1. Introduction

Nowadays, owing to its high torque density and high efficiency, the rare-earth permanent-magnet (PM) (such as NdFeB) synchronous machine (PMSM) is widely used for industrial applications, such as electric vehicle (EV) traction application [

1,

2,

3]. Unfortunately, the volatile price of NdFeB after 2011 as well as a limited flux-weakening capacity have immensely limited their further development for EV applications, which require a low cost and a wide speed range [

4]. For this reason, owing to their advantages such as mature technology, robust structure, relatively low cost, and excellent flux-weakening performance, induction machines (IMs) are often more competitive for EV applications [

1]. However, the low efficiency and power factor of IMs increase the battery cost, which plays a dominant role in the whole EV cost.

To balance the performance and cost, permanent-magnet-assisted synchronous reluctance machines (PMA-SynRMs) are employed, which can not only reduce the amount of PMs by increasing the reluctance torque with a high saliency ratio, but also keep a relatively high efficiency due to the added PMs [

5,

6,

7,

8]. PMA-SynRMs with NdFeB were designed for EV applications in References [

9,

10]. To reduce the cost further, the use PMA-SynRMs with ferrite magnets has also attracted much attention. PMA-SynRMs with ferrite magnets, which have the same efficiency and power density as those with rare-earth magnets, were investigated in Reference [

11]. However, the arc-shaped magnets increase the manufacturing difficulty and cost. Thus, a new PMA-SynRM with rectangular-shaped ferrite magnets was designed, taking the manufacturing problem into consideration [

12].

Recently, due to its enhanced fault-tolerant capacity compared with a conventional three-phase machine, the multiphase machine has become a competitive candidate for safety-critical applications. Fractional-slot concentrated winding (FSCW) is always used together with a multiphase machine owing to its short end-turn windings, high slot filling factor, and low cogging torque [

13,

14]. Moreover, the inherent high self-inductance of FSCW can enhance its flux-weakening ability and fault-tolerant capacity. A PMA-SynRM equipped with multiphase FSCW seems to be very attractive for EV application. Unfortunately, FSCW often produces a large number of undesirable space harmonics in stator magnetomotive force (MMF), which induces significant eddy loss in PMs and thus decreases the efficiency and increases the irreversible demagnetization risk of the PMs [

15,

16]. What is more, several papers show that FSCW is not suitable for salient-pole machines because of its weak ability to output reluctance torque [

17]. In Reference [

18], four stators—two integral-slot distributed windings (ISDWs) and two FSCWs—were designed using the same interior PM rotor. The comparison results show that the reluctance torques of the interior PMSMs with FSCWs are much lower than those with ISDWs.

To improve the situation, it is necessary to suppress the MMF harmonics of the FSCWs. It has been reported that, for FSCW, an appropriate pole and slot combination will aid in the reduction of the MMF harmonics. In Reference [

19], it was reported that asymmetrical six-phase winding with 30 degrees between the two three-phase windings has better MMF distribution than symmetrical six-phase winding. The paper therefore focuses on the selection of the fractional-slot winding, particularly the number of slots and poles necessary to achieve asymmetrical six-phase winding. The effect of the single- or double-layer FSCW on the MMF harmonics was investigated in Reference [

20]. The study indicates that by employing double-layer winding type, the 24-slot/22-pole six-phase machine can effectively reduce the sub-harmonic compared with the single-layer one. Adding extra flux barriers in the no-winding teeth is also a technique used to reduce the MMF harmonics [

21]. Some other winding topologies have also been proposed to reduce the MMF harmonics. Multilayer winding [

22,

23] and winding with different numbers of turns per coil side [

24,

25] were also employed to enhance the quality of the stator MMF distribution. These winding configurations significantly enhance the manufacturing cost. Reference [

26] shows a new concept—the concept of stator shifting, in which the conventional 12-slot/10-pole three-phase machine is divided into two sets of three-phase winding and the final 24-slot/10-pole dual three-phase winding configuration is obtained by placing a right phase shift between the two sets of windings. The new 24-slot/10-pole winding can effectively reduce the MMF harmonics. Also, in recent literature, some new winding configurations, such as 24-slot/10-pole [

27,

28,

29,

30] and 18-slot/8-pole [

31], which were developed from the conventional 12-slot/10-pole and 9-slot/8-pole winding configurations, have been proposed by employing the concept of stator shifting.

