1. Introduction

The iron and steel industry is an energy-intensive industry. According to statistics [

1], it takes up more than 15% of China’s total energy demand. Therefore, efficient utilization of energy is very significant to cost saving in iron and steel enterprises. Byproduct gas is a kind of important secondary energy in the iron and steel industry. About 34% of coal is converted into byproduct gas during the production process [

2,

3]. Accordingly, the recovery and utilization of the byproduct gas are of great significance to achieving energy saving and emission reduction for iron and steel enterprises.

Byproduct gas is generated during the iron and steel making progress and is supplied to many related plants as a source of fuel. The remaining gas is sent to the self-provided power plant to generate steam and electricity. There is volatility in the generation and consumption of byproduct gas, and this would lead to an imbalance between gas supply and demand. An effective solution to this problem is to install gasholders as buffers. Since gasholders are limited in capacity, temporary excess and gas shortage usually occur. Therefore, it is necessary to optimize the scheduling of a byproduct gas system in advance to reduce byproduct gas shortage and flaring.

To make better use of byproduct gas, many researchers have devoted their work to the scheduling of byproduct gas in iron and steel enterprises. There are two typical scheduling methods, including the reasoning method [

4,

5] and the mathematical programming method [

6,

7,

8,

9,

10,

11,

12,

13,

14]. The reasoning method formulates dispatching rules to maintain the gasholders within the safety operation zone. It has the advantages of simplicity and low computational time complexity. Compared with the reasoning method, the mathematical programming method can achieve an optimal solution. Akimoto et al. [

6] first developed a mixed integer linear programming (MILP) model to optimize the gas scheduling by considering the stability of the byproduct gas system. Kim and Han [

7] adopted the MILP model to optimize the gasholder level control and gas distribution on different boilers simultaneously. Integer variables ware adopted to express the switch states of the boiler burners. In 2010, Hong et al. [

8] built the multiple period mathematical model according to the characteristics of the gas system. The model optimized the distribution of byproduct gas in both the cogeneration system and the production system. In 2013, Sun et al. [

9,

10] proposed a nonlinear mathematical programming model for byproduct gas scheduling by considering the change of boiler efficiency. And the decomposition and coordination method was developed to solve the optimization problem. In 2015, Zhao et al. [

11,

12] proposed the short period optimal scheduling model and discussed the influence of different weights on the results of optimal byproduct gas allocation. De Oliveira Junior et al. [

13] improved the optimal scheduling model of byproduct gas system and proposed the rule-based weights determination method. In 2017, Hao et al. [

14] established an MILP-based scheduling model to evaluate the load shifting potential of on-site power plant under time-of-use power price. MILP is an effective method to solve the optimal scheduling problem of byproduct gas. However, the models mentioned above assumed that there is no error in byproduct gas generation and consumption forecasting. In actual production processes, the amount of gas generation and consumption fluctuates greatly, and the inaccuracy of prediction would lead to uncertainties [

15,

16]. The optimal scheduling has the risk of violating constraints in some cases. Accordingly, it is of great significance to deal with the uncertainties correctly in the by-product gas scheduling to ensure the reliability of the gas system operation plan.

In this paper, we focus on byproduct gas system optimization scheduling considering prediction uncertainties. The generation and the consumption amount of byproduct gas are expressed as a fuzzy variable, and the fuzzy optimal scheduling model of the gas system is established. And the credibility theory is introduced to the model. The uncertainty constraints in the model are transformed into deterministic constraints to provide an efficient solution. Furthermore, the risk cost is defined to quantify the risk of byproduct gas shortage and emission during the scheduling process. The best confidence level is determined through the trade-off between operation cost and risk cost. Compared with existing work, the main contributions of this paper are as follows.

(1) We adopted the fuzzy optimal approach to byproduct gas scheduling to deal with uncertainties. To the authors’ knowledge, this is the first time that the fuzzy optimal approach has been used for this problem. And the fuzzy chance constrained programming is introduced to coordinate profit and risk.

(2) To evaluate the risk caused by uncertainties, including byproduct gas shortage and emission, the risk cost is defined in this paper. Furthermore, the risk cost is used to help dispatchers select the appropriate confidence level.

The rest of the paper is organized as follows. Fuzzy chance constrained programming and credibility distribution of fuzzy variables are introduced in

Section 2. The overall byproduct gas system is described in

Section 3, and the influence of uncertainty on byproduct gas system is analyzed.

