A Comparison between Voltage and Reactive Power Feedback Schemes of DFIGs for Inter-Area Oscillation Damping Control

Abstract

:1. Introduction

2. Model Development

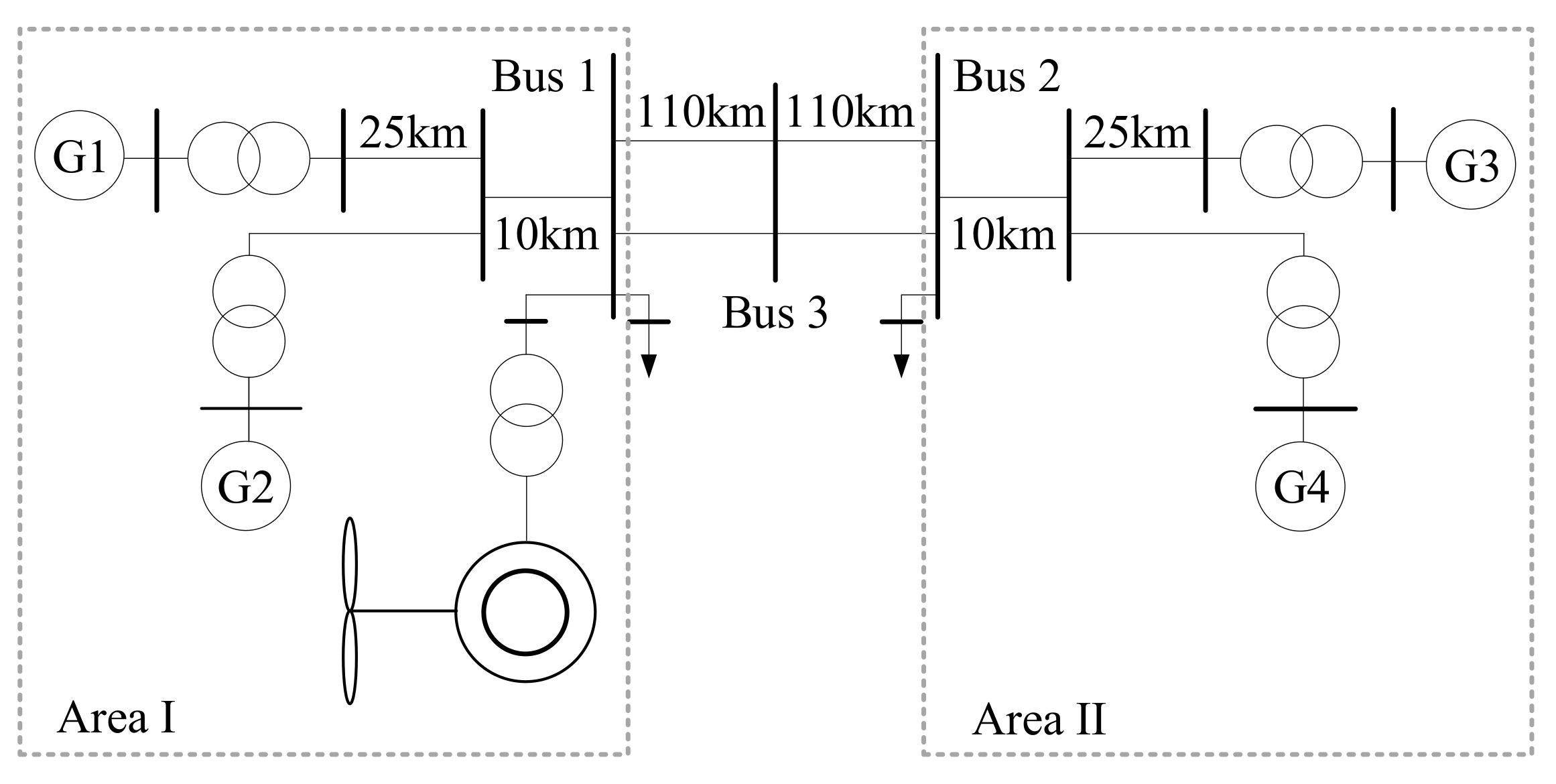

2.1. Two-Area Power System Model

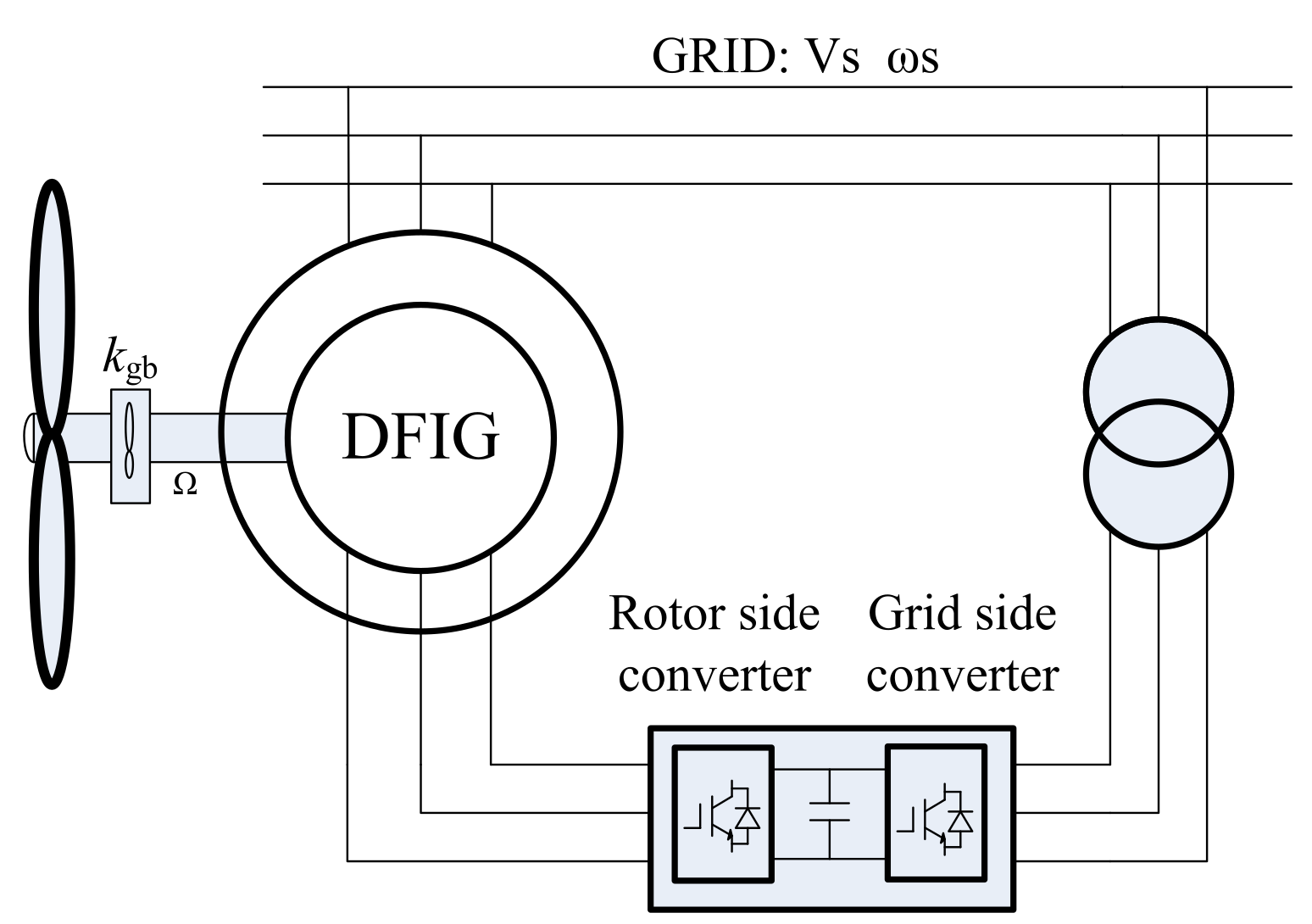

2.2. Model of Doubly Fed Induction Generator

2.2.1. Drive Train of Wind Turbine (WT)

2.2.2. Generator

2.2.3. Dynamics of DC Link

2.2.4. Dynamics of Converters

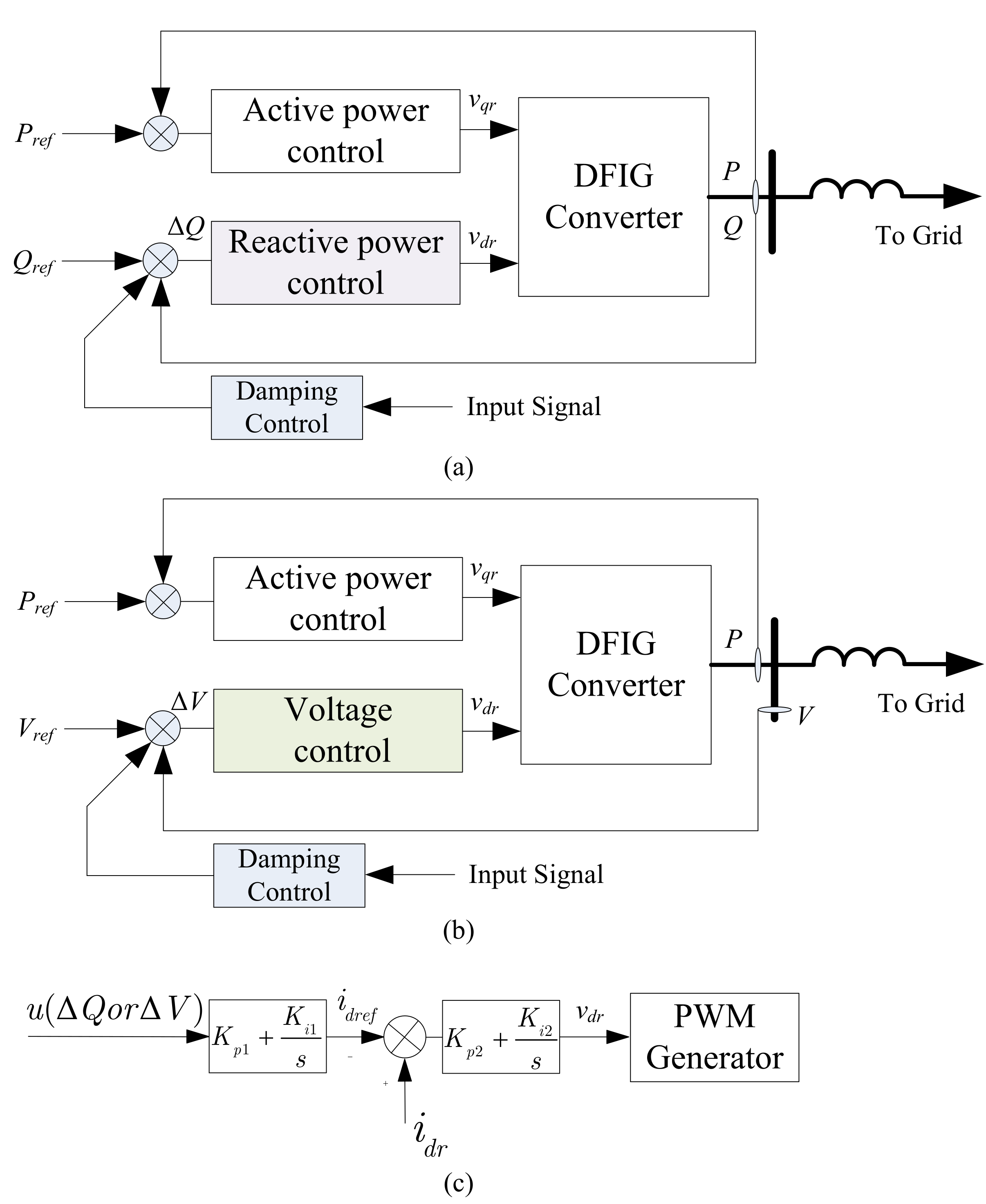

