An Improved Ant Lion Optimization Algorithm and Its Application in Hydraulic Turbine Governing System Parameter Identification

Abstract

:1. Introduction

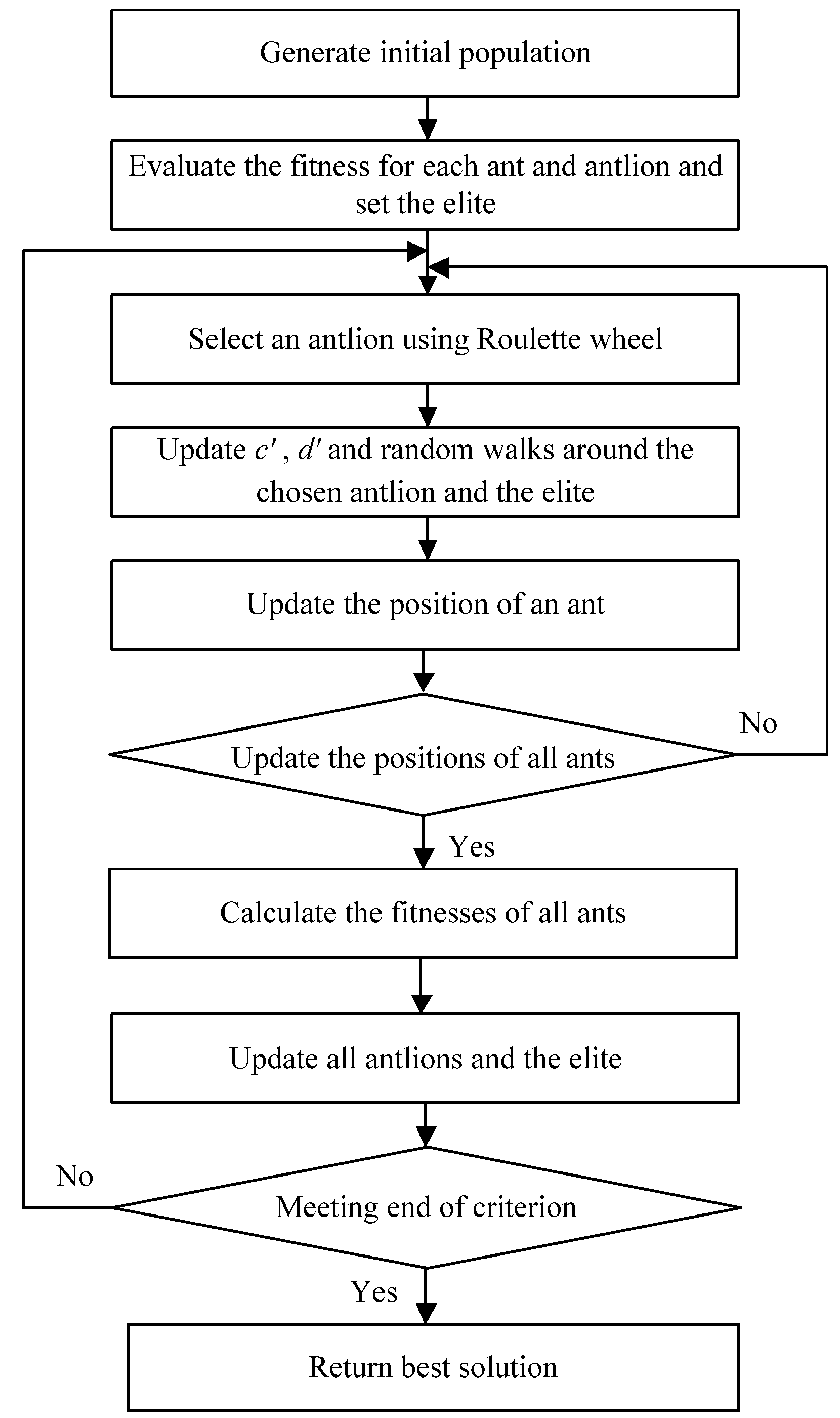

2. The Improved Ant Lion Optimization Algorithm

2.1. Brief Introduction of ALO

2.2. Improvements on ALO

2.2.1. Combination with Particle Swarm Optimization

