Permeability Change Caused by Stress Damage of Gas Shale

Abstract

:1. Introduction

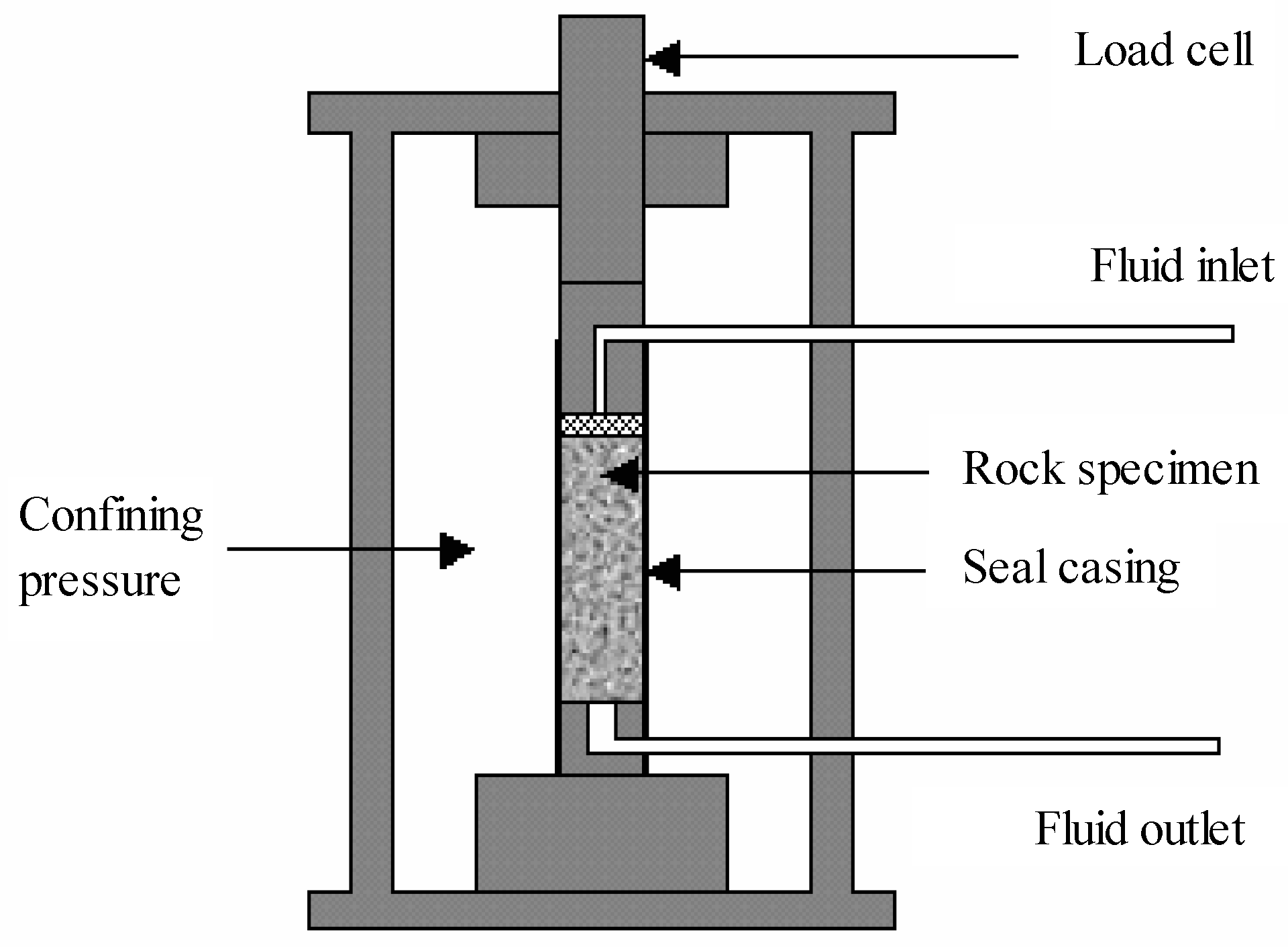

