Impacts of the Base-Level Cycle on Pore Structure of Mouth Bar Sand Bars: A Case Study of the Paleogene Kongdian Formation, Bohai Bay Basin, China

Abstract

:1. Introduction

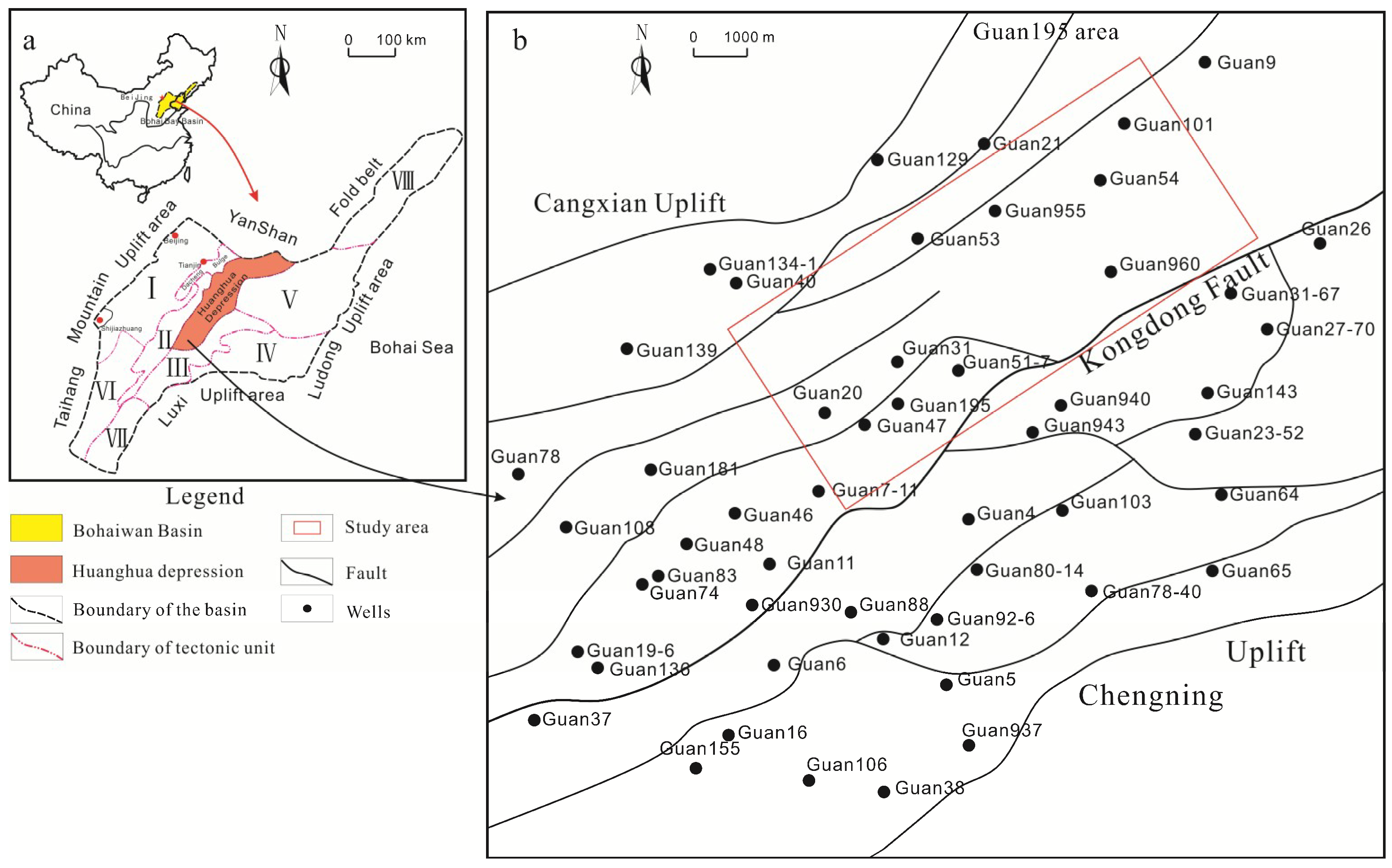

2. Geological Setting

3. Data and Experimental Method

4. Geological and Laboratory Modelling

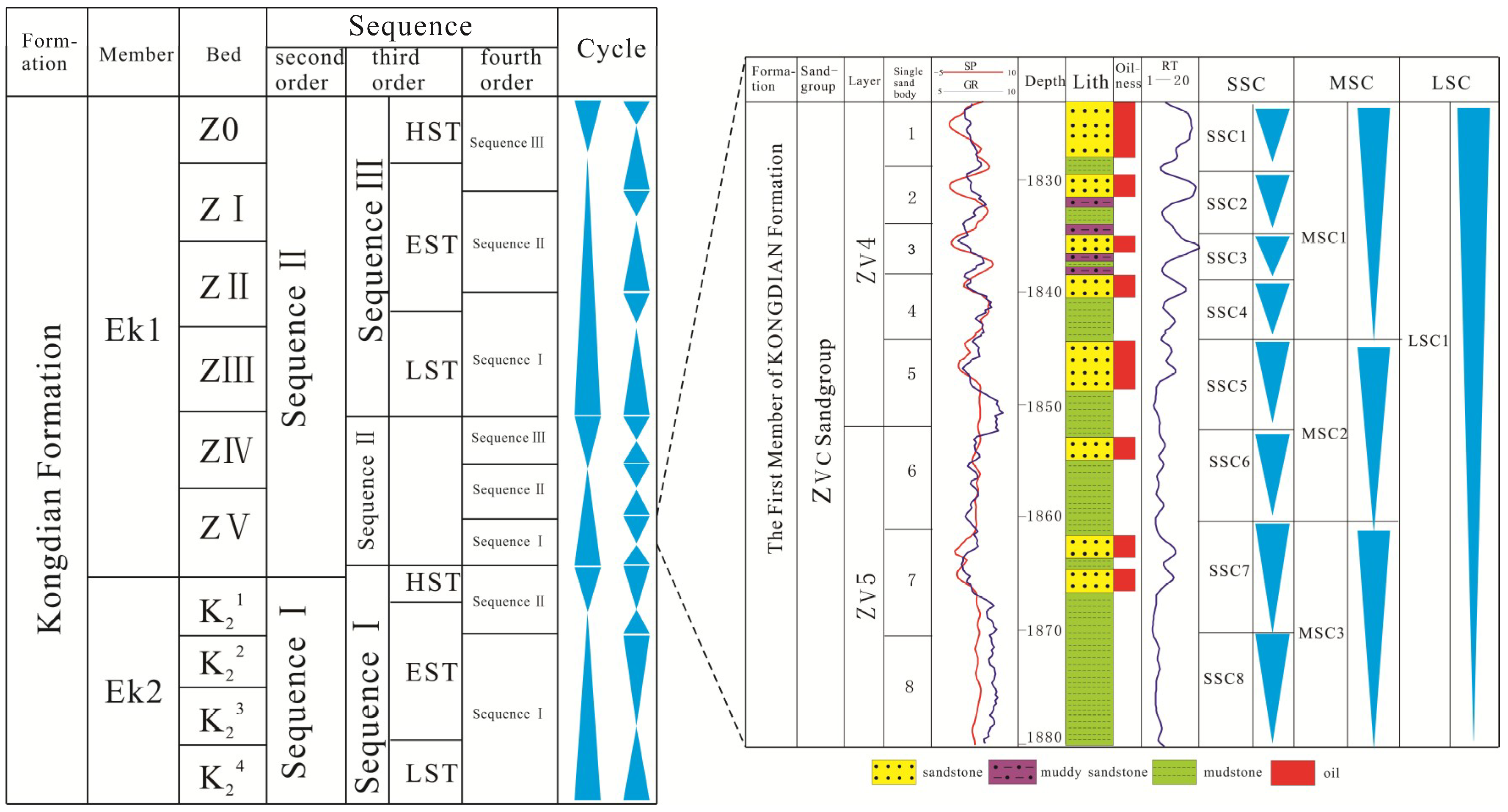

