Continuous Hydrothermal Liquefaction of Biomass in a Novel Pilot Plant with Heat Recovery and Hydraulic Oscillation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Feedstock Pre-Treatment

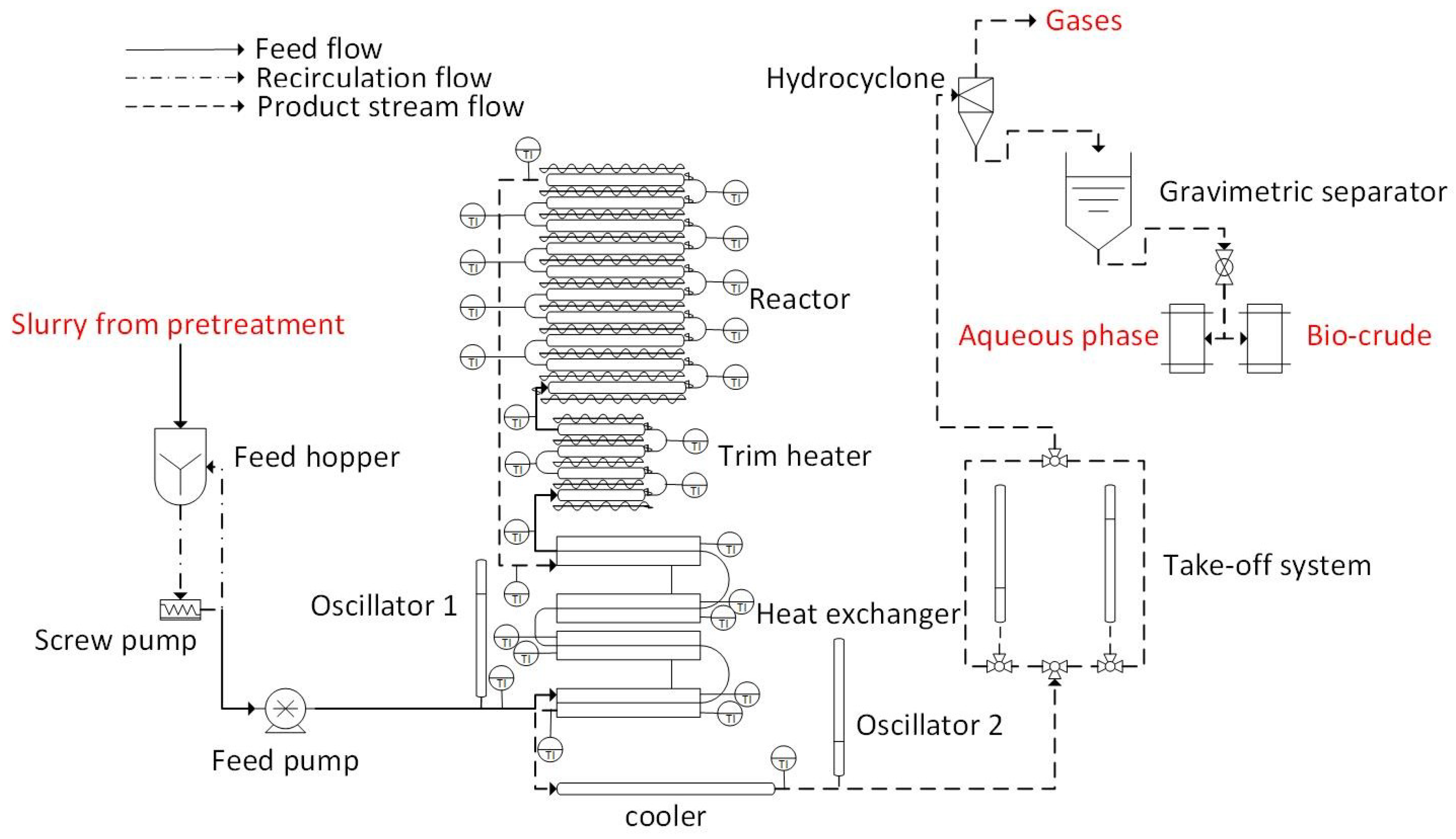

2.3. HTL Reactor System Description and Procedure

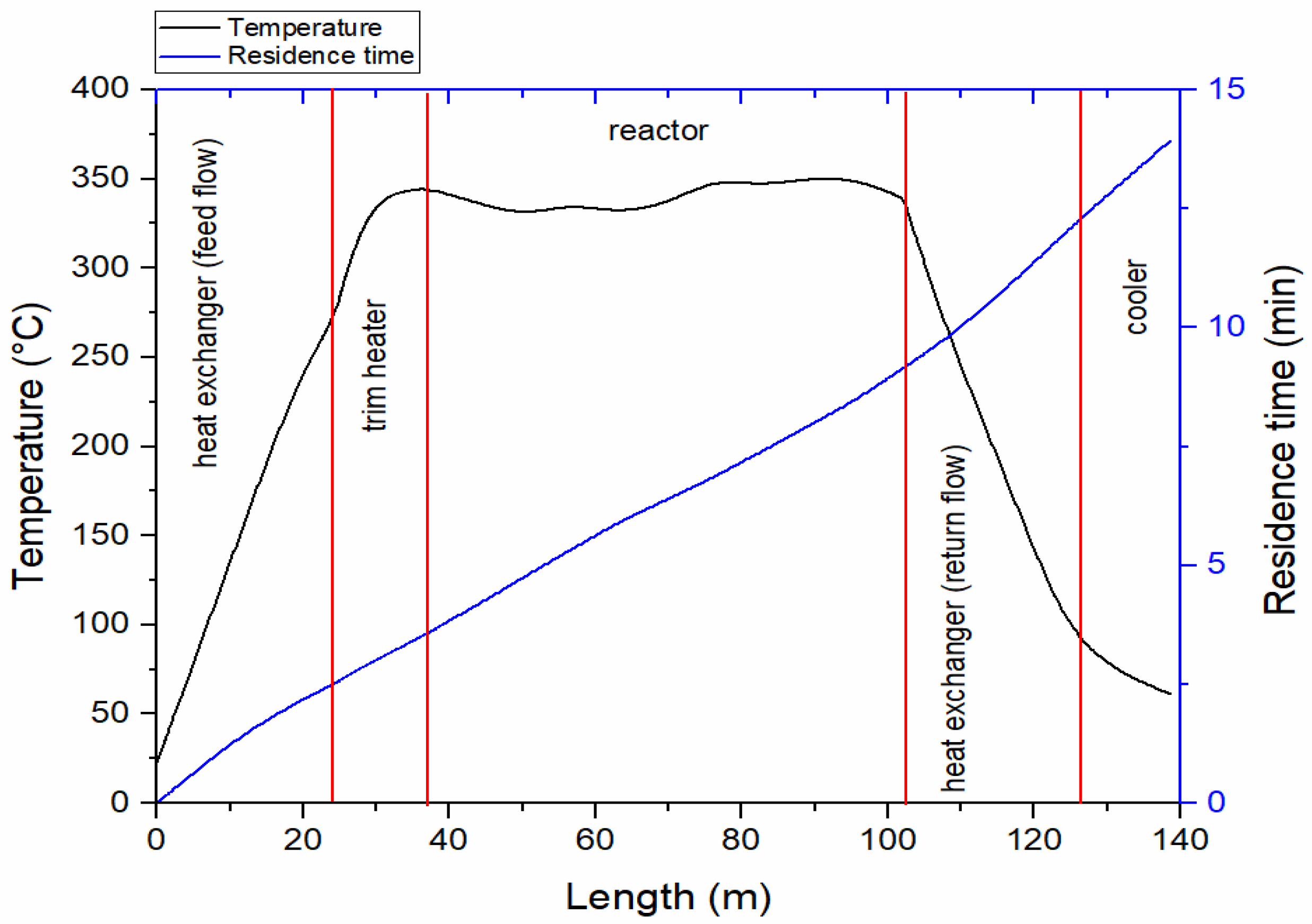

2.4. Residence Time and Energy Efficiency Calculations

2.5. Sample Work-Up and Analysis