2. Experimental Scheme

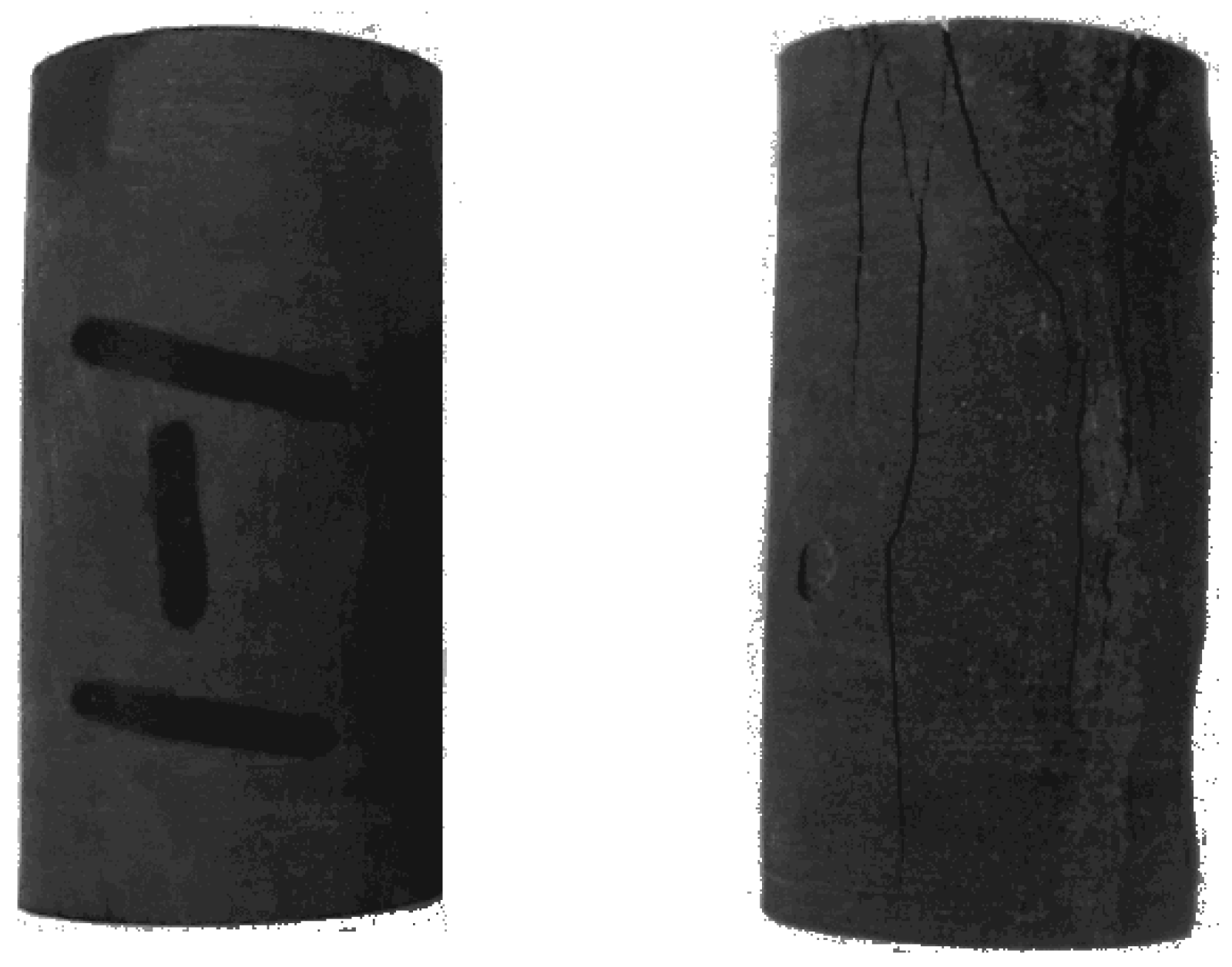

3. Experimental Results