4.1. Stratigraphic Correlation and Cycle Identification

4.2. Sedimentary Microfacies Characteristics

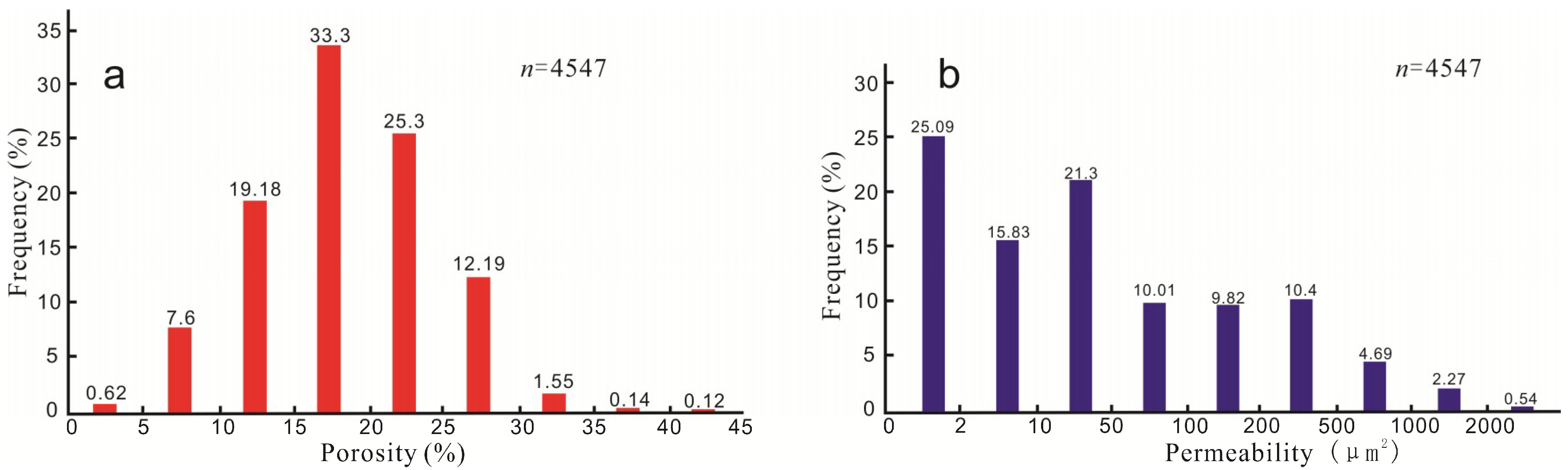

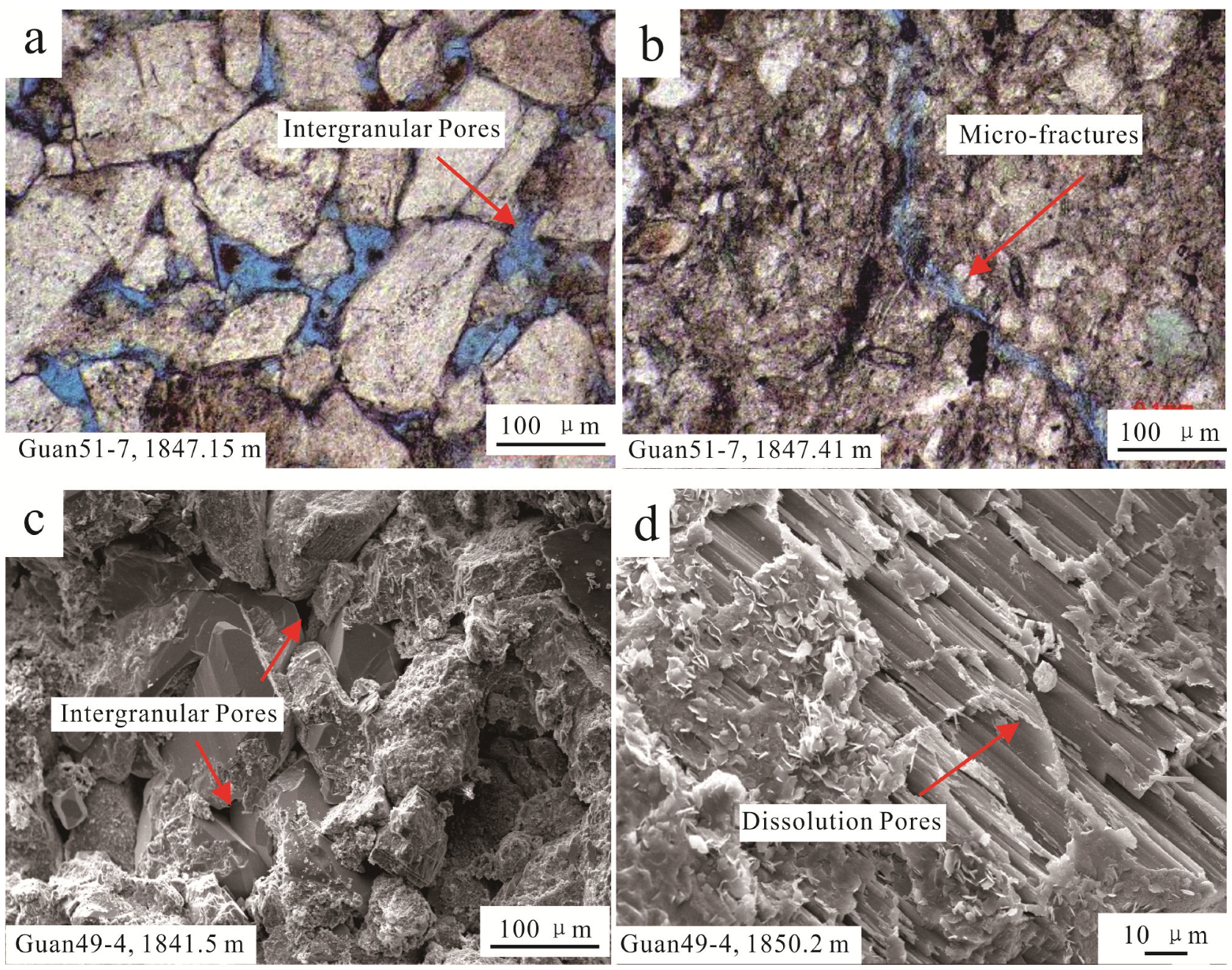

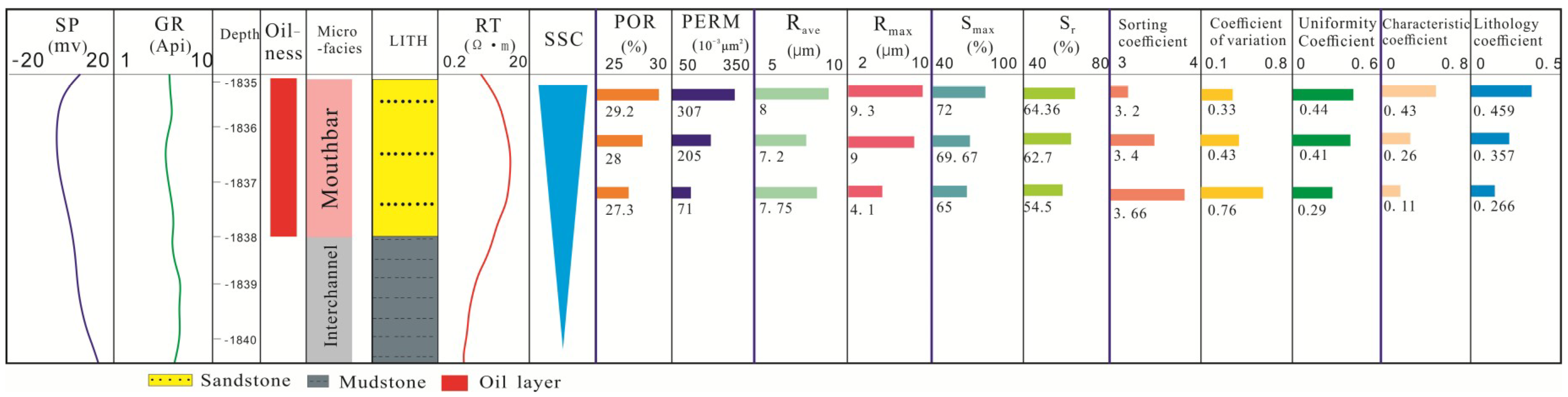

4.3. Petrophysical Properties and Pore Types

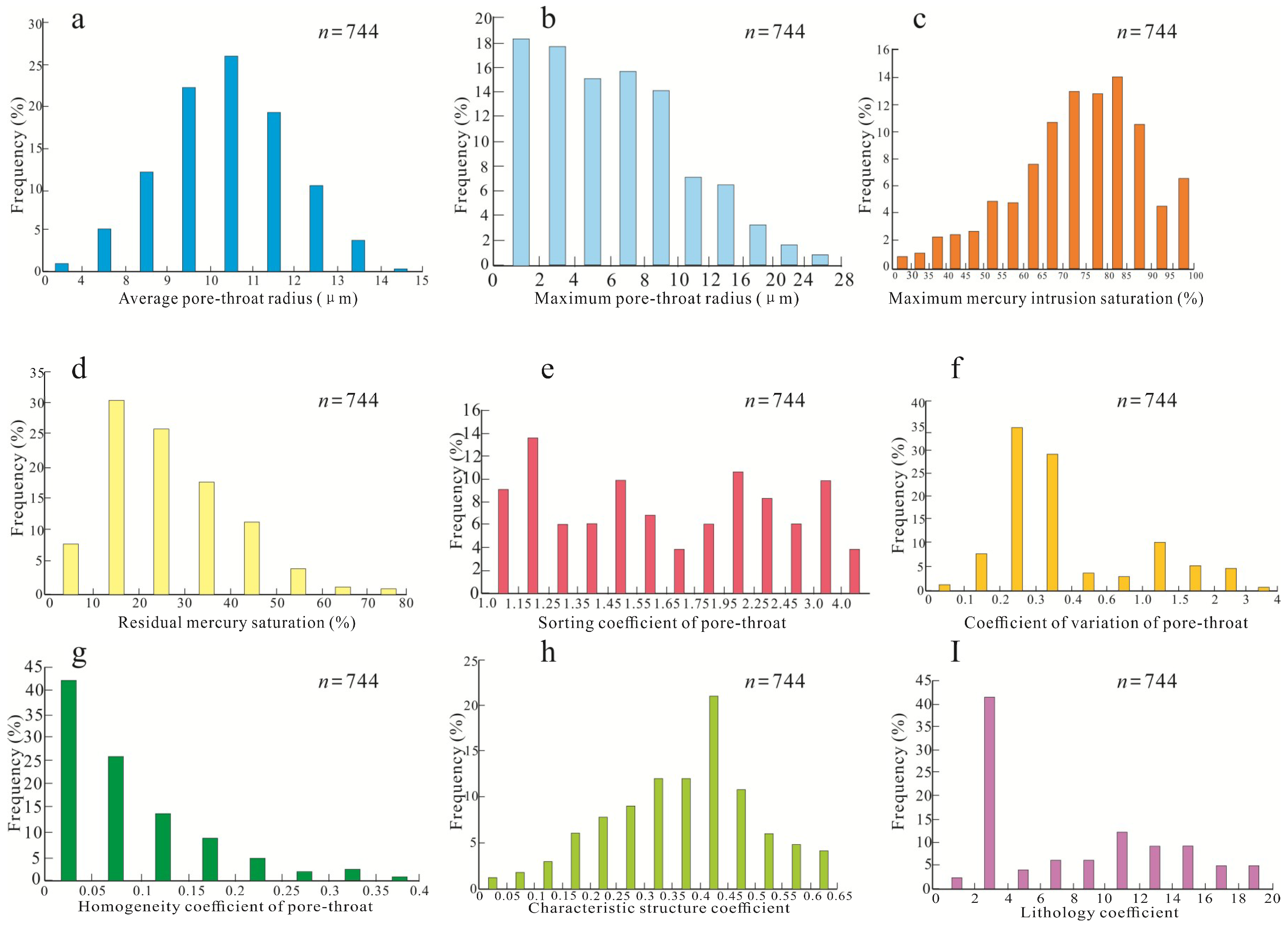

