1. Introduction

Combined heat and power (CHP) units are regarded as one of the most promising low carbon technologies in solving energy-related problems, because they have many advantages when compared with other energy generation technologies [

1]. First, compared to conventional energy generation systems, CHP systems have much higher overall output efficiencies and because of that CHP units are installed to reduce carbon emission [

2]. Secondly, in the case of renewable energy generation systems, climate change has less influence on CHP system control [

3]. Moreover, the installation cost of a CHP unit is gradually decreasing. In [

4], it is predicted that by the end of 2015 the capital cost of a CHP system will be around €374/kW. Similar to the prediction results shown in [

4], the micro-CHP installation cost in 2016 is £300/kW [

5]. Therefore, more micro-CHP units, whose output power is “kW level”, are being installed in domestic buildings.

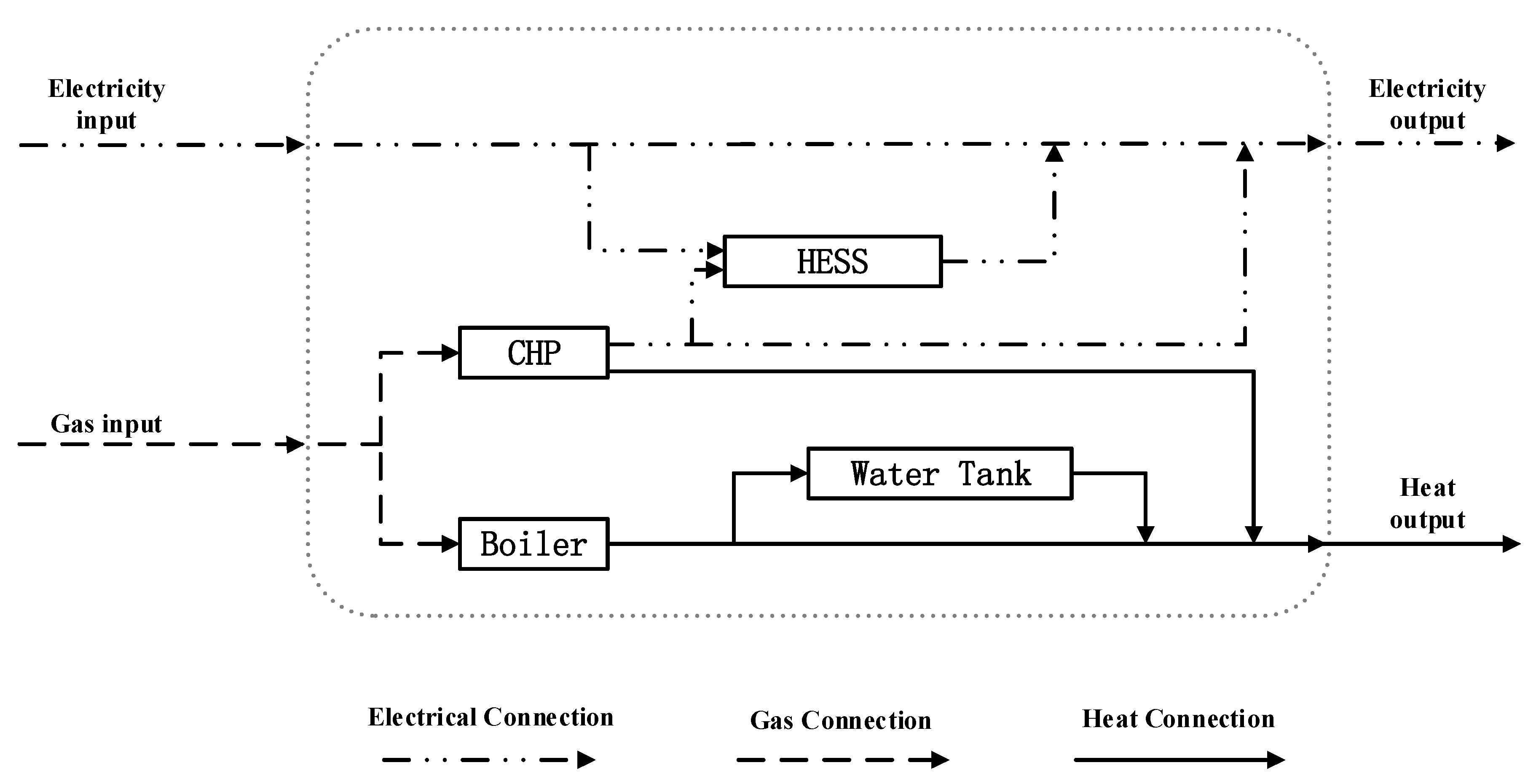

Batteries are still one of mature technologies to store electricity, and they can be used to improve energy system efficiency and to reduce carbon emissions; however, the installation cost and maintenance cost of a battery storage system are very high. Therefore, it is worth considering whether it is economical to install a battery storage system in a domestic building whose electricity load is supplied by a CHP unit and the grid and the heat load is supplied by a CHP unit and gas boiler. In this paper, battery storage systems are excluded.

Without an energy storage system, the key factors that can influence the daily energy costs and energy efficiency of aforementioned buildings are the capacity of CHP and the type of CHP [

6]. Previous literature has already shown that the electricity output efficiency of micro-CHP is a quarter of its rated value when the CHP is operated at 10% of its rated power. Meanwhile, the heat output efficiency can also be reduced, if the CHP is working at low input power [

1]. To increase energy efficiency and reduce emission, it is always preferable to have small capacity CHP in buildings. However, small scale CHP cannot meet the load at the peak demand time, even though it works at rated power. This will significantly increase the system’s daily energy costs. To reduce this cost, it is preferable to have large size capacity CHP. Thus, to improve both energy efficiency and system daily benefits, it is important to size CHP in domestic buildings.

To get an appropriate capacity of CHP, selecting sizing criteria is crucial, because optimisation results will differ depending upon the optimisation criteria used. Types of CHP and particular demand are two crucial criteria that are used to size the CHP. This paper considers two common types of CHP: gas engine and fuel cell. The main difference between these two CHP units is in output efficiency. Fuel cell CHP normally has a higher electricity to heat output efficiency ratio compared to gas engine CHP [

7]. In [

8], the rated electricity to heat output efficiency ratios for the fuel cell and gas engine CHP are about 33% and 74% respectively. In this paper, two types of CHP have been used as examples to optimise the size of CHP and the daily energy costs.

In domestic buildings, there are normally two types of demands: heat and electricity. As mentioned before, they can be used as another criteria to size CHP. This is because the heat and electricity consumption patterns in a domestic house are quite different from each other. In [

4,

9], using the heat demand curve to size and control the CHP is preferable, because CHP thermal output efficiency is normally greater than electricity, and in [

4], it is assumed that the redundant electricity can be sold back to the grid. However, there are increasingly higher requirements to sell electricity back to the grid in Europe. For example, the European standard EN50160 states that the 10-min average root mean square voltage deviation should not exceed ±10% of the nominal voltage [

10]. Considering this and the fact that many electricity meters do not have the ability to record electricity sent back to the grid, this paper assumes that there is no financial benefit from export, thus export is avoided.

There are many methods can be used to size a CHP and optimise system daily energy costs, for example the MR method, the GA method, the linear programming (LP) method and the nonlinear programming (NLP) method. Considering the fact that the LP method needs to linearise all constraints which can lead to loss of accuracy in the optimisation results, and the fact that NLP has trouble in distinguishing between the local minima and the global minimum, the MR, in this paper, will be used to optimise the size of a gas engine and fuel cell CHP for a domestic house, based firstly on the daily heat load and secondly on the electricity load curves. This is because the MR can cover an ‘average’ heat and electricity demand instead of covering the maximal heat or electricity demand, and thus can make full use of CHP capacity and improve CHP output efficiencies [

4]. Because the GA is a powerful tool to deal with multivariable non-linear problems, the GA will be used to calculate the optimal daily operational cost. In the following work, two methods are used to find the best capacity of CHP and the theoretical minimum daily energy cost. The first one is the combination of the MR and the GA methods, which firstly optimises the CHP capacity by the MR method and then optimises the daily energy cost for the CHP capacity obtained by the MR method through the GA method. Another one only uses the GA method to find the optimal daily energy costs for different CHP capacity. By finding the theoretical minimum daily energy cost from the optimal daily energy costs, the best capacity of CHP can be acquired.

To reduce variables in the optimisation algorithms, [

11] assumes that the CHP output efficiencies are constants for different operational conditions. However, this assumption gives a higher energy efficiency and a lower daily energy cost in optimisation results. In order to eliminate the impacts of this assumption, this paper uses the experimental results in [

1] to formulate the CHP output efficiencies as functions that are only related to CHP input power. This will improve the accuracy of optimisation results and the output efficiencies of CHP.

