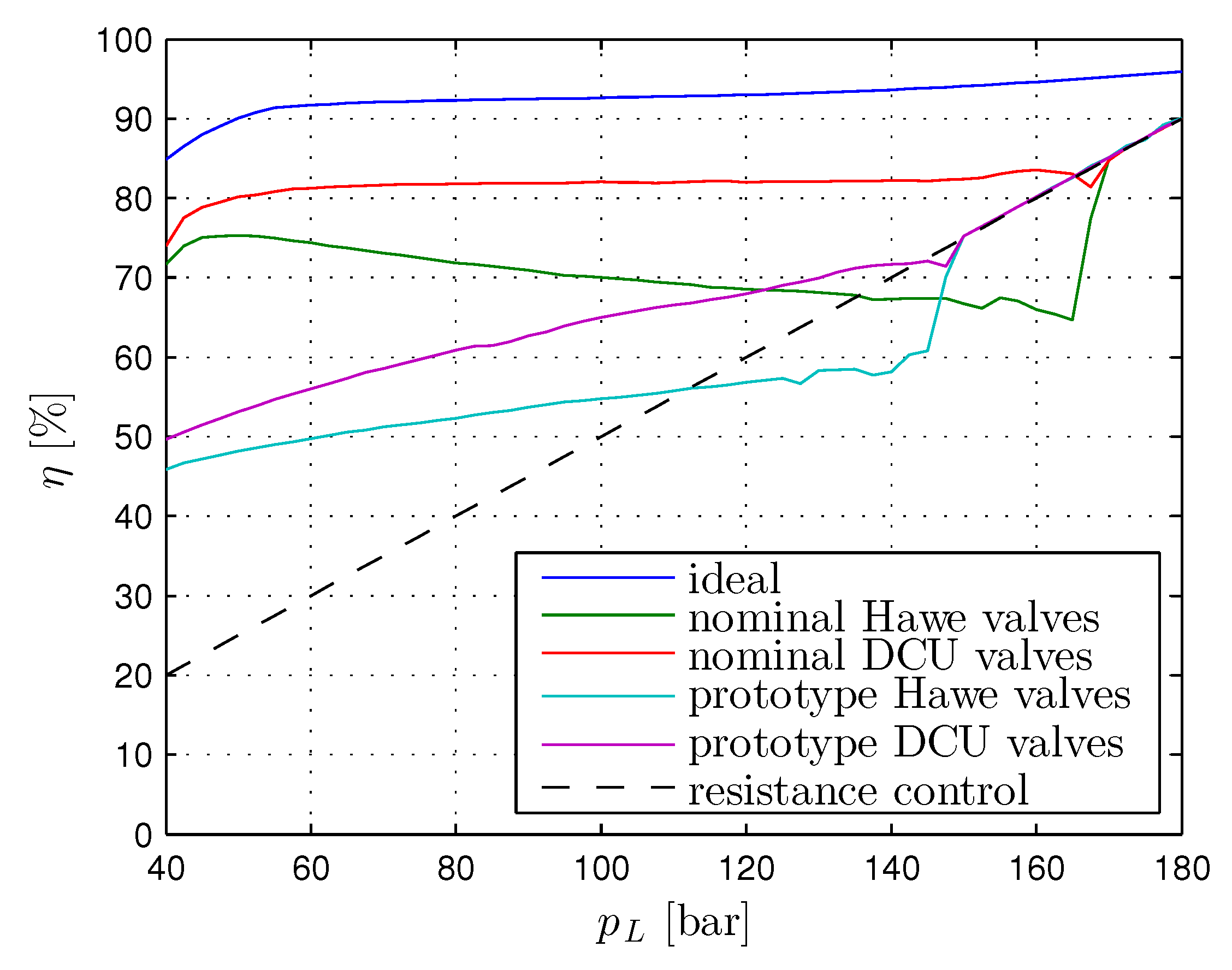

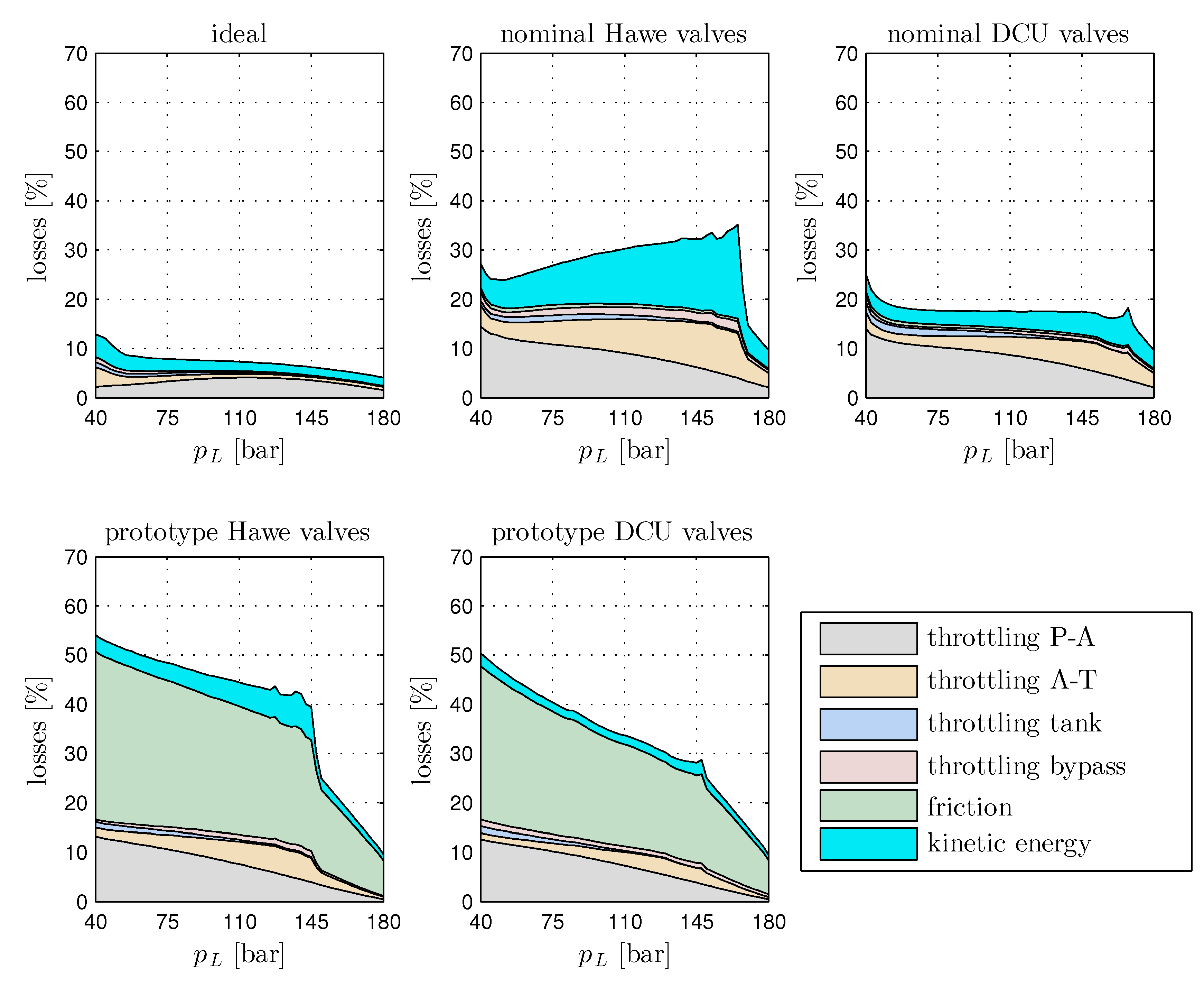

The simulation results according to the measurements showed that the energy efficiency can be improved by a faster check valve and a improved bearing and sealing system of the piston. In this section the developed check valve and bearing system with the corresponding simulation models are presented.

3.1. Fast Plate Type Check Valve

Many researchers in the field of fast switching hydraulic systems, particularly in high frequency oscillation pumps and hydraulic converters, classified the valves as bottleneck of these systems (Leati [

23] and Kogler [

24]). Various problems like cavitation, overpressure peaks and cross-flow can occur if the valve is not fast enough in relation to the movement of the piston.

Such fast check valves are not commercially available. Thus, a fast check valve (DCU) had to be developed for the HSD. A fast dynamic response of the valve is required to minimize the overpressure, back flow and cavitation effects. The technical needs on the check valve design can be summarized as:

a small moving mass (plate and equivalent spring mass) in conjunction with a stiff spring

a large active diameter

a sufficient large flow passage

a reduced dead volume and short connections

The opening dynamics of the valve depends strongly on the active diameter (diameter on which the difference pressure acts) and the mass of the plate. A small mass of the plate in conjunction with a stiff spring ensures a high closing dynamics. To minimize the valve losses and enable a fast response, the flow passage should be relatively large compared to the maximum stroke of the plate. To achieve these high flow rates at small plate displacements a multi-disc plate is utilized (Hoerbiger plate principle). This multi-disc plate uses multiple metering edges to increase the flow at a certain displacement. A design with three metering edges turned out to be an optimal solution for the given valve size.

To achieve a compact design of the check valve, instead of the coil spring a wave type spring from the company Smalley

® was selected. This wave spring has half of the volume of a coil spring [

25]. Durability problems, as reported by Leati [

23], can be avoided if the maximal compression of the spring is less than the working displacement given by the data sheet. The developed valve was in use for more than 5 million cycles without any problems.

