A Review of Airside Heat Transfer Augmentation with Vortex Generators on Heat Transfer Surface

Abstract

1. Introduction

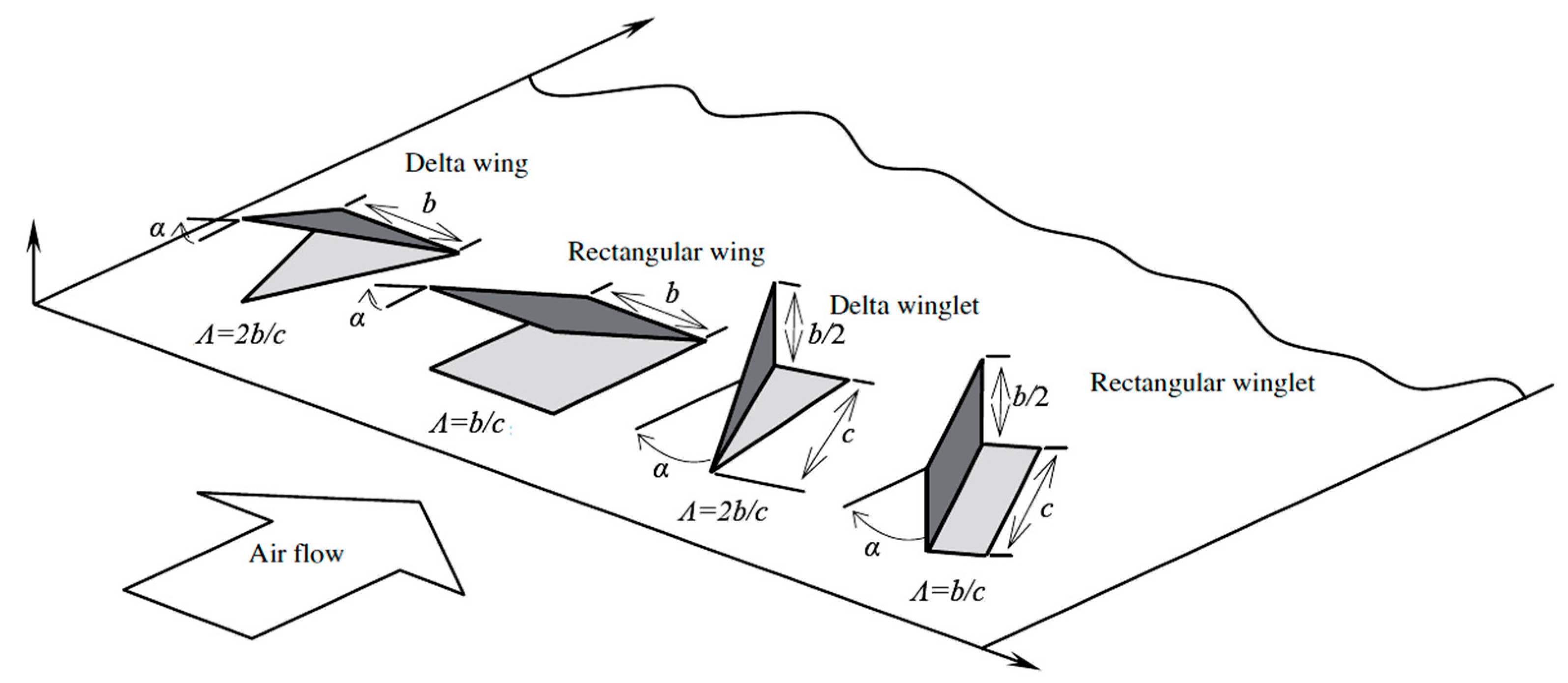

2. Vortex Generators

3. Experimental and Numerical Methods

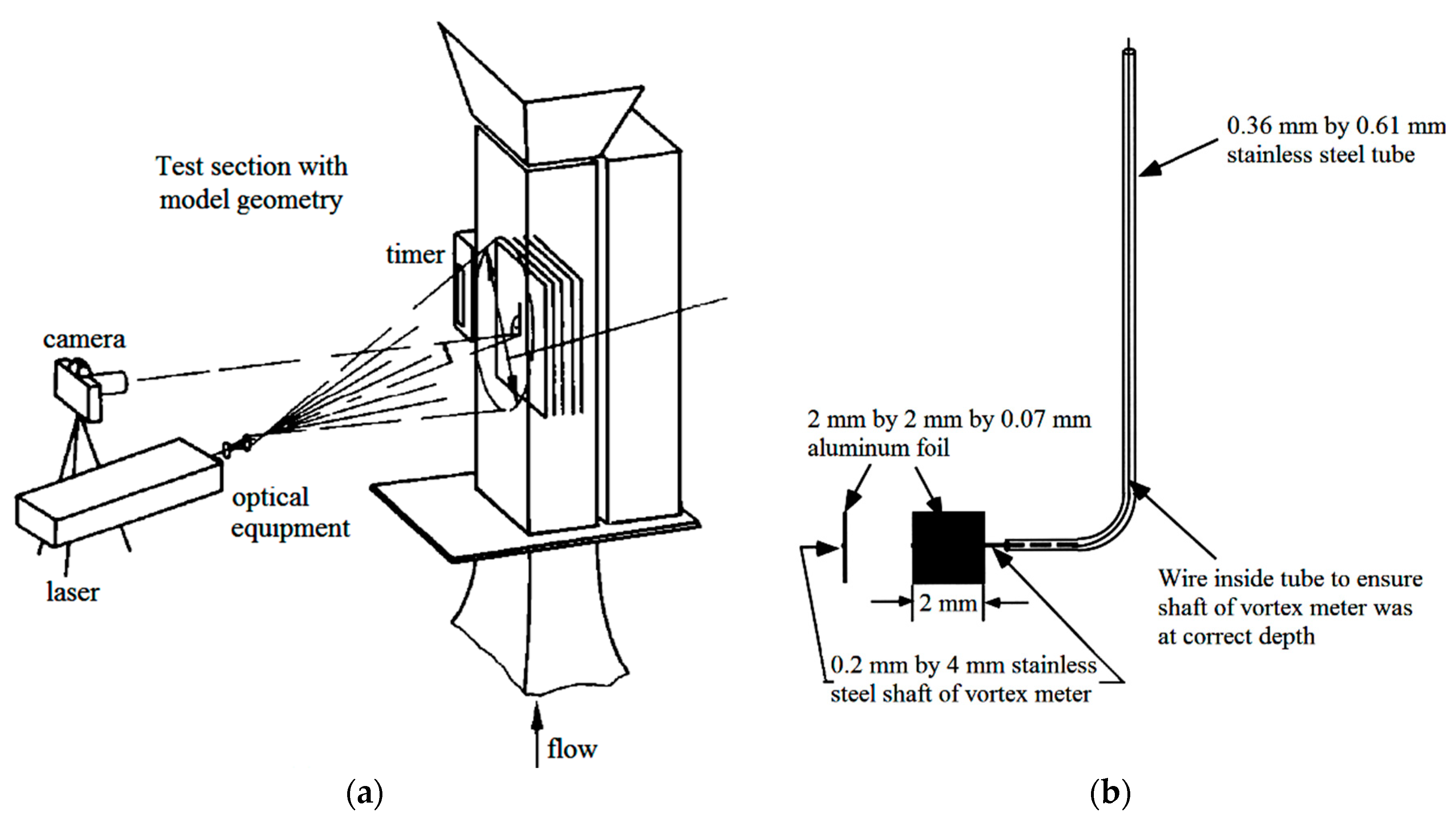

3.1. Experiment Techniques

3.2. Numerical Methodology

4. Thermohydraulic Performances

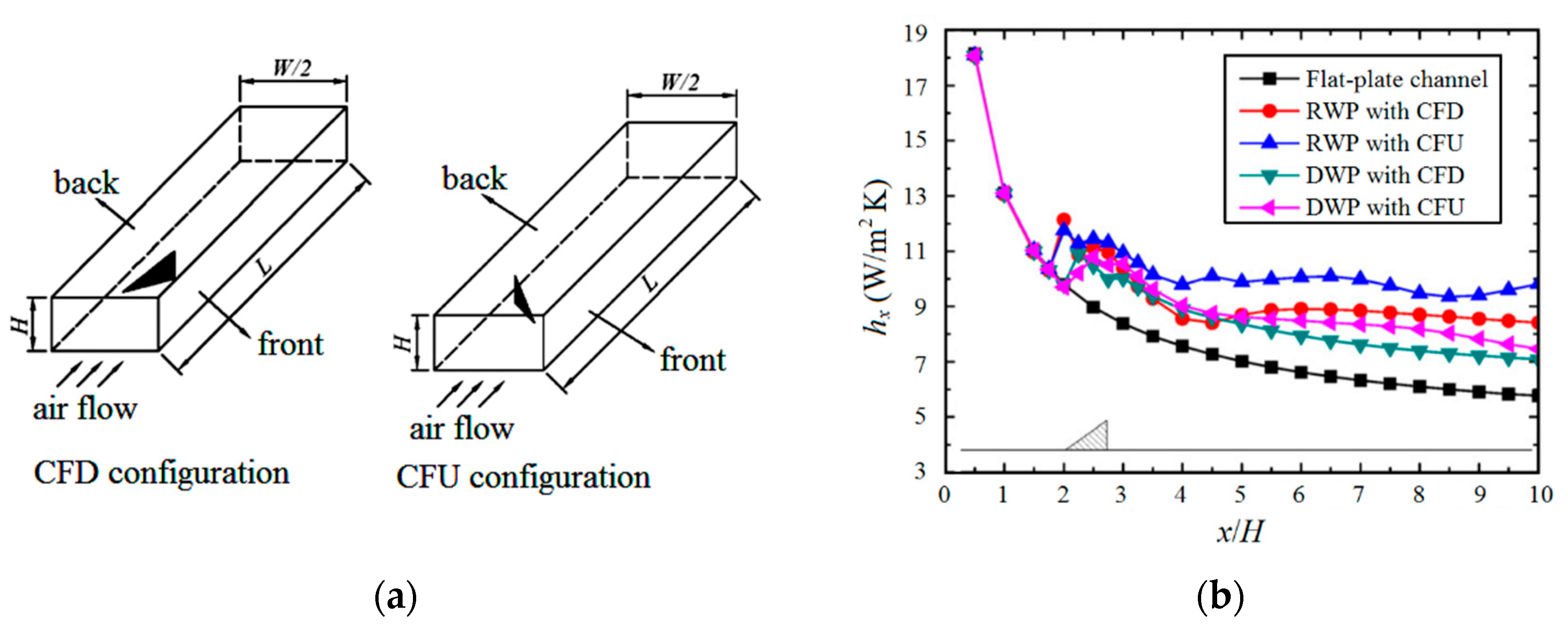

4.1. Vortex Generators on Flat Plates

4.1.1. Interaction of Flow and Heat Transfer

4.1.2. Effect of Geometry Parameters

4.1.3. Performance of Recently Proposed Vortex Generators

4.2. Vortex Generators in Finned Circular-Tube Heat Exchangers

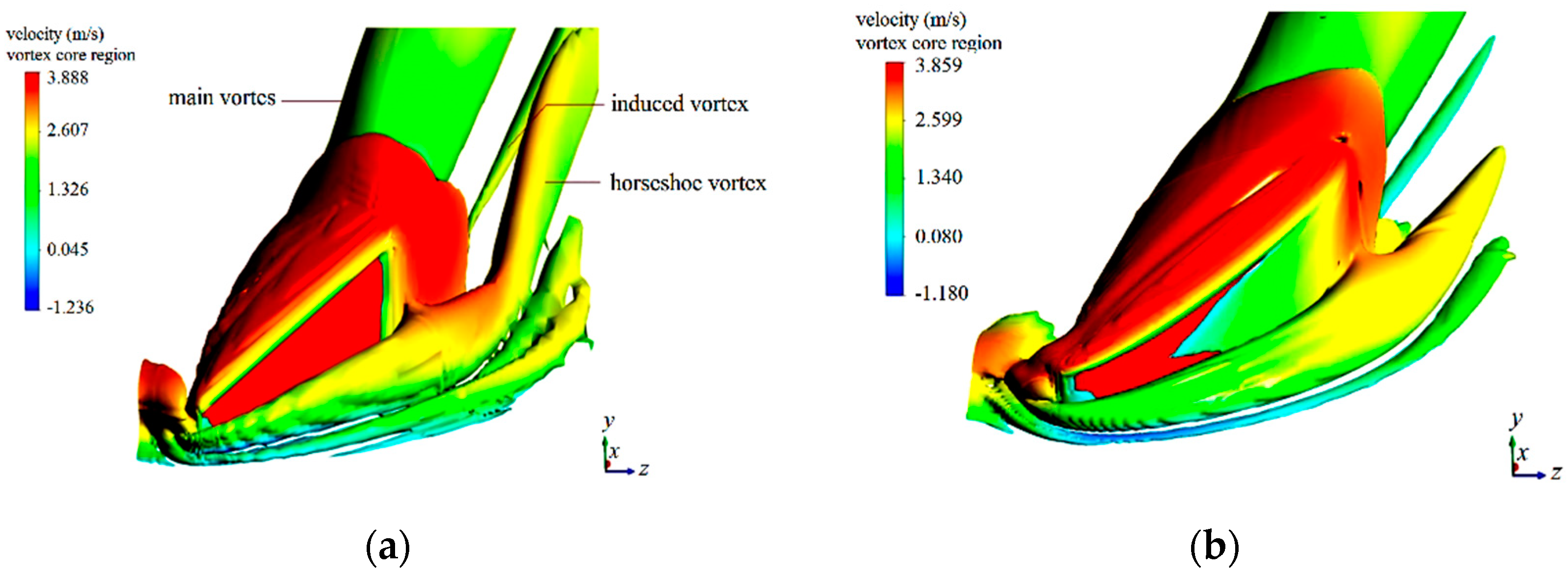

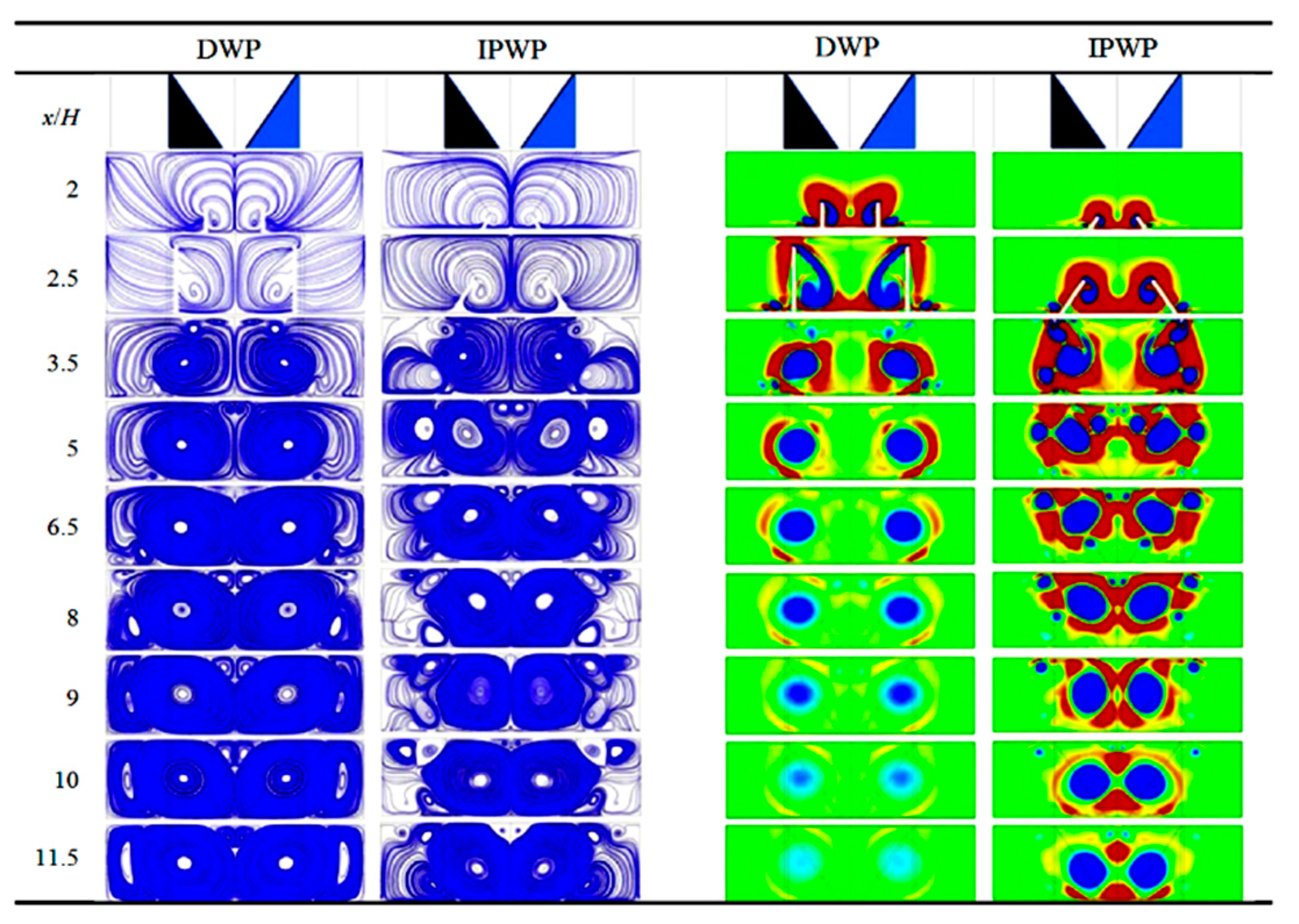

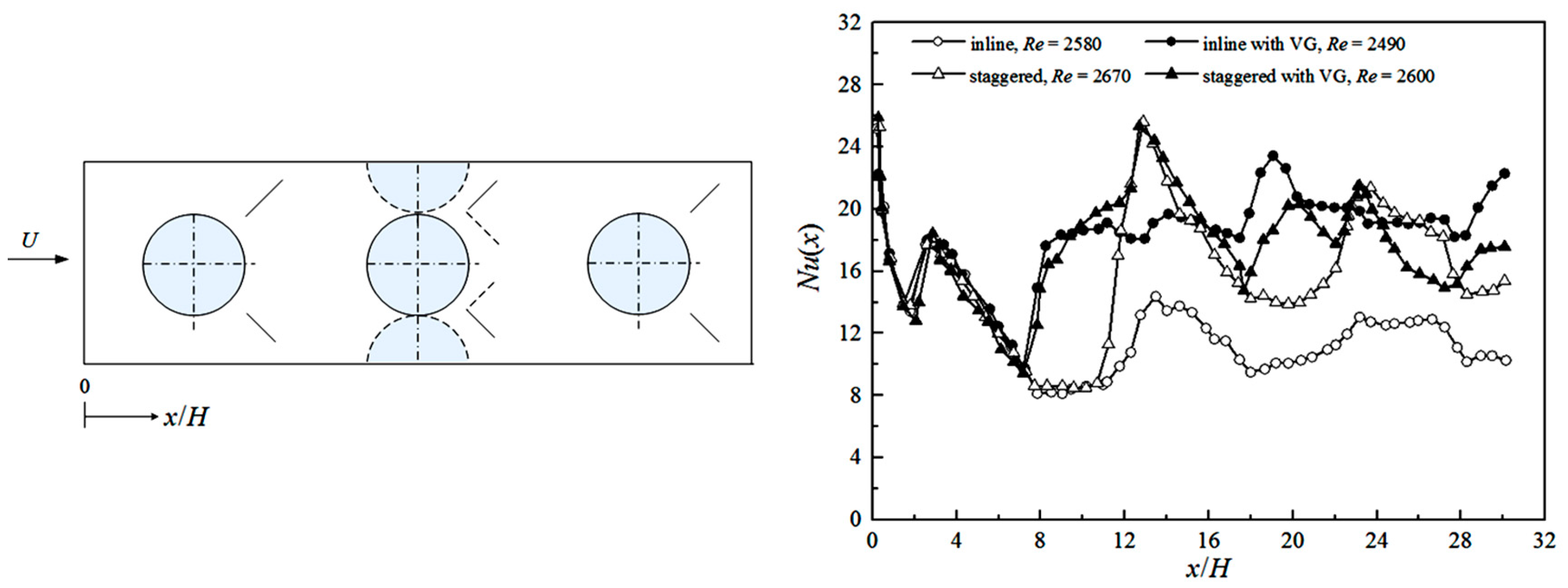

4.2.1. Interaction of Flow and Heat Transfer

4.2.2. Effect of Geometry Parameters

4.2.3. Performance of Recently Proposed Vortex Generators

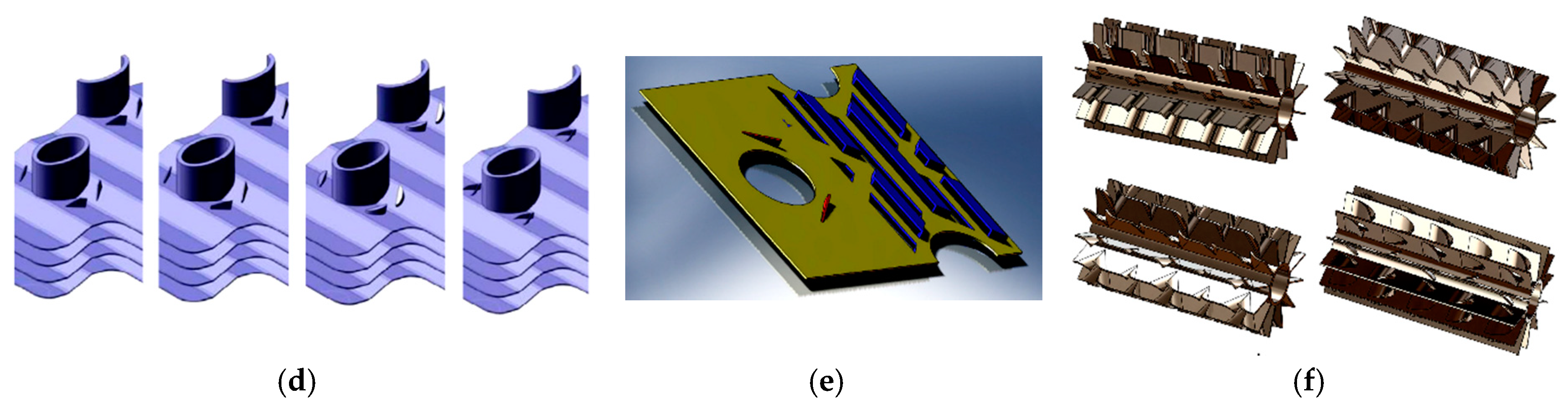

4.3. Vortex Generators in Finned Flat-Tube Heat Exchangers

4.4. Vortex Generators in Finned Oval-Tube Heat Exchanger

5. Concluding Remarks

6. Recommendations for Future Works

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| a | geometry parameter |

| A | area, m2 |

| b | geometry parameter |

| c | geometry parameter |

| cp | specific heat, J·kg−1·K−1 |

| CD | drag coefficient |

| d | diameter, m |

| D | total drag force, N |

| Dh | hydraulic diameter, m |

| e | ellipticity ratio |

| E | fan power per unit core volume |

| f | friction factor; frequency, Hz; formula |

| h | heat transfer coefficient, W·m−2·K−1; height, m |

| H | height, m; distance between two plates, m |

| j | Colburn factor |

| J | vorticity flux |

| k | thermal conductivity, W·m−1·K−1 |

| L | length, m |

| Nu | Nusselt number |

| p | pressure, Pa |

| Pe | Peclet number |

| Pr | Prandtl number |

| Q | quality factor |

| Ra | area ratio |

| Re | Reynolds number |

| S | projected area, m2; Strouhal number |

| Se | dimensionless parameter |

| St | Stanton number |

| T | temperature, K |

| u | velocity, m·s−1 |

| V | velocity, m·s−1 |

| x,y,z | Cartesian coordinates, m |

| Z | heat transfer per unit temperature difference and per unit core volume |

| Greek letters | |

| α | angle of attack |

| β | inclination angle; span angle |

| θ | skew angle; momentum thickness of boundary layer, m |

| ρ | density, kg·m−3 |

| μ | dynamic viscosity, Pa·s |

| ν | kinematic viscosity, m2·s−1 |

| δ | thickness, m |

| Λ | aspect ratio |

| Γ | vortex circulation |

| δ99 | boundary layer thickness |

| Ω | goodness factor |

| Subscripts | |

| 0 | reference |

| b | boundary layer |

| c | channel; core-to-plate |

| e | cross |

| j | jet |

| m | volume average |

| ref | reference |

| s | cross-section average |

| x | streamwise direction |

| y | transverse direction |

| v | vortex generator |

| Abbreviations | |

| ARW | angle rectangular winglet |

| CARW | curved angle rectangular winglet |

| CCD | charged coupled device |

| CDVGs | curve delta vortex generators |

| CDW | curved delta winglet |

| CFD | computational fluid dynamics; common-flow-down |

| CFD-CFD | common-flow-down in series |

