Watching the Smoke Rise Up: Thermal Efficiency, Pollutant Emissions and Global Warming Impact of Three Biomass Cookstoves in Ghana

Abstract

:1. Introduction

2. Materials and Methods

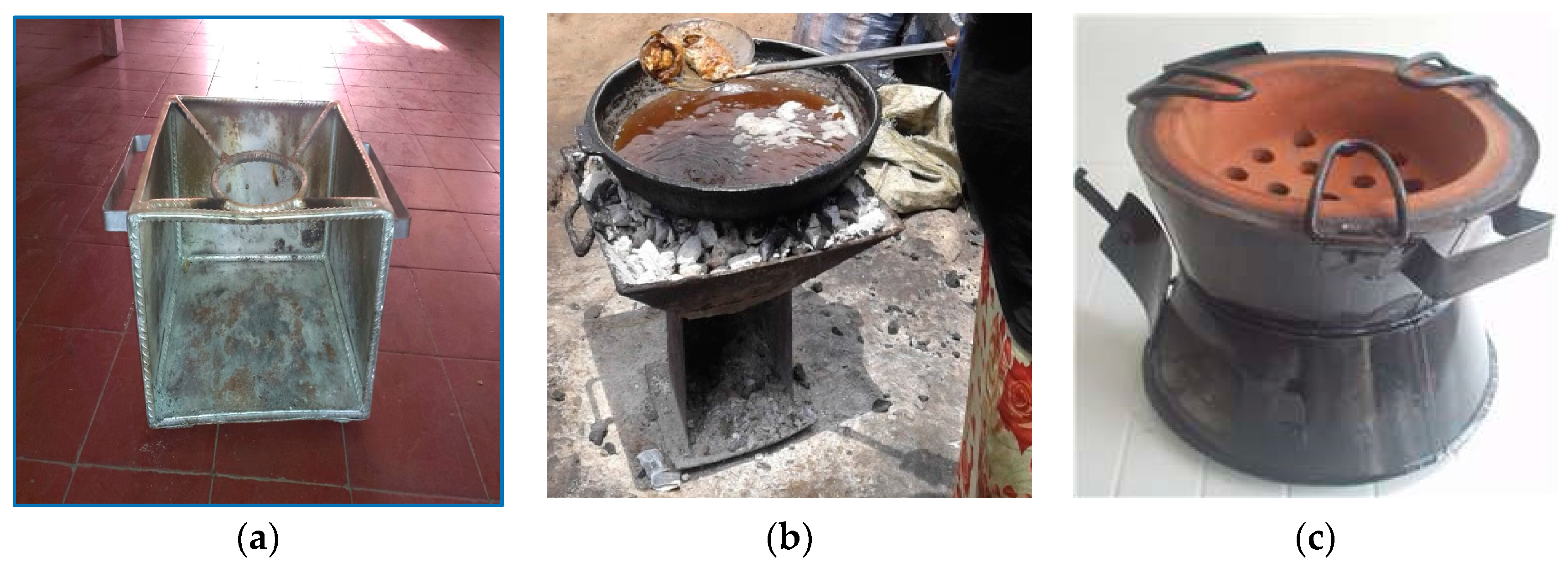

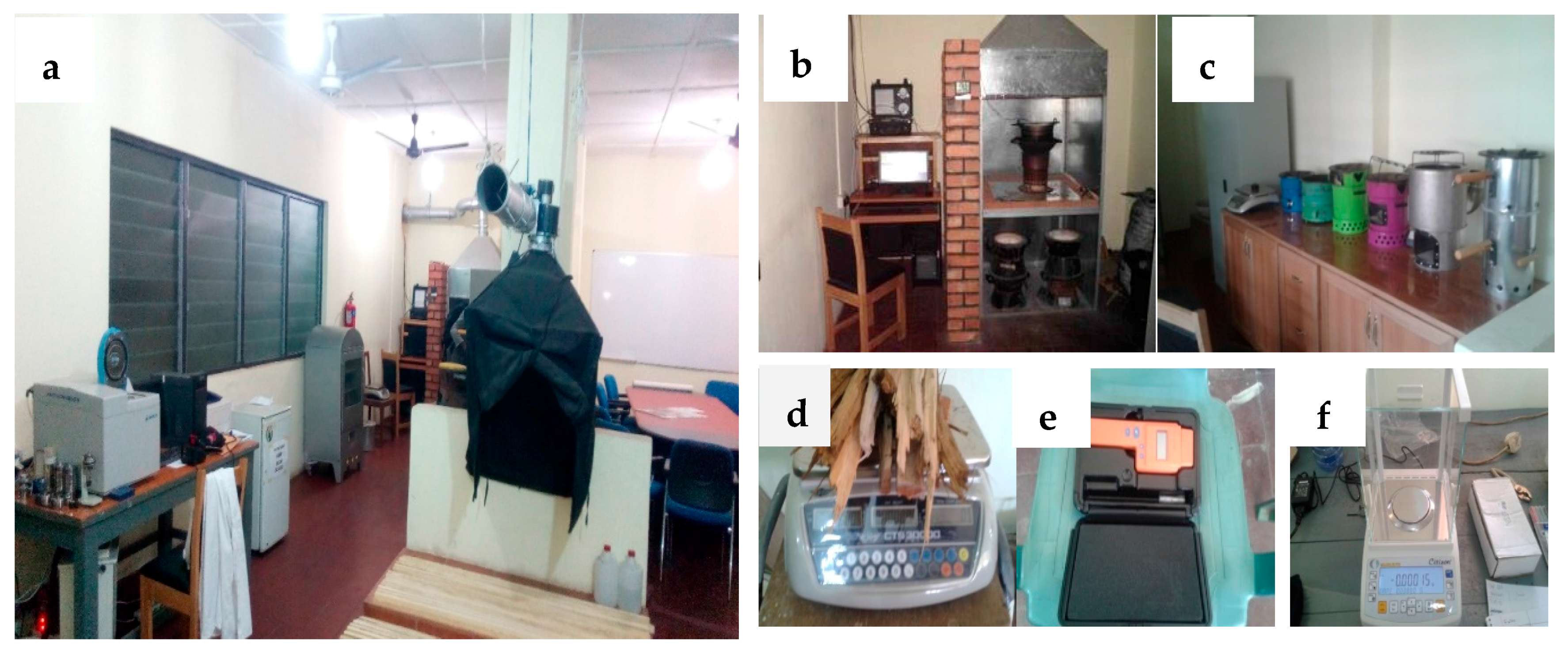

2.1. Materials

