A Computational Tool for Comparative Energy Cost Analysis of Multiple-Crop Production Systems

Abstract

:1. Introduction

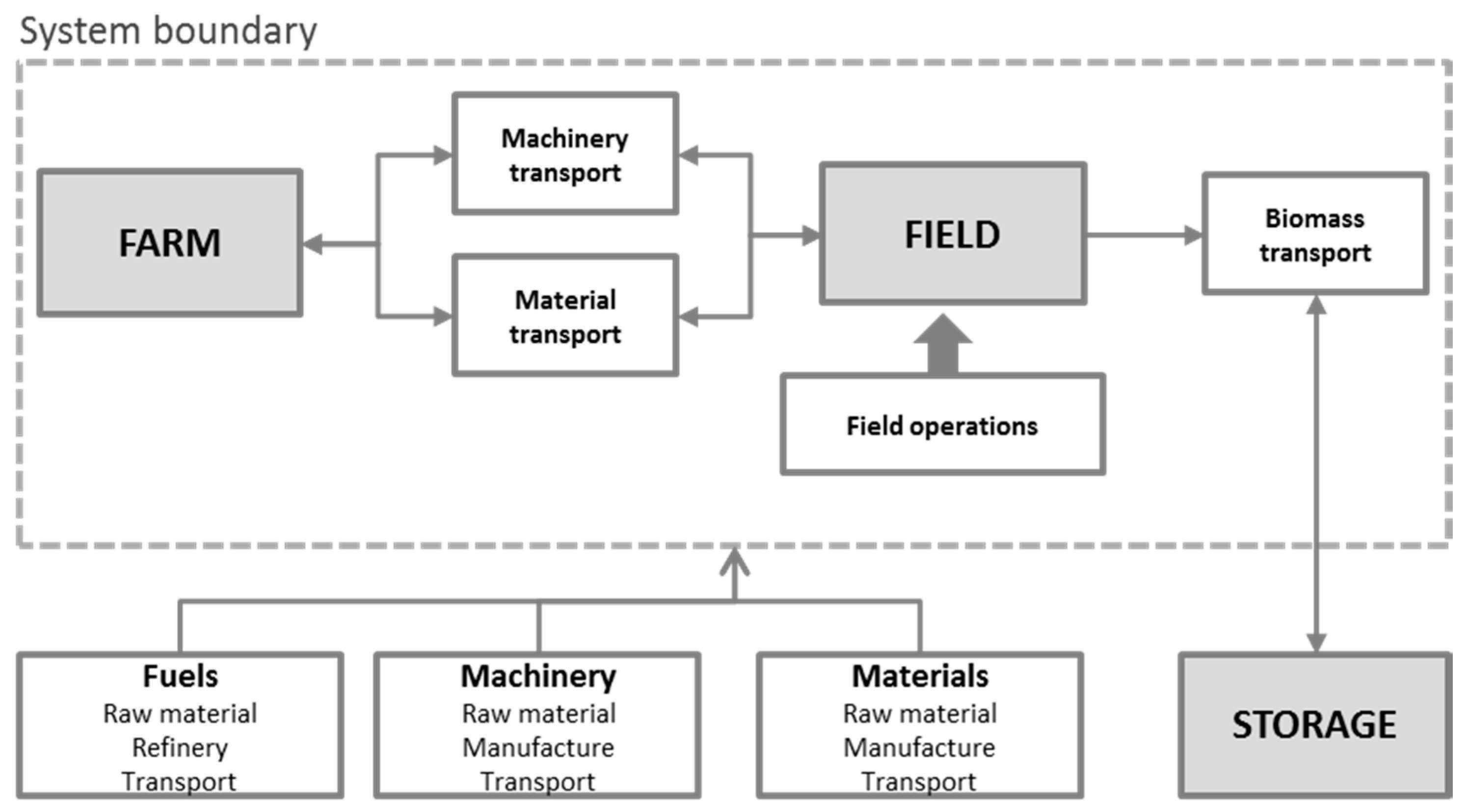

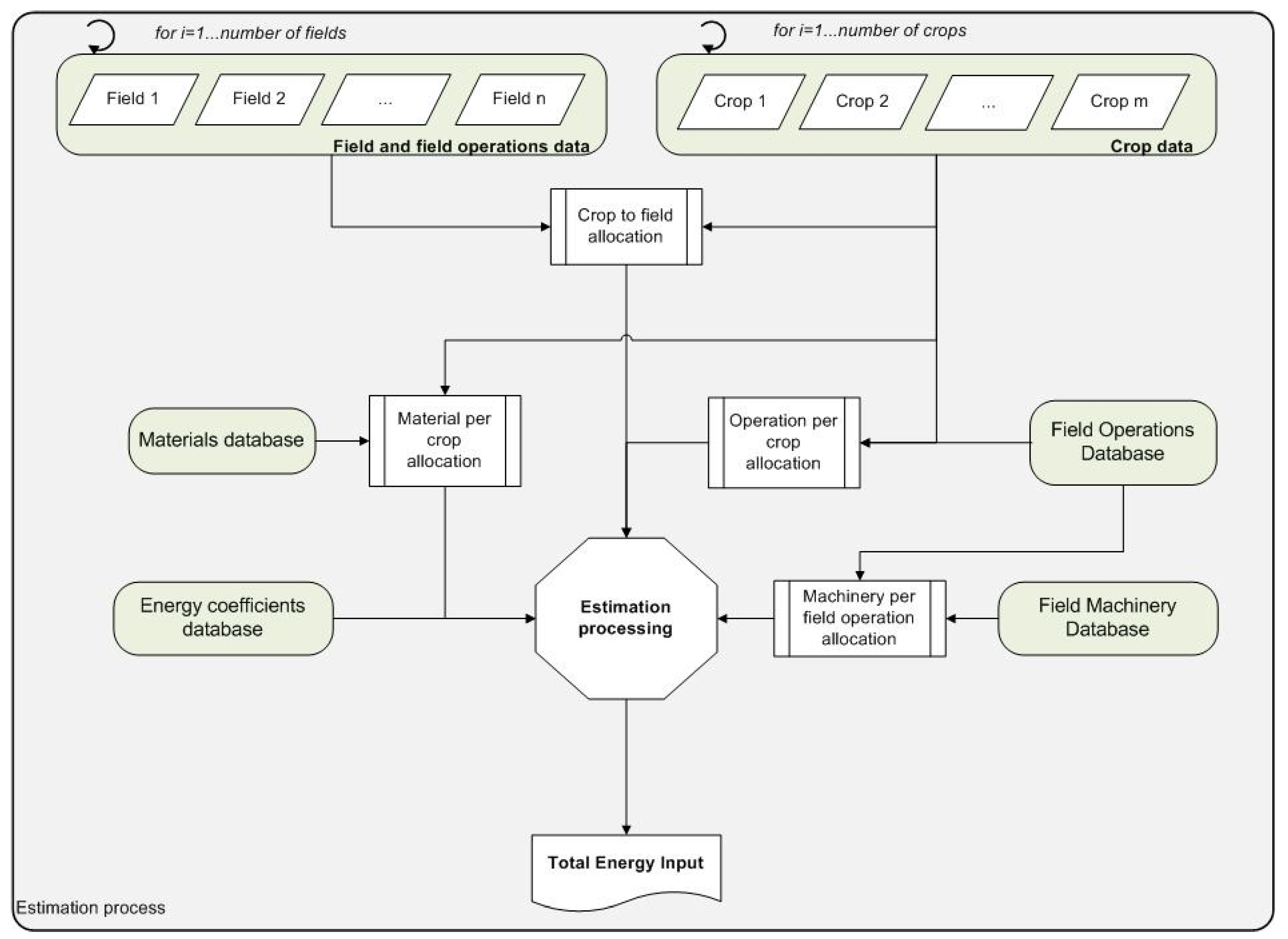

2. The Computational Tool

- General production inputs, which include the field (e.g., field area) and the crop parameters (e.g., crop yield).

- Field and transport operations inputs, which include all the parameters related to operations (in-field and transport) that are performed each year for each crop, as well as any other related parameter (e.g., operating speed).

- Field machinery inputs, which include the tractor-specific parameters (e.g., tractor power, tractor weight, machinery embodied energy) and the equipment-specific parameters (e.g., operating width).

- Material specific inputs, which include the embodied energy and the material used, such as agrochemicals, fertilizers and propagation means.