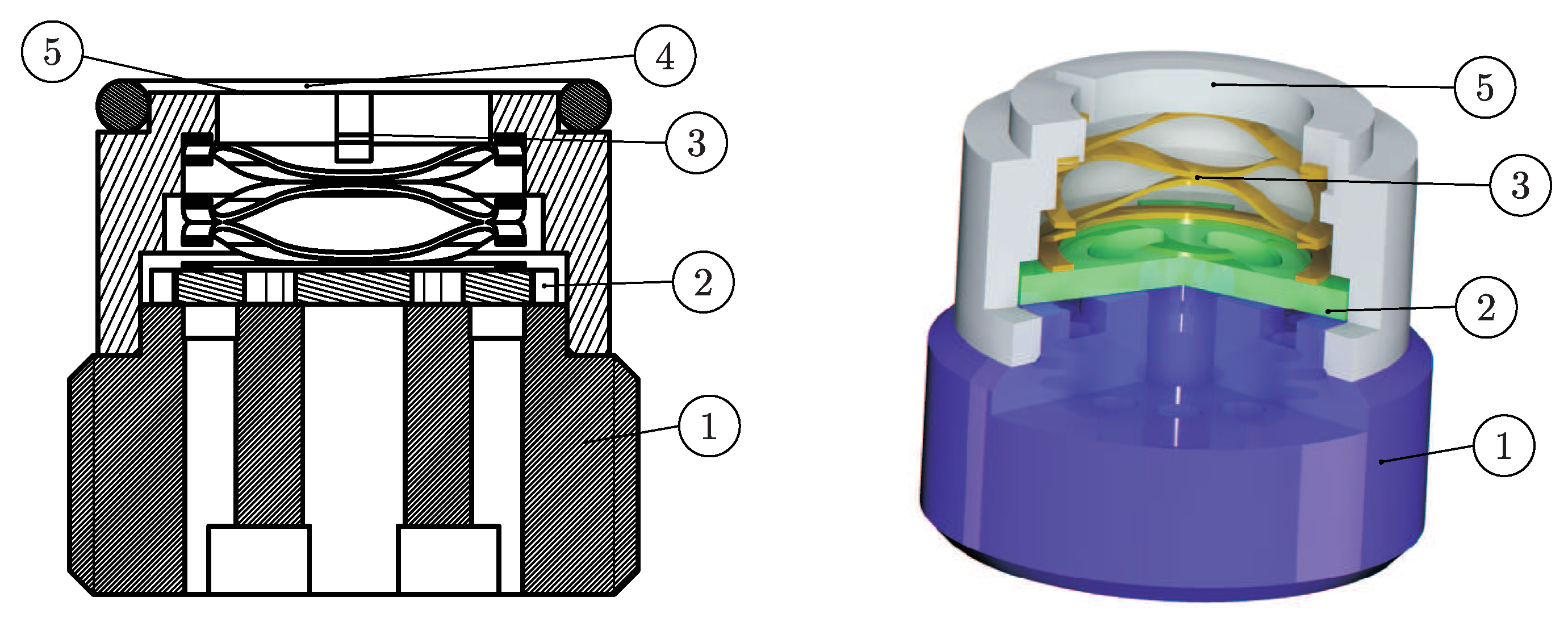

In

Figure 9 the mechanical design of the check valve with the mechanical parameters listed in

Table 1 is shown. The check valve has a full opening stroke of

. Comparable, commercially available valves have a stroke from

up to

. The check valve was designed with a

and

thread.

The plate has a thickness of (what can be further optimized) and was produced by water jet cutting to avoid thermal and mechanical distortion. The nominal overlap between body and plate is . This overlap is necessary to ensure a nearly leakage free valve, particularly if manufacturing tolerances are taken into account.

