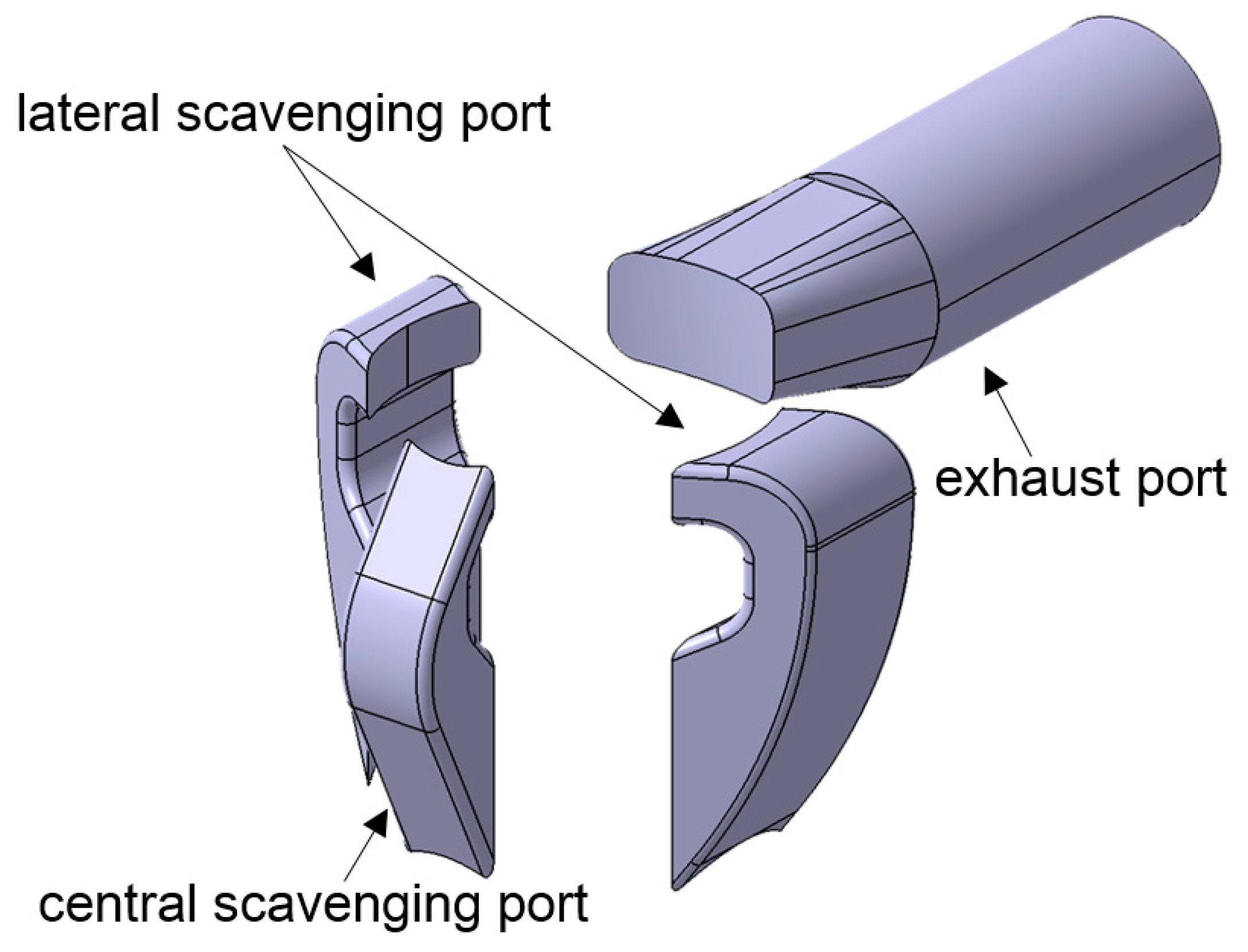

2.3. 3D AVL FIRE Simulation Model

3. Orthogonal Experiment Design

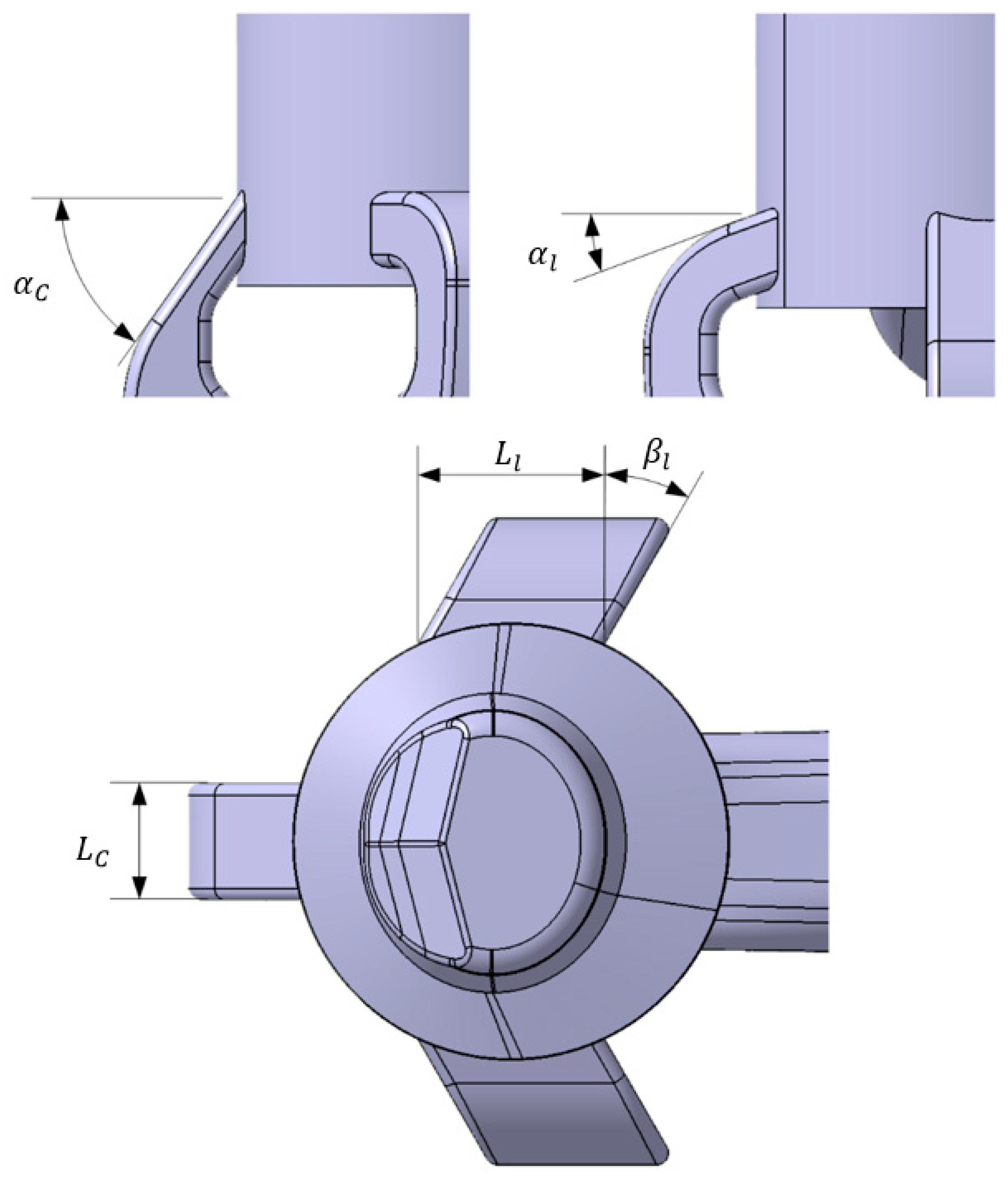

3.1. Optimal Design Determinants

3.2. Evaluation Objective Function

4. Simulation Results Analysis

4.1. OED Results Analysis

4.2. Verification of the Best Factors Combination

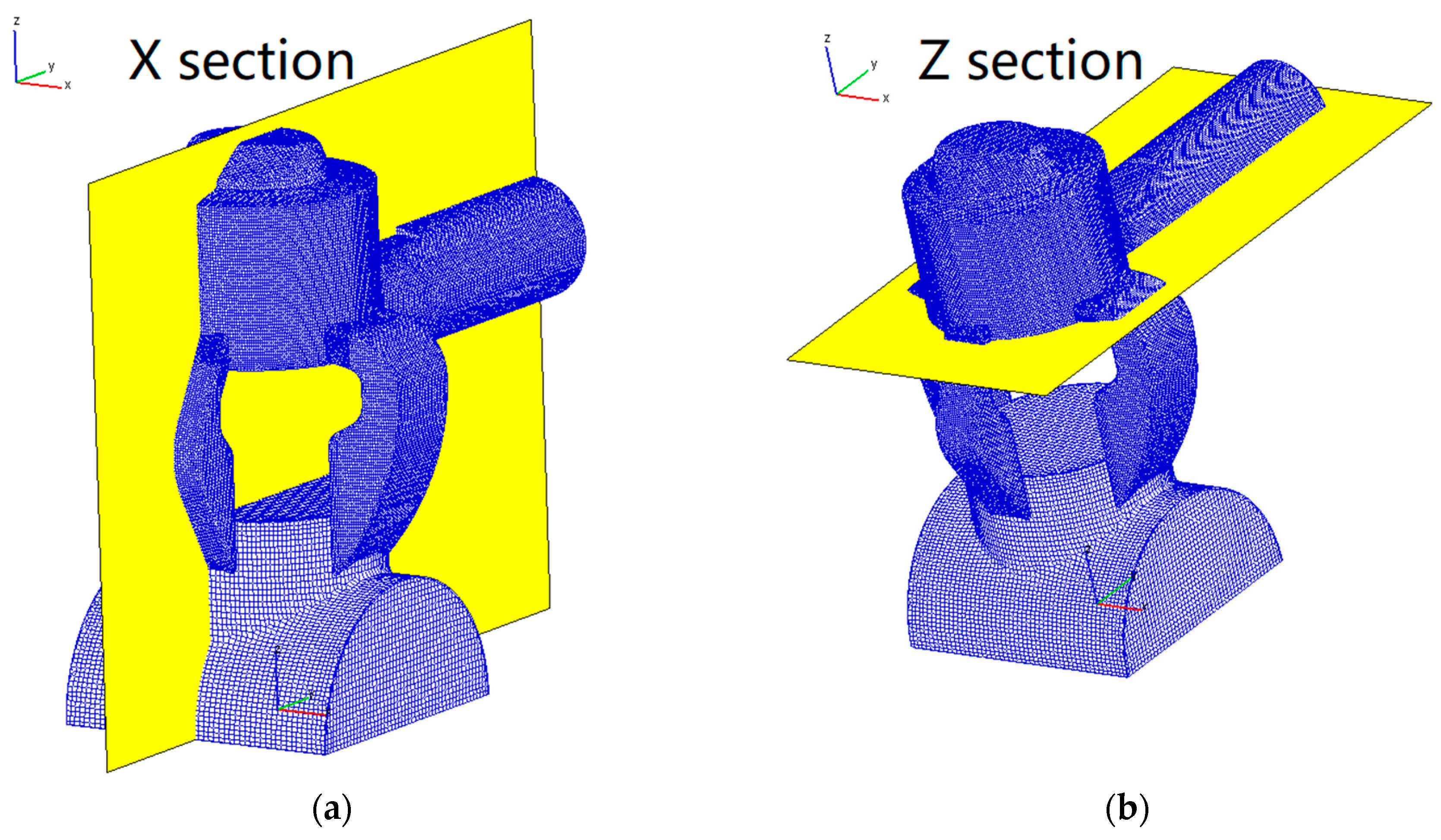

4.3. 3D Flow Field Visualization

- (1)