3. Case Study Description

3.1. The Selected Crops

3.2. Production Scenario

3.2.1. Miscanthus Production

3.2.2. Arundo donax Production

3.2.3. Switchgrass Production

3.3. Input Parameters

4. Results

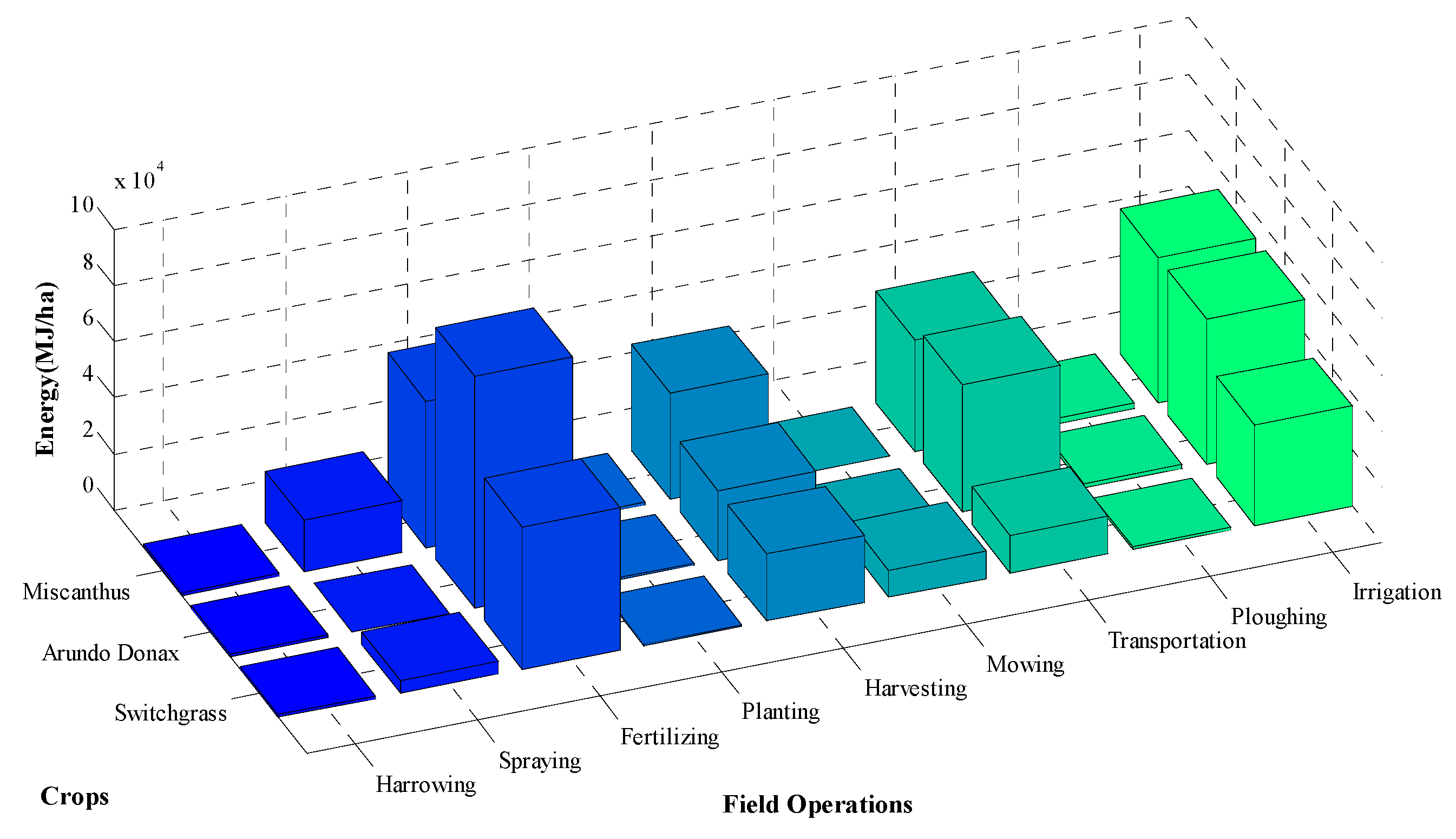

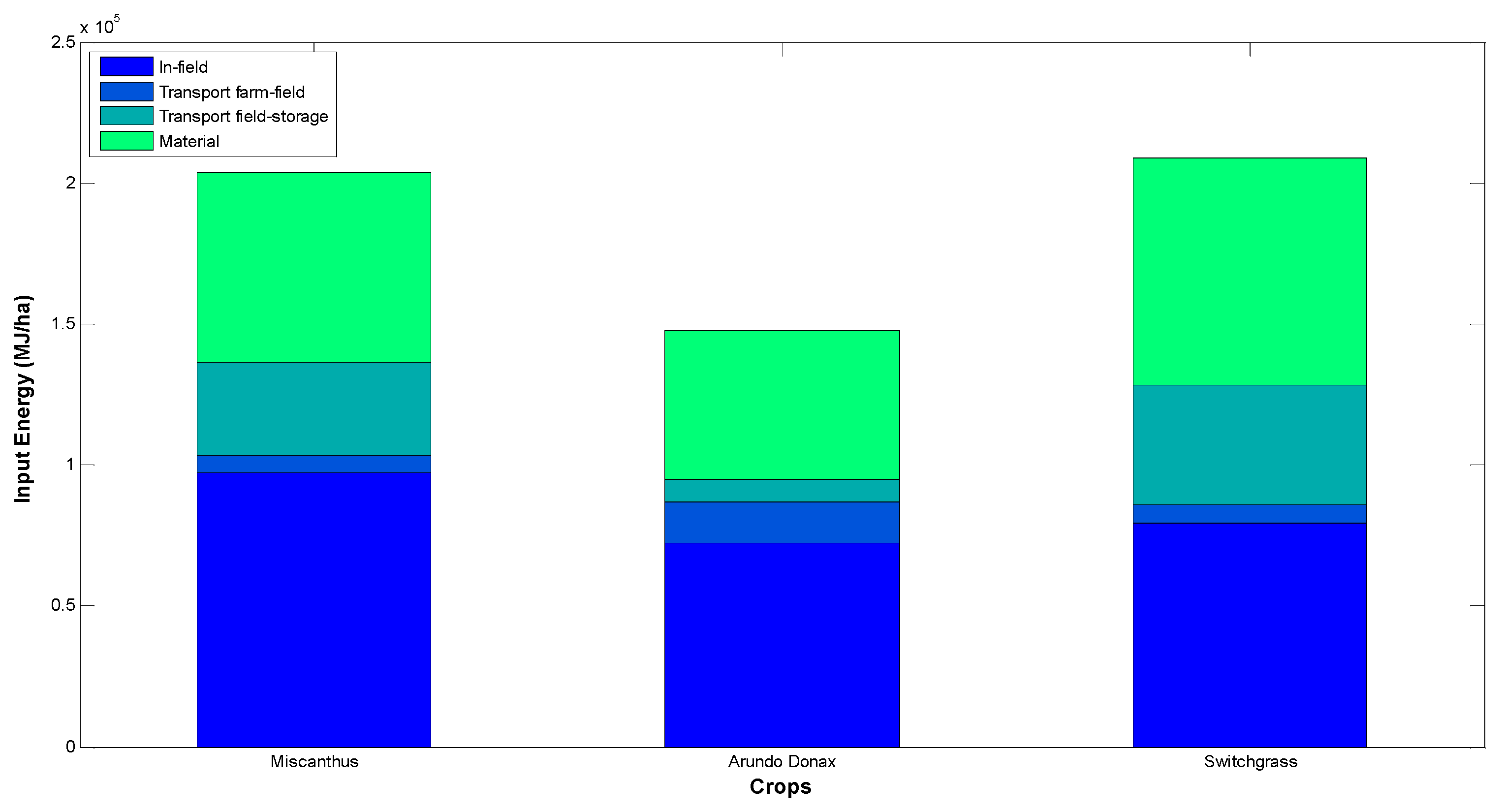

4.1. Basic Scenarios

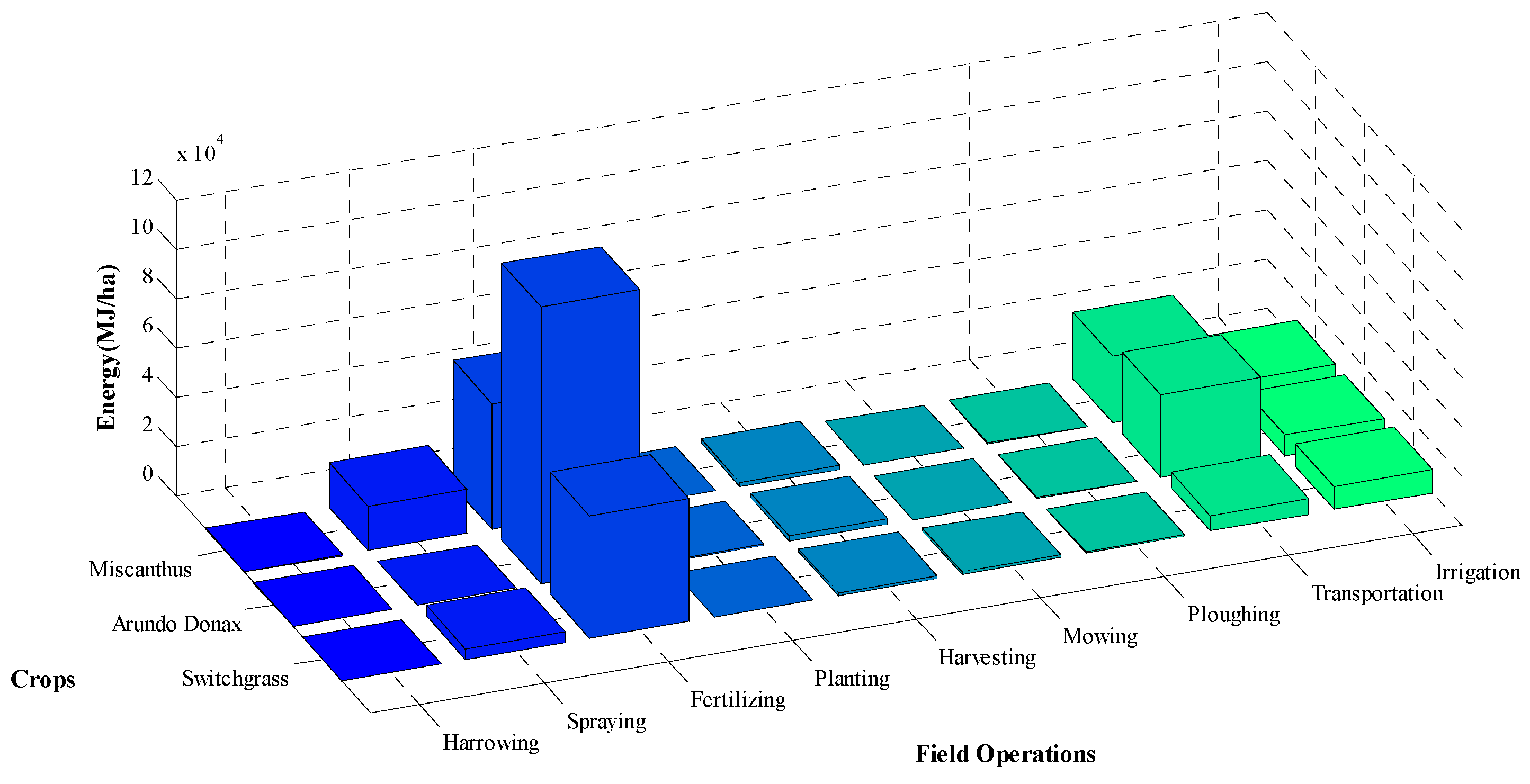

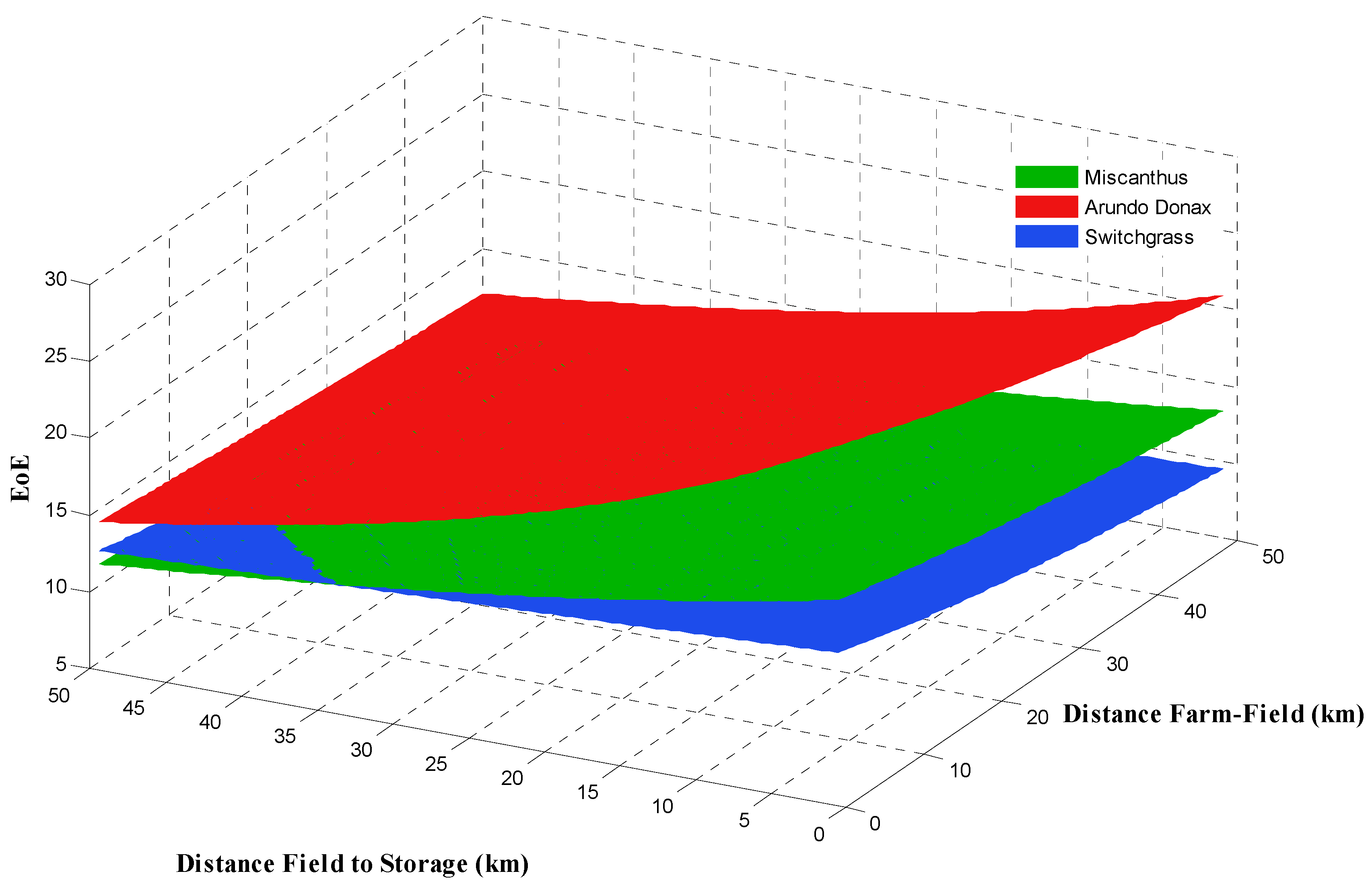

4.2. The Effect of Distance

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| EI | Energy Input |

| EO | Energy Output |

| EIU | Energy Input per unit area |

| EOU | Energy Output per unit area |

| EoE | Efficiency of energy |

| EB | Energy balance |

References

- Ren, L.; Cafferty, K.; Roni, M.; Jacobson, J.; Xie, G.; Ovard, L.; Wright, C. Analyzing and comparing biomass feedstock supply systems in China: Corn stover and sweet sorghum case studies. Energies 2015, 8, 5577–5597. [Google Scholar] [CrossRef]

- Busato, P.; Berruto, R. A web-based tool for biomass production systems. Biosyst. Eng. 2014, 120, 102–116. [Google Scholar] [CrossRef]

- Castillo-Villar, K.K.; Minor-Popocatl, H.; Webb, E. Quantifying the impact of feedstock quality on the design of bioenergy supply chain networks. Energies 2016, 9, 203. [Google Scholar] [CrossRef]

- Puigjaner, L.; Pérez-Fortes, M.; Laínez-Aguirre, J.M. Towards a carbon-neutral energy sector: Opportunities and challenges of coordinated bioenergy supply Chains-A PSE approach. Energies 2015, 8, 5613–5660. [Google Scholar] [CrossRef]