| CFD-CFU | combined common-flow-down and common-flow-up |

| CFU | common-flow-up |

| CFU-CFU | common-flow-up in series |

| CRW | curved rectangular winglet |

| CRVGs | curve rectangular vortex generators |

| CTW | curved trapezoidal winglet |

| CTWPs | curved trapezoidal winglet pairs |

| DW | delta winglet |

| DWP | delta winglet pair |

| DWPs | delta winglet pairs |

| IRW | inline rows of winglet |

| LCT | liquid crystal thermography |

| LDV | laser doppler velocimetry |

| LLS | laser light sheets |

| MAC | marker-and-cell |

| PIV | particle image velocimetry |

| RTW | rectangular trapezoidal winglet |

| RW | rectangular winglet |

| RWP | rectangular winglet pair |

| RWPs | rectangular winglet pairs |

| RVGs | rectangular vortex generators |

| SRW | staggered rows of winglet |

| TW | trapezoidal winglet |

| TWPs | trapezoidal winglet pairs |

| VGs | vortex generators |

| WW | wheeler wishbone |

References

- Thulukkanam, K. Heat Exchanger Design Handbook; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Joule, J.P. On the surface-condensation of steam. Philos. Trans. R. Soc. Lond. 1861, 151, 133–160. [Google Scholar] [CrossRef]

- Wang, C.C. Recent progress on the air-side performance of fin-and-tube heat exchangers. Int. J. Heat Exch. 2000, 1, 49–76. [Google Scholar]

- Tian, L.; He, Y.; Chu, P.; Tao, W. Numerical study of flow and heat transfer enhancement by using delta winglets in a triangular wavy fin-and-tube heat exchanger. J. Heat Transf. 2009, 131, 091901. [Google Scholar] [CrossRef]

- Fiebig, M. Vortices, generators and heat transfer. Chem. Eng. Res. Des. 1998, 76, 108–123. [Google Scholar] [CrossRef]

- Wang, C.C.; Lo, J.; Lin, Y.T.; Liu, M.S. Flow visualization of wave-type vortex generators having inline fin-tube arrangement. Int. J. Heat Mass Transf. 2002, 45, 1933–1944. [Google Scholar] [CrossRef]

- Depaiwa, N.; Chompookham, T.; Promvonge, P. Thermal enhancement in a solar air heater channel using rectangular winglet vortex generators. In Proceedings of the IEEE 2010 Proceedings of the International Conference on Energy and Sustainable Development: Issues and Strategies (ESD), Chiang Mai, Thailand, 2–4 June 2010; pp. 1–7. [Google Scholar]

- Jacobi, A.M.; Shah, R.K. Heat transfer surface enhancement through the use of longitudinal vortices: A review of recent progress. Exp. Therm. Fluid Sci. 1995, 11, 295–309. [Google Scholar] [CrossRef]

- Wang, C.C.; Lo, J.; Lin, Y.T.; Wei, C.S. Flow visualization of annular and delta winglet vortex generators in fin-and-tube heat exchanger application. Int. J. Heat Mass Transf. 2002, 45, 3803–3815. [Google Scholar] [CrossRef]

- Stehlík, P.; Jegla, Z.; Kilkovský, B. Possibilities of intensifying heat transfer through finned surfaces in heat exchangers for high temperature applications. Appl. Therm. Eng. 2014, 70, 1283–1287. [Google Scholar] [CrossRef]

- Bergles, A.E. Recent developments in enhanced heat transfer. Heat Mass Transf. 2011, 47, 1001. [Google Scholar] [CrossRef]

- Ahmed, H.E.; Mohammed, H.A.; Yusoff, M.Z. An overview on heat transfer augmentation using vortex generators and nanofluids: Approaches and applications. Renew. Sustain. Energy Rev. 2012, 16, 5951–5993. [Google Scholar] [CrossRef]