2.2. Initial Test Conditions

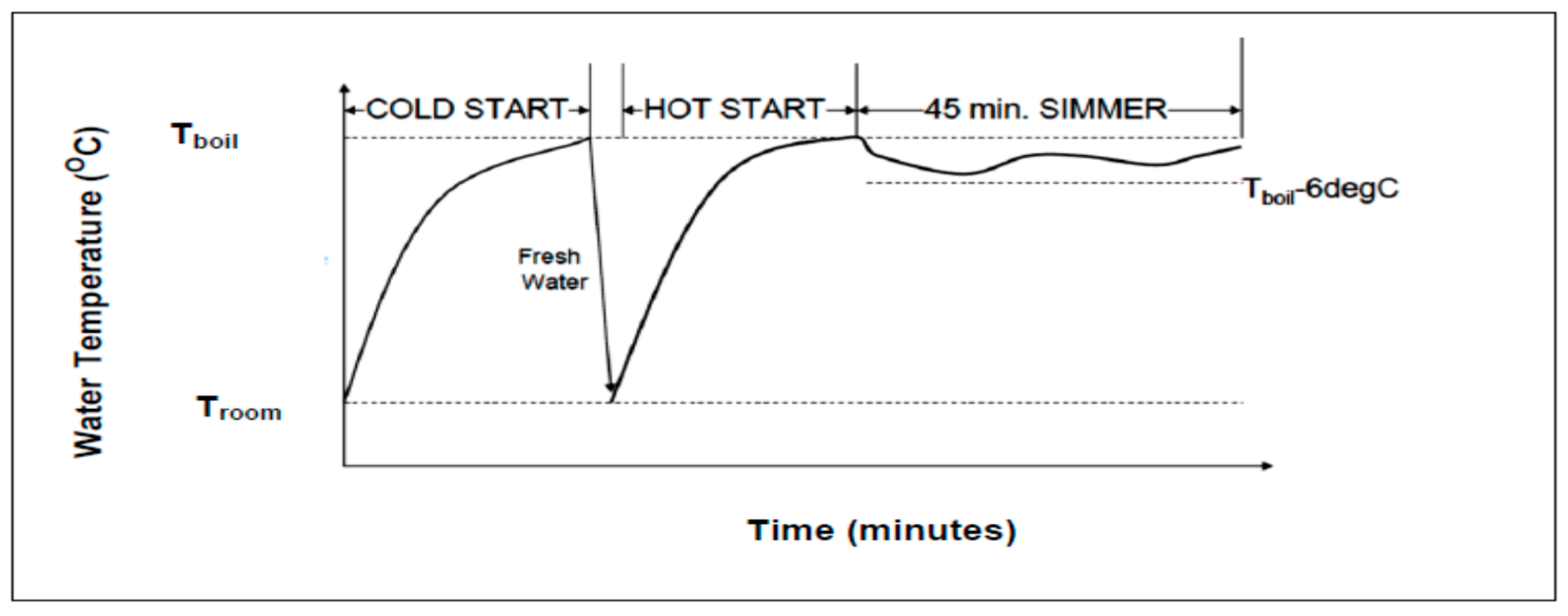

2.3. Methods and Data Analysis

3. Results and Discussion

3.1. Fuel and Energy Consumption, Time to Boil, and Thermal Efficiency

3.1.1. Fuel and Energy Consumption

3.1.2. Time to Boil

3.1.3. Thermal Efficiency

3.2. Emission Performance Results

