Numerical Analysis of the Combustion and Emission Characteristics of Diesel Engines with Multiple Injection Strategies Using a Modified 2-D Flamelet Model

Abstract

:1. Introduction

2. Model Framework

2.1. Modified 2-D Flamelet Model

2.2. Further Modification of 2-D Flamelet Model

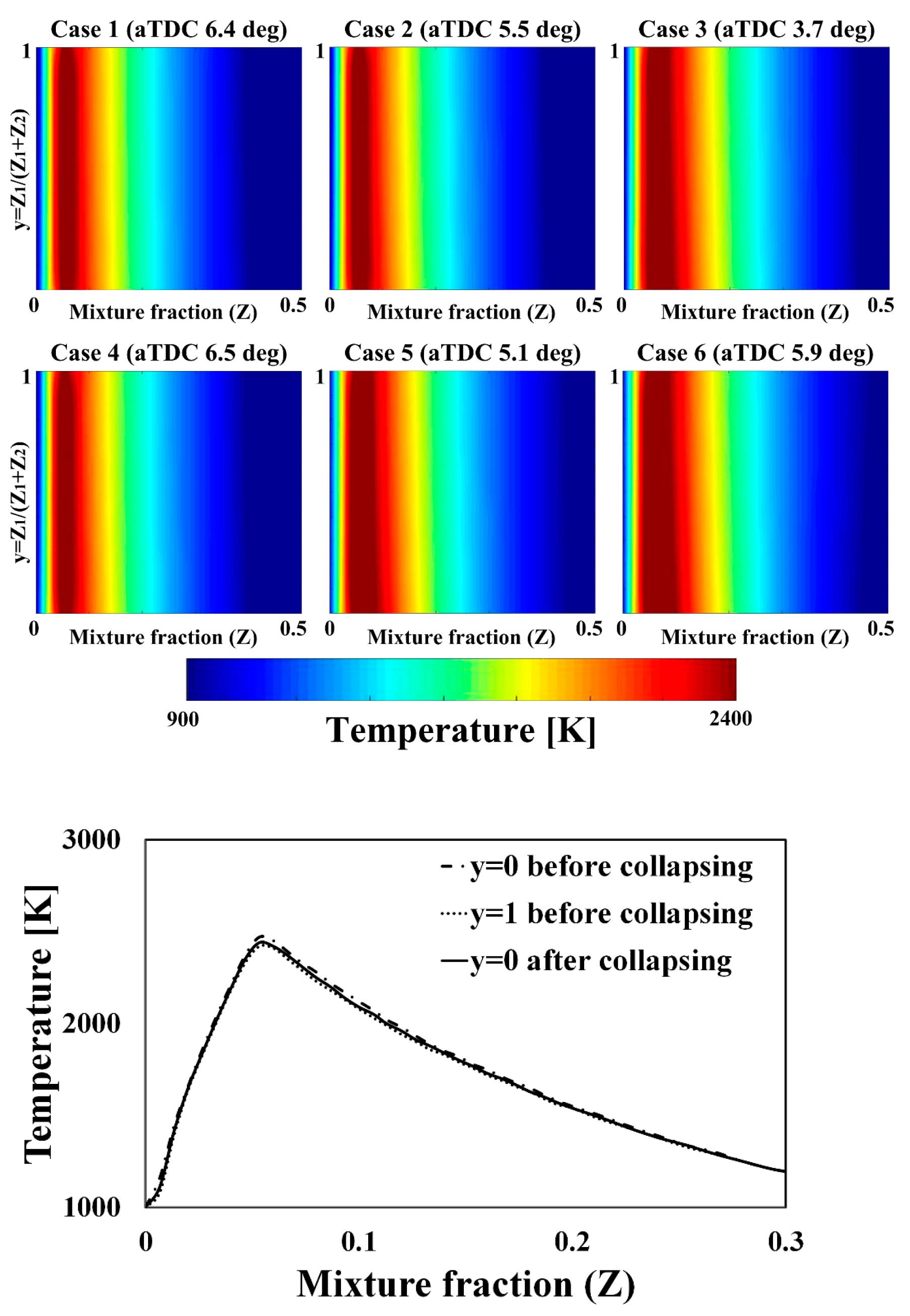

2.3. Collapse of 2-D Flamelet Solution

2.4. Linking with CFD Solver

2.5. Modeling Strategies for Diesel Engine Simulation

- From the start of the first injection until the start of the second injection

- From the start of the second injection until two mixture fields are merged

- From the start of the merging of mixture fields until the start of the third injection