- Fiebig, M. Vortices and heat transfer. ZAMM 1997, 77, 3–18. [Google Scholar] [CrossRef]

- Aris, M.S.; Owen, I.; Sutcliffe, C.J. The development of active vortex generators from shape memory alloys for the convective cooling of heated surfaces. Int. J. Heat Mass Transf. 2011, 54, 3566–3574. [Google Scholar] [CrossRef]

- Lin, Z.M.; Wang, L.B.; Zhang, Y.H. Numerical study on heat transfer enhancement of circular tube bank fin heat exchanger with interrupted annular groove fin. Appl. Therm. Eng. 2014, 73, 1465–1476. [Google Scholar] [CrossRef]

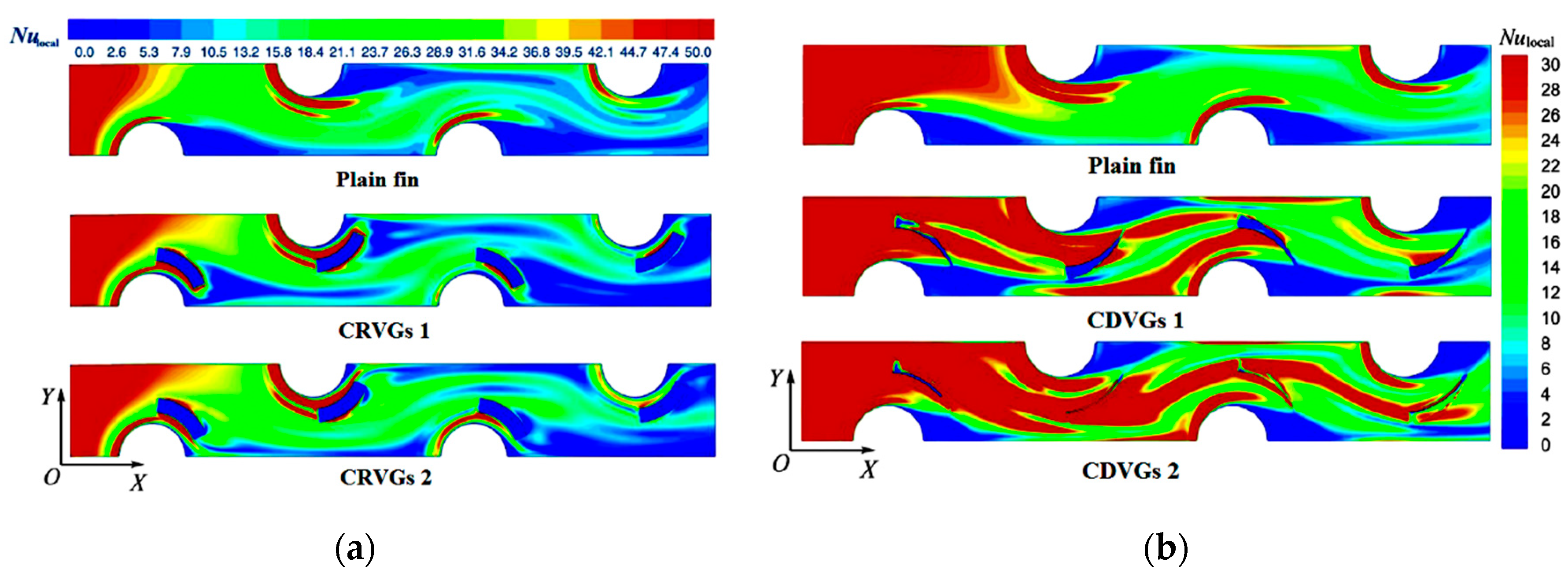

- Gong, B.; Wang, L.B.; Lin, Z.M. Heat transfer characteristics of a circular tube bank fin heat exchanger with fins punched curve rectangular vortex generators in the wake regions of the tubes. Appl. Therm. Eng. 2015, 75, 224–238. [Google Scholar] [CrossRef]

- He, J.; Liu, L.; Jacobi, A.M. Air-side heat-transfer enhancement by a new winglet-type vortex generator array in a plain-fin round-tube heat exchanger. J. Heat Transf. 2010, 132, 071801. [Google Scholar] [CrossRef]

- Zhou, G.; Ye, Q. Experimental investigations of thermal and flow characteristics of curved trapezoidal winglet type vortex generators. Appl. Therm. Eng. 2012, 37, 241–248. [Google Scholar] [CrossRef]

- Zhou, G.; Feng, Z. Experimental investigations of heat transfer enhancement by plane and curved winglet type vortex generators with punched holes. Int. J. Therm. Sci. 2014, 78, 26–35. [Google Scholar] [CrossRef]

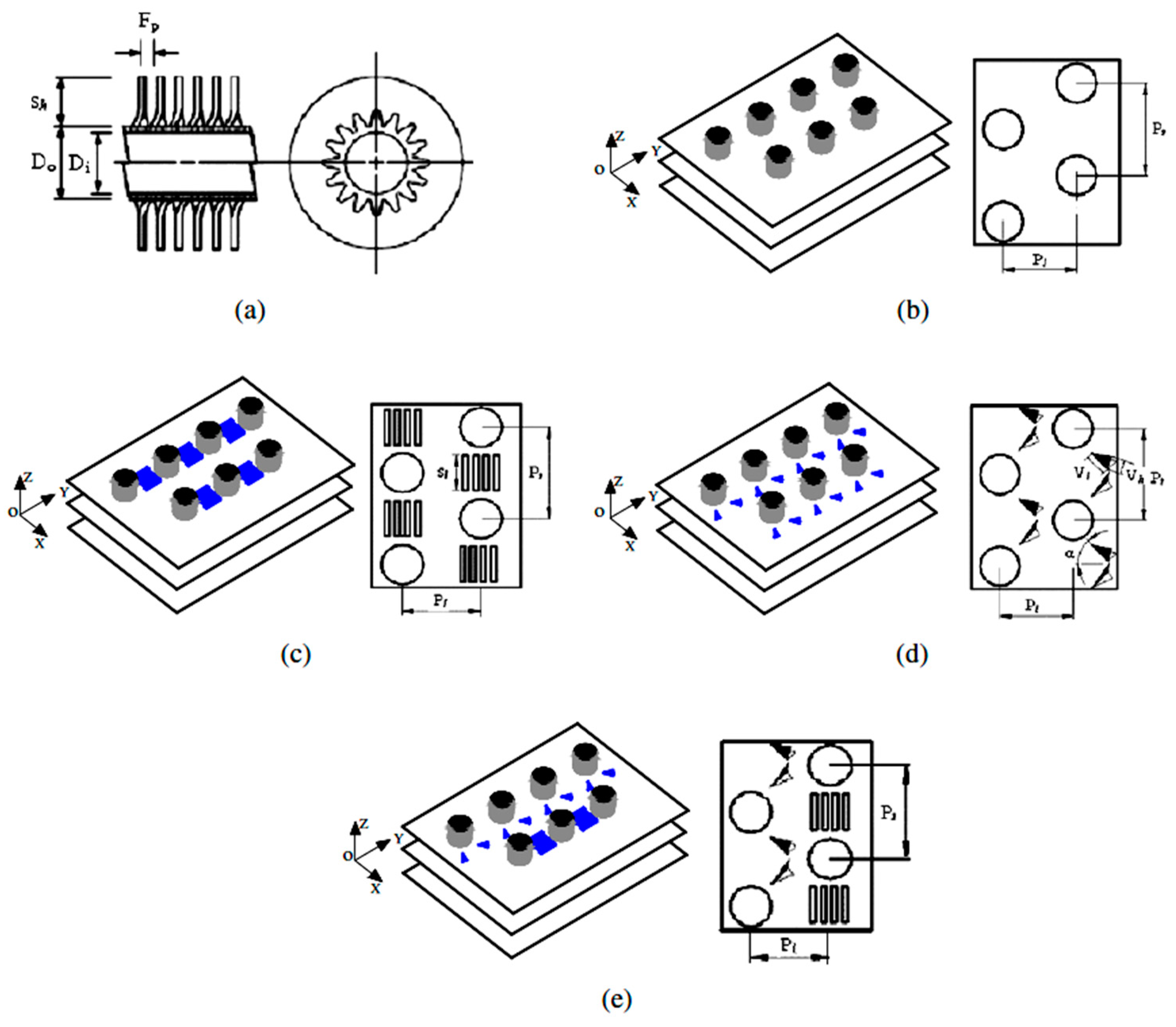

- Lotfi, B.; Zeng, M.; Sundén, B.; Wang, Q. 3D numerical investigation of flow and heat transfer characteristics in smooth wavy fin-and-elliptical tube heat exchangers using new type vortex generators. Energy 2014, 73, 233–257. [Google Scholar] [CrossRef]

- Lotfi, B.; Sundén, B.; Wang, Q. An investigation of the thermo-hydraulic performance of the smooth wavy fin-and-elliptical tube heat exchangers utilizing new type vortex generators. Appl. Energy 2016, 162, 1282–1302. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, W.; Gou, Q.; Luo, Z.; Lu, Y. Numerical simulation of heat transfer and fluid flow characteristics of composite fin. Int. J. Heat Mass Transf. 2014, 75, 414–424. [Google Scholar] [CrossRef]

- Garimella, S.V.; Eibeck, P.A. Enhancement of single phase convective heat transfer from protruding elements using vortex generators. Int. J. Heat Mass Transf. 1991, 34, 2431–2433. [Google Scholar] [CrossRef]

- Fiebig, M.; Kallweit, P.; Mitra, N.; Tiggelbeck, S. Heat transfer enhancement and drag by longitudinal vortex generators in channel flow. Exp. Therm. Fluid Sci. 1991, 4, 103–114. [Google Scholar] [CrossRef]

- Tiggelbeck, S.; Mitra, N.; Fiebig, M. Flow structure and heat transfer in a channel with multiple longitudinal vortex generators. Exp. Therm. Fluid Sci. 1992, 5, 425–436. [Google Scholar] [CrossRef]

- Tiggelbeck, S.; Mitra, N.; Fiebig, M. Experimental investigations of heat transfer enhancement and flow losses in a channel with double rows of longitudinal vortex generators. Int. J. Heat Mass Transf. 1993, 36, 2327–2337. [Google Scholar] [CrossRef]

- Fiebig, M.; Valencia, A.; Mitra, N.K. Wing-type vortex generators for fin-and-tube heat exchangers. Exp. Therm. Fluid Sci. 1993, 7, 287–295. [Google Scholar] [CrossRef]

- Tiggelbeck, S.; Mitra, N.K.; Fiebig, M. Comparison of wing-type vortex generators for heat transfer enhancement in channel flows. J. Heat Transf. 1994, 116, 880–885. [Google Scholar] [CrossRef]

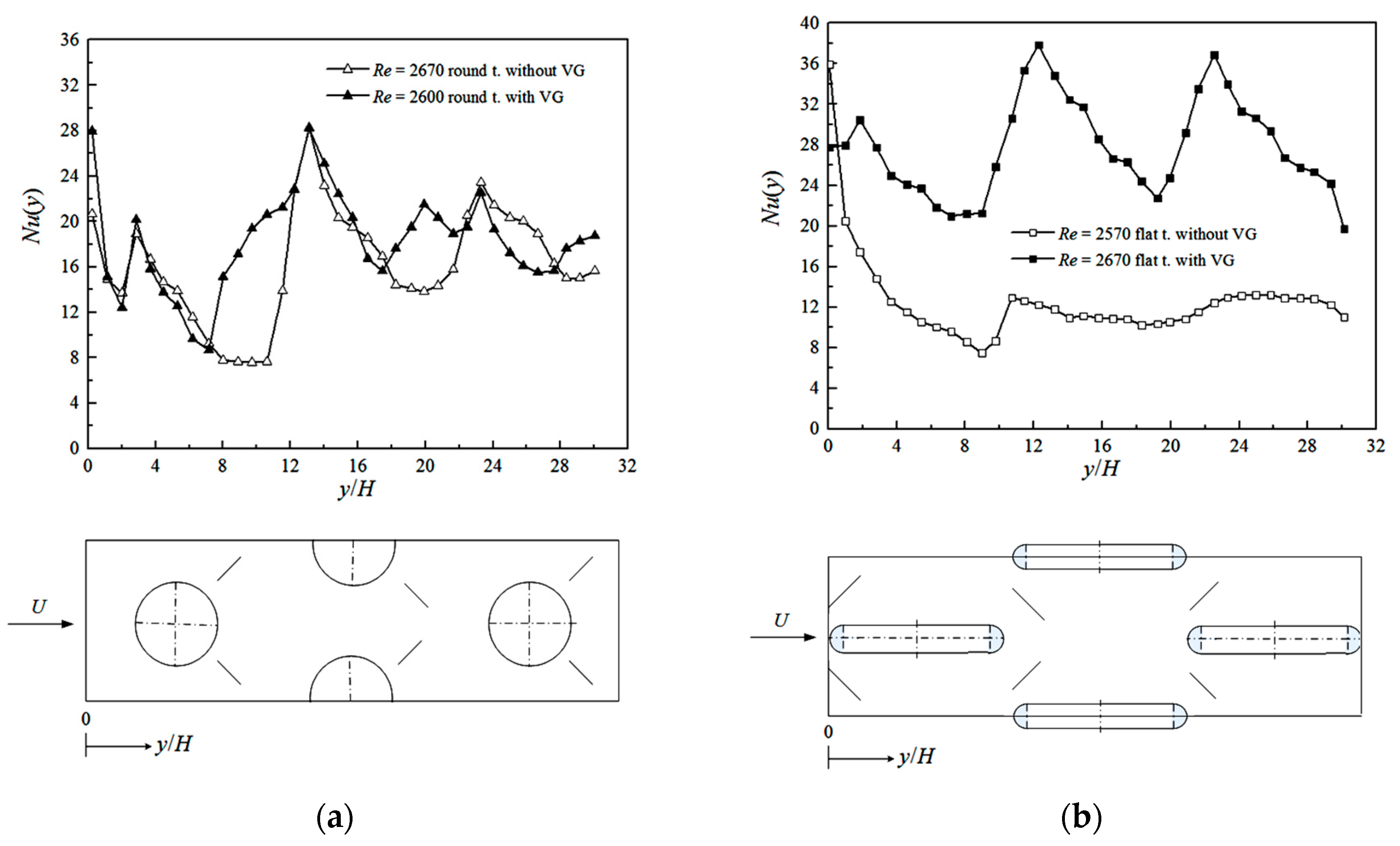

- Fiebig, M.; Valencia, A.; Mitra, N.K. Local heat transfer and flow losses in fin-and-tube heat exchangers with vortex generators: A comparison of round and flat tubes. Exp. Therm. Fluid Sci. 1994, 8, 35–45. [Google Scholar] [CrossRef]

