Figure 1.

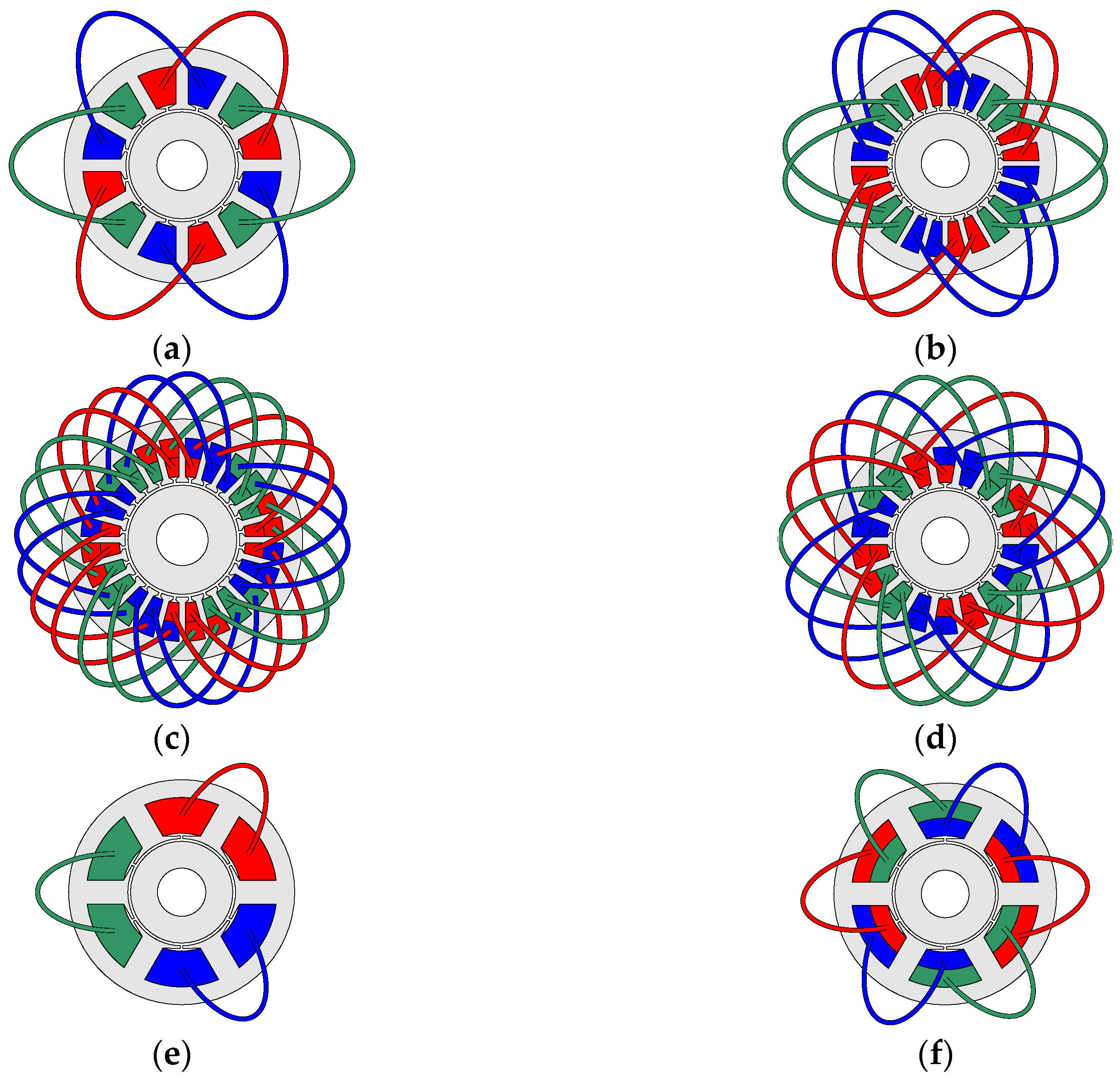

Different examples of four pole machine winding configurations (a) integral-slot distributed-winding (ISDW) (p = 2, Qs = 12, nl,w,s = 1); (b) ISDW (p = 2, Qs = 24, nl,w,s = 1); (c) ISDW (p = 2, Qs = 24, nl,w,s = 2, τa = 1); (d) fractional-slot distributed-winding FSDW (p = 2, Qs = 18, nl,w,s = 2); (e) fractional-slot concentrated-winding FSCW (p = 2, Qs = 6, nl,w,s = 1); (f) FSCW (p = 2, Qs = 6, nl,w,s = 2).

Figure 1.

Different examples of four pole machine winding configurations (a) integral-slot distributed-winding (ISDW) (p = 2, Qs = 12, nl,w,s = 1); (b) ISDW (p = 2, Qs = 24, nl,w,s = 1); (c) ISDW (p = 2, Qs = 24, nl,w,s = 2, τa = 1); (d) fractional-slot distributed-winding FSDW (p = 2, Qs = 18, nl,w,s = 2); (e) fractional-slot concentrated-winding FSCW (p = 2, Qs = 6, nl,w,s = 1); (f) FSCW (p = 2, Qs = 6, nl,w,s = 2).

Figure 2.

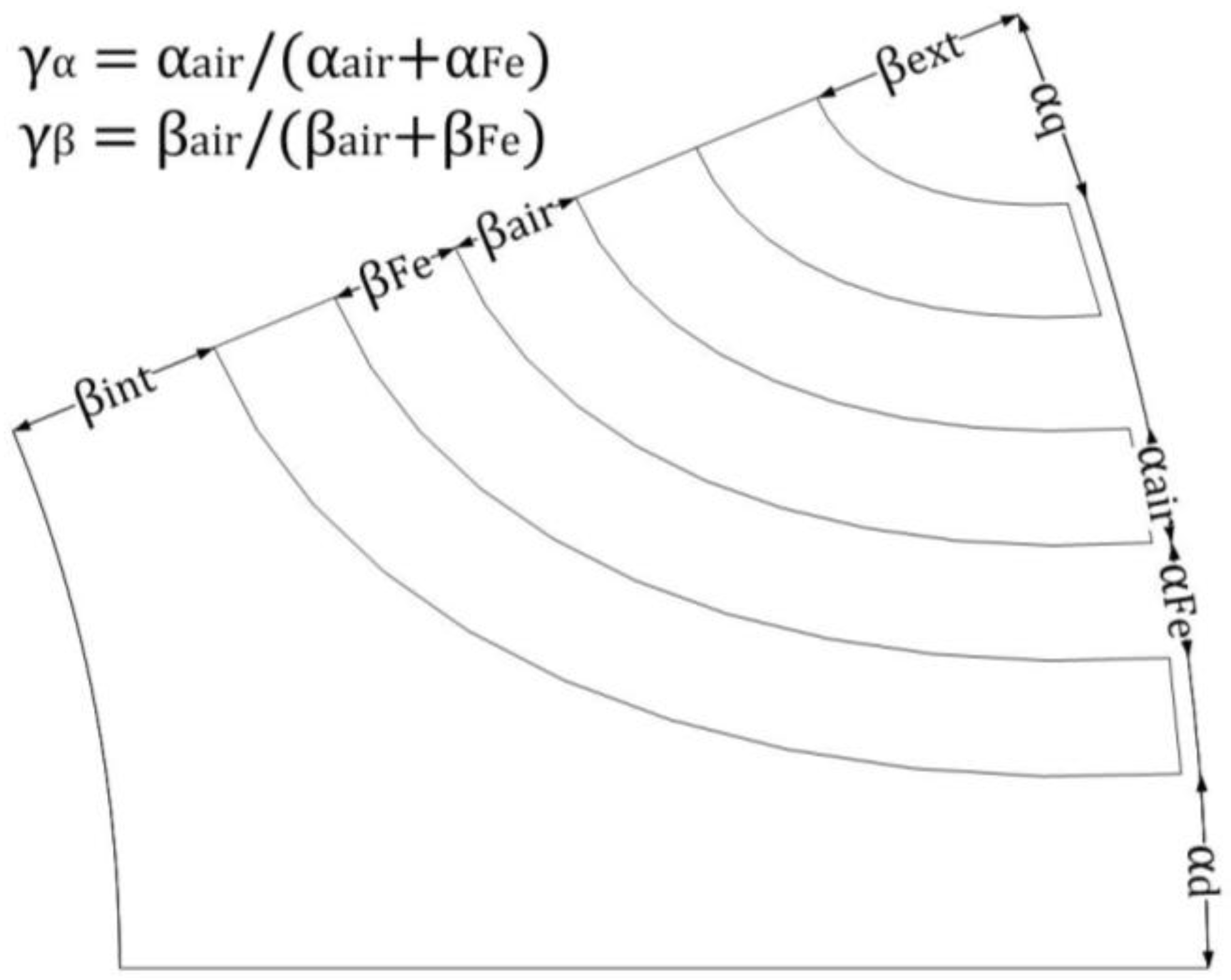

Elliptic-shaped barrier rotor geometry.

Figure 2.

Elliptic-shaped barrier rotor geometry.

Figure 3.

