A Fast Multi-Switched Inductor Balancing System Based on a Fuzzy Logic Controller for Lithium-Ion Battery Packs in Electric Vehicles

Abstract

:1. Introduction

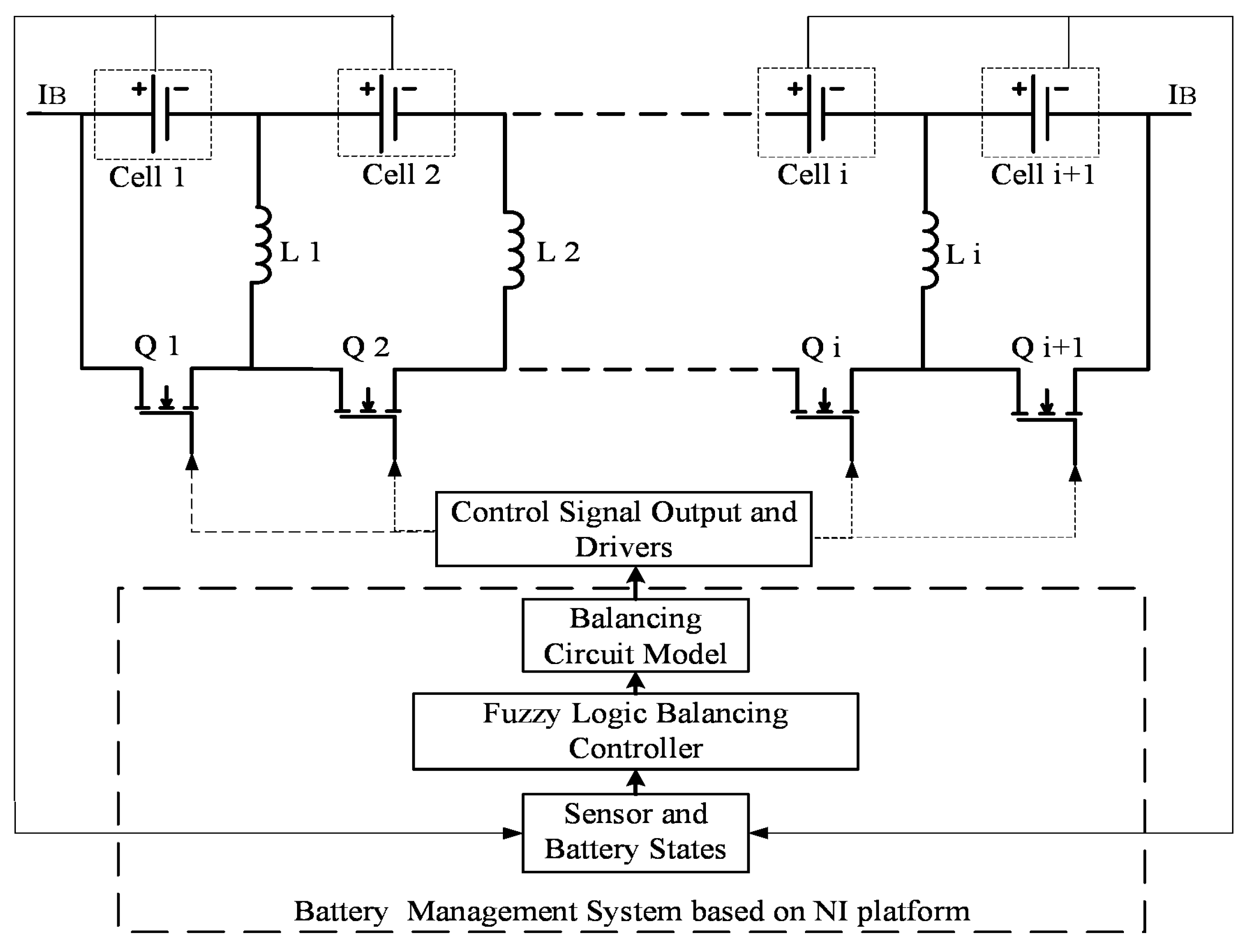