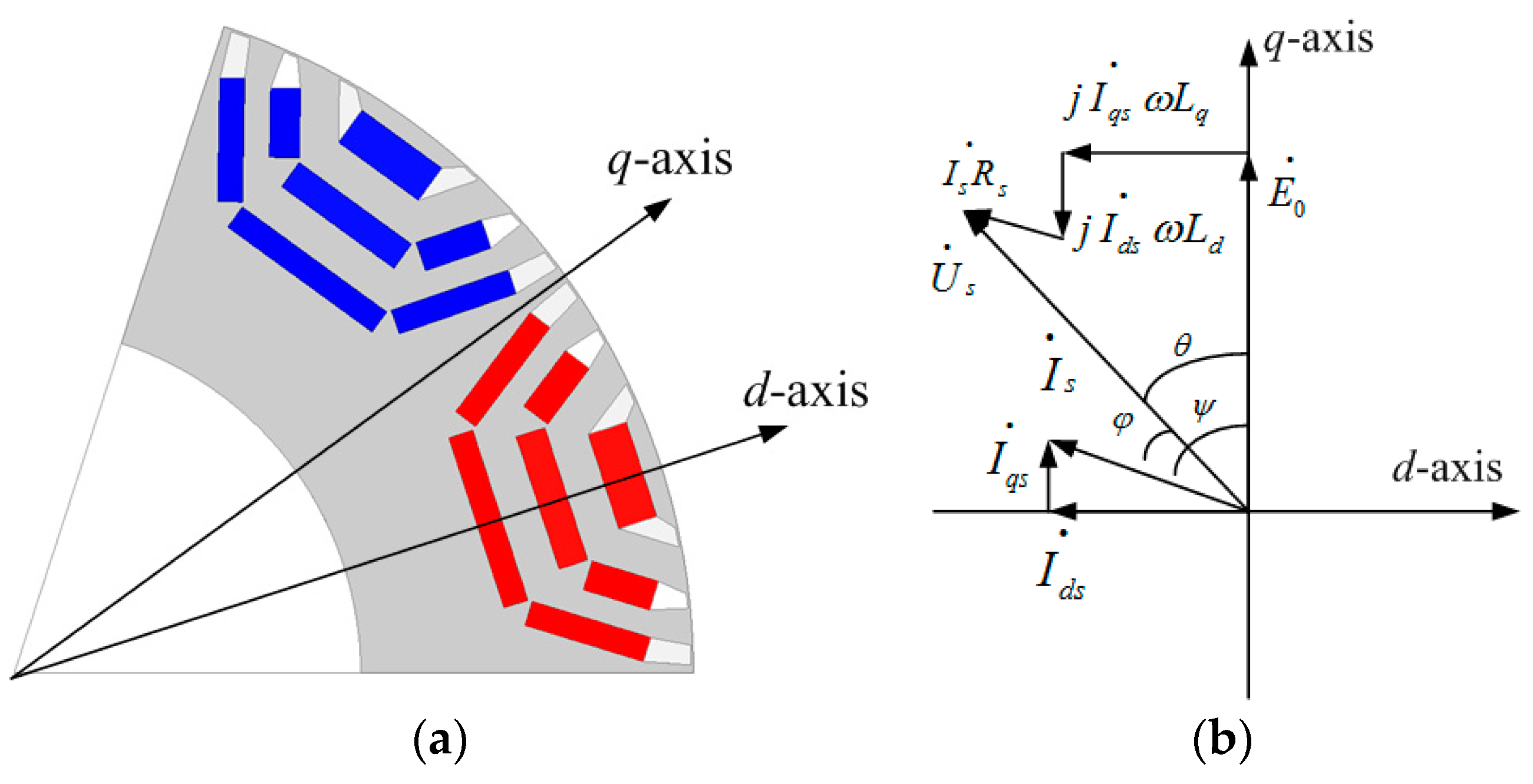

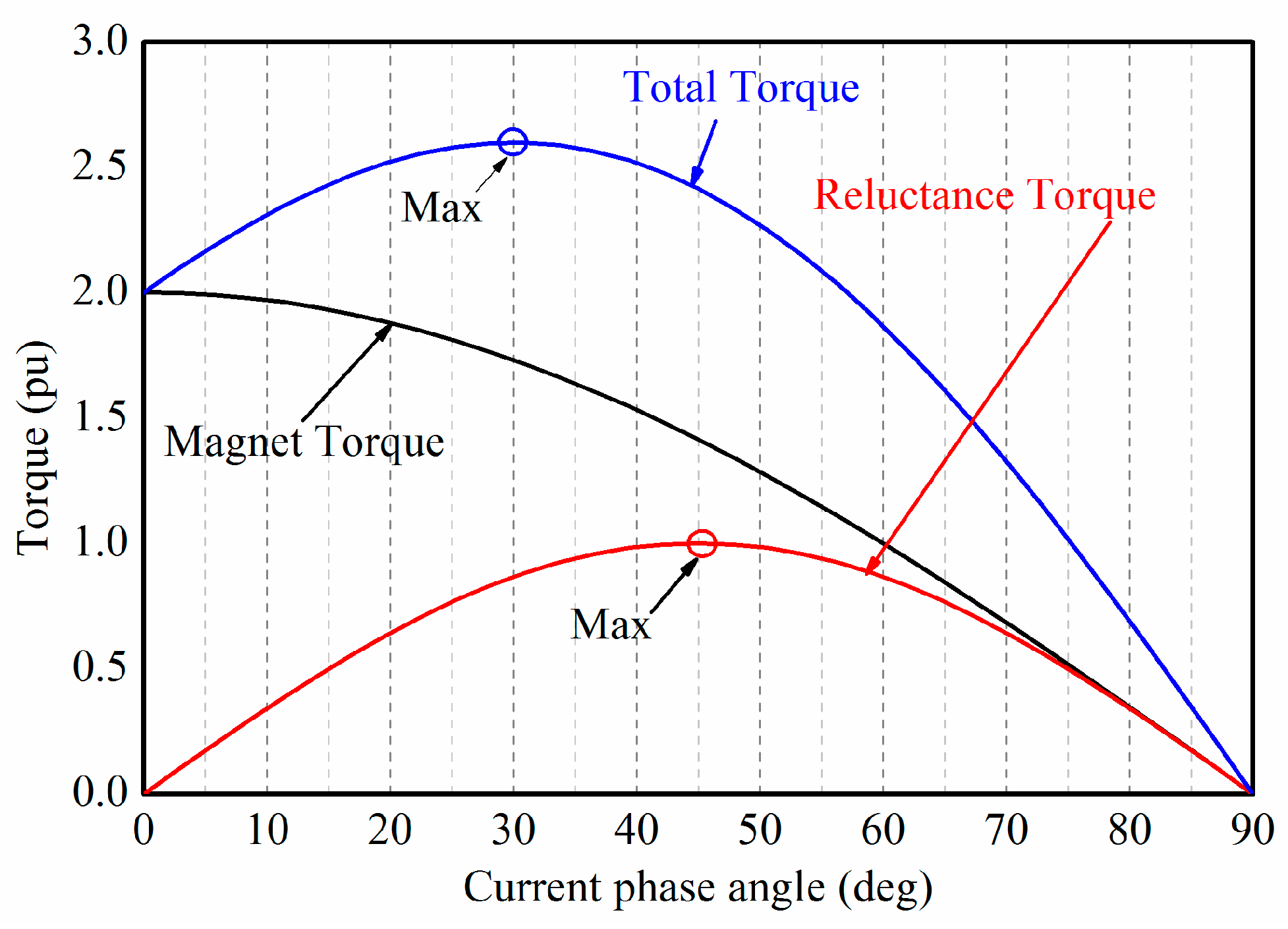

Although the new winding configurations after using the concept of stator shifting can significantly reduce the content of the MMF harmonics, they are rarely used in salient-pole machines. What is more, whether the optimized stator MMF distribution indeed improves the usage of the reluctance torque has not yet been fully investigated. In this paper, the 24-slot/10-pole six-phase winding, which was developed from the conventional 12-slot/10-pole six-phase winding using the same concept, is used in a PMA-SynRM. A PMA-SynRM equipped with the conventional 12-slot/10-pole six-phase winding is also designed. All of the parameters, such as the rotor dimensions, turns-per-phase, slot filling factor, inner and outer diameters, and stack length, are the same except the number of slots. The widths of the teeth are adjusted to the different numbers of slots in the stator. With the same rated current, the average torque, torque ripple, various loss components, and efficiency are compared. Then, with different current magnitudes, the total torque characteristics, the reluctance torques, and the inductances of the two machines under different current phase angles ψ (the leading angle of the current vector from the q-axis) are also compared. Finally, the different output capacities of the two machines are obtained, and may offer a possible way to enhance the reluctance torque in salient-pole machines. This paper aims to investigate the relationship between the stator MMF harmonics and the usage of the reluctance torque. Both the MMF harmonics and the reluctance torque can’t be measured directly by experiment. Therefore, the investigation is carried out using the finite-element method (FEM), which is expected to show the comparison more clearly and then, to give a fair judgment.