The major contributions of this paper are: (1) two different sizing CHP methods (the MR and the GA) are used to find the optimal size of CHP. The computation time is significantly reduced by using the MR method and the optimal costs are lower when using the GA method; (2) The CHP output efficiencies are formulated to functions which are only related to input power and this gives a more accurate optimisation result compared to using constant CHP output efficiencies as optimisation criteria; (3) Different types of CHP and loads are considered as sizing criteria, and the optimisation results will give suggestions for engineers on how to choose and size CHP.

3. CHP Sizing and System Optimisation

In the following parts,

Section 3.1 demonstrates how to size CHP by the MR method according to different sizing criteria. After obtaining the best CHP capacities for different sizing criteria,

Section 3.2 shows how to use the GA method to optimise the daily energy cost. Similar to

Section 3.2,

Section 3.3 uses the same methodology (GA) to optimise the daily energy cost for different types of CHP and find the theoretical best CHP capacities for different CHP. In

Section 3.4, effective CHP energy efficiency and average CHP input power to rated power ratio will be defined to test CHP efficacy performance.

3.1. Sizing CHP by the MR Method

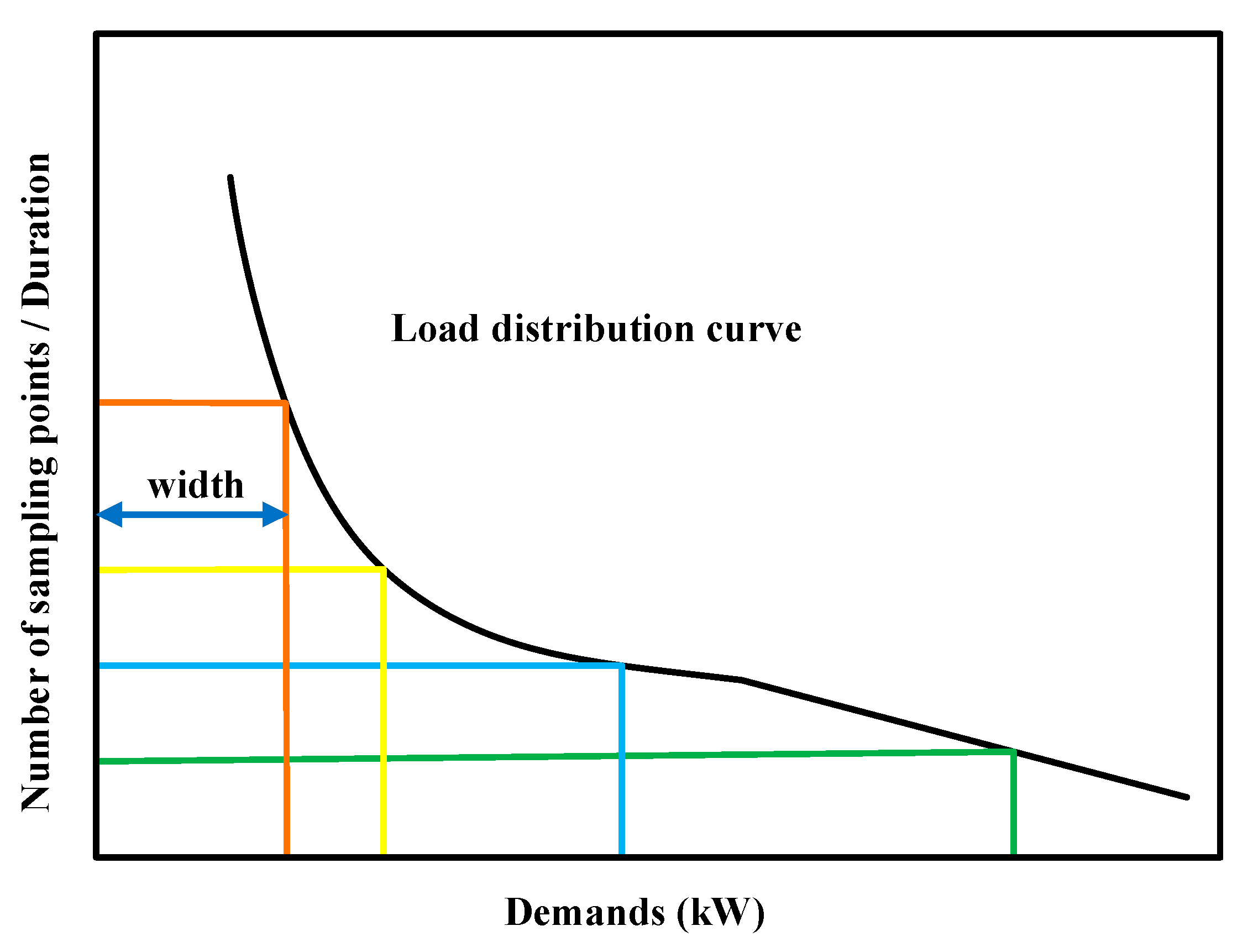

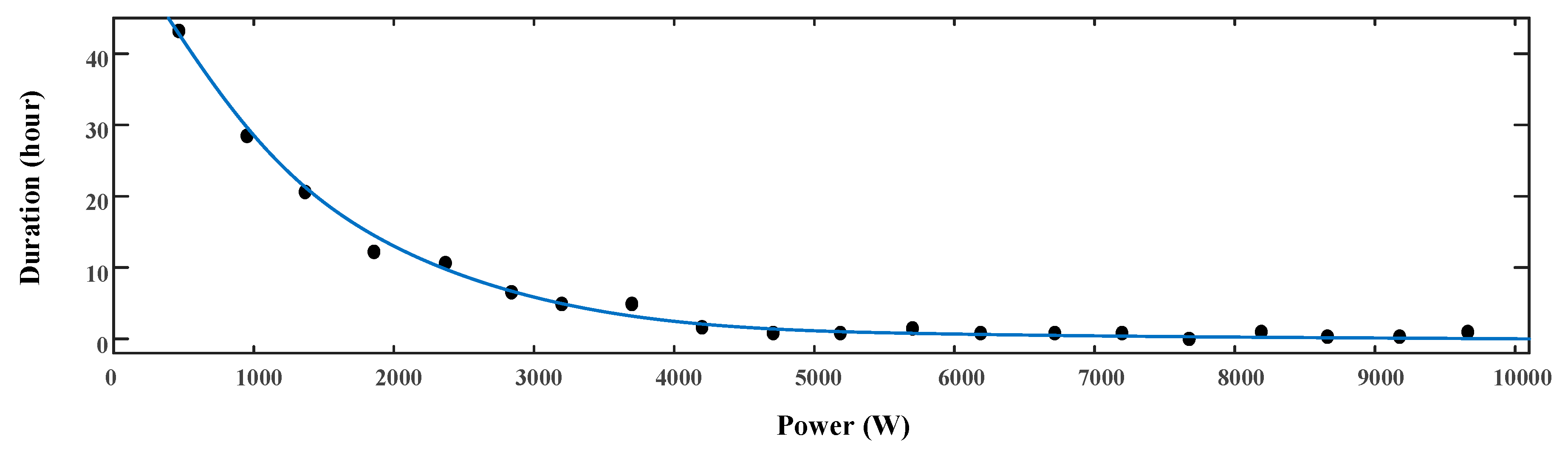

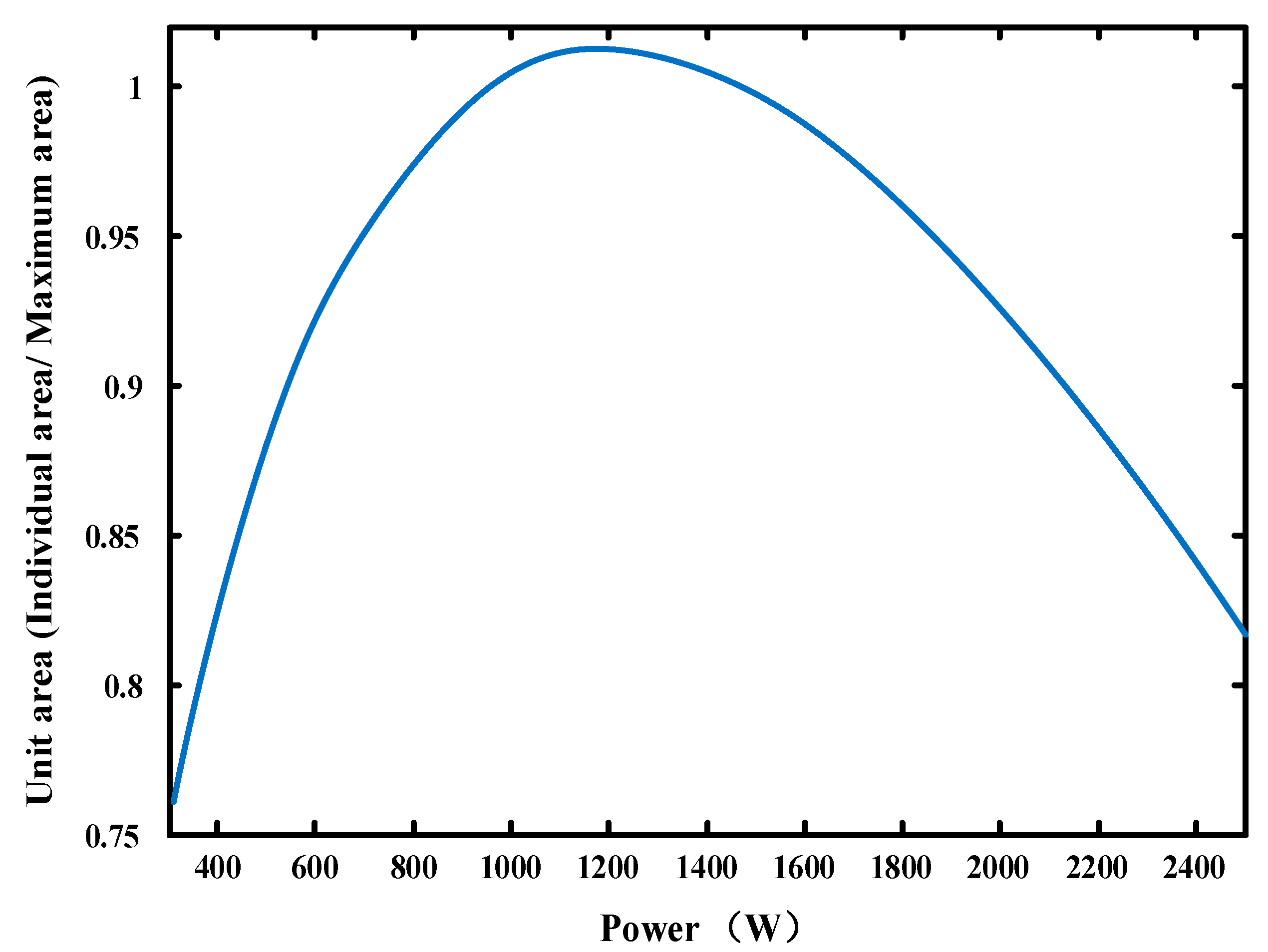

To use the MR method to size CHP based on electricity loads, five steps need to be taken. Firstly, recording every minute’s electricity demand in a year as sampling points is necessary. Secondly, the minimum and the maximum electricity demands in a year need to be found, and then equally divided into 10–20 intervals between maximum and minimum electricity demands. Too many intervals (more than 20) will cause the load distribution curve to fluctuate, and this will cause problems to formulate load distribution curves. On the other hand, few intervals (less than 10) will reduce the accuracy of curve fitting result. Therefore, 10–20 intervals between maximum and minimum electricity demands are needed. Thirdly, all sampling points need to be placed into related intervals and the number of sampling points in each interval must be calculated. The fourth step is to plot the load distribution curve as shown in

Figure 1. Finally, based on the load distribution curve, sufficient rectangles need to be drawn as shown in

Figure 1, and a rectangle which has the maximum area can be found. The demand (width) of this rectangle should be the capacity of CHP rated electricity output. At this step, the more rectangles that are plotted, the more accurate a result will be acquired.