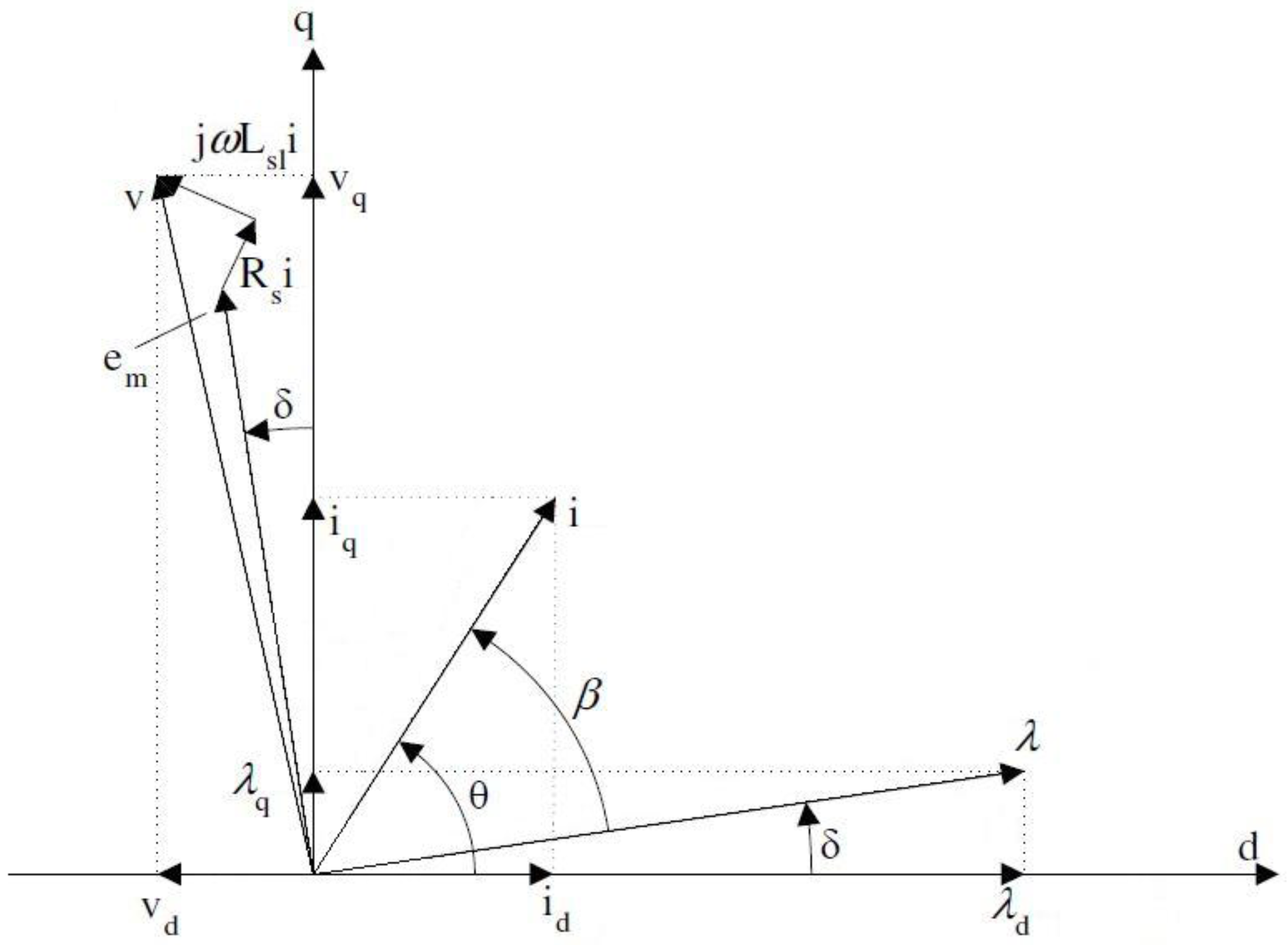

Synchronous reluctance machine (SynRM) vector diagram [

19].

Figure 3.

Synchronous reluctance machine (SynRM) vector diagram [

19].

Figure 4.

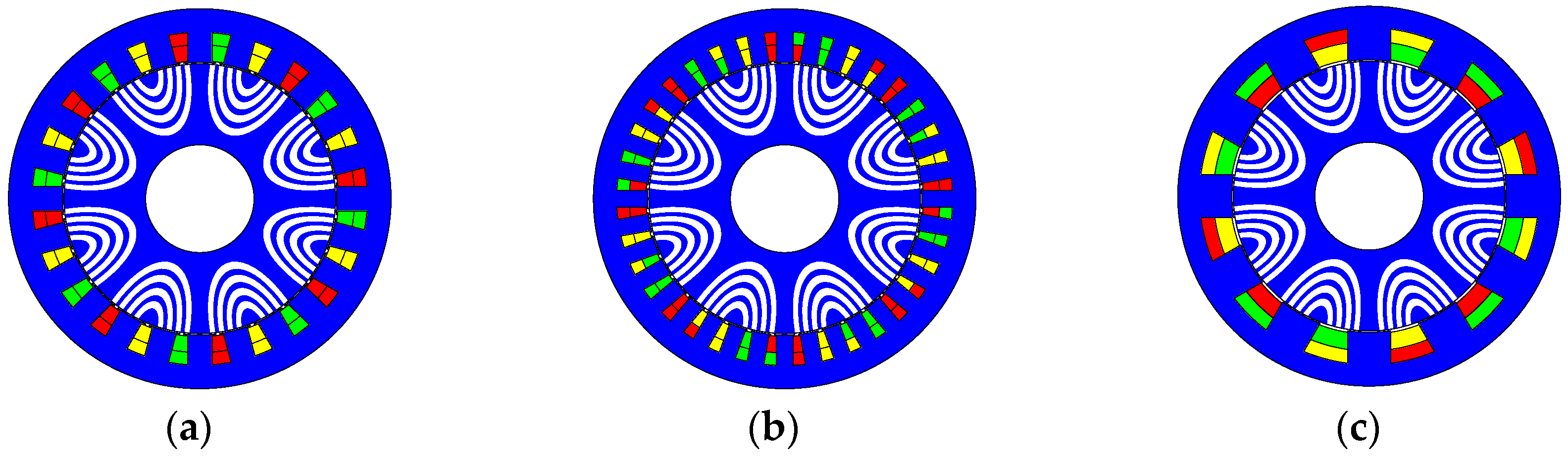

Sample machine geometries (a) ISDW (p = 4, Qs = 24); (b) FSDW (p = 4, Qs = 36); (c) FSCW (p = 4, Qs = 12, nl,w,s = 2).

Figure 4.

Sample machine geometries (a) ISDW (p = 4, Qs = 24); (b) FSDW (p = 4, Qs = 36); (c) FSCW (p = 4, Qs = 12, nl,w,s = 2).

Figure 5.

(a) Prototype rotor lamination; (b) Prototype rotor.

Figure 5.

(a) Prototype rotor lamination; (b) Prototype rotor.

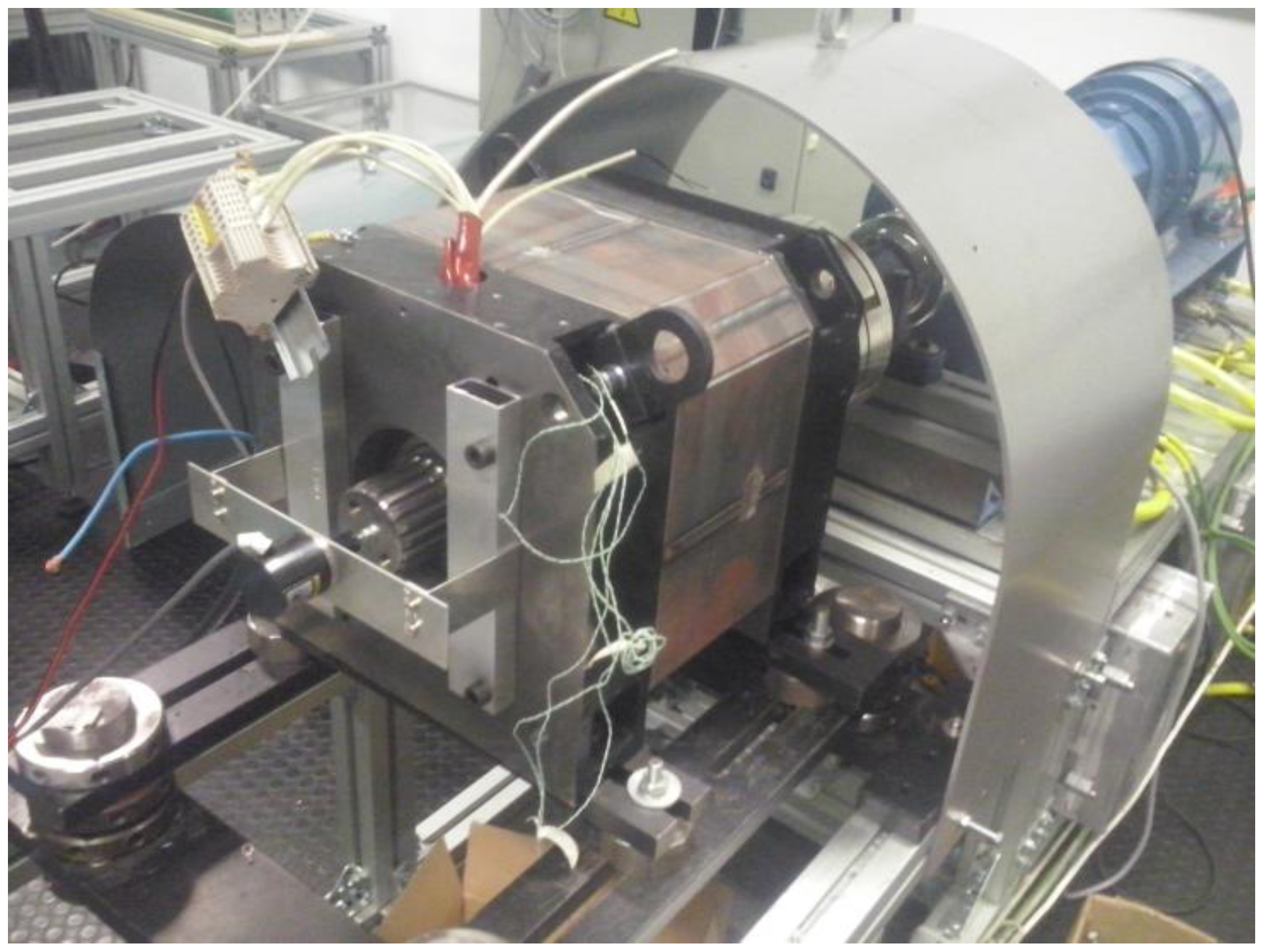

Figure 6.