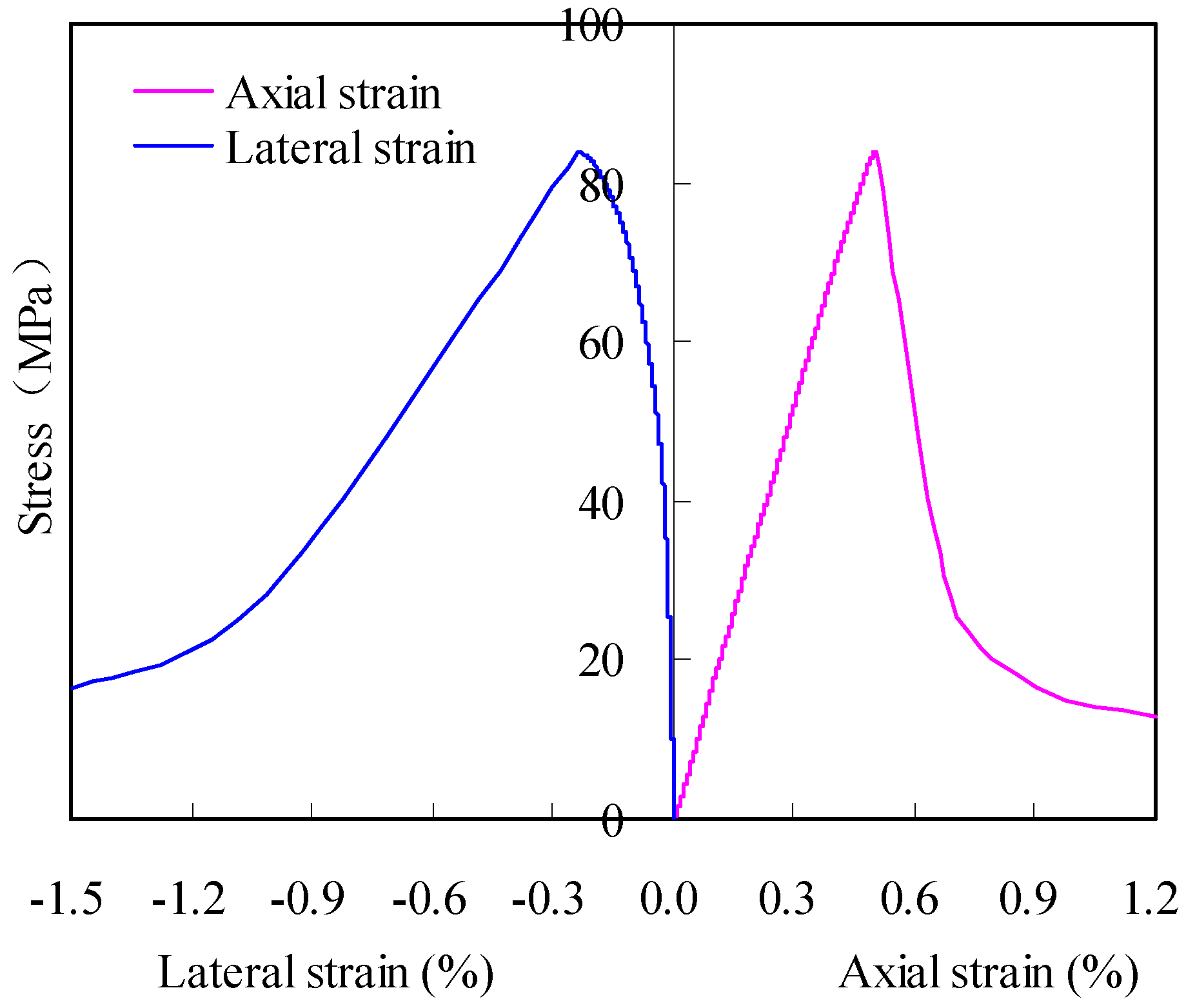

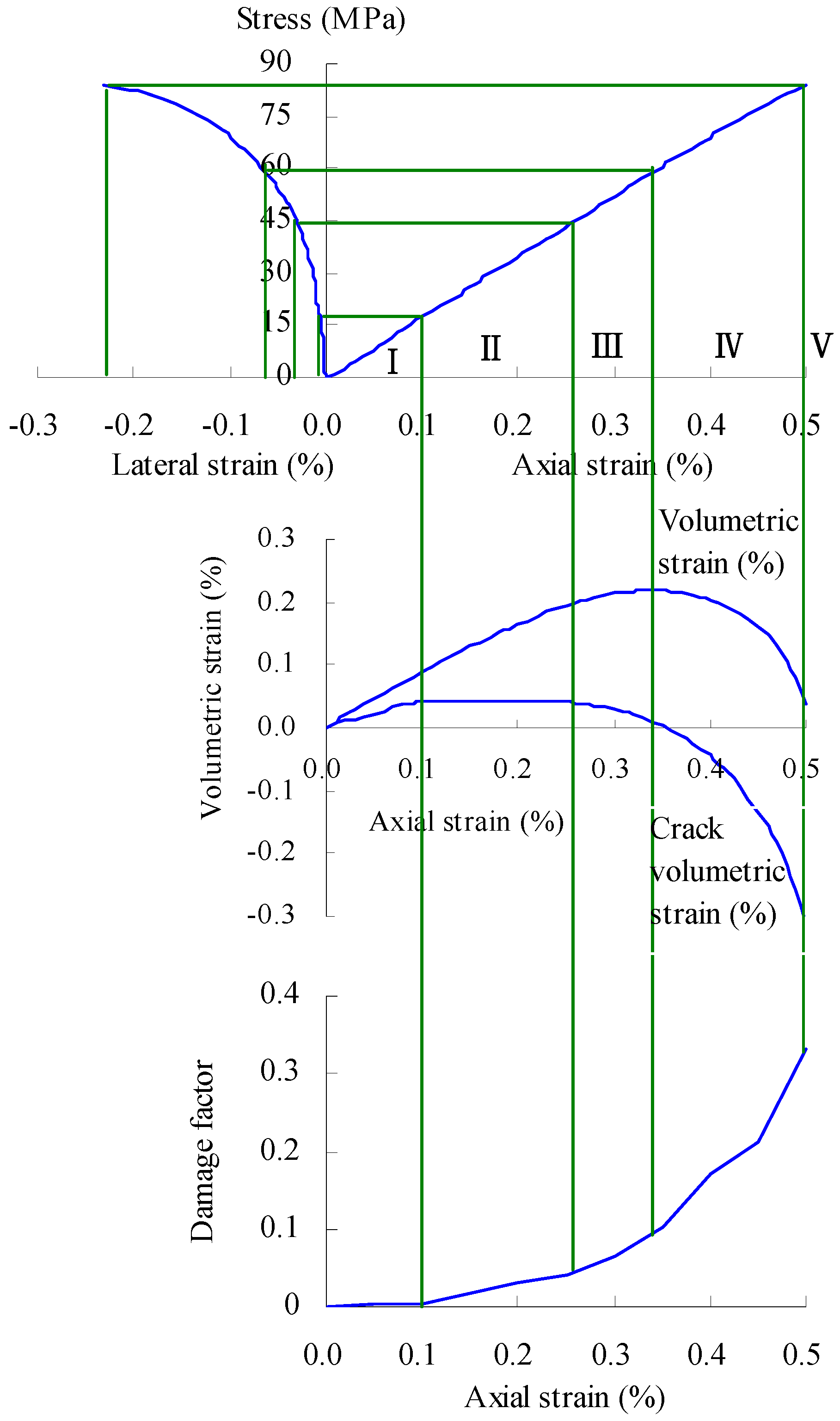

3.1. Total Stress–Strain Curve of Shale