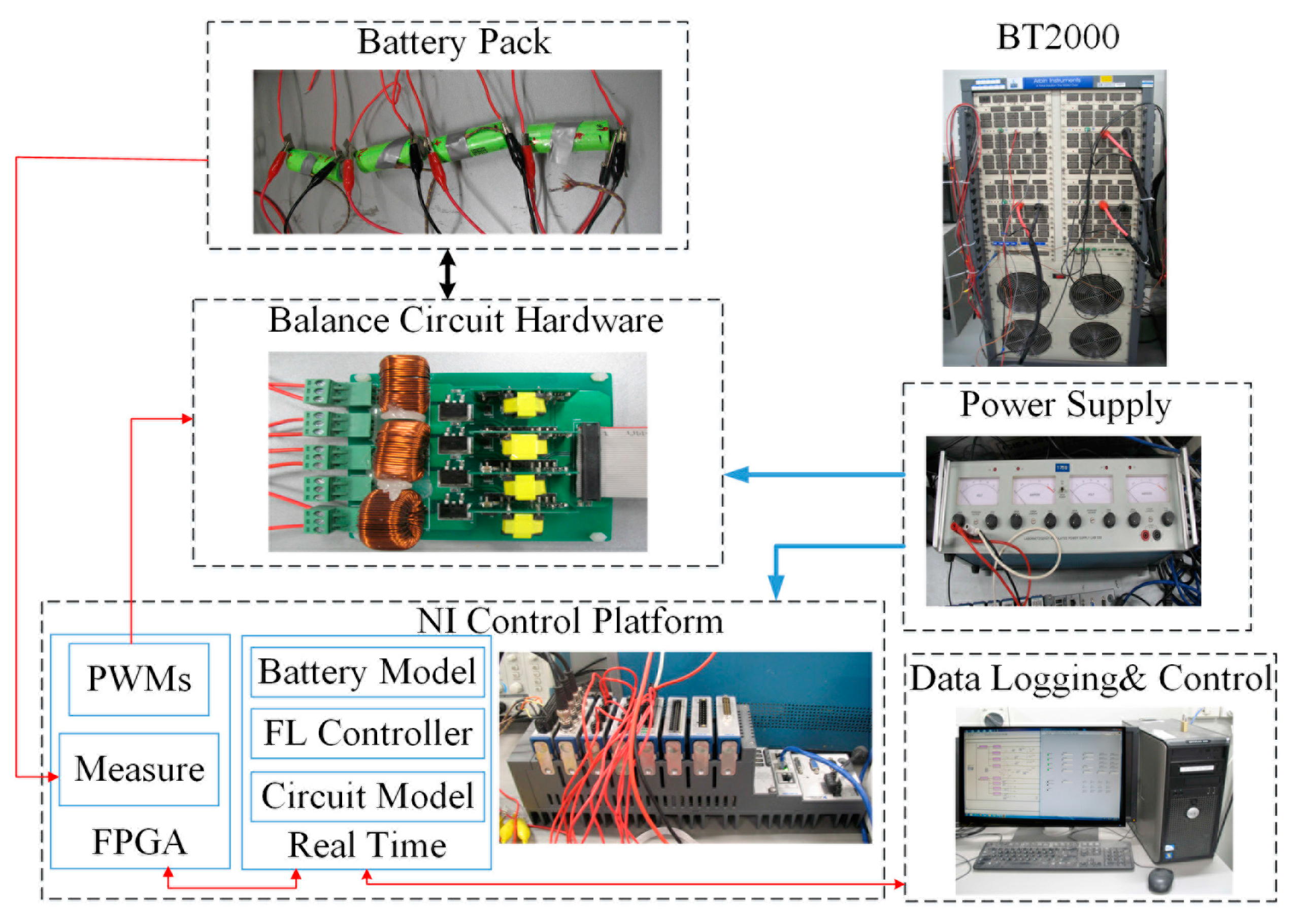

2. Results Multi-Switched Inductor Balancing System

2.1. Multi-Switched Indictor Balancing Circuit

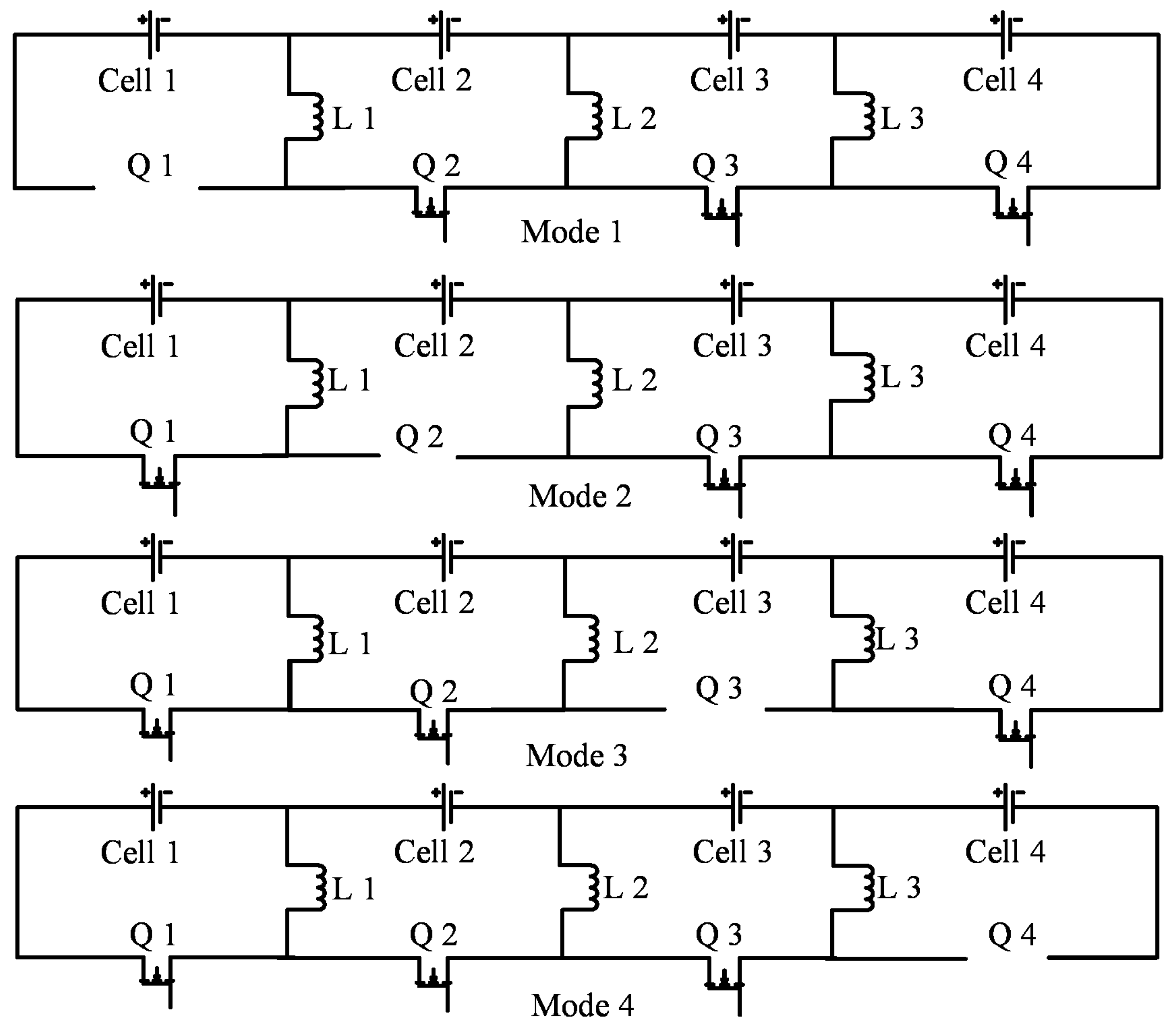