2.2.5. Controller of Doubly Fed Induction Generator Converters

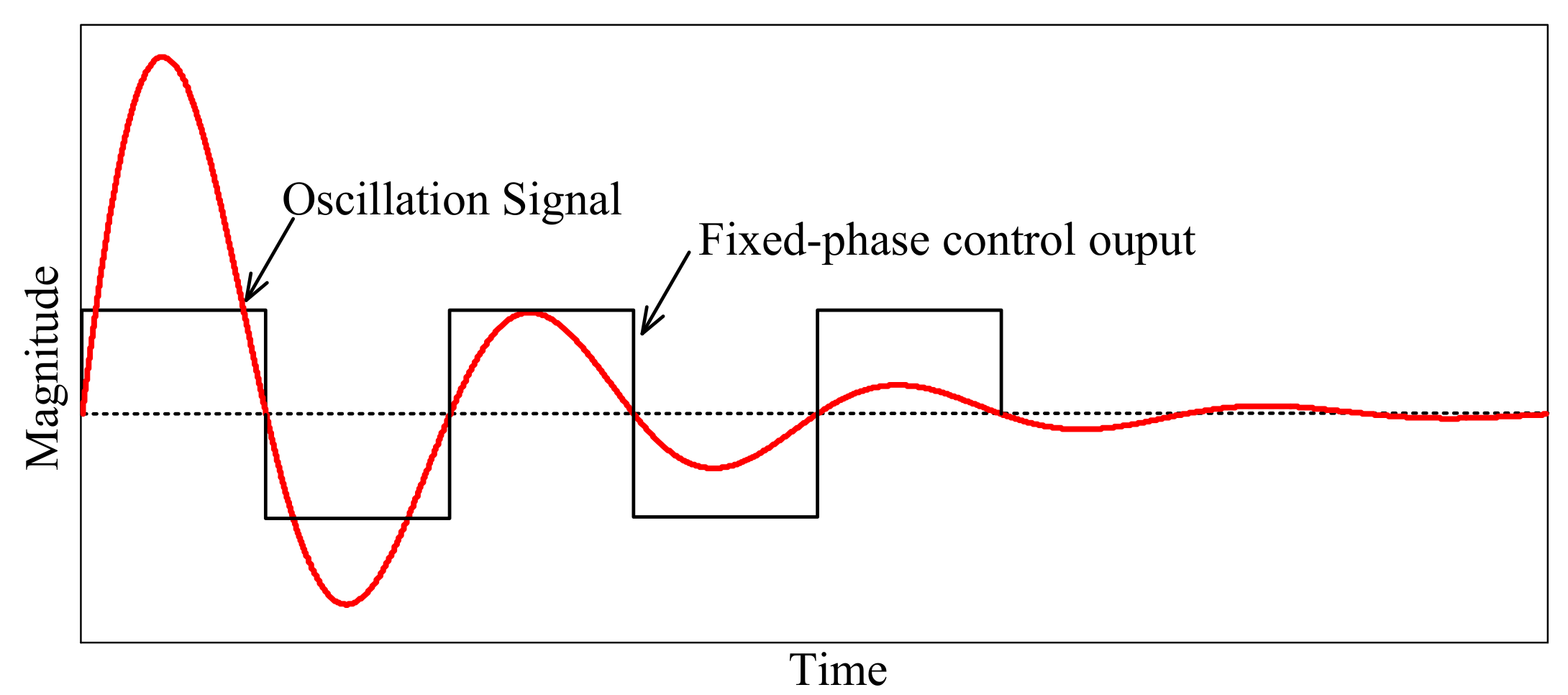

2.3. Oscillation Damping Controls

3. Comparison Analysis

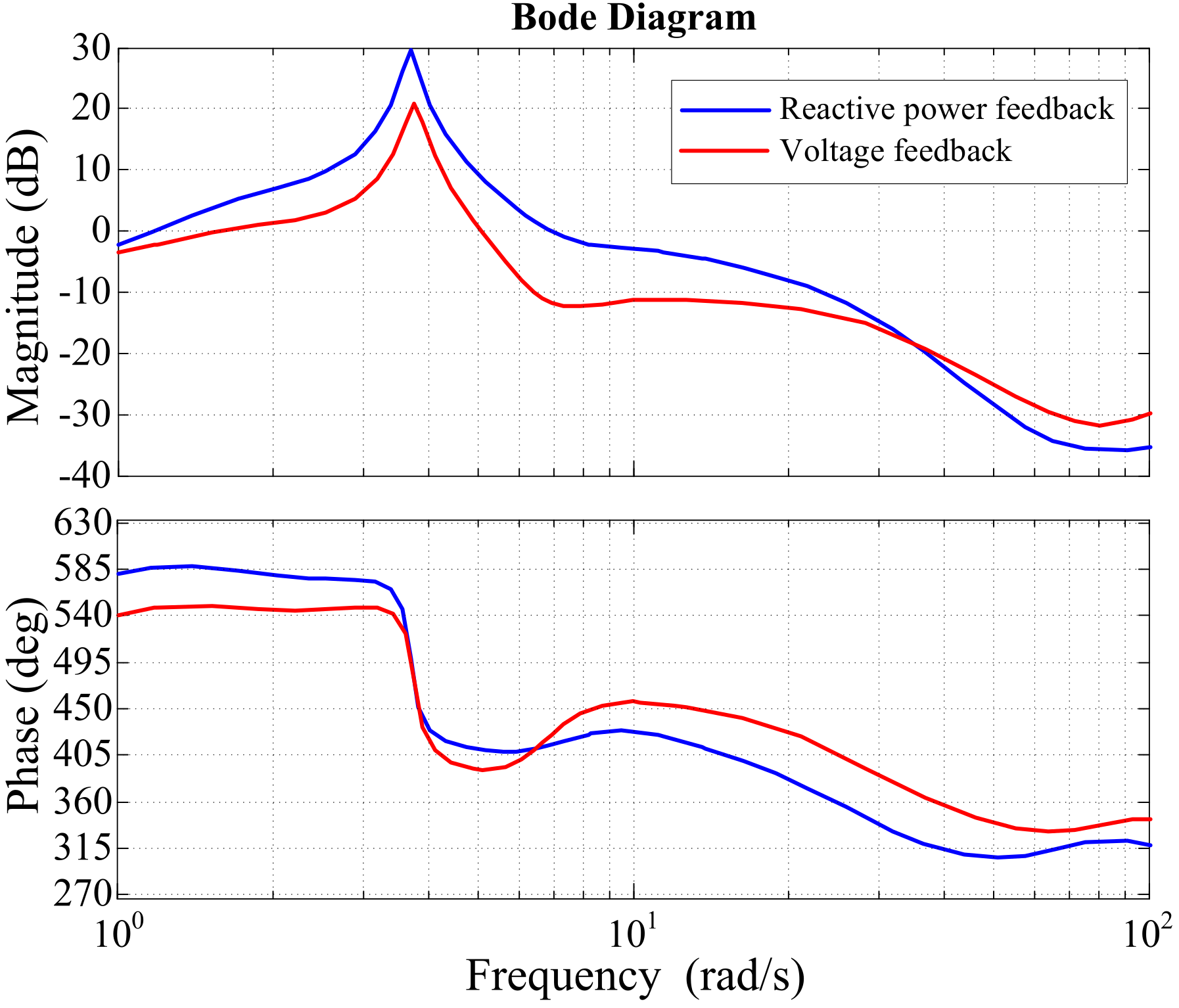

3.1. Frequency Domain Analysis

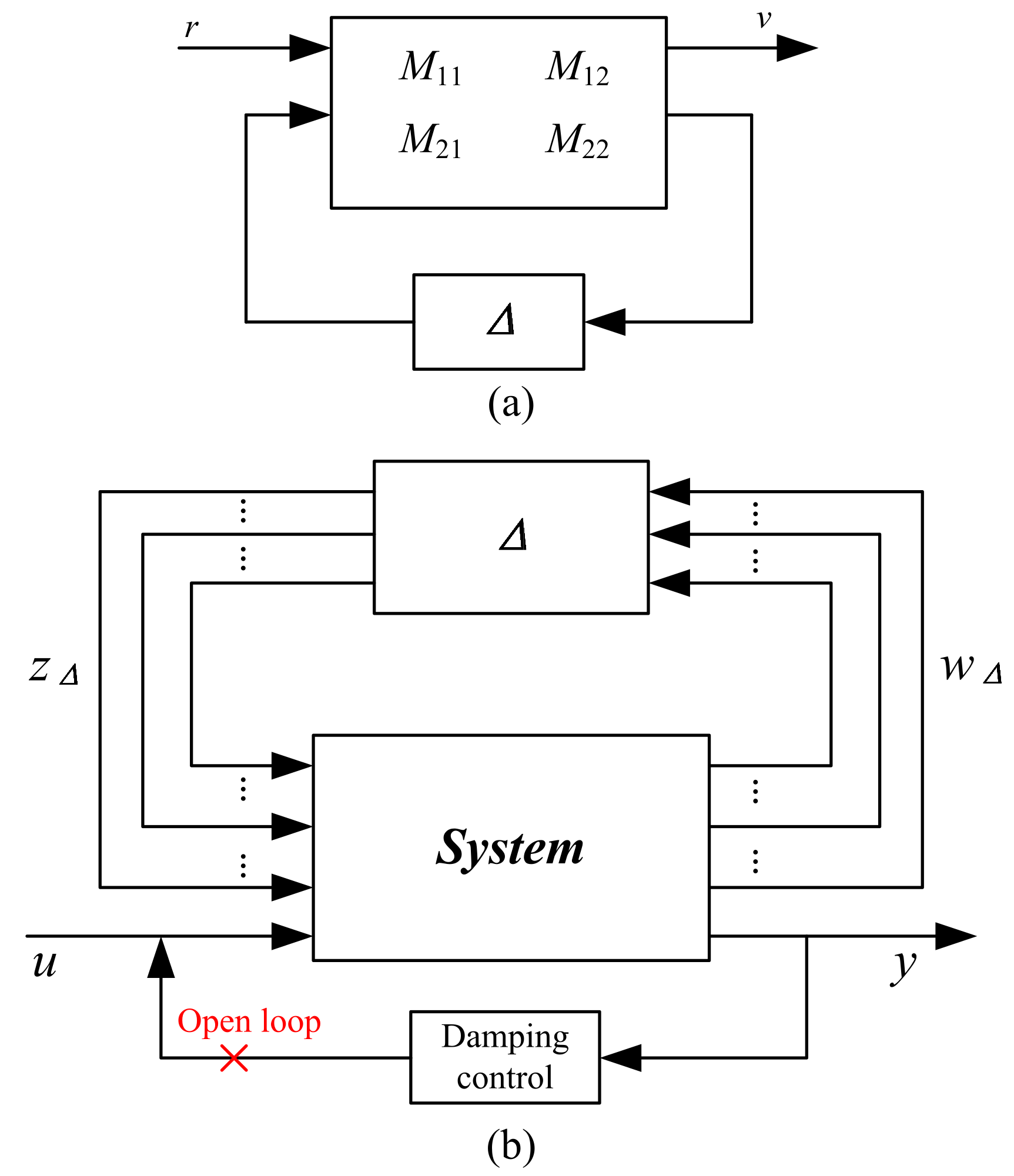

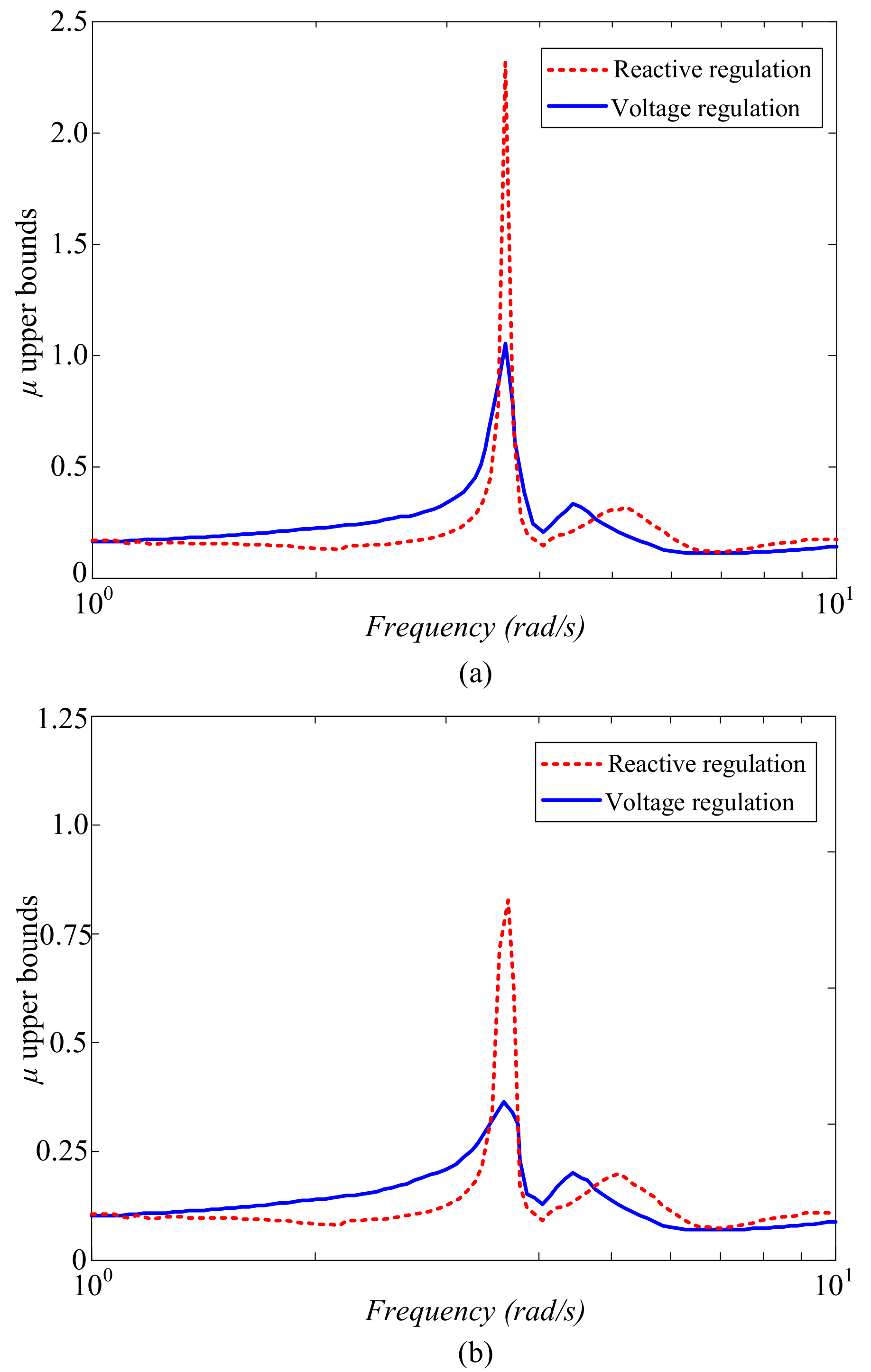

3.2. Robustness Analysis Based on -Analysis

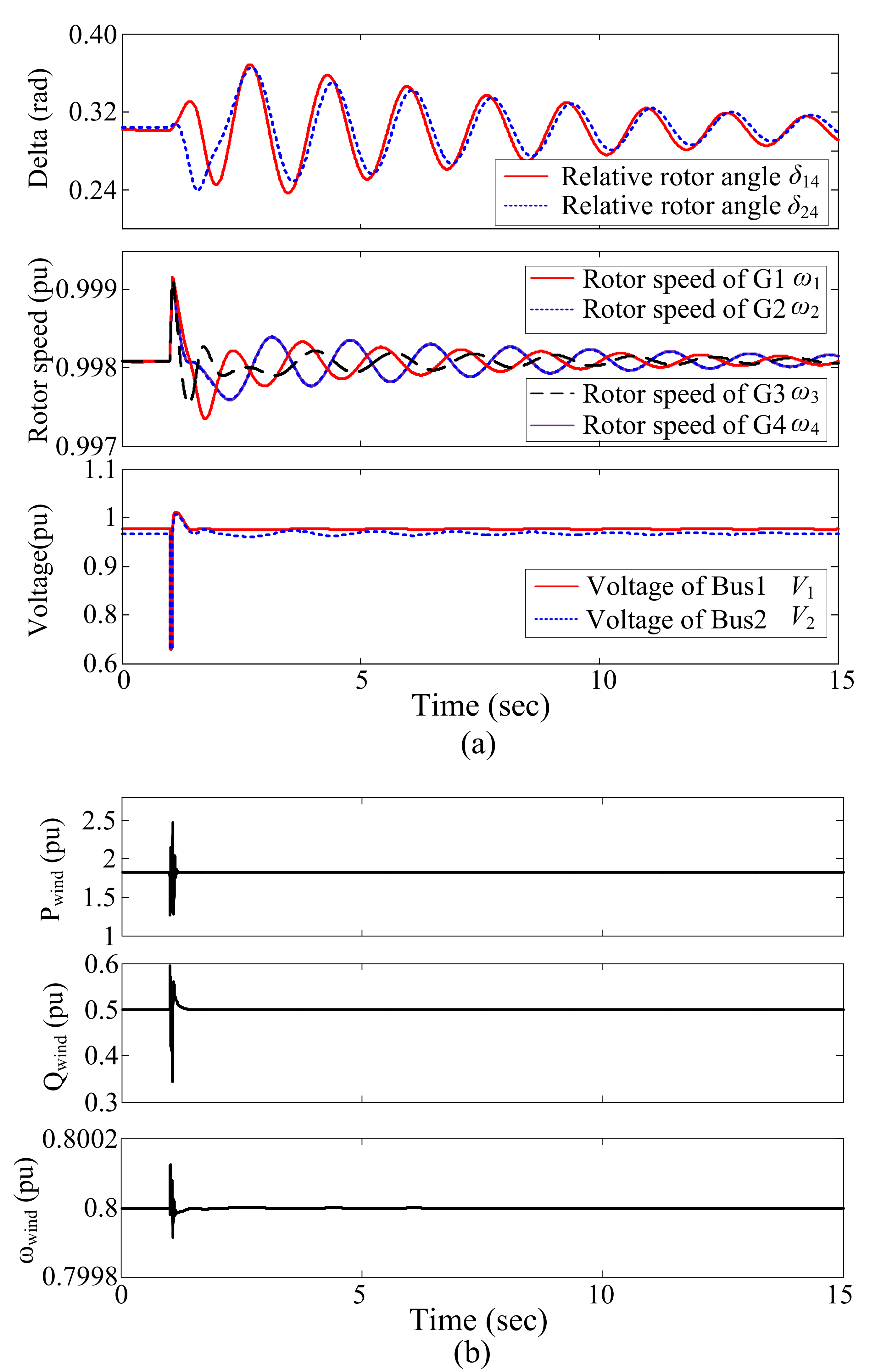

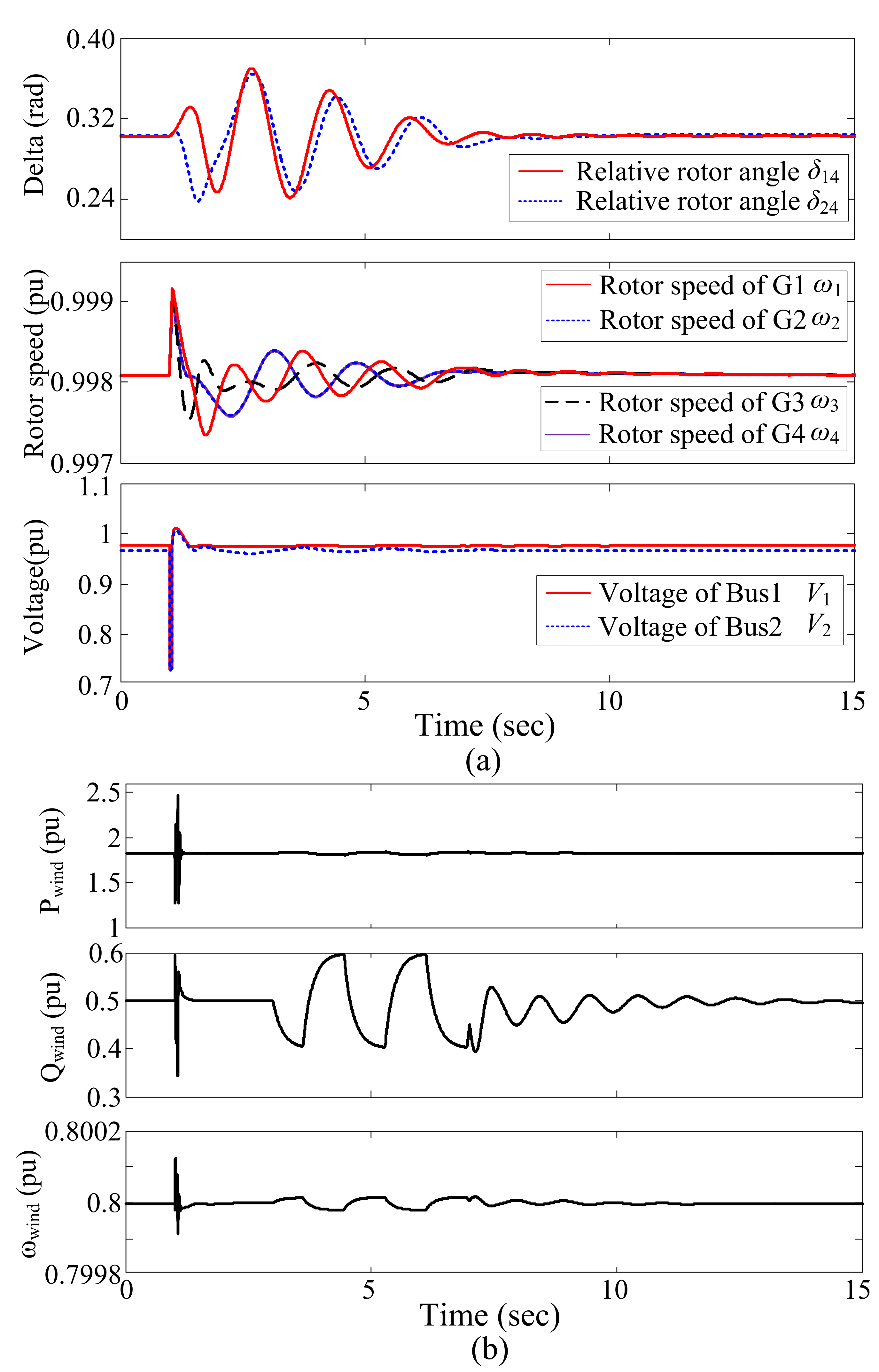

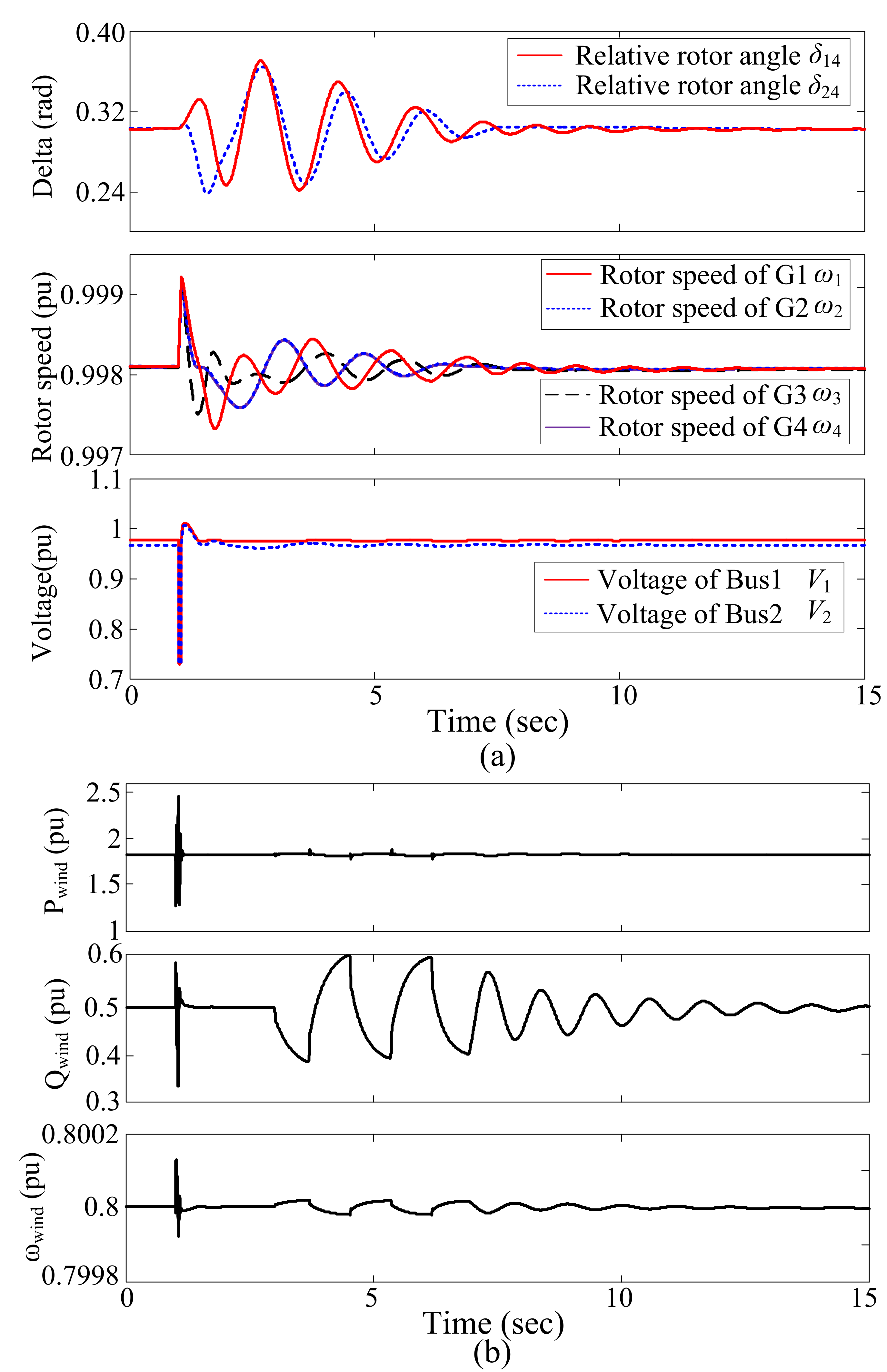