Section 4 demonstrates mathematical formulation on fuzzy byproduct gas scheduling. Risk analysis of byproduct gas system scheduling is provided in

Section 5.

Section 6 presents the results from a case study. Finally, the paper is concluded in

Section 7.

3. Problem Description

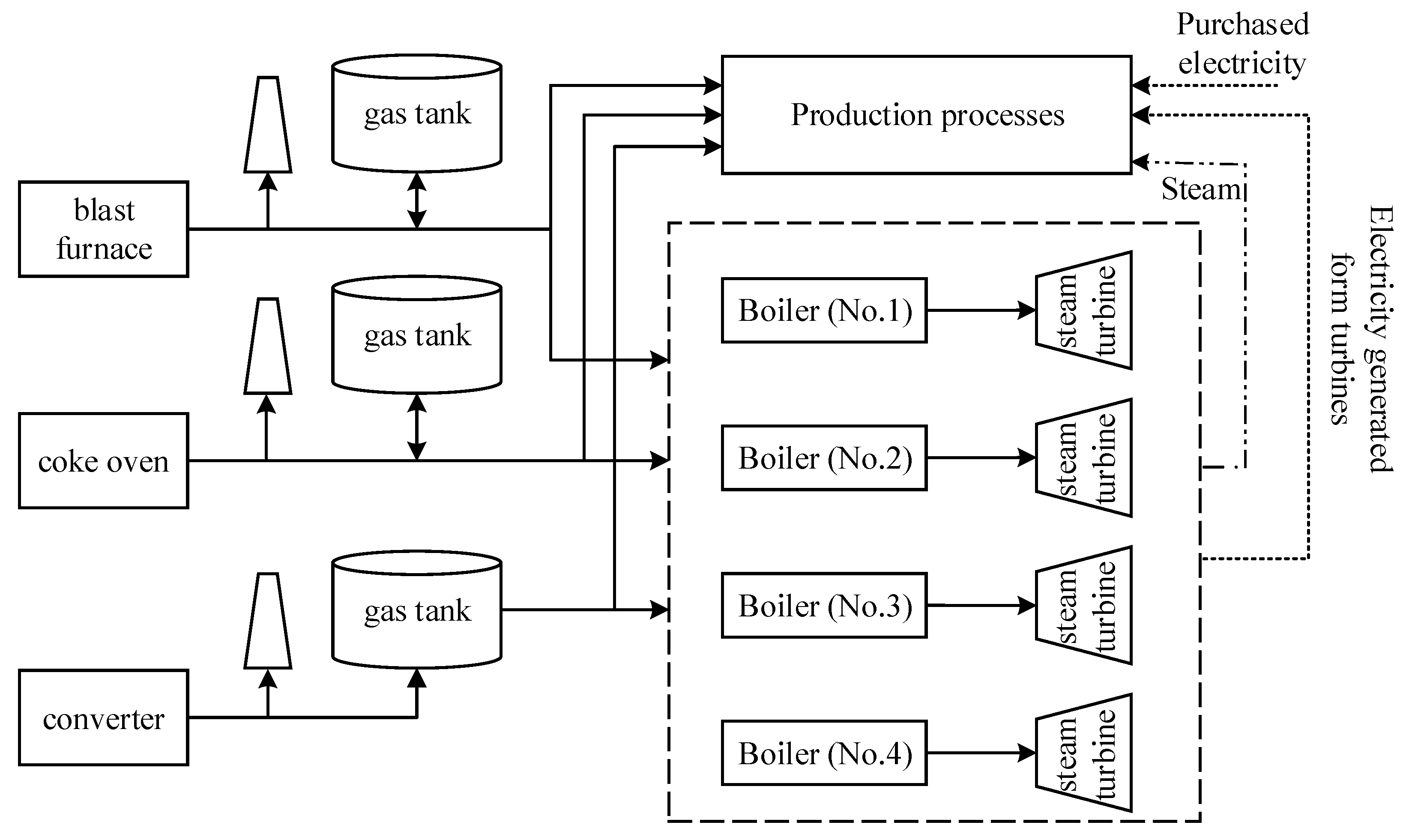

As shown in

Figure 1, byproduct gas generated in iron and steel plant includes blast furnace gas (BFG), coke oven gas (COG), and Linz-Donawitz converters gas (LDG). After the byproduct gas is produced, it is transported to various production units through the gas pipe network to provide the necessary energy. The remaining gas is sent to the gas boiler of the self-owned power plant to generate electricity through a steam turbine. The gasholder is a storage device in the gas system, which plays a role of buffer. Byproduct gas is first supplied to production equipment. And the gas consumption of production equipment cannot be controlled by the operators of the byproduct distribution system. Then the surplus gas is consumed by boilers in the power plant. The power plant consumption can be controlled following the scheduling plan.