2.2. Balancing Principle

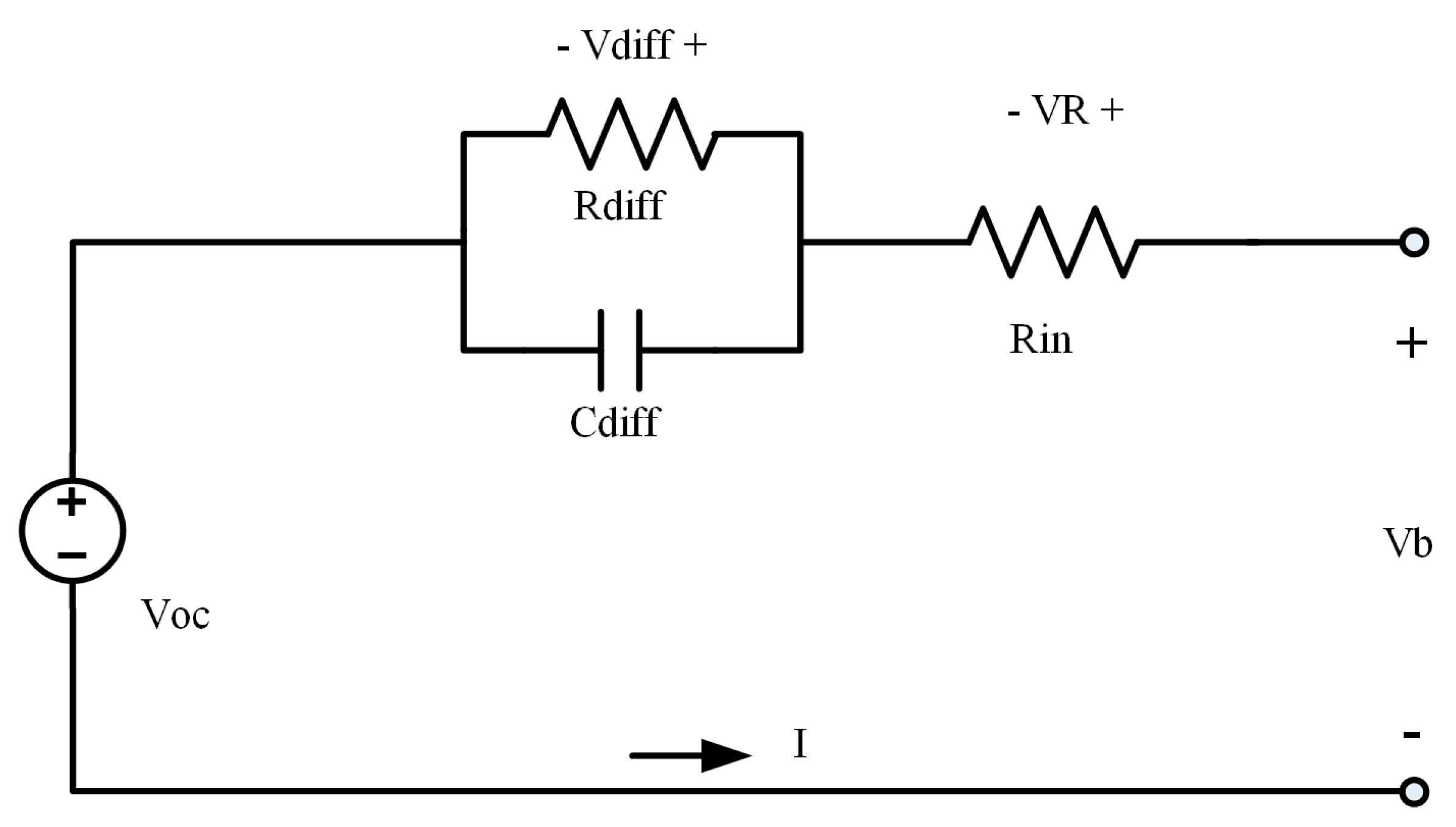

2.3. Balancing Criterion Estimation

3. Fuzzy Logic Controller Design

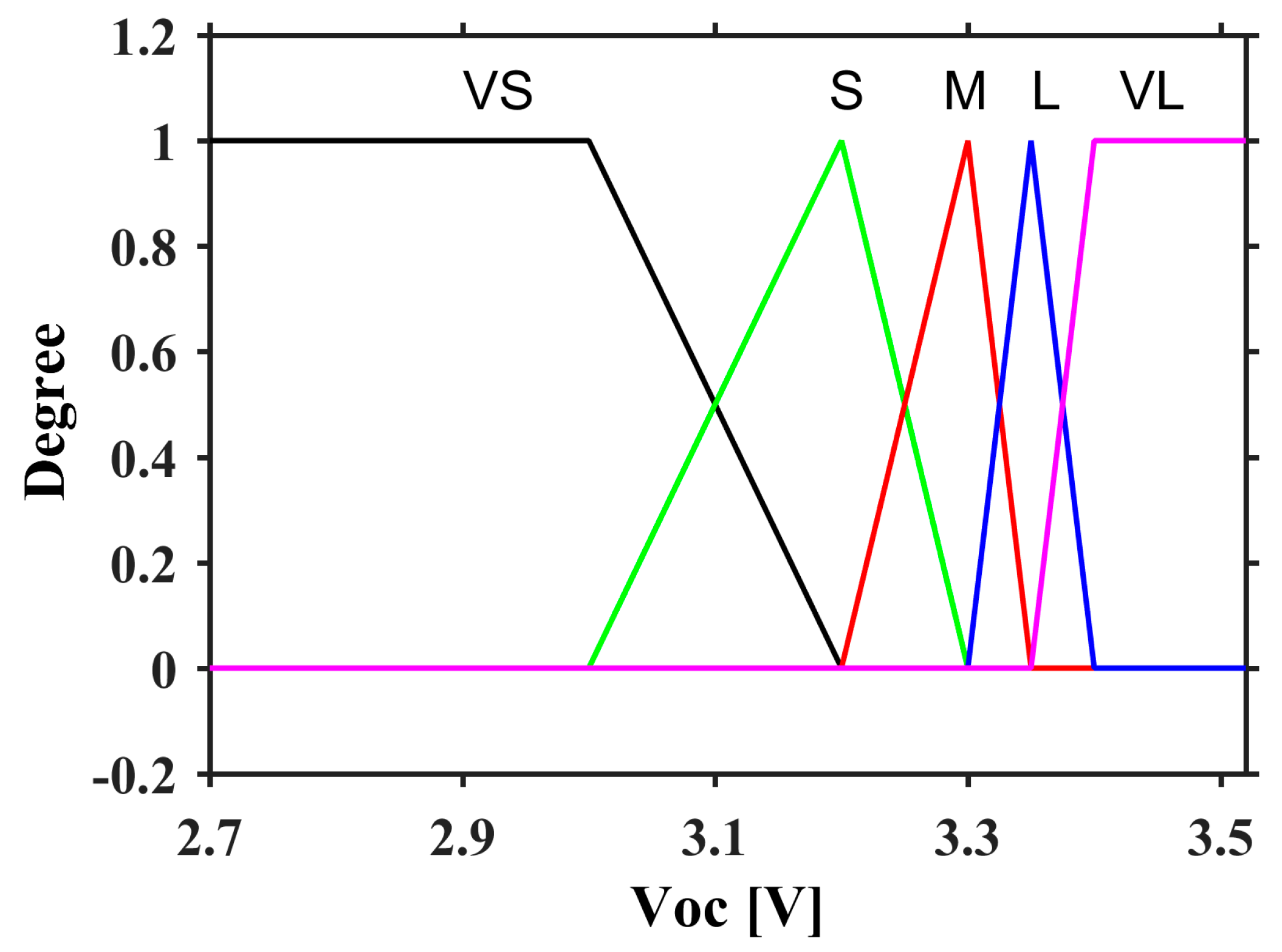

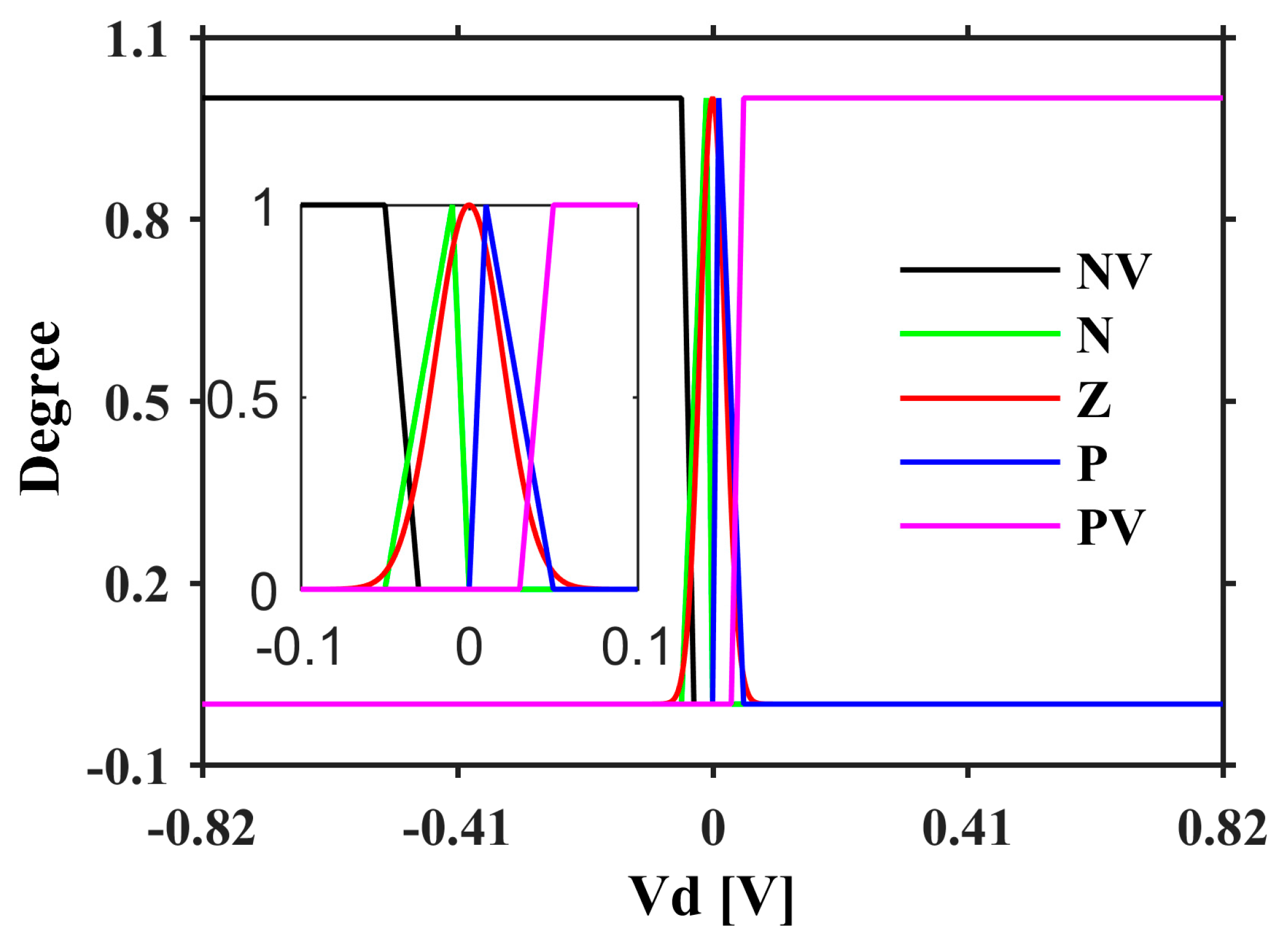