3.3. Time Domain Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Value | Value | ||

|---|---|---|---|

| 0.003 | 0.19 | ||

| 1.8 | 1.7 | ||

| 0.00178 | 0.000929 | ||

| 0.8125 | 0.11414 | ||

| 0.00841 | 0.01334 | ||

| 0.0939 | 0.0812 |

| Value | Value | ||

|---|---|---|---|

| Stator resistance | 0.007 | Stator self-reactance | 0.18 |

| Rotor resistance | 0.005 | Rotor self-reactance | 0.156 |

| 1 | 100 | ||

| 0.05 | 5 | ||

| 1 | 100 | ||

| 0.002 | 0.05 | ||

| 0.3 | 5 |

References

- Yao, J.; Li, H.; Chen, Z.; Xia, X.; Li, X.Q.; Liao, Y. Enhanced control of a DFIG-based wind-power generation system with series grid-side converter under unbalanced grid voltage conditions. IEEE Trans. Power Electron. 2013, 28, 3167–3181. [Google Scholar] [CrossRef]

- Boutoubat, M.; Mokrani, L.; Machmoum, M. Control of a wind energy conversion system equipped by a DFIG for active power generation and power quality improvement. Renew. Energy 2013, 50, 378–386. [Google Scholar] [CrossRef]

- Edrah, M.; Lo, K.L.; Anaya-Lara, O. Impacts of high penetration of DFIG wind turbines on rotor angle stability of power systems. IEEE Trans. Sustain. Energy 2015, 6, 759–766. [Google Scholar] [CrossRef]

- Domínguez-García, J.L.; Gomis-Bellmunt, O.; Bianchi, F.D.; Sumper, A. Power oscillation damping supported by wind power: A review. Renew. Sustain. Energy Rev. 2012, 16, 4994–5006. [Google Scholar] [CrossRef]