- Gentry, M.C.; Jacobi, A.M. Heat transfer enhancement by delta-wing vortex generators on a flat plate: Vortex interactions with the boundary layer. Exp. Therm. Fluid Sci. 1997, 14, 231–242. [Google Scholar] [CrossRef]

- Kotcioğlu, İ.; Ayhan, T.; Olgun, H.; Ayhan, B. Heat transfer and flow structure in a rectangular channel with wing-type vortex generator. Turk. J. Eng. Environ. Sci. 1998, 22, 185–196. [Google Scholar]

- Torii, K.; Kwak, K.M.; Nishino, K. Heat transfer enhancement accompanying pressure-loss reduction with winglet-type vortex generators for fin-tube heat exchangers. Int. J. Heat Mass Transf. 2002, 45, 3795–3801. [Google Scholar] [CrossRef]

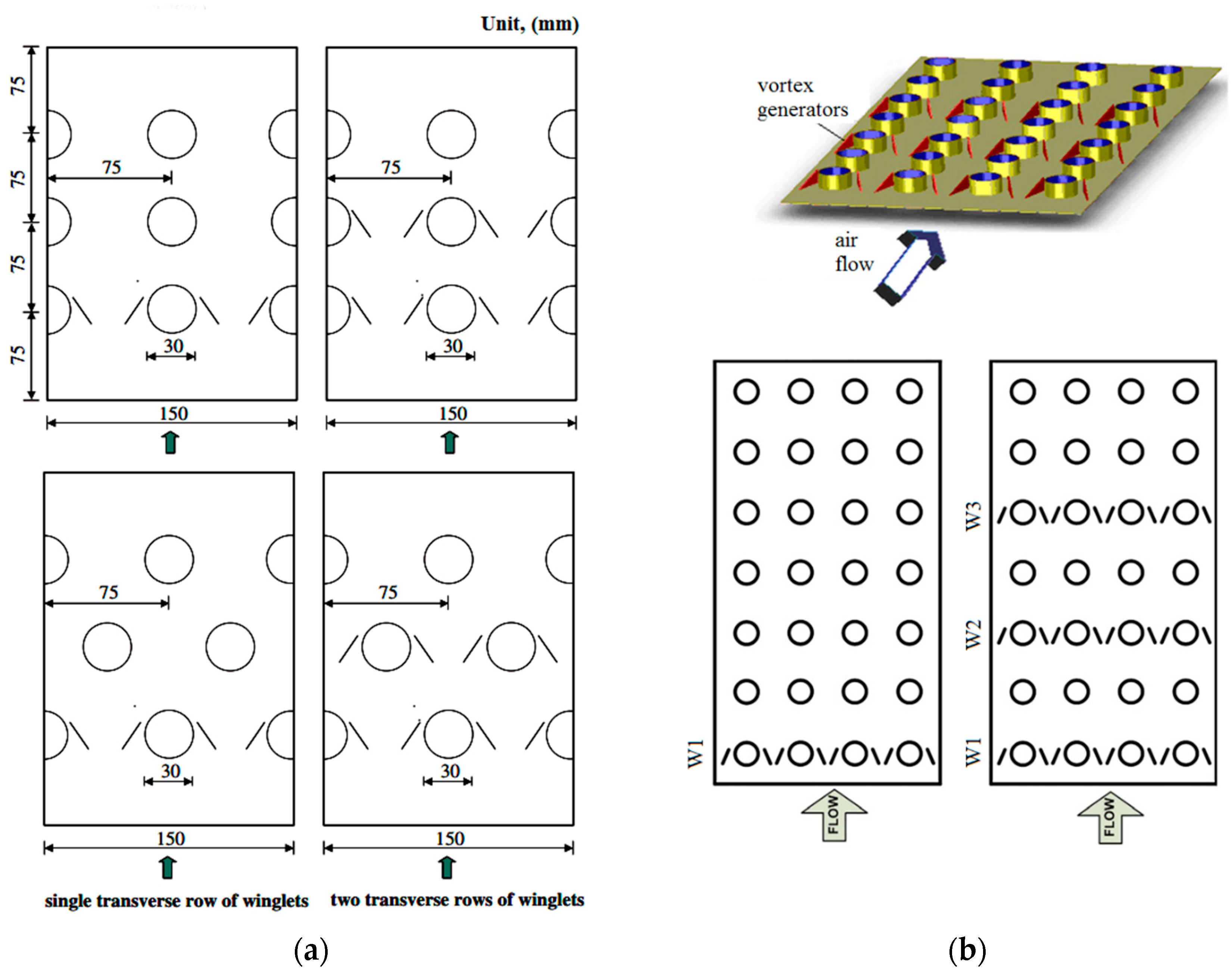

- Kwak, K.M.; Torii, K.; Nishino, K. Heat transfer and pressure-drop penalty for the number of tube rows of staggered finned-tube bundles with a single transverse row of winglets. Int. J. Heat Mass Transf. 2003, 46, 175–180. [Google Scholar] [CrossRef]

- Kwak, K.M.; Torii, K.; Nishino, K. Simultaneous heat transfer enhancement and pressure loss reduction for finned-tube bundles with the first or two transverse rows of built-in winglets. Exp. Therm. Fluid Sci. 2005, 29, 625–632. [Google Scholar] [CrossRef]

- Gentry, M.C.; Jacobi, A.M. Heat transfer enhancement by delta-wing-generated tip vortices in flat-plate and developing channel flows. Urbana 2002, 124, 1158–1168. [Google Scholar] [CrossRef]

- Yoo, S.Y.; Park, D.S.; Chung, M.H.; Lee, S.Y. Heat transfer enhancement for fin-tube heat exchanger using vortex generators. J. Mech. Sci. Technol. 2002, 16, 109–115. [Google Scholar] [CrossRef]

- Yuan, Z.X.; Tao, W.Q.; Yan, X.T. Experimental study on heat transfer in ducts with winglet disturbances. Heat Transf. Eng. 2003, 24, 76–84. [Google Scholar] [CrossRef]

- Chen, T.Y.; Shu, H.T. Flow structures and heat transfer characteristics in fan flows with and without delta-wing vortex generators. Exp. Therm. Fluid Sci. 2004, 28, 273–282. [Google Scholar] [CrossRef]

- Leu, J.S.; Wu, Y.H.; Jang, J.Y. Heat transfer and fluid flow analysis in plate-fin and tube heat exchangers with a pair of block shape vortex generators. Int. J. Heat Mass Transf. 2004, 47, 4327–4338. [Google Scholar] [CrossRef]

- O’Brien, J.E.; Sohal, M.S.; Wallstedt, P.C. Local heat transfer and pressure drop for finned-tube heat exchangers using oval tubes and vortex generators. J. Heat Transf. 2004, 126, 826–835. [Google Scholar] [CrossRef]

- Sommers, A.D.; Jacobi, A.M. Air-side heat transfer enhancement of a refrigerator evaporator using vortex generation. Int. J. Refrig. 2005, 28, 1006–1017. [Google Scholar] [CrossRef]

- Pesteei, S.M.; Subbarao, P.M.V.; Agarwal, R.S. Experimental study of the effect of winglet location on heat transfer enhancement and pressure drop in fin-tube heat exchangers. Appl. Therm. Eng. 2005, 25, 1684–1696. [Google Scholar] [CrossRef]

- Shi, B.; Wang, L.; Gen, F.; Zhang, Y. The optimal fin spacing for three-row flat tube bank fin mounted with vortex generators. Heat Mass Transf. 2006, 43, 91–101. [Google Scholar] [CrossRef]

- Allison, C.B.; Dally, B.B. Effect of a delta-winglet vortex pair on the performance of a tube-fin heat exchanger. Int. J. Heat Mass Transf. 2007, 50, 5065–5072. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Q.; Wang, L.; Zeng, M.; Huang, Y.; Xiao, Z. Experimental study of heat transfer enhancement in narrow rectangular channel with longitudinal vortex generators. Nucl. Eng. Des. 2007, 237, 686–693. [Google Scholar] [CrossRef]

- Joardar, A.; Jacobi, A.M. Heat transfer enhancement by winglet-type vortex generator arrays in compact plain-fin-and-tube heat exchangers. Int. J. Refrig. 2008, 31, 87–97. [Google Scholar] [CrossRef]

- Tang, L.H.; Min, Z.; Xie, G.N.; Wang, Q.W. Fin pattern effects on air-side heat transfer and friction characteristics of fin-and-tube heat exchangers with large number of large-diameter tube rows. Heat Transf. Eng. 2009, 30, 171–180. [Google Scholar] [CrossRef]

- Tang, L.H.; Zeng, M.; Wang, Q.W. Experimental and numerical investigation on air-side performance of fin-and-tube heat exchangers with various fin patterns. Exp. Therm. Fluid Sci. 2009, 33, 818–827. [Google Scholar] [CrossRef]

- Hernon, D.; Patten, N. Hotwire Measurements Downstream of a Delta Winglet Pair at Two Angles of Attack. In Proceedings of the ASME 2009 Heat Transfer Summer Conference collocated with the InterPACK09 and 3rd Energy Sustainability Conferences, San Francisco, CA, USA, 19–23 July 2009; pp. 777–784. [Google Scholar]

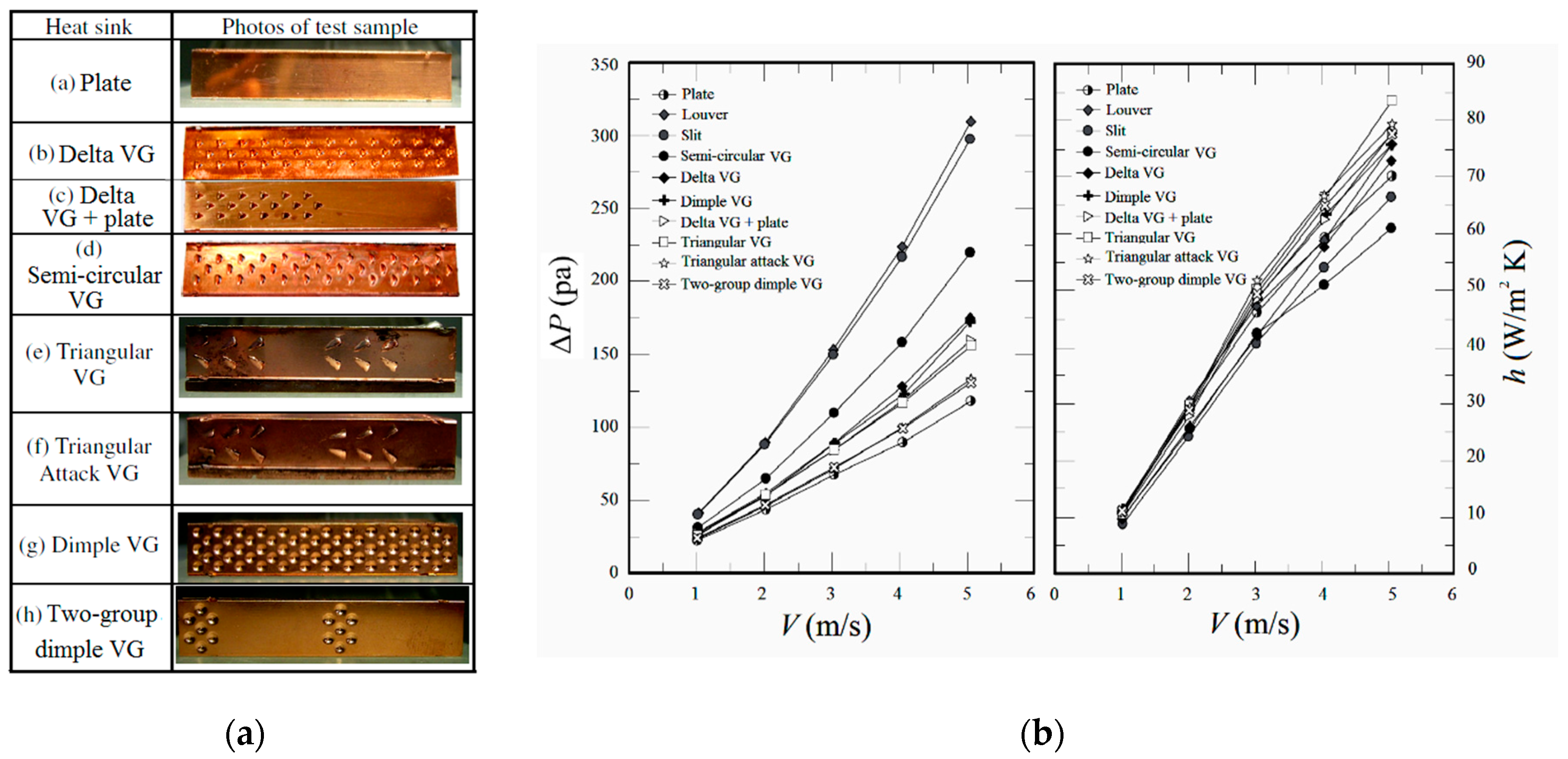

- Yang, K.S.; Li, S.L.; Chen, Y.; Chien, K.H.; Hu, R.; Wang, C.C. An experimental investigation of air cooling thermal module using various enhancements at low Reynolds number region. Int. J. Heat Mass Transf. 2010, 53, 5675–5681. [Google Scholar] [CrossRef]

- Promvonge, P.; Chompookham, T.; Kwankaomeng, S.; Thianpong, C. Enhanced heat transfer in a triangular ribbed channel with longitudinal vortex generators. Energy Convers. Manag. 2010, 51, 1242–1249. [Google Scholar] [CrossRef]

- Chompookham, T.; Thianpong, C.; Kwankaomeng, S.; Promvonge, P. Heat transfer augmentation in a wedge-ribbed channel using winglet vortex generators. Int. Commun. Heat Mass Transf. 2010, 37, 163–169. [Google Scholar] [CrossRef]

- Min, C.; Qi, C.; Kong, X.; Dong, J. Experimental study of rectangular channel with modified rectangular longitudinal vortex generators. Int. J. Heat Mass Transf. 2010, 53, 3023–3029. [Google Scholar] [CrossRef]