2.2.2. Chaotic Mutation Operator

2.2.3. A Serial-Parallel Combined Method to Obtain Mutant Particles

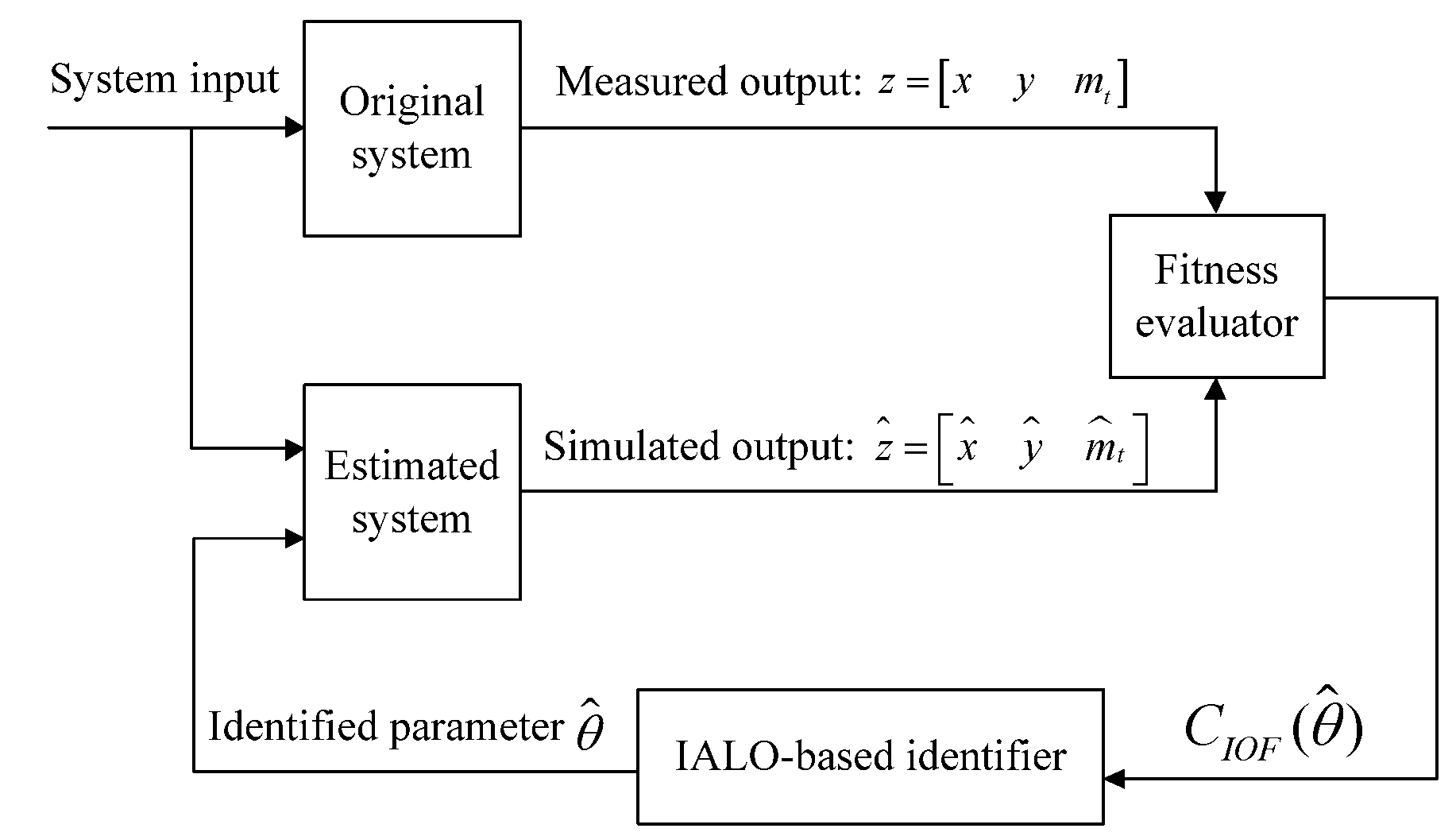

3. Parameter Identification for HTGS Based on IALO

3.1. Objective Function

3.2. Parameter Identification Strategy

4. Experiments and Results Analysis