2. Winding Configurations and MMF Analysis

FSCWs that satisfy

Q = 2

p+/−2, where

Q denotes the number of slots and

p denotes the number of poles, are often employed by multiphase machines to maximize their winding factor and enhance their fault-tolerant capacity [

32]. For a six-phase machine, the slot number is also required to satisfy

Q = 6

k, where

k is a positive integer. Here, by way of example, 12-slot/10-pole machines with both three-phase and six-phase winding layouts are analyzed, as shown in

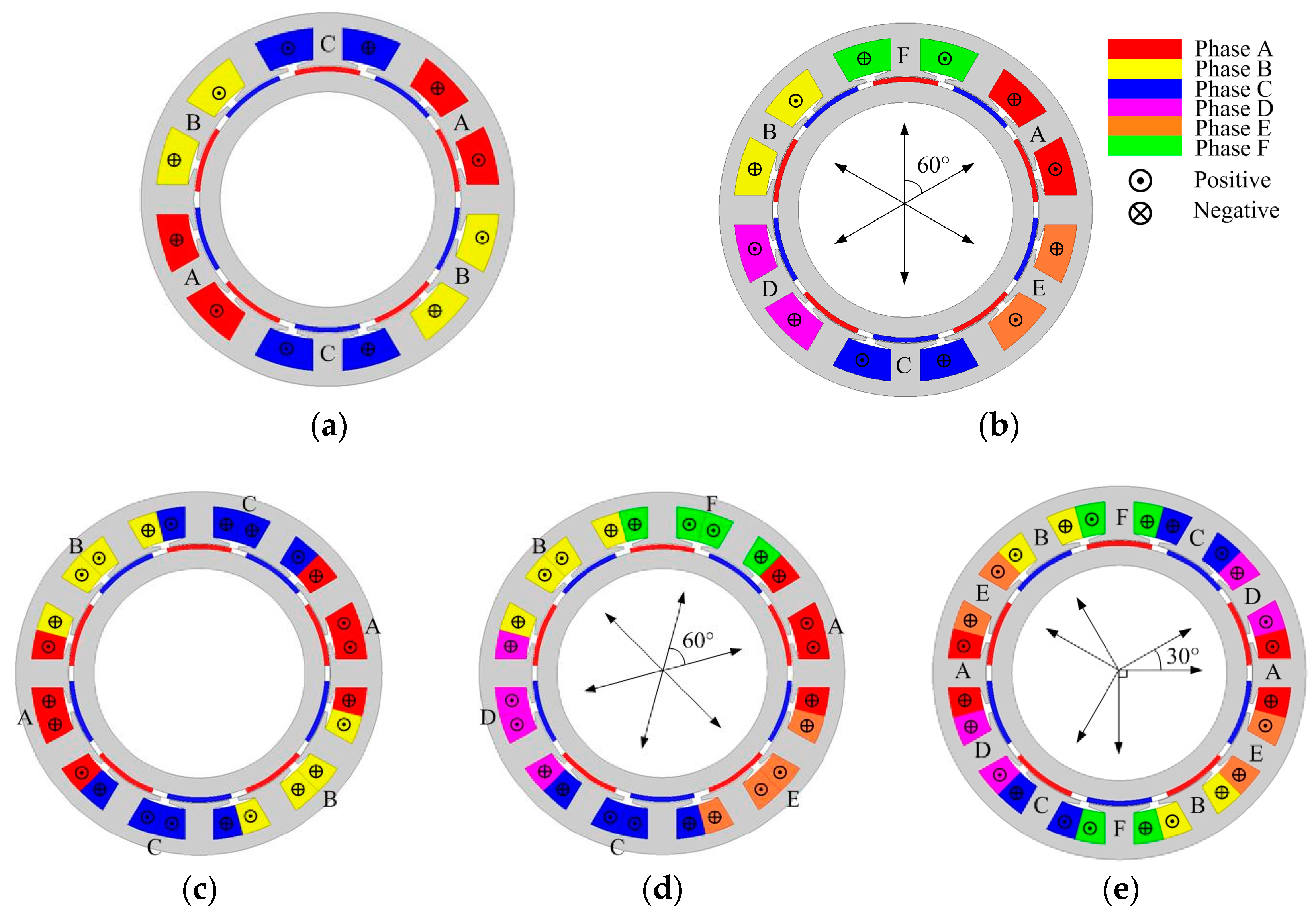

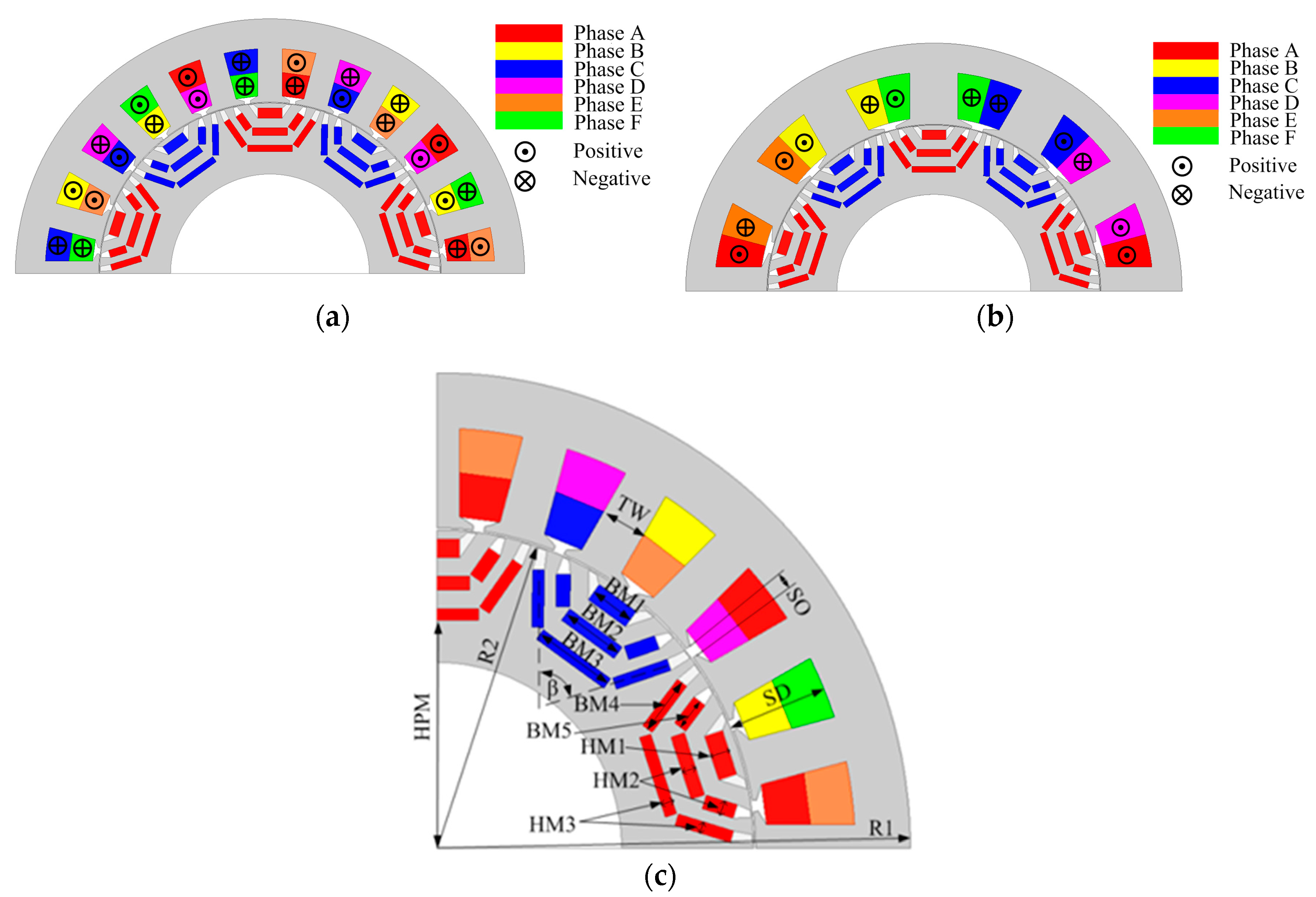

Figure 1.

In

Figure 1, it can be found that there is only one kind of six-phase winding configuration (Winding II) for a single-layer 12-slot/10-pole winding type, while there can be two different kinds of six-phase winding configurations for a double-layer winding type—symmetric six-phase (Winding IV) and asymmetric six-phase winding (Winding V). The symmetric six-phase windings with a 60-degree phase belt have electromagnetic features similar to a conventional 60-degree three-phase winding [