The optimization problem of byproduct gas distribution is to find a solution that maintains the stability of the byproduct gas system and minimizes the electricity purchasing. The stability of the byproduct gas system includes the gasholder stability and the boiler operation stability. The amount of gas in the gasholder is expected to be maintained near the normal level to avoid gas shortage and emission. The stability of boilers is achieved by minimize the switching times of the burners. In recent years, some studies have been performed on optimal distribution of byproduct gas.

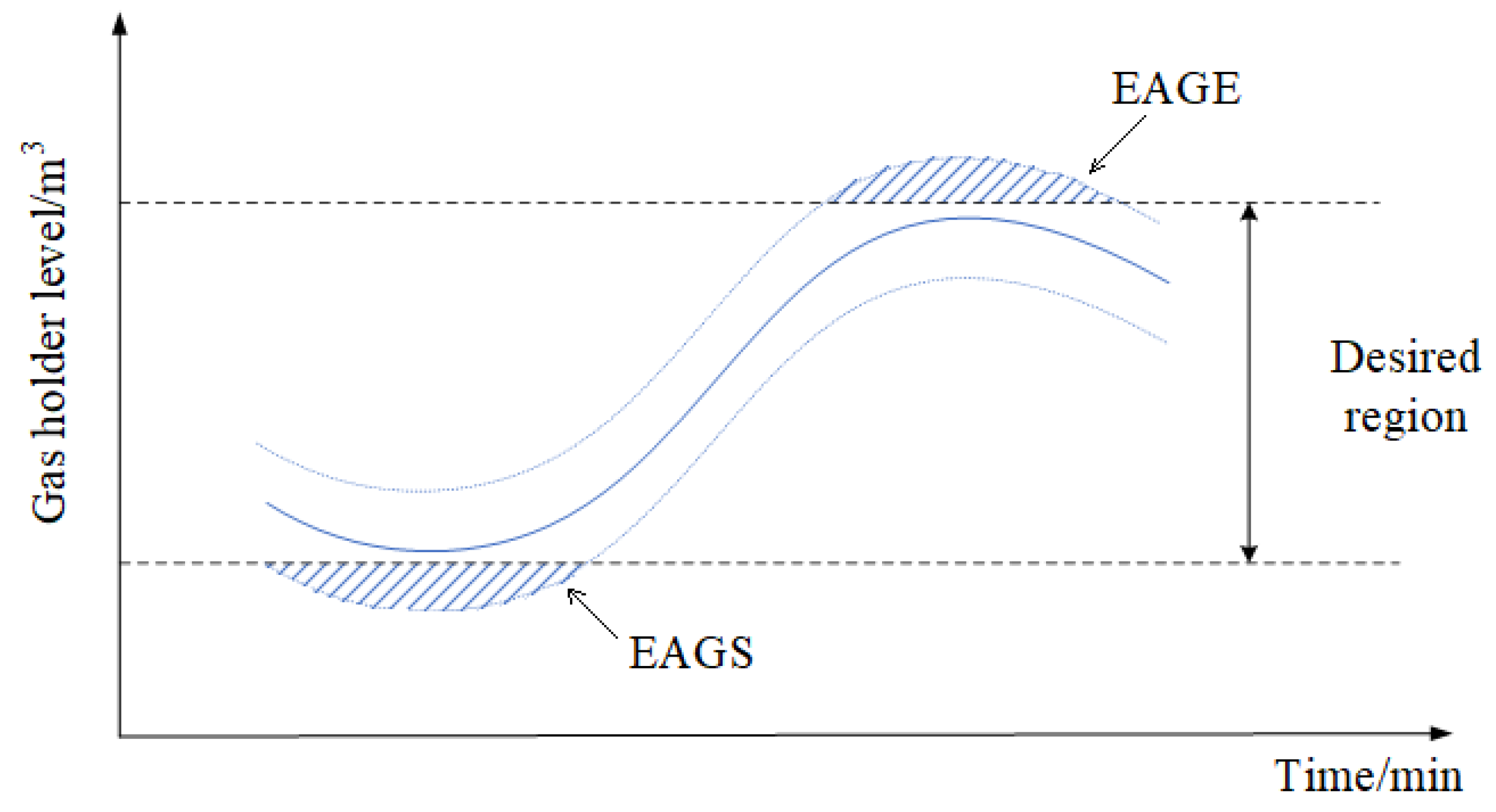

The models of byproduct gas system scheduling are mainly based upon the forecasting of gas generation and consumption. Since the gas generation and consumption fluctuate greatly, the prediction error of the gas generation and consumption is inevitable. Therefore, the scheduling process is faced with many uncertainties. As shown in