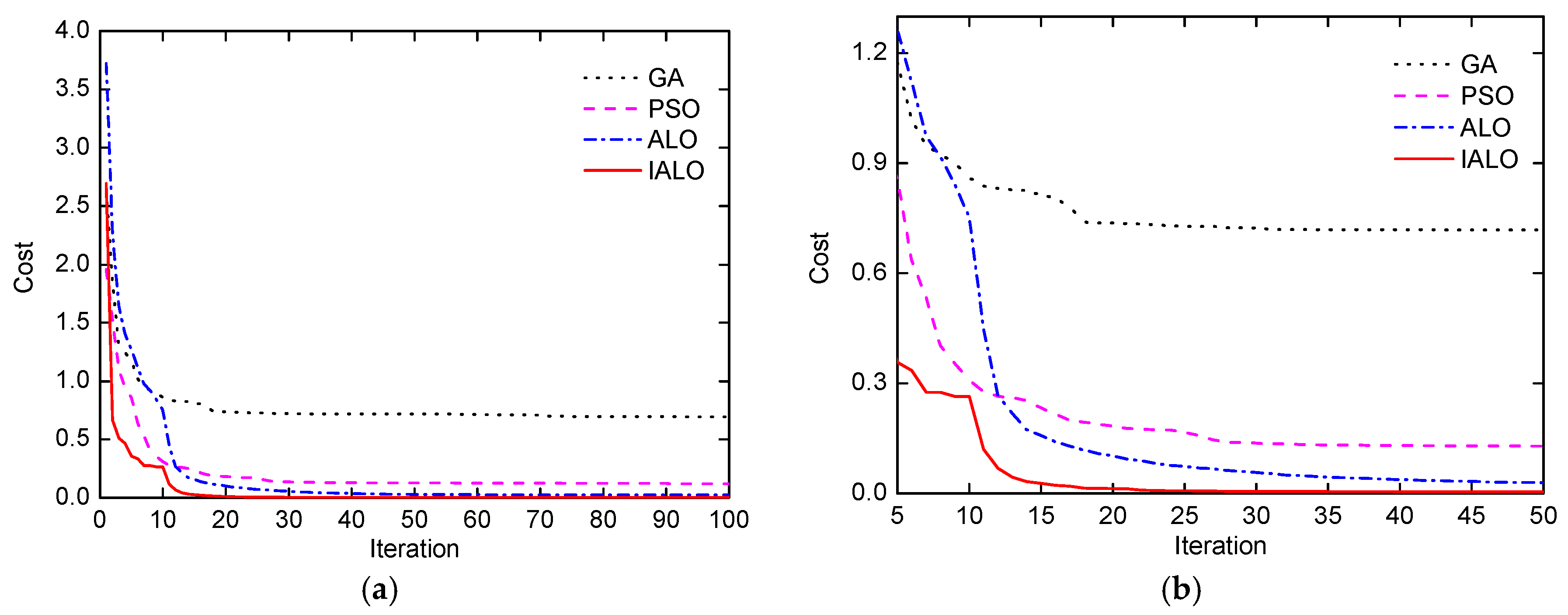

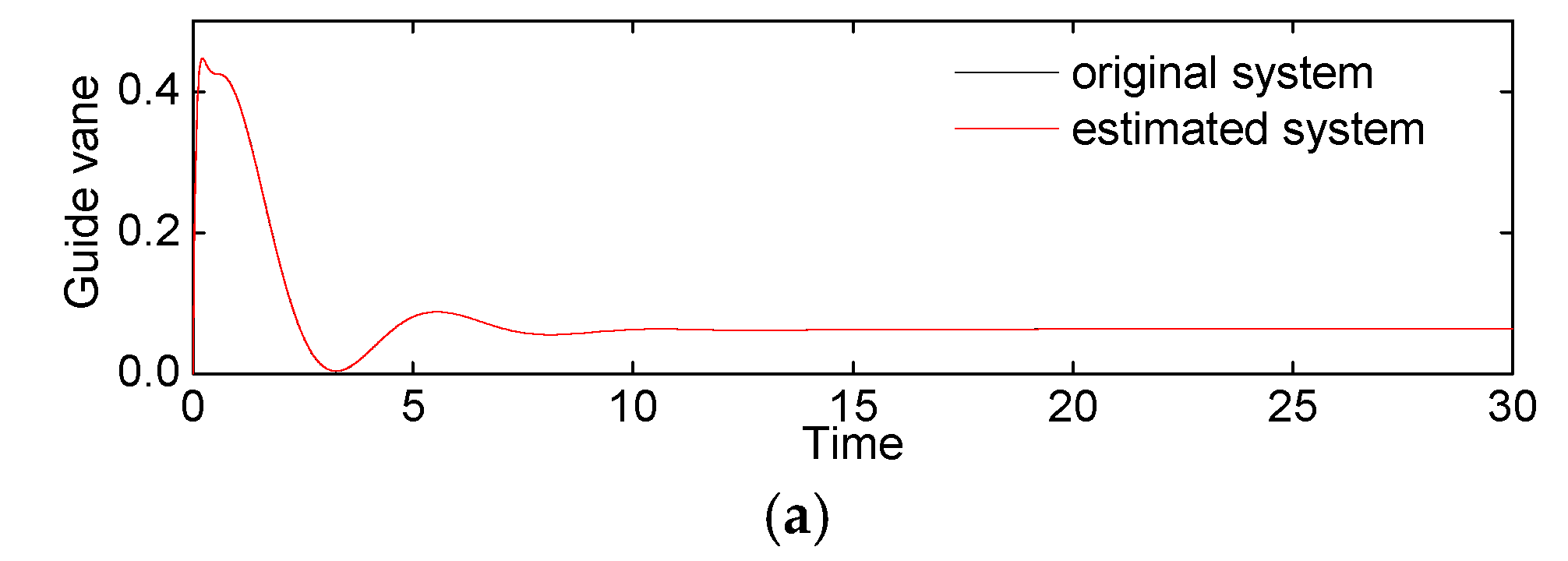

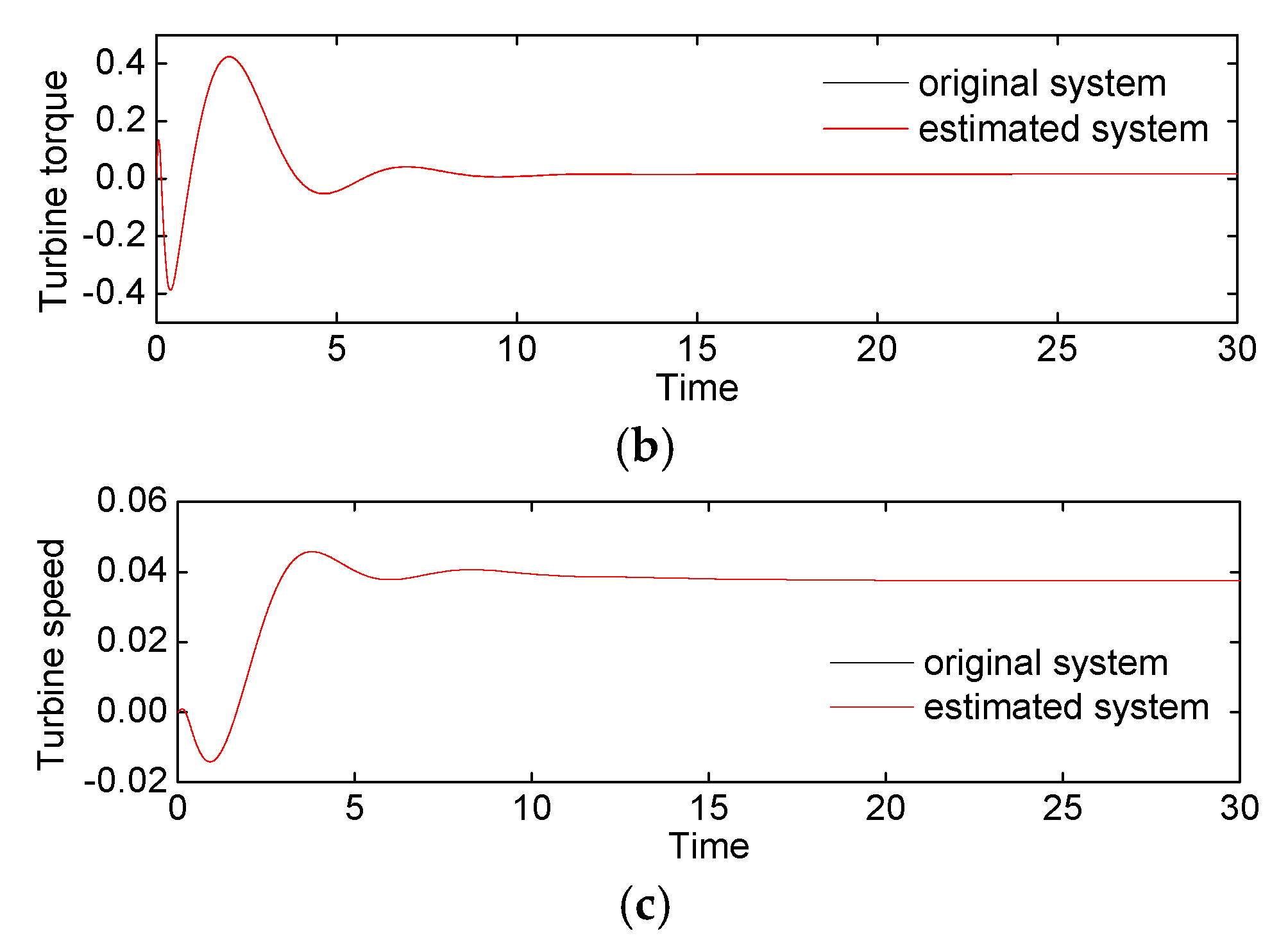

4.1. Comparison of Different Identification Methods under No-Load Condition

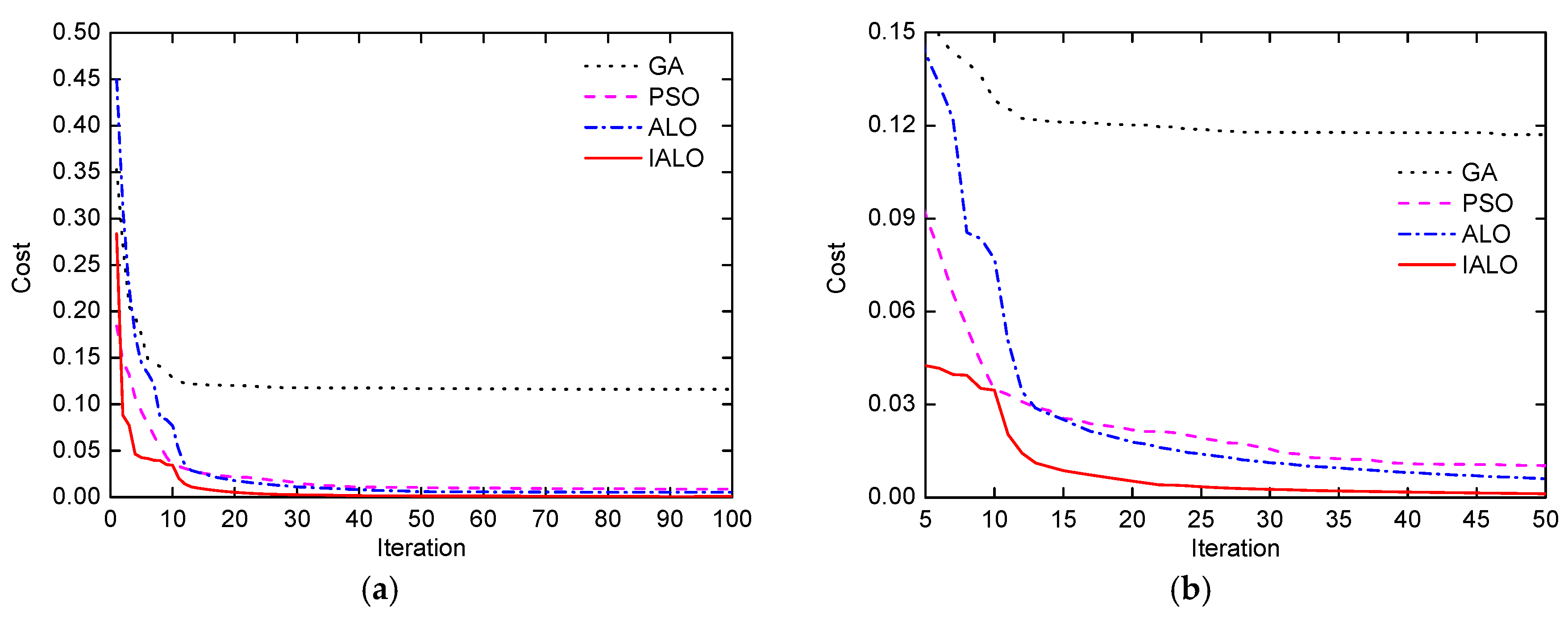

4.2. Comparison of Different Identification Methods under Load Condition

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