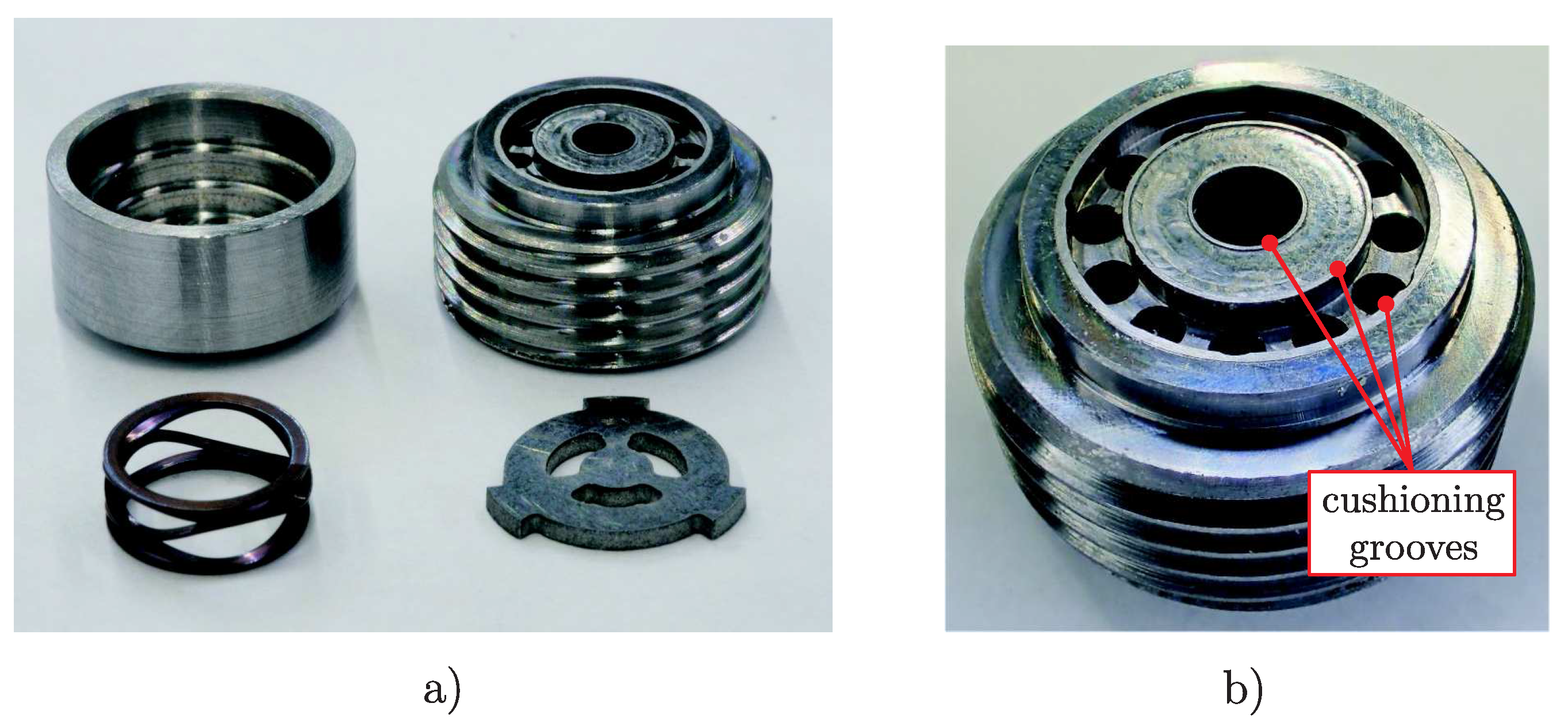

To reduce the landing speed of the plate at the end stops (and further to limit the wear and noise), a novel groove cushioning mechanism is applied. This kind of cushioning groove is a very simple, compact and cheap solution and can be integrated easily. Also well-known oil stiction problems of parallel gaps, as a strong response delay, can be minimized. Details to the concept were published by Scheidl et al. [

26].

In

Figure 10 the prototype of the DCU G3/8 check valve is depicted. The body and the housing are pressed together with an interference fit.

In the simplest possible case check valves are treated as logic elements. The valve opens and the flow can pass if the pressure difference is positive. In the opposite case, the flow is prohibited and the valve closes immediately when is negative.

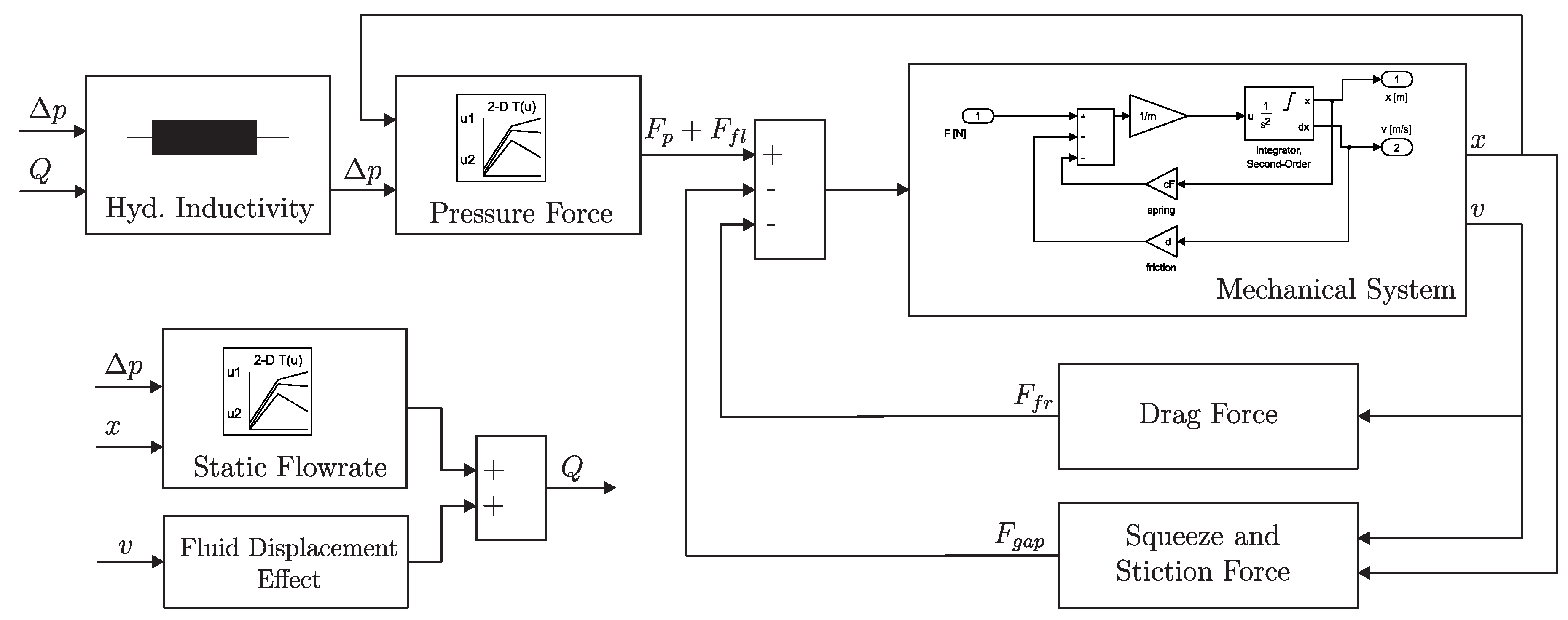

If the valve response has influence on the overall system behaviour a more elaborate model is necessary. Although the mechanical design of check valves is simple, the detailed physical descriptions of the dynamics and the flow processes are rather complex. With a generic model the influence of various effects and the related design parameters can be studied easily with one simulation model. The structure of the developed check valve model in Simulink, which was used for the simulations, is depicted in

Figure 11.