3.2. Daily Energy Costs Optimisation by the GA Method

The daily energy cost objective function of a domestic building can be written as:

In Equation (1),

F(

t) is the daily energy cost in pence,

Ce(

t) and

Cg(

t) are the electricity price and gas price in each minute in a day respectively, and optimisation varibles

PEin(

t),

PGin(

t) and

PCHPin(

t) are the imported average electrical energy from the grid, imported gas to supply the boiler and imported gas to supply the CHP in each minute respectively. To meet the electricity demand and heat demand in the building, the equality constraints can be generated as:

In Equations (2) and (3),

PE(

t) and

PH(

t) are the electrical energy demand and heat demand of the domestic building respectively in each minute.

ηCHPE and

ηCHPH are the CHP output electricity and heat efficiency respectively.

ηB is the boiler’s gas to heat conversion efficiency. In addition, system limitations give extra inequality constraints which can be listed as follows:

Equations (4) and (5) describe the CHP electricity and heat output efficiency limitation. Equation (6) shows that a CHP unit can either be switched off or work at its feasible operational conditions. In Equation (6),

PR is rated/optimal power/capacity of CHP and

ζ is a scaling factor. In [

1], CHP input power can vary from 10% to 100% to its rated power. In this work,

ζ is set as 10% and the optimal capacities acquired by the MR method will be used to find the daily optimal energy cost for each scenario. Equations (7) and (8) demonstrate that the electricity and heat can only be imported, not exported. In other words, they describe the direction of power flow.

As mentioned in the Introduction to this paper, both CHP heat and electricity output efficiencies decrease if CHP is working at low input power situations. In this work, CHP output efficiencies are formulated to functions which relate to CHP input power.

Table 1 shows the efficiencies of the CHP for different CHP inputs, obtained from [

1].

Based on

Table 1, the electricity and heat output efficiencies of a general CHP unit can be formulated with the MATLAB curve fitting toolbox as follows:

In (9) and (10),

ξE and

ξH are the CHP electricity and heat output efficiency coefficients, and these values only relate to the type of CHP, or in other words, the design of CHP.

Table 2 summarizes the electricity and heat output efficiency coefficients of the gas engine and the fuel cell CHP used in this paper.