Experimental setup for a prototype SynRM.

Figure 6.

Experimental setup for a prototype SynRM.

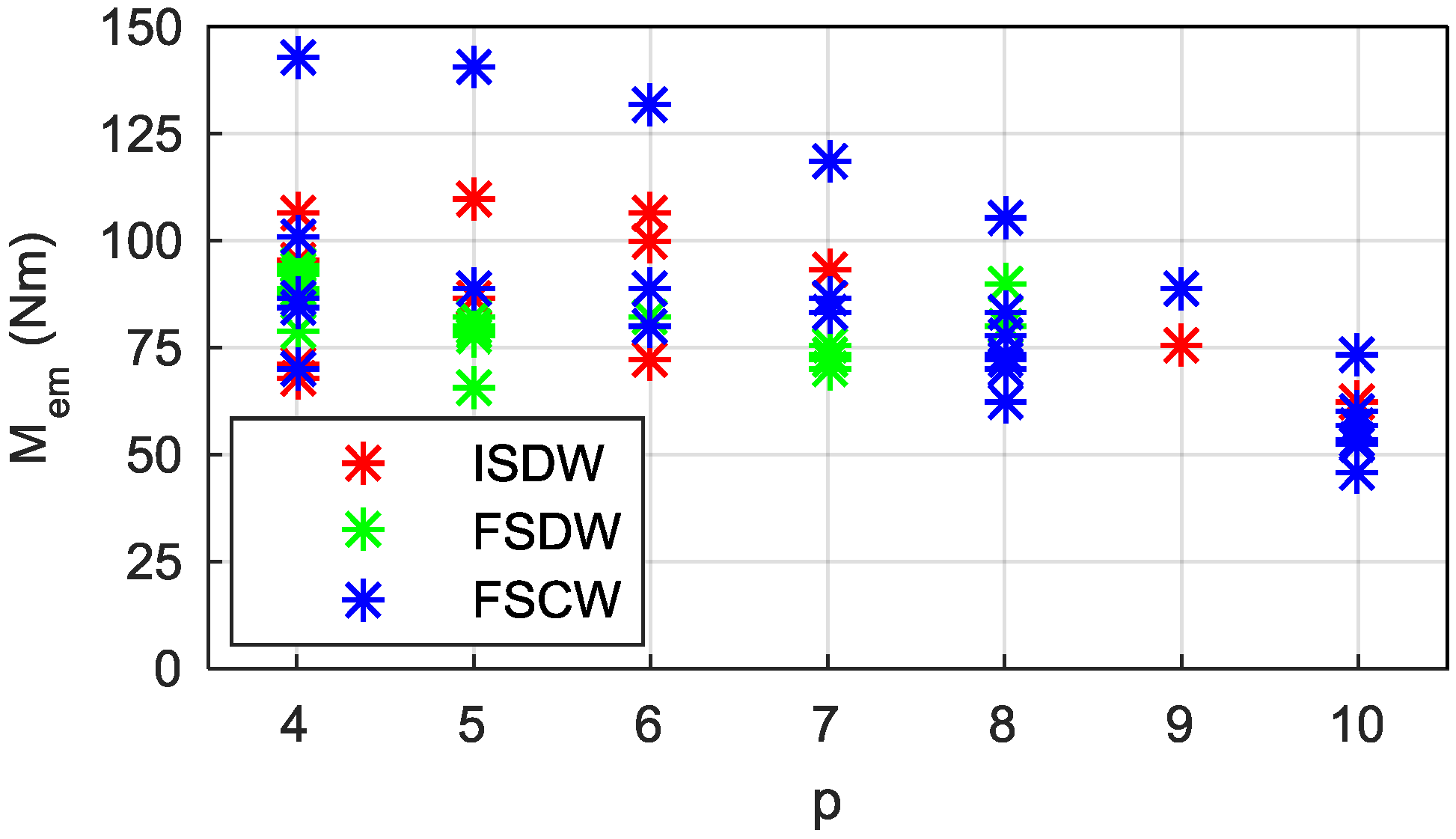

Figure 7.

Mean electromagnetic torque (Mem) versus pole pair number (p) and winding type.

Figure 7.

Mean electromagnetic torque (Mem) versus pole pair number (p) and winding type.

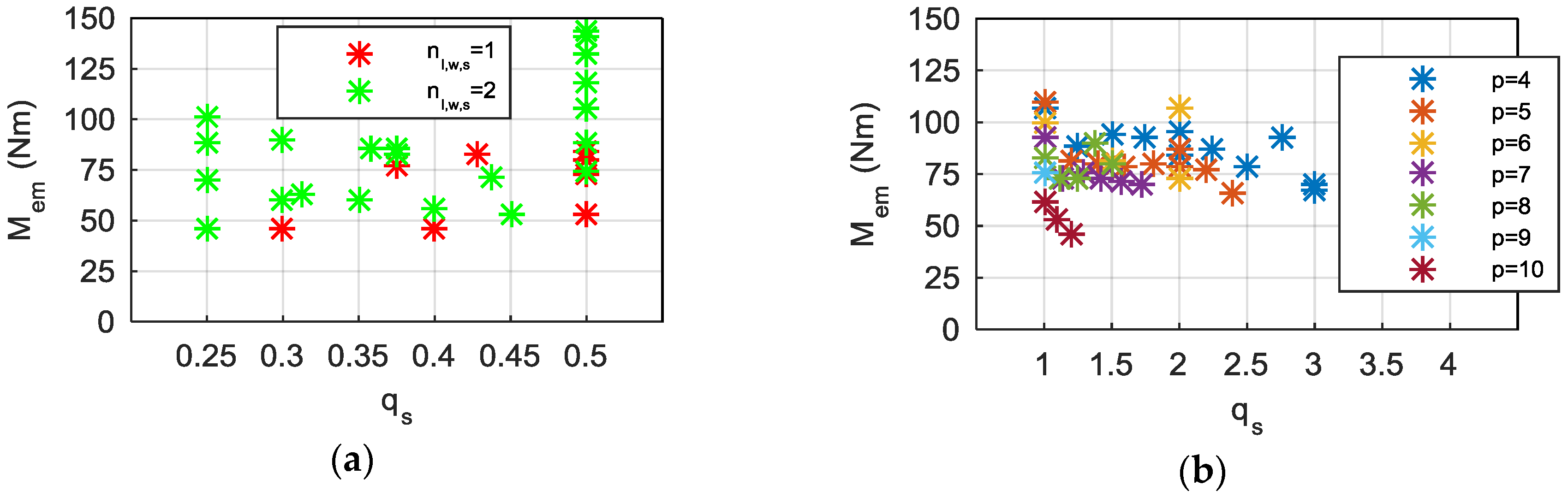

Figure 8.

Mean electromagnetic torque (Mem) versus number of stator slots per pole and phase (qs) (a) and slot layer number (nl,w,s) for FSCW machines; (b) and pole pair number (p) for ISDW and FSDW machines.

Figure 8.

Mean electromagnetic torque (Mem) versus number of stator slots per pole and phase (qs) (a) and slot layer number (nl,w,s) for FSCW machines; (b) and pole pair number (p) for ISDW and FSDW machines.

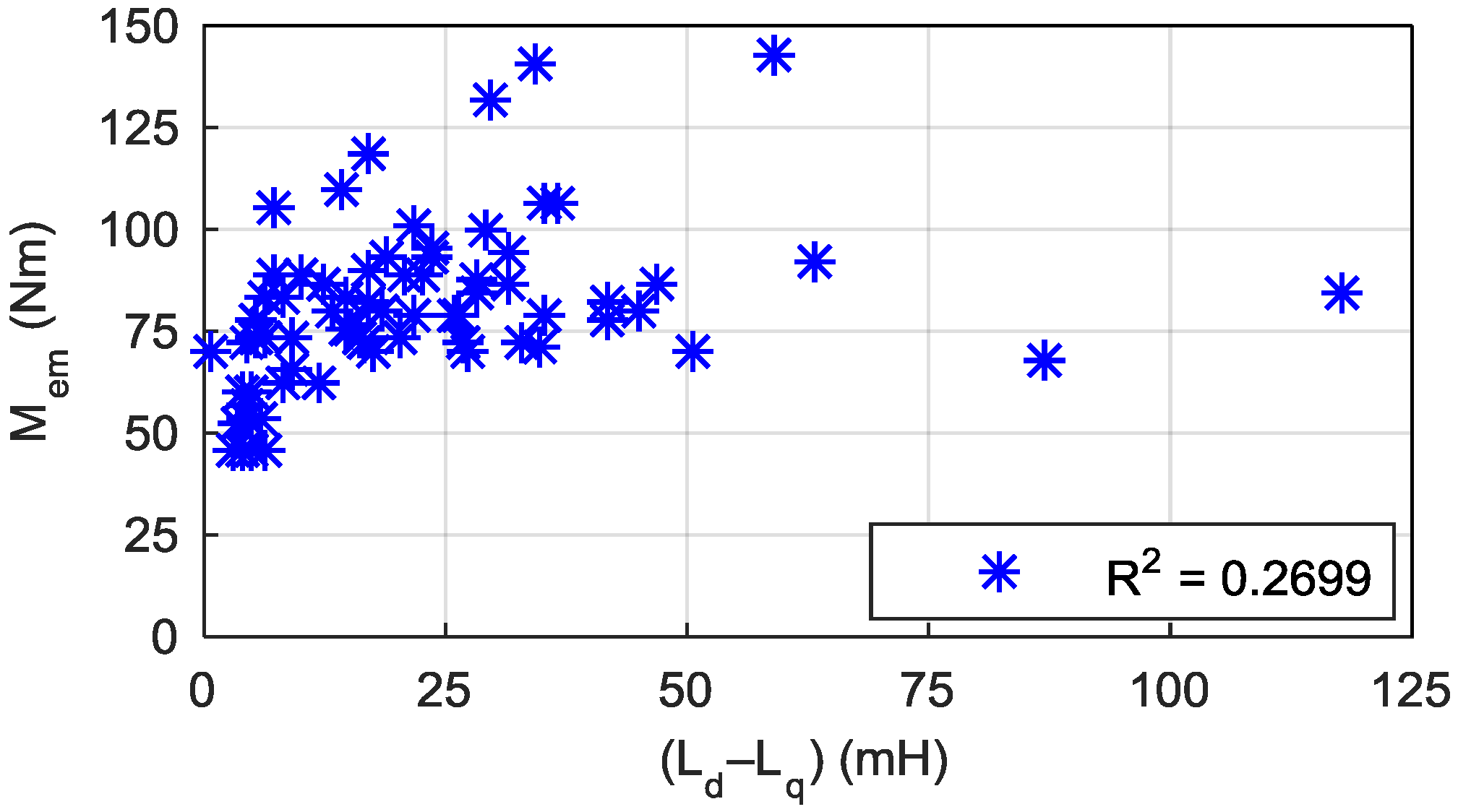

Figure 9.