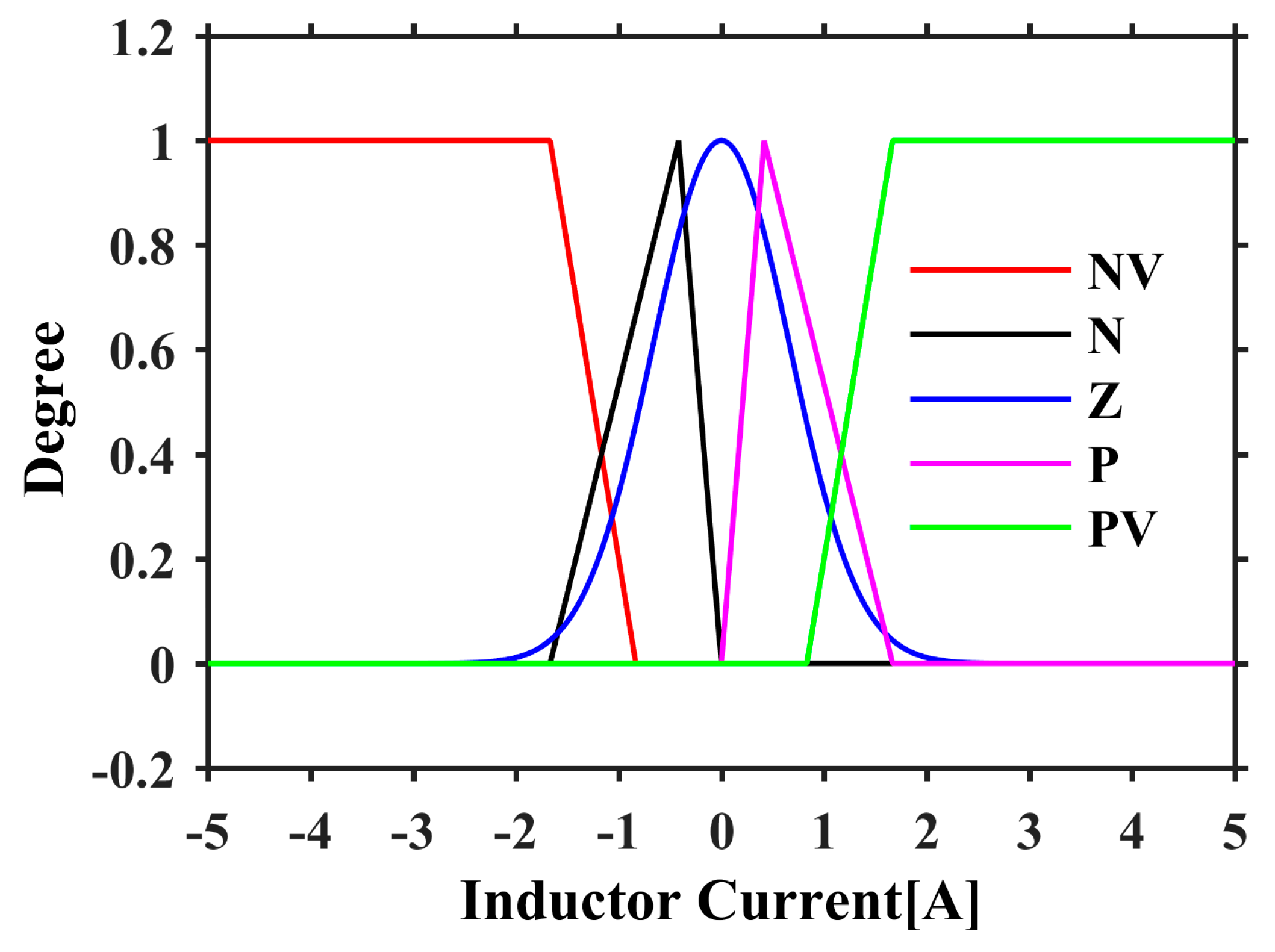

3.1. Membership Functions

3.2. Fuzzy Logic Controller

- Rule 01: IF = NV and = VS THEN = NV;

- Rule 25: IF = PV and = VL THEN = PV.