33], as shown in

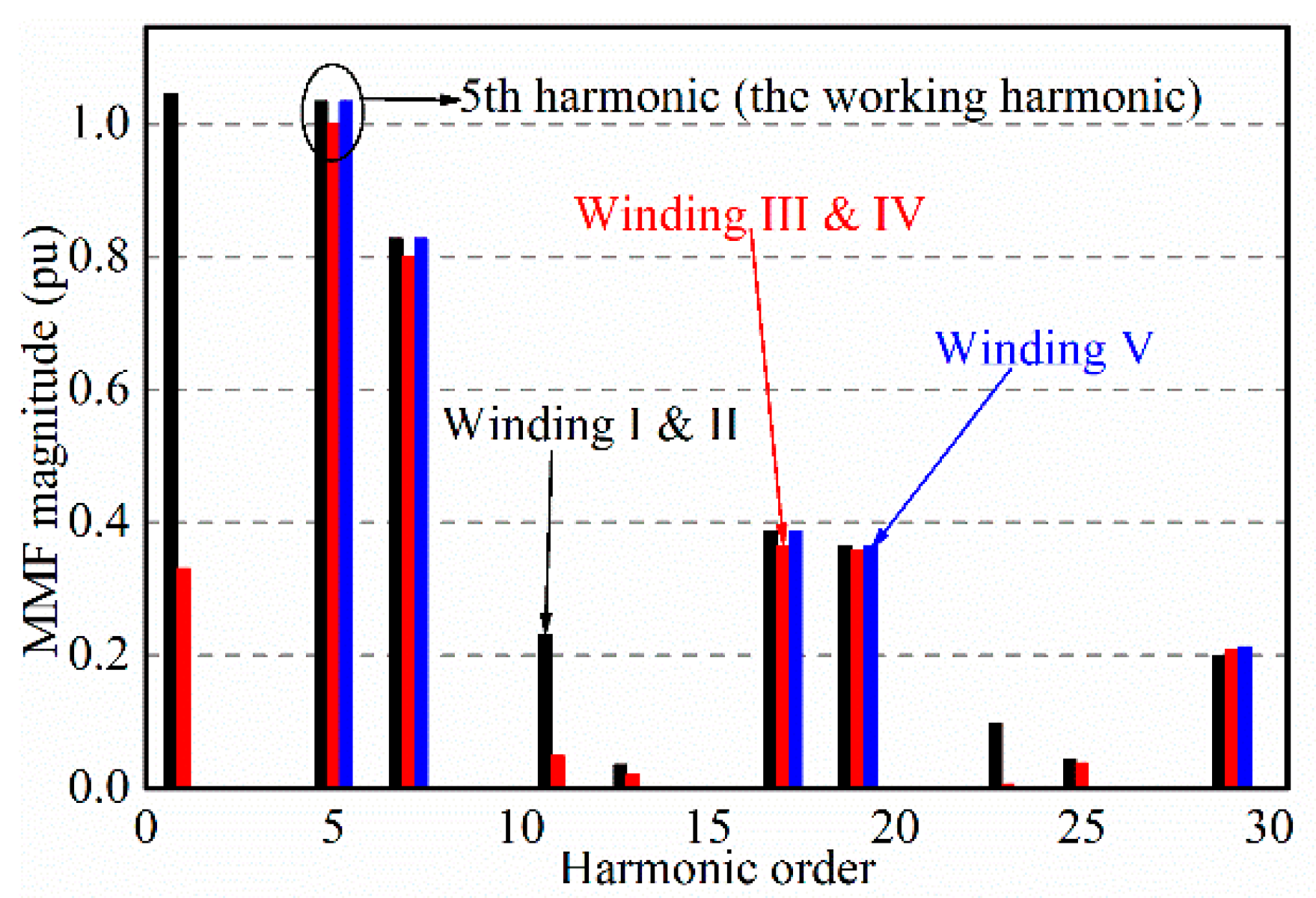

Table 1. The symmetric six-phase windings (Winding II and Winding IV) possess the same winding factors and MMF distributions as the three-phase windings (Winding I and Winding III). For three-phase and symmetric six-phase windings, a double-layer winding type will lower the winding factor because the double layer winding will introduce an extra winding distribution factor. It should be highlighted that the content of MMF harmonics of 12-slot/10-pole asymmetric six-phase winding is almost half of the other four winding configurations. Moreover, its winding factor is not reduced, even though it is double-layer compared with the single-layer winding type. With the same ampere-turns, the simulated results of the MMF distributions of the five different winding configurations are obtained, as shown in