The flow rate can be calculated with CFD simulations or with an analytical model. In both cases the flow rate due to the fluid displacement effect of the moving valve plate can be included. The pressure force can be determined from the CFD simulation results or with an analytical model by specifying the active area on which the pressure acts and a flow force coefficient. The plate dynamics are modelled with the momentum equation of the valve plate.

The squeeze and stiction force model is also part of the generic simulation model. More details about the squeeze and stiction force model as well as the other modelled effects were published by Leati et al. [

27].

Calculations based on analytical models only provide an initial approximation of the characteristic of the valve. With the power of CFD tools, advanced numerical analysis can be done to identify the flow and force characteristics of valves. The developed check valve was extensively analysed by means of the open source CFD software OpenFoam.

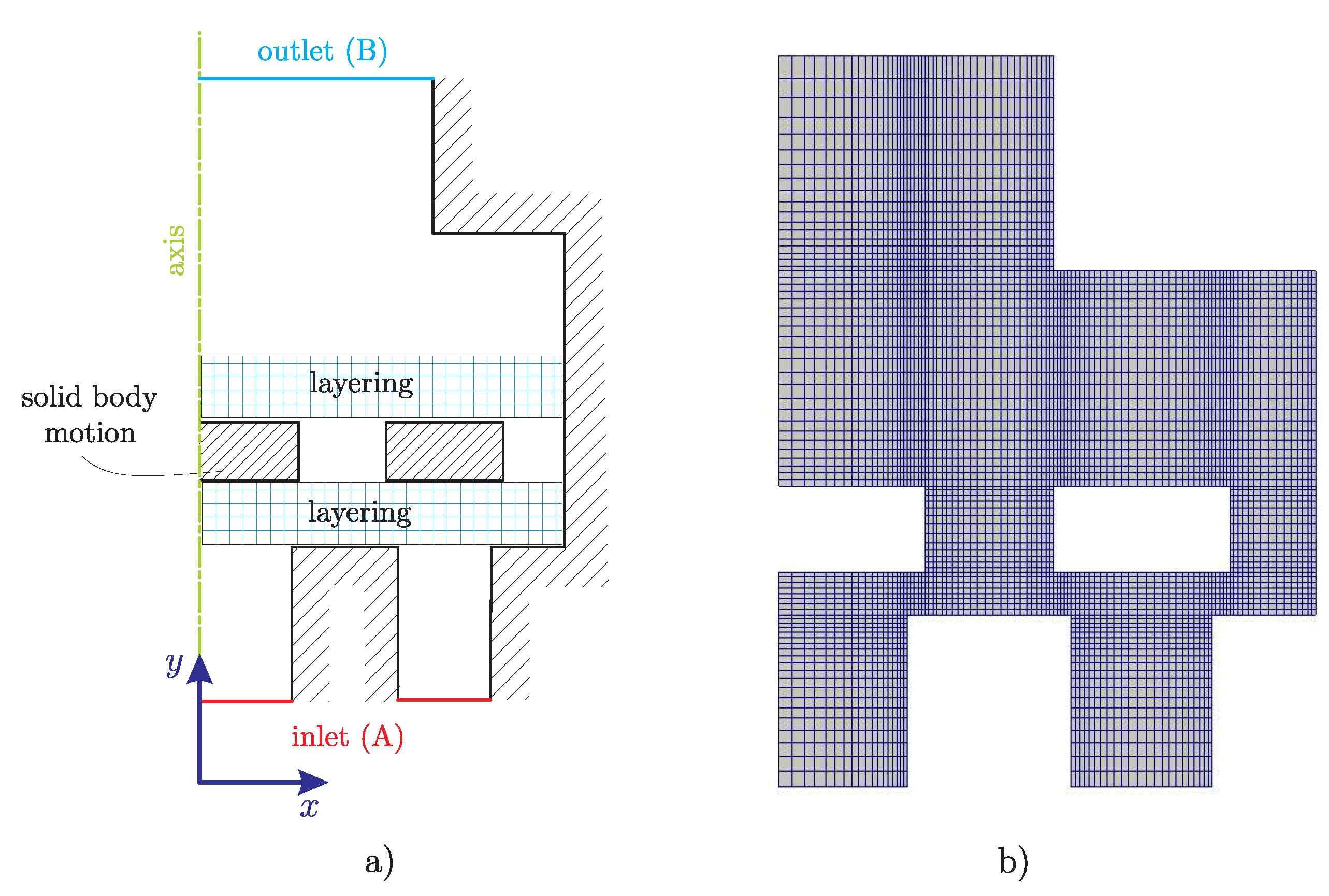

The geometry of the check valve is assumed to be axisymmetric. Due to the design of the valve the spring is not considered. The wedge shaped computational domain has been discretised by

hexahedral cells. The grid resolution in the gap between plate and housing is 190 points in radial and 18 points in axial direction and corresponds to an average cells size of ≈

.