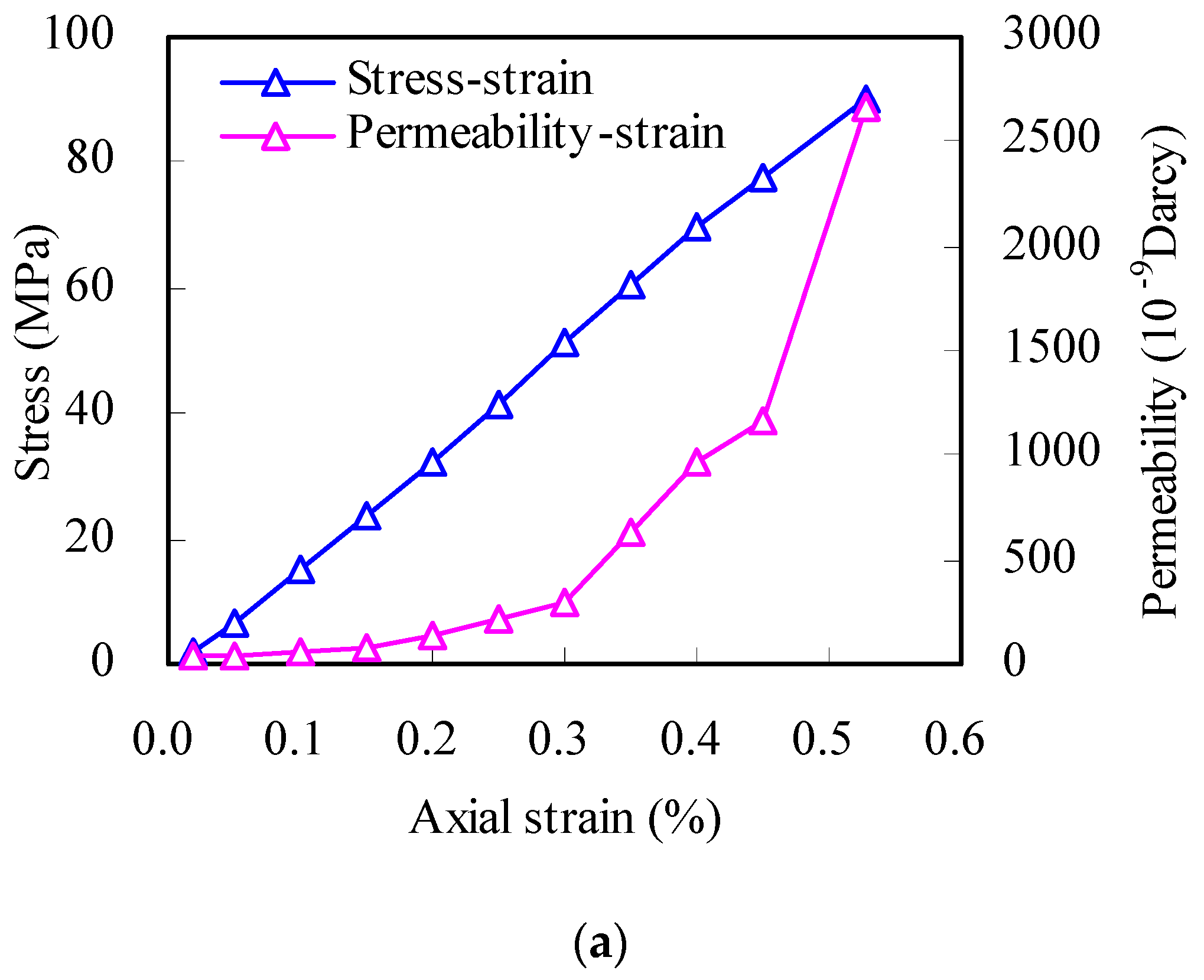

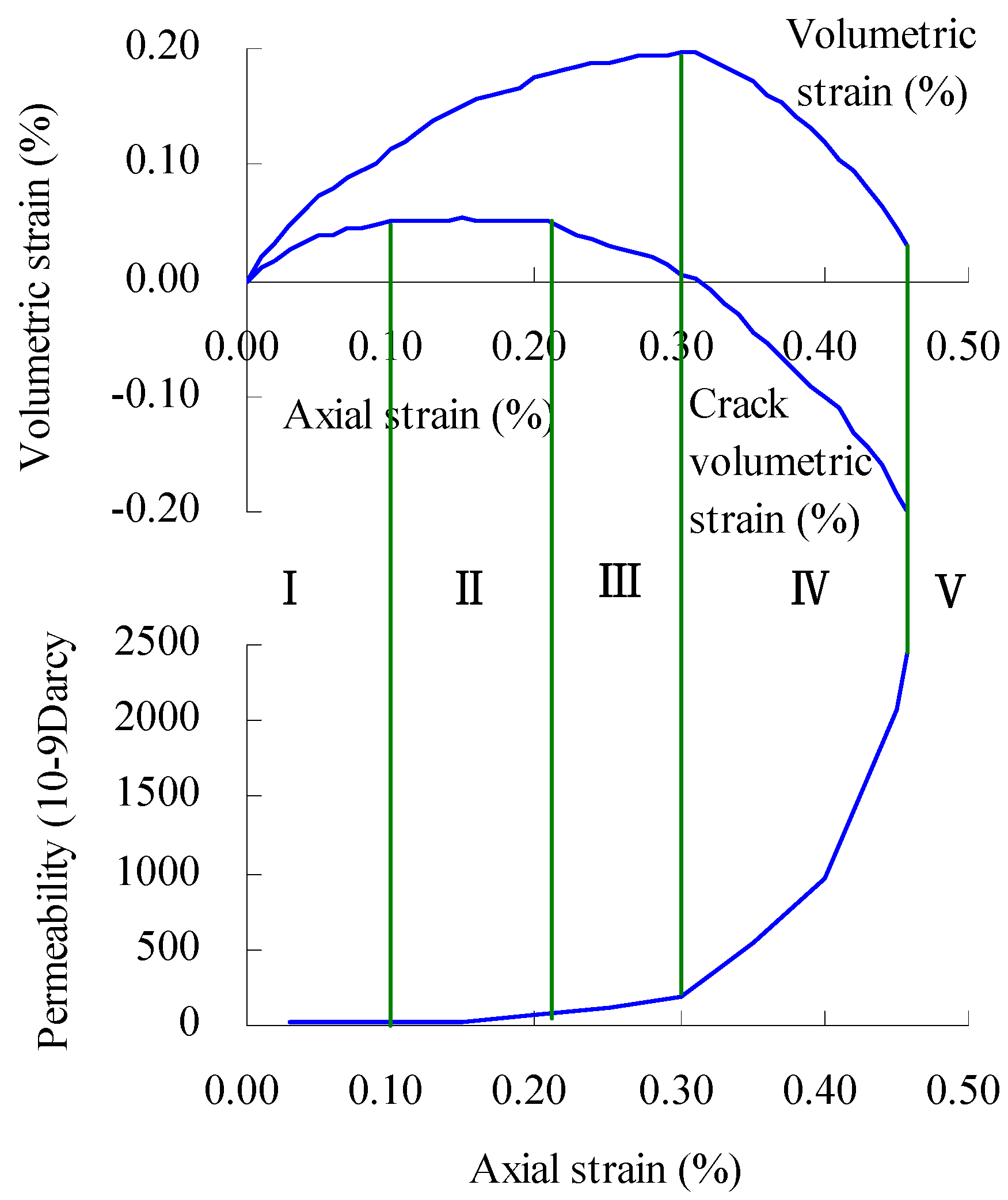