Figure 2. For these 12-slot/10-pole machines, the 5th harmonic component is the working one and the others are all the undesirable harmonics. It can be seen that the main MMF harmonic orders of Winding I–IV are 1, 5, 7, 11, 13, 17, and 19 (satisfied with 6

k ± 1 as shown in

Table 1). For Windings III and IV, the magnitudes of the 5th harmonic (the working harmonic in a 5-pole-pair machine) are lower than the other three winding topologies because of their lower winding factors. But, Windings III and IV can greatly suppress the 1st harmonic compared with Windings I and II. As for Winding V, it not only produces a higher 5th harmonic, but also completely eliminates the 1st harmonic. With the aim of enhancing the quality of MMF distribution, Winding V is the best choice.

According to References [

4,

34], it can be found that for FSCWs, the most harmful MMF harmonics are those which are close to the fundamental harmonic (also called the synchronous harmonic in Reference [

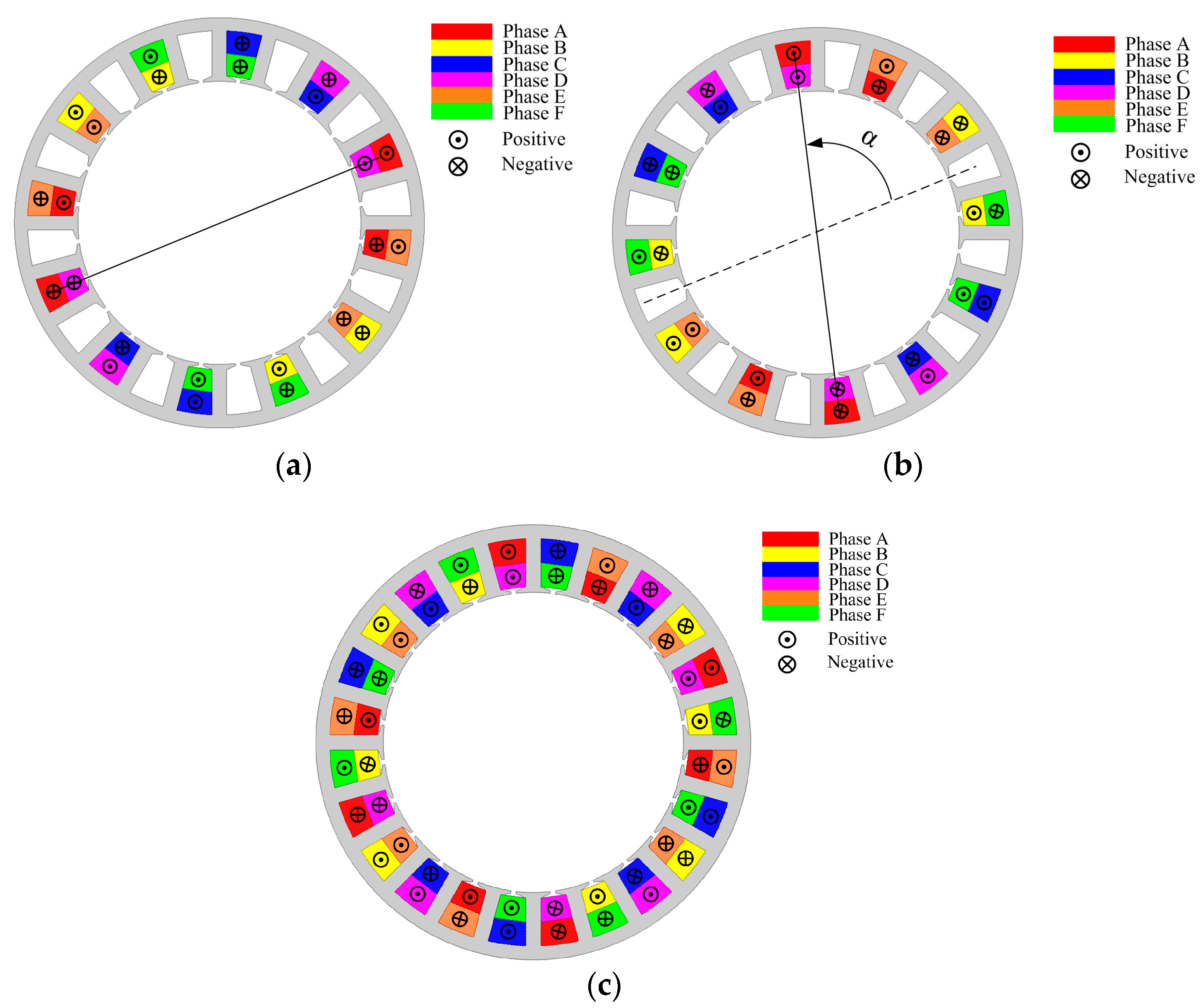

4]). Here, for a 5-pole-pair FSCW machine, the most harmful MMF harmonics will be the 1st and 7th harmonics, knowing that the fundamental harmonic is the fifth harmonic. Although Winding V can eliminate the 1st harmonic, the magnitude of the 7th one is still high, which will lead to serious PM eddy loss and then reduce the efficiency and increase the risk of irreversible demagnetization of the PMs. What is more, it will have a significant negative influence on the utilization of reluctance torque in a salient-pole machine. To cancel the 1st and 7th harmonics at the same time, the concept of stator shifting is employed, which is an effective way to suppress the undesirable MMF harmonics by using two FSCW stators with the same slot/pole combination to form a new stator. In this paper, due to its excellent stator MMF distribution, the concept of stator shifting is employed by 12-slot/10-pole asymmetric six-phase winding (Winding V), which implies that a 24-slot/10-pole machine with two sets of Winding V will be obtained, as shown in

Figure 3. By increasing the coil pitch to two and doubling the number of the slots, two sets of Winding V can be placed in the new 24-slot stator. It should be noted that the 24-slot/10-pole configuration no longer satisfies the relation

Q = 2

p+/−2, so that its winding factor will significantly decrease if it still employs a tooth-coil winding (coil pitch equals 1).The second Winding V (as shown in

Figure 3b) is obtained by shifting the first Winding V (as shown in

Figure 3a) with a certain mechanical angle

α. Different

α results in different phase shifts between the two sets of windings which will lead to different winding factors and different stator MMF distributions.