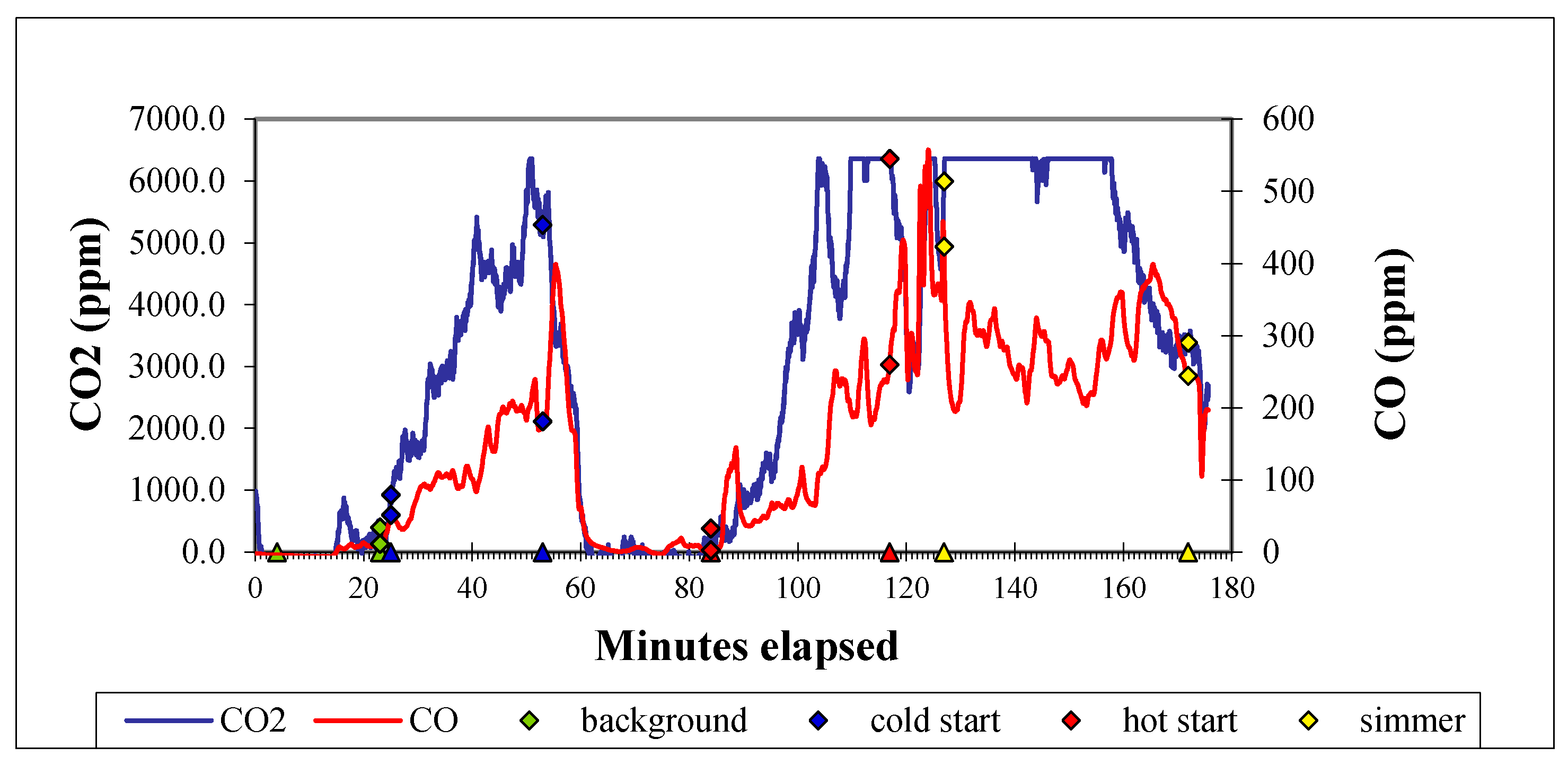

3.2.1. General Emissions

3.2.2. CO2 and CO Emissions

3.2.3. Particulate Matter (PM2.5)

3.2.4. Emission Factors

3.3. Pot Temperature and Relative Humidity

3.4. Standard Guidelines for the Indicators (Tier Designation)

3.5. Specific Emissions