Figure 12 shows the computational domain and the corresponding mesh (for visibility each second point is shown only).

The 3d mesh with a resolution of 200 points around the circumference was generated by rotating the 2d mesh around the central axis. The generated mesh has one million hexahedral cells.

A mesh convergence study was carried out for the 3d and 2d meshes by computations with coarser and finer resolutions. For the 2d simulations (laminar and

SST turbulence model) the mesh with 25,000 cells is sufficiently fine to predict the flow behaviour of the check valve. The mesh resolution of one million cells in 3d delivers quite good results for laminar and LES simulations. For a Direct Numerical Simulation (DNS) a finer resolution in several areas is necessary to resolve the smallest eddies. The final mesh for the DNS has two million cells and meets the requirements of the Kolmogorov microscale for small difference pressures. The Kolmogorov microscale is the smallest scale in turbulent flow, in which viscosity dominates and the turbulent kinetic energy is dissipated into heat as described by Hoffmann et al. [

28].

On both ports of the valve an uniform pressure boundary condition was applied. The surfaces of the housing and the plate are considered as walls.

A proper estimation of the turbulent phenomena is important to determine the check valve flow characteristics. One of the most suitable turbulence models for this kind of flow is the SST. Default values for the model constants were used. A no-slip boundary condition was imposed on the walls (housing and plate) of the valve. No wall function was used because of the small values near the wall. Also the boundary conditions at the inlet and outlet have to be specified for the turbulent quantities, which were done by specifying the turbulence intensity with 5% and the turbulence length scale (hydraulic diameter of the inlet and outlet). The LES simulations were performed with an one equation eddy viscosity turbulence model with the default values of the model constants.

For the simulations the pimpleFoam solver with linear interpolation schemes was used and convergence of each simulation was checked by means of relative and absolute residuals.

OpenFoam’s dynamic mesh capability is used to simulate problems where the mesh is distorted due to the motion on the boundaries. Also the plate type check valve’s plate motion is fully considered in the remeshing procedures. Therefore the equation of motion of the plate has to be solved at each time step.

There are different dynamic mesh schemes predefined in OpenFoam, namely, smoothing, layering and re-meshing. Also a combination of these three schemes can be used in one case and so the most challenging dynamic mesh problems can be solved. However, the plate motion of the check valve is only a linear boundary motion.

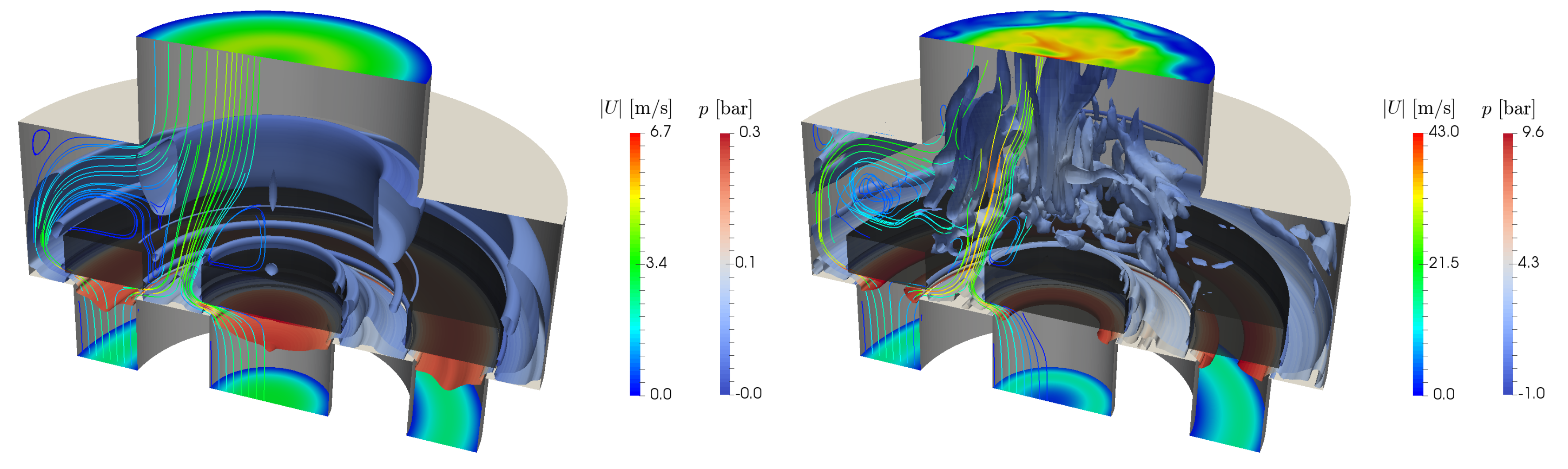

For example the flow characteristics were studied and the transition between the laminar and turbulent flow regime by means of DNS. In

Figure 13 the flow through the check valve for two different pressures are shown. For example, the simulation needed a computation time of 48 h on 12 cores of an Intel Xeon E5-2680 v3 CPU with 2.5 GHz. The vortices are illustrated by

isosurfaces. The

-criterion is based on the velocity gradient tensor

and proposes that the second largest eigenvalue

of the symmetric tensor

at each point is negative inside the vortex core (Jeong and Hussain [

29]). The gradient velocity tensor can be decomposed in the symmetric components

and antisymmetric components

. Also the velocity streamlines show the vortices in the flow regime. For

the

isosurface is symmetric and the streamlines indicate a laminar flow through the valve. The streamlines which have the source on the depicted plane stay on this plane. For a turbulent flow regime the streamlines do not stay in the same plane due to the stochastic behaviour of the flow. For

the turbulent streamlines can be seen clearly. The

isosurface shows the stochastic structure of the vortices.