- Aris, M.S.; McGlen, R.; Owen, I.; Sutcliffe, C.J. An experimental investigation into the deployment of 3-D, finned wing and shape memory alloy vortex generators in a forced air convection heat pipe fin stack. Appl. Therm. Eng. 2011, 31, 2230–2240. [Google Scholar] [CrossRef]

- Wu, J.M.; Tao, W.Q. Effect of longitudinal vortex generator on heat transfer in rectangular channels. Appl. Therm. Eng. 2012, 37, 67–72. [Google Scholar] [CrossRef]

- Wu, J.M.; Zhang, H.; Yan, C.H.; Wang, Y. Experimental study on the performance of a novel fin-tube air heat exchanger with punched longitudinal vortex generator. Energy Convers. Manag. 2012, 57, 42–48. [Google Scholar] [CrossRef]

- Wang, C.C.; Chen, K.Y.; Liaw, J.S.; Tseng, C.Y. An experimental study of the air-side performance of fin-and-tube heat exchangers having plain, louver, and semi-dimple vortex generator configuration. Int. J. Heat Mass Transf. 2015, 80, 281–287. [Google Scholar] [CrossRef]

- Abdelatief, M.A.; Ahmed, S.A.E.S.; Mesalhy, O.M. Experimental and numerical study on thermal-hydraulic performance of wing-shaped-tubes-bundle equipped with winglet vortex generators. Heat Mass Transf. 2018, 54, 727–744. [Google Scholar] [CrossRef]

- Wu, X.; Lin, Z.M.; Liu, S.; Su, M.; Wang, L.C.; Wang, L. Experimental study on the effects of fin pitches and tube diameters on the heat transfer and fluid flow characteristics of a fin punched with curved delta-winglet vortex generators. Appl. Therm. Eng. 2017, 119, 560–572. [Google Scholar] [CrossRef]

- Kanaris, A.G.; Mouza, A.A.; Paras, S.V. Flow and heat transfer prediction in a corrugated plate heat exchanger using a CFD code. Chem. Eng. Technol. 2006, 29, 923–930. [Google Scholar] [CrossRef]

- Bhutta, M.M.A.; Hayat, N.; Bashir, M.H.; Khan, A.R.; Ahmad, K.N.; Khan, S. CFD applications in various heat exchangers design: A review. Appl. Therm. Eng. 2012, 32, 1–12. [Google Scholar] [CrossRef]

- Fiebig, M.; Brockmeier, U.; Mitra, N.K.; Gü termann, T. Structure of velocity and temperature fields in laminar channel flows with longitudinal vortex generators. Numer. Heat Transf. 1989, 15, 281–302. [Google Scholar] [CrossRef]

- Biswas, G.; Mitra, N.K.; Fiebig, M. Computation of laminar mixed convection flow in a channel with wing type built-in obstacles. J. Thermophys. Heat Transf. 1989, 3, 447–453. [Google Scholar] [CrossRef]

- Biswas, G.; Chattopadhyay, H. Heat transfer in a channel with built-in wing-type vortex generators. Int. J. Heat Mass Transf. 1992, 35, 803–814. [Google Scholar] [CrossRef]

- Zhu, J.X.; Fiebig, M.; Mitra, N.K. Comparison of numerical and experimental results for a turbulent flow field with a longitudinal vortex pair. J. Fluids Eng. 1993, 115, 270–274. [Google Scholar] [CrossRef]

- Zhu, J.X.; Mitra, N.K.; Fiebig, M. Effects of longitudinal vortex generators on heat transfer and flow loss in turbulent channel flows. Int. J. Heat Mass Transf. 1993, 36, 2339–2347. [Google Scholar] [CrossRef]

- Biswas, G.; Mitra, N.K.; Fiebig, M. Heat transfer enhancement in fin-tube heat exchangers by winglet type vortex generators. Int. J. Heat Mass Transf. 1994, 37, 283–291. [Google Scholar] [CrossRef]

- Biswas, G.; Deb, P.; Biswas, S. Generation of longitudinal streamwise vortices-a device for improving heat exchanger design. Trans. Am. Soc. Mech. Eng. J. Heat Transf. 1994, 116, 588–597. [Google Scholar] [CrossRef]

- Deb, P.; Biswas, G.; Mitra, N.K. Heat transfer and flow structure in laminar and turbulent flows in a rectangular channel with longitudinal vortices. Int. J. Heat Mass Transf. 1995, 38, 2427–2444. [Google Scholar] [CrossRef]

- Biswas, G.; Torii, K.; Fujii, D.; Nishino, K. Numerical and experimental determination of flow structure and heat transfer effects of longitudinal vortices in a channel flow. Int. J. Heat Mass Transf. 1996, 39, 3441–3451. [Google Scholar] [CrossRef]

- Chen, Y.; Fiebig, M.; Mitra, N.K. Heat transfer enhancement of finned oval tubes with staggered punched longitudinal vortex generators. Int. J. Heat Mass Transf. 2000, 43, 417–435. [Google Scholar] [CrossRef]

- Vasudevan, R.; Eswaran, V.; Biswas, G. Winglet-type vortex generators for plate-fin heat exchangers using triangular fins. Numer. Heat Transf. Part A Appl. 2000, 38, 533–555. [Google Scholar]

- Sohankar, A.; Davidson, L. Effect of inclined vortex generators on heat transfer enhancement in a three-dimensional channel. Numer. Heat Transf. Part A Appl. 2001, 39, 433–448. [Google Scholar] [CrossRef]

- Tiwari, S.; Maurya, D.; Biswas, G.; Eswaran, V. Heat transfer enhancement in cross-flow heat exchangers using oval tubes and multiple delta winglets. Int. J. Heat Mass Transf. 2003, 46, 2841–2856. [Google Scholar] [CrossRef]

- Prabhakar, V.; Biswas, G.; Eswaran, V. Numerical prediction of heat transfer in a channel with a built-in oval-tube and various arrangements of the vortex generators. Numer. Heat Transf. Part A Appl. 2003, 44, 315–333. [Google Scholar] [CrossRef]

- Jain, A.; Biswas, G.; Maurya, D. Winglet-type vortex generators with common-flow-up configuration for fin-tube heat exchangers. Numer. Heat Transf. Part A Appl. 2003, 43, 201–219. [Google Scholar] [CrossRef]

- Joardar, A.; Jacobi, A.M. A numerical study of flow and heat transfer enhancement using an array of delta-winglet vortex generators in a fin-and-tube heat exchanger. J. Heat Transf. 2007, 129, 1156–1167. [Google Scholar] [CrossRef]

- Wu, J.M.; Tao, W.Q. Investigation on laminar convection heat transfer in fin-and-tube heat exchanger in aligned arrangement with longitudinal vortex generator from the viewpoint of field synergy principle. Appl. Therm. Eng. 2007, 27, 2609–2617. [Google Scholar] [CrossRef]

- Wu, J.M.; Tao, W.Q. Numerical study on laminar convection heat transfer in a rectangular channel with longitudinal vortex generator. Part A: Verification of field synergy principle. Int. J. Heat Mass Transf. 2008, 51, 1179–1191. [Google Scholar] [CrossRef]

- Wu, J.M.; Tao, W.Q. Numerical study on laminar convection heat transfer in a channel with longitudinal vortex generator. Part B: Parametric study of major influence factors. Int. J. Heat Mass Transf. 2008, 51, 3683–3692. [Google Scholar] [CrossRef]

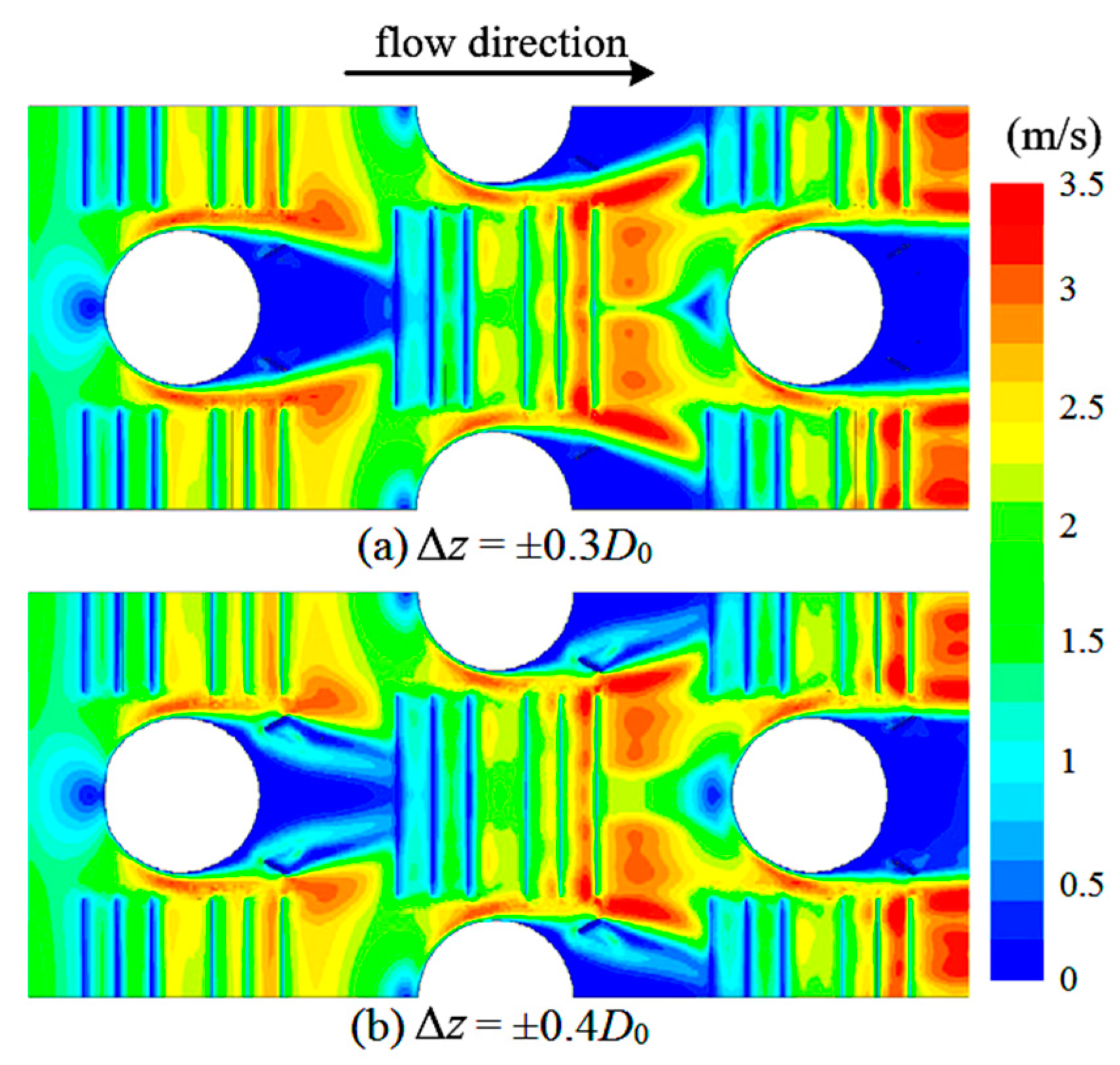

- Song, K.W.; Wang, L.B.; Fan, J.F.; Zhang, Y.H.; Liu, S. Numerical study of heat transfer enhancement of finned flat tube bank fin with vortex generators mounted on both surfaces of the fin. Heat Mass Transf. 2008, 44, 959–967. [Google Scholar] [CrossRef]

- Chang, L.M.; Wang, L.B.; Song, K.W.; Sun, D.L.; Fan, J.F. Numerical study of the relationship between heat transfer enhancement and absolute vorticity flux along main flow direction in a channel formed by a flat tube bank fin with vortex generators. Int. J. Heat Mass Transf. 2009, 52, 1794–1801. [Google Scholar] [CrossRef]

- Tian, L.T.; He, Y.L.; Lei, Y.G.; Tao, W.Q. Numerical study of fluid flow and heat transfer in a flat-plate channel with longitudinal vortex generators by applying field synergy principle analysis. Int. Commun. Heat Mass Transf. 2009, 36, 111–120. [Google Scholar] [CrossRef]

- Chu, P.; He, Y.L.; Tao, W.Q. Three-dimensional numerical study of flow and heat transfer enhancement using vortex generators in fin-and-tube heat exchangers. J. Heat Transf. 2009, 131, 091903. [Google Scholar] [CrossRef]

- Onishi, H.; Yonekura, H.; Tada, Y.; Takimoto, A. Heat transfer performance of finless flat-tube heat exchanger with vortex generator. In Proceedings of the 14th International Heat Transfer Conference, Washington, DC, USA, 8–13 August 2010; Volume 4, pp. 799–807. [Google Scholar]

- Lei, Y.G.; He, Y.L.; Tian, L.T.; Chu, P.; Tao, W.Q. Hydrodynamics and heat transfer characteristics of a novel heat exchanger with delta-winglet vortex generators. Chem. Eng. Sci. 2010, 65, 1551–1562. [Google Scholar] [CrossRef]

- Zeng, M.; Tang, L.H.; Lin, M.; Wang, Q.W. Optimization of heat exchangers with vortex-generator fin by Taguchi method. Appl. Therm. Eng. 2010, 30, 1775–1783. [Google Scholar] [CrossRef]

- Lemouedda, A.; Breuer, M.; Franz, E.; Botsch, T.; Delgado, A. Optimization of the angle of attack of delta-winglet vortex generators in a plate-fin-and-tube heat exchanger. Int. J. Heat Mass Transf. 2010, 53, 5386–5399. [Google Scholar] [CrossRef]

- Wu, J.M.; Tao, W.Q. Impact of delta winglet vortex generators on the performance of a novel fin-tube surfaces with two rows of tubes in different diameters. Energy Convers. Manag. 2011, 52, 2895–2901. [Google Scholar] [CrossRef]

- Hwang, S.W.; Kim, D.H.; Min, J.K.; Jeong, J.H. CFD analysis of fin tube heat exchanger with a pair of delta winglet vortex generators. J. Mech. Sci. Technol. 2012, 26, 2949–2958. [Google Scholar] [CrossRef]

- Pal, A.; Bandyopadhyay, D.; Biswas, G.; Eswaran, V. Enhancement of heat transfer using delta winglet type vortex generators with a common-flow-up arrangement. Numer. Heat Transf. Part A Appl. 2012, 61, 912–928. [Google Scholar]

- He, Y.L.; Han, H.; Tao, W.Q.; Zhang, Y.W. Numerical study of heat transfer enhancement by punched winglet-type vortex generator arrays in fin-and-tube heat exchangers. Int. J. Heat Mass Transf. 2012, 55, 5449–5458. [Google Scholar] [CrossRef]