- Hughes, F.M.; Anaya-Lara, O.; Jenkins, N.; Strbac, G. A power system stabilizer for DFIG-based wind generation. IEEE Trans. Power Syst. 2006, 21, 763–772. [Google Scholar] [CrossRef]

- Mishra, Y.; Mishra, S.; Tripathy, M.; Senroy, N.; Dong, Z.Y. Improving stability of a DFIG-based wind power system with tuned damping controller. IEEE Trans. Energy Convers. 2009, 24, 650–660. [Google Scholar] [CrossRef]

- Wickramasinghe, A.; Perera, S.; Agalgaonkar, A.; Meegahapola, L. Synchronous mode operation of DFIG based wind turbines for improvement of power system inertia. Renew. Energy, 2016, 95, 152–161. [Google Scholar] [CrossRef]

- Tsourakis, G.; Nomikos, B.M.; Vournas, C.D. Contribution of doubly fed wind generators to oscillation damping. IEEE Trans. Energy Convers. 2009, 24, 783–791. [Google Scholar] [CrossRef]

- Mishra, Y.; Mishra, S.; Li, F.; Dong, Z.Y.; Bansal, R.C. Small-Signal Stability Analysis of a DFIG-Based Wind Power System Under Different Modes of Operation. IEEE Trans. Energy Convers. 2009, 24, 972–982. [Google Scholar] [CrossRef]