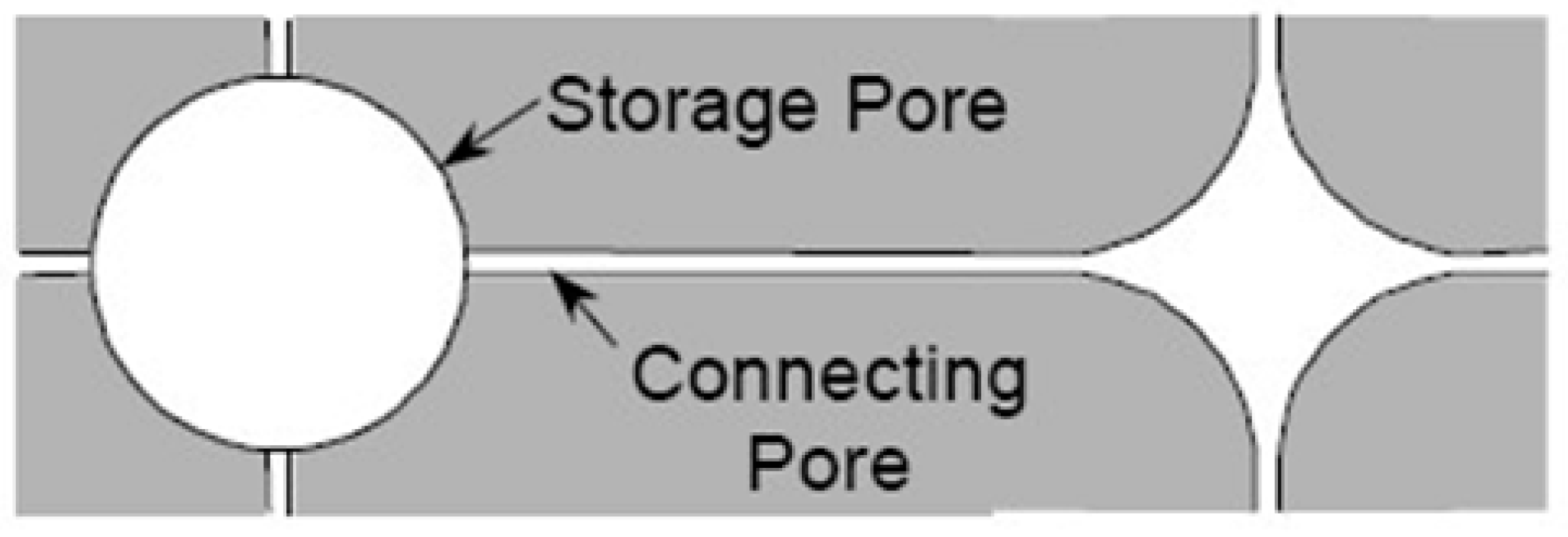

3.2. Permeability Variation during Shale Loading

4. Analysis

5. Conclusions

- (1)