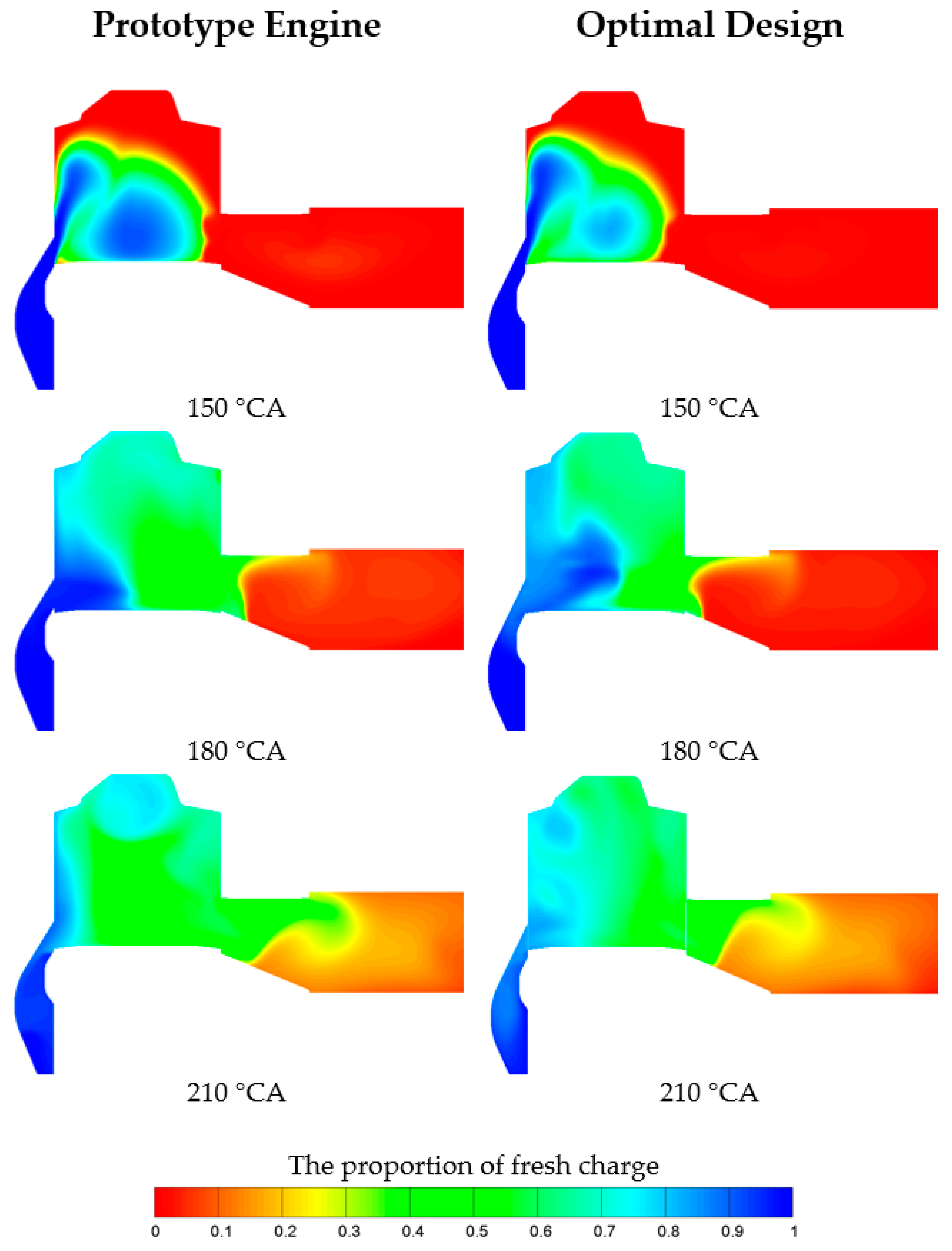

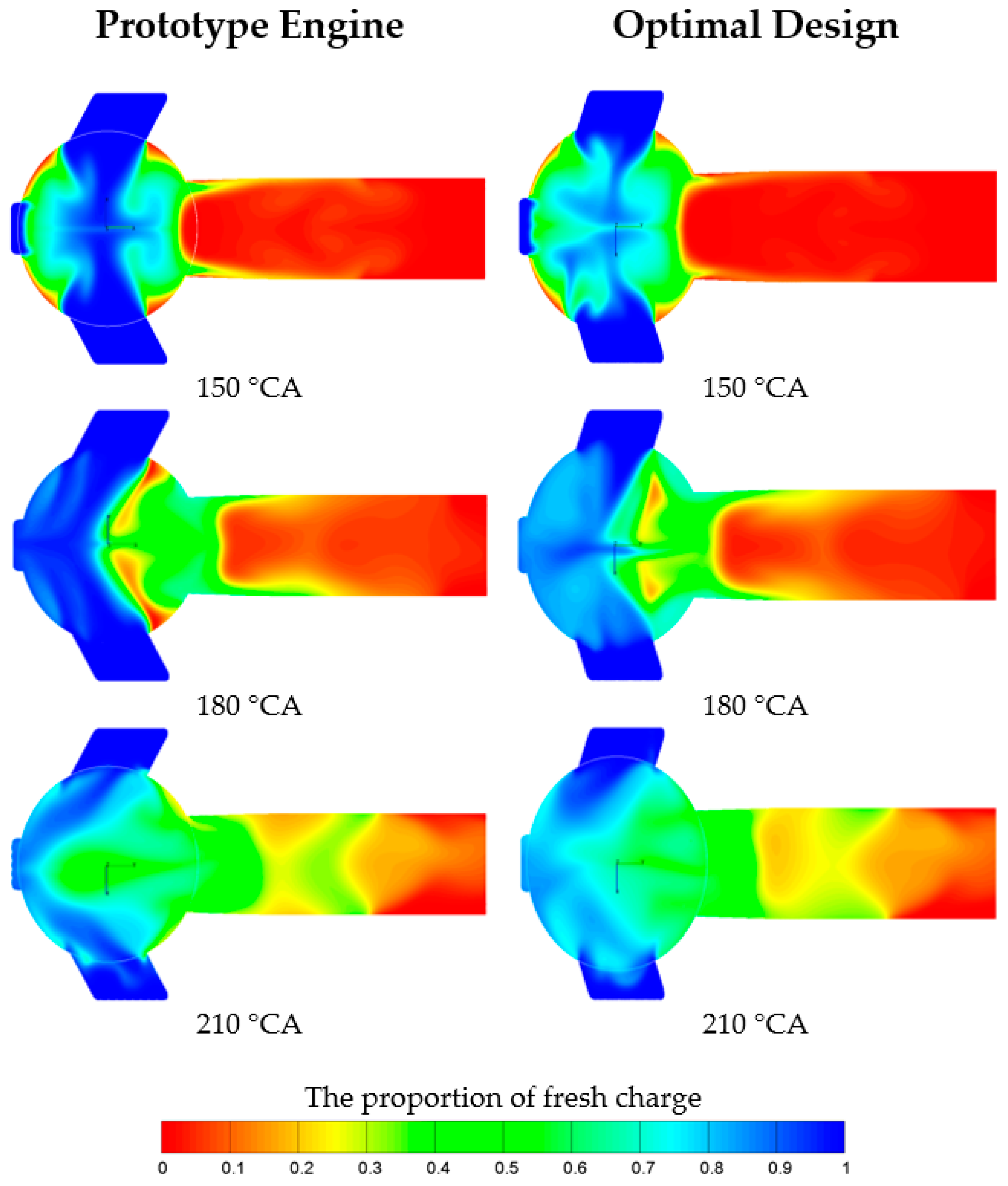

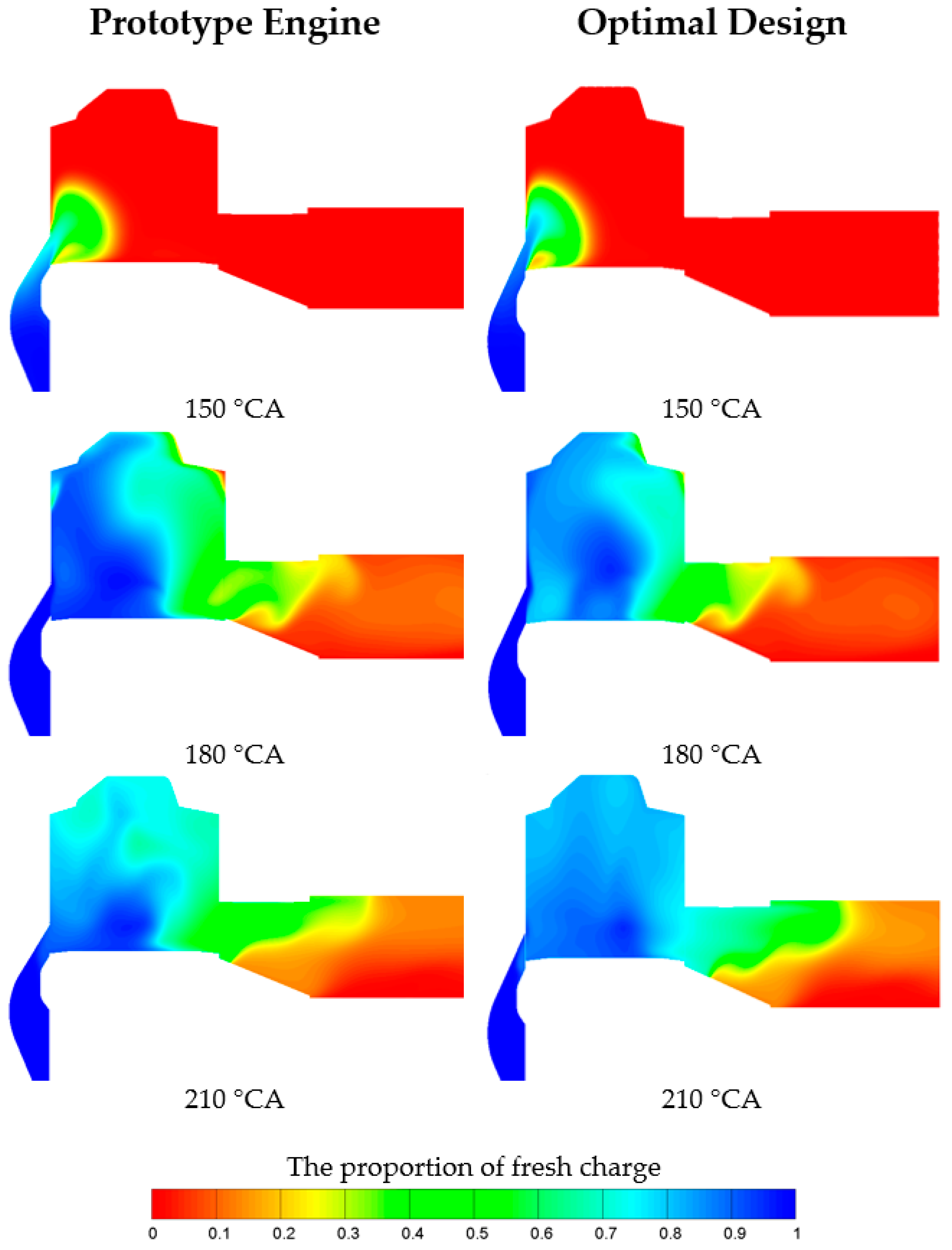

- As shown in Figure 19, Figure 20, Figure 21 and Figure 22, when comparing the scavenging process of the prototype engine under two operating conditions, it is not difficult to find that the fresh intake charge under the high load is less than that of the partial load in the initial stage of the scavenging process (150 °CA). The in-cylinder pressure under the high load is higher than that of the partial load and the exhaust process takes a longer time, thus the in-cylinder pressure is still at a high level after the scavenging port opening. As a result, the pressure of the fresh charge is not enough to enter the cylinder in the early scavenging phase. Contrastingly, the fresh charge intake under the high load is notably more than that of the partial load at 180 °CA and 210 °CA. Because the throttle is wide open under the high load, the crankcase pressure is higher and the piston motion is faster and the crankcase scavenged process is more effective, thus more fresh charge is delivered into the cylinder. This significant difference can be perceived based on the simulation data as well.

- (2)

- As shown in Figure 19 and Figure 20, when comparing the simulation results of the prototype engine and optimal design under the partial load, it can be found that at 150 °CA, the fresh charge intake of the prototype engine case is more than that of the optimal design case, especially around the lateral scavenging ports; at 180 °CA, the situation is similar to the high load simulation results, fresh charge distribution is biased toward the upper part of the cylinder with a larger “coverage area” after the optimal design; at 210 °CA, the optimal design results still show advantages over the prototype engine results in the scavenging quality. For the latter case, fresh charge is concentrated on the side of the central scavenging port as shown in the relevant Z cross-sectional views. Both lateral scavenging ports are inclined toward the central scavenging port. In consequence, corresponding gas motion due to the arrangement of the lateral scavenging ports hinders the fresh charge from entering the cylinder through the central scavenging port, and eventually gives rise to airflow obstruction and reduces the scavenging quality.

- (3)

- As shown in Figure 21 and Figure 22, when comparing the simulation results of the prototype engine and optimal design under the high load, it can be concluded that their gas composition distributions in the cylinder at 150 °CA are similar; at 180 °CA, fresh charge inside the cylinder is more biased toward the upper part in the optimal design results; at 210 °CA, fresh charge has reached more than 75% of the area of the entire cylinder after optimization. By contrast, the proportion of fresh charge in the combustion area is relatively low in the prototype engine case, which means the burned gas has not been cleared out of the cylinder even in the final scavenging phase.

5. Discussion and Conclusions

- (1)