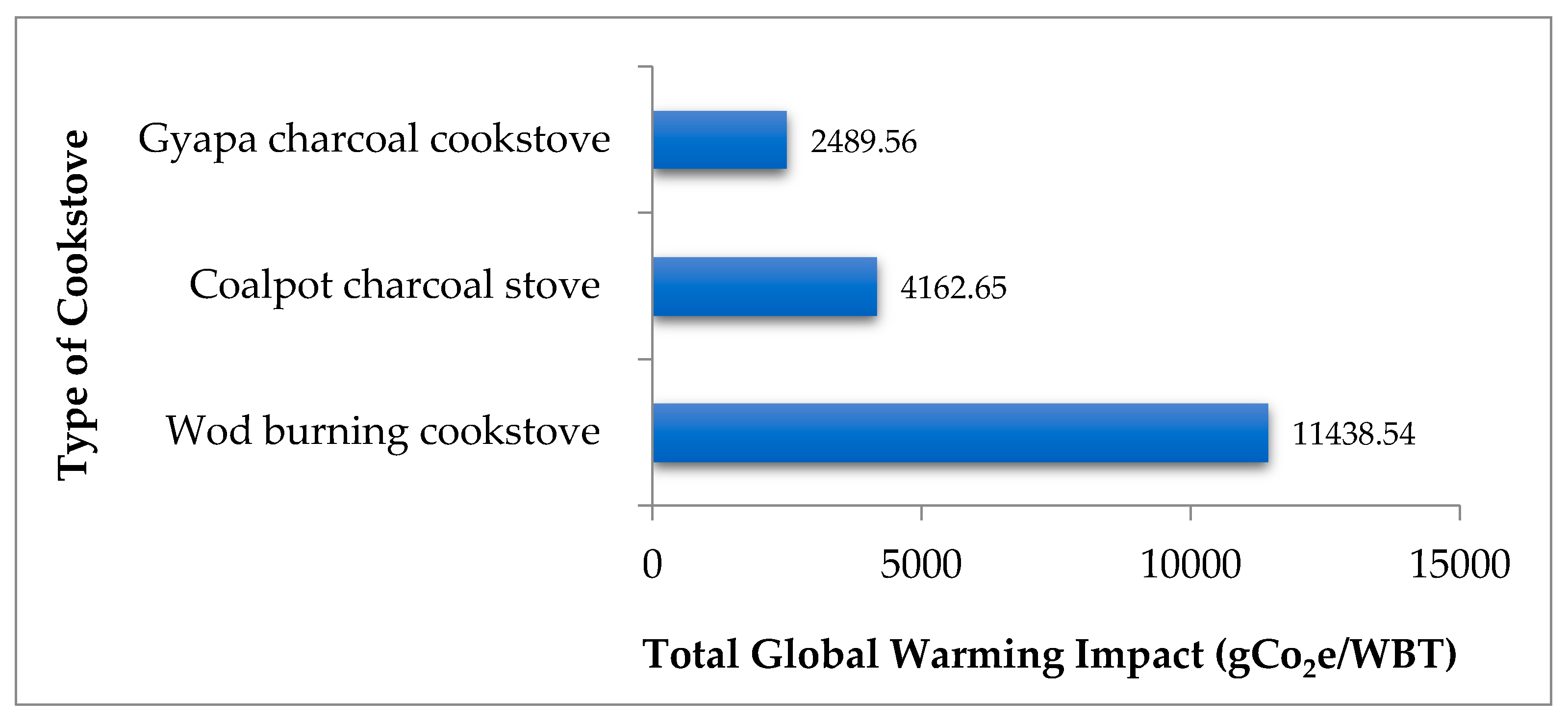

3.6. Total Global Warming Impact

3.7. Potential Annual Savings in Tonnes CO2 Equivalent

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- World Health Organisation (WHO). The Global Health Risks; WHO: Geneva, Switzerland, 2009. [Google Scholar]