In dynamic simulations the mesh changes over time due to the motion of the plate. The layering method is used as depicted in

Figure 12. A new dynamic mesh class based on the

movingConeTopoFvMesh class was developed. The

sixDoFRigidBodyMotion class was included to treat the motion of the plate.

The valve plate has only one translational degree of freedom and a tilting of the plate is not taken into account. A quite fine mesh was used in the area of the closing gap to resolve the flow inside the gap domain.

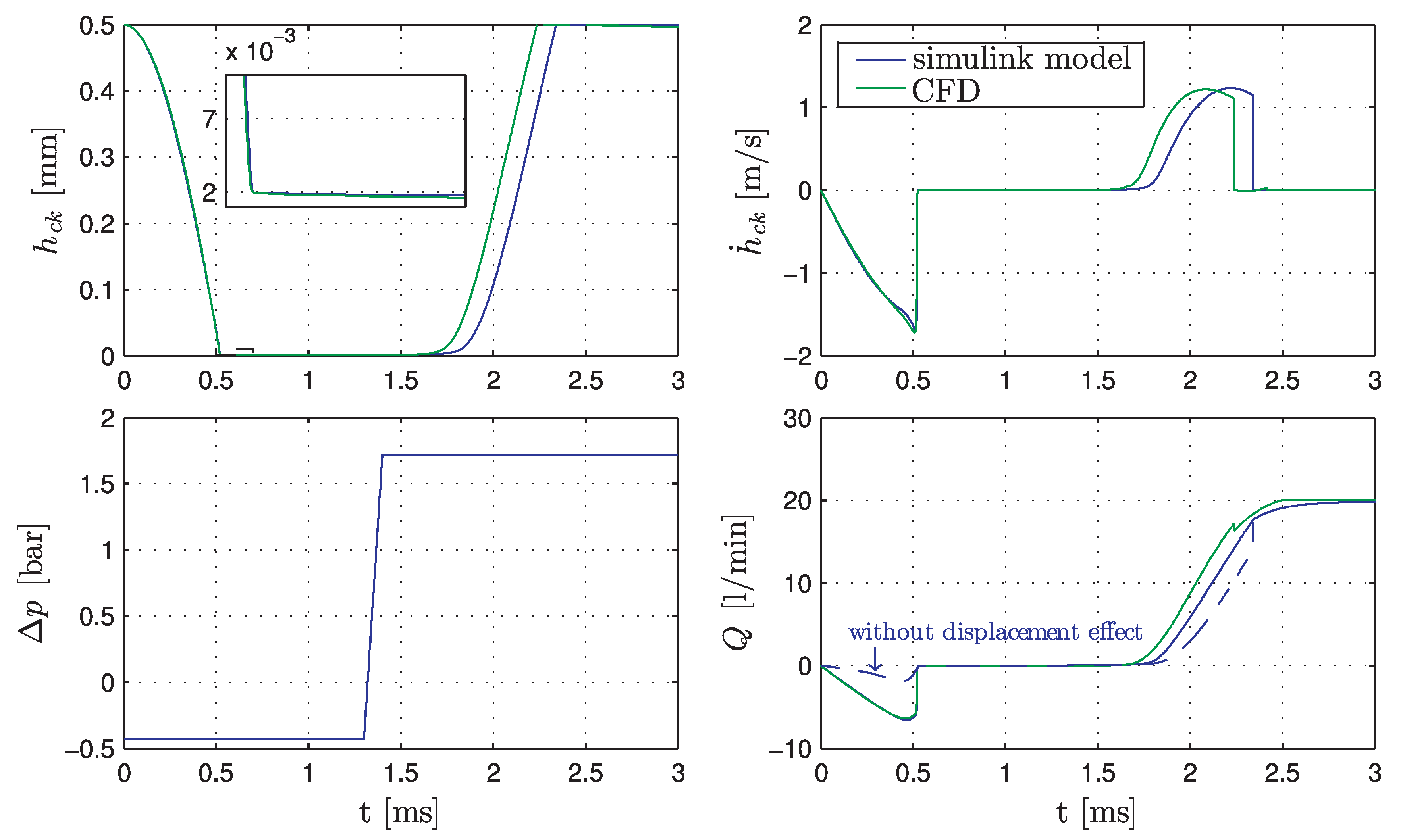

Figure 14 compares the results of the numerical CFD simulation performed by the

pimpleDyMFoam solver with the developed simulation model (see

Figure 11) for a given difference pressure profile

. At the beginning of the simulation the check valve is in the fully opened position and the difference pressure is zero. At

the difference pressure is quickly decreased from

to

. Due to the decreasing pressure and the spring force the plate begins to move and to close the check valve. The oil squeeze force limits the fast closing the check valve. The minimum gap height between valve plate and housing for the closed check valve is below

for the given geometry and pressure profile. The minimum gap height influences the magnitude of the stiction force which causes a response delay in valve opening.