Figure 2, if the predicted value is completely accurate, the gas holder could be maintained within the safe region. For example, affected by the uncertainties of gas generation and consumption, the holder level may be lower than the minimum safe level (named expected additional gas shortage, EAGS) or upper than the maximum safe level (named expected additional gas excess, EAGE), which leads to the risk of byproduct gas shortage or emission. A simple way to solve this problem is to reserve part of gas holder volume. Nevertheless, the reserved volume reduces the adjustable volume of the gas holder, resulting in an increase of the system operation cost. Therefore, to deal with the uncertainties, the risk of byproduct gas shortage or emission should be controlled within a certain range, and the benefit and the risk are expected to be balanced.

4. Model Establishment for Byproduct Gas Scheduling

4.1. Fuzzy Variables in Byproduct Gas System

One of the main characters of the fuzzy approach is that uncertain parameters can be expressed by fuzzy variables. In our work, triangle membership function is applied to express the generation and consumption of byproduct gas. The maximum, minimum, and the most possible values of the generation and consumption of byproduct gas can be obtained by forecasting tools [

19,

20,

21,

22]. Fuzzy parameters of the byproduct gas generation and consumption can be stated as follows.

In the upper equations, and are fuzzy parameters of byproduct gas generation and consumption at time t, and are the predicted values of byproduct gas generation and consumption at time t. and are the upper bounds, and are the lower bounds. − and − correspond to the scaling factors of byproduct gas generation and consumption respectively.

4.2. Objective Function

According to the analysis of

Section 3, the formulated objective function aims to minimize the operation cost of the byproduct gas system. The operation cost includes the gasholder penalty cost, the burner switching cost, and the electricity purchasing cost. Accordingly, the operation cost is expressed as follows.

In Equation (13), the first term denotes the gasholder deviation cost and byproduct gas flaring cost. shows the difference between the current gasholder level and the normal gasholder level. indicates the amount of byproduct gas emission. The second term denotes the burner switching cost. is the number of burner switches of boilers. The third part states purchased electricity cost. is the demand for electricity and denotes the amount of electricity generated by power plants. is the unit cost of electricity.

4.3. Constraints

4.3.1. Constraints of Gas Holders

The mass balance constraint of gas holders is as follows:

is the gasholder level at time

t and

is the gasholder level at time

t − 1. The difference of the gasholder level between the two periods

equals to the surplus amount of the byproduct gas (the generation

minus the consumption

) minus the sum of the gas consumption in boilers

, and then minus the gas emission amount,

.

To prevent operational risks in the gasholder, it is necessary to restrict the safety range of the gasholder. Equations (15) and (16) represents the safety constraints.

represents the minimum safe level of the gasholder, and

represents the maximum safe level of the gasholder in Equation (16).

In deterministic models, the amount of gas production and consumption are expressed by predicted values, and the predicted values are assumed to be error-free in Equations (15) and (16). However, the scheduling results may have the risk of violating the safety constraints if prediction errors are not considered. In our work, the uncertainty of gas generation and consumption predictions are considered, and fuzzy variables are used to express the generation and consumption of byproduct gas. The credibility chance constraint of the gasholder can be expressed as follows:

The confidence level α is used to characterize the credibility of constraint satisfaction. The confidence level reflects the decision maker’s expectation of constraint satisfaction. According to

Section 2.2, Equations (17) and (18) can be converted to the following crisp equivalents.

4.3.2. Constraints of Boilers and Turbines

The surplus byproduct gas is used as fuel of the boilers. The energy and mass balance constraints of boilers are as follows.

Equation (21) represents the energy balance of boilers. The amount of thermal energy generated by byproduct gas burning in a boiler is equal to the value of energy used to heat the water into steam. Due to the energy losses in the process, the efficiency of the boiler is taken into account. indicates the amount of steam generated by the boiler, is the amount of water in the boiler. Equation (23) states that the amount of byproduct gas consumed by the boiler equals to the gas consumption volume in each burner multiplied by the number of the open burners in period t.