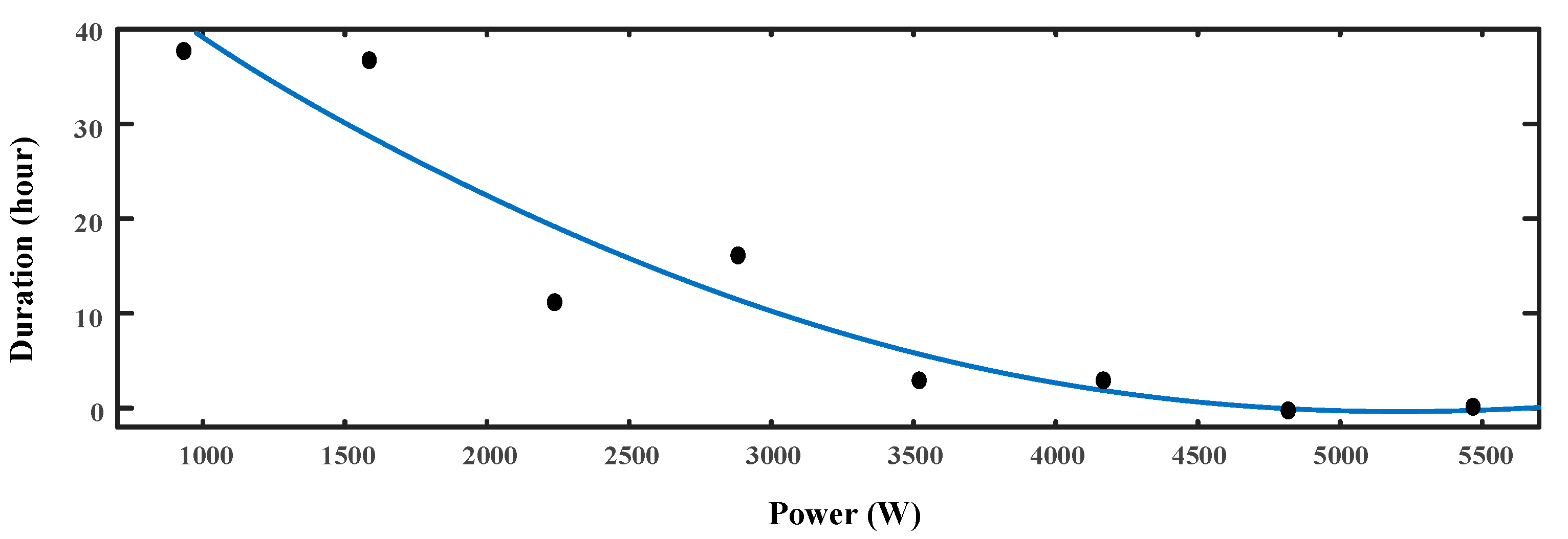

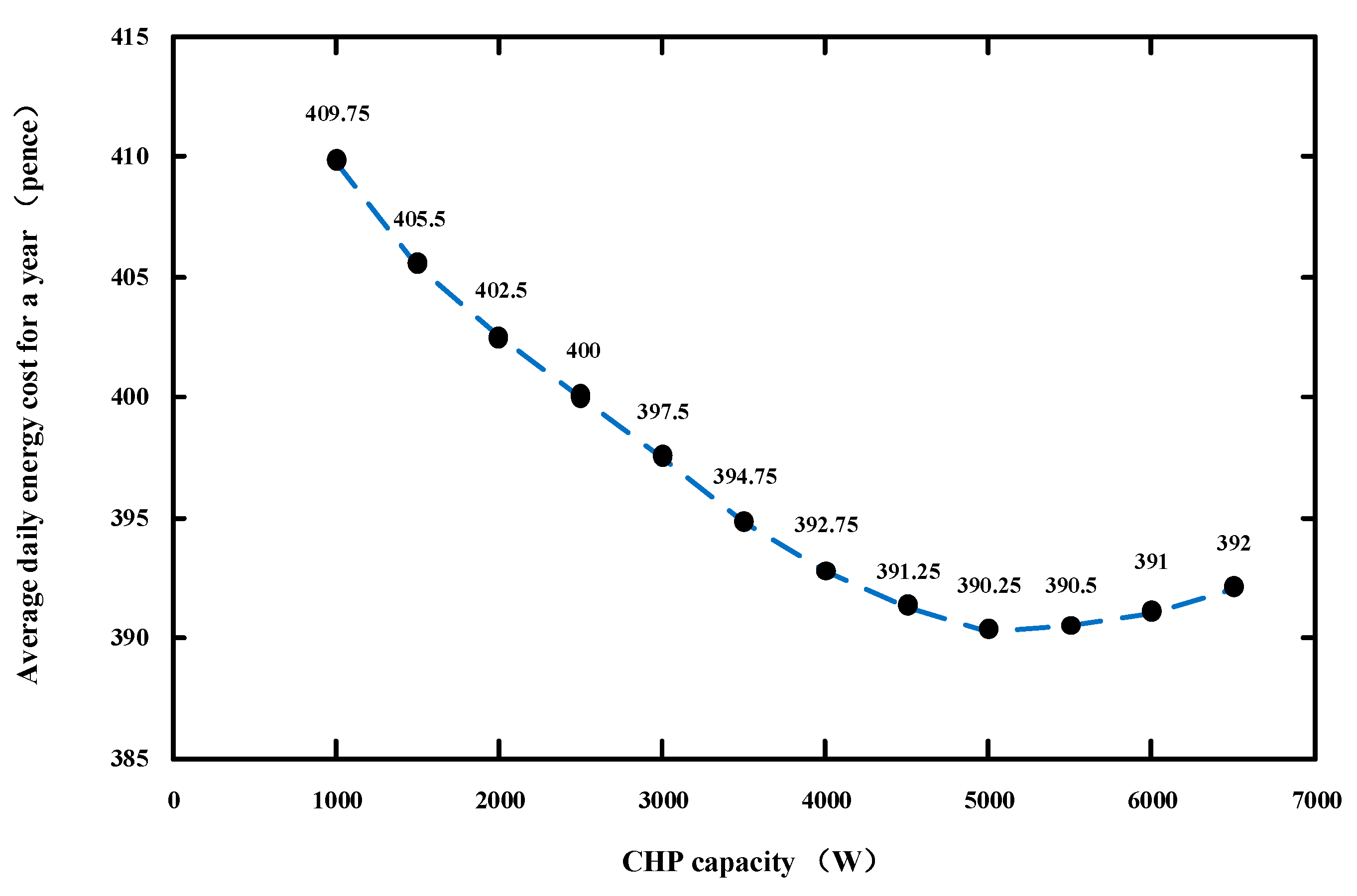

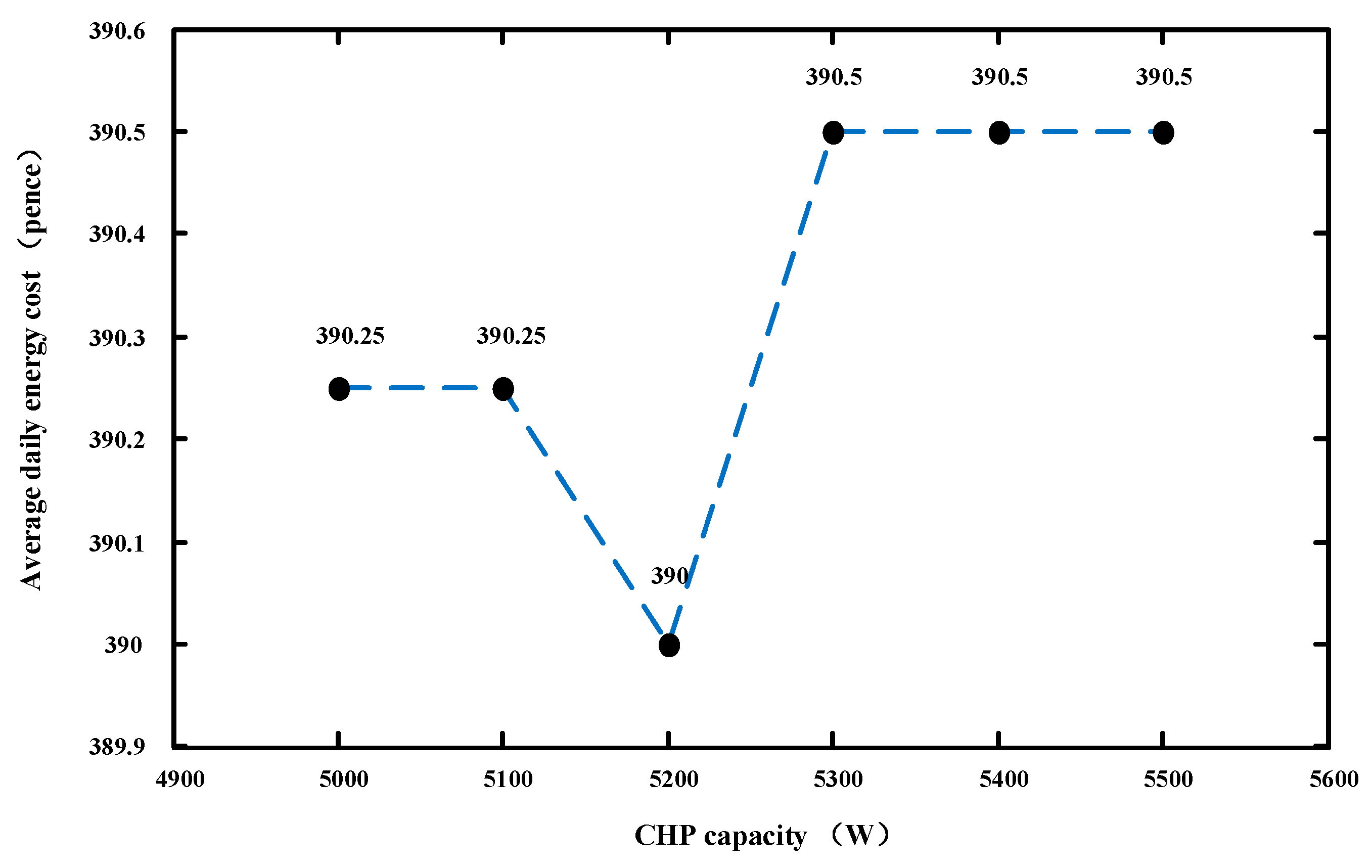

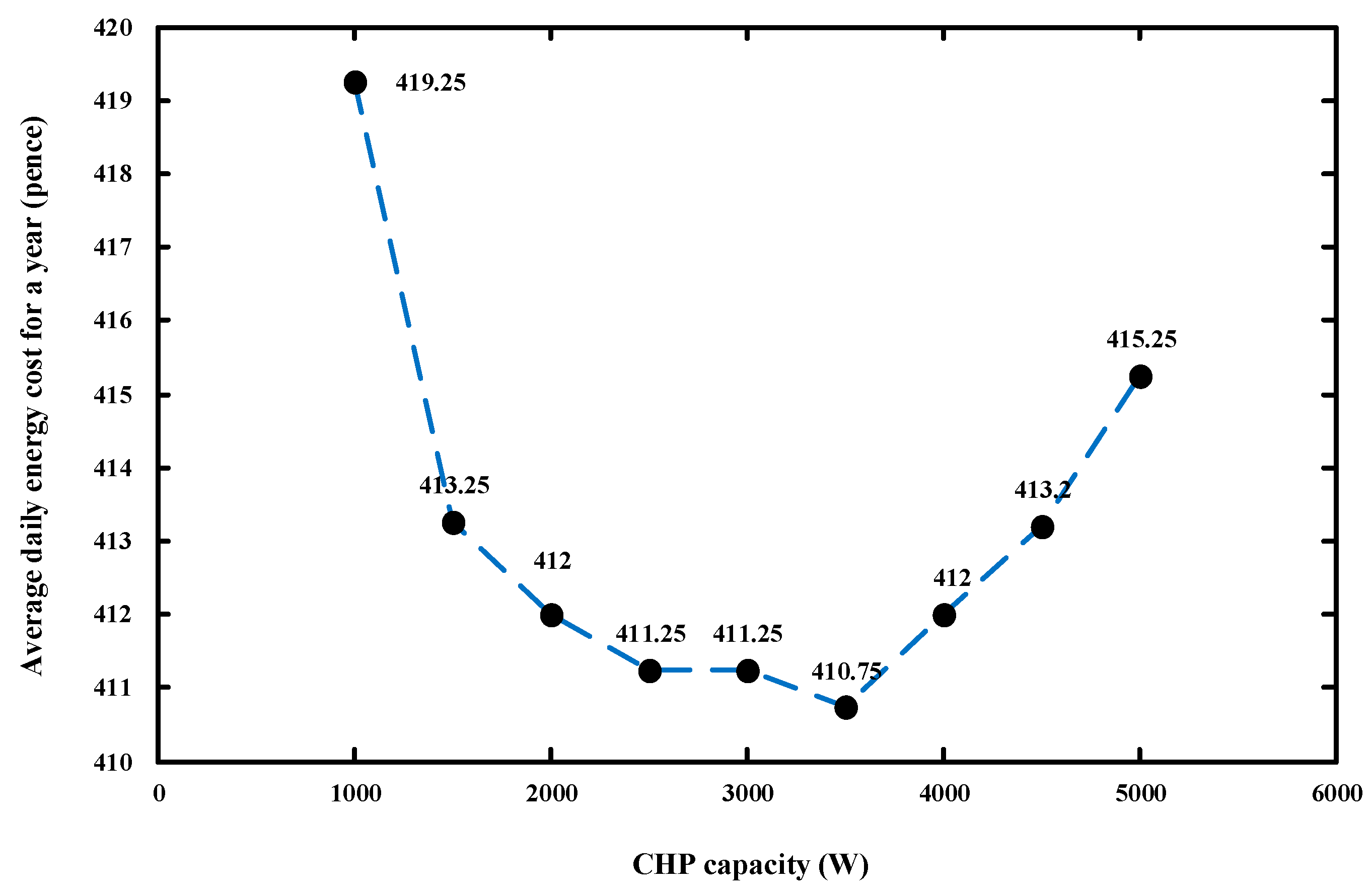

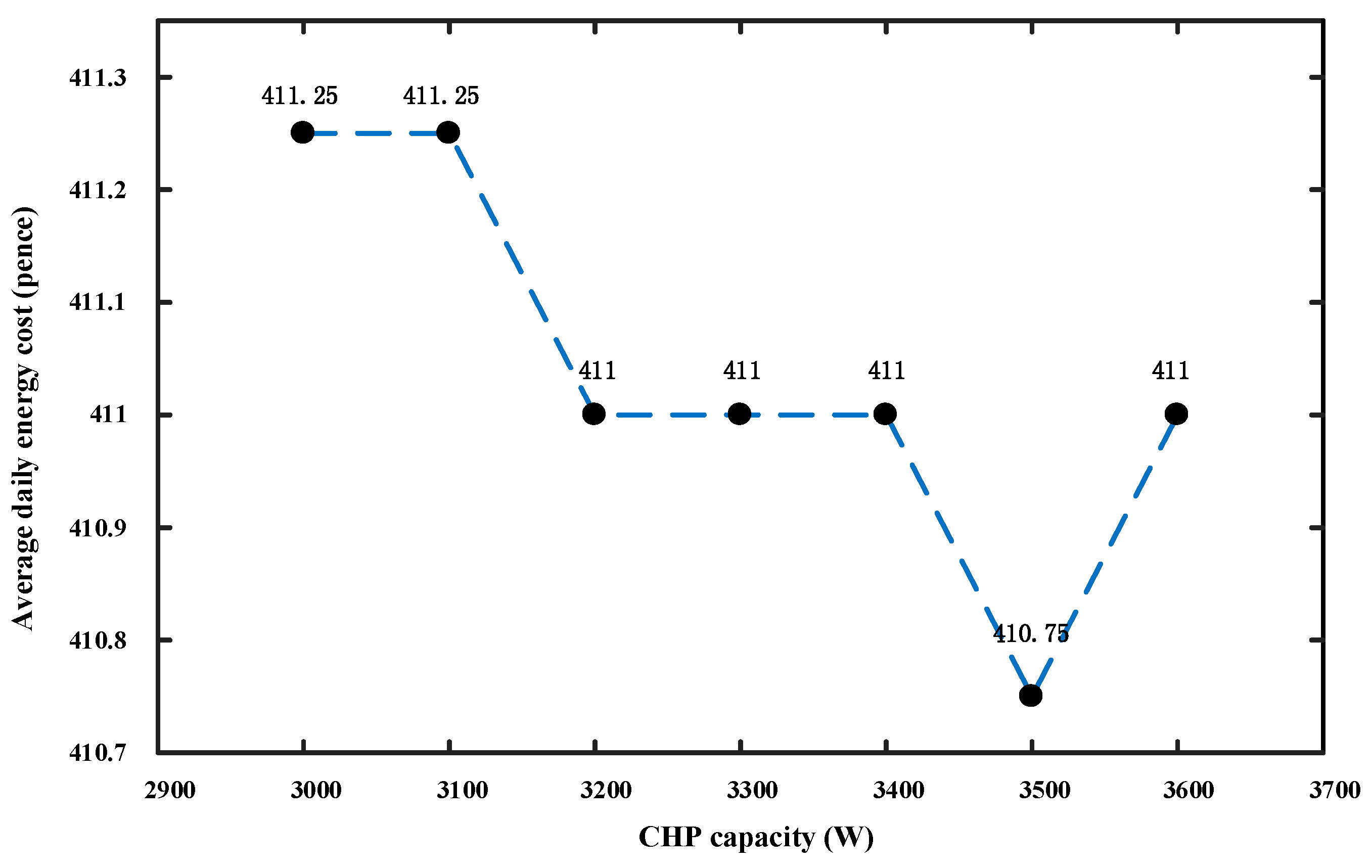

3.3. Theoretical Best Capacity of CHP by the GA Method

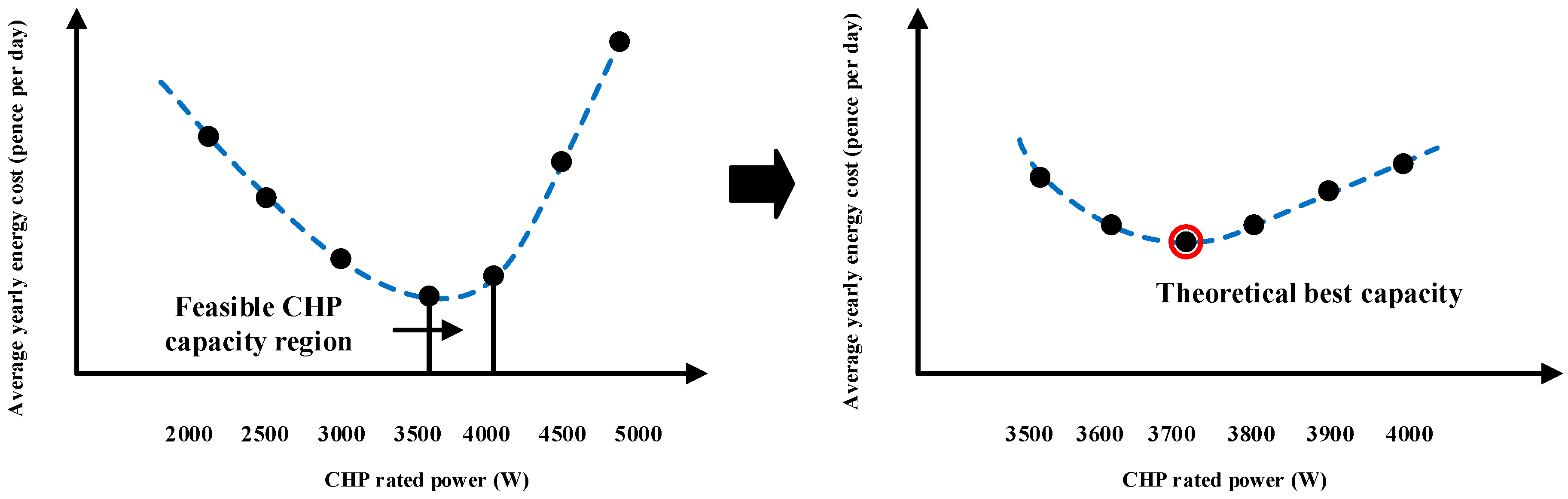

In this section, the GA method is used to optimise the daily energy costs for a system with different CHP installation capacities. Then, by comparing the daily energy costs for different CHP installation capacities, the theoretical best CHP capacity can be determined. However, considering the fact that the GA method normally takes a long computation time to get the optimisation results and that the output of commercial CHP units is normally quantified to 100 W, this work will calculate the best capacity of each type of CHP in discrete hundred Watt increments.