- Moment just before the third injection

3. Experimental and Simulation Setup

3.1. Experimental Setup

3.2. Numerical Implementation

4. Results and Discussion

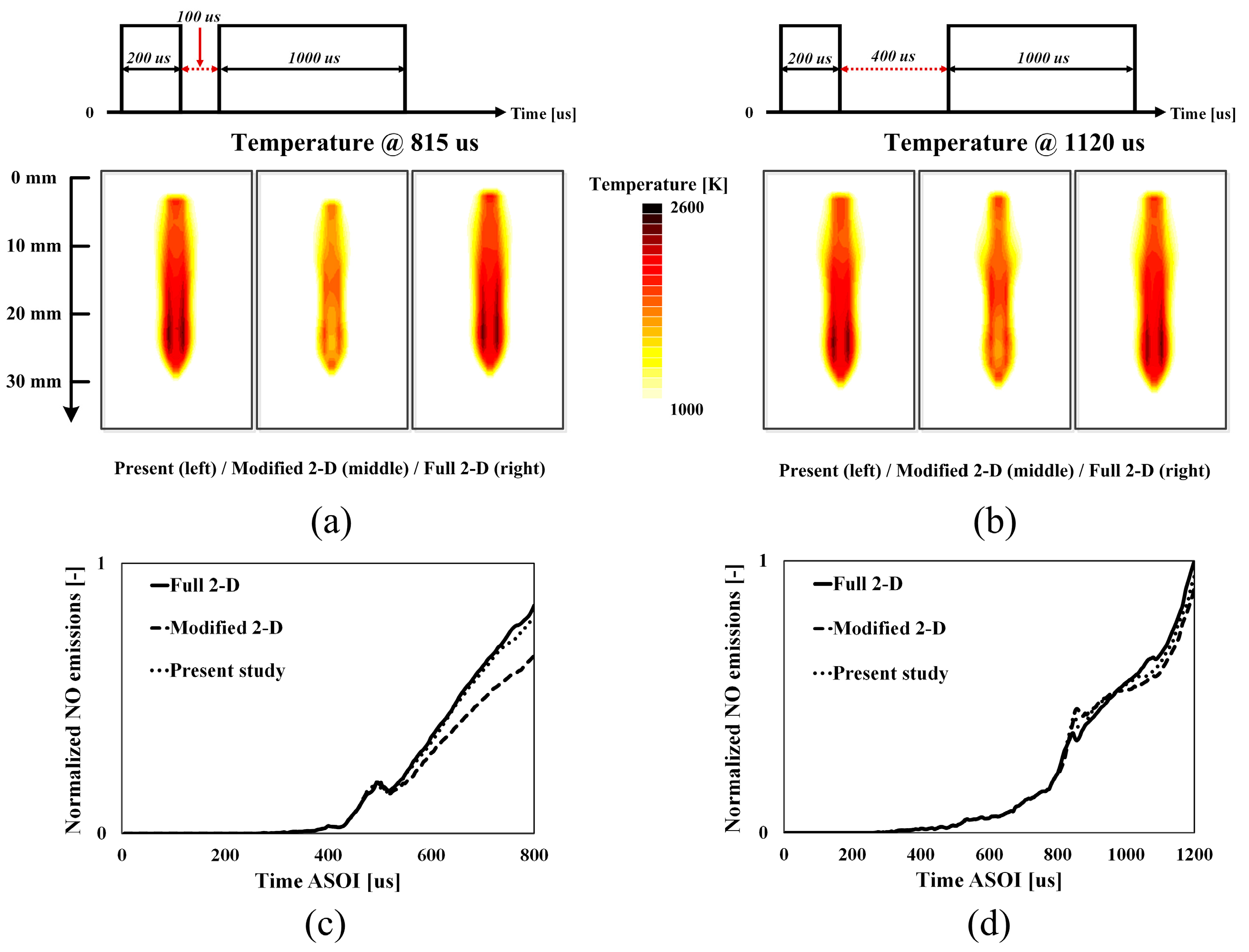

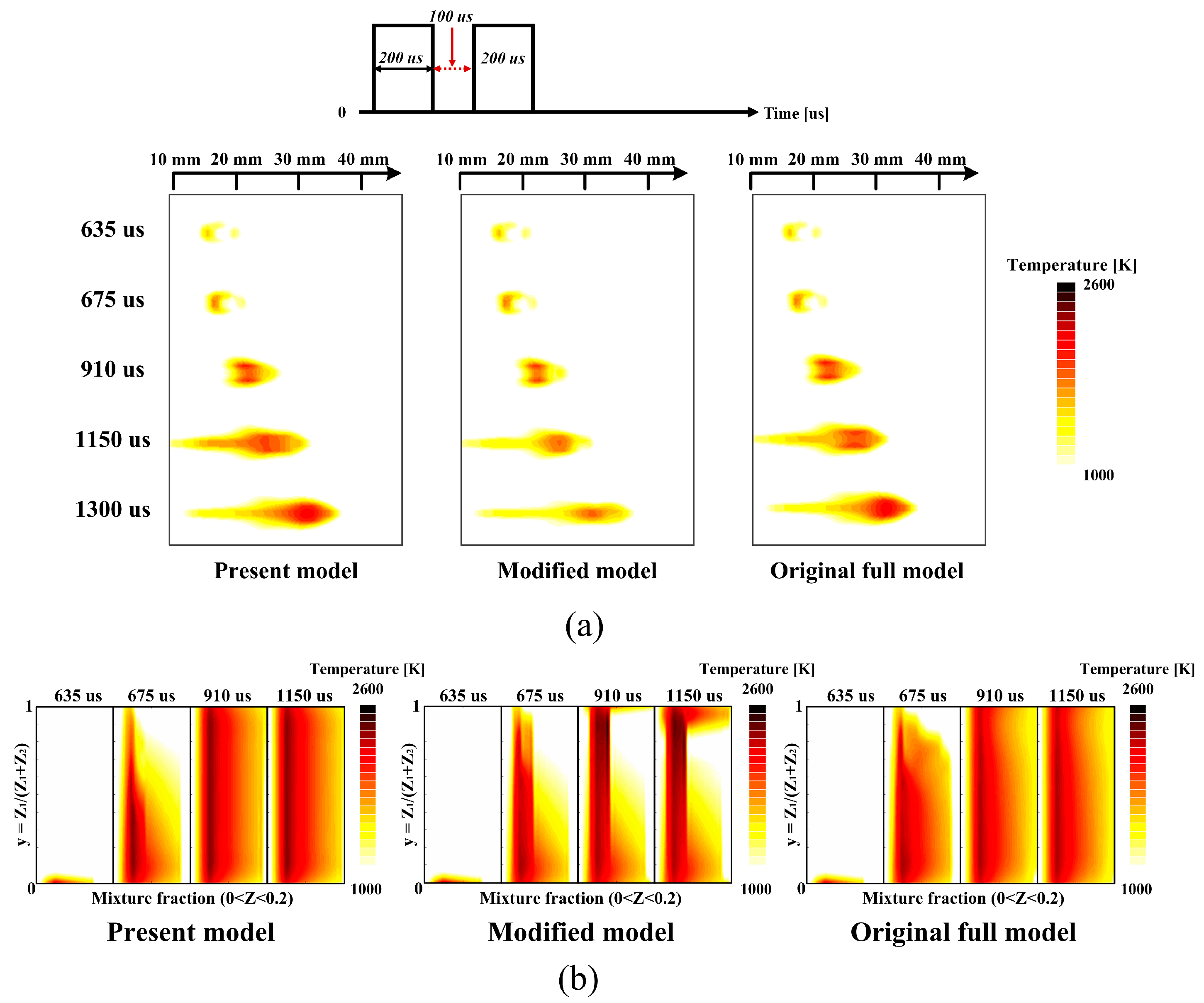

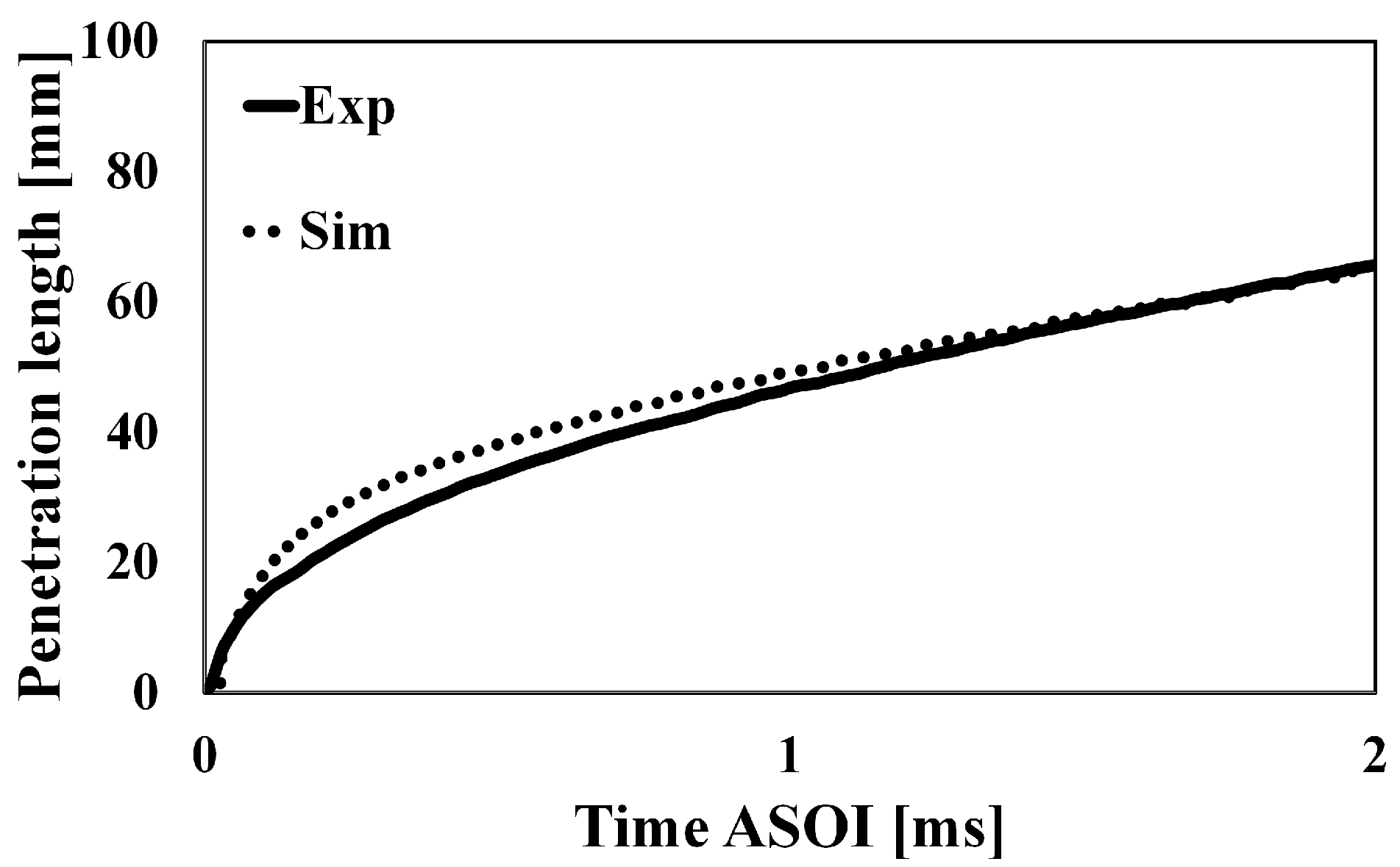

4.1. Validation of Modified 2-D Flamelet Model under Base Conditions

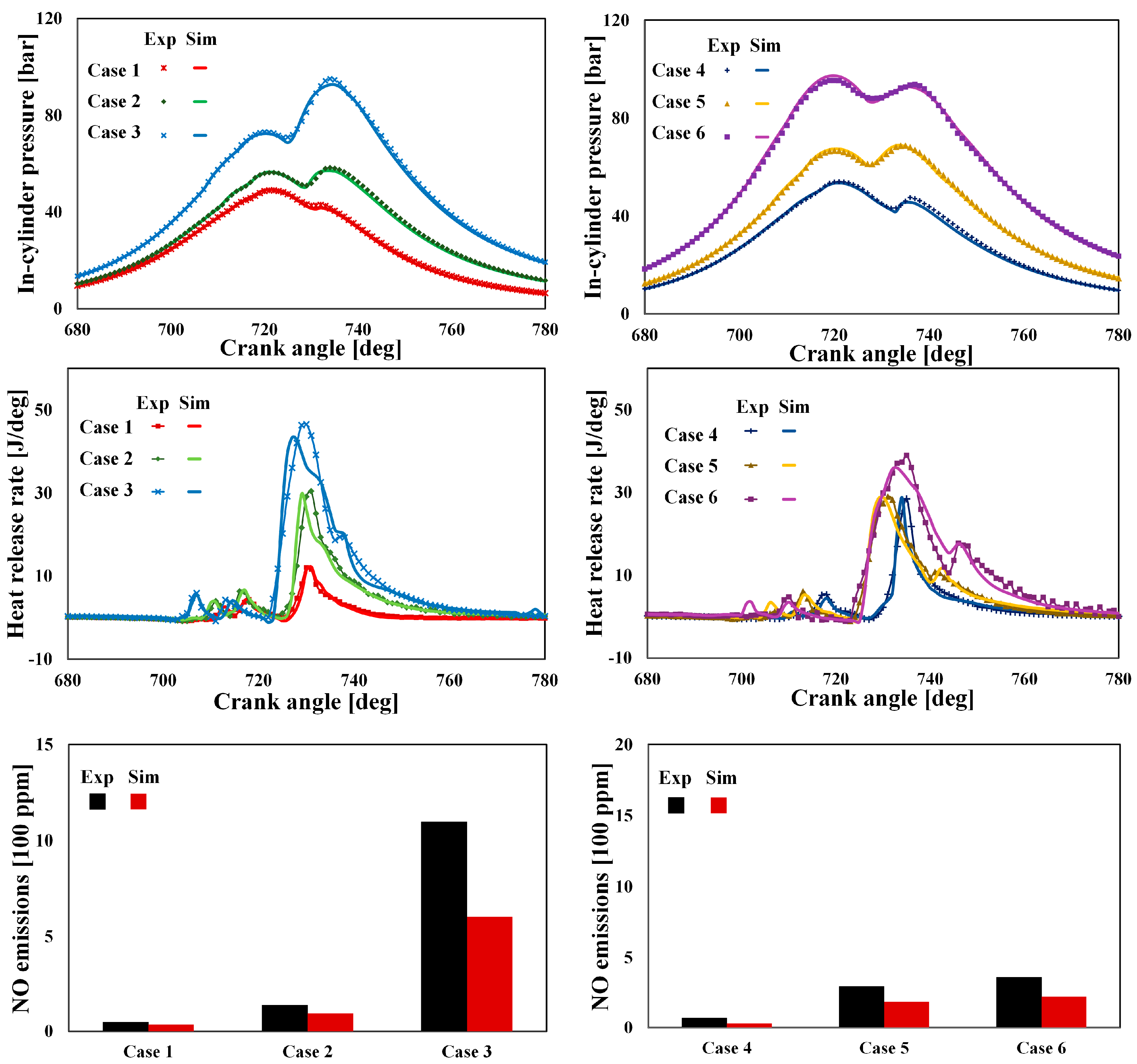

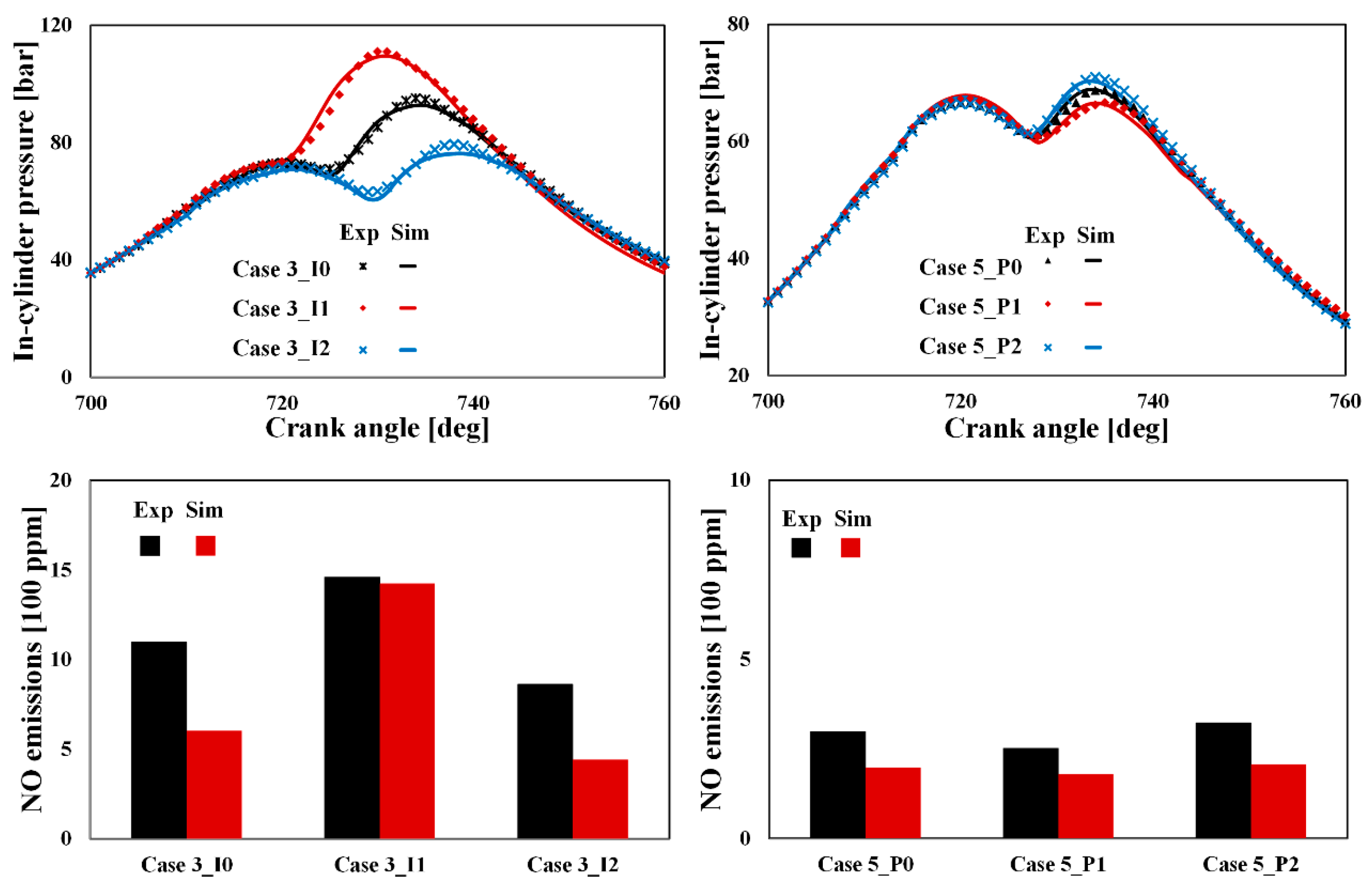

4.2. Validation of Injection Parameter Variations

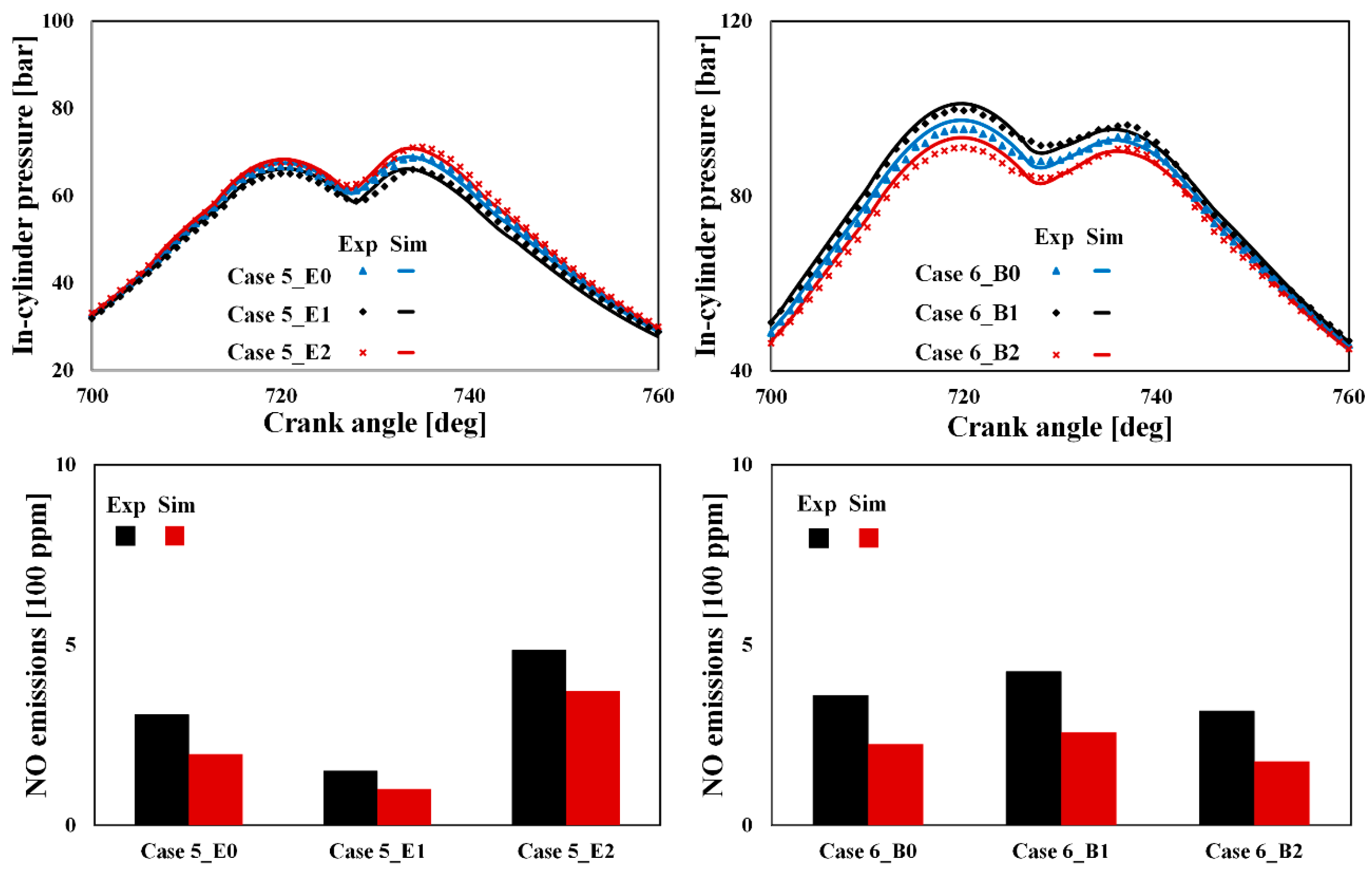

4.3. Validation of in-Cylinder Mixture Variations

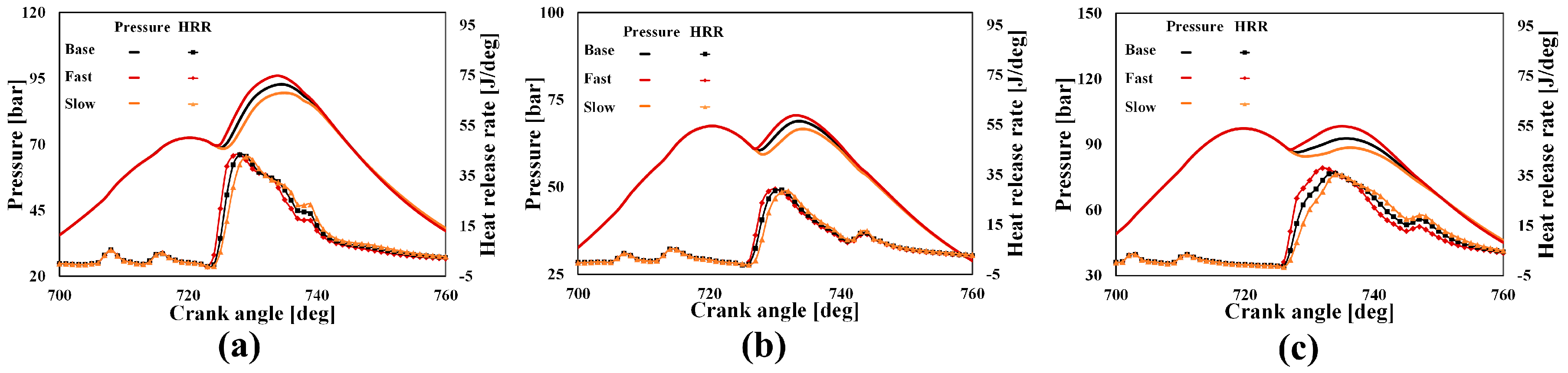

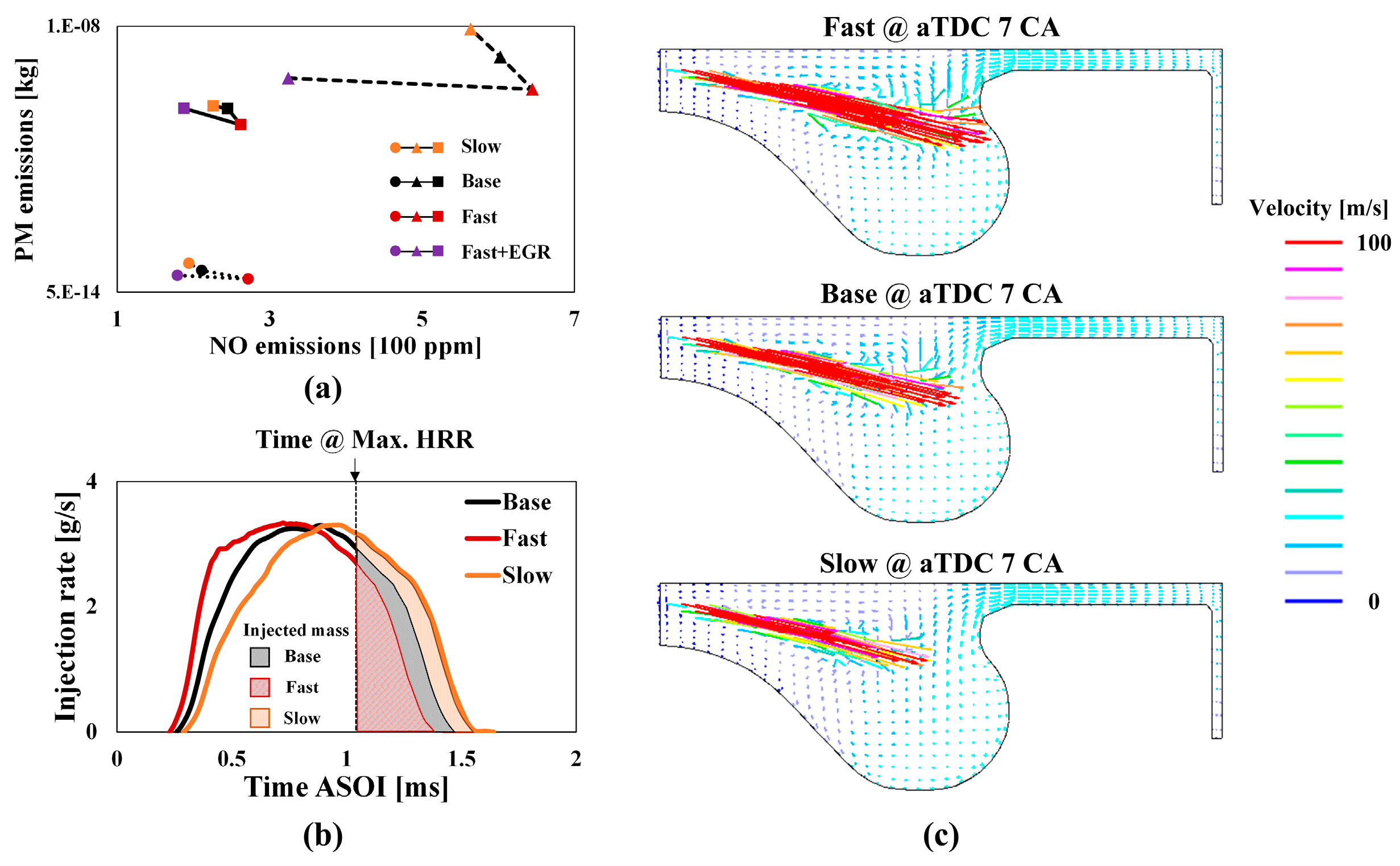