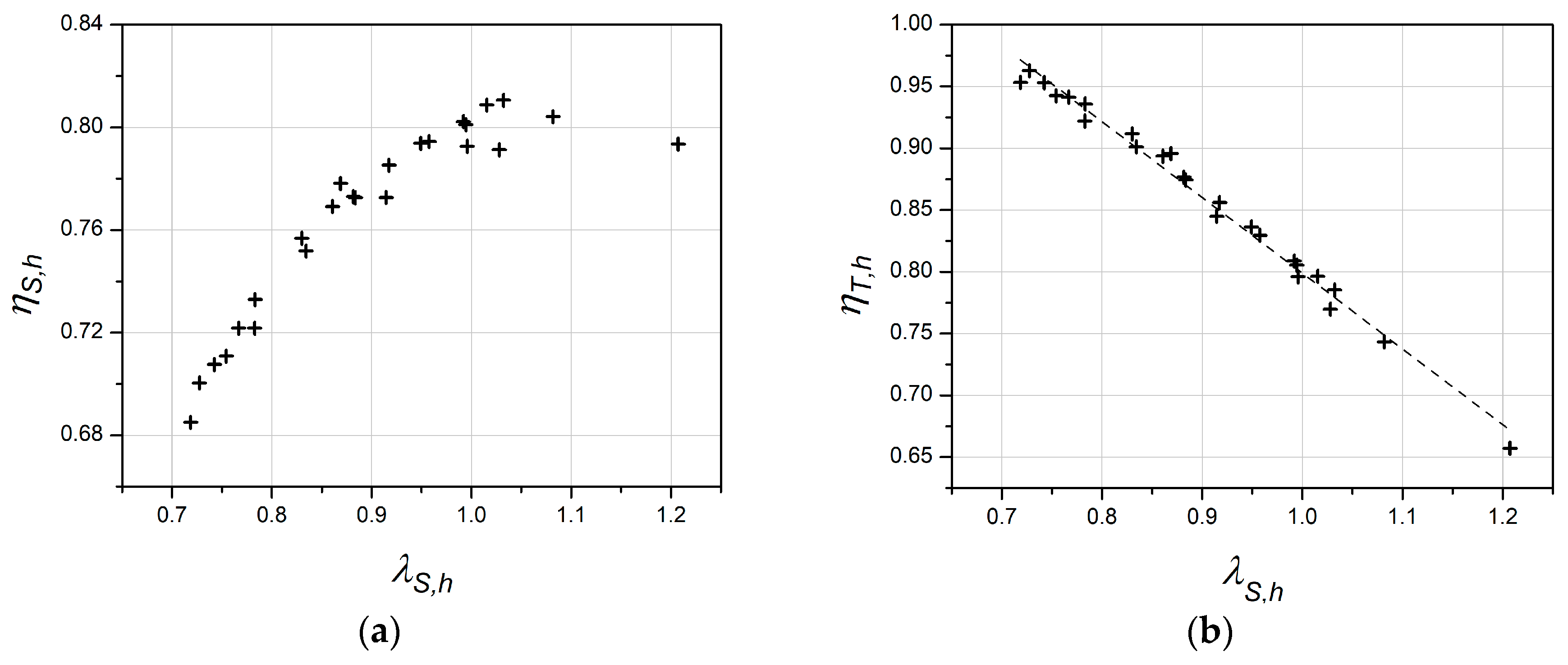

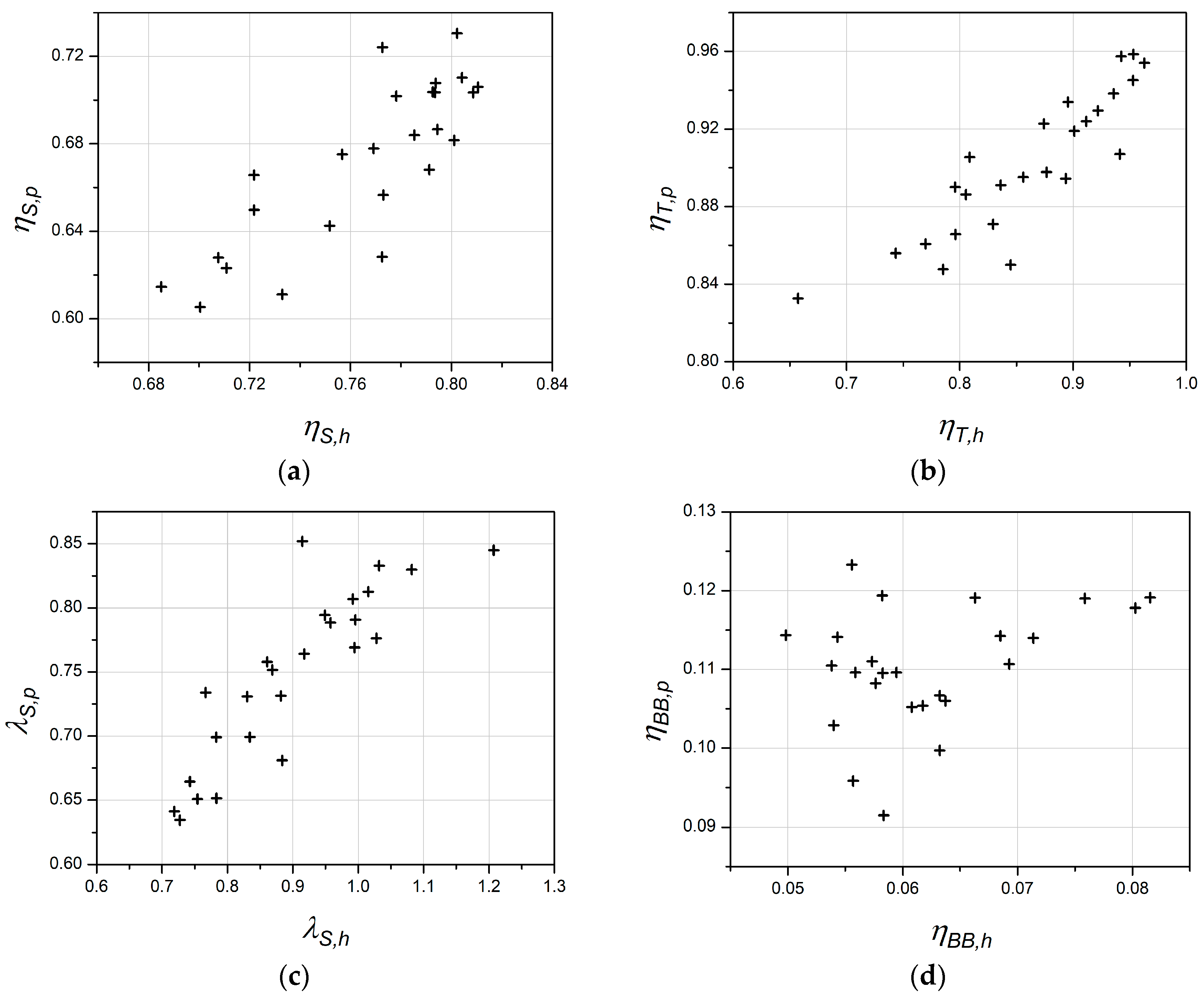

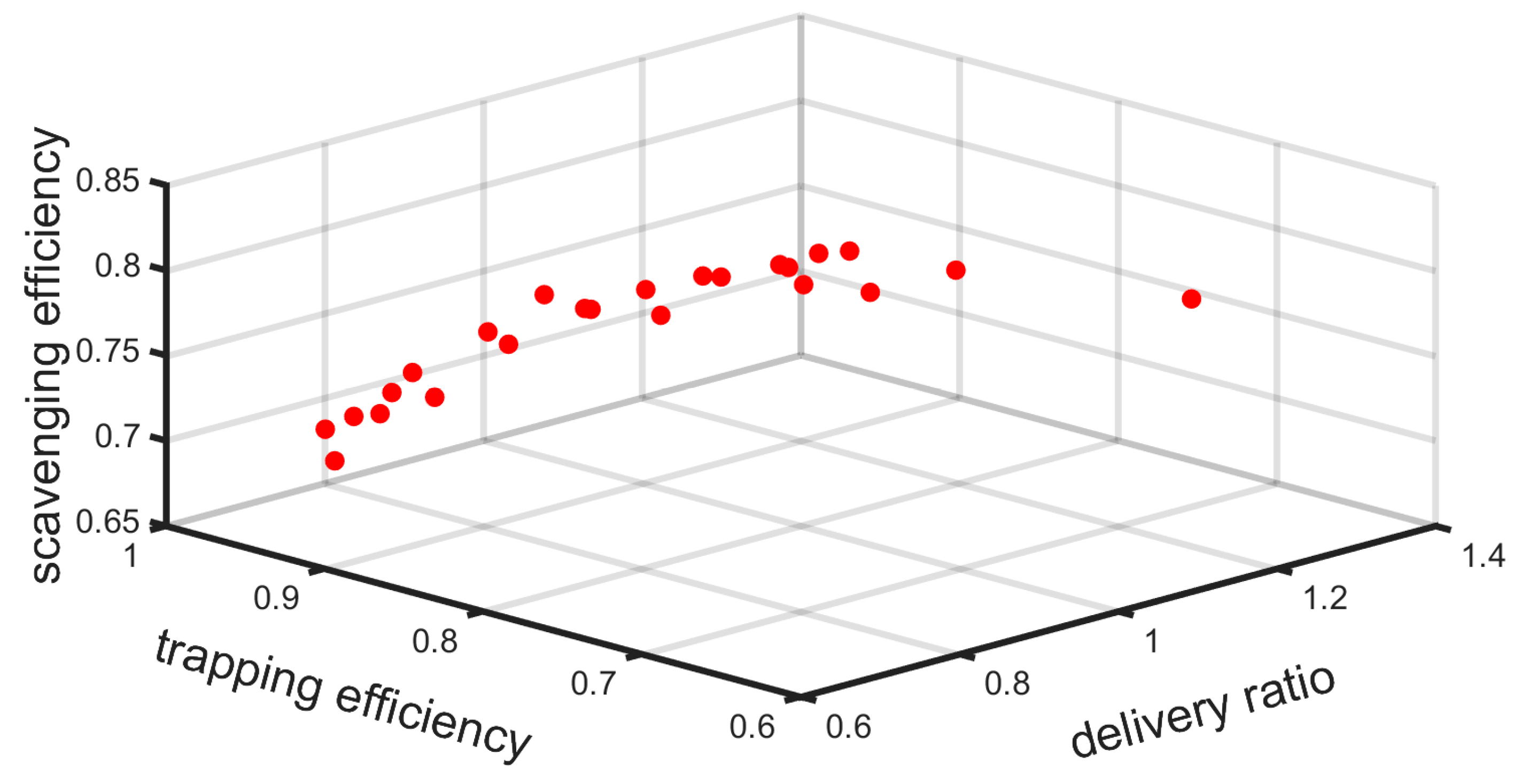

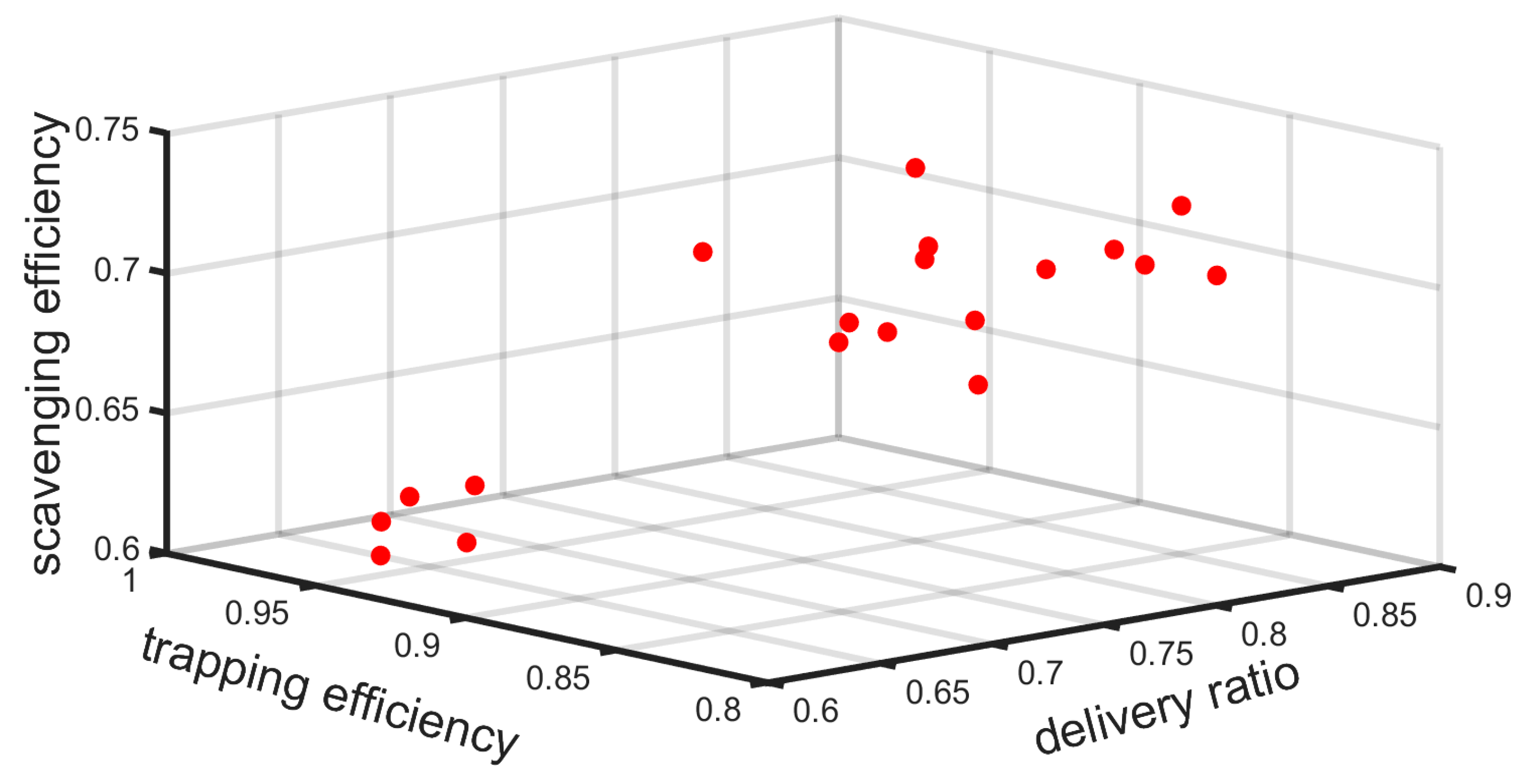

- With respect to the investigated prototype engine scavenging system, there exists an obvious trade-off relationship between the scavenging efficiency, , and trapping efficiency, , which makes it difficult to balance the power performance and fuel economy during the optimization process.

- (2)