Mean electromagnetic torque (Mem) versus the difference between direct and quadrature inductances (Ld − Lq).

Figure 9.

Mean electromagnetic torque (Mem) versus the difference between direct and quadrature inductances (Ld − Lq).

Figure 10.

Mean electromagnetic torque (Mem) versus the first harmonic of the air-gap flux density (Bagap1) for (a) ISDW and FSDW machines; (b) FSCW machines.

Figure 10.

Mean electromagnetic torque (Mem) versus the first harmonic of the air-gap flux density (Bagap1) for (a) ISDW and FSDW machines; (b) FSCW machines.

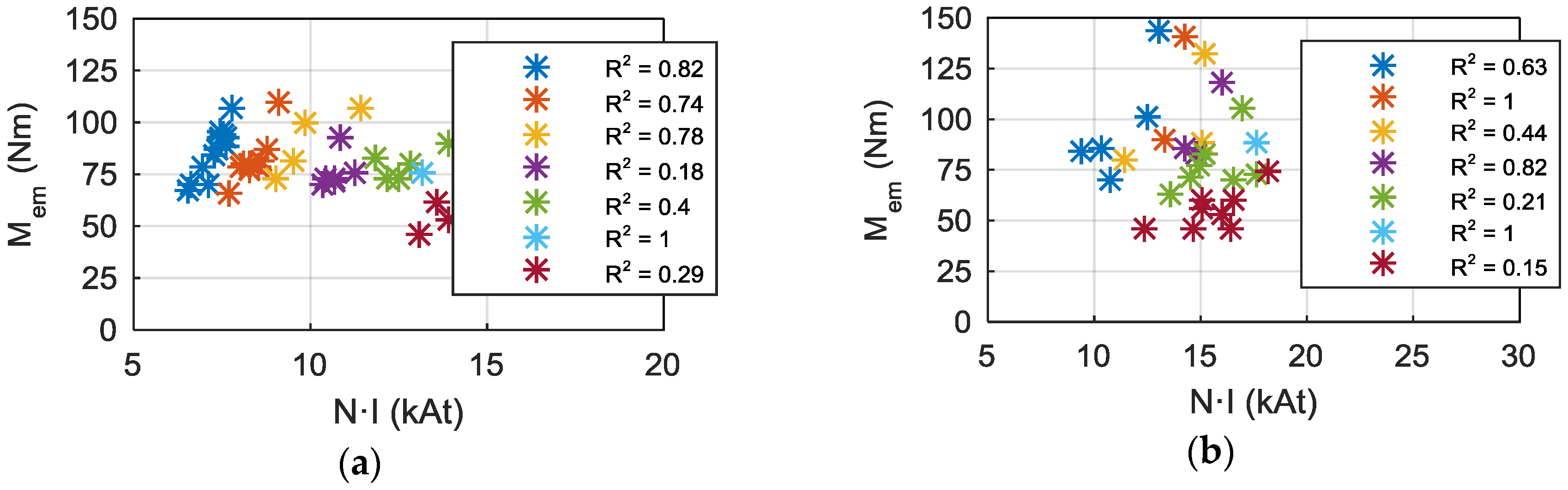

Figure 11.

Mean electromagnetic torque (Mem) versus the magnetomotive force (N·I) for (a) ISDW and FSDW machines; (b) FSCW machines.

Figure 11.

Mean electromagnetic torque (Mem) versus the magnetomotive force (N·I) for (a) ISDW and FSDW machines; (b) FSCW machines.

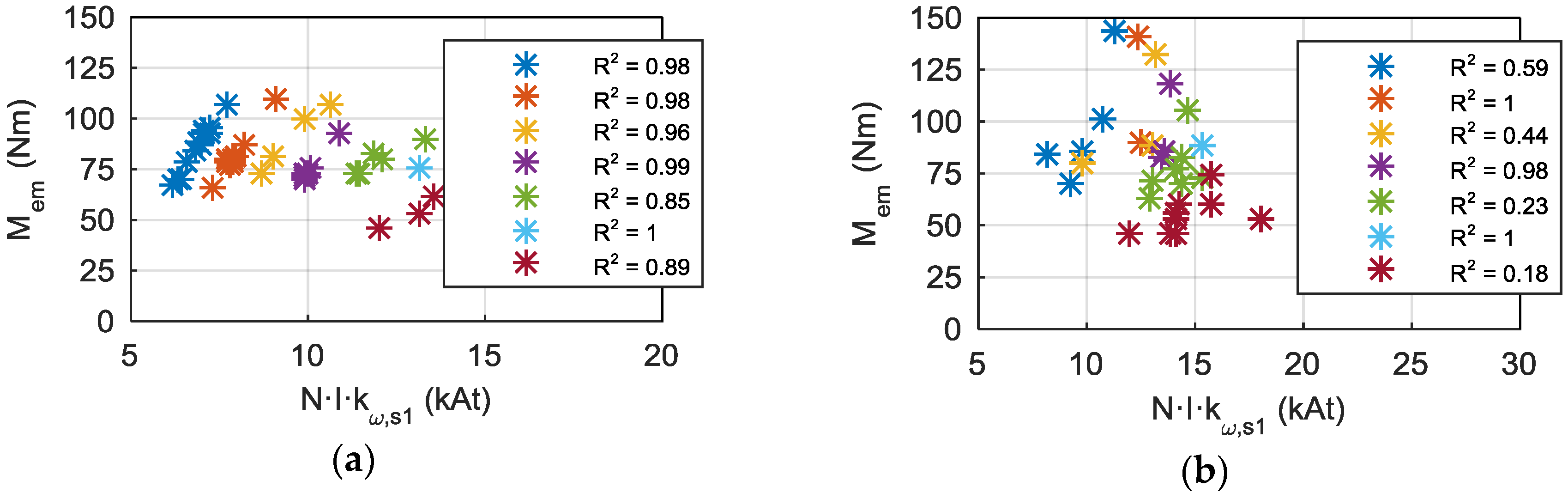

Figure 12.

Mean electromagnetic torque (Mem) versus the magnetomotive force multiplied by the first harmonic winding factor (N·I·kω,s1) for (a) ISDW and FSDW machines; (b) FSCW machines.

Figure 12.

Mean electromagnetic torque (Mem) versus the magnetomotive force multiplied by the first harmonic winding factor (N·I·kω,s1) for (a) ISDW and FSDW machines; (b) FSCW machines.

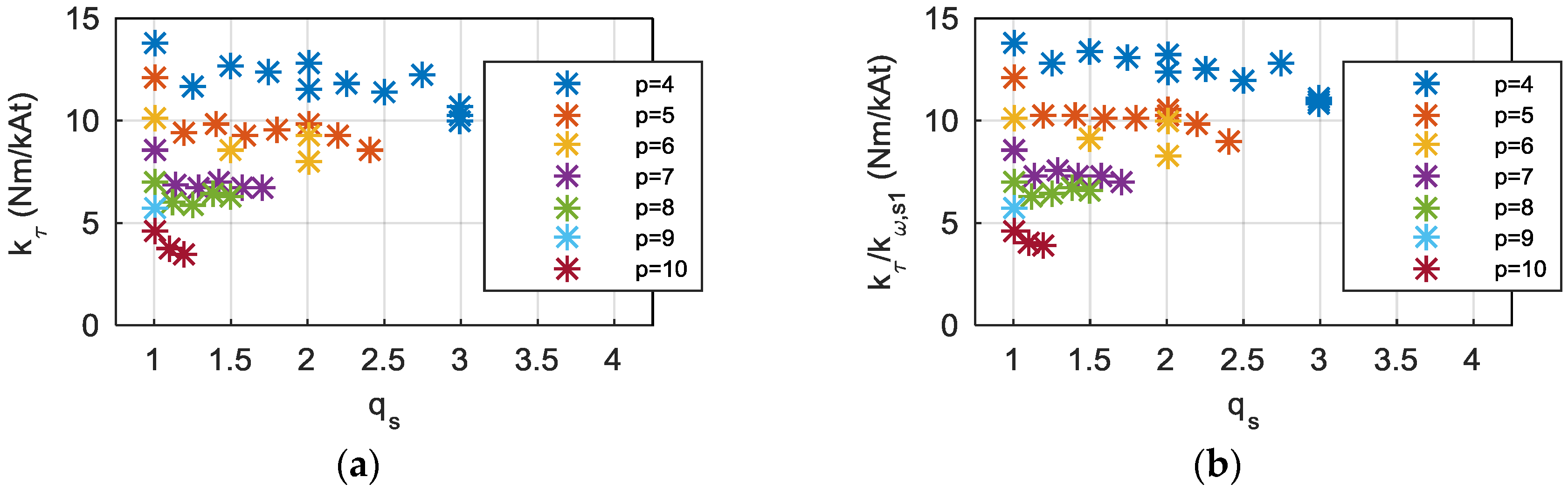

Figure 13.