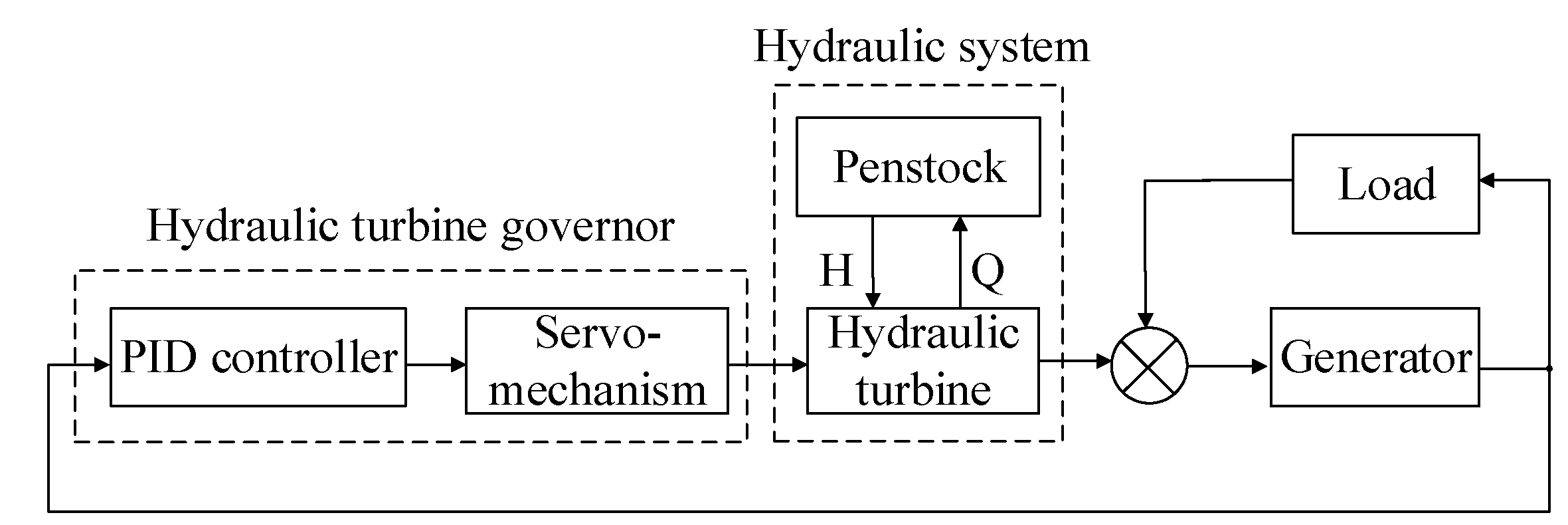

Appendix A

(1) Model of Hydraulic Turbine Governor

(2) Model of Hydraulic System

(3) Model of Generator and Load

References

- Demello, F.P.; Koessler, R.J.; Agee, J.; Anderson, P.M.; Doudna, J.H.; Fish, J.H.; Hamm, P.A.L.; Kundur, P.; Lee, D.C.; Rogers, G.J.; et al. Hydraulic turbine and turbine control models for system dynamic studies. IEEE Trans. Power Syst. 1992, 7, 167–179. [Google Scholar] [CrossRef]

- De Jaeger, E.; Janssens, N.; Malfliet, B.; Van De Meulebroeke, F. Hydro turbine model for system dynamic studies. IEEE Trans. Power Syst. 1994, 9, 1709–1715. [Google Scholar] [CrossRef]

- Trudnowski, D.J.; Agree, J.C. Identifying a hydraulic-turbine model from measured field data. IEEE Trans. Energy Convers. 1995, 10, 763–768. [Google Scholar] [CrossRef]

- Liu, C.Y.; Liang, X.L. Model identification of controlled subject for hydro turbine governing system. Water Resour. Power 2007, 25, 77–79. [Google Scholar] [CrossRef]