4.4. Numerical Analysis on the Effect of Injection Rate Shaping on Engine-Out Emissions

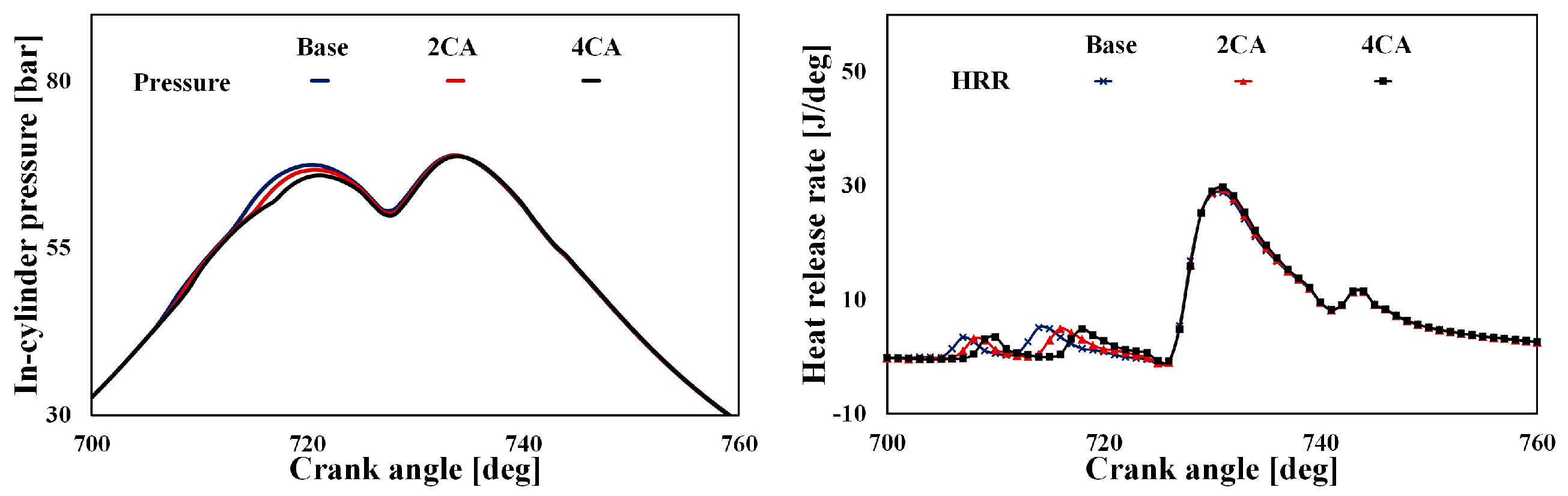

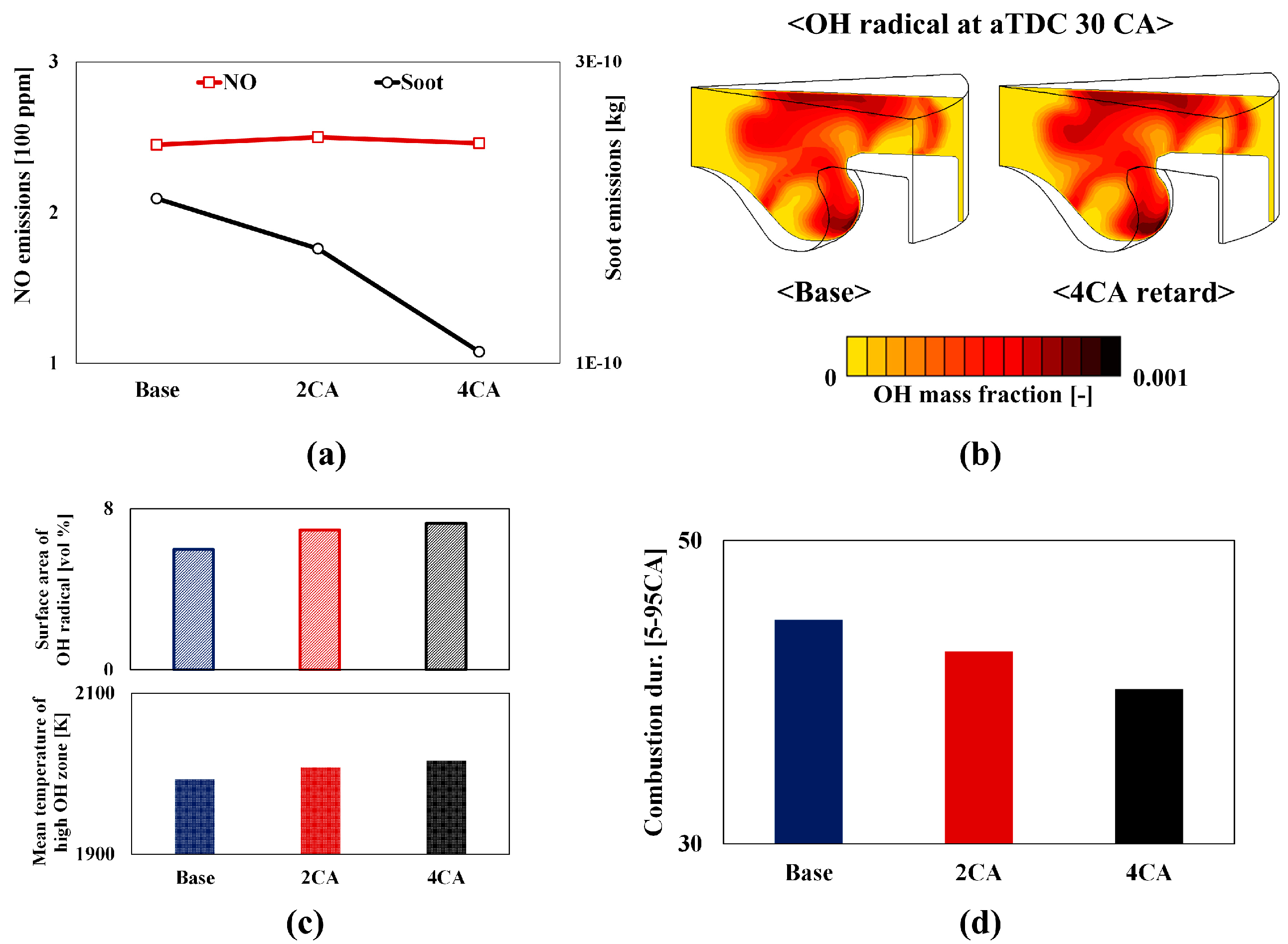

4.5. Numerical Analyses on the Effect of Dwell Time on NOx and Soot Emissions

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| 1-D | One dimensional |

| 2-D | Two dimensional |

| 3-D | Three dimensional |

| a constant in Equation (10) | |

| a constant in Equation (10) | |

| aBDC | after Bottom Dead Center |

| aTDC | after Top Dead Center |

| bBDC | before Bottom Dead Center |

| BDC | Bottom Dead Center |

| bTDC | before Top Dead Center |