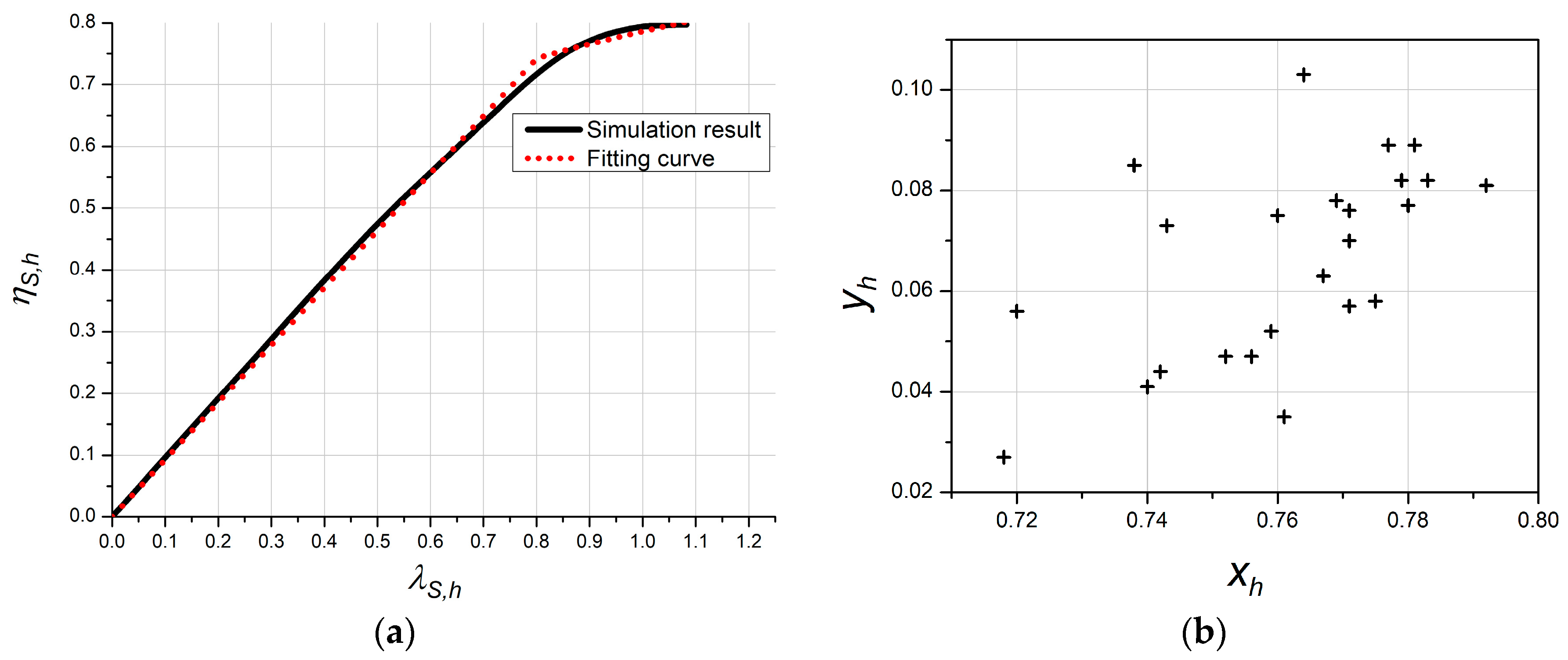

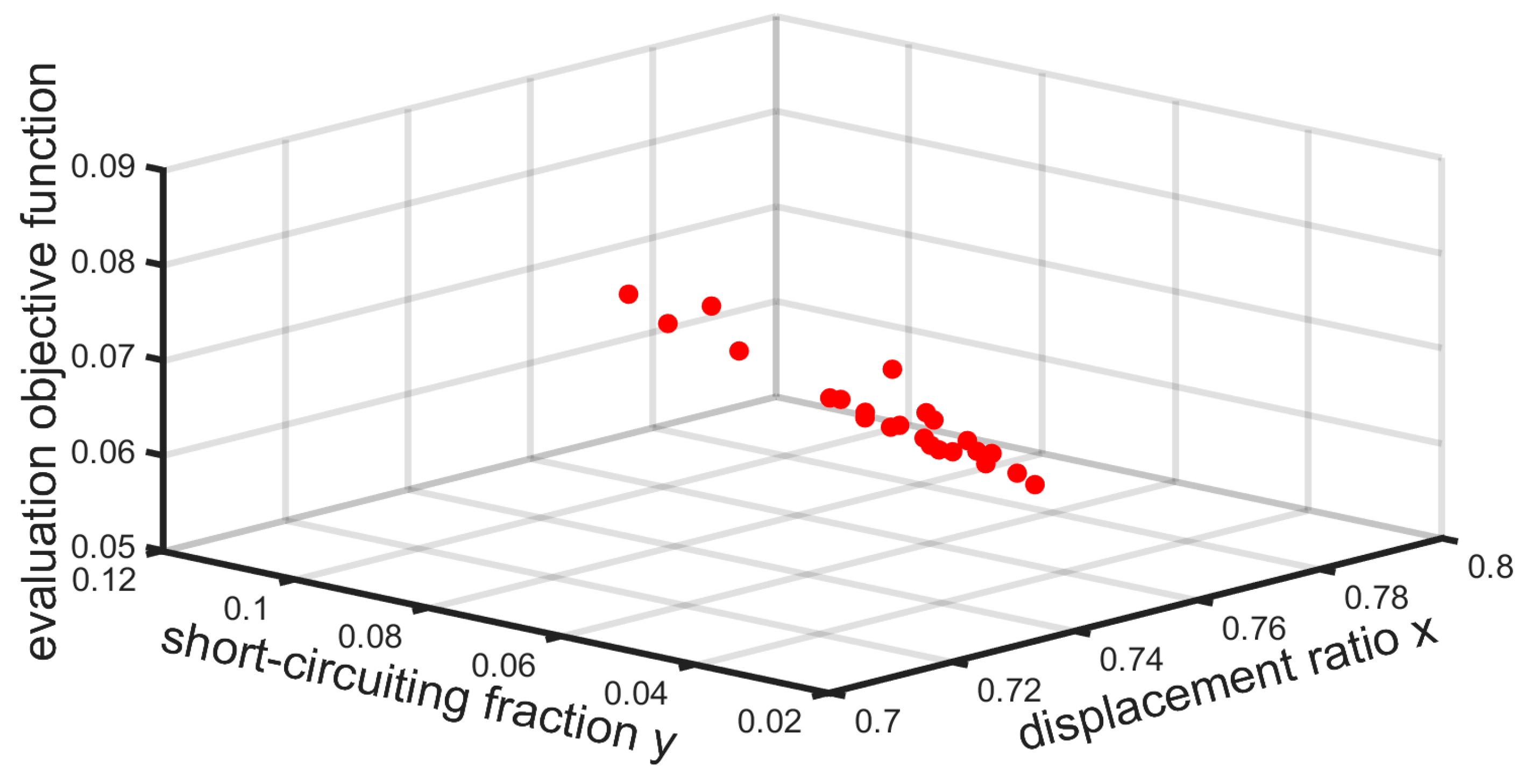

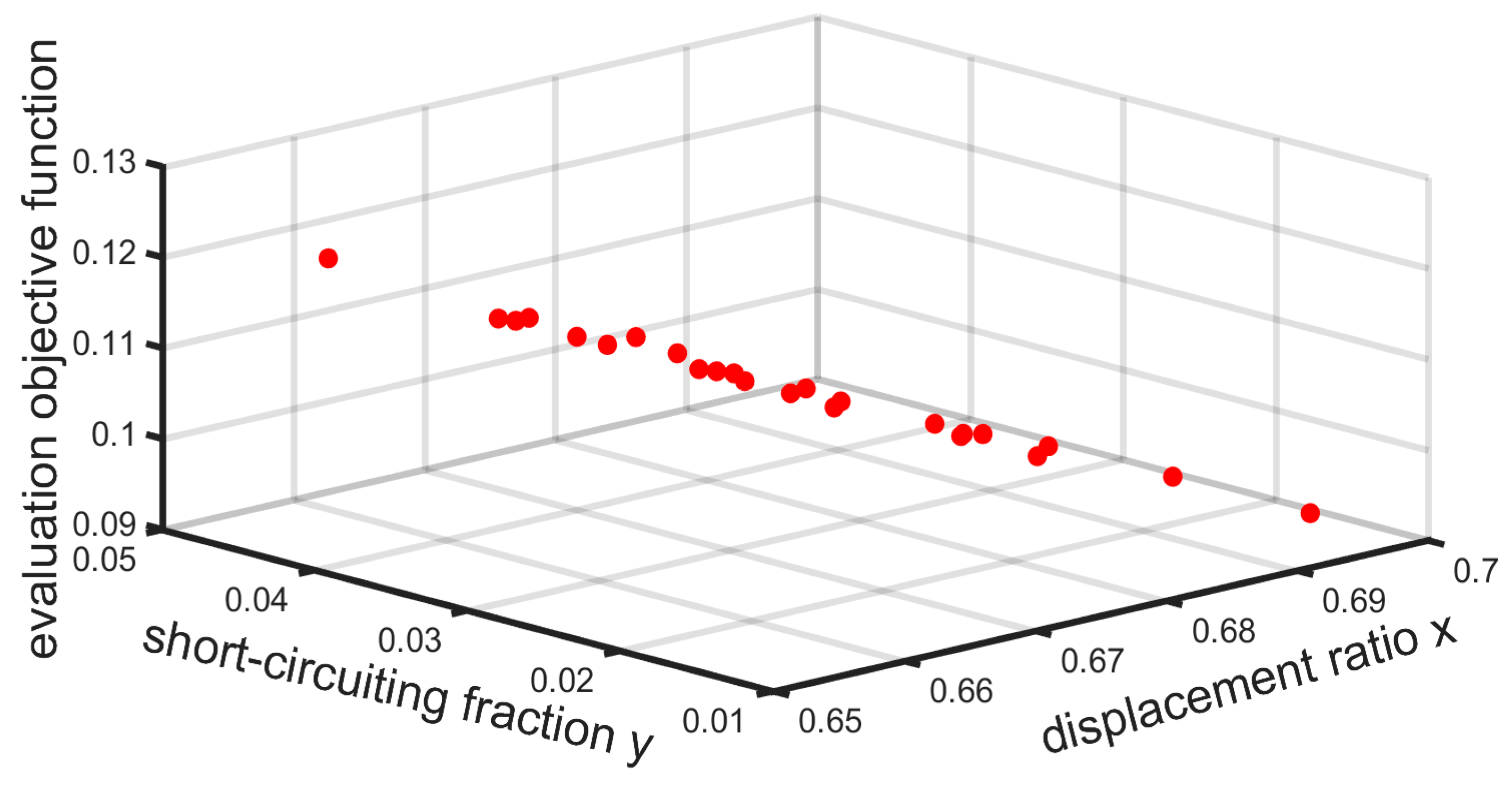

- Characteristics of the actual gas exchange process can be indicated by the key parameters, and , and the evaluation objective function, , based on the Benson/Bradham model was proven to reflect the scavenging quality precisely.

- (3)

- From the OED results analysis, it is clear that the slip angle of lateral scavenging ports, , has the most significant influence on , followed by the tilt angle of lateral scavenging ports, , while the tilt angle of the central scavenging port, , and the width ratio of the central scavenging port, , are not statistically significant in terms of their influence on . The best factors combination is = 60°, = 20°, = 20°, and = 23.81%.

- (4)

- Compared with the prototype engine, both and in the optimal design results are improved, yet declines to some extent. Taken together, the optimal design results show superior progress in power performance (IMEP) while marginally deteriorations in the fuel economy (ISFC), which makes it still acceptable overall.

- (5)

- Powerful visualization tools provided by AVL FIRE software can be employed to analyze the gas composition distribution inside the cylinder during the whole scavenging process.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclatures

| Abbreviations | |

| UAV | unmanned aerial vehicle |

| 1D | one-dimensional |

| 3D | three-dimensional |

| CFD | Computational Fluid Dynamics |

| BUSDIG | Boosted Uniflow Scavenged Direct Injection Gasoline |

| POD | Proper Orthogonal Decomposition |

| OP2S | Opposed-Piston 2-Stroke Diesel Engine |

| LICELGIS | Linear Internal Combustion Engine-Linear Generator Integrated System |

| OPHSDI | Opposed Piston High Speed Direct Injection Diesel Engine |

| OED | Orthogonal Experimental Design |

| IMEP | indicated mean effective pressure |

| ISFC | indicated specific fuel consumption |

| SPI | single point injection |

| CAD | Computer Aided Design |

| FEM | Fame Hexa Meshing |

| FEP | Fame Engine Plus |

| STM | Standard Transport Model |

| ECFM | Extended Coherent Flame Model |

| TKE | turbulence kinetic energy |

| TDC | top dead center |

| BDC | bottom dead center |

| SIMPLE | Semi-Implicit Method for Pressure Linked Equations |

| HWT | Hybrid Wall Treatment |

| SWF | Standard Wall Function |

| GSTB | Gradient Stabilized Biconjugate |

| Symbols | |

| mass of delivered fresh charge through all scavenging ports | |

| mass of delivered fresh charge retained in cylinder | |

| mass of delivered fresh charge leaking out of the cylinder | |

| mass of residual burned gas retained in cylinder | |

| mass of all trapped cylinder charge | |

| reference mass | |

| delivery ratio | |