Here, to avoid an uneven teeth stator, the angle

α between the two stators is limited to (2

k − 1)360°/

Q, where

k is a positive integer. Assuming that the magnitude of the 7th harmonic of one Winding V is

F7, the sum of the 7th harmonic of the two sets of Winding V can be obtained as follows:

It can be seen from (1) that the magnitude of the 7th harmonic will be minimum when the value of cos((2

k − 1)52.5°) is minimum. When

k is 3 or 10, the value of cos((2

k − 1)52.5°) reaches the lowest value. When

k is 3 or 10, the angle

α is 75° or 285°. Then, the MMF distributions with different values of

α are simulated by FEM. For the “combined” 24-slot stator, there will be 12 different values of

α, as listed in

Table 2. By analyzing the phasor diagrams of all 12 schemes, the phase shifts between the two sets of windings are reduced to six different schemes. The stator MMF distributions of the six different phase shifts are shown in

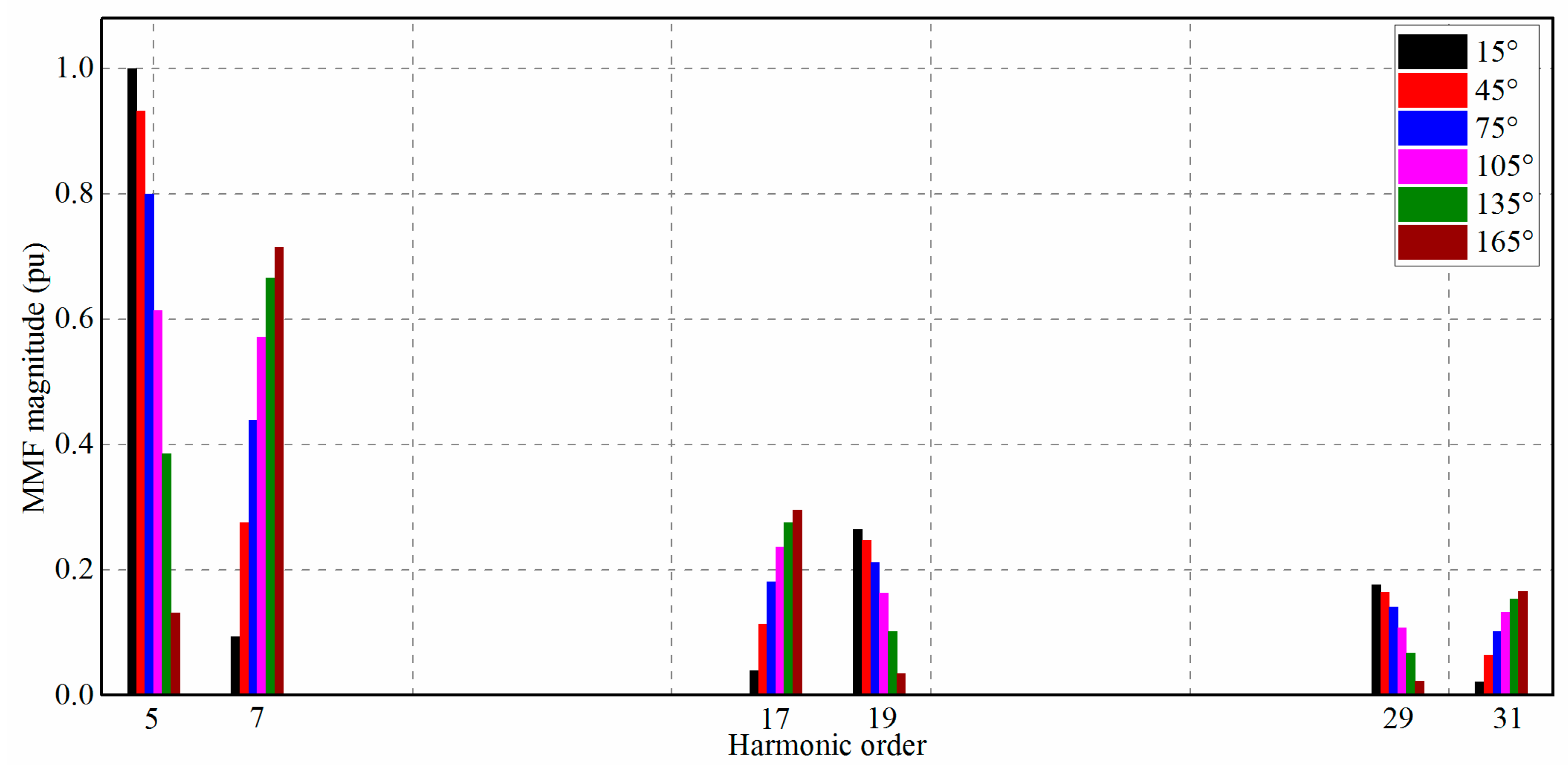

Figure 4, and their corresponding harmonic spectra are shown in

Figure 5. Firstly, it can be clearly seen that the different phase shifts will indeed have a significant influence on the stator MMF distributions. In

Figure 5, it can be found that all six schemes can cancel the 1st harmonic, owing to the advantage of Winding V. The magnitude of the 7th harmonic reaches the lowest value of 0.094 pu when the phase shift is 15°. It can be also found that the different phase shifts will result in different 5th harmonics (the working harmonic) which implies different winding factors. The winding factors with different phase shifts are listed in

Table 3.

It can be seen that the winding factor will reach the highest value of 0.958 when the phase shift is 15°, so the magnitude of the 5th harmonic is the highest when the phase shift is 15°, as shown in

Figure 5. The winding factor of Winding V is 0.966. This is to say that the proposed 24-slot/10-pole scheme with a phase shift of 15° between the two sets of Winding V can significantly suppress the 7th harmonic with just a little reduction in winding factor, compared with the 12-slot/10-pole with Winding V. Hence, the 15° phase shift is selected as the optimum phase shift and the corresponding winding layout is employed.