| CA | Crank Angle (degree) |

| CFD | Computational Fluid Dynamics |

| mean specific heat at constant pressure (J/kg·K) | |

| CPU | Central Processing Unit |

| D | scalar diffusion coefficient (m2/s) |

| DNS | Direct Numerical Simulation |

| EGR | Exhaust Gas Recirculation |

| erfc | complimentary error function in Equation (10) |

| EVC | exhaust valve close |

| EVO | exhaust valve open |

| exp | exponential function |

| h | enthalpy (J) |

| I | Interaction parameter |

| IVC | intake valve close |

| IVO | intake valve open |

| Le | Lewis number (-) |

| OH | hydroxide |

| RIF | Representative Interactive Flamelet |

| RNG | Re-Normalization Group |

| chemical production rate | |

| MI | Main injection |

| MFB | Mass fraction burned |

| N | Number of fuel streams |

| NO | nitric monoxide |

| NOx | nitric oxides |

| p | Pressure (bar) |

| probability density function | |

| Probability Density Function | |

| PI | Pilot Injection |

| PM | Particulate Matter |

| Po | Post injection |

| Radiative heat flux | |

| RANS | Reynolds-Averaged Navier-Stokes |

| RPM | Revolution per minute |

| t | time (s) |

| TDC | Top Dead Center |

| V | volume (m3) |

| spatial coordinate | |

| Y | species mass fraction |

| y | mixing parameter (-) |

| Z | overall mixture fraction (-) |

| mean mixture fraction | |

| Greek Symbols | |

| density (kg/m3) | |

| instantaneous scalar dissipation rate (1/s) | |

| joint scalar dissipation rate (1/s) | |

| domain averaged scalar dissipation rate conditioned on stoichiometric mixture (1/s) | |

| Subscripts | |

| 1 | fuel stream 1 |

| 2 | fuel stream 2 |

| i | ith species |

| j | jth fuel stream |

| k | kth species |

| st | stoichiometric mixture |

References

- Heywood, J.B. Combustion in compression-ignition engines. In Internal Combustion Engine Fundamentals; McGraw-Hill Education: New York, NY, USA, 1988; pp. 491–566. ISBN 0-07-100499-8. [Google Scholar]