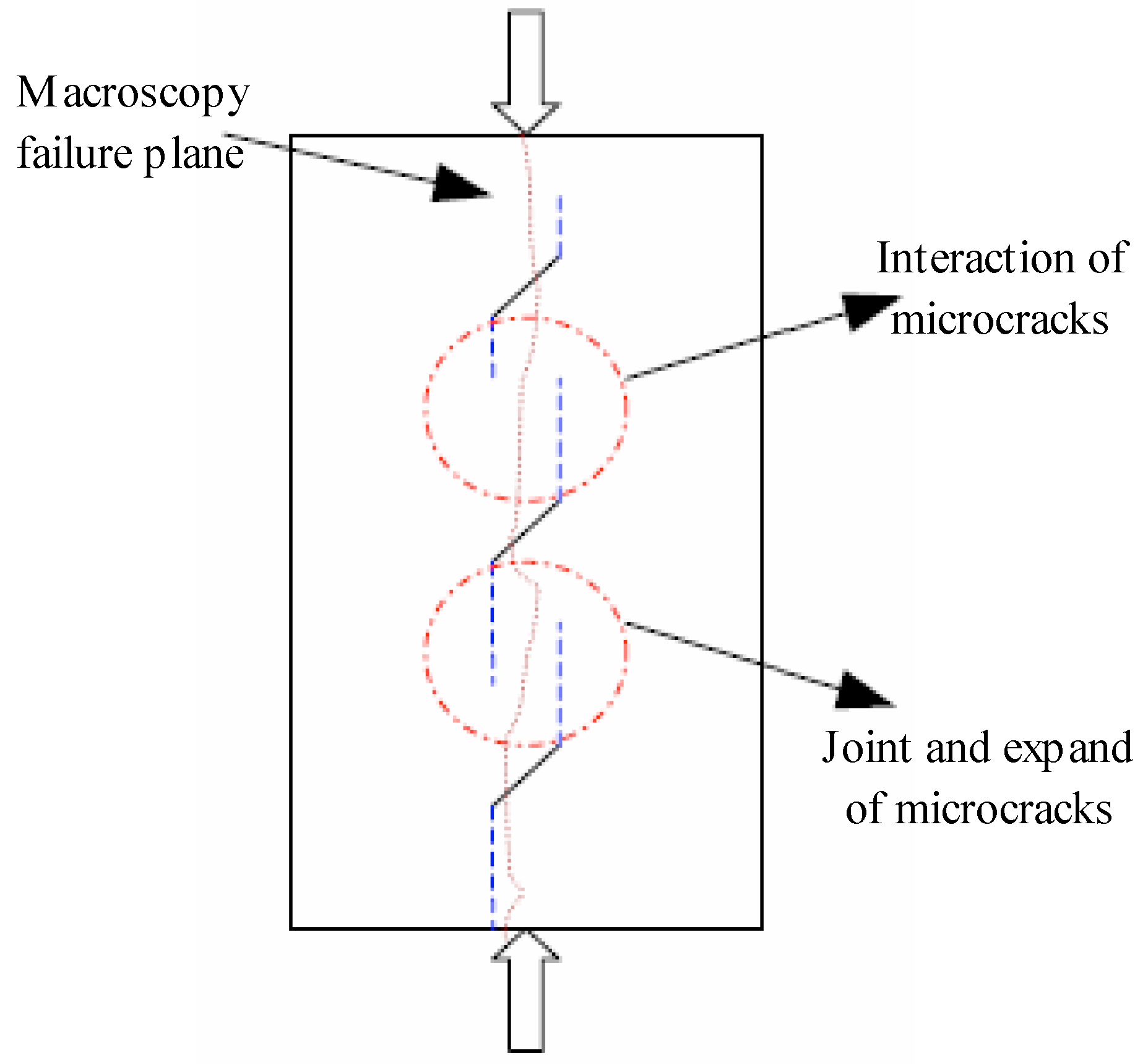

- Under uniaxial or low confining pressure (2 MPa in this test) the failure mode of hard brittle shale is axial splitting resulting from expansion and intersection of axial cracks. There is nearly no damage in the preliminary stage of loading; new cracks emerge and damage factors increase in the linear elastic stage; micro-cracks intersect and damage factors increase rapidly in the stable development of cracks; damage increases sharply in the volumetric dilatancy stage and the core enters the rapid damage stage

- (2)

- Stress damage can lead to an increase in shale permeability and the variation rule of permeability is similar with that of the stress damage.

- (3)

- During drilling of a shale gas well, increasing permeability of shale will accelerate seepage of drilling fluid into the formation, leading to pore pressure increase, which causes shale hydration and—ultimately—borehole instability. To maintain borehole stability, the rapid damage stage after volumetric dilatancy of shale should be avoided as much as possible. Hydraulic fracturing of shale gas reservoirs requires a great deal of water and increasing permeability will increase seepage of fracturing fluid into the formation. This effect should be considered in the fracturing design.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zou, C.; Dong, D.; Wang, S.; Li, J.; Li, X.; Wang, Y.; Cheng, K. Geological characteristics and resource potential of shale gas in China. Pet. Explor. Dev. 2010, 37, 641–653. [Google Scholar] [CrossRef]

- Shen, W.; Li, X.; Xu, Y.; Sun, Y.; Huang, W. Gas Flow Behavior of Nanoscale Pores in Shale Gas Reservoirs. Energies 2017, 10, 751. [Google Scholar] [CrossRef]

- Wu, Y.; Li, X. Numerical simulation of the propagation of hydraulic and natural fracture using Dijkstra’s algorithm. Energies 2016, 9, 519. [Google Scholar] [CrossRef]

- Liu, H.; Ranjith, P.G.; Georgi, D.T.; Lai, B. Some key technical issues in modelling of gas transport process in shales: A review. Geomech. Geophys. Geo-Eng. Geo-Resour. 2016, 2, 231–243. [Google Scholar] [CrossRef]

- Li, X.; Feng, Z.; Han, G.; Elsworth, D.; Marone, C.; Saffer, D.; Cheon, D.-S. Breakdown pressure and fracture surface morphology of hydraulic fracturing in shale with H2O, CO2 and N2. Geomech. Geophys. Geo-Eng. Geo-Resour. 2016, 2, 63–76. [Google Scholar] [CrossRef]