The daily energy cost functions, constraints and equations of this work are similar to

Section 3.2. However, compared to

Section 3.2,

PR will be treated as another new variable. This work will first find the feasible CHP capacity region and then find the best capacity of both type of CHP. The CHP output power will first be assumed to be 1000 W, and there will be 500 W increase every time until the output power of CHP reaches a point after which the daily energy cost will always increase with the increase of CHP capacity. At this stage, the GA method will be used to calculate the average daily energy cost for each CHP capacity. By plotting the rated capacity and average yearly energy costs graph, a feasible CHP capacity region can be acquired. Then the maximum and minimum capacity of this region is divided into five equal intervals, which means that four more samples need to be tested. By using the GA method to optimise daily energy costs of these four points, the theoretical best CHP can be acquired.

Figure 2 shows this method.

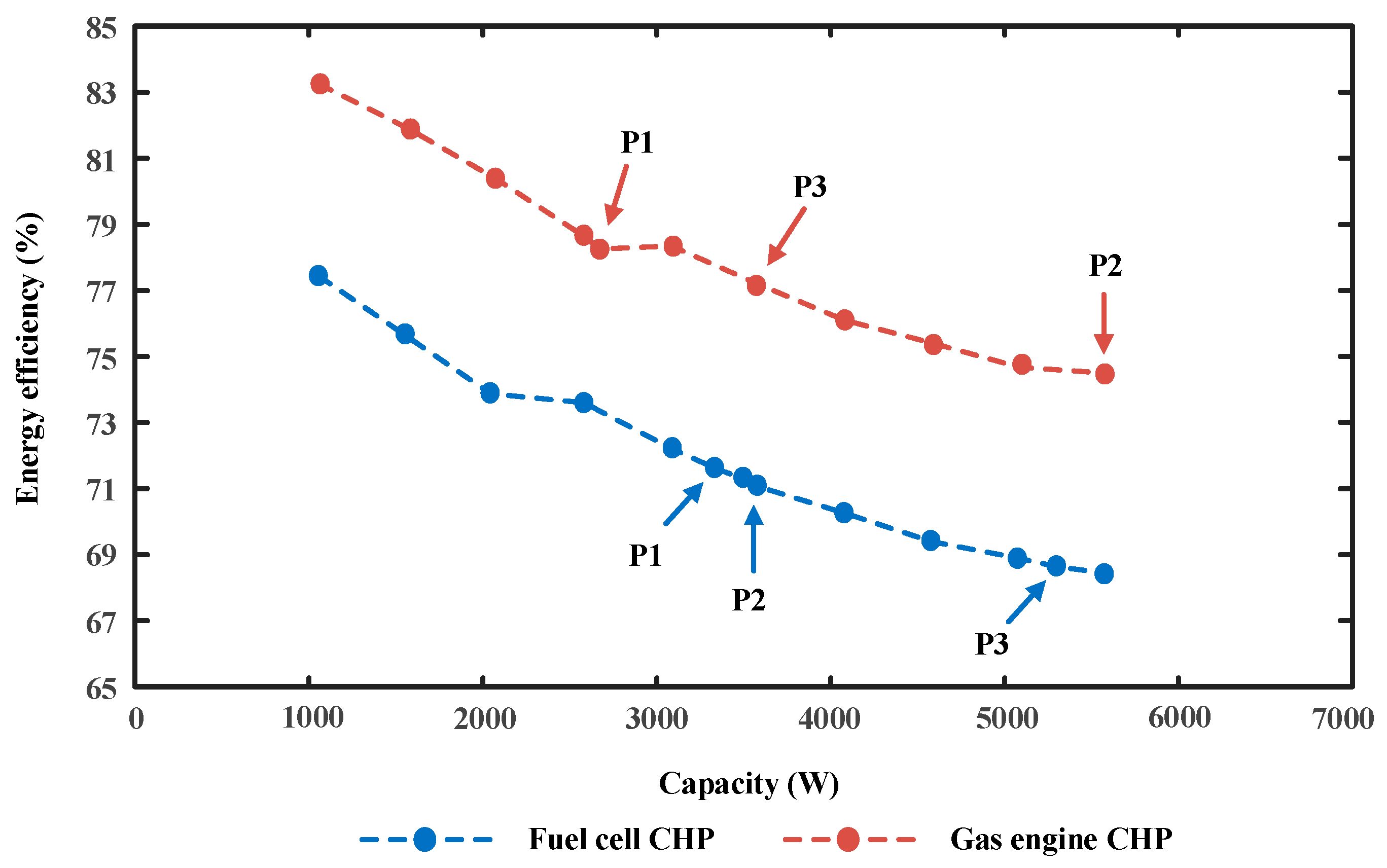

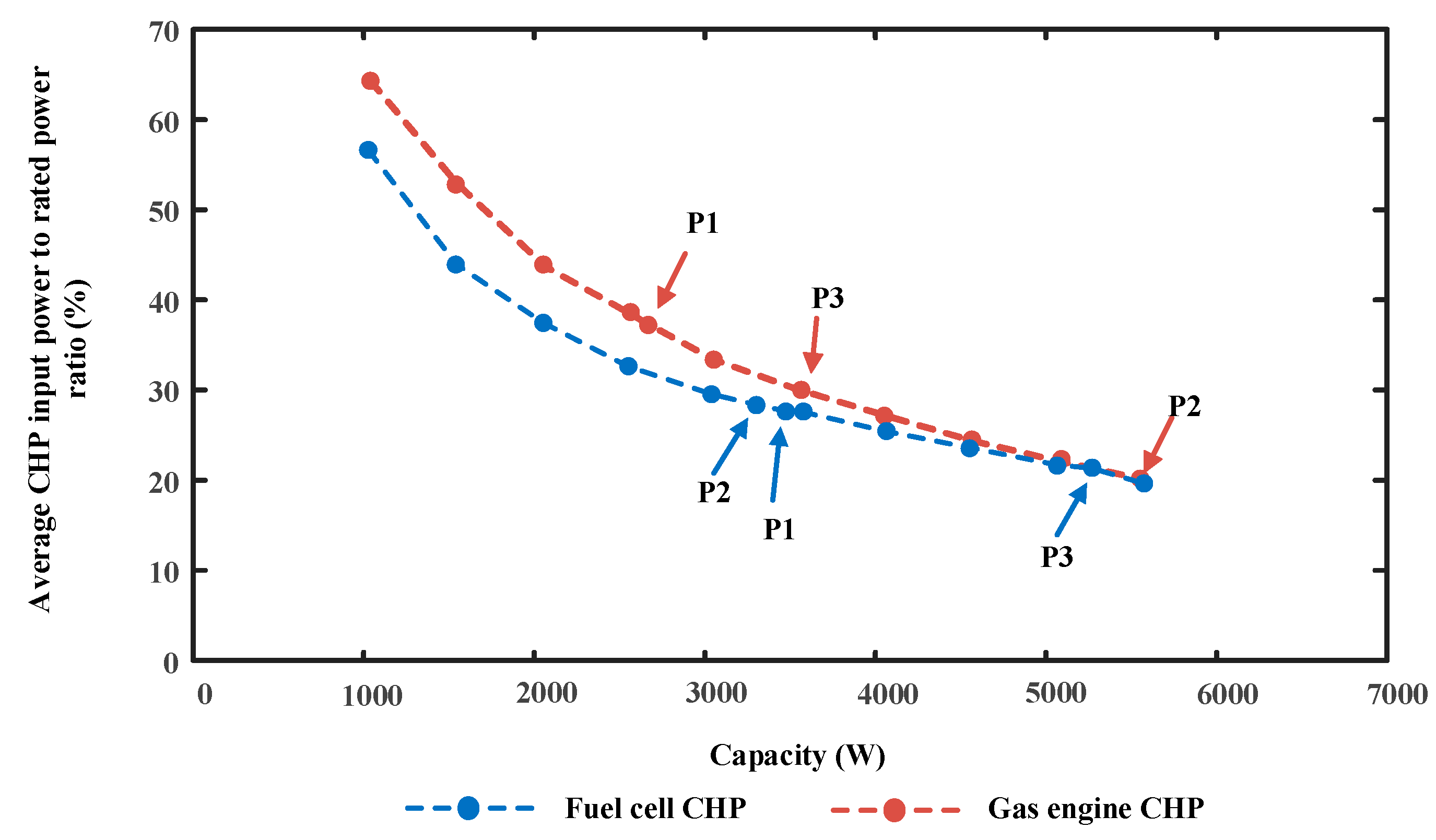

3.4. Effective CHP Energy Efficiency and Average CHP Input Power to Rated Power Ratio

As mentioned in the Introduction, CHP is a high output efficiency energy generator. However, system energy efficiency can be significantly reduced if an inappropriate capacity CHP unit is installed. Here, two parameters are defined to test the