- Yang, X.D.; Dong, C.; Lu, W.H. Parameters identification for hydraulic turbine governing systems based on genetic algorithm. Relay 2006, 34, 27–30. [Google Scholar] [CrossRef]

- Liu, C.; Liu, N.; Sun, X.; Cui, J. The research and application on parameter identification of hydraulic turbine regulating system based on particle swarm optimization and uniform design. In Proceedings of the International Conference on Computer Science and Information Technology (ICCSIT 2010), Chengdu, China, 9–11 July 2010; pp. 605–608. [Google Scholar]

- Kuo, P.; Zhou, J.; Li, C.; He, H. Identification of hydraulic turbine governor system parameters based on bacterial foraging optimization algorithm. In Proceedings of the Sixth International Conference on Natural Computation (ICNC 2010), Yantai, China, 10–12 August 2010; pp. 3339–3343. [Google Scholar]

- Xiao, Z.; Wang, S.; Zeng, H.; Yuan, X. Identifying of hydraulic turbine generating unit model based on neural network. In Proceedings of the IEEE International Intelligent System Design and Applications, Jinan, China, 16–18 October 2006; pp. 113–117. [Google Scholar] [CrossRef]

- Mirjalili, S. The ant lion optimizer. Adv. Eng. Softw. 2015, 83, 80–98. [Google Scholar] [CrossRef]

- Mirjalili, S.; Jangir, P.; Saremi, S. Multi-objective ant lion optimizer: A multi-objective optimization algorithm for solving engineering problems. Appl. Intell. 2016, 1–17. [Google Scholar] [CrossRef]

- Saxena, P.; Kothari, A. Ant lion optimization algorithm to control side lobe level and null depths in linear antenna arrays. AEU Int. J. Electron. Commun. 2016, 70, 1339–1349. [Google Scholar] [CrossRef]

- Petrović, M.; Petronijević, J.; Mitić, M.; Vuković, N.; Miljković, Z.; Babić, B. The ant lion optimization algorithm for integrated process planning and scheduling. Appl. Mech. Mater. 2016, 834, 187–192. [Google Scholar] [CrossRef]

- Man, K.F.; Tang, K.S.; Kwong, S. Genetic algorithms: Concepts and applications. IEEE Trans. Ind. Electron. 1996, 43, 519–534. [Google Scholar] [CrossRef]

- Gao, L.; Dai, Y.; Xia, J. Parameter identification of hydro generation system with fluid transients based on improved genetic algorithm. In Proceedings of the Fifth International Conference on Natural Computation (ICNC 2009), Tianjin, China, 14–16 August 2009; pp. 398–402. [Google Scholar]

- Liu, B.; Wang, L.; Jin, Y.; Tang, F.; Huang, D. Improved particle swarm optimization combined with chaos. Chaos Solitons Fractals 2005, 25, 1261–1271. [Google Scholar] [CrossRef]

- Li, C.; Zhou, J. Parameters identification of hydraulic turbine governing system using improved gravitational search algorithm. Energy Convers. Manag. 2011, 52, 374–381. [Google Scholar] [CrossRef]

- Chen, Z.; Yuan, X.; Tian, H.; Ji, B. Improved gravitational search algorithm for parameter identification of water turbine regulation system. Energy Convers. Manag. 2014, 78, 306–315. [Google Scholar] [CrossRef]

- Liu, C.Y.; He, X.S.; Li, C.W.; Wang, Z.; Zhang, E.B. Improved artificial fish swarm algorithm for parameter identification of hydroelectric turbine-conduit system. Electr. Power Autom. Equip. 2013, 33, 54–58. [Google Scholar] [CrossRef]

- Lampart, M.; Oprocha, P. Chaotic sub-dynamics in coupled logistic maps. Phys. D Nonlinear Phenom. 2016, 335, 45–53. [Google Scholar] [CrossRef]

- Shen, Z.Y. Hydraulic Turbine Regulation, 3rd ed.; Water Power Press: Beijing, China, 1988; pp. 181–199. ISBN 9787801244123. [Google Scholar]