| scavenging efficiency | |

| trapping efficiency | |

| charging efficiency | |

| instant burned gas volume in the cylinder | |

| the whole cylinder volume | |

| displacement ratio | |

| short-circuiting fraction | |

| tilt angle of the central scavenging port | |

| tilt angle of lateral scavenging ports | |

| slip angle of lateral scavenging ports | |

| width ratio of the central scavenging port | |

| width of the central scavenging port | |

| width of single lateral scavenging port | |

| elementary evaluation objective function | |

| evaluation objective function for the high load | |

| evaluation objective function for the partial load | |

| combined evaluation objective function | |

| significance level for the variance analysis | |

References

- Ma, S.; Ma, L.; Xiao, B.; Yuan, Z. In Analysis of medium-sized unmanned aerial vehicle (UAV) maintenance and support organization. In Proceedings of the 2014 Prognostics and System Health Management Conference, Zhangjiajie, China, 24–27 August 2014; pp. 583–588. [Google Scholar]

- Groff, E.G. Automotive Two-Stroke-Cycle Engine Development in the 1980–1990’s; Technical Paper for SAE International: Detroit, MI, USA, 2016. [Google Scholar]

- Feng, G.; Zhou, M. Assessment of heavy fuel aircraft piston engine types. Tsinghua Sci. Technol. 2016, 56, 1114–1121. [Google Scholar]

- Mavinahally, N.S. An Historical Overview of Stratified Scavenged Two-Stroke Engines-1901 through 2003; Technical Paper for SAE International: Detroit, MI, USA, 2004. [Google Scholar]

- Hori, H. Scavenging Flow Optimization of Two-Stroke Diesel Engine by Use of CFD; Technical Paper for SAE International: Detroit, MI, USA, 2000. [Google Scholar]

- Merker, G.P.; Gerstle, M. Evaluation on Two Stroke Engines Scavenging Models; Technical Paper for SAE International: Detroit, MI, USA, 1997. [Google Scholar]

- Ma, F.; Zhao, Z.; Zhang, Y.; Wang, J.; Feng, Y.; Su, T.; Zhang, Y.; Liu, Y. Simulation Modeling Method and Experimental Investigation on the Uniflow Scavenging System of an Opposed-Piston Folded-Cranktrain Diesel Engine. Energies 2017, 10, 727. [Google Scholar] [CrossRef]

- Brynych, P.; Macek, J.; Novella, R.; Thein, K. Representation of Two-Stroke Engine Scavenging in 1D Models Using 3D Simulations; Technical Paper for SAE International: Detroit, MI, USA, 2018. [Google Scholar]

- Mattarelli, E.; Rinaldini, C.A.; Savioli, T. Port Design Criteria for 2-Stroke Loop Scavenged Engines; Technical Paper for SAE International: Detroit, MI, USA, 2016. [Google Scholar]

- Wang, X.; Ma, J.; Zhao, H. Evaluations of Scavenge Port Designs for a Boosted Uniflow Scavenged Direct Injection Gasoline (BUSDIG) Engine by 3D CFD Simulations; Technical Paper for SAE International: Detroit, MI, USA, 2016. [Google Scholar]