performance of CHP sizing results. First, the effective CHP energy efficiency is defined to calculate the average whole year CHP energy efficiency with different CHP capacities. Another parameter, average CHP input power to rated power ratio, is defined to illustrate whether the CHP is fully utilised. Equations (11) and (12) are the functions to show effective CHP energy efficiency and average CHP input power to rated power ratio:

In (11), ῆCHP is effective CHP energy efficiency, ηCHPE(t) and ηCHPH(t) are the CHP electricity and heat output efficiency in tth minute respectively and L’ is the number of samples. In (11), both ηCHPE(t) and ηCHPH(t) should be greater than zero, because to calculate the effective CHP energy efficiency, the CHP switch off state should not be considered. In (12), hCHP is the average CHP input power to rated power ratio.

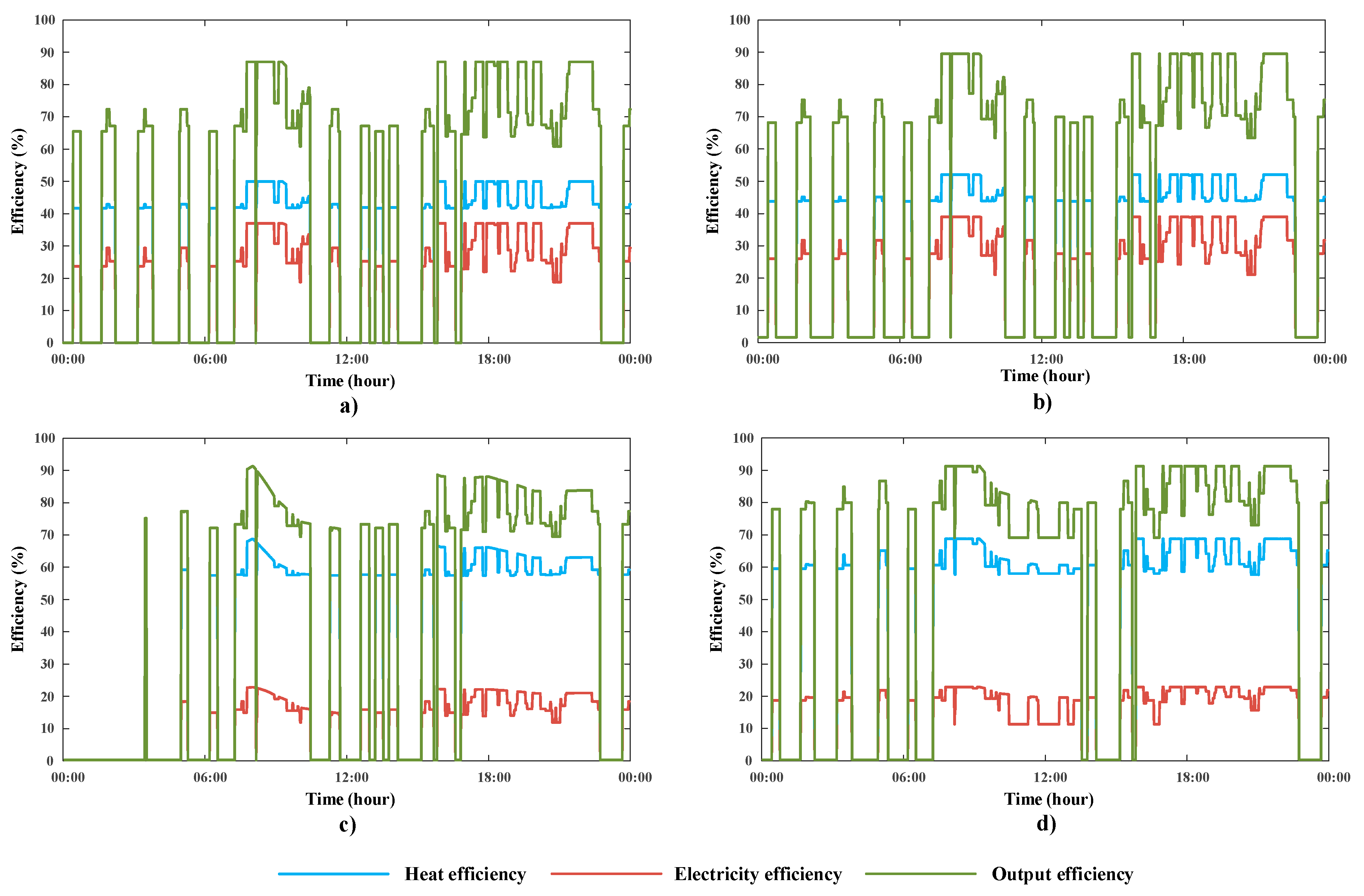

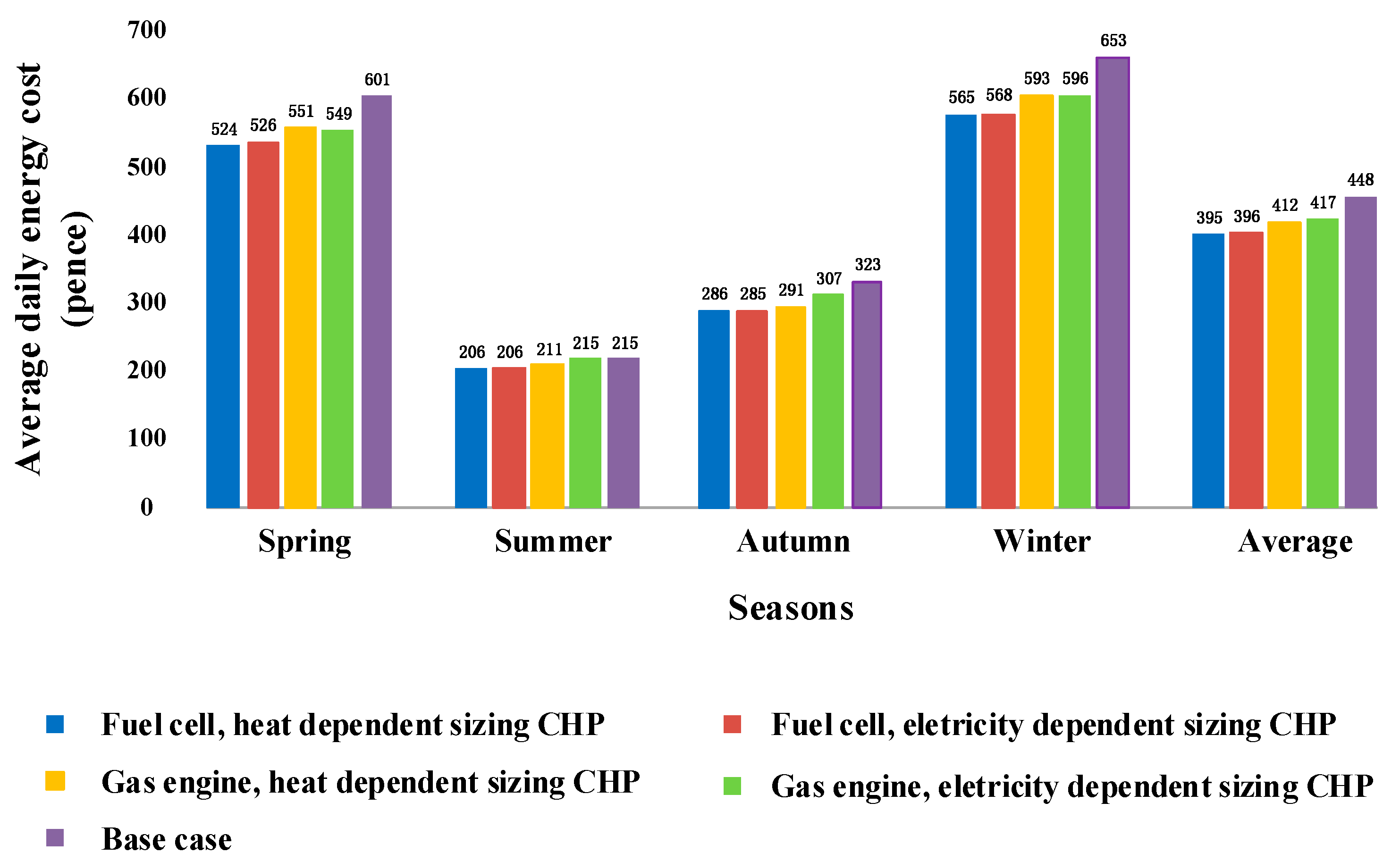

6. Analysis and Discussion

Table 4 is a summary of the work in this chapter. The average daily investment in this table is calculated based on the installation costs of gas engine and fuel cell CHP showing in [

8]. However, the installation costs of gas engine and fuel cell CHP showing in [

8] are higher than the present CHP installation costs. This is because [

8] shows CHP installation costs 7 years ago. With the development of the micro-CHP technology, the installation costs of micro-CHP have already been reduced.