- Sopegno, A.; Rodias, E.; Bochtis, D.; Busato, P.; Berruto, R.; Boero, V.; Sørensen, C. Model for energy analysis of Miscanthus production and transportation. Energies 2016, 9, 392. [Google Scholar] [CrossRef]

- Kitani, O. CIGR Handbook of Agricultural Engineering Volume V; CIGR–The I.; ASAE Publication: St. Joseph, MI, USA, 1999; Volume V. [Google Scholar]

- Vermerris, W. Genetic Improvement of Bioenergy Crops; Springer: Berlin, Germany, 2008. [Google Scholar]

- Atkinson, C.J. Establishing perennial grass energy crops in the UK: A review of current propagation options for Miscanthus. Biomass Bioenergy 2009, 33, 752–759. [Google Scholar] [CrossRef]

- Angelini, L.G.; Ceccarini, L.; Nassi o Di Nasso, N.; Bonari, E. Comparison of Arundo donax L. and Miscanthus x giganteus in a long-term field experiment in Central Italy: Analysis of productive characteristics and energy balance. Biomass Bioenergy 2009, 33, 635–643. [Google Scholar] [CrossRef]

- Mantineo, M.; D’Agosta, G.M.; Copani, V.; Patanè, C.; Cosentino, S.L. Biomass yield and energy balance of three perennial crops for energy use in the semi-arid Mediterranean environment. Field Crops Res. 2009, 114, 204–213. [Google Scholar] [CrossRef]

- Lewandowski, I.; Scurlock, J.M.O.; Lindvall, E.; Christou, M. The development and current status of perennial rhizomatous grasses as energy crops in the US and Europe. Biomass Bioenergy 2003, 25, 335–361. [Google Scholar] [CrossRef]

- Angelini, L.G.; Ceccarini, L.; Bonari, E. Biomass yield and energy balance of giant reed (Arundo donax L.) cropped in central Italy as related to different management practices. Eur. J. Agron. 2005, 22, 375–389. [Google Scholar] [CrossRef]

- Christian, D.G.; Elbersen, H.W.; Bassam, N.E.; Sauerbeck, G.; Alexopoulou, E.; Sharma, N.; Piscioneri, I.; de Visser, P.; van den Berg, D. Switchgrass (Panicum virgatum L.) as an Alternative Energy Crop in Europe—Initiation of a Productivity Network; Agrotechnological Research Institute: Wageningen, The Netherlands, 2001. [Google Scholar]

- Bassam, N.E. Handbook of Bioenergy Crops: A Complete Reference to Species, Development and Applications; Earthscan: London, UK, 2010. [Google Scholar]

- Schmer, M.R.; Vogel, K.P.; Mitchell, R.B.; Perrin, R.K. Net energy of cellulosic ethanol from switchgrass. Proc. Natl. Acad. Sci. USA 2008, 105, 464–469. [Google Scholar] [CrossRef] [PubMed]

- Farrell, A.E.; Plevin, R.J.; Turner, B.T.; Jones, A.D.; O’Hare, M.; Kammen, D.M. Ethanol can contribute to energy and environmental goals. Science 2006, 311, 506–508. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.Q. Development and Use of GREET 1.6 Fuel-Cycle Model for Transportation Fuels and Vehicle Technologies; Anl/Esd/Tm-163; Argonne National Laboratory: Lemont, IL, USA, 2001.

- Sokhansanj, S.; Mani, S.; Turhollow, S.; Kumar, A.; Bransby, D.; Lynd, L.; Laser, M. Large-scale production, harvest and logistics of switchgrass (Panicum virgatum L.)—Current technology and envisioning a mature technology. Biofuels Bioprod. Biorefin. 2009, 3, 124–141. [Google Scholar] [CrossRef]

- Pyter, R.; Heaton, E.; Dohleman, F.; Voigt, T.; Long, S. Agronomic experiences with Miscanthus x giganteus in Illinois, USA. Methods Mol. Biol. 2009, 581, 41–52. [Google Scholar] [PubMed]

- Garten, C.T.; Smith, J.L.; Tyler, D.D.; Amonette, J.E.; Bailey, V.L.; Brice, D.J.; Castro, H.F.; Graham, R.L.; Gunderson, C.A.; Izaurralde, R.C.; et al. Intra-annual changes in biomass, carbon, and nitrogen dynamics at 4-year old switchgrass field trials in west Tennessee, USA. Agric. Ecosyst. Environ. 2010, 136, 177–184. [Google Scholar] [CrossRef]

- Lewandowski, I.; Clifton-Brown, J.C.; Scurlock, J.M.O.; Huisman, W. Miscanthus: European experience with a novel energy crop. Biomass Bioenergy 2000, 19, 209–227. [Google Scholar] [CrossRef]

- Heaton, E.A.; Dohleman, F.G.; Miguez, A.F.; Juvik, J.A.; Lozovaya, V.; Widholm, J.; Zabotina, O.A.; McIsaac, G.F.; David, M.B.; Voigt, T.B.; et al. Miscanthus. A Promising Biomass Crop. Adv. Bot. Res. 2010, 56, 76–137. [Google Scholar]

- Piscioneri, I.; Pignatelli, V.; Palazzo, S.; Sharma, N. Switchgrass production and establishment in the Southern Italy climatic conditions. Energy Convers. Manag. 2001, 42, 2071–2082. [Google Scholar] [CrossRef]

- Caslin, B.; Finnan, J.; Easson, L. Miscanthus Best Practice Guidelines; Teagasc and Agri-Food and Biosciences Institute: Belfast, UK, 2011.