- He, Y.L.; Chu, P.; Tao, W.Q.; Zhang, Y.W.; Xie, T. Analysis of heat transfer and pressure drop for fin-and-tube heat exchangers with rectangular winglet-type vortex generators. Appl. Therm. Eng. 2013, 61, 770–783. [Google Scholar] [CrossRef]

- Sinha, A.; Raman, K.A.; Chattopadhyay, H.; Biswas, G. Effects of different orientations of winglet arrays on the performance of plate-fin heat exchangers. Int. J. Heat Mass Transf. 2013, 57, 202–214. [Google Scholar] [CrossRef]

- Huisseune, H.; T’Joen, C.; De Jaeger, P.; Ameel, B.; De Schampheleire, S.; De Paepe, M. Influence of the louver and delta winglet geometry on the thermal hydraulic performance of a compound heat exchanger. Int. J. Heat Mass Transf. 2013, 57, 58–72. [Google Scholar] [CrossRef]

- Jang, J.Y.; Hsu, L.F.; Leu, J.S. Optimization of the span angle and location of vortex generators in a plate-fin and tube heat exchanger. Int. J. Heat Mass Transf. 2013, 67, 432–444. [Google Scholar] [CrossRef]

- Hu, W.L.; Song, K.W.; Guan, Y.; Chang, L.M.; Liu, S.; Wang, L.B. Secondary flow intensity determines Nusselt number on the fin surfaces of circle tube bank fin heat exchanger. Int. J. Heat Mass Transf. 2013, 62, 620–631. [Google Scholar] [CrossRef]

- Song, K.W.; Wang, L.B. The effectiveness of secondary flow produced by vortex generators mounted on both surfaces of the fin to enhance heat transfer in a flat tube bank fin heat exchanger. J. Heat Transf. 2013, 135, 041902. [Google Scholar] [CrossRef]

- Saha, P.; Biswas, G.; Sarkar, S. Comparison of winglet-type vortex generators periodically deployed in a plate-fin heat exchanger—A synergy based analysis. Int. J. Heat Mass Transf. 2014, 74, 292–305. [Google Scholar] [CrossRef]

- Gholami, A.A.; Wahid, M.A.; Mohammed, H.A. Heat transfer enhancement and pressure drop for fin-and-tube compact heat exchangers with wavy rectangular winglet-type vortex generators. Int. Commun. Heat Mass Transf. 2014, 54, 132–140. [Google Scholar] [CrossRef]

- Zhao, X.B.; Tang, G.H.; Ma, X.W.; Tao, W.Q. Numerical investigation of heat transfer and erosion characteristics for H-type finned oval-tube with longitudinal vortex generators and dimples. Appl. Energy 2014, 127, 93–104. [Google Scholar] [CrossRef]

- Lin, Z.M.; Wang, L.B. A multi-domain coupled numerical method for a flat tube bank fin heat exchanger with delta winglet vortex generators. Numer. Heat Transf. Part A Appl. 2014, 65, 1204–1229. [Google Scholar] [CrossRef]

- Behfard, M.; Sohankar, A. Numerical investigation for finding the appropriate design parameters of a fin-and-tube heat exchanger with delta winglet vortex generators. Heat Mass Transf. 2016, 52, 21–37. [Google Scholar] [CrossRef]

- Lin, Z.M.; Liu, C.P.; Lin, M.; Wang, L.B. Numerical study of flow and heat transfer enhancement of circular tube bank fin heat exchanger with curved delta winglet vortex generators. Appl. Therm. Eng. 2015, 88, 198–210. [Google Scholar] [CrossRef]

- Sinha, A.; Chattopadhyay, H.; Iyengar, A.K.; Biswas, G. Enhancement of heat transfer in a fin-tube heat exchanger using rectangular winglet type vortex generators. Int. J. Heat Mass Transf. 2016, 101, 667–681. [Google Scholar] [CrossRef]

- Oneissi, M.; Habchi, C.; Russeil, S.; Bougeard, D.; Lemenand, T. Novel design of delta winglet pair vortex generator for heat transfer enhancement. Int. J. Therm. Sci. 2016, 109, 1–9. [Google Scholar] [CrossRef]

- Esmaeilzadeh, A.; Amanifard, N.; Deylami, H.M. Comparison of simple and curved trapezoidal longitudinal vortex generators for optimum flow characteristics and heat transfer augmentation in a heat exchanger. Appl. Therm. Eng. 2017, 125, 1414–1425. [Google Scholar] [CrossRef]

- Harlow, F.H.; Welch, J.E. Numerical calculation of time-dependent viscous incompressible flow of fluid with free surface. Phys. Fluids 1965, 8, 2182–2189. [Google Scholar] [CrossRef]

- Hirt, C.W.; Nichols, B.D.; Romero, N.C. SOLA: A Numerical Solution Algorithm for Transient Fluid Flows; Los Alamos Scientific Lab.: Los Alamos, NM, USA, 1975. [Google Scholar]

- Cebeci, T.; Shao, J.P.; Kafyeke, F.; Laurendeau, E. Computational Fluid Dynamics for Engineers; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Guo, Z.Y.; Li, D.Y.; Wang, B.X. A novel concept for convective heat transfer enhancement. Int. J. Heat Mass Transf. 1998, 41, 2221–2225. [Google Scholar] [CrossRef]

- Tao, W.Q.; Guo, Z.Y.; Wang, B.X. Field synergy principle for enhancing convective heat transfer—Its extension and numerical verifications. Int. J. Heat Mass Transf. 2002, 45, 3849–3856. [Google Scholar] [CrossRef]

- Tao, W.Q.; He, Y.L.; Wang, Q.W.; Qu, Z.G.; Song, F.Q. A unified analysis on enhancing single phase convective heat transfer with field synergy principle. Int. J. Heat Mass Transf. 2002, 45, 4871–4879. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Tao, W.Q.; Shah, R.K. The field synergy (coordination) principle and its applications in enhancing single phase convective heat transfer. Int. J. Heat Mass Transf. 2005, 48, 1797–1807. [Google Scholar] [CrossRef]

| Reference | Vortex Generators (VGs) | Re | Methodology | Measurement |

|---|---|---|---|---|

| Garimella and Eibeck [23] | Two different half-delta wings in a horizontal channel. | 700–5200 | An array of 30 heated copper elements mounted on the detachable hatch in six spanwise rows for heat transfer. | Heat transfer enhancement, pressure drop. |

| Fiebig et al. [24] | Delta and rectangular wings on a flat plate. | 1360–2270 | A laser light sheet used for the flow visualization, unsteady liquid crystal thermography to determine the local heat transfer coefficients. | Flow pattern, local heat transfer coefficient, drag coefficient, Colburn j-factor, normalized heat transfer enhancement. |

| Tiggelbeck et al. [25,26] | Single and double rows of half-delta wings on a flat plate. | 1600–8000 | Tracer particles of evaporating glycerine used for observations of the flow structure, laser light sheets to observe the visible flow field, a liquid crystal thermography used for local heat transfer measurements. | Flow pattern and vortex property, local Nu number, average Nu number and drag coefficient. |

| Fiebig et al. [27] | DWPs in a finned circular-tube heat exchanger. | 600–2700 | A hot-wire anemometer at 2 mm intervals to measure the axial velocity, a liquid crystal thermography used for local heat transfer measurements. | Nu number distribution, local Nu number, average Nu number and apparent friction factor. |

| Tiggelbeck et al. [28] | Delta wing, rectangular wing, DWPs and RWPs on a flat plate. | 2000–9000 | A thermochromic liquid crystal thermography to measure the local heat transfer on the wall. | Local Nu number. |

| Fiebig et al. [29] | DWPs in finned circular and flat-tube heat exchangers. | 600–3000 | A liquid crystal thermography used for local heat transfer measurements. | Nu number distribution, local Nu number, average Nu number and apparent friction factor. |

| Gentry and Jacobi [30] | Delta wings on a flat plate. | 600, 800, 1000 | A laser light sheet used for flow visualization, naphthalene sublimation experiments to provide convection coefficients. | Sherwood number, drag coefficient. |

| Kotcioğlu et al. [31] | RWPs on a flat plate. | 3000–30,000 | A smoke generator used for laminar main flow visualization in a Hele–Shaw apparatus. | Flow pattern, average Nu number and friction factor. |

| Wang et al. [6,9] | Interrupted annular and delta winglets in a finned circular-tube heat exchanger. | 500, 1500, 3300 | Water tunnel apparatus used to visualize the flow pattern, a dye-injection technique with a digital video camera used for the flow visualization. | Flow pattern. |

| Torii et al. [32,33,34] | DWPs in a finned circular-tube heat exchanger. | 350–2100 | A stainless steel ribbon heating screen uniformly spread over an entire cross section at the inlet of the test section to heat the flow quickly and uniformly. | Colburn j-factor, friction factor. |

| Gentry and Jacobi [35] | Delta wings on a flat plate. | 300–2000 | A laser light sheet used for flow visualization, naphthalene sublimation experiments to provide convection coefficients, a vane-type vortex meter and a potential-flow model with flow visualization to infer vortex strength. | Flow pattern, dimensionless vortex circulation, Sherwood number distribution, average Sherwood number, heat transfer enhancement, pressure-drop penalty. |

| Yoo et al. [36] | RWPs in a finned circular-tube heat exchanger. | 800–4500 | Naphthalene sublimation technique to measure local mass transfer coefficients, analogy equation between heat and mass transfer to calculate heat transfer coefficients. | Nu number distribution, local Nu number, average Nu number and apparent friction factor. |

| Yuan et al. [37] | RWPs on a flat plate. | 5000–47,000 | Twenty-five rows of copper-constantan thermocouple mounted uniformly in the flow direction to measure local heat transfer coefficients. | Local Nu number, average Nu number and friction factor, correlations for average Nu number and apparent Darcy friction factor. |

| Chen and Shu [38] | Delta wings on a flat plate. | 4430–11,820 | Laser Doppler velocimetry to characterize the flow structures and measure three-component mean and fluctuating velocity, 25 thermocouples mounted in the flow direction to measure the surface temperature. | Velocity structure, near-wall flow parameters, average Nu number. |

| Leu et al. [39] | RWPs in a finned circular-tube heat exchanger. | 400–3000 | Dye-injection technique with a digital video camera used for the flow visualization, infrared thermal camera to measure temperature distribution, a precision hot-wire instrument to measure inlet velocity. | Temperature field, Nu number distribution, average heat transfer coefficient and pressure drop. |

| O’Brien et al. [40] | DWPs in a finned oval-tube heat exchanger. | 600–6500 | A precision imaging infrared camera to measure the local fin surface temperature distributions, an inline precision mass flow meter to monitor the airflow rate. | Heat transfer coefficient distribution, average Nu number and friction factor. |

| Sommers and Jacobi [41] | Delta wings in a finned circular-tube heat exchanger. | 500–1300 | An upstream cooling coil and a controlled steam injection system to control the temperature and humidity of the air, hot-bulb anemometry to measure the airflow velocity. | Overall thermal resistance, pressure-drop penalty, Colburn j-factor, Fanning friction factor, volume goodness factor, average frost density with time. |

| Pesteei et al. [42] | DWPs in parallel plates with a single cylindrical obstacle. | 2250 | Total 23 thermocouples fitted on half section of the fin surface to measure the local temperature distribution. | Local heat transfer coefficient, average Nu number and apparent friction factor. |

| Shi et al. [43] | DWPs in a finned flat-tube heat exchanger. | <3000 | Naphthalene sublimation technique for heat–mass transfer analogy. | Nu number distribution, local Nu number, friction factor, JF factor. |

| Allison and Dally [44] | DWPs in a finned circular-tube heat exchanger. | 2600, 3400, 4600 | Dye-injection technique with a digital video camera used for the flow visualization. | Colburn j-factor, Fanning friction factor, JF factor. |

| Wang et al. [45] | RWPs on a flat plate. | 3000–20,000 | Deionized water as working fluid. | Local Nu number, average Nu number and friction factor, correlations for average Nu number and friction factor. |

| Joardar and Jacobi [46] | DWPs in a finned circular-tube heat exchanger. | 220–960 | An upstream cooling coil and a controlled steam injection system to control the temperature and humidity of the air, a static mixer at the fan outlet and a centrifugal mixer to ensure a thoroughly mixed flow of uniform temperature and humidity. | Average heat transfer coefficient, thermal resistance, pressure drop, Colburn j-factor, friction factor, volume goodness factor. |

| Tang et al. [47,48] | DWPs and mixed fins in a finned circular-tube heat exchanger. | 4000–10,000 | Steam-air system employed for the accomplishment of steam-to-air heat exchange, a Pitot-tube meter connected to an inclined draft gauges or U-tube water column manometer for measurement of the air flow rate. | Average Nu number and pressure drop, Colburn j-factor, friction factor, heat transfer performance comparison criteria, correlations of Nu number and friction factor. |

| Hernon and Patten [49] | DWPs on a flat plate. | A constant temperature anemometer system to measure mean and fluctuation velocities. | Time-averaged local velocity, boundary layer thickness. | |

| He et al. [17] | V type DWPs in a finned circular-tube heat exchanger. | 1400–3400 | A 6-junction, equally spaced thermocouple grid and another 12-junction grid used to detect the air temperatures at the inlet and downstream of the specimen, respectively. | Average heat transfer coefficient, pressure drop, Colburn j-factor, Fanning friction factor, area goodness and volume goodness factors. |

| Yang et al. [50] | Delta wings, semi-circular wings, triangular wings and dimple wings on a flat plate. | 120–600 | A multiple nozzle code tester to measure the air flowrate, an air straightener equalizer and a mixer avoid and minimize the effect of flow maldistribution. | Average heat transfer coefficient and pressure drop, Colburn j-factor, friction factor, inverse Graetz number. |

| Promvonge et al. [51,52] | Combined ribs and winglets in a triangular ribbed channel. | 5000–22,000 | A multiple nozzle code tester based on the ASHRAE 41.2 standard to measure the air flowrate, an air straightener equalizer and a mixer avoid and minimize the effect of flow maldistribution. | Average Nu number and friction factor, performance evaluation criteria. |

| Min et al. [53] | Modified RWPs on a flat plate. | 5000–17,500 | A hot-wire anemometer to measure the channel inlet velocity, an infrared imaging camera to obtain quantitative thermal visualization images, 54 thermocouples installed at the channel exits to measure the average outlet temperature, a PIV measurement with CCD camera and to generate glycerol particles for the flow visualization. | Average Nu number and friction factor, local Nu number, secondary flow vector distribution. |