3. Results and Discussion

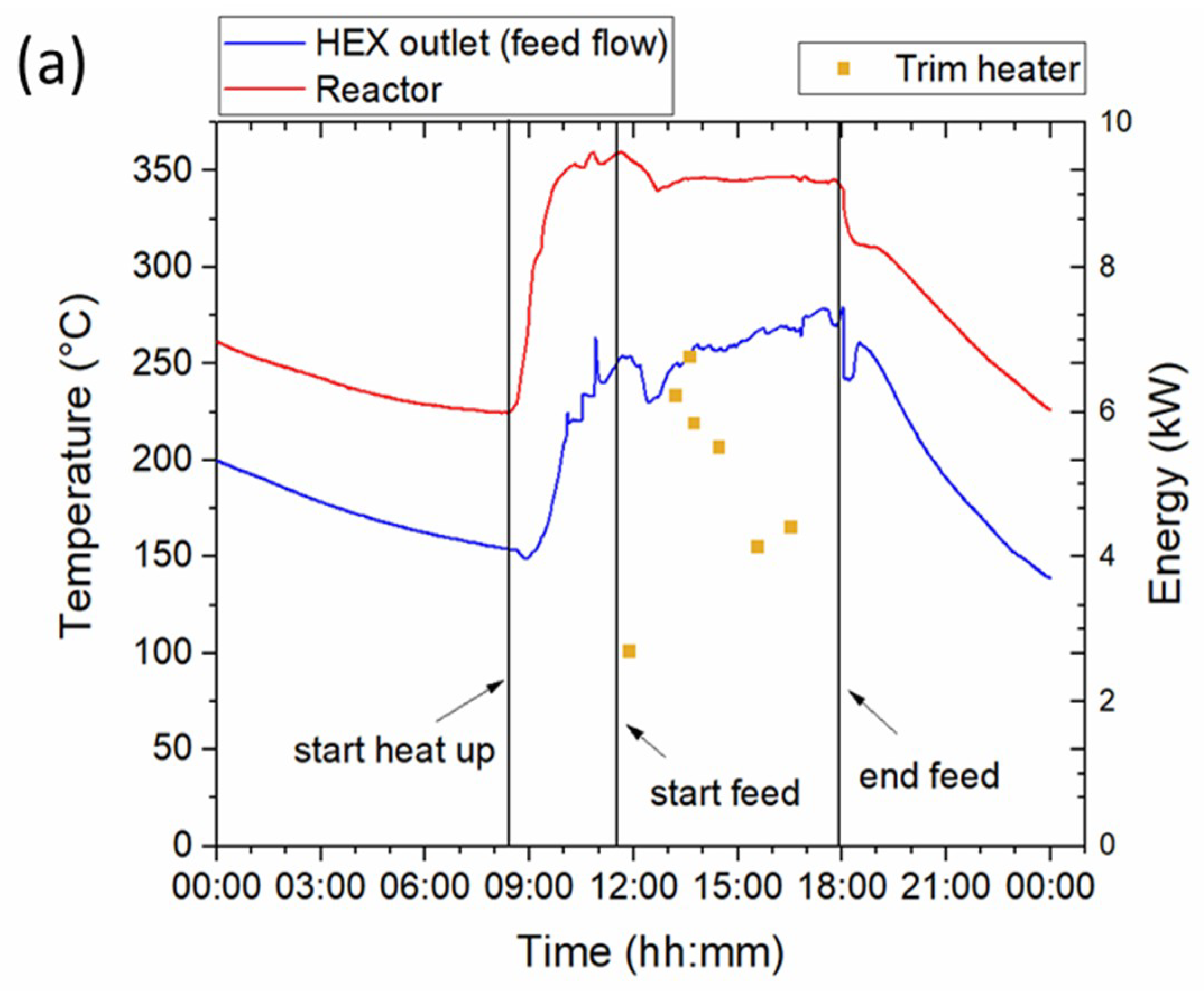

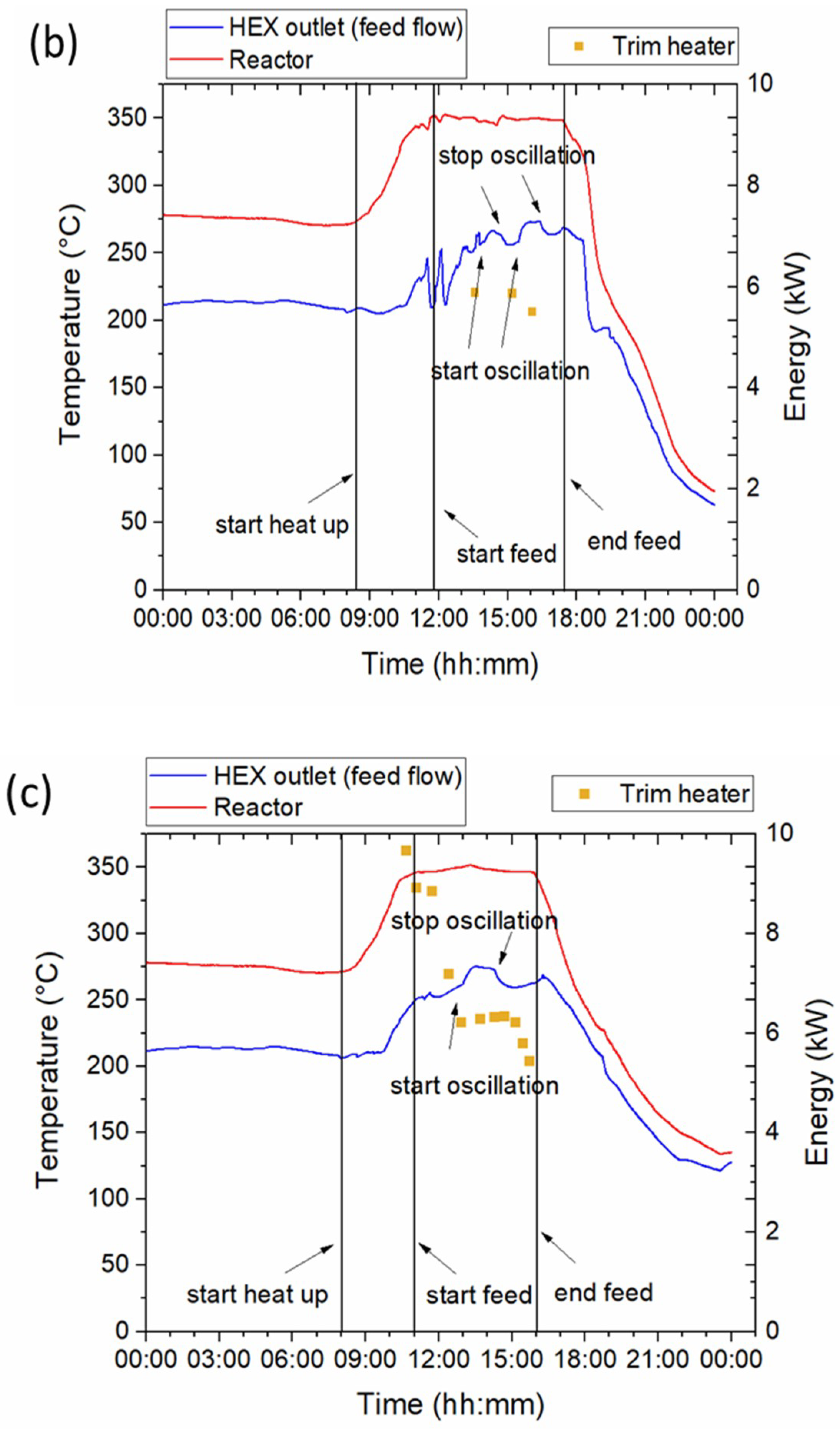

3.1. Reactor Performance

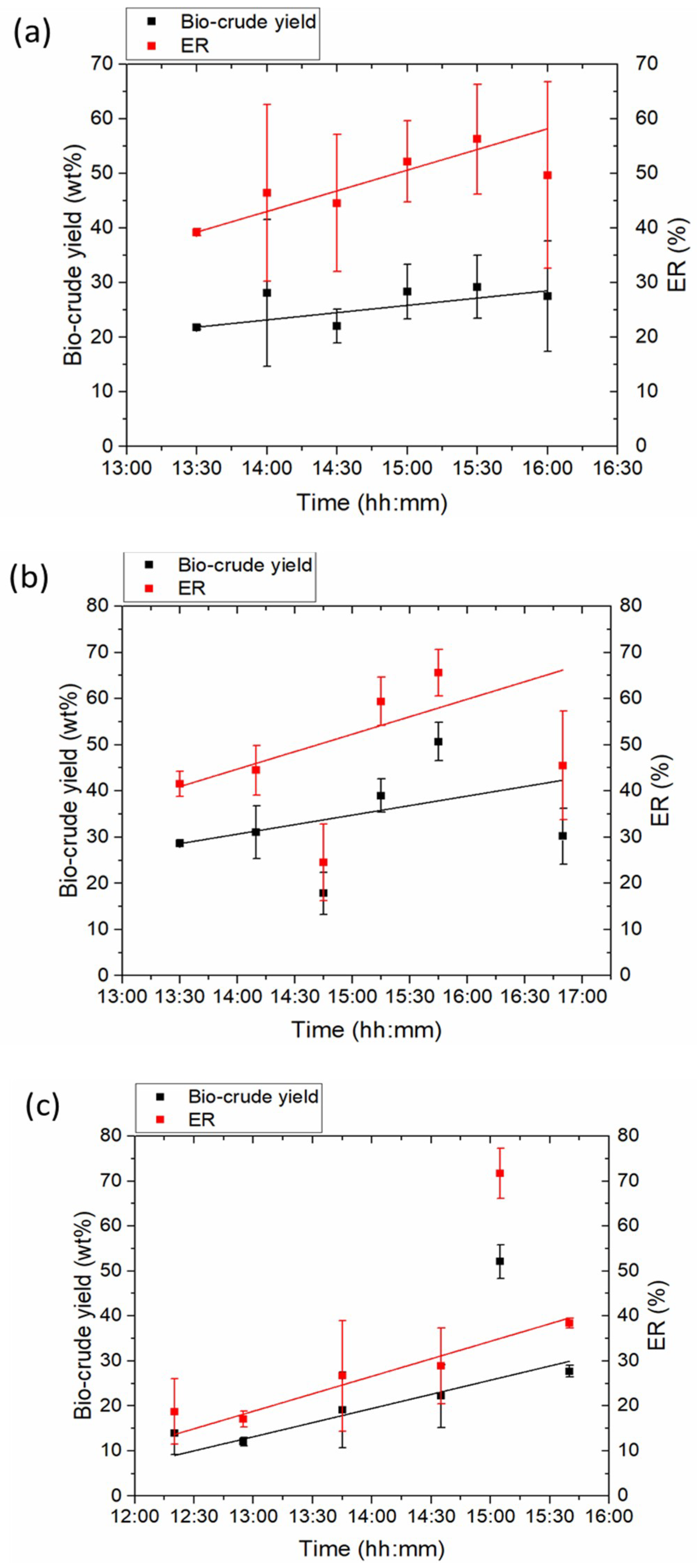

3.2. Bio-Crude Yields and Analysis

3.3. Energy Considerations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Savage, P.E.; Levine, R.B.; Huelsman, C.M. Hydrothermal Processing of Biomass for Biofuels. In Thermochemical Conversion of Biomass to Liquid Fuels and Chemicals; Crocker, M., Ed.; Royal Society of Chemistry: London, UK, 2010; pp. 192–221. [Google Scholar]

- Zhu, Y.; Biddy, M.J.; Jones, S.B.; Elliott, D.C.; Schmidt, A.J. Techno-economic analysis of liquid fuel production from woody biomass via hydrothermal liquefaction (HTL) and upgrading. Appl. Energy 2014. [Google Scholar] [CrossRef]