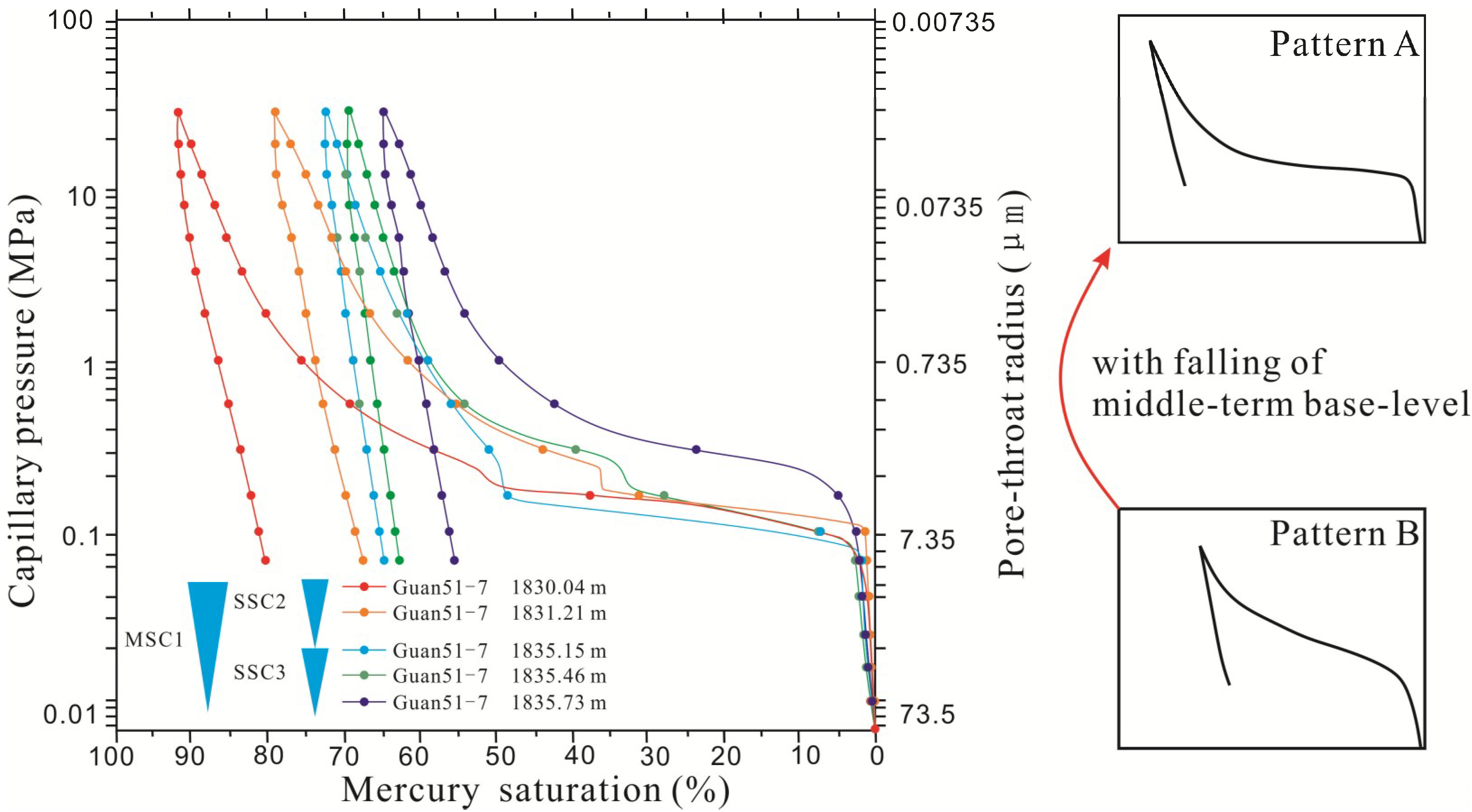

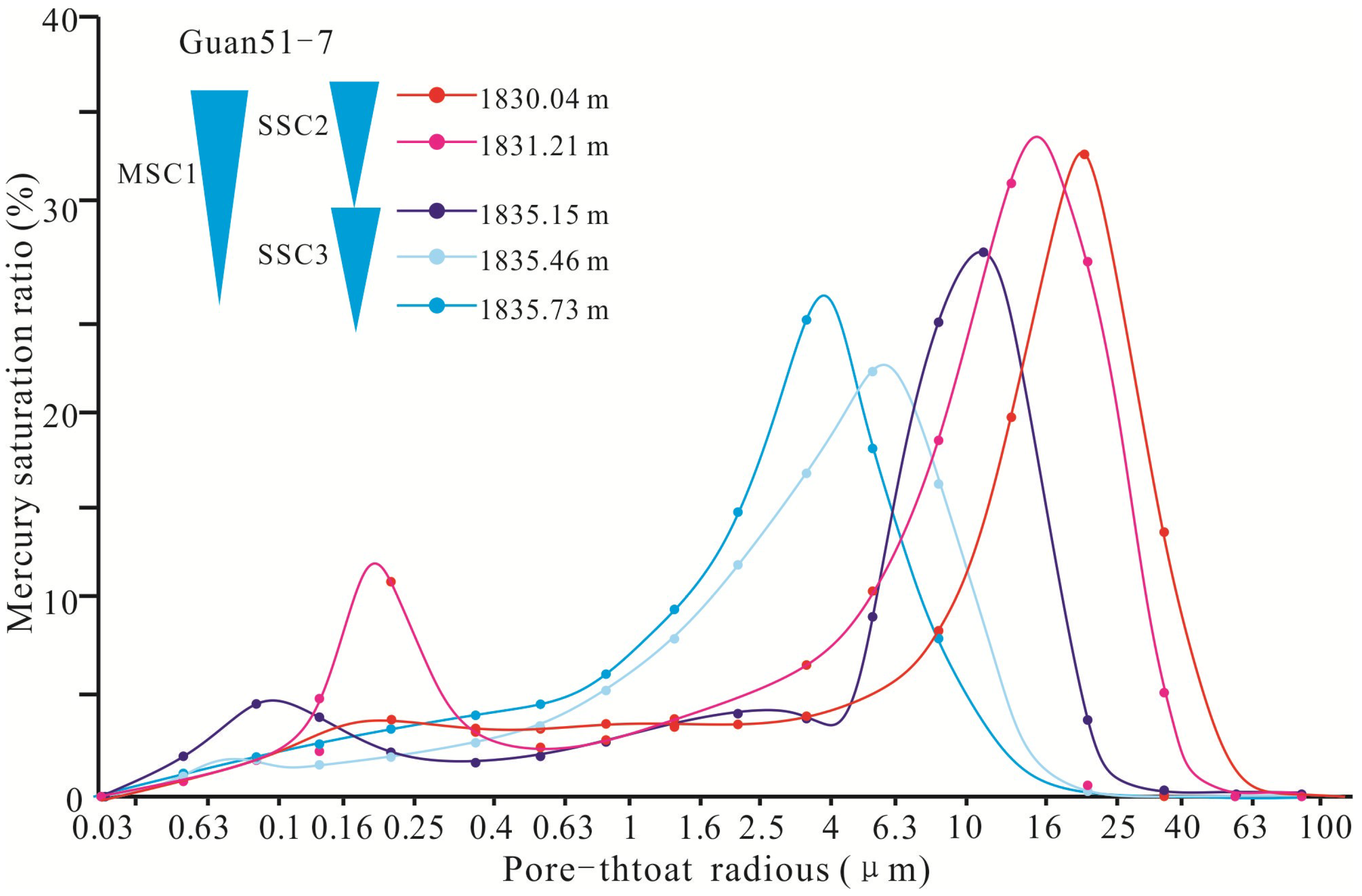

4.4. The Results Obtained from Pressure-Controlled Mercury Injection Testing

5. Discussion

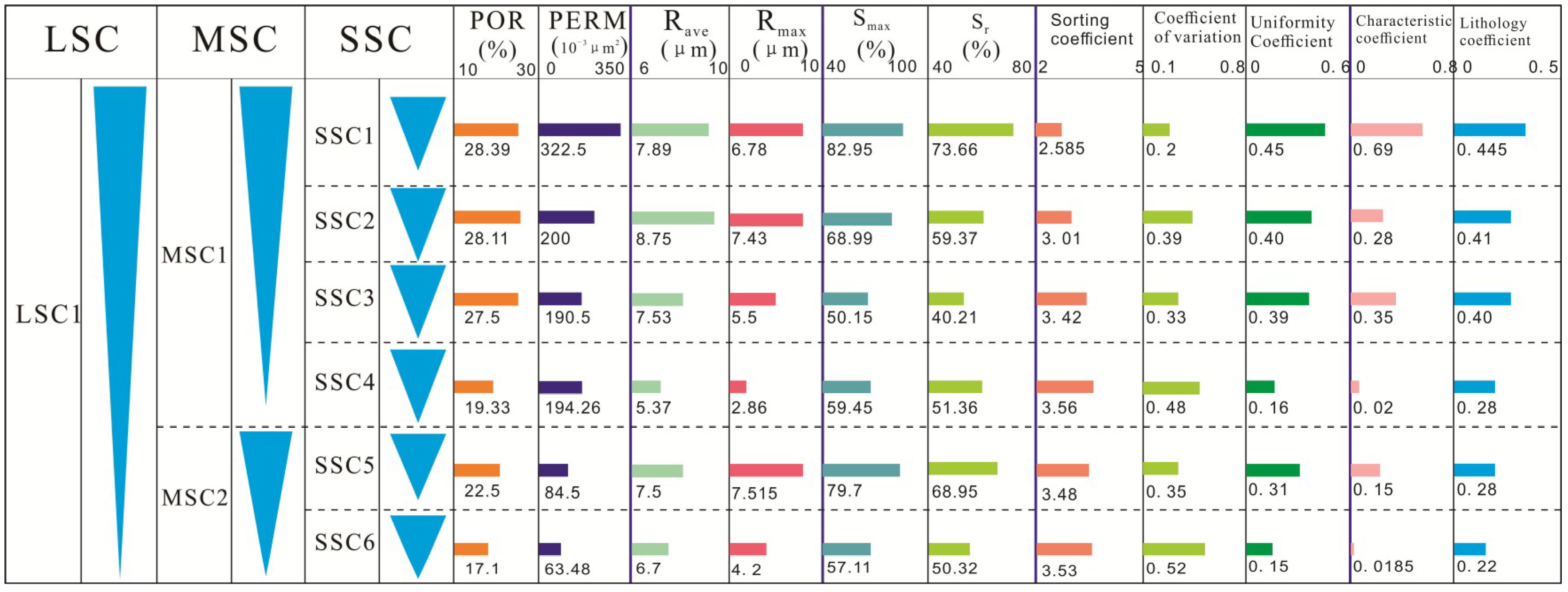

5.1. Relationship between Short-Term Base-Level Cycle and Pore Structure

5.2. Relationship between Middle-Term Base-Level Cycle and the Pore Structure

5.3. Relationship between Long-Term Base-Level Cycle and the Pore Structure

5.4. Summary

6. Conclusions

- Three types of pores (intergranular pores, dissolution pores, and micro fractures) exist in the Kongdian Formation of the Wang guantun oilfield. The pore structures of the different types of pores are different. Intrusion and extrusion curves of PMI were divided into three patterns: the curves of pattern A have minimum Pt, widest horizontal stages, and maximum intake of mercury, which altogether represent larger pore throat radius, better sorting, and weaker heterogeneity. The intrusion curves of most samples in mouth bar sand bodies belong to pattern A or pattern B.