| Aris et al. [54] | Delta wings in a finned circular-tube heat exchanger. | 330–960 | An orifice unit located after the fan to determine the air mass flow rate. | Average Nu number and Darcy friction factor. |

| Aris et al. [14] | Delta wings on a flat plate. | 1573–3712 | A 16-mm thick copper block heated by two cartridge heaters to obtain a uniform temperature condition, an infrared camera to acquire surface temperature distribution. | Local Nu number, average Nu number and apparent friction factor. |

| Wu and Tao [55] | Delta wings and punched holes on a flat plate. | 500–2000 | A thermocouple mesh with eight thermocouples to measure the nearly uniform inlet air temperature distribution, a thermocouples mesh with 16 thermocouples to measure the outlet temperature distribution, 16 thermocouples embedded in the upper and lower sheets to measure the wall temperature distribution. | Temperature distribution, average Nu number. |

| Zhou and Ye [18] | RWPs, TWPs, DWPs, CTWPs on a flat plate. | 700–26,800 | A thermocouple mesh with 12 T-type thermocouples to measure the outlet temperature distribution, 21 T-type thermocouples embedded in the copper plate to measure the wall temperature distribution. | Average Nu number and friction factor. |

| Wu et al. [56] | DWPs in a novel finned circular-tube heat exchanger. | A nozzle flow meter to measure the air flowrate. | Average heat transfer coefficient and pressure drop. | |

| Zhou and Feng [19] | RWPs, TWPs, DWPs, CTWPs with or without holes on winglet on a flat plate. | 650–21,000 | A thermocouple mesh with 12 T-type thermocouples to measure the outlet temperature distribution, 21 T-type thermocouples embedded in the copper plate to measure the wall temperature distribution. | Average Nu number and Darcy friction factor. |

| Wang et al. [57] | Semi-dimple winglet pairs in plain or louvre finned circular-tube heat exchanger. | A multiple nozzle code tester to measure the air flowrate, an air straightener equalizer and a mixer avoid and minimize the effect of flow maldistribution. | Average heat transfer coefficient and pressure drop. | |

| Abdelatie et al. [58] | RWPs in a wing-shaped-tubes-bundle heat exchanger. | 1850–9700 | Eight thermocouples on two grids at the entrance and the exit to measure inlet and outlet air average temperatures, an alcohol thermometer with wet wick surrounded bulb to measure the wet bulb temperatures at the inlet and the exit. | Average Nu number and drag coefficient. |

| Wu et al. [59] | Curved DWPs in a finned circular-tube heat exchanger. | 500–4200 | Eight thermocouples on two grids at the entrance and the exit to measure inlet and outlet air temperatures, an alcohol thermometer with wet wick surrounded bulb to measure the wet bulb temperatures at the inlet and the exit. | Average Nu number and friction factor, average heat transfer coefficient and pressure drop, JF factor, correlations for average Nu number and Darcy friction factor. |

| Reference | VGs | Re | Methodology | Measurement |

|---|---|---|---|---|

| Fiebig et al. [62] | Delta winglets or delta wings on a flat plate. | 500–2000 | SOLA algorithm, unsteady laminar model, incompressible flow, hydrodynamically developed inlet velocity and constant inlet temperature. | Velocity structure, temperature field. |

| Biswas et al. [63] | Delta wings on a flat plate. | 500–1815 | Modified MAC algorithm, unsteady laminar model, uniform inlet velocity and constant inlet temperature. | Velocity structure, temperature field, local Nu number and friction factor. |

| Biswas et al. [64] | Delta wings and punched holes on a flat plate. | 500–1815 | Modified MAC algorithm, unsteady laminar model, uniform inlet velocity and constant inlet temperature. | Velocity structure, temperature field, local Nu number and friction factor. |

| Zhu et al. [65] | DWPs on a flat plate. | 67,000 | SOLA algorithm, unsteady k–ε turbulence model, incompressible flow, inlet velocity component profile from experiment. | Velocity structure. |

| Zhu et al. [66] | Delta wings, rectangular wings, DWPs and RWPs on a flat plate. | 50,000 | SOLA algorithm, unsteady k–ε turbulence model, incompressible flow, hydrodynamically developed inlet velocity and constant inlet temperature. | Velocity structure, temperature field, local Nu number, average Nu number and apparent friction factor. |

| Biswas et al. [67] | DWPs in a circular-tube heat exchanger. | 500–1000 | Modified MAC algorithm, unsteady laminar model, fully developed inlet velocity and constant inlet temperature. | Velocity structure, temperature field, local Nu number. |

| Biswas et al. [68] | Delta wings and DWPs on a flat plate. | 500–3000 | Modified MAC algorithm, unsteady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Velocity structure, local Nu number and skin friction coefficient. |

| Deb et al. [69] | DWPs on a flat plate. | 400–1000 | Modified MAC algorithm, unsteady laminar model and k–ε turbulence model, incompressible flow. | Velocity structure, local Nu number and skin friction coefficient. |

| Biswas et al. [70] | Delta winglets on a flat plate. | 1580 | Modified MAC algorithm, unsteady laminar model, fully developed inlet velocity and constant inlet temperature. | Velocity structure, local Nu number and quality factor. |

| Chen et al. [71] | Punched delta winglets in a finned oval-tube heat exchanger. | 300 | Steady laminar model, incompressible flow, fully developed inlet velocity and constant inlet temperature. | Velocity structure, temperature field, pressure distributions, local Nu number and pressure drop. |

| Vasudevan et al. [72] | Triangular duct with delta winglet. | 100, 200 | Steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Velocity structure, temperature field, local Nu number. |

| Sohankar and Davidson [73] | Inclined block shapes on a flat plate. | 400–1500 | Unsteady laminar incompressible flow, uniform inlet velocity and constant inlet temperature. Second-order central or third-order QUICK differencing scheme to discretize the convective term and second-order central differencing scheme to discretize the others. | Velocity structures, Nu number distribution, local Nu number, average Nu number and apparent friction factor. |

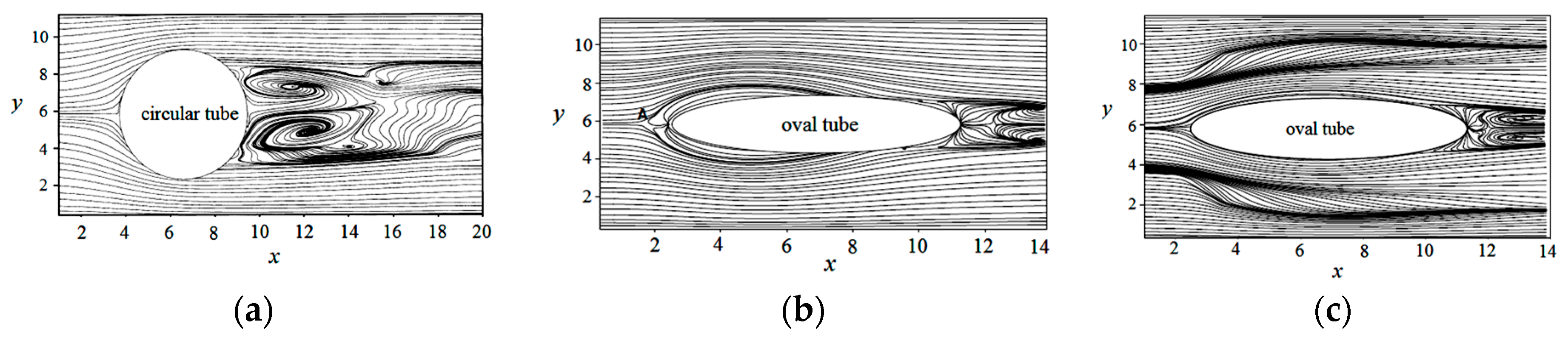

| Tiwari et al. [74] | DWPs in a finned oval-tube heat exchanger. | 500, 1000, 1500 | Steady laminar model, uniform inlet velocity and constant inlet temperature. Finite-volume formulation to discretize the governing equations. | Velocity structures, Nu number distribution, local Nu number. |

| Prabhakar et al. [75] | DWPs in a finned oval-tube heat exchanger. | 1300 | Steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Finite-volume formulation to discretize the governing equations. | Velocity structures, Nu number distribution, local Nu number. |

| Jain et al. [76] | DWPs in a finned circular-tube heat exchanger. | 1000 | Steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Finite-volume formulation to discretize the governing equations. | Velocity structures, Nu number distribution, local Nu number. |

| Leu et al. [39] | RWPs in a finned circular-tube heat exchanger. | 400–3000 | Steady k–ε turbulence model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Temperature field, Nu number distribution, average heat transfer coefficient and Fanning friction factor. |

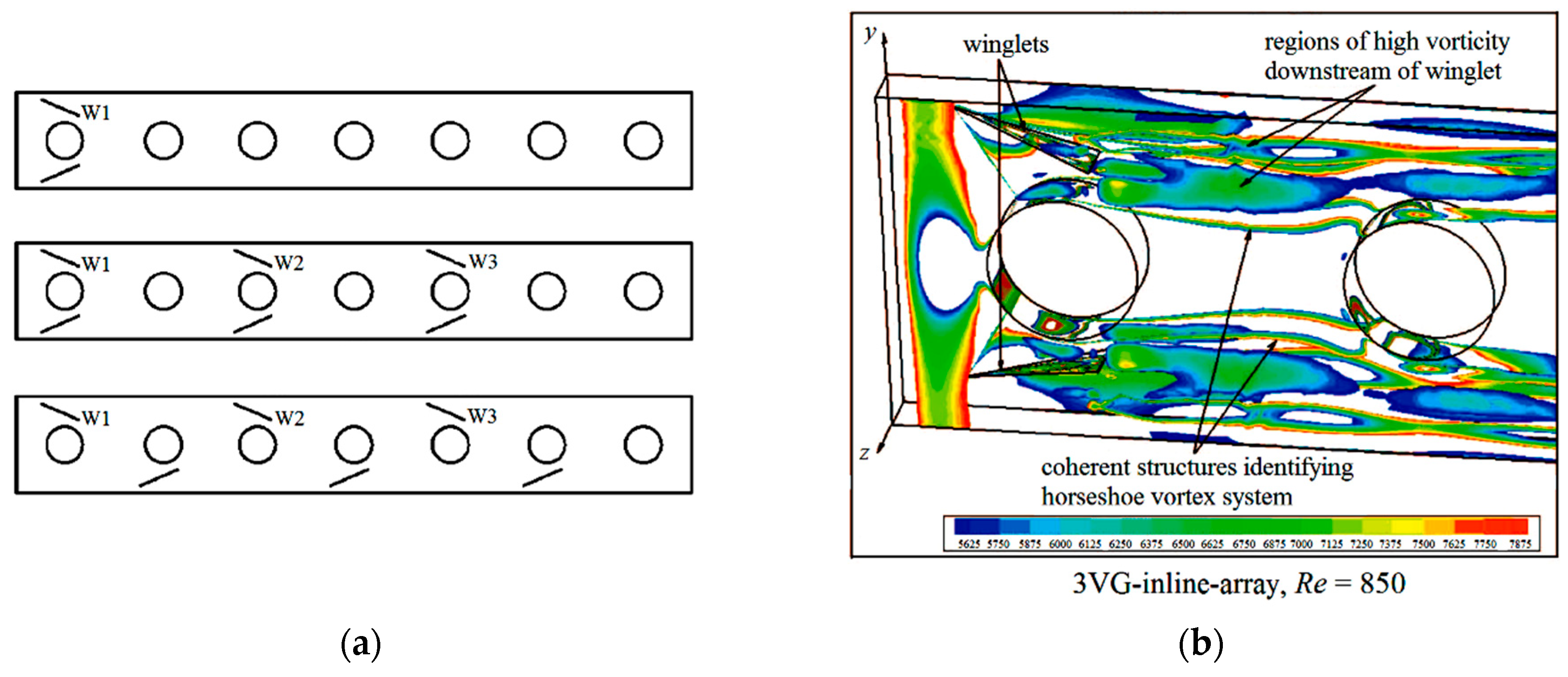

| Joardar and Jacobi [77] | DWPs in a finned circular-tube heat exchanger. | 330–850 | FLUENT solver, unsteady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Finite-volume formulation using a fully implicit higher-order upwind differencing scheme to discretize the governing equations, SIMPLEC algorithm to couple the pressure and velocity. | Velocity structure, heat flux distribution, local heat flux, average heat flux and friction factor. |

| Wu and Tao [78] | DWPs in a finned circular-tube heat exchanger. | 800–2000 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Second upwind scheme to discretize the convection term, SIMPLEC algorithm to couple the pressure and velocity. | Velocity structure, temperature field, average Nu number, synergy angle. |

| Wu and Tao [79,80] | Rectangular winglet in a rectangular channel. | 800–3000 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Second-order upwind scheme to discretize the convective term, central difference scheme to discretize the diffusion term, SIMPLEC algorithm to couple the pressure and velocity. | Velocity structure, temperature field, local pressure and Nu number, average Nu number and Fanning friction factor. |

| Song et al. [81] | DWPs in a finned flat-tube heat exchanger. | 200–1900 | Steady laminar model, incompressible flow, periodicity conditions in the inlet and exit. Power scheme to discretize the convective terms, SIMPLE algorithm to couple the velocity and pressure. | Nu number distribution, local Nu number, average Nu number and friction factor. |

| Chang et al. [82] | DWPs in a finned flat-tube heat exchanger. | 300–1700 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Power scheme to discretize the convective terms, SIMPLE algorithm to couple the velocity and pressure. | Absolute vorticity flux and Nu number distributions, local absolute vorticity flux and Nu number, average Nu number and friction factor. |

| Tang et al. [48] | DWPs in a finned circular-tube heat exchanger. | 4000–100,000 | FLUENT solver, standard k–ε turbulence model, incompressible flow, uniform inlet velocity and constant inlet temperature. QUICK scheme to discretize the convection terms and central finite differencing to discretize the diffusion terms, SIMPLEC algorithm to solve the pressure field. | Correlations of Nu number and friction factor. |

| Tian et al. [4] | DWPs in a triangular wavy fin-tube heat exchanger. | 500–5000 | FLUENT solver, steady RNG k–ε turbulence model, incompressible flow, uniform inlet velocity and constant inlet temperature. Central difference scheme to discretize the diffusion term, and the SIMPLEC algorithm to couple the pressure and velocity. | Velocity structure, temperature field, local heat transfer coefficient, average Nu number and friction factor, area goodness and volume goodness factors. |