- Ma, J.; Zhao, H. The Modeling and Design of a Boosted Uniflow Scavenged Direct Injection Gasoline (BUSDIG) Engine; Technical Paper for SAE International: Detroit, MI, USA, 2015. [Google Scholar]

- Wang, X.; Ma, J.; Zhao, H. Analysis of the Effect of Intake Plenum Design on the Scavenging Process in a 2-Stroke Boosted Uniflow Scavenged Direct Injection Gasoline (BUSDIG) Engine; Technical Paper for SAE International: Detroit, MI, USA, 2017. [Google Scholar]

- Khoury, R.R.E.; Errera, M.; Khoury, K.E.; Nemer, M. Efficiency of coupling schemes for the treatment of steady state fluid-structure thermal interactions. Int. J. Therm. Sci. 2017, 115, 225–235. [Google Scholar] [CrossRef]

- Rinaldini, C.A.; Mattarelli, E.; Golovitchev, V. CFD Analyses on 2-Stroke High Speed Diesel Engines. SAE Int. J. Engines 2011, 7, 2240–2256. [Google Scholar] [CrossRef]

- Zirngibl, S.; Held, S.; Prager, M.; Wachtmeister, G. Experimental and Simulative Approaches for the Determination of Discharge Coefficients for Inlet and Exhaust Valves and Ports in Internal Combustion Engines; Technical Paper for SAE International: Detroit, MI, USA, 2017. [Google Scholar]

- Nuccio, P.; Denno, D.D.; Magno, A. Development through Simulation of a Turbocharged 2-Stroke G.D.I. Engine Focused on a Range-Extender Application; Technical Paper for SAE International: Detroit, MI, USA, 2017. [Google Scholar]

- Cui, L.; Wang, T.; Sun, K.; Lu, Z.; Che, Z.; Sun, Y. Numerical Analysis of the Steady-State Scavenging Flow Characteristics of a Two-Stroke Marine Engine; Technical Paper for SAE International: Detroit, MI, USA, 2017. [Google Scholar]

- Xie, Z.; Zhao, Z.; Zhang, Z. Numerical Simulation of an Opposed-Piston Two-Stroke Diesel Engine; Technical Paper for SAE International: Detroit, MI, USA, 2015. [Google Scholar]

- Zang, P.; Wang, Z.; Fu, Y.; Sun, C. Investigation of Scavenging Process for Steady-State Operation of a Linear Internal Combustion Engine-Linear Generator Integrated System; Technical Paper for SAE International: Detroit, MI, USA, 2017. [Google Scholar]

- Mattarelli, E.; Rinaldini, C.A.; Savioli, T.; Cantore, G.; Warey, A.; Potter, M.; Gopalakrishnan, V.; Balestrino, S. Scavenge Ports Optimization of a 2-Stroke Opposed Piston Diesel Engine; Technical Paper for SAE International: Detroit, MI, USA, 2017. [Google Scholar]

- Li, Z.; He, B.-q.; Zhao, H. Influences of intake ports and pent-roof structures on the flow characteristics of a poppet-valved two-stroke gasoline engine. Int. J. Engine Res. 2016, 17, 1077–1091. [Google Scholar] [CrossRef]

- He, C.; Xu, S. Transient Gas Exchange Simulation and Uniflow Scavenging Analysis for a Unique Opposed Piston Diesel Engine; Technical Paper for SAE International: Detroit, MI, USA, 2016. [Google Scholar]

- Zhou, L.; Zhang, H.; Zhao, Z.; Zhang, F. Research on Opposed Piston Two-Stroke Engine for Unmanned Aerial Vehicle by Thermodynamic Simulation; Technical Paper for SAE International: Detroit, MI, USA, 2017. [Google Scholar]

- Zhao, F. Simulation Analysis and Optimization on the Scavenging Process for the Uniflow-Scavenge Diesel Engine. Master’s Thesis, Dalian University of Technology, Dalian, China, 6 July 2010. [Google Scholar]

- Grljušić, M.; Tolj, I.; Radica, G.; Sciubba, E. An Investigation of the Composition of the Flow in and out of a Two-Stroke Diesel Engine and Air Consumption Ratio. Energies 2017, 10, 1. [Google Scholar] [CrossRef]

- Taylor, C.F. The Internal-Combustion Engine in Theory and Practice: Thermodynamics, Fluid Flow, Performance, 2nd ed.; MIT Press: Cambridge, UK, 1985. [Google Scholar]

- Γ Technologies, Engine Performance Application Manual, GT-Power Version 7.1. Available online: http://www.gtisoft.com/ (accessed on 19 July 2018).

- Ma, F.K.; Wang, J.; Feng, Y.N.; Zhang, Y.G.; Su, T.X.; Zhang, Y.; Liu, Y.H. Parameter Optimization on the Uniflow Scavenging System of an OP2S-GDI Engine Based on Indicated Mean Effective Pressure (IMEP). Energies 2017, 10, 368. [Google Scholar] [CrossRef]

- Dong, X.F.; Zhao, C.L.; Zhang, F.J.; Zhao, Z.F.; Xie, Z.Y. Experiment on the Scavenging Process of Opposed-Piston Two-Stroke Diesel Engine. Trans. CSICE 2015, 33, 362–369. [Google Scholar]

- Sher, E.; Harari, R. A simple and realistic model for the scavenging process in a crankcase-scavenged two-stroke cycle engine. Proc. Inst. Mech. Eng. Part A J. Power Energy 1991, 205, 129–137. [Google Scholar] [CrossRef]

- Wu, J. Similar design method used on the port size on the two-stroke diesel engine. Trans. Eng. Thermophys. 1981, 2, 145–153. [Google Scholar]

- Dang, D.; Wallace, F.J. Some single zone scavenging models for two-stroke engines. Int. J. Mech. Sci. 1992, 34, 595–604. [Google Scholar] [CrossRef]

- Kim, I.Y.; DeWeck, O.L. Adaptive weighted sum method for multi-objective optimization: A new method for Pareto front generation. Struct. Multidiscip. Optim. 2006, 31, 105–116. [Google Scholar] [CrossRef]

| Parameters | Value | Unit |

|---|---|---|

| Total displacement | 498 | cm3 |

| Bore | 75 | mm |

| Stroke | 56 | mm |

| Connecting rod | 110 | mm |

| Compress ratio | 10.6 | - |

| Rated power | 32 | kW |

| Rated speed | 6500 | r/min |

| Rated torque | 47 | N·m |

| Number of scavenging ports | 3 | - |

| Number of exhaust ports | 1 | - |

| Scavenging port opening | 110 | °CA |

| Exhaust port opening | 94 | °CA |

| Scavenging port closing | 250 | °CA |

| Exhaust port closing | 266 | °CA |

| Ignition timing (high/partial load) | 347/352 | °CA |

| Ambient temperature | 298 | K |

| Ambient pressure | 1.013 | bar |

| Intake pressure | 1.105 | bar |

| Exhaust back pressure | 1.013 | bar |

| Assumed air fuel ratio | 13.24 | - |

| Equivalence ratio | 1.11 | - |

| Condition Parameters | High Load | Partial Load |

|---|---|---|

| Engine speed (rpm) | 6000 | 4500 |

| Fuel | 2% synthetic oil with 93 octane petrol | |

| Assumed air fuel ratio | 13.24 | |

| Equivalence ratio | 1.11 | |

| Ambient temperature (K) | 298 | |

| Ambient pressure (bar) | 1.013 | |

| Intake pressure (bar) | 1.105 | |

| Exhaust back pressure (bar) | 1.013 | |

| Ignition timing (°CA) | 347 | 352 |

| Boundary temperature of the combustion chamber wall (K) | 528 | 497 |

| Boundary temperature of the crankcase (K) | 330 | 312 |

| Boundary temperature of the cylinder (K) | 504 | 480 |

| Boundary temperature of the exhaust duct (K) | 476 | 460 |

| Initial temperature of the crankcase (K) | 364 | 358 |

| Initial pressure of the crankcase (bar) | 1.105 | 0.984 |

| Initial temperature of the cylinder (K) | 1719 | 1476 |

| Initial pressure of the cylinder (bar) | 4.922 | 3.017 |

| Initial temperature of the exhaust duct (bar) | 1.013 | 1.013 |

| Initial pressure of the exhaust duct (K) | 734 | 582 |

| Level | (°) | (°) | (°) | (mm) | (mm) | |

|---|---|---|---|---|---|---|

| 1 | 45 | −10 | 10 | 14.29% | 12 | 36 |

| 2 | 50 | 0 | 20 | 19.05% | 16 | 34 |

| 3 | 55 | 10 | 30 | 23.81% | 20 | 32 |

| 4 | 60 | 20 | 40 | 28.57% | 24 | 30 |

| 5 | 65 | 30 | 50 | 33.33% | 28 | 28 |

| No. | (°) | (°) | (°) | |

|---|---|---|---|---|

| 1 | 45 | −10 | 10 | 14.29% |

| 2 | 45 | 0 | 20 | 19.05% |

| 3 | 45 | 10 | 30 | 23.81% |

| 4 | 45 | 20 | 40 | 28.57% |

| 5 | 45 | 30 | 50 | 33.33% |

| 6 | 50 | −10 | 20 | 23.81% |

| 7 | 50 | 0 | 30 | 28.57% |

| 8 | 50 | 10 | 40 | 33.33% |

| 9 | 50 | 20 | 50 | 14.29% |

| 10 | 50 | 30 | 10 | 19.05% |

| 11 | 55 | −10 | 30 | 33.33% |

| 12 | 55 | 0 | 40 | 14.29% |

| 13 | 55 | 10 | 50 | 19.05% |

| 14 | 55 | 20 | 10 | 23.81% |

| 15 | 55 | 30 | 20 | 28.57% |

| 16 | 60 | −10 | 40 | 19.05% |

| 17 | 60 | 0 | 50 | 23.81% |

| 18 | 60 | 10 | 10 | 28.57% |

| 19 | 60 | 20 | 20 | 33.33% |

| 20 | 60 | 30 | 30 | 14.29% |

| 21 | 65 | −10 | 50 | 28.57% |

| 22 | 65 | 0 | 10 | 33.33% |

| 23 | 65 | 10 | 20 | 14.29% |

| 24 | 65 | 20 | 30 | 19.05% |

| 25 | 65 | 30 | 40 | 23.81% |

| No. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.028 | 0.770 | 0.791 | 0.764 | 0.103 | 0.066 | 0.776 | 0.861 | 0.668 | 0.658 | 0.046 | 0.119 | 0.185 |