- The pore structure heterogeneity in the early stage of the falling period of short-term base-level was stronger than that in the late stage, and pore size gradually became larger with the falling of short-term base-level; with the falling of middle-term base level, the pore size of late single mouth bar sand bodies were larger than those of early single mouth bar sand bodies, and the intrusion curves of samples tended to change from pattern B to pattern A; the pore size, porosity, and permeability in mouth bar sand bodies generally became larger with the falling of long-term base-level.

- In the oilfield production process, especially in the delta depositional environment of a continental fault depression basin, the pore structure of the sand bodies in the late stage of the falling period of base-level cycles are better, and those sand bodies are also the more favorable targets for production.

Author Contributions

Funding

Conflicts of Interest

References

- Durner, W. Hydraulic conductivity estimation for soils with heterogeneous pore structure. Water. Resour. Res. 1994, 30, 211–223. [Google Scholar] [CrossRef]

- Nelson, P.H. Pore throat sizes in sandstones, tight sandstones, and shales. AAPG Bull. 2009, 93, 329–340. [Google Scholar] [CrossRef]

- Ross, D.J.; Bustin, R.M. The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs. Mar. Petrol. Geol. 2009, 26, 916–927. [Google Scholar] [CrossRef]

- Ge, X.; Fan, Y.; Li, J.; Zahid, M.A. Pore structure characterization and classification using multifractal theory—An application in Santanghu basin of western China. J. Petrol. Sci. Eng. 2015, 127, 297–304. [Google Scholar] [CrossRef]

- Wang, X.; Hou, J.; Song, S.; Wang, D.M.; Gong, L.; Ma, K.; Liu, Y.M.; Li, Y.Q.; Lin, Y. Combining pressure-controlled porosimetry and rate-controlled porosimetry to investigate the fractal characteristics of full-range pores in tight oil reservoirs. J. Petrol. Sci. Eng. 2018, 171, 353–361. [Google Scholar] [CrossRef]

- Wang, R. Characteristics of micro-pore throat in ultra-low permeability sandstone reservoir. Acta Petrol. Sin. 2009, 30, 560–563. [Google Scholar] [CrossRef]

- Cai, J.C.; Wei, W.; Hu, X.Y.; Liu, R.C.; Wang, J.J. Fractal characterization of dynamic fracture network extension in porous media. Fractals 2017, 25, 1750023. [Google Scholar] [CrossRef]

- Li, C.; Ostadhassan, M.; Guo, S.; Gentzis, T.; Kong, L. Application of PeakForce tapping mode of atomic force microscope to characterize nanomechanical properties of organic matter of the Bakken Shale. Fuel 2018, 233, 894–910. [Google Scholar] [CrossRef]

- Li, C.; Ostadhassan, M.; Gentzis, T.; Kong, L.; Carvajal-Ortiz, H.; Bubach, B. Nanomechanical characterization of organic matter in the Bakken formation by microscopy-based method. Mar. Petrol. Geol. 2018, 96, 128–138. [Google Scholar] [CrossRef]

- Gong, L.; Fu, X.F.; Gao, S.; Zhao, P.Q.; Luo, Q.Y.; Zeng, L.B.; Yue, W.T.; Zhang, B.J.; Liu, B. Characterization and Prediction of Complex Natural Fractures in the Tight Conglomerate Reservoirs: A Fractal Method. Energies 2018, 11, 2311. [Google Scholar] [CrossRef]

- Gu, M.W.; Lu, S.F.; Xiao, D.H.; Guo, S.; Zhang, L. Present Situation of Core Mercury Injection Technology of Unconventional Oil and Gas Reservoir. Acta Geol. Sin.-Engl. 2015, 89 (Suppl. S1), 388–389. [Google Scholar] [CrossRef]

- Xi, K.L.; Cao, Y.C.; Beyene, G.H.; Zhu, R.K.; Jens, J.; Knut, B.; Zhang, X.X.; Helge, H. How does the pore throat size control the reservoir quality and oiliness of tight sandstones? The case of the Lower Cretaceous Quantou Formation in the southern Songliao Basin, China. Mar. Petrol. Geol. 2016, 76, 1–15. [Google Scholar] [CrossRef]

- Wang, X.; Hou, J.; Liu, Y.; Ji, L.; Sun, J. Studying reservoir heterogeneity by Analytic Hierarchy Process and Fuzzy Logic, case study of Es1x formation of the Wang guan tun oilfield, China. J. Petrol. Sci. Eng. 2017, 156, 858–867. [Google Scholar] [CrossRef]

- Cerepi, A.; Humbert, L.; Burlot, R. Pore-scale complexity of a calcareous material by time-controlled mercury porosimetry. Stud. Surf. Sci. Catal. 2000, 128, 449–458. [Google Scholar] [CrossRef]

- Zhao, J.J.; Liu, Z.W.; Xie, Q.C.; Zhou, J.P. Micro Pore Throat Structural Classification of Chang 7 Tight Oil Reservoir of Jiyuan Oilfield in Ordos Basin. China. Petrol. Exploit. 2014, 19, 73–79. [Google Scholar] [CrossRef]

- Zhu, H.Y.; An, L.Z.; Jiao, C.Y. The difference between constant-rate mercury injection and constant-pressure mercury injection and the application in reservoir assessment. Nat. Gas Geosci. 2015, 26, 1316–1322. [Google Scholar] [CrossRef]

- Curtis, M.E.; Ambrose, R.J.; Sondergeld, C.H. Transmission and Scanning Electron Microscopy Investigation of Pore Connectivity of Gas Shales on the Nanoscale. In Proceedings of the North American Unconventional Gas Conference and Exhibition, The Woodlands, TX, USA, 14–16 June 2011. [Google Scholar]