In the power plant, steam is used to generate electricity through the turbines. The energy and mass balance in the power generation process can be expressed as follows.

In Equation (24), the electricity generated by the steam turbine is equal to the amount of steam into the turbine multiplied by enthalpy of steam and the efficiency of the turbine . Steam balance is expressed by Equation (26). represents the demand for steam in the production process.

According to Equations (13), (14), (19)–(26), the by-product gas optimization scheduling model is established based on fuzzy chance constrained optimization.

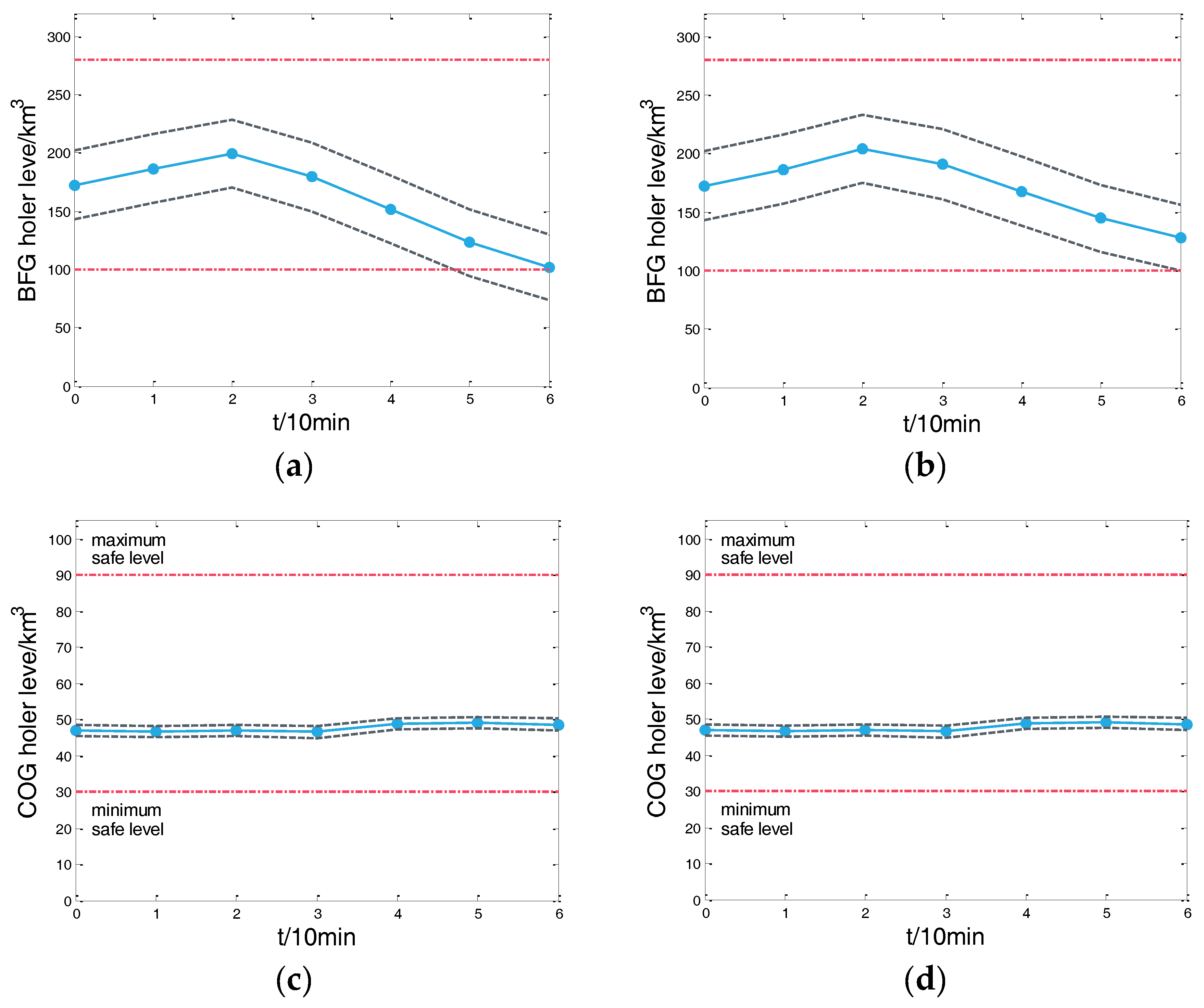

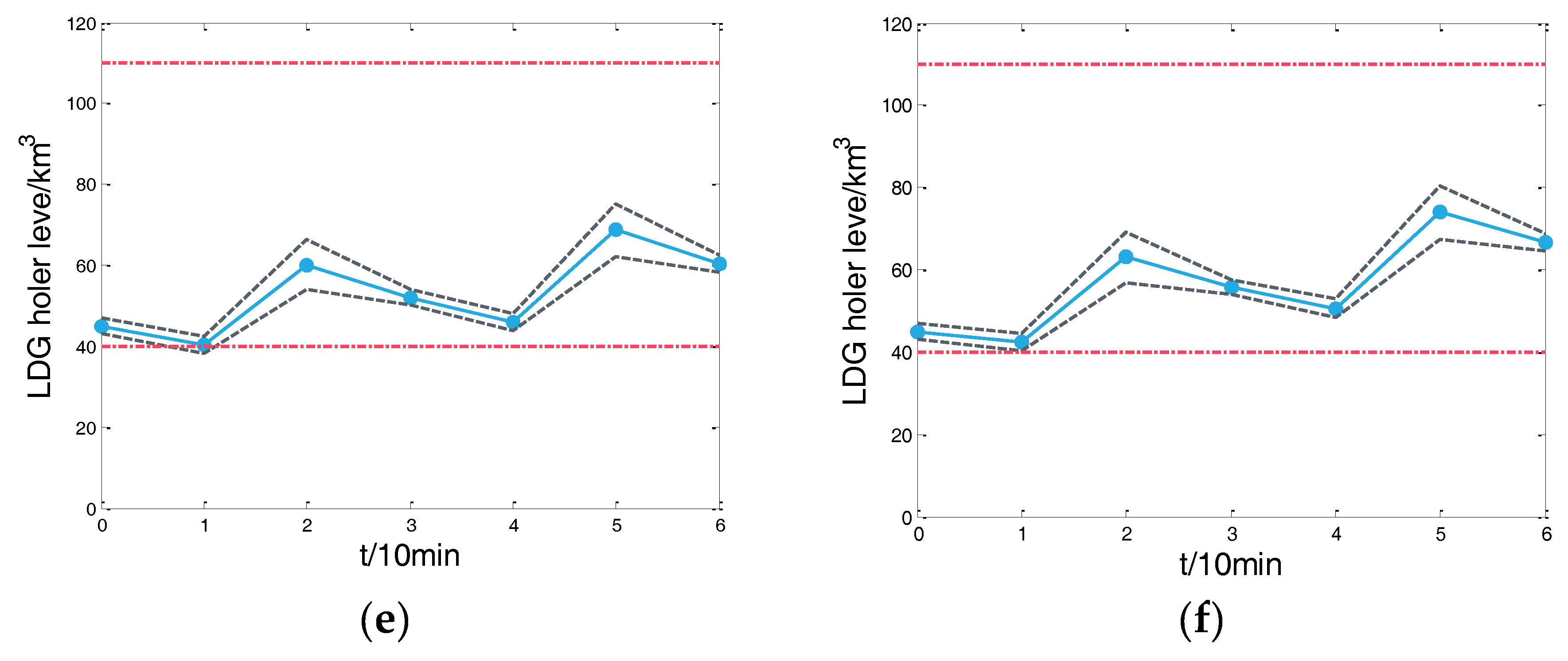

5. Risk Analysis of Byproduct Gas System Scheduling

Although the constraints are satisfied with a certain confidence level, there still exists the risk of gas shortage or excess during byproduct gas dispatching. In this section, the risk of gas shortage and excess is quantified, and then the risk cost is defined. Furthermore, the appropriate confidence level is selected by making a compromise between the operating cost and risk cost of the system.

According to Equation (14), the gas holder level can be expressed as follows.

According to additional rules of the fuzzy variables, the gasholder level is a triangle fuzzy variable

expressed as

, here

According to

Section 2.3, the credibility density function of

is

The risk of byproduct gas scheduling mainly includes the risk of EAGS and the risk of EAGE, which can be seen in the

Section 3,

Figure 2. The risks of EAGS and EAGE as follows:

Accordingly, the risk cost (

RC) of byproduct gas system is defined as

and represent the risk coefficients, which can be determined by actual situations. In our work, and were set to and respectively. The meaning of the variables mentioned above can be seen in the Nomenclature.