- Elliott, D.C.; Biller, P.; Ross, A.B.; Schmidt, A.J.; Jones, S.B. Hydrothermal liquefaction of biomass: Developments from batch to continuous process. Bioresour. Technol. 2015, 178, 147–156. [Google Scholar] [CrossRef] [PubMed]

- Ramirez, J.A.; Brown, R.J.; Rainey, T.J. Liquefaction biocrudes and their petroleum crude blends for processing in conventional distillation units. Fuel Process. Technol. 2017, 167, 674–683. [Google Scholar] [CrossRef]

- Pedersen, T.H.; Jensen, C.U.; Sandström, L.; Rosendahl, L.A. Full characterization of compounds obtained from fractional distillation and upgrading of a HTL biocrude. Appl. Energy 2017, 202, 408–419. [Google Scholar] [CrossRef]

- Lappa, E.; Christensen, P.S.; Klemmer, M.; Becker, J.; Iversen, B.B. Hydrothermal liquefaction of Miscanthus × Giganteus: Preparation of the ideal feedstock. Biomass Bioenergy 2016, 87, 17–25. [Google Scholar] [CrossRef]

- Zhong, C.; Wei, X. A comparative experimental study on the liquefaction of wood. Energy 2004, 29, 1731–1741. [Google Scholar] [CrossRef]

- Biller, P.; Johannsen, I.; Souza dos Passos, J.; Ottosen, L.D.M. Primary sewage sludge filtration using biomass filter aids and subsequent hydrothermal co-liquefaction. Water Res. 2017, 130, 58–68. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.J.; Yuan, X.Z.; Zhu, H.N.; Li, H.; Liu, Y.; Wang, X.L.; Zeng, G. Comparative studies of thermochemical liquefaction characteristics of microalgae, lignocellulosic biomass and sewage sludge. Energy 2013, 56, 52–60. [Google Scholar] [CrossRef]

- Toor, S.S.; Rosendahl, L.; Nielsen, M.P.; Glasius, M.; Rudolf, A.; Iversen, S.B. Continuous production of bio-oil by catalytic liquefaction from wet distiller’s grain with solubles (WDGS) from bio-ethanol production. Biomass Bioenergy 2012. [Google Scholar] [CrossRef]

- Ross, A.B.; Biller, P.; Kubacki, M.L.; Li, H.; Lea-Langton, A.; Jones, J.M. Hydrothermal processing of microalgae using alkali and organic acids. Fuel 2010. [Google Scholar] [CrossRef]

- Biller, P.; Ross, A.B. Potential yields and properties of oil from the hydrothermal liquefaction of microalgae with different biochemical content. Bioresour. Technol. 2011. [Google Scholar] [CrossRef] [PubMed]

- Jazrawi, C.; Biller, P.; Ross, A.B.; Montoya, A.; Maschmeyer, T.; Haynes, B.S. Pilot plant testing of continuous hydrothermal liquefaction of microalgae. Algal Res. 2013. [Google Scholar] [CrossRef]

- Anastasakis, K.; Ross, A.B. Hydrothermal liquefaction of the brown macro-alga Laminaria Saccharina: Effect of reaction conditions on product distribution and composition. Bioresour. Technol. 2011. [Google Scholar] [CrossRef] [PubMed]

- Anastasakis, K.; Ross, A.B. Hydrothermal liquefaction of four brown macro-algae commonly found on the UK coasts: An energetic analysis of the process and comparison with bio-chemical conversion methods. Fuel 2015, 139. [Google Scholar] [CrossRef]

- Elliott, D.C.; Hart, T.R.; Neuenschwander, G.G.; Rotness, L.J.; Roesijadi, G.; Zacher, A.H.; Magnuson, J.K. Hydrothermal processing of macroalgal feedstocks in continuous-flow reactors. ACS Sustain. Chem. Eng. 2014. [Google Scholar] [CrossRef]

- Raikova, S.; Le, C.D.; Beacham, T.A.; Jenkins, R.W.; Allen, M.J.; Chuck, C.J. Towards a marine biorefinery through the hydrothermal liquefaction of macroalgae native to the United Kingdom. Biomass Bioenergy 2017, 107, 244–253. [Google Scholar] [CrossRef]

- Shuping, Z.; Yulong, W.; Mingde, Y.; Kaleem, I.; Chun, L.; Tong, J. Production and characterization of bio-oil from hydrothermal liquefaction of microalgae Dunaliella tertiolecta cake. Energy 2010. [Google Scholar] [CrossRef]

- Brown, T.M.; Duan, P.; Savage, P.E. Hydrothermal liquefaction and gasification of Nannochloropsis sp. Energy Fuels 2010, 24, 3639–3646. [Google Scholar] [CrossRef]

- Vardon, D.R.; Sharma, B.K.; Scott, J.; Yu, G.; Wang, Z.; Schideman, L.; Zhang, Y.; Strathmann, T.J. Chemical properties of biocrude oil from the hydrothermal liquefaction of Spirulina algae, swine manure, and digested anaerobic sludge. Bioresour. Technol. 2011. [Google Scholar] [CrossRef] [PubMed]

- Snowden-Swan, L.J.; Zhu, Y.; Bearden, M.D.; Seiple, T.E.; Jones, S.B.; Schmidt, A.J.; Billing, J.M.; Hallen, R.T.; Hart, T.R.; Liu, J.; et al. Conceptual Biorefinery Design and Research Targeted for 2022: Hydrothermal Liquefaction Processing of Wet Waste to Fuels; PNNL-27186; Pacific Northwest National Laboratory: Richland, WA, USA, 2017.

- Déniel, M.; Haarlemmer, G.; Roubaud, A.; Weiss-Hortala, E.; Fages, J. Energy valorisation of food processing residues and model compounds by hydrothermal liquefaction. Renew. Sustain. Energy Rev. 2016, 54, 1632–1652. [Google Scholar] [CrossRef]

- Skaggs, R.L.; Coleman, A.M.; Seiple, T.E.; Milbrandt, A.R. Waste-to-Energy biofuel production potential for selected feedstocks in the conterminous United States. Renew. Sustain. Energy Rev. 2018, 82, 2640–2651. [Google Scholar] [CrossRef]

- Marrone, P.A. Genifuel Hydrothermal Processing Bench-Scale Technology Evaluation Project; The Water Research Foundation: Denver, CO, USA, 2016; ISBN 9781780408408. [Google Scholar]

- Gai, C.; Li, Y.; Peng, N.; Fan, A.; Liu, Z. Co-liquefaction of microalgae and lignocellulosic biomass in subcritical water. Bioresour. Technol. 2015, 185, 240–245. [Google Scholar] [CrossRef] [PubMed]