- Stanglmaier, R.; Roberts, C. Homogeneous Charge Compression Ignition (HCCI): Benefits, Compromises, and Future Engine Applications; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1999. [Google Scholar]

- Lee, S.; Reitz, R.D. Spray Targeting to Minimize Soot and CO Formation in Premixed Charge Compression Ignition (PCCI) Combustion with a HSDI Diesel Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Kokjohn, S.L.; Hanson, R.M.; Splitter, D.A.; Reitz, R.D. Fuel reactivity controlled compression ignition (RCCI): A pathway to controlled high-efficiency clean combustion. Int. J. Eng. Res. 2011, 12, 209–226. [Google Scholar] [CrossRef]

- Di Sarli, V.; Di Benedetto, A. Modeling and simulation of soot combustion dynamics in a catalytic diesel particulate filter. Chem. Eng. Sci. 2015, 137, 69–78. [Google Scholar] [CrossRef]

- Di Sarli, V.; Landi, G.; Lisi, L.; Saliva, A.; Di Benedetto, A. Catalytic diesel particulate filters with highly dispersed ceria: Effect of the soot-catalyst contact on the regeneration performance. Appl. Catal. B Environ. 2016, 197, 116–124. [Google Scholar] [CrossRef]

- Tow, T.C.; Pierpont, D.A.; Reitz, R.D. Reducing Particulate and NOx Emissions by Using Multiple Injections in a Heavy Duty DI Diesel Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1994. [Google Scholar]

- Shundoh, S.; Komori, M.; Tsujimura, K.; Kobayashi, S. NOx Reduction from Diesel Combustion Using Pilot Injection with High Pressure Fuel Injection; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1992. [Google Scholar]

- Nehmer, D.A.; Reitz, R.D. Measurement of the Effect of Injection Rate and Split Injections on Diesel Engine Soot and NOx Emissions; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1994. [Google Scholar]

- Chen, S. Simultaneous Reduction of NOx and Particulate Emissions by Using Multiple Injections in a Small Diesel Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2000. [Google Scholar]

- Miyaki, M.; Fujisawa, H.; Masuda, A.; Yamamoto, Y. Development of New Electronically Controlled Fuel Injection System ECD-U2 for Diesel Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1991. [Google Scholar]

- Guerrassi, N.; Dupraz, P. A Common Rail Injection System for High Speed Direct Injection Diesel Engines; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- Benajes, J.; Molina, S.; Garcia, J. Influence of Pre- and Post-Injection on the Performance and Pollutant Emissions in a HD Diesel Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Payri, R.; Benajes, J.; Molina, S.; Soare, V. Investigation of the influence of injection rate shaping on the spray characteristics in a diesel common rail system equipped with a piston amplifier. J. Fluids Eng. 2005, 127, 1102–1110. [Google Scholar]

- Bianchi, G.M.; Pelloni, P.; Corcione, F.E.; Luppino, F. Numerical Analysis of Passenger Car HSDI Diesel Engines with the 2nd Generation of Common Rail Injection Systems: The Effect of Multiple Injections on Emissions; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Corcione, F.E.; Vaglieco, B.M.; Corcione, G.E.; Lavorgna, M. Potential of Multiple Injection Strategy for Low Emission Diesel Engines; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Schmid, M.; Leipertz, A.; Fettes, C. Influence of Nozzle Hole Geometry, Rail Pressure and Pre-Injection on Injection, Vaporisation and Combustion in a Single-Cylinder Transparent Passenger Car Common Rail Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2002. [Google Scholar]

- Patterson, M.A.; Kong, S.C.; Hampson, G.J.; Reitz, R.D. Modeling the Effects of Fuel Injection Characteristics on Diesel Engine Soot and NOx Emissions; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1994. [Google Scholar]

- Han, Z.; Uludogan, A.; Hampson, G.J.; Reitz, R.D. Mechanism of Soot and NOx Emission Reduction Using Multiple-Injection in a Diesel Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1996. [Google Scholar]

- Wang, D.; Zhang, C.; Wang, Y. A numerical study of multiple fuel injection strategies for NOx reduction from DI Diesel engines. Int. J. Green Energy 2007, 4, 453–470. [Google Scholar] [CrossRef]

- Peters, N. Laminar diffusion flamelet models in a non-premixed turbulent combustion. Prog. Energy Combust. Sci. 1984, 10, 319–339. [Google Scholar] [CrossRef]

- Hasse, C.; Peters, N. A two mixture fraction flamelet model applied to split injections in a DI Diesel engine. Proc. Combust. Inst. 2005, 30, 2755–2762. [Google Scholar] [CrossRef]

- Pitsch, H.; Wan, Y.P.; Peters, N. Numerical Investigation of Soot Formation and Oxidation under Diesel Engine Conditions; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1995. [Google Scholar]

- Lim, J.; Lee, S.; Min, K. Combustion modelling of split injection in HSDI Diesel engines. Combust. Sci. Technol. 2010, 183, 180–201. [Google Scholar] [CrossRef]

- Kim, G.; Min, K. Numerical Study on the Multiple Injection Strategy in Diesel Engines Using a Modified 2-D Flamelet Model; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Felsch, C.; Gauding, M.; Hasse, C.; Vogel, S.; Peters, N. An extended flamelet model for multiple injections in DI Diesel engines. Proc. Combust. Inst. 2009, 32, 2775–2783. [Google Scholar] [CrossRef]

- Mittal, V.; Cook, D.J.; Pitsch, H. An extended multi-regime flamelet model for IC engines. Combust. Flame 2012, 159, 2767–2776. [Google Scholar] [CrossRef]

- Doran, E.M.; Pitsch, H.; Cook, D.J. A priori testing of two-dimensional unsteady flamelet model for three-feed combustion systems. Proc. Combust. Inst. 2013, 34, 1317–1324. [Google Scholar] [CrossRef]

- Pitsch, H.; Barths, H.; Peters, N. Three-Dimensional Modelling of NOx and Soot Formation in DI-Diesel Engines Using Detailed Chemistry Based on the Interactive Flamelet Approach; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1996. [Google Scholar]

- Hergart, C.; Barths, H.; Peters, N. Modeling the Combustion in a Small-Bore Diesel Engine Using a Method Based on Representative Interactive Flamelets; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1999. [Google Scholar]

- Pitsch, H.; Riesmeier, E.; Peters, N. Unsteady flamelet modelling of soot formation in turbulent diffusion flames. Combust. Sci. Technol. 2000, 158, 389–406. [Google Scholar] [CrossRef]