- Mendhe, V.A.; Mishra, S.; Khangar, R.G.; Kamble, A.D.; Kumar, D.; Varma, A.K.; Bannerjee, M. Organo-petrographic and pore facets of Permian shale beds of Jharia Basin with implications to shale gas reservoir. J. Earth Sci. 2017, 28, 897–916. [Google Scholar] [CrossRef]

- Singh, H. Representative Elementary Volume (REV) in spatio-temporal domain: A method to find REV for dynamic pores. J. Earth Sci. 2017, 28, 391–403. [Google Scholar] [CrossRef]

- Zhao, P.; Cai, J.; Huang, Z.; Ostadhassan, M.; Ran, F. Estimating permeability of shale gas reservoirs from porosity and rock compositions. Geophysics 2018, 83, MR283–MR294. [Google Scholar] [CrossRef]

- Kong, L.; Ostadhassan, M.; Li, C.; Tamimi, N. Pore characterization of 3D-printed gypsum rocks: A comprehensive approach. J. Mater. Sci. 2018, 53, 5063–5078. [Google Scholar] [CrossRef]

- Bloomfield, J.; Gooddy, D.; Bright, M.; Williams, P. Pore throat size distributions in permo-triassic sandstones from the United Kingdom and some implications for contaminant hydrogeology. Hydrogeol. J. 2001, 9, 219–230. [Google Scholar] [CrossRef]

- Bai, B.; Zhu, R.K.; Wu, S.T.; Yang, W.J.; Jeff, G. Multi- scale of Nano (Micro)-CT study on microscopic pore structure of tight sandstone of Yanchang Formation, Ordos Basin. Petrol. Explor. Dev. 2013, 40, 329–333. [Google Scholar] [CrossRef]

- Kong, L.; Ostadhassan, M.; Li, C.; Tamimi, N. Can 3-D Printed Gypsum Samples Replicate Natural Rocks? An Experimental Study. Rock Mech. Rock Eng. 2018, 1–14. [Google Scholar] [CrossRef]

- Ju, Y.; Sun, Y.; Tan, J.; Bu, H.; Han, K.; Li, X.; Fang, L. The composition, pore structure characterization and deformation mechanism of coal-bearing shales from tectonically altered coalfields in eastern China. Fuel 2018, 234, 626–642. [Google Scholar] [CrossRef]

- Tang, S.W.; Wang, L.; Cai, R.J. The evaluation of electrical impedance of three-dimensional fractal networks embedded in a cube. Fractals 2017, 25, 1740005. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, N.; Sima, L.Q.; Meng, F.; Guo, Y.H. Pore Structure Characterization of the Tight Reservoir: Systematic Integration of Mercury Injection and Nuclear Magnetic Resonance. Energy Fuel 2018, 32, 7471–7484. [Google Scholar] [CrossRef]

- Wang, X.X.; Hou, J.G.; Liu, Y.M.; Zhao, P.Q.; Ma, K.; Wang, D.M.; Ren, X.X.; Yan, L. Overall PSD and fractal characteristics of tight oil reservoirs: A case study of lucaogou formation in junggar basin, China. Fractals 2019, 1, 1940005. [Google Scholar] [CrossRef]

- Read, W.A.; Forsyth, I.H. Allocycles and Autocycles in the Upper Part of the Limestone Coal Group (Pendleian E1) in the Glasgow–Stirling Region of the Midland Valley of Scotland. Geol. J. 1989, 24, 121–137. [Google Scholar] [CrossRef]

- Deng, H.W.; Wang, H.L.; Li, X.Z. Identification, comparison technique and application of sequence stratigraphic datum. Petrol. Nat. Gas Geol. 1996, 17, 177–184. [Google Scholar] [CrossRef]

- Zheng, R.C.; Yin, S.M.; Peng, J. Sedimentary dynamics analysis of base level cycle structure and superimposed style. J. Sediment. 2000, 18, 369–375. [Google Scholar] [CrossRef]

- Deng, H.W.; Wang, H.L.; Ning, N. Principle of sediment volume distribution: Basic theory of high resolution stratigraphy. Front. Earth Sci. 2000, 7, 305–313. [Google Scholar] [CrossRef]

- Miall, A.D. Reconstructing the architecture and sequence stratigraphy of the preserved fluvial record as a tool for reservoir development: A reality check. AAPG Bull. 2006, 90, 989–1002. [Google Scholar] [CrossRef]

- Pittman, E.D. Relationship of porosity and permeability to various parameters derived from mercury injection-capillary pressure curves for sandstone (1). AAPG Bull. 1992, 76, 191–198. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D. Comparison of low-field NMR and mercury intrusion porosimetry in characterizing pore size distributions of coals. Fuel 2012, 95, 152–158. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.; Chalmers, G.; He, L. Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Wang, S.; Wu, T.; Cao, X.; Zheng, Q.; Ai, M. A Fractal Model for Gas Apparent Permeability in Microfractures of Tight/shale Reservoirs. Fractals 2017, 25, 1750036. [Google Scholar] [CrossRef]

- Toledo, P.G.; Scriven, L.E.; Davis, H.T. Pore-space statistics and capillary pressure curves from volume-controlled porosimetry. SPE Form. Eval. 1994, 9, 46–54. [Google Scholar] [CrossRef]

- Zhao, H.; Ning, Z.; Wang, Q.; Zhang, R.; Zhao, T.; Niu, T.; Zeng, Y. Petrophysical characterization of tight oil reservoirs using pressure-controlled porosimetry combined with rate-controlled porosimetry. Fuel 2015, 154, 233–242. [Google Scholar] [CrossRef]

- Wang, X.; Hou, J.G.; Liu, Y.M.; Dou, L.X.; Sun, J.; Gong, X. Quantitative characterization of vertical heterogeneity of mouth bar based on the analitic hierarchy process and the fuzzy mathematics: A case study of Guan195 fault block of Wangguantun Oilfield. Nat. Gas Geosci. 2017, 1914–1923. [Google Scholar] [CrossRef]

- Liang, H.W.; Wu, S.H.; Yue, D.L. Base-level cyclic controls on the reservoir macro-heterogeneity: A case study of the mouth bar in 2block of the Shengtuo oilfield. J. Chin. Univ. Min. Technol. 2013, 42, 413–420. [Google Scholar] [CrossRef]