(a) Torque constant (kT); (b) Torque constant divided by the first harmonic winding factor (kτ/kω,s1) versus the number of stator slots per pole and phase (qs) and pole pair number (p) for ISDW and FSDW machines.

Figure 13.

(a) Torque constant (kT); (b) Torque constant divided by the first harmonic winding factor (kτ/kω,s1) versus the number of stator slots per pole and phase (qs) and pole pair number (p) for ISDW and FSDW machines.

Figure 14.

Torque ripple (Mem,ripple) versus (a) pole pair number (p) and winding type; (b) stator slot number per pole and phase (qs).

Figure 14.

Torque ripple (Mem,ripple) versus (a) pole pair number (p) and winding type; (b) stator slot number per pole and phase (qs).

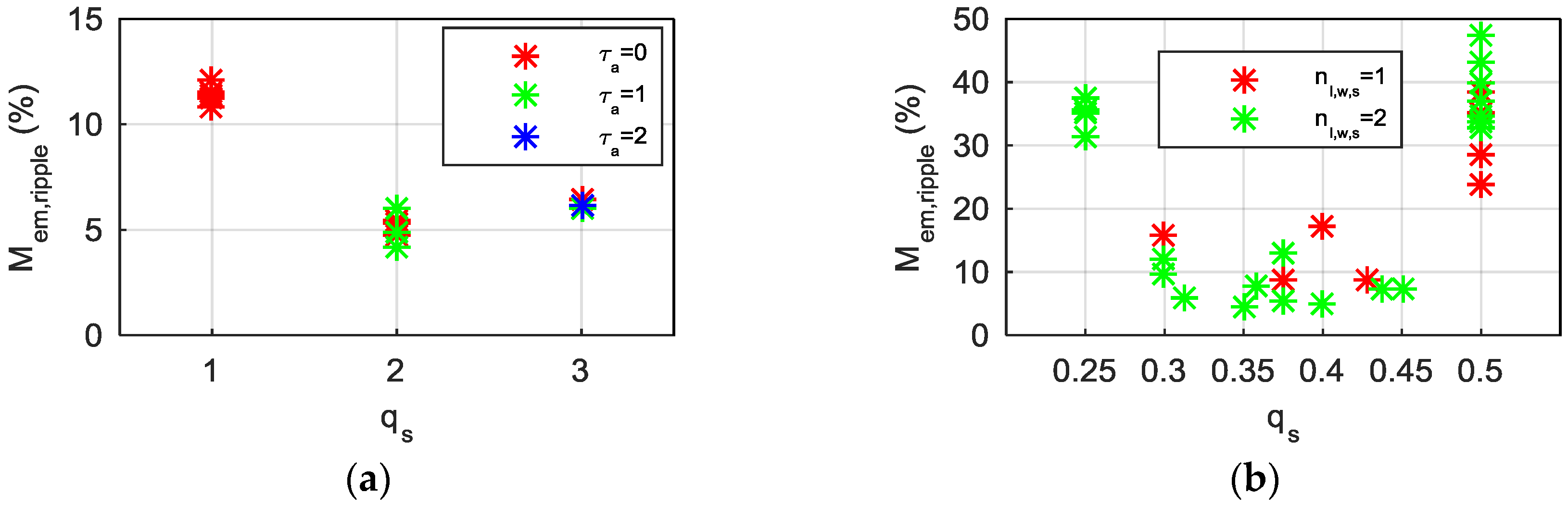

Figure 15.

Torque ripple (Mem,ripple) versus stator slot number per pole and phase (qs) (a) and short pitching (τa) for ISDW machines; (b) and slot layer number (nl,w,s) for FSCW machines.

Figure 15.

Torque ripple (Mem,ripple) versus stator slot number per pole and phase (qs) (a) and short pitching (τa) for ISDW machines; (b) and slot layer number (nl,w,s) for FSCW machines.

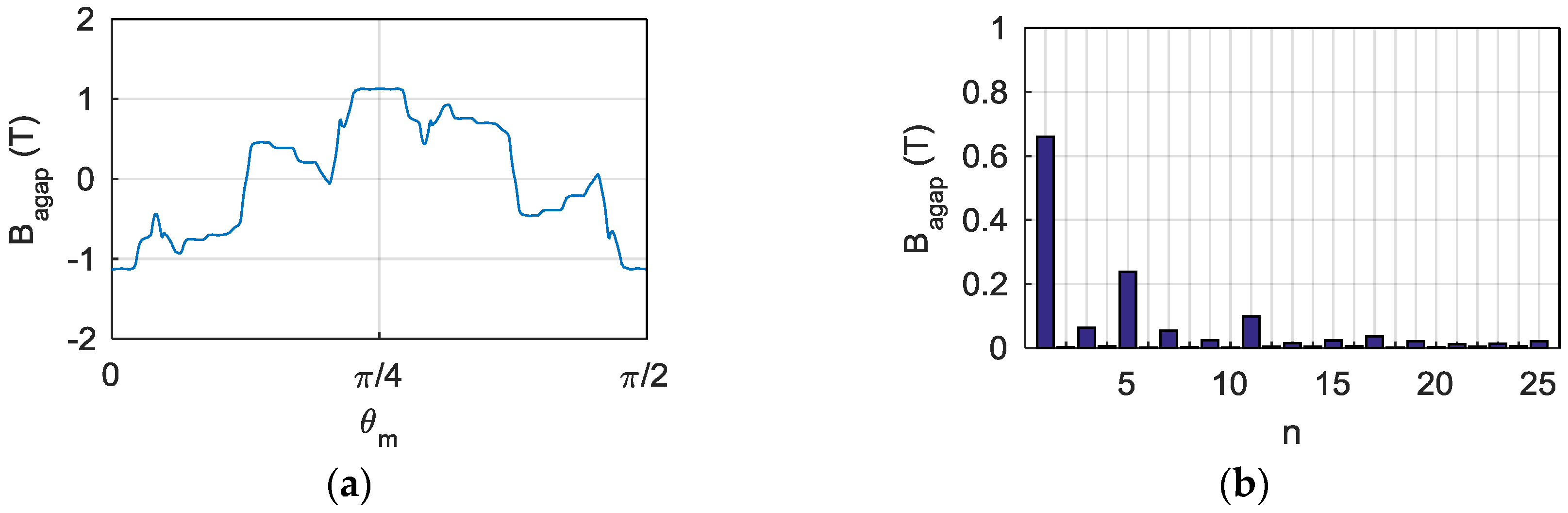

Figure 16.

Air-gap flux density (Bagap) (a) waveform; (b) harmonic spectrum; for the p = 4, Qs = 24 machine.

Figure 16.

Air-gap flux density (Bagap) (a) waveform; (b) harmonic spectrum; for the p = 4, Qs = 24 machine.

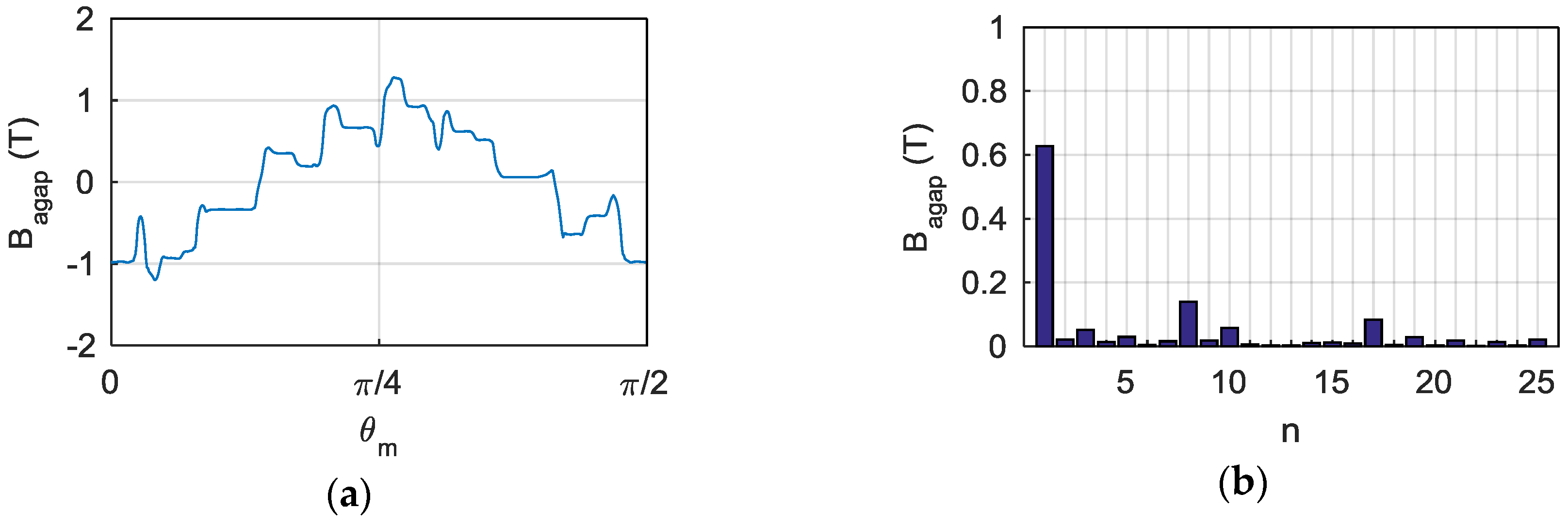

Figure 17.

Air-gap flux density (Bagap) (a) waveform; (b) harmonic spectrum; for the p = 4, Qs = 36 machine.

Figure 17.

Air-gap flux density (Bagap) (a) waveform; (b) harmonic spectrum; for the p = 4, Qs = 36 machine.

Figure 18.

Air-gap flux density (Bagap) (a) waveform; (b) harmonic spectrum; for the p = 4, Qs = 12 and nl,w,s = 2 machine.

Figure 18.