3.3. Adaptivity

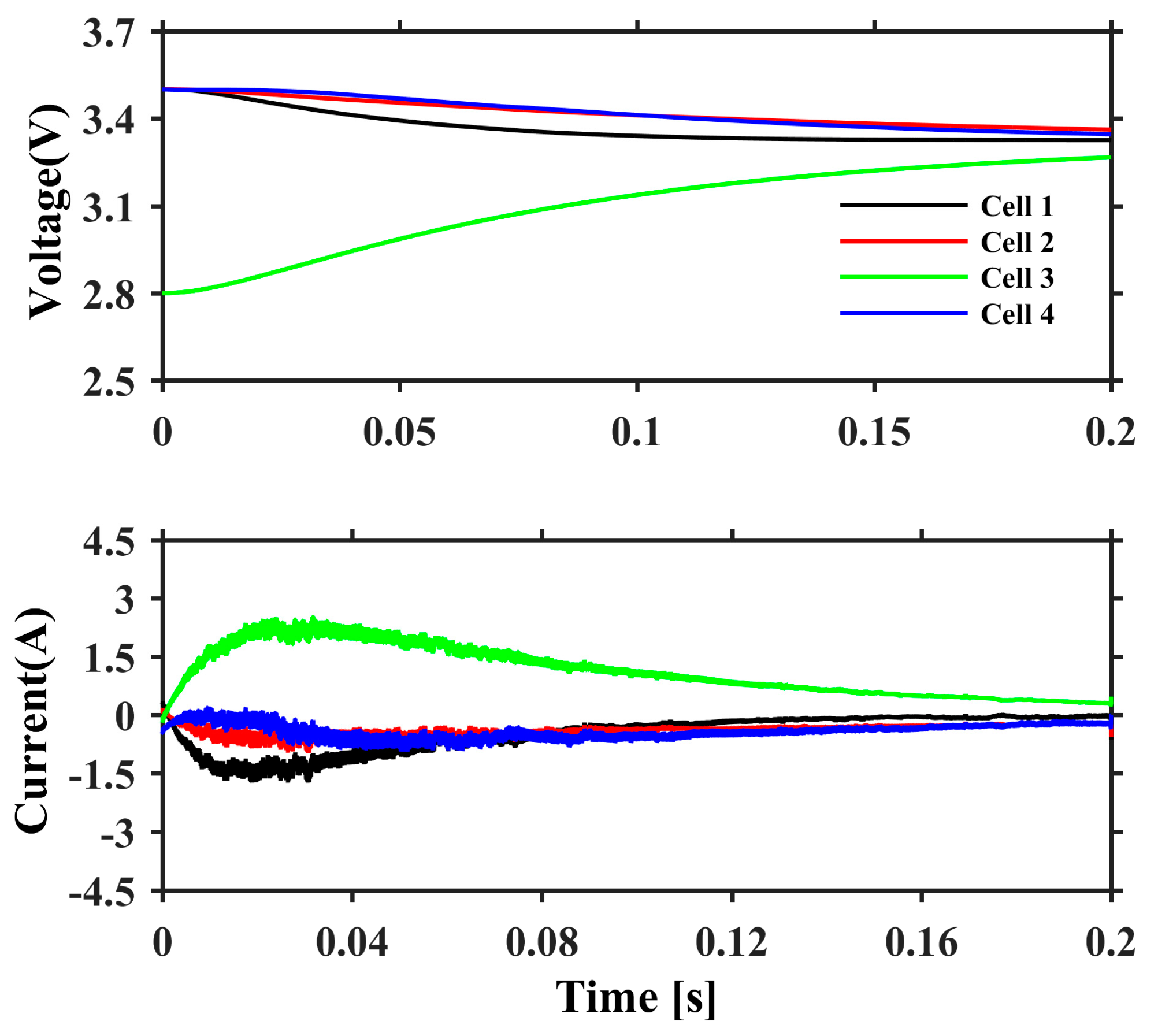

4. Experimental Results

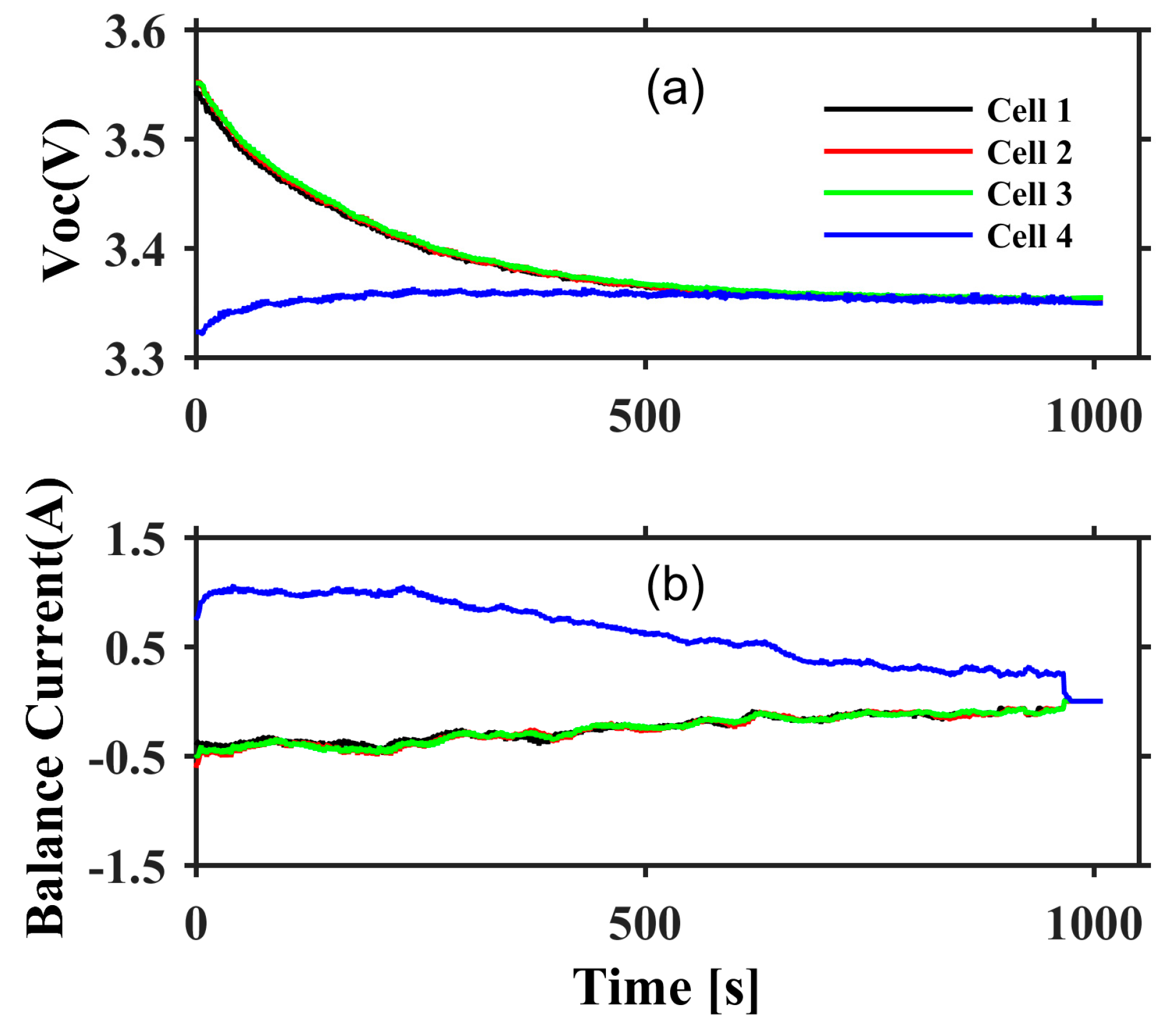

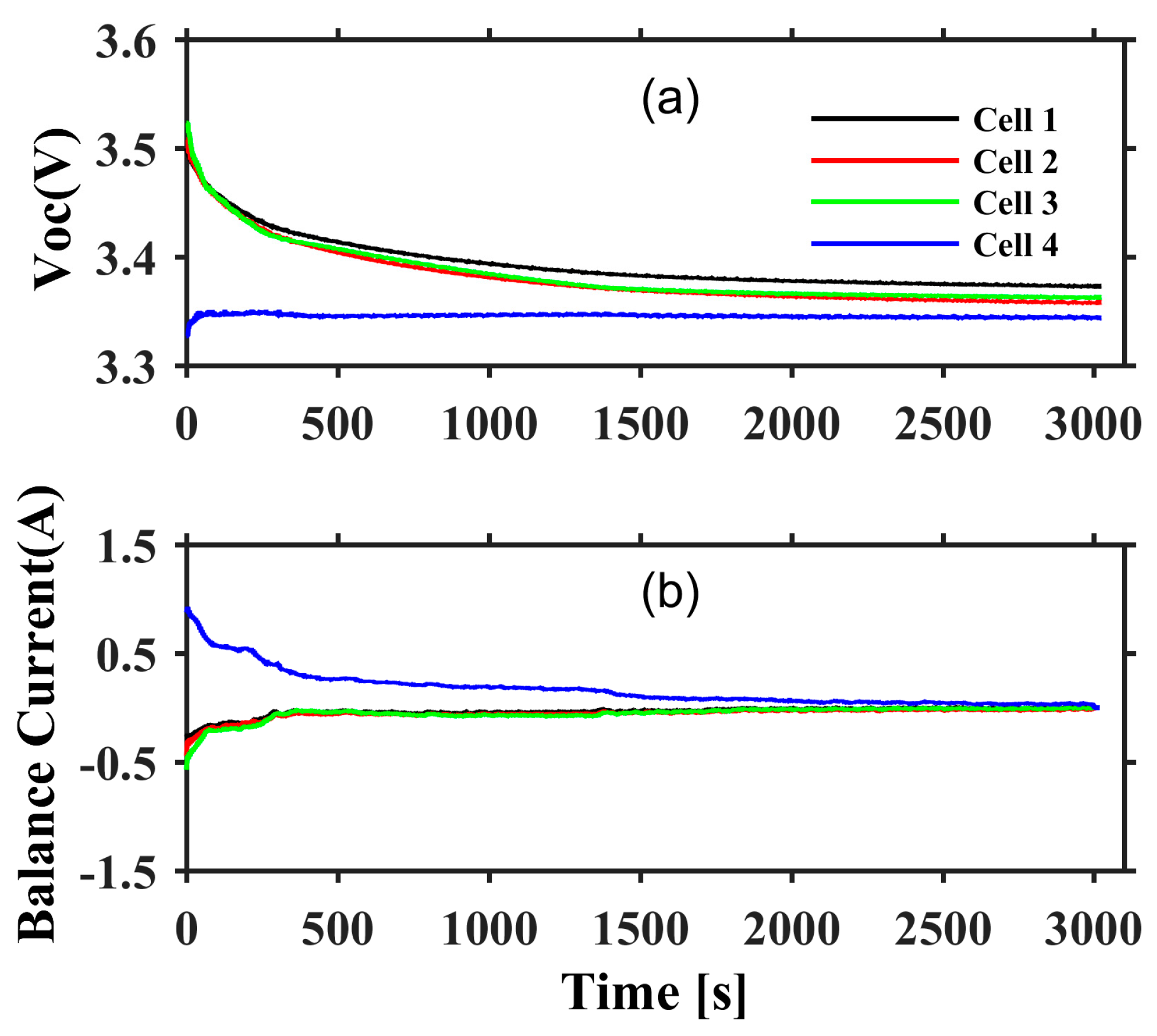

4.1. Experimental Results for LiFePO4 Battery Pack

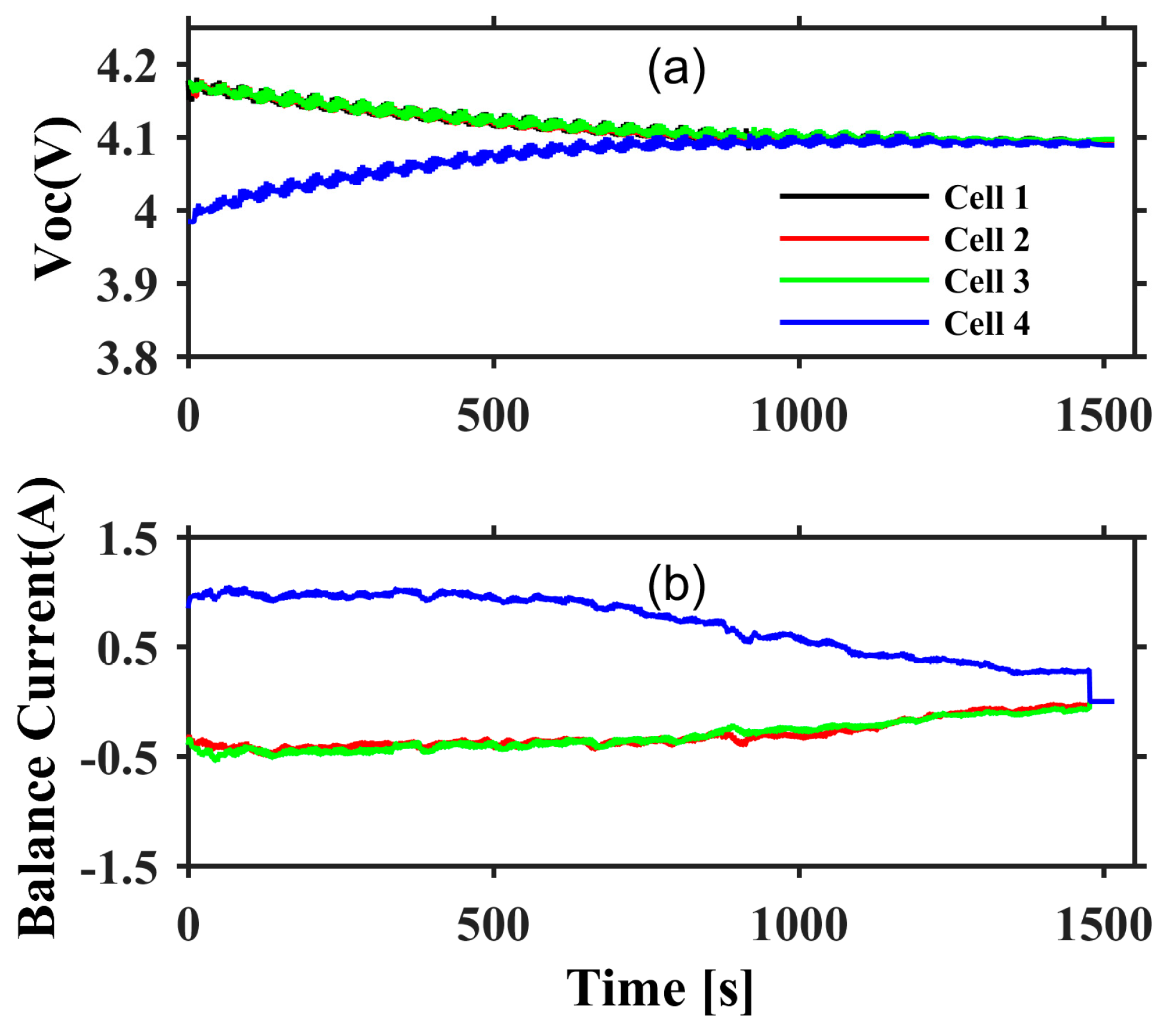

4.2. Experimental Results for NCA Battery Pack

5. Discussions

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Mulder, G.; Omar, N.; Pauwels, S.; Meeus, M.; Leemans, F.; Verbrugge, B.; De Nijs, W.; Van den Bossche, P.; Six, D.; Van Mierlo, J. Comparison of commercial battery cells in relation to material properties. Electrochim. Acta 2013, 87, 473–488. [Google Scholar] [CrossRef]