- Lim, S.S.; Vos, T.; Flaxman, A.D.; Danaei, G.; Shibuya, K.; Adair-Rohani, H.; Amann, M.; Anderson, H.R.; Andrews, K.G.; Aryee, M.; et al. A comparative risk assessment of burden of disease and injury attributable to 67 risk factors and risk factor clusters in 21 regions, 1990–2010: A systematic analysis for the global burden of disease study 2010. Lancet 2012, 380, 2224–2260. [Google Scholar] [CrossRef]

- World Health Organisation (WHO). Burden of Disease from Household Air Pollution for 2012; Public Health, Social and Environmental Determinants of Health Department, WHO: Geneva, Switzerland, 2014. [Google Scholar]

- Ghana Statistical Service (GSS). Main report. In Ghana Living Standards Survey Round 6 (GLSS 6); GSS: Accra, Ghana, 2014. [Google Scholar]

- Global Alliance for Clean Cookstove (GACC). Available online: http://cleancookstoves.org/country-profiles/focus-countries/1-ghana.html (accessed on 3 December 2016).

- World Health Organisation (WHO). Household Air Pollution and Health. Media Centre Fact sheet N°292. Available online: http://www.who.int/mediacentre/factsheets/fs292/en/ (accessed on 3 February 2016).

- Jerneck, A.; Olsson, L. A smoke-free kitchen: initiating community based co-production for cleaner cooking and cuts in carbon emissions. J. Clean. Prod. 2013, 60, 208–215. [Google Scholar] [CrossRef]

- Global Alliance for Clean Cookstove (GACC). Impact Areas: Environment; GACC: Washington, DC, USA, 2016. [Google Scholar]

- Global Alliance for Clean Cookstove (GACC). Clean Cookstoves and Climate Change; GACC: Washington, DC, USA, 2016. [Google Scholar]

- Ekouevi, K.; Freeman, K.K.; Soni, R. Understanding the Differences between Cookstoves, LiveWire, a Knowledge Note Series for the Energy and Extractive Global Practice; World Bank: Washington, DC, USA, 2014. [Google Scholar]

- World Bank. The environment department (climate change). In Household Cookstoves, Environment, Health, and Climate Change: A New Look at an Old Problem; World Bank: Washington, DC, USA, 2011. [Google Scholar]

- Stockholm Energy Institute (SEI). Assessing the Climate Impacts of Cookstove Projects: Issues in Emissions Accounting, Policy Brief; SEI: Stockholm, Sweden, 2013. [Google Scholar]

- Ramanathan, V.; Carmichael, G. Global and regional climate changes due to black carbon. Nat. Geosci. 2008, 1, 221–227. [Google Scholar] [CrossRef]

- Gustafsson, O.; Krusa, M.; Zencak, Z.; Sheesley, R.J.; Granat, L.; Engstrom, E.; Praveen, P.S.; Rao, P.S.; Leck, C.; Rodhe, H. Brown clouds over South Asia: Biomass or fossil fuel combustion? Science 2009, 323, 495–498. [Google Scholar] [CrossRef] [PubMed]

- Bruce, N.; Pope, D.; Rehfuess, E.; Balakrishnan, K.; Adair-Rohani, H.; Dora, C. WHO indoor air quality guidelines on household fuel combustion: Strategy implications of new evidence on interventions and exposure risk functions. Atmos. Environ. 2015, 106, 451–457. [Google Scholar] [CrossRef]

- Bond, T.C.; Doherty, S.J.; Fahey, D.W.; Forster, P.M.; Berntsen, T.; Deangelo, B.J.; Flanner, M.G.; Ghan, S.; Karcher, B.; Koch, D.; et al. Bounding the role of black carbon in the climate system: A scientific assessment. J. Geophys. Res. Atmos. 2013, 118, 5380–5552. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). Changes in atmospheric constituents and in radiative forcing. In Climate Change 2007: The Physical Science Basis. Contribution of Working Group I to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change; Solomon, S., Qin, D., Manning, M., Chen, Z., Marquis, M., Averyt, K.B., Tignor, M., Miller, H.L., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2007. [Google Scholar]

- Global Alliance for Clean Cookstove (GACC). The water boiling test version 4.2.3. In Cookstove Emissions and Efficiency in a Controlled Laboratory Setting; GACC: Washington, DC, USA, 2014. [Google Scholar]

- Berkley Air Monitoring Group. Stove Performance Inventory Report; Prepared for the Global Alliance for Clean Cookstoves; United Nations Foundation: Washington, DC, USA, 2012. [Google Scholar]

- Volunteers in Technical Assistance (VITA). Water Boiling Test Version 4.1.2 VITA Water Boiling Test (WBT 4.1.2). 2009. Available online: http://www.pciaonline.org/files/WBT4.1.2_0_0.pdf (accessed on 23 June 2016).