- Yu, Y.; Kim, S.; Kim, Y. Numerical modelling for auto-ignition and combustion process of fuel sprays in high-pressure environment. Combust. Sci. Technol. 2001, 168, 85–112. [Google Scholar] [CrossRef]

- Jones, W.P.; Whitelaw, J.H. Calculation methods for reacting turbulent flows: A review. Combust. Flame 1982, 48, 1–26. [Google Scholar] [CrossRef]

- Pitsch, H.; Chen, M.; Peters, N. Unsteady flamelet modelling of turbulent hydrogen-air diffusion flames. Symposium (Int.) Combust. 1998, 27, 1057–1064. [Google Scholar] [CrossRef]

- Girimaji, S.S. Assumed β-pdf model for turbulent mixing: Validation and extension to multiple scalar mixing. Combust. Sci. Technol. 1991, 78, 177–196. [Google Scholar] [CrossRef]

- Kee, R.J.; Rupley, F.M.; Miller, J.A. The Chemkin Thermodynamic Data Base. No. SAND-87-8215B, Technical Report; USA, 1990. Available online: https://www.osti.gov/scitech/biblio/7073290-chemkin-thermodynamic-data-base/ (accessed on 28 August 2017).

- Yakhot, V.; Orszag, S.A. Renormalization group analysis of turbulence. I. Basic theory. J. Sci. Comput. 1986, 1, 3–51. [Google Scholar] [CrossRef]

- Patel, A.; Kong, S.C.; Reitz, R.D. Development and Validation of a Reduced Reaction Mechanism for HCCI Engine Simulations; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- GRI-Mech 3.0. Available online: http://www.me.berkeley.edu/gri_mech/ (accessed on 17 July 2017).

- Reitz, R.D.; Diwakar, R. Effect of Drop Breakup on Fuel Sprays; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1986. [Google Scholar]

- Bardi, M.; Payri, R.; Malbec, L.M.; Bruneaux, G.; Pickett, L.M.; Manin, J.; Bazyn, T.; Genzale, C.L. Engine combustion network: Comparison of spray development vaporization, and combustion in different combustion vessels. At. Sprays 2012, 22, 807–842. [Google Scholar] [CrossRef]

- Herzog, P.L.; Bürgler, L.; Winklhofer, E.; Zelenka, P.; Cartellieri, W. NOx Reduction Strategies for DI Diesel Engines; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1992. [Google Scholar]

- Desantes, J.M.; Benajes, J.; Molina, S.; Gonzelez, C.A. The modification of the fuel injection rate in heavy-duty diesel engines. Part 1: Effect on engine performance and emissions. Appl. Therm. Eng. 2004, 24, 2701–2714. [Google Scholar] [CrossRef]

- Ikemoto, M.; Omae, K.; Shimode, K.; Toda, N. Diesel spray and combustion development using nozzle flow visualization, spray and combustion analyses. In Proceedings of the International Conference: SIA Powertrain—Rouen 2016, Rouen, France, 1–2 June 2016; Available online: http://www.sia.fr/evenements/12-sia-powertrain-rouen-2016?calendrier=1#planning/ (accessed on 28 July 2017).

- Hardy, W.L.; Reitz, R.D. An Experimental Investigation of Partially Premixed Combustion Strategies Using Multiple Injections in a Heavy-Duty Diesel Engine; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Poorghasemi, K.; Ommi, F.; Yaghmaei, H.; Namaki, A. An investigation of high pressure post injection on soot and NO emissions in a DI diesel engine. J. Mech. Sci. Technol. 2012, 26, 269–281. [Google Scholar] [CrossRef]

- Diwakar, R.; Domenech-Llopis, V. Physics of Combustion Noise Reduction with Multiple Injections in a DI Diesel Engine—A Computational Study; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Kim, M.; Yoon, S.; Lee, C. Impact of split injection strategy on the exhaust emissions and soot particulates from a compression ignition engine fueled with neat biodiesel. Energy Fuels 2008, 22, 1260–1265. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Bore | 77.2 mm |

| Stroke | 84.5 mm |

| Connecting rod length | 140.0 mm |

| Displacement | 1592 cc (396 cc/cylinder) |

| Compression ratio | 17.3:1 |

| Piston bowl shape | ω-type |

| IVO/IVC | aTDC 17 CA/aBDC 14 CA |

| EVO/EVC | bBDC 23 CA/bTDC 20 CA |

| Injection system | Common-rail with solenoid injector |

| Spray angle | 156° |

| Injector hole diameter | 0.124 mm |

| Injector number of holes | 7 |

| Case | RPM | Fuel Mass (mg) | EGR Rate (%) | Injection Strategies | Equivalent Ratio |

|---|---|---|---|---|---|

| 1 | 1500 | 4 | 35.4 | Triple Injection (PI/PI/MI) | 0.29 |

| 2 | 1500 | 13.5 | 22.6 | 0.67 | |

| 3 | 1500 | 26.6 | 0 | Quadruple Injection (PI/PI/MI/Po) | 0.73 |

| 4 | 2000 | 8.85 | 33 | Triple Injection (PI/PI/MI) | 0.52 |

| 5 | 2000 | 17.1 | 16.1 | Quadruple Injection (PI/PI/MI/Po) | 0.62 |

| 6 | 2500 | 28.2 | 10.4 | 0.65 |

| Case | Details of Parametric Variations |

|---|---|

| 3-I1 | Injection timing Δ = −4 CA from case 3 |

| 3-I2 | Injection timing Δ = +4 CA from case 3 |

| 5-P1 | Injection pressure Δ = −100 bar from case 5 |

| 5-P2 | Injection pressure Δ = +100 bar from case 5 |

| 5-E1 | EGR rate Δ = −8% (abs.) from case 5 |

| 5-E2 | EGR rate Δ = +8% (abs.) from case 5 |

| 6-B1 | Boost pressure Δ = −4% (rel.) from case 6 |

| 6-B2 | Boost pressure Δ = +4% (rel.) from case 6 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, G.; Moon, S.; Lee, S.; Min, K. Numerical Analysis of the Combustion and Emission Characteristics of Diesel Engines with Multiple Injection Strategies Using a Modified 2-D Flamelet Model. Energies 2017, 10, 1292. https://doi.org/10.3390/en10091292

Kim G, Moon S, Lee S, Min K. Numerical Analysis of the Combustion and Emission Characteristics of Diesel Engines with Multiple Injection Strategies Using a Modified 2-D Flamelet Model. Energies. 2017; 10(9):1292. https://doi.org/10.3390/en10091292

Chicago/Turabian StyleKim, Gyujin, Sunyoung Moon, Seungha Lee, and Kyoungdoug Min. 2017. "Numerical Analysis of the Combustion and Emission Characteristics of Diesel Engines with Multiple Injection Strategies Using a Modified 2-D Flamelet Model" Energies 10, no. 9: 1292. https://doi.org/10.3390/en10091292

APA StyleKim, G., Moon, S., Lee, S., & Min, K. (2017). Numerical Analysis of the Combustion and Emission Characteristics of Diesel Engines with Multiple Injection Strategies Using a Modified 2-D Flamelet Model. Energies, 10(9), 1292. https://doi.org/10.3390/en10091292