- Hood, E.E.; Nelson, P.; Powell, R. Plant Biomass Conversion; Wiley-Blackwell: Hoboken, NJ, USA, 2011. [Google Scholar]

- Renz, M.; Undersander, D.; Casler, M. Establishing and Managing Switchgrass. Available online: http://fyi.uwex.edu/forage/establishing-and-managing-switchgrass/ (accessed on 16 June 2017).

- Boydston, R. Managing Weeds in Switchgrass Grown for Biofuel. Available online: http://css.wsu.edu/biofuels/files/2012/09/Boydston_2010_Switchgrass_Workshop.pdf (accessed on 15 March 2017).

- ASABE. Agricultural Machinery Management Data. In ASABE Standards; American Society of Agricultural and Biological Engineers (ASABE): St. Joseph, MI, USA, 2011; pp. 1–9. [Google Scholar]

- Wells, C. Total Energy Indicators of Agricultural Sustainability: Dairy Farming Case Study; Technical Paper 2001/3; Ministry of Agriculture and Forestry: Wellington, New Zealand, 2001.

- Barber, A. Seven Case Study Farms: Total Energy & Carbon Indicators for New Zealand Arable & Outdoor Vegetable Production; AgriLINK New Zealand Ltd.: Kumeu, New Zealand, 2004; p. 46. [Google Scholar]

- Saunders, C.; Barber, A.; Taylor, G. Food Miles—Comparative Energy/Emissions Performance of New Zealand’s Agriculture Industry; Research Report No. 285; Agribusiness & Economics Research Unit, Lincoln University: Lincoln, New Zealand, 2006. [Google Scholar]

- Phocaides, A. Technical Handbook on Pressurized Irrigation Techniques; Food and Agriculture Organization of the United Nations: Rome, Italy, 2000; pp. 1–196. [Google Scholar]

- Diotto, A.V.; Folegatti, M.V.; Duarte, S.N.; Romanelli, T.L. Embodied energy associated with the materials used in irrigation systems: Drip and centre pivot. Biosyst. Eng. 2014, 121, 38–45. [Google Scholar] [CrossRef]

| Field Operation | Year | |||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||||||||||||||||||||

| C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | C1 | C2 | C3 | |

| Plowing | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Disk-harrow | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Agrochemical spreading | ● | ○ | ● | ○ | ○ | ● | ○ | ○ | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Planting/Seeding | ● | ● | ● | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| Fertilization | ● | ● | ● | ● | ● | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Mowing | ○ | ○ | ○ | ○ | ○ | ● | ○ | ○ | ● | ○ | ○ | ● | ○ | ○ | ● | ○ | ○ | ● | ○ | ○ | ● | ○ | ○ | ● | ○ | ○ | ● | ○ | ○ | ● |

| Harvesting | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Irrigation | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Biomass transport | ○ | ○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Operations | Operating Width 1 (m) | Operating Speed 2 (km·h−1) | Field Efficiency 2 | Tractor Embodied Energy 3 (MJ·kg−1) | Implement Embodied Energy 3 (MJ·kg−1) | Tractor Weight 4 (103 kg) | Implement Weight 1 (103 kg) | Tractor Estimated Life 2 (103 h) | Implement Estimated Life 2 (103 h) | Fuel Energy Content 4,5 (MJ·L−1) | Tractor Power (kW) | Lubricants Energy Content 6 (MJ·L−1) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plough | 3 | 7 | 0.85 | 138 | 180 | 6.76 | 2.30 | 16 | 2 | 41.2 | 120 | 46 |

| Disk-harrow | 4.5 | 10 | 0.80 | 138 | 149 | 6.76 | 1.80 | 16 | 2 | 41.2 | 120 | 46 |

| Agrochemical Spreading | 24.4 | 11 | 0.70 | 138 | 129 | 2.93 | 3.35 | 12 | 1.2 | 41.2 | 50 | 46 |

| Fertilization | 24.4 | 11 | 0.70 | 138 | 129 | 2.93 | 3.35 | 12 | 1.2 | 41.2 | 50 | 46 |

| Planting/Seeding | 3.15 | 9 | 0.65 | 138 | 133 | 2.93 | 1.20 | 12 | 1.5 | 41.2 | 50 | 46 |

| Mowing | 3.1 | 11 | 0.80 | 138 | 110 | 6.76 | 0.65 | 12 | 2 | 41.2 | 120 | 46 |

| Harvesting | 1.83 | 5 | 0.70 | 138 | 116 | 6.76 | 0.90 | 16 | 2.5 | 41.2 | 120 | 46 |

| Transport | - | - | - | - | - | 6.76 | - | 12 | - | 41.2 | 120 | 46 |

| Operations | Average Road Speed (km·h−1) | Tanker/Wagon Weight (kg) | Tanker/Wagon Embodied Energy (MJ·kg−1) | Tanker/Wagon Estimated Life 1 (103 h) | Fuel Road Consumption 2 (L·km−1) | Wagon Full Volume 2 (m3) |