- Kelley, M.; Donnelly, R.A. The Humongous Book of Statistics Problems; Penguin Group (USA) Inc.: New York, NY, USA, 2009. [Google Scholar]

- Peck, R.; Olsen, C.; Devore, J. Introduction to Statistics and Data Analysis; Brook/Cole Cengage Learning: Boston, MA, USA, 2012. [Google Scholar]

- Jetter, J.J.; Kariher, P. Solid-fuel household cook stoves: Characterization of performance and emissions. Biomass Bioenergy 2009, 33, 294–305. [Google Scholar] [CrossRef]

- Energica, Ghana. Pre-Feasibility Study for an Improved Cook Stoves Project in Northern Ghana Report Submitted to: CARE Denmark; Danish Energy Agency: Accra, Ghana, 2009. [Google Scholar]

- Boafo-Mensah, G.; Ampomah-Benefo, K.; Bentumah Animpong, M.A.; Oduro, W.O.; Kotey, E.N.; Akufo-Kumi, K.; Laryea, G.N. Thermal efficiency of charcoal fired cookstoves in Ghana. Glob. Adv. Res. J. Eng. Technol. Innov. 2013, 2, 102–110. [Google Scholar]

- Adkins, E.; Tyler, E.; Wang, J.; Siriri, D.; Modi, V. Field testing and survey evaluation of household biomass cookstoves in rural sub-Saharan Africa. Energy Sustain. Dev. 2010, 14, 172–185. [Google Scholar] [CrossRef]

- Kshirsagar, M.P.; Kalamkar, V.R. A comprehensive review on biomass cookstoves and a systematic approach for modern cookstove design. Renew. Sustain. Energy Rev. 2014, 30, 580–603. [Google Scholar] [CrossRef]

- Global Alliance for Clean Cookstove (GACC). Cookstoves and Fuels; GACC: Washington, DC, USA, 2013. [Google Scholar]

- Pennise, D.; Brant, S.; Agbeve, S.M.; Quaye, W.; Mengesha, F.; Tadele, W.; Wofchuck, T. Indoor air quality impacts of an improved wood stove in Ghana and an ethanol stove in Ethiopia. Energy Sustain. Dev. 2009, 13, 71–76. [Google Scholar] [CrossRef]

- World Health Organisation (WHO). Guidelines for Indoor Air Quality: Household Fuel Combustion; WHO: Geneva, Switzerland, 2014. [Google Scholar]

- Partnership for Clean Indoor Air (PCIA). Test Results of Cook Stove Performanc; Aprovecho Research Center, Shell Foundation, and United States Environmental Protection Agency: Washington, DC, USA, 2011. [Google Scholar]

- Wardoyo, A.Y.P.; Morawska, L.; Ristovski, Z.D.; Jamriska, M.; Carr, S.; Johnson, G. Size distribution of particles emitted from grass fires in the Northern Territory, Australia. Atmos. Environ. 2007, 41, 8609–8619. [Google Scholar] [CrossRef]

- Gómez, D.R.; Watterson, J.D.; Americano, B.B.; Ha, C.; Marland, G.; Matsika, E.; Namayanga, L.E.; Osman-Elasha, B.; Kalenga Saka, J.D.; Treanton, K.; et al. Chapter 2: Stationary Combustion, Volume 2, Energy. 2006 IPCC Guidelines for National Greenhouse Gas Inventories. 2006. Available online: http://www.ipccnggip.iges.or.jp/public/2006gl/pdf/2_Volume2/V2_2_Ch2_Stationary_Combustion.pdf (accessed on 15 November 2016).

- Particulate Emissions from Biomass Combustion in IEA Countries. Available online: http://vbt.ebi.kit.edu/index.pl/themen/mahe_wirbel/literatur/Wood-Single-Aspects/Emissions/Partikulate-Emissions-from-Biomass-Combustion-in-IEA-Countries_Nussbaumer_IEA_2008.pdf (accessed on 3 December 2016).

- Amaral, S.S.; Andrade de Carvalho, J.; Maria Angélica Martins Costa, M.A.M.; Pinheiro, C. Particulate matter emission factors for biomass combustion. Atmosphere 2016, 7, 1–25. [Google Scholar]

- Arundel, V.A.; Sterling, E.M.; Biggin, J.H.; Sterling, D.T. Indirect health effects of relative humidity in indoor environments. Environ. Health Perspect. 1986, 65, 351–361. [Google Scholar] [CrossRef] [PubMed]

- HEVAC Humidity Group. Humidity and its Impact on Human Comfort and Wellbeing in Occupied Buildings. Available online: http://www.humiditysolutions.co.uk/wp-content/uploads/2016/06/HUMIDITY-AND-THE-IMPACT-ON-HUMAN-COMFORT-250416.pdf (accessed on 3 December 2016).