Air-gap flux density (Bagap) (a) waveform; (b) harmonic spectrum; for the p = 4, Qs = 12 and nl,w,s = 2 machine.

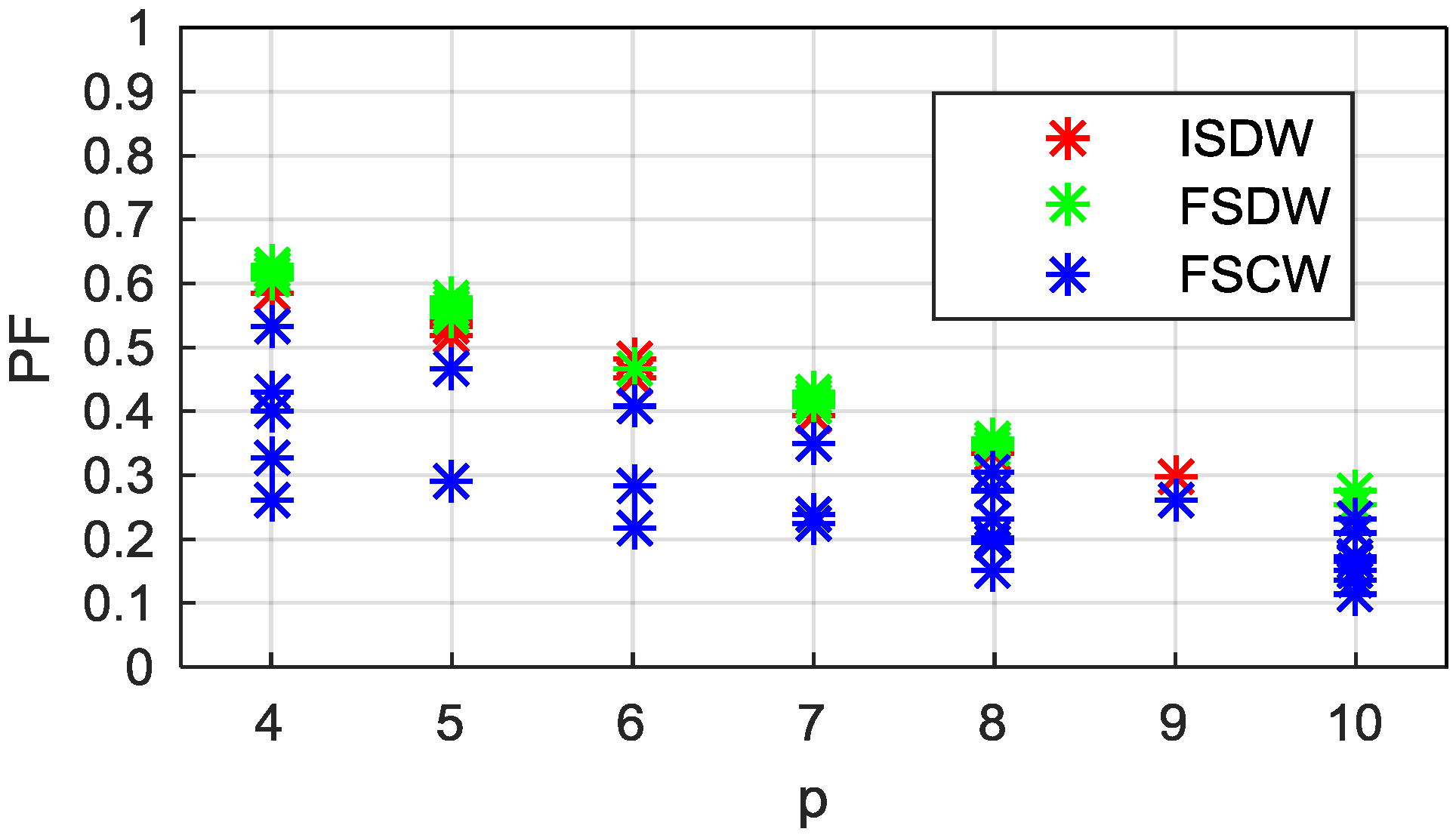

Figure 19.

Power factor (PF) versus pole pair number (p) and winding type.

Figure 19.

Power factor (PF) versus pole pair number (p) and winding type.

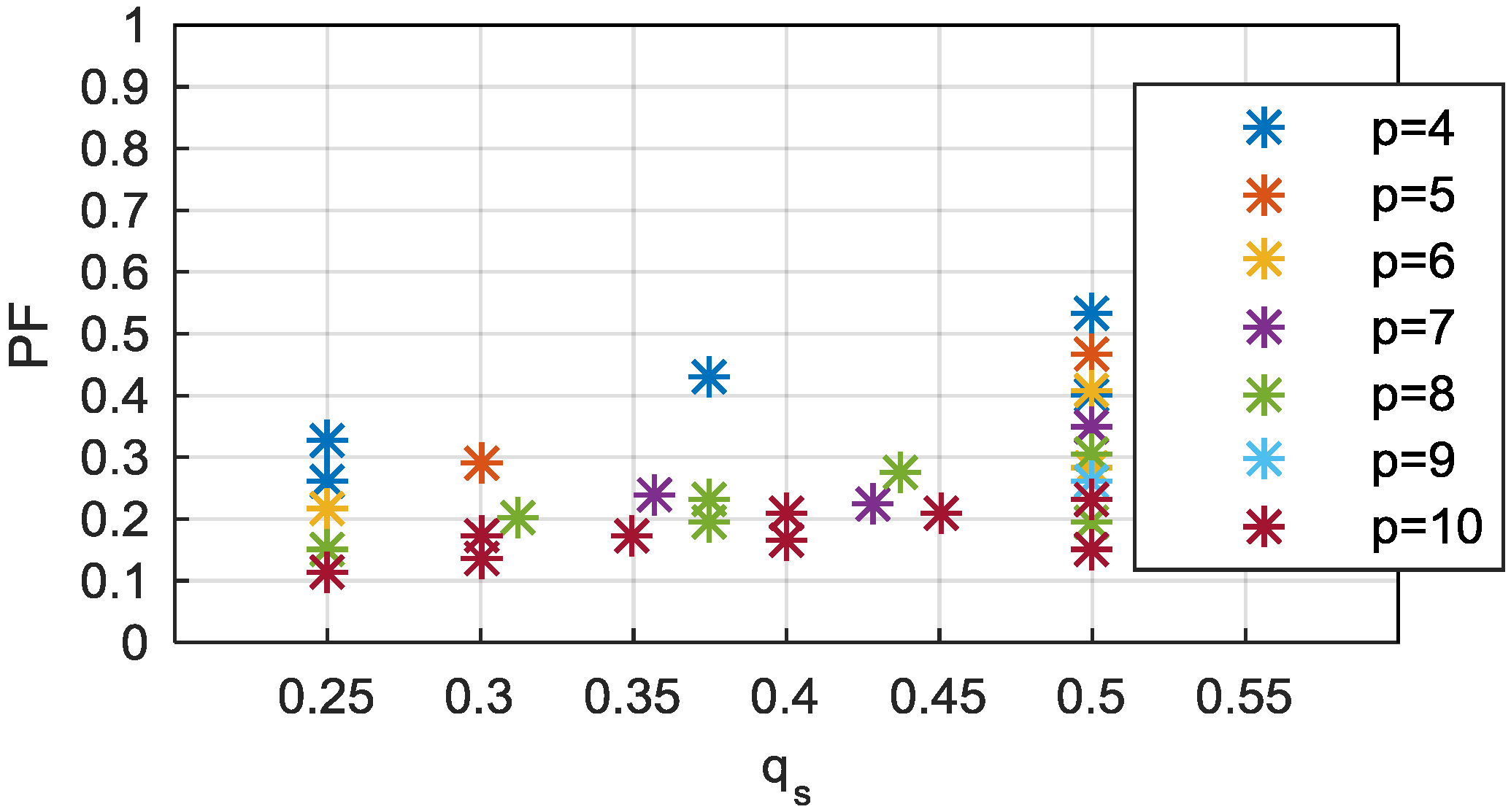

Figure 20.

Power factor (PF) versus stator slot number per pole and phase (qs) for FSCW machines.

Figure 20.

Power factor (PF) versus stator slot number per pole and phase (qs) for FSCW machines.