| Tian et al. [83] | Delta winglets on a flat plate. | 470–1700 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. SIMPLEC algorithm to couple the pressure and velocity, second-order upwind scheme to discretize the convection terms, central difference scheme to discretize the diffusion term. | Velocity structure, temperature field, local pressure coefficient, heat transfer coefficient, average Nu number and friction factor, intersection angle. |

| Chu et al. [84] | RWPs in a finned circular-tube heat exchanger. | 500–880 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Second-order upwind scheme to discretize the governing equations, SIMPLE algorithm to couple the pressure and velocity. | Velocity structure, temperature field, local Nu number, average Nu number and friction factor, intersection angle. |

| Onishi et al. [85] | Rectangular winglets in a finless flat-tube heat exchanger. | 710–2130 | FLUENT solver, unsteady laminar model, uniform inlet velocity and constant inlet temperature. QUICK scheme to discretize the convection terms and central finite differencing to discretize the diffusion terms, SIMPLE algorithm to solve the pressure field. | Velocity structure, temperature field, average Nu number and pressure coefficient, area goodness and volume goodness factors. |

| Lei et al. [86] | DWPs in a finned circular-tube heat exchanger. | 600–2600 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. SIMPLEC algorithm to couple the pressure and velocity, QUICK scheme with third-order precision to discretize the convection terms. | Velocity structure, temperature field, local Nu number, average heat transfer coefficient and friction factor, intersection angle. |

| Zeng et al. [87] | DWPs in a finned circular-tube heat exchanger. | 4200–12,200 | FLUENT solver, steady k–ε turbulence model, incompressible flow, uniform inlet velocity and constant inlet temperature. SIMPLEC algorithm to couple the pressure and velocity. | Average Nu number and Darcy friction factor, performance evaluation criteria. |

| Lemouedda et al. [88] | DWPs in a finned circular-tube heat exchanger. | 200–1200 | STAR-CD solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. A central scheme of second-order accuracy for the spatial discretization of the computational domain. | Velocity structure, temperature field, heat transfer rate, power input. |

| Aris et al. [54] | Delta wings in a finned circular-tube heat exchanger. | 300 | Steady laminar model, uniform inlet velocity and constant inlet temperature. | Temperature field, local Nu number. |

| Wu and Tao [89] | DWPs in a novel finned circular-tube heat exchanger. | 800–2000 | FLUENT solver, steady laminar model, uniform inlet velocity and constant inlet temperature. Second-order upwind scheme to discretize the convective terms, SIMPLEC algorithm to couple the pressure and velocity. | Average Nu number and pressure drop. |

| Hwang et al. [90] | DWPs in a finned circular-tube heat exchanger. | 130–5180 | RNG k–ε turbulence model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Velocity structure, pressure distribution, temperature field, Colburn j-factor, friction factor. |

| Pal et al. [91] | DWPs in a finned circular-tube heat exchanger. | <800 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Velocity structure, temperature field, local Nu number, area goodness factor. |

| He et al. [92] | Punched winglet pairs in a finned circular-tube heat exchanger. | 600–2600 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Velocity structure, local Nu number, average heat transfer coefficient and pressure drop, area goodness and volume goodness factors. |

| He et al. [93] | RWPs in a finned circular-tube heat exchanger. | 550–880 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Second-order upwind scheme to discretize the convective terms, SIMPLE algorithm to couple the pressure and velocity. | Velocity structure, temperature field, average heat transfer coefficient and pressure drop, overall performance. |

| Sinha et al. [94] | DWPs on a flat plate. | 250–1580 | Modified MAC algorithm, laminar model, fully developed inlet velocity profile and constant inlet temperature. | Velocity structure, temperature field, local Nu number, overall performance. |

| Huisseune et al. [95] | DWPs in a louvred-fin-tube heat exchanger. | 220–915 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. SIMPLE algorithm to implement the coupling between pressure and velocity, second-order upwind scheme to discretize the convection terms, central difference scheme to discretize the diffusion term. | Velocity structure, Colburn j-factor, Fanning friction factor. |

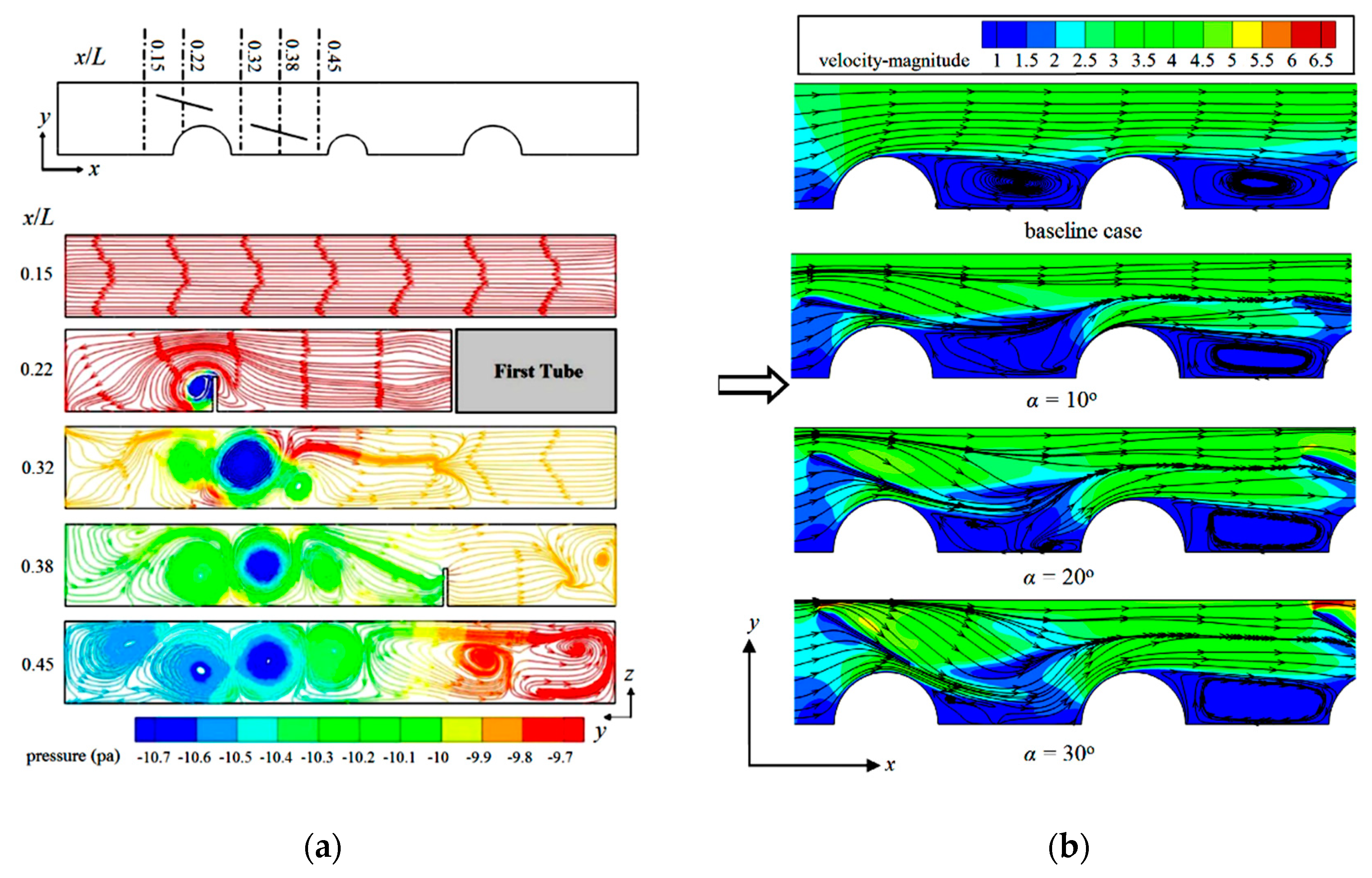

| Jang et al. [96] | Pairs of inclined block-shape VGs in a finned circular-tube heat exchanger. | 400–1200 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Third-order upwind scheme to model the convective terms, second-order central difference schemes to discretize the viscous and source terms. | Velocity structure, temperature field, Colburn j-factor, Fanning friction factor. |

| Hu et al. [97] | DWPs in a finned circular-tube heat exchanger. | 200–1900 | Laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. A control volume to integrate the governing equations, power scheme approximation to discretize the convective terms, second-order central difference scheme to discretize the diffusion terms, SIMPLE algorithm to couple the velocity and pressure. | Local heat transfer coefficient and Nu number, average Nu number and friction factor, secondary flow intensity. |

| Song and Wang [98] | DWPs in a finned flat-tube heat exchanger. | 200–1600 | Steady laminar model, incompressible flow, periodical fully developed heat transfer and fluid flow conditions. Power scheme, and central difference to discretize the convective and diffusion terms, SIMPLE algorithm to couple the velocity and pressure. | Local Nu number and absolute vorticity flux, average Nu number and friction factor. |

| Lotfi et al. [20] | DWPs in a smooth wavy fin elliptical-tube heat exchanger. | 500–3000 | SST k–ε turbulence model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Nu numbe distribution, average Nu number and friction factor, Colburn j-factor, area goodness and volume goodness factors. |

| Saha et al. [99] | DWPs and RWPs on a flat plate. | 50–200 | Modified MAC algorithm, unsteady laminar model, and incompressible flow, periodic boundary conditions for both inlet velocity and temperature. | Velocity structure, temperature field, Nu number distribution, local Nu number and frictional loss, average Nu number and friction factor. |

| Gholami et al. [100] | Wavy RWPs in a finned circular-tube heat exchanger. | 400–800 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Velocity structure, pressure distribution, temperature field, average Nu number and friction factor. |

| Zhao et al. [101] | RWPs in an H-type finned oval-tube heat exchanger. | 22,504–40,509 | RNG k–ε turbulence model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Velocity structure, temperature field, average Nu number, performance evaluation criteria. |

| Wu et al. [22] | DWPs in a slit finned circular-tube heat exchanger. | 304–2130 | Steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Velocity structure, temperature field, average Nu number and friction factor, JF factor, field synergy angle, equivalent thermal resistance. |

| Lin and Wang [102] | DWPs in a finned flat-tube heat exchanger. | 1300–2400 | Steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Control volume method, a stability-guaranteed second-order difference scheme and a second-order central difference scheme respectively to discretize the governing equations, the convective terms, and the viscous terms. | Velocity structure, average Nu number and friction factor, local integral mean main flow velocity. |

| Lin et al. [15] | Interrupted annular groove fins in a finned circular-tube heat exchanger. | 600–2500 | Steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Control volume method, a stability-guaranteed second-order difference scheme and a second-order central difference scheme respectively to discretize the governing equations, the convective terms and the viscous terms. | Velocity structure, average Nu number and friction factor, local integral mean main flow velocity. |

| Gong et al. [16] | Curved RWPs in a finned circular-tube heat exchanger. | 800–3000 | FLUENT solver, steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. | Velocity structure, Nu number distribution, average Nu number and friction factor, JF factor. |

| Behfard and Sohankar [103] | DWPs in a finned circular-tube heat exchanger. | 1000 | FLUENT solver, steady SST k–ε turbulence model, uniform inlet velocity and constant inlet temperature. Second-order upwind scheme to discretize the convective terms, SIMPLE algorithm to couple the pressure and velocity. | Velocity structure, temperature field, local pressure, average Nu number and Fanning friction factor, performance evaluation criteria. |

| Lin et al. [104] | Curved DWPs in a finned circular-tube heat exchanger. | 1100–3000 | Steady laminar model, incompressible flow, uniform inlet velocity and constant inlet temperature. Control volume method to discretize the governing equations. Second-order central difference scheme employed for the viscous terms. | Velocity structure, Nu number distribution, local intensity of secondary flow and Nu number, average Nu number and friction factor, JF factor. |

| Lotfi et al. [21] | RTW, ARW, CARW and WW in a wavy fin elliptical-tube heat exchanger. | 500–3000 | CFX solver, steady SST k–ε turbulence model, uniform inlet velocity and constant inlet temperature. | Velocity structure, temperature field, average Nu number, synergy angle. |

| Sinha et al. [105] | RWPs in a finned circular-tube heat exchanger. | 250–1500 | FLUENT solver, steady laminar model, fully developed velocity profile for the axial inlet velocity, finite-volume scheme. SIMPLE algorithm to couple the pressure and velocity, second-order upwind scheme to discretize the convection terms, central difference scheme to discretize the diffusion terms. | Velocity structure, temperature field, local Nu number, Fanning friction factor, quality factor. |

| Oneissi et al. [106] | DWPs on a flat plate. | 270–30,000 | FLUENT solver, steady laminar and SST k–ε turbulence model, uniform inlet velocity and constant inlet temperature. | Velocity structure, local Nu number, Fanning friction factor, vorticity property. |

| Esmaeilzadeh et al. [107] | TWPs and curved TWPs on a flat plate. | 7000–35,000 | FLUENT solver, steady Reynolds stress turbulence model, incompressible flow, uniform inlet velocity and constant inlet temperature. SIMPLEC algorithm to couple the pressure and velocity. | Velocity structure, local heat transfer coefficient, average Nu number and friction factor, overall performance. |

| Abdelatie et al. [58] | RWPs in a wing-shaped tubes-bundle heat exchanger. | 1850–9700 | RNG k–ε turbulence model, incompressible flow, uniform inlet velocity and constant inlet temperature. SIMPLE pressure-based solution algorithm to implement the velocity–pressure coupling. | Average Nu number and friction factor, heat transfer effectiveness, area goodness factor and efficiency index. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, L.; Tassou, S.A. A Review of Airside Heat Transfer Augmentation with Vortex Generators on Heat Transfer Surface. Energies 2018, 11, 2737. https://doi.org/10.3390/en11102737

Chai L, Tassou SA. A Review of Airside Heat Transfer Augmentation with Vortex Generators on Heat Transfer Surface. Energies. 2018; 11(10):2737. https://doi.org/10.3390/en11102737

Chicago/Turabian StyleChai, Lei, and Savvas A. Tassou. 2018. "A Review of Airside Heat Transfer Augmentation with Vortex Generators on Heat Transfer Surface" Energies 11, no. 10: 2737. https://doi.org/10.3390/en11102737

APA StyleChai, L., & Tassou, S. A. (2018). A Review of Airside Heat Transfer Augmentation with Vortex Generators on Heat Transfer Surface. Energies, 11(10), 2737. https://doi.org/10.3390/en11102737