- Elliott, D.C.; Schmidt, A.J.; Hart, T.R.; Billing, J.M. Conversion of a wet waste feedstock to biocrude by hydrothermal processing in a continuous-flow reactor: Grape pomace. Biomass Convers. Biorefinery 2017, 7, 455–465. [Google Scholar] [CrossRef]

- Elliott, D.C.; Hart, T.R.; Schmidt, A.J.; Neuenschwander, G.G.; Rotness, L.J.; Olarte, M.V.; Zacher, A.H.; Albrecht, K.O.; Hallen, R.T.; Holladay, J.E. Process development for hydrothermal liquefaction of algae feedstocks in a continuous-flow reactor. Algal Res. 2013. [Google Scholar] [CrossRef]

- Marrone, P.A.; Elliott, D.C.; Billing, J.M.; Hallen, R.T.; Hart, T.R.; Kadota, P.; Moeller, J.C.; Randel, M.A.; Schmidt, A.J. Bench-scale evaluation of hydrothermal processing technology for conversion of wastewater solids to fuels. Water Environ. Res. 2018, 90, 329–342. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Liang, X.; Jazrawi, C.; Montoya, A.; Yuen, A.; Cole, A.J.; Neveux, N.; Paul, N.A.; de Nys, R.; Maschmeyer, T.; et al. Continuous hydrothermal liquefaction of macroalgae in the presence of organic co-solvents. Algal Res. 2016. [Google Scholar] [CrossRef]

- Pedersen, T.H.; Grigoras, I.F.; Hoffmann, J.; Toor, S.S.; Daraban, I.M.; Jensen, C.U.; Iversen, S.B.; Madsen, R.B.; Glasius, M.; Arturi, K.R.; et al. Continuous hydrothermal co-liquefaction of aspen wood and glycerol with water phase recirculation. Appl. Energy 2016. [Google Scholar] [CrossRef]

- Jensen, C.U.; Rodriguez Guerrero, J.K.; Karatzos, S.; Olofsson, G.; Iversen, S.B. Fundamentals of HydrofactionTM: Renewable crude oil from woody biomass. Biomass Convers. Biorefinery 2017, 7, 495–509. [Google Scholar] [CrossRef]

- Nabi, M.N.; Rahman, M.M.; Islam, M.A.; Hossain, F.M.; Brooks, P.; Rowlands, W.N.; Tulloch, J.; Ristovski, Z.D.; Brown, R.J. Fuel characterisation, engine performance, combustion and exhaust emissions with a new renewable Licella biofuel. Energy Convers. Manag. 2015, 96, 588–598. [Google Scholar] [CrossRef]

- ChemistryViews. First Commercial-Scale Cat-HTRTM Plant. Available online: https://www.chemistryviews.org/details/news/986073/First_Commercial-Scale_Cat-HTR_Plant.html (accessed on 28 August 2018).

- Pilot Project to Turn Biosolids into Crude Oil. Available online: https://www.sustainabilitymatters.net.au/content/energy/news/pilot-project-to-turn-biosolids-into-crude-oil-763693234 (accessed on 3 September 2018).

- The Silver in Silva: The Story of Steeper Energy and SGF’s’s $59M Advanced Biofuels Project in Norway: Biofuels Digest. Available online: http://www.biofuelsdigest.com/bdigest/2018/01/16/the-silver-in-silva-the-story-of-steeper-energys-59m-advanced-biofuels-project-in-norway/ (accessed on 28 August 2018).

- Hydrothermal Processing of Wastewater Solids. Available online: http://www.genifuel.com/text/Genifuel Case Study for BlueTech Forum 2018 Innovation Showcase.pdf (accessed on 28 August 2018).

- Johannsen, I.; Adamsen, A.P.S.; Kilsgaard, B.S.; Milkevych, V. A Method and Apparatus for Producing Biofuel in an Oscillating Flow Production Line under Supercritical Fluid Conditions. U.S. Patent Publication No. WO/2016/004958, 14 January 2016. [Google Scholar]

- Johanssen, I.; More, D.; Kilsgaard, B.S. Hydrothermal liquefaction of biomass: A pilot plant. Biofuels 2016, 63–65. [Google Scholar]

- Channiwala, S.A.; Parikh, P.P. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 2002. [Google Scholar] [CrossRef]

- Berglin, E.J.; Enderlin, C.W.; Schmidt, A.J. Review and Assessment of Commercial Vendors/Options for Feeding and Pumping Biomass Slurries for Hydrothermal Liquefaction; PNNL-21981; Pacific Northwest National Laboratory: Richland, WA, USA, 2012.

- Madsen, R.B.; Anastasakis, K.; Biller, P.; Glasius, M. Rapid determination of water, total acid number and phenolics content in bio-crude from hydrothermal liquefaction of biomass using FT-IR. Energy Fuels 2018, 32, 7660–7669. [Google Scholar] [CrossRef]

- Faeth, J.L.; Valdez, P.J.; Savage, P.E. Fast hydrothermal liquefaction of Nannochloropsis sp. to produce biocrude. Energy Fuels 2013. [Google Scholar] [CrossRef]

- Gollakota, A.; Savage, P.E. Hydrothermal Liquefaction of Model Food Waste Biomolecules and Ternary Mixtures under Isothermal and Fast Conditions. ACS Sustain. Chem. Eng. 2018, 6, 9018–9027. [Google Scholar] [CrossRef]

- Biller, P.; Sharma, B.K.; Kunwar, B.; Ross, A.B. Hydroprocessing of bio-crude from continuous hydrothermal liquefaction of microalgae. Fuel 2015. [Google Scholar] [CrossRef]

- Xu, D.; Savage, P.E. Characterization of biocrudes recovered with and without solvent after hydrothermal liquefaction of algae. Algal Res. 2014, 6, 1–7. [Google Scholar] [CrossRef]

- Jena, U.; Das, K.C.; Kastner, J.R. Effect of operating conditions of thermochemical liquefaction on biocrude production from Spirulina platensis. Bioresour. Technol. 2011. [Google Scholar] [CrossRef] [PubMed]

- Pedersen, T.H.; Rosendahl, L.A. Production of fuel range oxygenates by supercritical hydrothermal liquefaction of lignocellulosic model systems. Biomass Bioenergy 2015, 83, 206–215. [Google Scholar] [CrossRef]

- Madsen, R.B.; Biller, P.; Jensen, M.M.; Becker, J.; Iversen, B.B.; Glasius, M. Predicting the Chemical Composition of Aqueous Phase from Hydrothermal Liquefaction of Model Compounds and Biomasses. Energy Fuels 2016. [Google Scholar] [CrossRef]

- Madsen, R.B.; Zhang, H.; Biller, P.; Goldstein, A.H.; Glasius, M. Characterizing Semivolatile Organic Compounds of Biocrude from Hydrothermal Liquefaction of Biomass. Energy Fuels 2017, 31, 4122–4134. [Google Scholar] [CrossRef]