- Nitta, N.; Wu, F.; Lee, J.T.; Yushin, G. Li-ion battery materials: Present and future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Cao, J.; Schofield, N.; Emadi, A. Battery balancing methods: A comprehensive review. In Proceedings of the 2008 VPPC IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–6. [Google Scholar]

- Uno, M.; Tanaka, K. Double-Switch Single-Transformer Cell Voltage Equalizer Using a Half-Bridge Inverter and a Voltage Multiplier for Series-Connected Supercapacitors. IEEE Trans. Veh. Technol. 2012, 61, 3920–3930. [Google Scholar] [CrossRef]

- Uno, M.; Kukita, A. Double-Switch Equalizer Using Parallel- or Series-Parallel-Resonant Inverter and Voltage Multiplier for Series-Connected Supercapacitors. IEEE Trans. Power Electron. 2014, 29, 812–828. [Google Scholar] [CrossRef]

- Baughman, A.C.; Ferdowsi, M. Double-Tiered Switched-Capacitor Battery Charge Equalization Technique. IEEE Trans. Ind. Electron. 2008, 55, 2277–2285. [Google Scholar] [CrossRef]

- Lu, R.; Zhu, C.; Tian, L.; Wang, Q. Super-Capacitor Stacks Management System With Dynamic Equalization Techniques. IEEE Trans. Magn. 2007, 43, 254–258. [Google Scholar] [CrossRef]

- Kim, M.-Y.; Kim, C.-H.; Kim, J.-H.; Moon, G.-W. A Chain Structure of Switched Capacitor for Improved Cell Balancing Speed of Lithium-Ion Batteries. IEEE Trans. Ind. Electron. 2014, 61, 3989–3999. [Google Scholar] [CrossRef]

- Park, S.-H.; Park, K.-B.; Kim, H.-S.; Moon, G.-W.; Youn, M.-J. Single-Magnetic Cell-to-Cell Charge Equalization Converter With Reduced Number of Transformer Windings. IEEE Trans. Power Electron. 2012, 27, 2900–2911. [Google Scholar] [CrossRef]

- Li, S.; Mi, C.C.; Zhang, M. A high efficiency low cost direct battery balancing circuit using a multi-winding transformer with reduced switch count. In Proceedings of the 2012 Twenty-Seventh Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA, 5–9 February 2012; pp. 2128–2133. [Google Scholar]

- Li, S.; Mi, C.C.; Zhang, M. A High-Efficiency Active Battery-Balancing Circuit Using Multiwinding Transformer. IEEE Trans. Ind. Appl. 2013, 49, 198–207. [Google Scholar] [CrossRef]

- Lim, C.-S.; Lee, K.-J.; Ku, N.-J.; Hyun, D.-S.; Kim, R.-Y. A Modularized Equalization Method Based on Magnetizing Energy for a Series-Connected Lithium-Ion Battery String. IEEE Trans. Power Electron. 2014, 29, 1791–1799. [Google Scholar] [CrossRef]

- Shin, J.-W.; Seo, G.-S.; Chun, C.-Y.; Cho, B.-H. Selective flyback balancing circuit with improved balancing speed for series connected lithium-ion batteries. In Proceedings of the 2010 International Power Electronics Conference (IPEC), Sapporp, Japan, 21–24 June 2010; pp. 1180–1184. [Google Scholar]

- Imtiaz, A.M.; Khan, F.H. Time Shared Flyback Converter; Based Regenerative Cell Balancing Technique for Series Connected Li-Ion Battery Strings. IEEE Trans. Power Electron. 2013, 28, 5960–5975. [Google Scholar] [CrossRef]

- Einhorn, M.; Roessler, W.; Fleig, J. Improved Performance of Serially Connected Li-Ion Batteries With Active Cell Balancing in Electric Vehicles. IEEE Trans. Veh. Technol. 2011, 60, 2448–2457. [Google Scholar] [CrossRef]

- Park, H.-S.; Kim, C.-E.; Moon, G.-W.; Lee, J.-H. A Modularized Charge Equalizer for an HEV Lithium-Ion Battery String. IEEE Trans. Ind. Electron. 2009, 56, 1464–1476. [Google Scholar] [CrossRef]

- Park, H.-S.; Kim, C.-H.; Park, K.-B.; Moon, G.-W.; Lee, J.-H. Design of a Charge Equalizer Based on Battery Modularization. IEEE Trans. Veh. Technol. 2009, 58, 3216–3223. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Cheng, M.-W. Intelligent control battery equalization for series connected lithium-ion battery strings. IEEE Trans. Ind. Electron. 2005, 52, 1297–1307. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Cheng, G.-T. Quasi-Resonant Zero-Current-Switching Bidirectional Converter for Battery Equalization Applications. IEEE Trans. Power Electron. 2006, 21, 1213–1224. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Duh, J.-Y. Fuzzy-controlled individual-cell equaliser using discontinuous inductor current-mode Cu & circk convertor for lithium-ion chemistries. IEE Proc. Electr. Power Appl. 2005, 152, 1271–1282. [Google Scholar] [CrossRef]

- Lee, W.C.; Drury, D.; Mellor, P. An integrated design of active balancing and redundancy at module level for Electric Vehicle batteries. In Proceedings of the 2012 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 18–20 June 2012; pp. 1–6. [Google Scholar]

- Ling, R.; Dong, Y.; Yan, H.; Wu, M.; Chai, Y. Fuzzy-PI control battery equalization for series connected lithium-ion battery strings. In Proceedings of the 2012 7th International Power Electronics and Motion Control Conference (IPEMC), Harbin, China, 2–5 June 2012; pp. 2631–2635. [Google Scholar]

- Nguyen, N.; Oruganti, S.K.; Na, K.; Franklin, B. An Adaptive Backward Control Battery Equalization System for Serially Connected Lithium-ion Battery Packs. IEEE Trans. Veh. Technol. 2014, 63, 3651–3660. [Google Scholar] [CrossRef]

- Cassani, P.A.; Williamson, S.S. Feasibility Analysis of a Novel Cell Equalizer Topology for Plug-In Hybrid Electric Vehicle Energy-Storage Systems. IEEE Trans. Veh. Technol. 2009, 58, 3938–3946. [Google Scholar] [CrossRef]