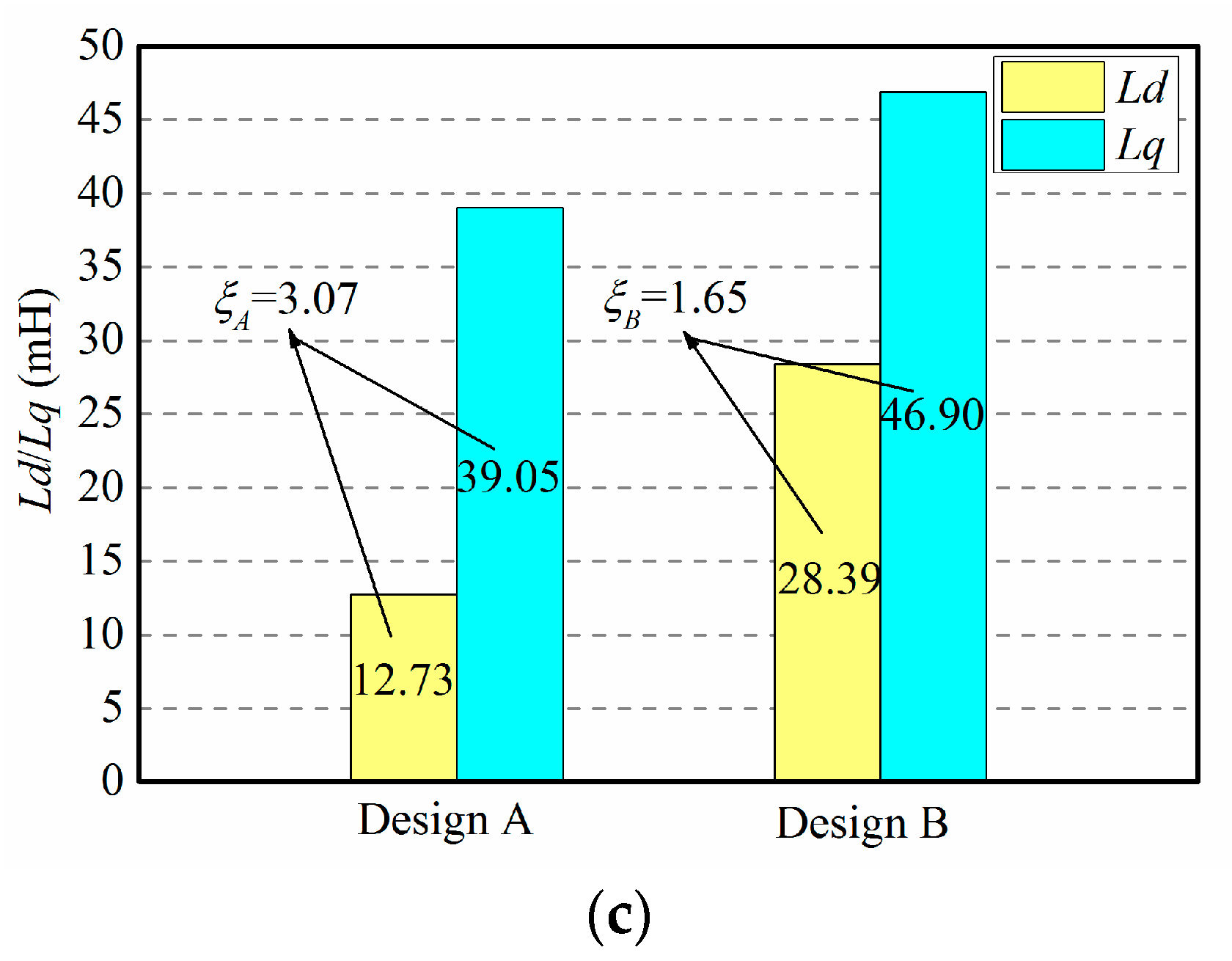

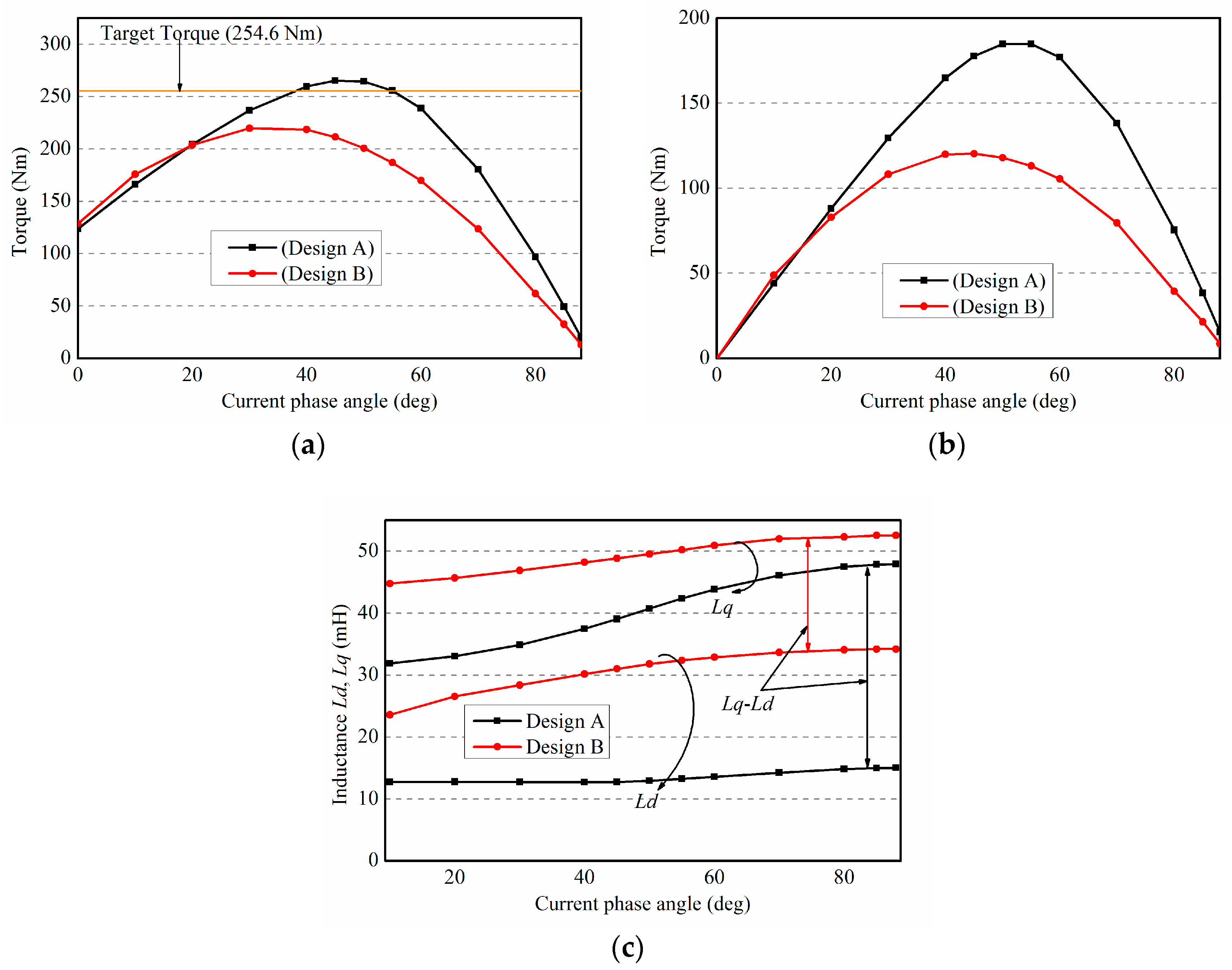

3. Machine Design and Specifications

In this paper, to show that the reduction of MMF harmonics does not automatically lead to a reduction of the reluctance torque, two PMA-SynRMs whose reluctance torques are dominant components of the total torques are designed for comparison, as shown in