- Smith, K.R.; Uma, R.; Kishore, V.V.N.; Zhang, J.; Joshi, V.; Khalil, M.A.K. Greenhouse implications of household stoves: An analysis for India. Annu. Rev. Energy Environ. 2000, 25, 741–763. [Google Scholar] [CrossRef]

- Global Alliance for Clean Cookstove (GACC). How does the Alliance Define “Clean” and “Efficient”? Tracking Progress towards 100M by 2020; GACC: Washington, DC, USA, 2016. [Google Scholar]

- MacCarty, N.; Ogle, D.; Still, D. A laboratory comparison of the global warming impact of five major types of biomass cooking stoves. Energy Sustain. Dev. 2008, 12, 56–65. [Google Scholar] [CrossRef]

- Du, X. Responding to global changes as a community of common destiny. Engineering 2016, 2, 52–54. [Google Scholar] [CrossRef]

- Global Alliance for Clean Cookstove (GACC). The Opportunity; GACC: Washington, DC, USA, 2013. [Google Scholar]

| Property | Wood | Charcoal | |

|---|---|---|---|

| Units | Value | Value | |

| Fuel species | Acacia farnesiana | Azadirachta indica (Neem) | |

| Average dimensions of fuel (W × H × L) | cm × cm × cm | 2 × 3 × 40 | 2 × 3 × 6 |

| Wood moisture content (MC) | % (wet) | 7.0 | 8.0 |

| Gross calorific value | MJ/kg (dry) | 19.2 | 29.4 |

| Net calorific value | MJ/kg (dry) | 17.9 | 28.2 |

| Effective calorific value | MJ/kg (wet) | 16.5 | 25.7 |

| Performance Metrics | Wood-Burning Cookstove | Coalpot Charcoal Stove | Gyapa Charcoal Cookstove | |||

|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | |

| High power thermal efficiency (%) | 12.20 | 2.03 | 23.30 | 0.29 | 30.00 | 1.85 |

| Low power specific fuel consumption rate (MJ/min/L) | 0.13 | 0.07 | 0.106 | 0.01 | 0.107 | 0.01 |

| Time to boil 5 L of water (min) | 31.70 | 3.53 | 25.50 | 2.80 | 23.10 | 3.37 |

| Fuel to cook 5 L of water (g) | 2872.3 | 390 | 1178.1 | 230 | 1036 | 212 |

| Energy consumption rate (kJ/min) | 1237 | 269 | 844 | 152 | 669 | 75S |

| Firepower (Watt) | 8589.7 | 3377.13 | 6066 | 934.07 | 4802.7 | 909.88 |

| No. of replicates | 3 | 3 | 3 | |||

| Emission Measures | Wood-Burning Cookstove | Coalpot Charcoal Cookstove | Gyapa Charcoal Cookstove |

|---|---|---|---|

| CO to Cook 5 L of Water (g) | 330.3 | 137.4 | 108.6 |

| PM2.5 to Cook 5 L of Water (mg) | 22,210.4 | 556.5 | 5258.9 |

| CO2 to Cook 5 L of Water (g) | 10,811.0 | 3901.7 | 2082 |

| Indoor Emissions, CO (g/min) | 2.95 | 1.64 | 2.32 |

| Indoor Emissions, PM2.5 (mg/min) | 169.8 | 5.3 | 9.95 |

| Total Global Warming Impact (g CO2e) | 11,438.54 | 4162.65 | 2489.56 |

| Emission Factors | Wood-Burning Cookstove | Coalpot Charcoal Stove | Gyapa Charcoal Cookstove |

|---|---|---|---|

| PM2.5 emissions factor (mg/kJ) | 0.43 | 0.02 | 0.18 |

| CO2 emission factor (kg/TJ) | 119,550 | 117,440 | 71,660 |

| CO emissions factor (mg/kJ) | 6.43 | 4.14 | 3.74 |

| PM2.5 emissions factor (g/kg) | 7.74 | 0.47 | 5.06 |

| CO2 emission factor (g/kg) | 3766.90 | 3306.44 | 2009.6 |

| CO emissions factor (g/kg) | 115.09 | 116.44 | 104.42 |

| Thermal Efficiency—Tier Designations | Remarks | |||||

| Wood-burning cookstove (Tier 0) | Coalpot charcoal cookstove (Tier 1–2) | Gyapa charcoal cookstove (Tier 2–3) | With Tier 2–3 the Gyapa charcoal cookstove is counted as efficient. | |||