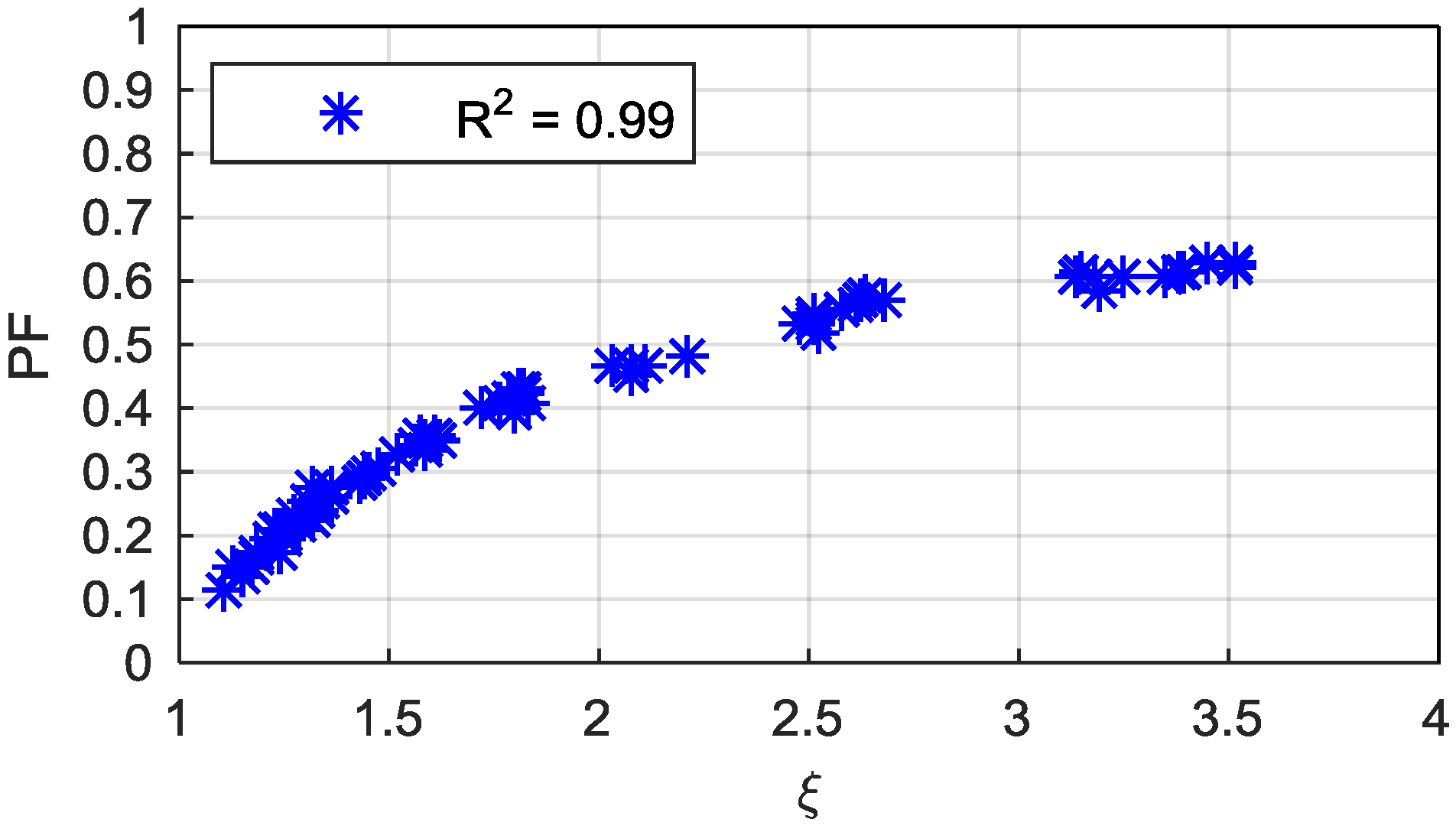

Figure 21.

Power factor (PF) versus saliency ratio (ξ).

Figure 21.

Power factor (PF) versus saliency ratio (ξ).

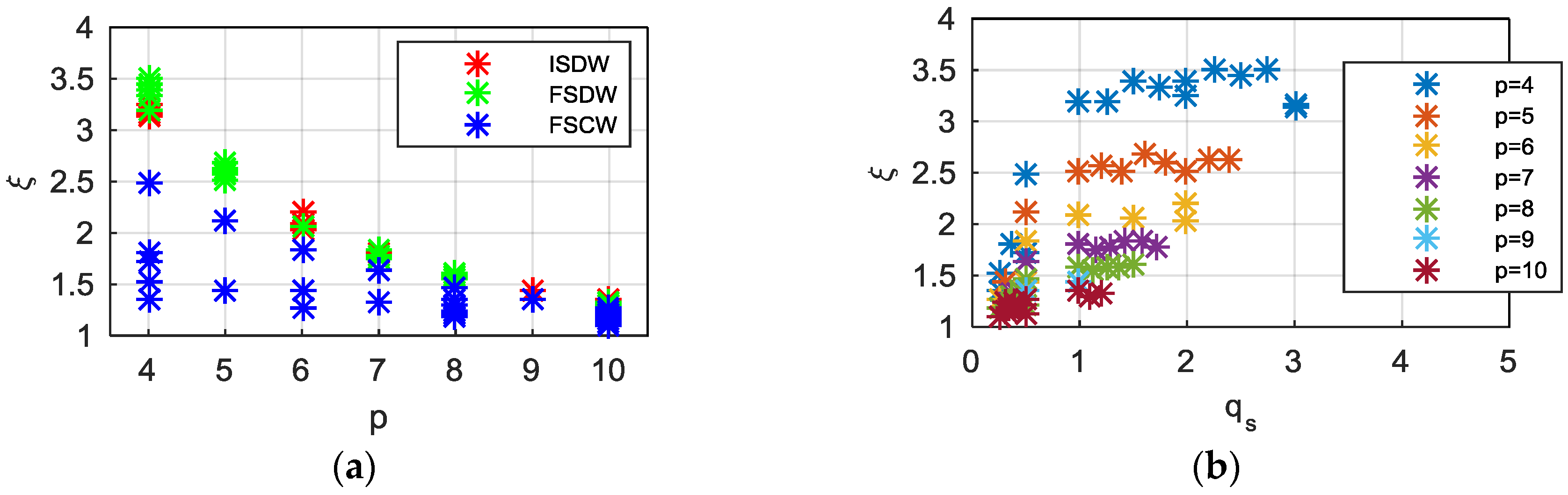

Figure 22.

Saliency ratio (ξ) versus (a) pole pair number (p) and winding type; (b) stator slot number per pole and phase (qs) and pole pair number (p).

Figure 22.

Saliency ratio (ξ) versus (a) pole pair number (p) and winding type; (b) stator slot number per pole and phase (qs) and pole pair number (p).

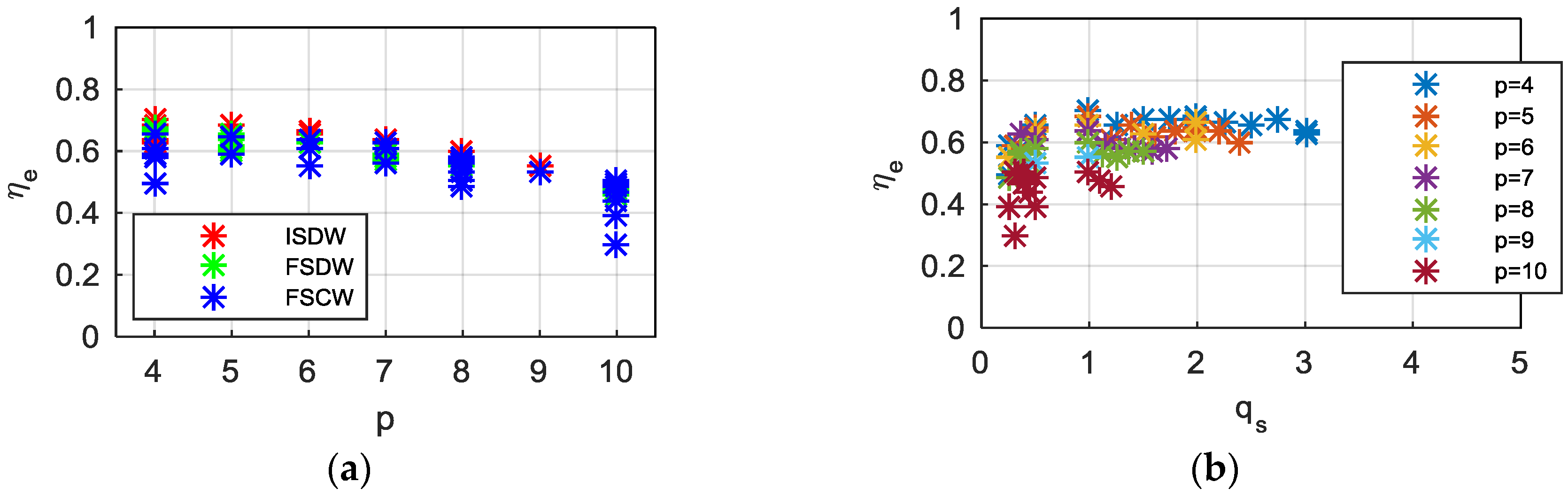

Figure 23.

Electromagnetic efficiency (ηe) versus (a) pole pair number (p) and winding type; (b) stator slot number per pole and phase (qs) and pole pair number (p).

Figure 23.

Electromagnetic efficiency (ηe) versus (a) pole pair number (p) and winding type; (b) stator slot number per pole and phase (qs) and pole pair number (p).

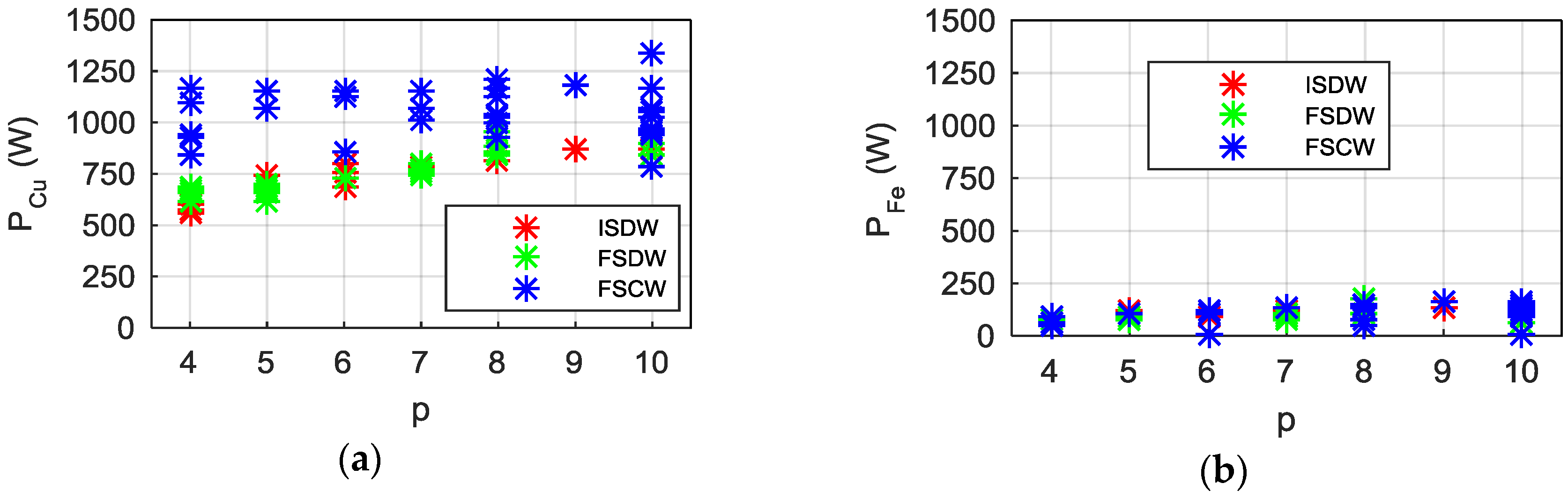

Figure 24.