Figure 6. The optimal 24-slot/10-pole six-phase winding investigated above is employed by Design A. The 12-slot/10-pole six-phase winding whose content of the stator MMF harmonic is relatively high is employed by Design B. For the sake of comparison, the same rotors are used for the two machines. The same stator inner and outer diameters are also used. In addition, the same turns per phase are also utilized. Although the widths of the stator teeth are adjusted to the different numbers of slots, the slot area and slot filling factor are still kept the same. The design specifications for the machines are listed in

Table 4. The main dimensions are shown in

Figure 6c and

Table 5. For the sake of the relatively large amount of permanent magnet volumes, the cheap PM, a ferrite magnet (DM 4545) whose coercive force is 334 kA/m and remnant flux density is 0.45 T at 20 °C, is used. Also, to avoid increasing manufacturing costs, the PMs are rectangular-shaped. In

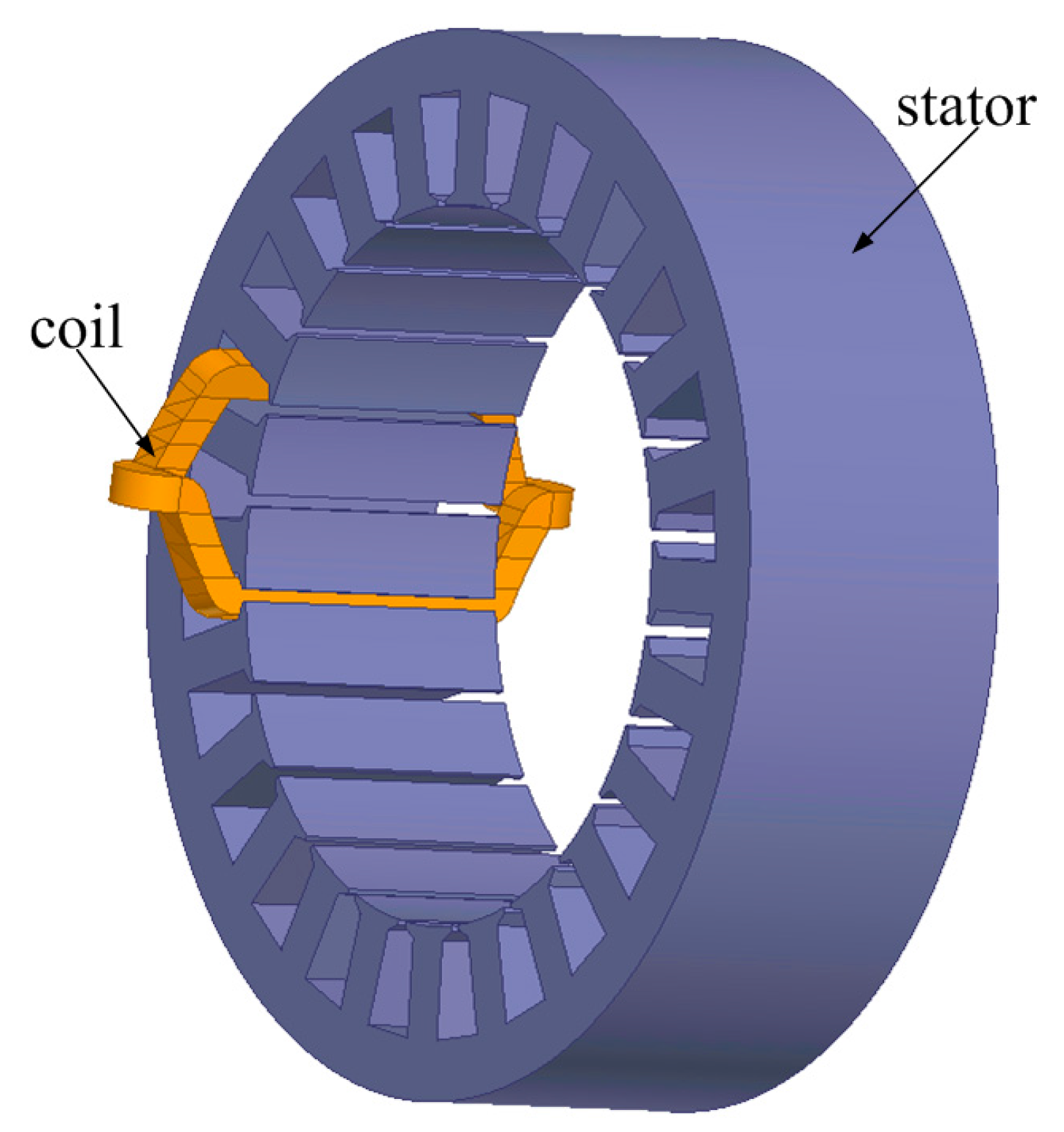

Table 5, it can be found that the phase resistance of Design A is larger than that of Design B because the length of the coil of Design A is 500.4 mm, while it is only 426.4 mm in Design B, resulting from the longer end-windings of Design A. This is because Design A can no longer be tooth-concentrated due to its increased coil pitch, as shown in

Figure 7.

With the same rated currents, the stator MMF distributions and their corresponding harmonic spectra are obtained, as shown in

Figure 8. Design B produces a higher 5th harmonic (working harmonic) owing to its higher winding factor (0.966), in comparison to that produced in Design A (0.958). Both machines can completely eliminate the 1st harmonic. The magnitude of the 7th harmonic of Design A is greatly suppressed, as analyzed above, while it is still very high in Design B. The different magnitudes of the 7th harmonic of the two different machines result in different harmonic leakage inductances, which will finally make a difference to the reluctance torque outputting capacity.