| Indoor Emissions (PM2.5)—Tier Designations | ||||||

| Wood-burning cookstove (Tier 0) | Coalpot charcoal cookstove (Tier 3) | Gyapa charcoal cookstove (Tier 2) | With Tier 3 the coalpot charcoal cookstove is counted as clean. | |||

| IWA Tier Designation (Standard Guideline) | ||||||

| units | Tier 0 | Tier 1 | Tier 2 | Tier 3 | Tier 4 | |

| High power thermal efficiency | % | <15 | ≥15 | ≥25 | ≥35 | ≥45 |

| Low power specific consumption | MJ/min/L | >0.05 | ≤0.05 | ≤0.039 | ≤0.028 | ≤0.017 |

| Indoor emissions CO | g/min | >0.97 | ≤0.97 | ≤0.62 | ≤0.49 | ≤0.42 |

| Indoor emissions PM | mg/min | >40 | ≤40 | ≤17 | ≤8 | ≤2 |

| Specific Emissions (g/L) | Wood-Burning Cookstove | Coalpot Charcoal Stove | Gyapa Charcoal Cookstove |

|---|---|---|---|

| Cold Start | |||

| CO g/L | 21.63 | 16.43 | 14.40 |

| CO2 g/L | 672.87 | 258.47 | 139.67 |

| PM2.5 mg/L | 2562.97 | 32.13 | 64.40 |

| Hot Start | |||

| CO g/L | 16.53 | 16.37 | 16.13 |

| CO2 g/L | 560.97 | 287.10 | 139.50 |

| PM2.5 mg/L | 2324.43 | 39.10 | 40.94 |

| Simmer | |||

| CO g/L | 72.17 | 17.80 | 14.03 |

| CO2 g/L | 1980.67 | 502.73 | 309.50 |

| PM2.5 mg/L | 5059.37 | 68.53 | 72.03 |

| Stove Type | TGWI to Complete 1 WBT (Approx. 1 Meal) (gCO2e) | TGWI to Complete 7 WBT (Approx. 7 Meals/Week) (gCO2e) | TGWI to Complete 52 Weeks @ 7 WBT/Week (Approx 364 Meals/Week) (gCO2e) | Annual TGWI Projection (Tonnes CO2e) |

|---|---|---|---|---|

| Wood-burning cookstove | 11,438.54 | 80,069.78 | 4,163,629 | 4 |

| Coalpot charcoal stove | 4162.65 | 29,138.55 | 1,515,205 | 2 |

| Gyapa charcoal cookstove | 2489.56 | 17,426.92 | 906,199.8 | 1 |

| Potential Savings of the Gyapa Cookstove over Wood-burning and Coalpot Charcoal Stoves | ||||

| Potential saving over wood-burning cookstove | 3 (75%) | |||

| Potential saving over coalpot charcoal stove | 1 (50%) | |||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obeng, G.Y.; Mensah, E.; Ashiagbor, G.; Boahen, O.; Sweeney, D.J. Watching the Smoke Rise Up: Thermal Efficiency, Pollutant Emissions and Global Warming Impact of Three Biomass Cookstoves in Ghana. Energies 2017, 10, 641. https://doi.org/10.3390/en10050641

Obeng GY, Mensah E, Ashiagbor G, Boahen O, Sweeney DJ. Watching the Smoke Rise Up: Thermal Efficiency, Pollutant Emissions and Global Warming Impact of Three Biomass Cookstoves in Ghana. Energies. 2017; 10(5):641. https://doi.org/10.3390/en10050641

Chicago/Turabian StyleObeng, George Y., Ebenezer Mensah, George Ashiagbor, Owusu Boahen, and Daniel J. Sweeney. 2017. "Watching the Smoke Rise Up: Thermal Efficiency, Pollutant Emissions and Global Warming Impact of Three Biomass Cookstoves in Ghana" Energies 10, no. 5: 641. https://doi.org/10.3390/en10050641

APA StyleObeng, G. Y., Mensah, E., Ashiagbor, G., Boahen, O., & Sweeney, D. J. (2017). Watching the Smoke Rise Up: Thermal Efficiency, Pollutant Emissions and Global Warming Impact of Three Biomass Cookstoves in Ghana. Energies, 10(5), 641. https://doi.org/10.3390/en10050641