- Patel, M.J.; May, E.F.; Johns, M.L. High-fidelity reservoir simulations of enhanced gas recovery with supercritical CO2. Energy 2016, 111, 548–559. [Google Scholar]

- Ampomah, W.; Balch, R.; Grigg, R.B.; Cather, M.; Gragg, E.; Will, R.A.; Dai, Z. Performance assessment of CO2-enhanced oil recovery and storage in the Morrow reservoir. Geomech. Geophys. Geo-Eng. Geo-Resour. 2017, 3, 245–263. [Google Scholar] [CrossRef]

- Meier, T.; Rybacki, E.; Backers, T.; Dresen, G. Influence of bedding angle on borehole stability: A laboratory investigation of transverse isotropic oil shale. Rock Mech. Rock Eng. 2015, 48, 1535–1546. [Google Scholar] [CrossRef]

- Yuan, J.; Deng, J.; Tan, Q.; Yu, B.; Jin, X. Borehole stability analysis of horizontal drilling in shale gas reservoirs. Rock Mech. Rock Eng. 2013, 46, 1157–1164. [Google Scholar] [CrossRef]

- Wu, Y.; Li, X.; He, J.; Zheng, B.; Sciubba, E. Mechanical properties of longmaxi black organic-rich shale samples from south china under uniaxial and triaxial compression states. Energies 2016, 9, 1088. [Google Scholar] [CrossRef]

- Sone, H.; Zoback, M.D. Mechanical properties of shale-gas reservoir rocks—Part 1: Static and dynamic elastic properties and anisotropy. Geophysics 2013, 78, 381–392. [Google Scholar] [CrossRef]

- Labani, M.M.; Rezaee, R. The importance of geochemical parameters and shale composition on rock mechanical properties of gas shale reservoirs: A case study from the Kockatea Shale and Carynginia Formation from the Perth Basin, Western Australia. Rock Mech. Rock Eng. 2015, 48, 1249–1257. [Google Scholar] [CrossRef]

- Heng, S.; Guo, Y.; Yang, C.; Daemen, J.J.; Li, Z. Experimental and theoretical study of the anisotropic properties of shale. Int. J. Rock. Mech. Min. Sci. 2015, 74, 58–68. [Google Scholar] [CrossRef]

- Yan, C.; Deng, J.; Cheng, Y.; Li, M.; Feng, Y.; Li, X. Mechanical Properties of Gas Shale During Drilling Operations. Rock Mech. Rock Eng. 2017, 50, 1753–1765. [Google Scholar] [CrossRef]

- Jin, Z.; Johnson, S.E. Effects of elastic anisotropy on primary petroleum migration through buoyancy-driven crack propagation. Geomech. Geophys. Geo-Eng. Geo-Resour. 2017, 1–14. [Google Scholar] [CrossRef]

- Yu, B.; Wang, Z.; Guo, B. Borehole Unstability Theory of Shale and Its Research Progress. Drill. Prod. Technol. 2007, 30, 16–21. [Google Scholar]

- Lora, R.V.; Ghazanfari, E.; Izquierdo, E.A. Geomechanical characterization of Marcellus shale. Rock Mech. Rock Eng. 2016, 49, 3403–3424. [Google Scholar] [CrossRef]

- Liu, M.; Jin, Y.; Lu, Y.; Chen, M.; Hou, B.; Chen, W.; Yu, X. A wellbore stability model for a deviated well in a transversely isotropic formation considering poroelastic effects. Rock Mech. Rock Eng. 2016, 49, 3671–3686. [Google Scholar] [CrossRef]

- Yan, C.; Deng, J.; Hu, L.; Chen, Z.; Yan, X.; Lin, H.; Tan, Q.; Yu, B. Brittle failure of shale under uniaxial compression. Arabian J. Geosci. 2015, 8, 2467–2475. [Google Scholar]

- Morrow, C.A.; Zhang, B.C.; Byerlee, J.D. Effective pressure law for permeability of Westerly granite under cyclic loading. J. Geophys. Res. Solid Earth 1986, 91, 3870–3876. [Google Scholar] [CrossRef]

- Ren, J.X.; Ge, X.R. Study of rock meso-damage evolution law and its constitutive model under uniaxial compression loading. Chin. J. Rock Mech. Eng. 2001, 20, 425–431. [Google Scholar]

- Wang, J.; Park, H.D. Fluid permeability of sedimentary rocks in a complete stress–strain process. Eng. Geol. 2002, 63, 291–300. [Google Scholar] [CrossRef]

- Kong, H.; Chen, Z.; Wang, L.; Shen, H. Experimental Study on Permeability of Crushed Gangues during Compaction. Int. J. Miner. Process. 2013, 124, 95–101. [Google Scholar] [CrossRef]

- Lu, J.; Lin, G.; Wang, Z. On the reduction of strength of concrete and supersonic inspection due to triaxial compressive loading history. Eng. Mech. 2002, 19, 52–57. [Google Scholar]

- Zhu, J.; Song, Y. Research on fatigue damage of concrete under biaxial compressive loading using ultrasonic velocity method. Chin. J. Rock Mech. Eng. 2004, 23, 2230–2234. [Google Scholar]

- Wang, H.; Song, Y. Ultrasonic pulses behaviour in various-size concrete specimens under compression. J. Dalian Univ. Technol. 2007, 47, 90–94. [Google Scholar]