- Liu, C.Y.; He, X.S.; He, F.J.; Wang, G.H.; Lin, Y.; Yan, Q.R. Refined modeling of hydraulic prime mover and its governing system for hydropower generation unit. Power Syst. Technol. 2015, 39, 230–235. [Google Scholar] [CrossRef]

| Working Condition | Transfer Coefficients of Turbine | |||||

|---|---|---|---|---|---|---|

| ex | ey | eh | eqx | eqy | eqh | |

| No-load | −1.0567 | 0.9080 | 1.4191 | −0.0574 | 0.7887 | 0.4571 |

| Load | −1.4673 | 0.7713 | 1.7179 | −0.4901 | 0.8184 | 0.7257 |

| Identified Parameters | System Real Value | Average of Identified Parameters (20 Trials) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| GA | PSO | ALO | IALO | ||||||

| PE | PE | PE | PE | ||||||

| Tw | 1.5 | 1.4916 | 0.0056 | 1.5031 | 0.0021 | 1.5139 | 0.0093 | 1.5026 | 0.0018 |

| Te | 0.53 | 0.5362 | 0.0117 | 0.5290 | 0.0018 | 0.5256 | 0.0083 | 0.5292 | 0.0015 |

| f | 0.01 | 0.0198 | 0.98 | 0.0155 | 0.55 | 0.0223 | 1.23 | 0.0122 | 0.22 |

| Ta’ | 12.0 | 12.5767 | 0.0481 | 11.8456 | 0.0129 | 11.6472 | 0.0294 | 11.9372 | 0.0052 |

| eg | 0.4433 | 0.5158 | 0.0725 | 0.4342 | 0.0205 | 0.4198 | 0.0530 | 0.4402 | 0.0070 |

| GA | PSO | ALO | IALO | |

|---|---|---|---|---|

| Mean best cost | 0.6943 | 0.1220 | 0.0255 | 0.0034 |

| Mean APE | 1.8017 | 1.7449 | 0.3159 | 0.1932 |

| Identified Parameters | System Real Value | Average of Identified Parameters (20 Trials) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| GA | PSO | ALO | IALO | ||||||

| PE | PE | PE | PE | ||||||

| Tw | 1.5 | 1.4106 | 0.0596 | 1.4781 | 0.0146 | 1.4714 | 0.0191 | 1.5026 | 0.0018 |

| Te | 0.53 | 0.6541 | 0.2341 | 0.5396 | 0.0181 | 0.5834 | 0.1008 | 0.5082 | 0.0411 |

| f | 0.01 | 0.0197 | 0.97 | 0.0076 | 0.24 | 0.0123 | 0.23 | 0.0094 | 0.06 |

| Ta’ | 12.0 | 12.1476 | 0.0123 | 12.0607 | 0.0051 | 11.9408 | 0.0049 | 12.0097 | 0.0008 |

| eg | 0.4433 | 0.4412 | 0.0047 | 0.3596 | 0.1888 | 0.4264 | 0.0381 | 0.4383 | 0.0113 |

| GA | PSO | ALO | IALO | |

|---|---|---|---|---|

| Mean best cost | 0.1162 | 0.0088 | 0.0054 | 0.0010 |

| Mean APE | 2.2760 | 0.7217 | 0.1403 | 0.0808 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, T.; Liu, C.; Guo, Q.; Yuan, Y.; Li, W.; Yan, Q. An Improved Ant Lion Optimization Algorithm and Its Application in Hydraulic Turbine Governing System Parameter Identification. Energies 2018, 11, 95. https://doi.org/10.3390/en11010095

Tian T, Liu C, Guo Q, Yuan Y, Li W, Yan Q. An Improved Ant Lion Optimization Algorithm and Its Application in Hydraulic Turbine Governing System Parameter Identification. Energies. 2018; 11(1):95. https://doi.org/10.3390/en11010095

Chicago/Turabian StyleTian, Tian, Changyu Liu, Qi Guo, Yi Yuan, Wei Li, and Qiurong Yan. 2018. "An Improved Ant Lion Optimization Algorithm and Its Application in Hydraulic Turbine Governing System Parameter Identification" Energies 11, no. 1: 95. https://doi.org/10.3390/en11010095

APA StyleTian, T., Liu, C., Guo, Q., Yuan, Y., Li, W., & Yan, Q. (2018). An Improved Ant Lion Optimization Algorithm and Its Application in Hydraulic Turbine Governing System Parameter Identification. Energies, 11(1), 95. https://doi.org/10.3390/en11010095