- Chen, K.; Lyu, H.; Hao, S.; Luo, G.; Zhang, S.; Chen, J. Separation of phenolic compounds with modified adsorption resin from aqueous phase products of hydrothermal liquefaction of rice straw. Bioresour. Technol. 2015, 182, 160–168. [Google Scholar] [CrossRef] [PubMed]

- Panisko, E.; Wietsma, T.; Lemmon, T.; Albrecht, K.; Howe, D. Characterization of the aqueous fractions from hydrotreatment and hydrothermal liquefaction of lignocellulosic feedstocks. Biomass Bioenergy 2015. [Google Scholar] [CrossRef]

- Jarvis, J.M.; Albrecht, K.O.; Billing, J.M.; Schmidt, A.J.; Hallen, R.T.; Schaub, T.M. Assessment of Hydrotreatment for Hydrothermal Liquefaction Biocrudes from Sewage Sludge, Microalgae, and Pine Feedstocks. Energy Fuels 2018, 32, 8483–8493. [Google Scholar] [CrossRef]

- Jensen, C.U.; Hoffmann, J.; Rosendahl, L.A. Co-processing potential of HTL bio-crude at petroleum refineries. Part 2: A parametric hydrotreating study. Fuel 2015. [Google Scholar] [CrossRef]

- Kapusta, K. Effect of ultrasound pretreatment of municipal sewage sludge on characteristics of bio-oil from hydrothermal liquefaction process. Waste Manag. 2018, 78, 183–190. [Google Scholar] [CrossRef]

- Prajitno, H.; Park, J.; Ryu, C.; Park, H.Y.; Lim, H.S.; Kim, J. Effects of solvent participation and controlled product separation on biomass liquefaction: A case study of sewage sludge. Appl. Energy 2018, 218, 402–416. [Google Scholar] [CrossRef]

- Toor, S.S.; Reddy, H.; Deng, S.; Hoffmann, J.; Spangsmark, D.; Madsen, L.B.; Holm-Nielsen, J.B.; Rosendahl, L.A. Hydrothermal liquefaction of Spirulina and Nannochloropsis salina under subcritical and supercritical water conditions. Bioresour. Technol. 2013, 131, 413–419. [Google Scholar] [CrossRef] [PubMed]

- Jensen, C.U. PIUS—Hydrofaction Platform with Integrated Upgrading Step; Ph.D. Serien for Det Ingeniør- og Naturvidenskabelige Fakultet; Aalborg Universitetsforlag: Aalborg, Denmark, 2018. [Google Scholar]

- Bjelić, S.; Yu, J.; Iversen, B.B.; Glasius, M.; Biller, P. Detailed Investigation into the Asphaltene Fraction of Hydrothermal Liquefaction Derived Bio-Crude and Hydrotreated Bio-Crudes. Energy Fuels 2018, 32, 3579–3587. [Google Scholar] [CrossRef]

| Miscanthus | Spirulina | Sewage Sludge | |

|---|---|---|---|

| Ash (wt%, dry) | 2.7 | 6.5 | 12.5 |

| C (wt%, dry) | 49.1 | 50.6 | 46.5 |

| H (wt%, dry) | 3.8 | 7 | 6.1 |

| N (wt%, dry) | 0.7 | 11.8 | 3.3 |

| S (wt%, dry) | 0.2 | 0.8 | 0.4 |

| O * (wt%, dry) | 43.5 | 23.3 | 31.2 |

| HHV (MJ/kg) | 17.1 | 23.3 | 19.8 |

| Feedstock | Extrusion | Catalyst (KOH 1.4 wt%) | CMC (0.25 wt%) | Slurry Mass (kg) | Slurry Dry Matter (wt%) |

|---|---|---|---|---|---|

| Miscanthus | Yes | Yes | Yes | 250 | 15.0 |

| Spirulina | No | No | No | 250 | 16.4 |

| Sewage sludge | No | No | No | 500 | 4.0 |

| Time | Miscanthus HR (%) | Spirulina HR (%) | Sewage Sludge HR (%) |

|---|---|---|---|

| 11:00–12:00 | 72.8 | ||

| 12:00–13:00 | 69.1 | 66.5 | 73.7 |

| 13:00–14:00 | 73.3 | 73.1 | 77.9 a |

| 13:20–14:20 | 78.5 a | ||

| 14:00–15:00 | 74.8 | 75.5 | 76.7 a |

| 15:00–16:00 | 76.7 | 75.5 | 75.3 |

| 16:00–17:00 | 77.6 | 76.9 | |

| 17:00–18:00 | 79.9 | 77.5 | |

| Average | 75.2 | 74.2 | 75.3 |

| Bio-Crude Yield (wt%) | C (wt%) (db) | ± | H (wt%) (db) | ± | N (wt%) (db) | ± | S (wt%) (db) | ± | O * (wt%) (db) | HHV (MJ/kg) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Miscanthus | |||||||||||

| MIS-1-a | 21.6 | 69.2 | 1.1 | 6.9 | 0.18 | 1.2 | 0.04 | 0.29 | 0.05 | 17.9 | 30.5 |

| MIS-1-b | 22.1 | 67.1 | 0.5 | 6.6 | 0.14 | 1.2 | 0.01 | 0.22 | 0.04 | 19.7 | 29.1 |

| MIS-2-a | 18.6 | 70.2 | 1.4 | 7.2 | 0.04 | 1.2 | 0.01 | 0.28 | 0.02 | 17.2 | 31.2 |

| MIS-2-b | 37.6 | 59.8 | 5.0 | 6.4 | 1.19 | 1.0 | 0.15 | 0.18 | 0.05 | 26.7 | 25.6 |

| MIS-3-a | 24.2 | 77.9 | 10.3 | 8.4 | 0.13 | 1.3 | 0.13 | 0.15 | 0.08 | 7.4 | 36.6 |

| MIS-3-b | 19.9 | 66.0 | 0.6 | 6.9 | 0.39 | 1.0 | 0.01 | 0.13 | 0.09 | 17.1 | 29.8 |

| MIS-4-a | 24.8 | 69.6 | 3.6 | 6.9 | 0.65 | 1.2 | 0.08 | 0.17 | 0.05 | 14.1 | 31.4 |

| MIS-4-b | 31.9 | 66.9 | 3.3 | 7.3 | 0.32 | 1.1 | 0.07 | 0.19 | 0.02 | 19.9 | 29.8 |

| MIS-5-a | 33.3 | 69.7 | 0.4 | 7.7 | 0.10 | 1.1 | 0.01 | 0.14 | 0.01 | 17.3 | 31.6 |