|---|---|---|---|---|---|---|

| Plough | 20 | - | - | - | 0.71 | - |

| Disk-harrow | 20 | - | - | - | 0.71 | - |

| Agrochemical Spreading | 20 | 1500 | 108 | 3 | 0.188 | - |

| Fertilization | 20 | 6800 | 108 | 3 | 0.188 | - |

| Planting/Seeding | 20 | 2500 | 108 | 3 | 0.188 | - |

| Mowing | 20 | - | 108 | 3 | 0.71 | - |

| Harvesting | 20 | - | 108 | 3 | 0.71 | - |

| Transport | 20 | 14,500 | 108 | 3 | 0.71 | 40 |

| Lift (m) | Irrigation Useful Life 1 (Years) | PVC Pipe Embodied Energy 2 (MJ·kg−1) | Efficiency | Electricity Energy Coefficient 3,4 (MJ·KWh−1) | ||||

|---|---|---|---|---|---|---|---|---|

| Well | Drip Irrigation | System | Pump 1 | Driving 1 (Electric Motors) | Irrigation System | |||

| 10 | 21 | 3 | 20 | 110.66 | 0.70 | 0.80 | 0.70 | 8.1 |

| Field Operation | Crops | Energy Consumption (MJ·ha−1) | |||

|---|---|---|---|---|---|

| Fuel | Embodied | Material | Total | ||

| Ploughing | Miscanthus | 1616 | 281 | - | 1904 |

| Arundo donax | 1616 | 205 | - | 1827 | |

| Switchgrass | 954 | 151 | - | 1109 | |

| Disk-harrowing | Miscanthus | 949 | 152 | - | 1105 |

| Arundo donax | 785 | 120 | - | 909 | |

| Switchgrass | 785 | 120 | - | 908 | |

| Agrochemicals Spreading | Miscanthus | 91 | 73 | 18,160 | 18,326 |

| Arundo donax | - | - | - | - | |

| Switchgrass | 329 | 167 | 4189 | 4624 | |

| Planting/Seeding | Miscanthus | 571 | 135 | 69 | 779 |

| Arundo donax | 444 | 276 | 69 | 800 | |

| Switchgrass | 315 | 80 | 20 | 419 | |

| Fertilization | Miscanthus | 1094 | 1965 | 48,869 | 51,951 |

| Arundo donax | 932 | 1304 | 80,640 | 82,894 | |

| Switchgrass | 1004 | 1409 | 48,415 | 50,847 | |

| Mowing | Miscanthus | - | - | - | - |

| Arundo donax | - | - | - | - | |

| Switchgrass | 8749 | 832 | - | 9621 | |

| Harvesting | Miscanthus | 35,822 | 1856 | - | 37,793 |

| Arundo donax | 22,878 | 1975 | - | 24,934 | |

| Switchgrass | 22,878 | 1004 | - | 23,954 | |

| Irrigation * | Miscanthus | 43,740 | 8202 | - | 51,942 |

| Arundo donax | 43,740 | 8202 | - | 51,942 | |

| Switchgrass | 26,244 | 9322 | - | 35,566 | |

| Biomass transport | Miscanthus | 8771 | 27,041 | - | 39,639 |

| Arundo donax | 11,060 | 33,127 | - | 45,683 | |

| Switchgrass | 3897 | 6272 | - | 13,469 | |

| Crops | EI (GJ) | EO (GJ) | EIU (GJ·ha−1) | EOU (GJ·ha−1) | EoE | EB (GJ·ha−1) |

|---|---|---|---|---|---|---|

| Miscanthus | 203.4 | 3229 | 203.4 | 3229 | 15.87 | 3025.3 |

| Arundo donax | 209.0 | 4863 | 209.0 | 4863 | 23.27 | 4654.4 |

| Switchgrass | 140.5 | 1900 | 140.5 | 1900 | 13.52 | 1760.3 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodias, E.; Berruto, R.; Bochtis, D.; Busato, P.; Sopegno, A. A Computational Tool for Comparative Energy Cost Analysis of Multiple-Crop Production Systems. Energies 2017, 10, 831. https://doi.org/10.3390/en10070831

Rodias E, Berruto R, Bochtis D, Busato P, Sopegno A. A Computational Tool for Comparative Energy Cost Analysis of Multiple-Crop Production Systems. Energies. 2017; 10(7):831. https://doi.org/10.3390/en10070831

Chicago/Turabian StyleRodias, Efthymios, Remigio Berruto, Dionysis Bochtis, Patrizia Busato, and Alessandro Sopegno. 2017. "A Computational Tool for Comparative Energy Cost Analysis of Multiple-Crop Production Systems" Energies 10, no. 7: 831. https://doi.org/10.3390/en10070831

APA StyleRodias, E., Berruto, R., Bochtis, D., Busato, P., & Sopegno, A. (2017). A Computational Tool for Comparative Energy Cost Analysis of Multiple-Crop Production Systems. Energies, 10(7), 831. https://doi.org/10.3390/en10070831