(a) Copper losses (PCu); (b) and iron losses (PFe) versus pole pair number (p) and winding type.

Figure 24.

(a) Copper losses (PCu); (b) and iron losses (PFe) versus pole pair number (p) and winding type.

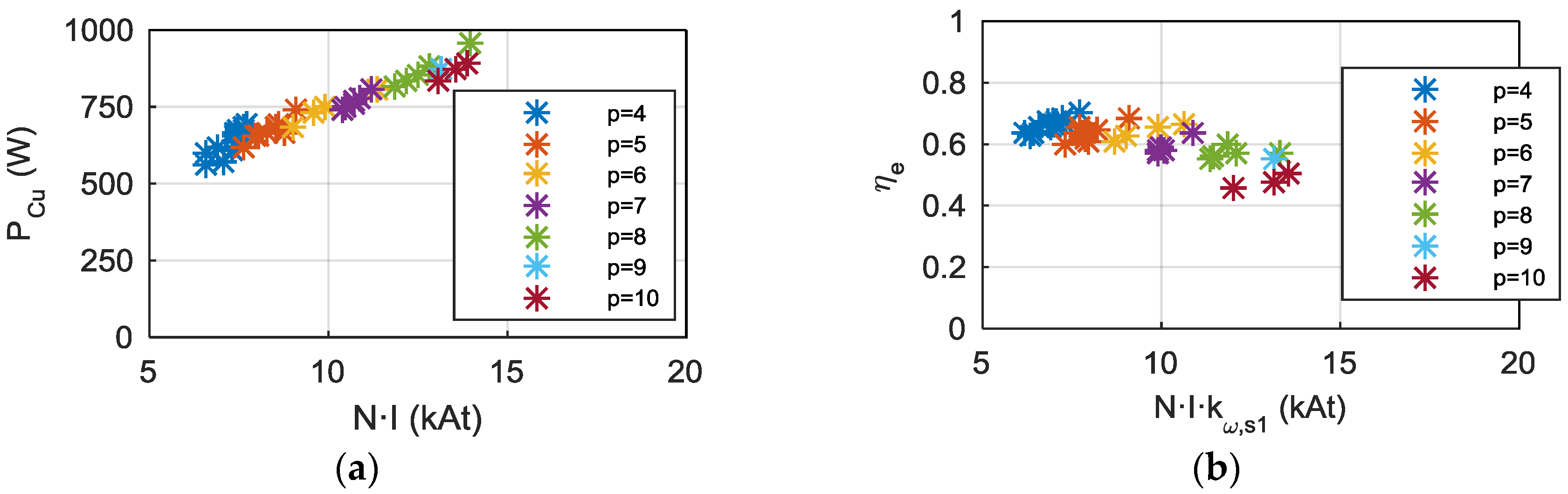

Figure 25.

(a) Copper losses (PCu) versus magnetomotive force (N·I) and pole pair number (p); (b) and electromagnetic efficiency (ηe) versus magnetomotive force multiplied by the first harmonic winding factor (N·I·kω,s1) and pole pair number (p); for ISDW and FSDW machines.

Figure 25.

(a) Copper losses (PCu) versus magnetomotive force (N·I) and pole pair number (p); (b) and electromagnetic efficiency (ηe) versus magnetomotive force multiplied by the first harmonic winding factor (N·I·kω,s1) and pole pair number (p); for ISDW and FSDW machines.

Figure 26.

p = 2, Qs = 48, τa = 2 SynRM geometry.

Figure 26.

p = 2, Qs = 48, τa = 2 SynRM geometry.

Table 1.

Pre-defined rotor geometric parameters.

Table 1.

Pre-defined rotor geometric parameters.

| Parameter | Value |

|---|

| αd | 0.2 |

| αq | 0.2 |

| βint | 0.2 |

| βext | 0.2 |

| γα | 0.5 |

| γβ | 0.5 |

| Number of barriers | 4 |

Table 2.

Sample machine characteristics.

Table 2.

Sample machine characteristics.

| Parameter Type | Parameter | Machine 1 | Machine 2 | Machine 3 |

|---|

| Machine topology | Winding type | ISDW | FSDW | FSCW |

| Pole number | 4 | 4 | 4 |

| Slot number | 24 | 36 | 12 |

| Geometry | Slot depth | 23.8 mm | 24.2 mm | 25.4 mm |

| Tooth width, parallel tooth | 19.4 mm | 13.4 mm | 33.9 mm |

| Slot opening | 3 mm | 3 mm | 22.5 mm |

| Copper slot fill factor | 0.45 | 0.45 | 0.59 |

| Rotor barrier number | 4 | 4 | 4 |

| Barrier geometry | αd = αq = βint = βext = 0.2; γα = γβ = 0.5 |

| Rotor barrier bridges | 0.8 mm | 0.8 mm | 0.8 mm |

| Machine performance | Stator teeth flux density | 1.52 T | 1.55 T | 1.6 T |

| Stator yoke flux density | 1.56 T | 1.45 T | 1.64 T |

| Maximum rotor barrier flux density | 2.31 T | 2.12 T | 2.19 T |

| Current density | 8 A/mm2 | 8 A/mm2 | 8 A/mm2 |

| Ld | 53.6 mH | 44.9 mH | 98.5 mH |

| Lq | 16.8 mH | 13.2 mH | 39.7 mH |

| Saliency ratio (ξ) | 3.19 | 3.39 | 2.48 |

Table 3.

Design specifications.

Table 3.

Design specifications.

| Parameter | Value |

|---|

| Rated torque (Nm) | 200 |

| Maximum voltage (V) | 400 |

| Maximum current (A) | 20 |

| Rated speed (rpm) | 160 |

Table 4.

Prototype SynRM characteristics.

Table 4.

Prototype SynRM characteristics.

| Parameter | Value |

|---|

| Electrical characteristic |

| Rated torque (Nm) | 200 |

| Rated voltage (V) | 335 |

| Rated current (A) | 14.6 |

| Rated speed (rpm) | 160 |

| Geometric characteristics |

| Number of pole pairs | 7 |

| Number of stator slots | 42 |

| Stack length (mm) | 150 |

| Stator outer diameter (mm) | 300 |

| Stator inner diameter (mm) | 215 |

| Air gap length (mm) | 0.8 |

Table 5.

Prototype results comparison.

Table 5.

Prototype results comparison.

| Parameter | Matlab-FEMM | Experimental Test | Difference (%) |

|---|

| Electromagnetic torque (Nm) | 200 | 200 | 0.0 |

| RMS phase current (A) | 14.1 | 13.6 | 3.7 |

| RMS line voltage (V) | 347 | 344 | 0.9 |

| Apparent power (kVA) | 8.48 | 8.12 | 4.4 |

| Input power (kW) | 4.82 | 4.46 | 8.1 |

| Output power (kW) | 3.35 | 3.35 | 0.0 |

| Power factor | 0.55 | 0.55 | 0.0 |

| Efficiency | 0.70 | 0.75 | 6.7 |

Table 6.

Design specifications and restrictions.

Table 6.

Design specifications and restrictions.

| Parameter | Value |

|---|

| Electrical Specifications |

| Rated speed (rpm) | 160 |

| Maximum voltage (V) | 400 |

| Maximum current (A) | 20 |

| Geometrical Restrictions |

| Stack length (mm) | 125 |

| Stator outer diameter (mm) | 300 |

| Stator inner diameter (mm) | 215 |

| Air-gap (mm) | 1 |

| Rotor inner diameter (mm) | 85 |

| Winding Restrictions |

| Fill factor, distributed winding | 0.45 |

| Copper slot fill factor, single layer concentrated winding | 0.65 |

| Copper slot fill factor, double layer concentrated winding | 0.6 |

| Current Density and Reference Flux-Densities |

| Current density (A/mm2) | 8 |

| Stator yoke peak flux density (T) | 1.6 |

| Stator teeth peak flux density (T) | 1.6 |

| Air-gap peak flux density (T) | 0.85 |

Table 7.

SynRM and permanent magnet synchronous machines (PMSM) characteristics for the same volume.

Table 7.

SynRM and permanent magnet synchronous machines (PMSM) characteristics for the same volume.

| Parameter | SynRM | PMSM |

|---|

| Electromagnetic torque (Nm) | 103 | 162 |

| Torque ripple (Nm) | 4.9 | 0.6 |

| Line voltage (V) | 319 | 330 |

| Phase current (A) | 5.7 | 6.5 |

| Apparent power (kVA) | 3.15 | 3.71 |

| Input power (kW) | 2.73 | 3.35 |

| Output power (kW) | 1.73 | 2.71 |

| Power factor | 0.85 | 0.90 |

| Efficiency | 0.63 | 0.81 |

Table 8.

SynRM and PMSM characteristics for the same torque requirement.

Table 8.

SynRM and PMSM characteristics for the same torque requirement.

| Parameter | SynRM | PMSM |

|---|

| Electromagnetic torque (Nm) | 162 | 162 |

| Torque ripple (Nm) | 7.5 | 0.6 |

| Line voltage (V) | 332 | 330 |

| Phase current (A) | 8.05 | 6.5 |

| Apparent power (kVA) | 4.63 | 3.71 |

| Input power (kW) | 3.92 | 3.35 |

| Output power (kW) | 2.71 | 2.71 |

| Power factor | 0.82 | 0.90 |

| Efficiency | 0.69 | 0.81 |