| MIS-5-b | 25.1 | 72.2 | 1.9 | 7.5 | 0.52 | 1.2 | 0.06 | 0.20 | 0.01 | 15.0 | 32.5 |

| MIS-6-a | 20.4 | 67.7 | 2.9 | 7.7 | 0.02 | 1.1 | 0.06 | 0.16 | 0.00 | 19.1 | 30.7 |

| MIS-6-b | 34.7 | 65.7 | 2.2 | 7.5 | 0.58 | 1.1 | 0.10 | 0.15 | 0.03 | 20.8 | 29.6 |

| Average | 26.2 | 68.5 | 2.8 | 7.3 | 0.35 | 1.2 | 0.06 | 0.19 | 0.04 | 17.7 | 30.7 |

| Spirulina | |||||||||||

| SP-1-a | 28.1 | 68.2 | 2.0 | 8.9 | 0.45 | 6.3 | 0.15 | 1.04 | 0.06 | 15.5 | 32.7 |

| SP-1-b | 29.2 | 69.7 | 1.0 | 9.6 | 0.37 | 6.5 | 0.10 | 1.28 | 0.06 | 9.9 | 34.6 |

| SP-2-a | 35.1 | 68.9 | 5.9 | 7.7 | 0.16 | 6.8 | 0.62 | 1.23 | 0.19 | 11.1 | 31.9 |

| SP-2-b | 27.0 | 74.7 | 1.6 | 7.8 | 0.06 | 7.6 | 0.31 | 1.26 | 0.06 | 2.8 | 34.9 |

| SP-3-a | 14.6 | 60.7 | 0.6 | 8.4 | 0.39 | 5.9 | 0.04 | 1.21 | 0.04 | 13.1 | 29.6 |

| SP-3-b | 21.0 | 69.2 | 0.1 | 9.2 | 0.08 | 6.5 | 0.06 | 1.23 | 0.01 | 11.1 | 33.6 |

| SP-4-a | 36.4 | 76.4 | 1.1 | 8.1 | 0.21 | 7.3 | 0.22 | 1.07 | 0.06 | 6.6 | 35.5 |

| SP-4-b | 41.5 | 75.3 | 0.5 | 8.3 | 0.39 | 7.2 | 0.18 | 1.19 | 0.05 | 7.3 | 35.3 |

| SP-5-a | 47.7 | 59.1 | 0.3 | 8.9 | 0.17 | 5.7 | 0.16 | 0.88 | 0.04 | 8.8 | 30.1 |

| SP-5-b | 53.6 | 60.8 | 1.6 | 8.3 | 0.57 | 6.0 | 0.04 | 0.96 | 0.06 | 6.6 | 29.9 |

| SP-6-a | 25.9 | 72.6 | 1.6 | 8.1 | 0.28 | 7.1 | 0.04 | 1.06 | 0.00 | 11.4 | 33.3 |

| SP-6-b | 34.4 | 73.0 | 3.6 | 10.0 | 0.05 | 6.8 | 0.08 | 1.07 | 0.17 | 9.5 | 36.3 |

| Average | 32.9 | 69.1 | 1.7 | 8.6 | 0.26 | 6.6 | 0.17 | 1.12 | 0.07 | 9.5 | 33.2 |

| Sewage sludge | |||||||||||

| SS-1-a | 17.4 | 56.5 | 0.1 | 6.9 | 0.02 | 2.2 | 0.06 | 0.42 | 0.05 | 2.3 | 27.0 |

| SS-1-b | 10.6 | 54.2 | 0.3 | 6.3 | 0.20 | 2.2 | 0.01 | 0.37 | 0.02 | 5.2 | 25.2 |

| SS-2-a | 11.3 | 62.4 | 1.2 | 5.5 | 0.06 | 2.6 | 0.04 | 0.49 | 0.03 | 2.9 | 27.5 |

| SS-2-b | 12.7 | 63.7 | 0.3 | 5.7 | 0.24 | 2.7 | 0.04 | 0.45 | 0.01 | 0.5 | 28.3 |

| SS-3-a | 25.0 | 58.0 | 0.1 | 7.1 | 0.21 | 2.4 | 0.03 | 0.47 | 0.05 | 3.3 | 27.8 |

| SS-3-b | 13.1 | 56.6 | 0.4 | 6.9 | 0.07 | 2.2 | 0.01 | 0.59 | 0.06 | 3.8 | 26.9 |

| SS-4-a | 27.2 | 56.7 | 0.4 | 5.7 | 0.11 | 2.4 | 0.01 | 0.47 | 0.02 | 8.2 | 25.2 |

| SS-4-b | 17.3 | 59.0 | 0.0 | 5.6 | 0.06 | 2.6 | 0.05 | 0.47 | 0.02 | 5.3 | 26.1 |

| SS-5-a | 49.4 | 57.3 | 1.9 | 7.2 | 0.47 | 2.3 | 0.08 | 0.45 | 0.05 | 11.1 | 26.9 |

| SS-5-b | 54.8 | 58.0 | 1.2 | 7.1 | 0.13 | 2.4 | 0.06 | 0.51 | 0.06 | 10.6 | 27.1 |

| SS-6-a | 28.6 | 57.3 | 3.1 | 7.1 | 0.15 | 2.3 | 0.11 | 0.49 | 0.06 | 9.8 | 26.9 |

| SS-6-b | 26.8 | 58.3 | 0.3 | 7.2 | 0.05 | 2.5 | 0.05 | 0.51 | 0.04 | 7.7 | 27.6 |

| Average | 24.5 | 58.2 | 0.8 | 6.5 | 0.15 | 2.4 | 0.05 | 0.47 | 0.04 | 5.9 | 26.9 |

| Moisture (wt%) | ± | Ash (wt%) (db) | ± | ER (%) | C in Bio-Crude (wt%) | C in Process Water (wt%) | |