- Tang, H.; Di, Y.; Zhang, Y.; Li, H. Impact of Stress-Dependent Matrix and Fracture Properties on Shale Gas Production. Energies 2017, 10, 996. [Google Scholar] [CrossRef]

- Brace, W.F. State of Stress in the Earth’s Crust. In Proceedings of the International Conference, Santa Monica, CA, USA, 13–14 June 1963. [Google Scholar]

- Eberhardt, E.; Stead, D.; Stimpson, B. Quantifying progressive pre-peak brittle fracture damage in rock during uniaxial compression. Int. J. Rock Mech. Min. Sci. 1999, 36, 361–380. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stead, D.; Stimpson, B. Effects of grain size on the initiation and propagation thresholds of stress-induced brittle fractures. Rock Mech. Rock Eng. 1999, 32, 81–99. [Google Scholar] [CrossRef]

- Zhou, J.; Yang, X.; Fu, W. Experimental test and fracture damage mechanical characteristics of brittle rock under uniaxial cyclic loading and unloading conditions. Chin. J. Rock Mech. Eng. 2010, 29, 1172–1183. [Google Scholar]

- Bobet, A.; Einstein, H.H. Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int. J. Rock Mech. Min. Sci. 1998, 35, 863–888. [Google Scholar] [CrossRef]

- Zhu, Z.; Sheng, Q.; Zhang, Z. Study on lateral deformational characteristics and damage mechanism of brittle rock. Rock Soil Mech. 2008, 29, 2137–2143. [Google Scholar]

- Shao, J.; Khazraei, R. Wellbore stability analysis in brittle rocks with continuous damage model. In Proceedings of the SPE/ISRM Rock Mechanics in Petroleum Engineering Conference, Delft, The Netherlands, 29–31 August 1994. [Google Scholar]

- Dusseault, M.B.; Gray, K.E. Mechanisms of stress-induced wellbore damage. In Proceedings of the SPE Formation Damage Control Symposium, Lafayette, LA, USA, 26–27 February 1992. [Google Scholar]

- Yang, Y.; Song, Y.; Chen, S. Test study on permeability properties of coal specimen in complete stress–strain process. Rock Soil Mech. 2007, 28, 381–385. [Google Scholar]

- Jia, L.; Chen, M.; Zhang, W.; Xu, T.; Zhou, Y.; Hou, B.; Jin, Y. Experimental study and Numerical Modeling of Brittle Fracture of Carbonate Rock under Uniaxial Compression. Mech. Res. Commun. 2013, 50, 58–62. [Google Scholar] [CrossRef]

- Eberhardt, E. Brittle Rock Fracture and Progressive Damage in Uniaxial Compression. Ph.D. Thesis, University of Saskatchewan, Saskatoon, Canada, April 1998. [Google Scholar]

- Hidalgo, K.P.; Carlsson, B.; Nordlund, E. Identifying deformation parameters governing failure of hard rock: A laboratory test study. In Proceedings of the 2009 International Symposium on Rock Mechanics: “Rock Characterisation, Modelling and Engineering Design Methods”, Hong Kong, China, 19–22 May 2009. [Google Scholar]

- Bieniawski, Z.T. Mechanism of brittle rock fracture, Part II: Experimental studies. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1967, 4, 395–406. [Google Scholar] [CrossRef]

- Martin, C.D.; Chandler, N.A. The progressive fracture of Lac du Bonnet granite. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1994, 31, 643–659. [Google Scholar] [CrossRef]

- Jones, F. A laboratory study of the effects of confining pressure on fracture flow and storage capacity in carbonate rock. J. Pet. Technol. 1975, 27, 21–27. [Google Scholar] [CrossRef]

- Zhou, W. Advanced Rock Mechanics; Water Resources and Electric Power Press: Beijing, China, 1990. [Google Scholar]

- Jia, S. Hydro-Mechanical Coupled Creep Damage Constitutive Model of Boom Clay, Back Analysis of Model Parameters and Its Engineering Application. Ph.D. Thesis, Wuhan Institute of Rock & Soil Mechanics, Chinese Academy of Sciences, Wuhan, China, June 2009. [Google Scholar]

- Sun, W.; Zuo, Y.; Wu, Z.; Xu, Y. Experimental study on seepage-damage evolution of shale. China Min. Mag. 2017, 26, 142–145. [Google Scholar]

| Core No. | Porosity (%) | Quartz Content (%) | Clay Mineral Content (%) |

|---|---|---|---|

| 1 | 4 | 34.6 | 39.8 |

| 2 | 6 | 37.1 | 45.2 |

| 3 | 5 | 41.2 | 40.3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, C.; Cheng, Y.; Deng, F.; Tian, J. Permeability Change Caused by Stress Damage of Gas Shale. Energies 2017, 10, 1350. https://doi.org/10.3390/en10091350

Yan C, Cheng Y, Deng F, Tian J. Permeability Change Caused by Stress Damage of Gas Shale. Energies. 2017; 10(9):1350. https://doi.org/10.3390/en10091350

Chicago/Turabian StyleYan, Chuanliang, Yuanfang Cheng, Fucheng Deng, and Ji Tian. 2017. "Permeability Change Caused by Stress Damage of Gas Shale" Energies 10, no. 9: 1350. https://doi.org/10.3390/en10091350

APA StyleYan, C., Cheng, Y., Deng, F., & Tian, J. (2017). Permeability Change Caused by Stress Damage of Gas Shale. Energies, 10(9), 1350. https://doi.org/10.3390/en10091350