- Mithulananthan, N.; Canizares, C.; Reeve, J.; Rogers, G. Comparison of PSS, SVC, and STATCOM controllers for damping power system oscillations. IEEE Trans. Power Syst. 2003, 18, 786–792. [Google Scholar] [CrossRef]

- Fan, L.; Yin, H.; Miao, Z. On Active/Reactive Power Modulation of DFIG-Based Wind Generation for Interarea Oscillation Damping. IEEE Trans. Energy Convers. 2011, 26, 513–521. [Google Scholar]

- Hansen, A.D.; Srensen, P.; Iov, F.; Blaabjerg, F. Control of variable speed wind turbines with doubly-fed induction generators. Wind Eng. 2004, 28, 411–434. [Google Scholar] [CrossRef]

- Yang, L.; Xu, Z.; Ostergaard, J.; Dong, Z.Y.; Wong, K.P. Advanced control strategy of DFIG wind turbines for power system fault ride through. IEEE Trans. Power Syst. 2012, 27, 713–722. [Google Scholar] [CrossRef]

- Mei, F.; Pal, B.C. Modeling and Small Signal Analysis of a Grid Connected Doubly Fed Induction Generator. In Proceedings of the IEEE PES General Meeting, San Francisco, CA, USA, 16 June 2005; pp. 358–367. [Google Scholar]

- Singh, M.; Allen, A.J.; Muljadi, E.; Gevorgian, V.; Zhang, Y.; Santoso, S. Interarea oscillation damping controls for wind power plants. IEEE Trans. Sustain. Energy 2015, 6, 967–975. [Google Scholar] [CrossRef]

- Tang, Y.; He, H.; Wen, J.; Liu, J. Power system stability control for a wind farm based on adaptive dynamic programming. IEEE Trans. Smart Grid 2015, 6, 166–177. [Google Scholar] [CrossRef]

- Fernandez, R.; Mantz, R.; Battaiotto, P. Contribution of wind farms to the network stability. In Proceedings of the IEEE Power Energy Society General Meeting, Montreal, QC, Canada, 18–22 June 2006. [Google Scholar]

- Muller, S.; Deicke, M.; de Doncker, R.W. Doubly fed induction generator systems for wind turbines. IEEE Ind. Appl. Mag. 2002, 8, 26–33. [Google Scholar] [CrossRef]

- Larsen, E.; Sanchez-Gasca, J.; Chow, J. Concepts for design of FACTS controllers to damp power swings. IEEE Trans. Power Syst. 1995, 10, 948–956. [Google Scholar] [CrossRef]

- Fan, L.; Feliachi, A.; Schoder, K. Selection and design of a TCSC control signal in damping power system inter-area oscillations for multiple operating conditions. Electr. Power Syst. Res. 2002, 62, 127–137. [Google Scholar] [CrossRef]

- MATLAB Help Tutorial, Version 7.8.0.347. The Math Works: Natick, MA, USA, 2009. Available online: http://www.mathworks.com/help/toolbox/physmod/powersys/ref/windturbinedoublyfedinductiongeneratorphasortype.html (accessed on 4 June 2017).

- Wu, F.; Zhang, X.P.; Godfrey, K.; Ju, P. Small signal stability analysis and optimal control of a wind turbine with doubly fed induction generator. IET Gener. Transm. Distrib. 2007, 1, 751–760. [Google Scholar] [CrossRef]

- Skogestad, S.; Postlethwaite, I. Multivariable Feedback Control-Analysis and Design; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Doyle, J.C. Analysis of feedback systems with structured uncertainties. IEE Proc. D 1982, 129, 242–250. [Google Scholar] [CrossRef]

- Morton, B.; McAfoos, R. A μ-test for Robustness Analysis of a Real-Parameter Variation Problem. In Proceedings of the American Control Conference, Boston, MA, USA, 19–21 June 1985; pp. 135–138. [Google Scholar]

| Control Scheme | 0.05 | 0.1 | 0.15 | 0.2 | 0.5 | 1 | 1.5 | 5 | |

|---|---|---|---|---|---|---|---|---|---|

| Reactive | f | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 |

| Power Feedback | Magnitude | 27.8 | 27.8 | 27.6 | 27.8 | 27.7 | 27.8 | 27.6 | 27.9 |

| Voltage | f | 3.74 | 3.74 | 3.74 | 3.74 | 3.74 | 3.74 | 3.74 | 3.74 |

| Feedback | Magnitude | 21.3 | 21.2 | 21.3 | 21.4 | 21.3 | 21.3 | 21.2 | 21.4 |

| Control Scheme | 1 | 2 | 5 | 8 | 10 | 15 | 20 | 30 | |

|---|---|---|---|---|---|---|---|---|---|

| Reactive | f | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 | 3.72 |

| Power Feedback | Magnitude | 15.4 | 20.5 | 25.0 | 26.2 | 27.7 | 27.8 | 27.6 | 27.9 |

| Voltage | f | 3.74 | 3.74 | 3.74 | 3.75 | 3.74 | 3.74 | 3.75 | 3.75 |

| Feedback | Magnitude | 6.9 | 11.5 | 18.9 | 20.6 | 21.3 | 22.1 | 21.8 | 22.3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, K.; Wang, Y. A Comparison between Voltage and Reactive Power Feedback Schemes of DFIGs for Inter-Area Oscillation Damping Control. Energies 2017, 10, 1206. https://doi.org/10.3390/en10081206

Liao K, Wang Y. A Comparison between Voltage and Reactive Power Feedback Schemes of DFIGs for Inter-Area Oscillation Damping Control. Energies. 2017; 10(8):1206. https://doi.org/10.3390/en10081206

Chicago/Turabian StyleLiao, Kai, and Yao Wang. 2017. "A Comparison between Voltage and Reactive Power Feedback Schemes of DFIGs for Inter-Area Oscillation Damping Control" Energies 10, no. 8: 1206. https://doi.org/10.3390/en10081206

APA StyleLiao, K., & Wang, Y. (2017). A Comparison between Voltage and Reactive Power Feedback Schemes of DFIGs for Inter-Area Oscillation Damping Control. Energies, 10(8), 1206. https://doi.org/10.3390/en10081206