|---|---|---|---|---|---|---|---|

| Miscanthus | |||||||

| MIS-1-a | 18.4 | 1.9 | 2.8 | 0.4 | 39.7 | 30.5 | 29.4 |

| MIS-1-b | 18.1 | 2.4 | 3.3 | 0.0 | 38.7 | 30.2 | 28.2 |

| MIS-2-a | 19.7 | 3.5 | 2.4 | 0.6 | 35.0 | 26.6 | 32.3 |

| MIS-2-b | 15.8 | 0.6 | 3.1 | 0.6 | 57.9 | 45.8 | 29.4 |

| MIS-3-a | 17.4 | 0.3 | 2.5 | 0.1 | 53.4 | 38.4 | 29.1 |

| MIS-3-b | 18.6 | 1.9 | 2.9 | 0.0 | 35.7 | 26.7 | 31.0 |

| MIS-4-a | 22.9 | 2.8 | 3.2 | 0.1 | 46.9 | 35.2 | 30.2 |

| MIS-4-b | 16.8 | 0.3 | 2.8 | 1.4 | 57.4 | 43.5 | 31.3 |

| MIS-5-a | 17.6 | 0.1 | 2.7 | 0.3 | 63.4 | 47.3 | 35.0 |

| MIS-5-b | 22.2 | 4.1 | 2.8 | 0.4 | 49.2 | 37.0 | 34.1 |

| MIS-6-a | 16.6 | 2 | 2.7 | 0.1 | 37.6 | 28.1 | 38.0 |

| MIS-6-b | 15.5 | 0.8 | 3.1 | 0.0 | 61.8 | 46.4 | 40.0 |

| Average | 18.3 | 1.7 | 2.8 | 0.3 | 48.1 | 36.3 | 32.3 |

| Spirulina | |||||||

| SP-1-a | 9.6 | 0.6 | 1.2 | 0.2 | 39.6 | 37.9 | 37.1 |

| SP-1-b | 15.2 | 1.0 | 5.1 | 1.0 | 43.5 | 40.1 | 43.1 |

| SP-2-a | 10.8 | 0.2 | 5.6 | 0.3 | 48.3 | 47.7 | 40.5 |

| SP-2-b | 15.0 | 1.1 | 7.8 | 0.3 | 40.7 | 39.9 | 39.8 |

| SP-3-a | 12.7 | 0.7 | 12.3 | 0.9 | 18.7 | 17.5 | 35.9 |

| SP-3-b | 10.9 | 0.4 | 4.0 | 0.2 | 30.4 | 28.7 | 35.9 |

| SP-4-a | 10.2 | 0.1 | 1.6 | 0.1 | 55.7 | 55.0 | 33.5 |

| SP-4-b | 12.8 | 1.5 | 2.3 | 0.1 | 63.1 | 61.7 | 39.0 |

| SP-5-a | 10.9 | 0.5 | 18.0 | 1.0 | 62.0 | 55.7 | 37.8 |

| SP-5-b | 14.2 | 1.1 | 19.2 | 2.6 | 69.2 | 64.4 | 41.9 |

| SP-6-a | 9.2 | 0.4 | 0.9 | 0.1 | 37.2 | 37.2 | 37.2 |

| SP-6-b | 10.2 | 0.7 | 0.9 | 0.2 | 53.8 | 49.7 | 37.8 |

| Average | 11.8 | 0.7 | 6.6 | 0.6 | 46.8 | 44.6 | 38.3 |

| Sewage sludge | |||||||

| SS-1-a | 13.6 | 0.1 | 33.5 | 2.7 | 23.9 | 21.2 | 39.9 |

| SS-1-b | 15.4 | 1.0 | 33.8 | 1.2 | 13.6 | 12.4 | 32.5 |

| SS-2-a | 14.5 | 0.5 | 27.9 | 1.4 | 15.8 | 15.2 | 38.2 |

| SS-2-b | 14.5 | 0.3 | 28.9 | 0.3 | 18.3 | 17.4 | 33.3 |

| SS-3-a | 14.6 | 1.6 | 30.7 | 0.0 | 35.4 | 31.3 | 33.6 |

| SS-3-b | 16.6 | 1.7 | 32.1 | 0.1 | 17.9 | 16.0 | 30.0 |

| SS-4-a | 14.0 | 0.7 | 28.3 | 1.0 | 34.8 | 33.2 | 26.7 |

| SS-4-b | 13.7 | 0.3 | 28.8 | 0.2 | 22.9 | 22.0 | 31.9 |

| SS-5-a | 13.1 | 1.6 | 23.4 | 0.1 | 67.7 | 61.1 | 38.4 |

| SS-5-b | 12.9 | 0.5 | 23.0 | 0.7 | 75.6 | 68.5 | 36.7 |

| SS-6-a | 13.5 | 0.5 | 24.7 | 0.0 | 39.2 | 35.3 | 40.2 |

| SS-6-b | 13.5 | 0.5 | 25.7 | 0.1 | 37.6 | 33.7 | 36.0 |

| Average | 14.2 | 0.8 | 28.4 | 0.7 | 33.6 | 30.6 | 34.8 |

| Miscanthus | Spirulina | Sewage Sludge | |

|---|---|---|---|

| Flow rate (L/h) | 60 | 60 | 60 |

| DM content | 0.15 | 0.16 | 0.04 |

| Time (h) | 1 | 1 | 1 |

| Feedstock consumed (kg, dry) | 9 | 9.8 | 2.4 |

| Energy in feedstock (kW, dry) | 42.7 (HHV = 17.1MJ/kg) | 63.1 (HHV = 23.3MJ/kg) | 13.2 (HHV = 19.8MJ/kg) |

| Bio-crude yield (wt%) | 26.2 | 32.9 | 24.5 |

| Energy in bio-crude (kW, dry) | 20.1 (HHV = 30.7 MJ/kg) | 29.9 (HHV = 33.2 MJ/kg) | 4.4 (HHV = 26.8 MJ/kg) |

| ηth (%) | 47 | 47.3 | 33.2 |

| Trim heater energy requirement (kW) | 4.4 | 5.5 | 5.4 |

| Reactor energy requirement (kW) | 2 | 2.8 | 2.5 |

| Main pump energy requirement (kW) | 0.7 | 0.7 | 0.7 |

| ηtot (%) | 40.4 | 41.4 | 20.1 |

| EROI | 2.8 | 3.3 | 0.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anastasakis, K.; Biller, P.; Madsen, R.B.; Glasius, M.; Johannsen, I. Continuous Hydrothermal Liquefaction of Biomass in a Novel Pilot Plant with Heat Recovery and Hydraulic Oscillation. Energies 2018, 11, 2695. https://doi.org/10.3390/en11102695

Anastasakis K, Biller P, Madsen RB, Glasius M, Johannsen I. Continuous Hydrothermal Liquefaction of Biomass in a Novel Pilot Plant with Heat Recovery and Hydraulic Oscillation. Energies. 2018; 11(10):2695. https://doi.org/10.3390/en11102695

Chicago/Turabian StyleAnastasakis, Konstantinos, Patrick Biller, René B. Madsen, Marianne Glasius, and Ib Johannsen. 2018. "Continuous Hydrothermal Liquefaction of Biomass in a Novel Pilot Plant with Heat Recovery and Hydraulic Oscillation" Energies 11, no. 10: 2695. https://doi.org/10.3390/en11102695

APA StyleAnastasakis, K., Biller, P., Madsen, R. B., Glasius, M., & Johannsen, I. (2018). Continuous Hydrothermal Liquefaction of Biomass in a Novel Pilot Plant with Heat Recovery and Hydraulic Oscillation. Energies, 11(10), 2695. https://doi.org/10.3390/en11102695