- Cassani, P.A.; Williamson, S.S. Design, Testing, and Validation of a Simplified Control Scheme for a Novel Plug-In Hybrid Electric Vehicle Battery Cell Equalizer. IEEE Trans. Ind. Electron. 2010, 57, 3956–3962. [Google Scholar] [CrossRef]

- Park, S.-H.; Kim, T.-S.; Park, J.-S.; Moon, G.-W.; Yoon, M.-J. A new buck-boost type battery equalizer. In Proceedings of the APEC 2009 Twenty-Fourth Annual IEEE Applied Power Electronics Conference and Exposition, Washington, DC, USA, 15–19 February 2009; pp. 1246–1250. [Google Scholar]

- Kim, M.-Y.; Kim, J.-H.; Moon, G.-W. Center-Cell Concentration Structure of a Cell-to-Cell Balancing Circuit With a Reduced Number of Switches. IEEE Trans. Power Electron. 2014, 29, 5285–5297. [Google Scholar] [CrossRef]

- Phung, T.H.; Crebier, J.-C.; Chureau, A.; Collet, A.; Nguyen, V. Optimized structure for next-to-next balancing of series-connected lithium-ion cells. In Proceedings of the 2011 Twenty-Sixth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Fort Worth, TX, USA, 6–11 March 2011; pp. 1374–1381. [Google Scholar]

- Nishijima, K.; Sakamoto, H.; Harada, K. A PWM controlled simple and high performance battery balancing system. In Proceedings of the 2000 IEEE 31st Annual Power Electronics Specialists Conference, Galway, Ireland, 23 June 2000; pp. 517–520. [Google Scholar]

- Mestrallet, F.; Kerachev, L.; Crebier, J.C.; Collet, A. Multiphase Interleaved Converter for Lithium Battery Active Balancing. IEEE Trans. Power Electron. 2014, 29, 2874–2881. [Google Scholar] [CrossRef]

- Moo, C.S.; Yao Ching, H.; Tsai, I.S. Charge equalization for series-connected batteries. IEEE Trans. Aerosp. Electron. Syst. 2003, 39, 704–710. [Google Scholar] [CrossRef]

- Javier, G.-L.; Enrique, R.-C.; Isabel, M.-M.; Miguel, A.G.-M. Battery equalization active methods. J. Power Sources 2014, 246, 934–949. [Google Scholar] [CrossRef]

- Cadar, D.; Petreus, D.; Patarau, T.; Etz, R. Fuzzy controlled energy converter equalizer for lithium ion battery packs. In Proceedings of the 2011 International Conference on Power Engineering, Energy and Electrical Drives (POWERENG), Malaga, Spain, 11–13 May 2011; pp. 1–6. [Google Scholar]

- Wu, K.C. Switch-Mode Power Converters: Design and Analysis; Academic Press: Cambridge, MA, USA, 2005. [Google Scholar]

- Chen, X.; Shen, W.; Cao, Z.; Kapoor, A. Adaptive gain sliding mode observer for state of charge estimation based on combined battery equivalent circuit model. Comput. Chem. Eng. 2014, 64, 114–123. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Luo, M.; Zhang, K. Robustness of full implication algorithms based on interval-valued fuzzy inference. Int. J. Approx. Reason. 2015, 62, 61–72. [Google Scholar] [CrossRef]

- Michels, K.; Klawonn, F.; Kruse, R.; Nürnberger, A. Fuzzy Control: Fundamentals, Stability and Design of Fuzzy Controllers; Springer: Berlin, Germany, 2007; Volume 200. [Google Scholar]

- Ross, T.J. Fuzzy Logic with Engineering Applications; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Zhou, Q.; Wu, W.; Liu, D.; Li, K.; Qiao, Q. Estimation of corrosion failure likelihood of oil and gas pipeline based on fuzzy logic approach. Eng. Fail. Anal. 2016, 70, 48–55. [Google Scholar] [CrossRef]

| Balancing Current | ||||||

|---|---|---|---|---|---|---|

| NV | N | Z | P | PV | ||

| VS | NV | NV | Z | Z | P | |

| S | NV | N | Z | P | PV | |

| M | NV | N | Z | P | PV | |

| L | NV | N | Z | P | PV | |

| VL | N | Z | Z | PV | PV | |

| Battery Type | LiFePO4 | NCA |

|---|---|---|

| Manufacture company | A123 | Samsung |

| Nominal capacity | 2.3 Ah | 2.5 Ah |

| Tested capacity | 2.13 Ah | 2.5 Ah |

| Internal resistance | 13 m | 22 m |

| Title | PI Controller | FL Controller | ||

|---|---|---|---|---|

| Charge (Ah) | Energy (Wh) | Charge (Ah) | Energy (Wh) | |

| Cell one | −0.0549 | −0.1933 | −0.0680 | −0.2386 |

| Cell two | −0.0680 | −0.2387 | −0.0717 | −0.2510 |

| Cell three | −0.0656 | −0.2303 | −0.0697 | −0.2444 |

| Cell four | +0.1299 | +0.3675 | +0.1758 | +0.5327 |

| Recovered capacity (energy) of cell four | 6% (5.1%) | 8.25% (7.4%) | ||

| Title | PI Controller | FL Controller | ||

|---|---|---|---|---|

| Charge (Ah) | Energy (Wh) | Charge (Ah) | Energy (Wh) | |

| Cell one | −0.0801 | −0.3363 | −0.1370 | −0.5750 |

| Cell two | −0.1075 | −0.4516 | −0.1352 | −0.5675 |

| Cell three | −0.1067 | −0.4478 | −0.1325 | −0.5562 |

| Cell four | +0.2382 | +0.8915 | +0.2989 | +1.1466 |

| Recovered capacity (energy) of cell four | 11.2% (10%) | 14% (12.74%) | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, X.; Shen, W.; Zhang, Y.; Hu, C. A Fast Multi-Switched Inductor Balancing System Based on a Fuzzy Logic Controller for Lithium-Ion Battery Packs in Electric Vehicles. Energies 2017, 10, 1034. https://doi.org/10.3390/en10071034

Cui X, Shen W, Zhang Y, Hu C. A Fast Multi-Switched Inductor Balancing System Based on a Fuzzy Logic Controller for Lithium-Ion Battery Packs in Electric Vehicles. Energies. 2017; 10(7):1034. https://doi.org/10.3390/en10071034

Chicago/Turabian StyleCui, Xiudong, Weixiang Shen, Yunlei Zhang, and Cungang Hu. 2017. "A Fast Multi-Switched Inductor Balancing System Based on a Fuzzy Logic Controller for Lithium-Ion Battery Packs in Electric Vehicles" Energies 10, no. 7: 1034. https://doi.org/10.3390/en10071034

APA StyleCui, X., Shen, W., Zhang, Y., & Hu, C. (2017). A Fast Multi-Switched Inductor Balancing System Based on a Fuzzy Logic Controller for Lithium-Ion Battery Packs in Electric Vehicles. Energies, 10(7), 1034. https://doi.org/10.3390/en10071034