- Tang, M.A.; Sun, B.L. Relationship between base-level cycles and hiberarchy of reservoir flow units of Lower Shihezi Formation in Daniudi Gas field. Acta Sedimentol. Sin. 2007, 1, 39–47. [Google Scholar] [CrossRef]

- Xu, E.A.; Li, X.L.; Wang, Q.K.; Xia, G.C.; Dong, L.Y.; Li, Z.W. Main controlling factor and model of Kongdian Formation hydrocarbon accumulation in Kongnan Area of Huanghua Depression. Fault Oil Gas Field 2014, 21, 278–281. [Google Scholar] [CrossRef]

- Neng, Y.; Qi, J.F.; LI, T.H.; Zhang, G.; Li, M.G.; Shi, K.T. Characteristics of Cenozoic Fault System and Its Significance in Petroleum Geology in Kongnan Area, Huanghua Depression. Geoscience 2009, 23, 1077–1084. [Google Scholar] [CrossRef]

- Sung, K.; Jin, Z.K.; Wang, X.W.; Zhang, A.H.; Duan, Z.Q.; Wang, C.S.; Zhang, G.H. Control of sedimentary facies on reservoir quality—An example from Zao II and III oil sets in Wangguantun Oilfield, Huanghua Depression. Petrol. Explor. Dev. 2006, 33, 335–339. [Google Scholar] [CrossRef]

- Shi, Z.Z.; Ji, Y.L. Fan-delta Sedimentation Formed under the Environment of Lake Level Frequently Varying—Taking the First Member of Kongdian Formation, Huanghua Depression as an Example. J. Xi’an Petrol. Inst. 2002, 17, 24–28. [Google Scholar] [CrossRef]

- Ziarani, A.S.; Aguilera, R. Pore throat radius and tortuosity estimation from formation resistivity data for tight-gas sandstone reservoirs. J. Appl. Geophys. 2012, 83, 65–73. [Google Scholar] [CrossRef]

- Yang, Q.; Qi, J.F.; Chang, D.S.; Li, M.G. Tectonpalaeogeography during the deposition of Paleogene Kongdian Formation in Kongnan area, Huanghua Depression of Bohai Bay Bain. J. Palaeogeogr. 2009, 3, 306–313. [Google Scholar] [CrossRef]

- Xue, L.F.; Sun, J.; Chen, C.W.; Xu, X.K.; Meng, Q.L.; Yan, Q.H. Tectonic sedimentary evolution of the first and second members of the Kongdian Formation in southern Kongdian, Huanghua depression. Sediment. Geol. Tethyan Geol. 2006, 28, 62–68. [Google Scholar] [CrossRef]

- Thomas, L.K.; Katz, D.L.; Tek, M.R. Threshold pressure phenomena in porous media. Soc. Petrol. Eng. J. 1968, 8, 174–184. [Google Scholar] [CrossRef]

- Rogers, J.J.; Head, W.B. Relationships between porosity, median size, and sorting coefficients of synthetic sands. J. Sediment. Res. 1961, 31, 467–470. [Google Scholar] [CrossRef]

- Brown, C.E. Coefficient of variation. In Applied Multivariate Statistics in Geohydrology and Related Sciences; Springer Science & Business Media: Berlin, Germany, 1998; pp. 155–157. [Google Scholar]

- Sepaskhah, A.R.; Ghahraman, B. The effects of irrigation efficiency and uniformity coefficient on relative yield and profit for deficit irrigation. Biosyst. Eng. 2004, 87, 495–507. [Google Scholar] [CrossRef]

- Washburn, E.W. The dynamics of capillary flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

| Micro-Facies Type | Curve Model | Lithological Characteristics | Logging Curve Characteristics | Sedimentary Structure |

|---|---|---|---|---|

| Mouth bar micro-facies |  | Medium sand; Fine sand | Funnel shaped; Box shaped | Cross bedding Wavy bedding Parallel bedding Lenticular bedding |

| Underwater distributary channel micro-facies |  | Gravel bearing sandstone; Medium sand; Fine sand | Bell shaped; Box shaped | Graded bedding Wavy bedding Parallel bedding Cross-bedding |

| Sheet sand |  | Medium sand; Fine sand | Finger shaped | Parallel bedding Cross-bedding |

| Distributary bay micro-facies |  | Mainly mudstone | Low amplitude tooth curve or straight section | Horizontal bedding Wormhole |

| Cycles | With the Falling of Base-Level | |||

|---|---|---|---|---|

| Pore Size | Pore-Throat Distribution | Porosity | Permeability | |

| SSC | Gradually increasing | Getting more uniform | Getting larger | Getting larger |

| MSC | Pore size of the sand body in the late period is larger | Getting more uniform | The porosity of the sand body in the late period is larger | The permeability of the sand body in the late period is larger |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Hou, J.; Liu, Y.; Ji, L.; Sun, J.; Gong, X. Impacts of the Base-Level Cycle on Pore Structure of Mouth Bar Sand Bars: A Case Study of the Paleogene Kongdian Formation, Bohai Bay Basin, China. Energies 2018, 11, 2617. https://doi.org/10.3390/en11102617

Wang X, Hou J, Liu Y, Ji L, Sun J, Gong X. Impacts of the Base-Level Cycle on Pore Structure of Mouth Bar Sand Bars: A Case Study of the Paleogene Kongdian Formation, Bohai Bay Basin, China. Energies. 2018; 11(10):2617. https://doi.org/10.3390/en11102617

Chicago/Turabian StyleWang, Xixin, Jiagen Hou, Yuming Liu, Ling Ji, Jian Sun, and Xun Gong. 2018. "Impacts of the Base-Level Cycle on Pore Structure of Mouth Bar Sand Bars: A Case Study of the Paleogene Kongdian Formation, Bohai Bay Basin, China" Energies 11, no. 10: 2617. https://doi.org/10.3390/en11102617

APA StyleWang, X., Hou, J., Liu, Y., Ji, L., Sun, J., & Gong, X. (2018). Impacts of the Base-Level Cycle on Pore Structure of Mouth Bar Sand Bars: A Case Study of the Paleogene Kongdian Formation, Bohai Bay Basin, China. Energies, 11(10), 2617. https://doi.org/10.3390/en11102617