First, this work proves that using heat demand as optimisation criteria can obtain better optimisation results compared with electricity demand. This is because average heat demand in a year is much greater than the electricity demand. Only using the heat demand as sizing criteria to size fuel cell and gas engine CHP for a terraced house which was built approximately 30 years ago is acceptable, because compared with the theoretical best size CHP, the average daily energy savings are over 90% of theoretical maximum savings. However, using electricity as sizing criteria for gas engine CHP can cause problems, because the heat to power ratio of gas engine CHP is very high and this may cause the CHP to generate high levels of redundant heat.

Secondly, when using the MR method to size the CHP, the benefit to cost ratios are higher in most of cases compared to when the GA method is used to size the CHP. This is because the MR method tries to find the CHP capacity that can meet most of the demand in a year and this will make full use of CHP capacity. Consequently, even though the daily energy cost savings cannot achieve its theoretical maximum, the significant reduction of investment cost makes the ratio higher.

Thirdly, the optimisation results show that it is difficult to deal with the conflict between operational cost, system investment and energy efficiency. The optimisation results also show that to get higher daily energy savings, it is preferable to install large capacity CHP, however, this will significantly increase the investment cost and reduce energy efficiency. This is because by increasing the capacity of the CHP, more electrical demand occurring at the peak energy price time can be supplied by the CHP, and this will reduce energy costs. However, by increasing the capacity of the CHP, average CHP input power to rated power ratio is reduced, which means the CHP is always working at low input power and this will lead to energy efficiency reduction. Moreover, the low average CHP input power to rated power ratio indicates that most of CHP capacity has not been fully utilised. This is the reason why CHP investment cost is very high.

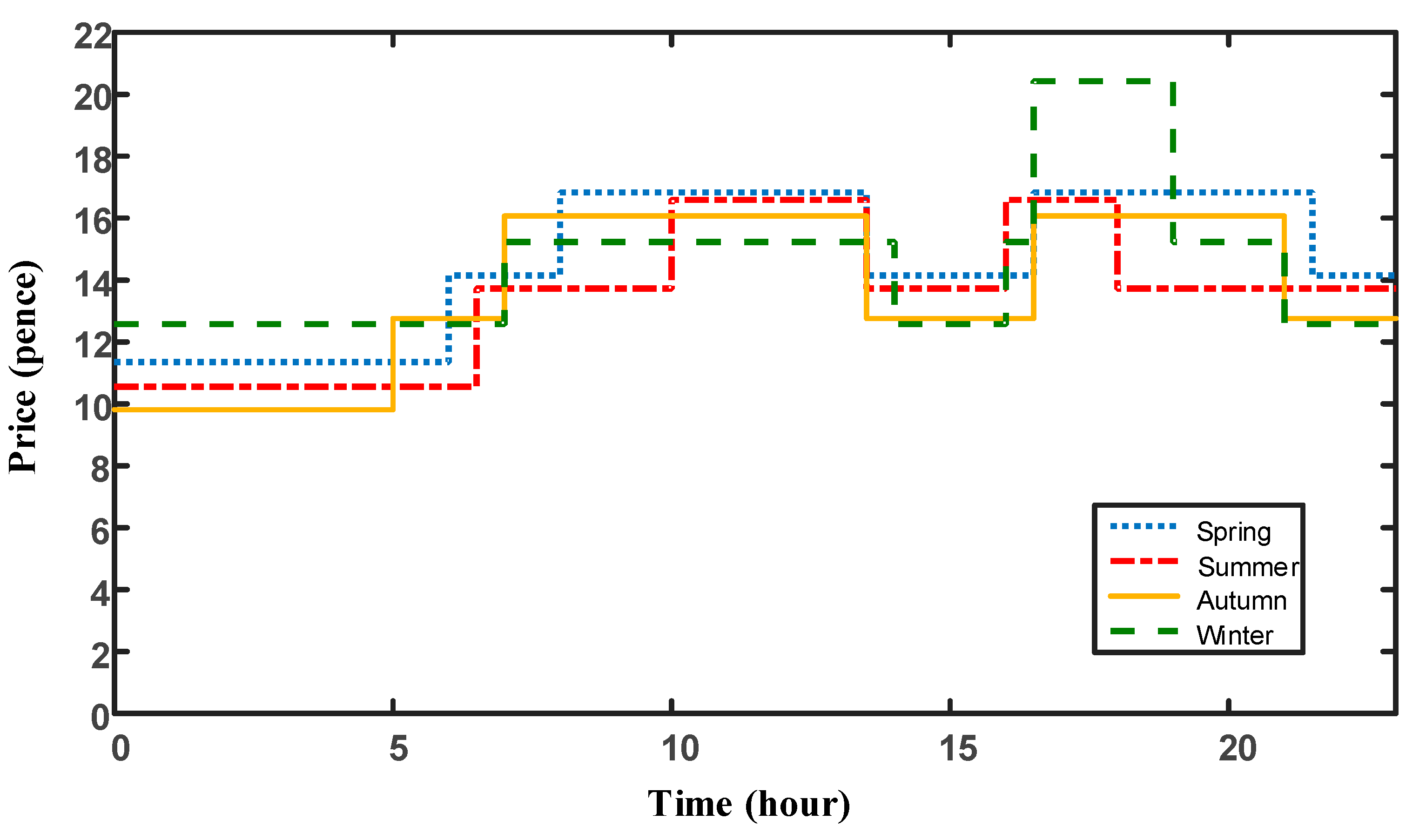

Fourthly, energy cost reduction is satisfactory in spring, autumn and especially winter. However, energy cost reduction in summer is disappointing. This is because the heat demand in summer is small compared with other seasons, therefore, the electricity generated by the CHP is limited. To increase energy cost reduction in summer, CHP capacity must be reduced, however, this can reduce energy cost reduction in other seasons. In order not to reduce energy cost reduction in other seasons, extra electrical energy must be stored in advance to supply the load at peak electricity price times.

Finally, the results also show that the computation time of the MR method is much shorter than the GA method. The calculation time of the GA method normally depends on the scale of CHP capacity.

Figure 10 and

Figure 13 show that within the feasible CHP capacity region, the average daily energy costs are very similar, therefore, in the future work, the scale of CHP capacity in the GA method can be set as 500 W rather than 100 W and this will increase computation efficiency and reduce computation time.

7. Conclusions

This paper has shown that different optimization methods will lead to different optimization settings and that thermodynamics alone is insufficient for determining the best design point of CHP units. In this paper, daily energy operational costs, investment costs and energy efficiency are all considered when using the MR and GA methods to size the CHP. The GA optimisation results show that by installing a 5200 W fuel cell CHP, the daily energy costs can be minimized which is 13% reduction compared to base case. However, to achieve this reduction, there will be about 3% energy efficiency reduction and 7% input power to rated power ratio reduction compared to the use of the MR method and the heat demand to size CHP. Using the MR method and the heat demand to size the CHP is acceptable because the MR method gives a higher benefit to cost ratio and energy efficiency. In addition, it makes more use of CHP capacity, even though it needs 5 pence extra to generate energy for a day. Considering the fact that battery energy storage systems (BESS) and heat storage systems (HESS) are well suited to domestic buildings due to their relatively safe, silent, scalable, low maintenance, and efficient characteristics, BESS and HESS may need to be installed in the future to deal with the conflict between energy efficiency, energy costs and system investments if the installation cost of energy storage systems could be reduced.