| 2 | 0.995 | 0.805 | 0.801 | 0.777 | 0.089 | 0.058 | 0.769 | 0.886 | 0.682 | 0.673 | 0.036 | 0.108 | 0.166 |

| 3 | 0.917 | 0.856 | 0.785 | 0.767 | 0.063 | 0.058 | 0.764 | 0.895 | 0.684 | 0.670 | 0.025 | 0.110 | 0.168 |

| 4 | 0.830 | 0.912 | 0.757 | 0.752 | 0.047 | 0.064 | 0.731 | 0.924 | 0.675 | 0.675 | 0.019 | 0.106 | 0.170 |

| 5 | 0.783 | 0.922 | 0.722 | 0.718 | 0.027 | 0.080 | 0.699 | 0.929 | 0.650 | 0.657 | 0.012 | 0.118 | 0.198 |

| 6 | 0.882 | 0.877 | 0.773 | 0.781 | 0.089 | 0.056 | 0.731 | 0.898 | 0.657 | 0.671 | 0.037 | 0.110 | 0.165 |

| 7 | 0.861 | 0.894 | 0.769 | 0.771 | 0.070 | 0.057 | 0.758 | 0.894 | 0.678 | 0.668 | 0.028 | 0.111 | 0.168 |

| 8 | 0.754 | 0.942 | 0.711 | 0.756 | 0.047 | 0.062 | 0.651 | 0.957 | 0.623 | 0.676 | 0.020 | 0.105 | 0.167 |

| 9 | 0.767 | 0.941 | 0.722 | 0.740 | 0.041 | 0.069 | 0.734 | 0.907 | 0.666 | 0.668 | 0.021 | 0.111 | 0.180 |

| 10 | 1.207 | 0.657 | 0.793 | 0.743 | 0.073 | 0.071 | 0.845 | 0.833 | 0.704 | 0.663 | 0.020 | 0.114 | 0.185 |

| 11 | 0.834 | 0.901 | 0.752 | 0.771 | 0.076 | 0.058 | 0.699 | 0.919 | 0.643 | 0.656 | 0.032 | 0.119 | 0.178 |

| 12 | 0.884 | 0.874 | 0.773 | 0.769 | 0.078 | 0.059 | 0.681 | 0.923 | 0.628 | 0.671 | 0.037 | 0.110 | 0.169 |

| 13 | 0.743 | 0.953 | 0.708 | 0.742 | 0.044 | 0.069 | 0.664 | 0.945 | 0.628 | 0.663 | 0.026 | 0.114 | 0.183 |

| 14 | 1.082 | 0.743 | 0.804 | 0.760 | 0.075 | 0.063 | 0.830 | 0.856 | 0.710 | 0.674 | 0.020 | 0.107 | 0.170 |

| 15 | 0.996 | 0.796 | 0.793 | 0.759 | 0.052 | 0.061 | 0.791 | 0.890 | 0.704 | 0.676 | 0.015 | 0.105 | 0.166 |

| 16 | 0.783 | 0.936 | 0.733 | 0.792 | 0.081 | 0.050 | 0.651 | 0.938 | 0.611 | 0.664 | 0.038 | 0.114 | 0.164 |

| 17 | 0.727 | 0.963 | 0.700 | 0.738 | 0.085 | 0.076 | 0.634 | 0.954 | 0.605 | 0.656 | 0.026 | 0.119 | 0.195 |

| 18 | 1.015 | 0.796 | 0.809 | 0.780 | 0.077 | 0.054 | 0.813 | 0.866 | 0.703 | 0.663 | 0.023 | 0.114 | 0.168 |

| 19 | 0.992 | 0.809 | 0.802 | 0.771 | 0.057 | 0.056 | 0.807 | 0.905 | 0.731 | 0.691 | 0.019 | 0.096 | 0.152 |

| 20 | 0.914 | 0.845 | 0.773 | 0.760 | 0.075 | 0.063 | 0.852 | 0.850 | 0.724 | 0.685 | 0.022 | 0.100 | 0.163 |

| 21 | 0.719 | 0.953 | 0.685 | 0.720 | 0.056 | 0.082 | 0.641 | 0.959 | 0.615 | 0.656 | 0.028 | 0.119 | 0.201 |

| 22 | 0.958 | 0.829 | 0.794 | 0.779 | 0.082 | 0.056 | 0.788 | 0.871 | 0.687 | 0.650 | 0.028 | 0.123 | 0.179 |

| 23 | 1.032 | 0.785 | 0.811 | 0.783 | 0.082 | 0.054 | 0.833 | 0.848 | 0.706 | 0.669 | 0.030 | 0.110 | 0.164 |

| 24 | 0.949 | 0.836 | 0.794 | 0.775 | 0.058 | 0.054 | 0.794 | 0.891 | 0.708 | 0.680 | 0.022 | 0.103 | 0.157 |

| 25 | 0.869 | 0.896 | 0.778 | 0.761 | 0.035 | 0.058 | 0.751 | 0.934 | 0.702 | 0.698 | 0.016 | 0.091 | 0.151 |

| Level | ||||

|---|---|---|---|---|

| 1 | 0.1774 | 0.1787 | 0.1776 | 0.1723 |

| 2 | 0.1733 | 0.1754 | 0.1626 | 0.1710 |

| 3 | 0.1733 | 0.1701 | 0.1667 | 0.1696 |

| 4 | 0.1684 | 0.1656 | 0.1640 | 0.1746 |

| 5 | 0.1701 | 0.1724 | 0.1913 | 0.1746 |

| Factors | Range |

|---|---|

| 0.0090 | |

| 0.0131 | |

| 0.0287 | |

| 0.0050 |

| Factors | Type III Sum of Squares | DOF | Mean Square | F | P |

|---|---|---|---|---|---|

| A () | 0.00236 | 4 | 0.000059 | 1.079 | 0.32755 |

| B () | 0.00050 | 4 | 0.000125 | 6.287 | 0.04845 |

| C () | 0.00291 | 4 | 0.000727 | 13.303 | 0.00131 |

| D () | 0.00010 | 4 | 0.000025 | 0.454 | 0.76752 |

| Error | 0.00044 | 8 | 0.000055 | - | - |

| Total | 0.00418 | 24 | - | - | - |

| Parameter | Prototype Engine | Optimal Design | ||

|---|---|---|---|---|

| High Load | Partial Load | High Load | Partial Load | |

| 0.889 | 0.730 | 0.979 | 0.785 | |

| 0.882 | 0.931 | 0.861 | 0.917 | |

| 0.784 | 0.680 | 0.843 | 0.720 | |

| 0.778 | 0.671 | 0.782 | 0.686 | |

| 0.071 | 0.030 | 0.057 | 0.018 | |

| 0.054 | 0.109 | 0.051 | 0.099 | |

| 0.163 | 0.150 | |||

| IMEP (bar) | 5.641 | 3.310 | 5.840 | 3.463 |

| ISFC [g/(kW·h)] | 251.4 | 306.7 | 253.2 | 310.4 |

| Factors | Prototype Engine | Optimal Design |

|---|---|---|

| (°) | 55 | 60 |

| (°) | 0 | 20 |

| (°) | 30 | 20 |

| 23.81% | 23.81% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, Y.; Duan, X.; Huang, K.; Song, Y.; Qian, J. Scavenging Ports’ Optimal Design of a Two-Stroke Small Aeroengine Based on the Benson/Bradham Model. Energies 2018, 11, 2739. https://doi.org/10.3390/en11102739

Qiao Y, Duan X, Huang K, Song Y, Qian J. Scavenging Ports’ Optimal Design of a Two-Stroke Small Aeroengine Based on the Benson/Bradham Model. Energies. 2018; 11(10):2739. https://doi.org/10.3390/en11102739

Chicago/Turabian StyleQiao, Yuan, Xucheng Duan, Kaisheng Huang, Yizhou Song, and Jianan Qian. 2018. "Scavenging Ports’ Optimal Design of a Two-Stroke Small Aeroengine Based on the Benson/Bradham Model" Energies 11, no. 10: 2739. https://doi.org/10.3390/en11102739

APA StyleQiao, Y., Duan, X., Huang, K., Song, Y., & Qian, J. (2018). Scavenging Ports’ Optimal Design of a Two-Stroke Small Aeroengine Based on the Benson/Bradham Model. Energies, 11(10), 2739. https://doi.org/10.3390/en11102739