At the difference pressure is increased to . The stiction forces cause a substantial response delay in valve opening of approximately . The CFD model response due to the pressure increase is faster than the developed Simulink model. This difference can have various reasons, such as the inductance effects of the inlet and outlet areas or the highly distorted mesh (high aspect ratio) in the fluid gap between housing and plate in the closed position of the valve.

Figure 14 shows a good accordance of the CFD simulation and the simulation model in Simulink depicted in

Figure 11 and confirms that the complex flow and motion behaviour can be described with a simplified model which could be included in more complex simulation models of hydraulic circuits with other hydraulic components involved. Further, the influence of the fluid displacement effect to the flow rate during the switching can be clearly seen.

3.2. Combined Hydrostatic Hydrodynamic Bearing System

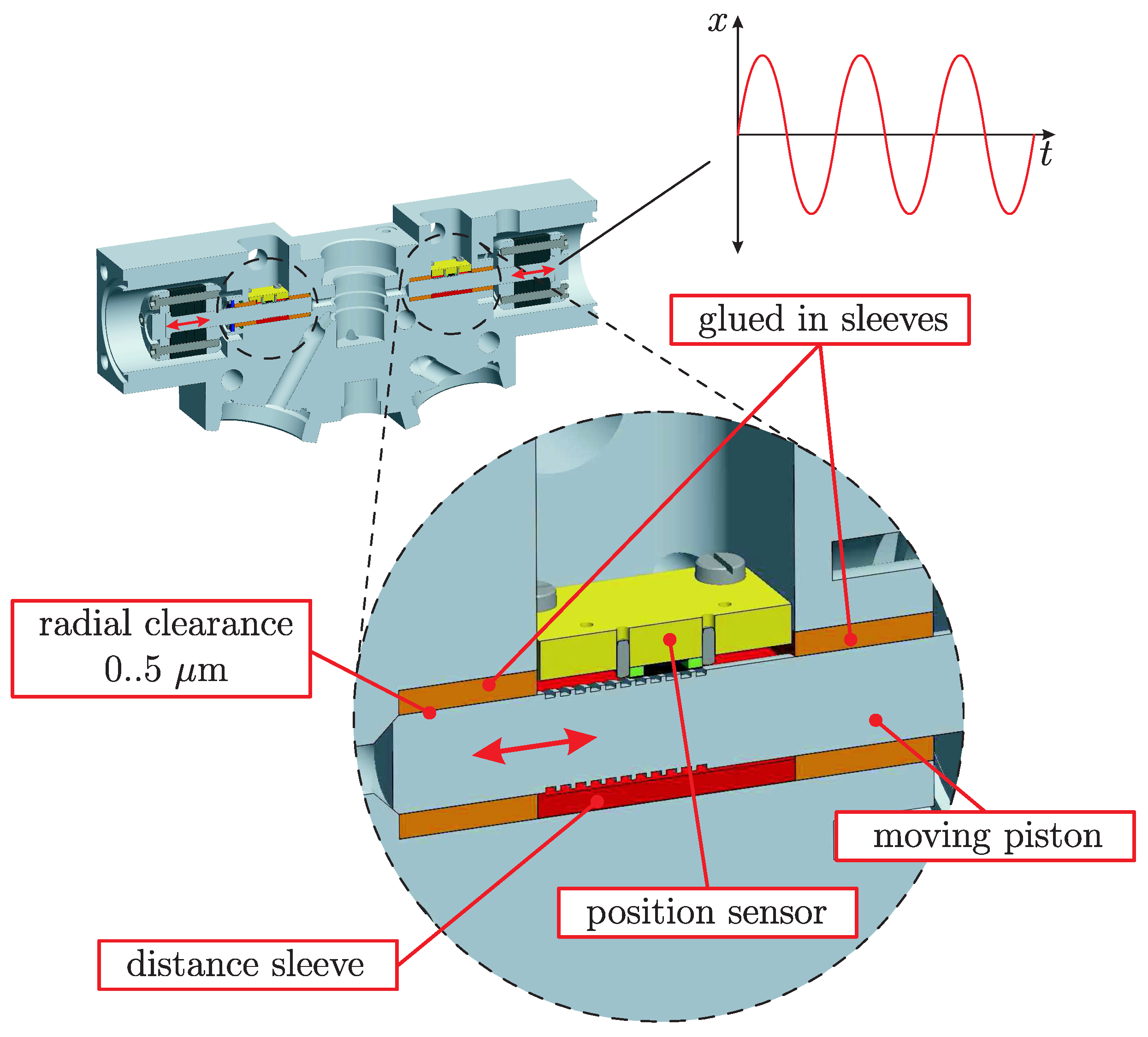

The initial guidance system depicted in

Figure 15 consists of two short steel sleeves to guide the piston made of steel. Between both steel sleeves the position sensor is placed. The corresponding sensor installation chamber is connected to the leakage line. The pistons with the additional masses are oscillating with a frequency up to

and an amplitude of

. The pressures at both ends of the pistons vary from 0–250

according to the operation principle and depending on the actual load of the hydraulic converter.

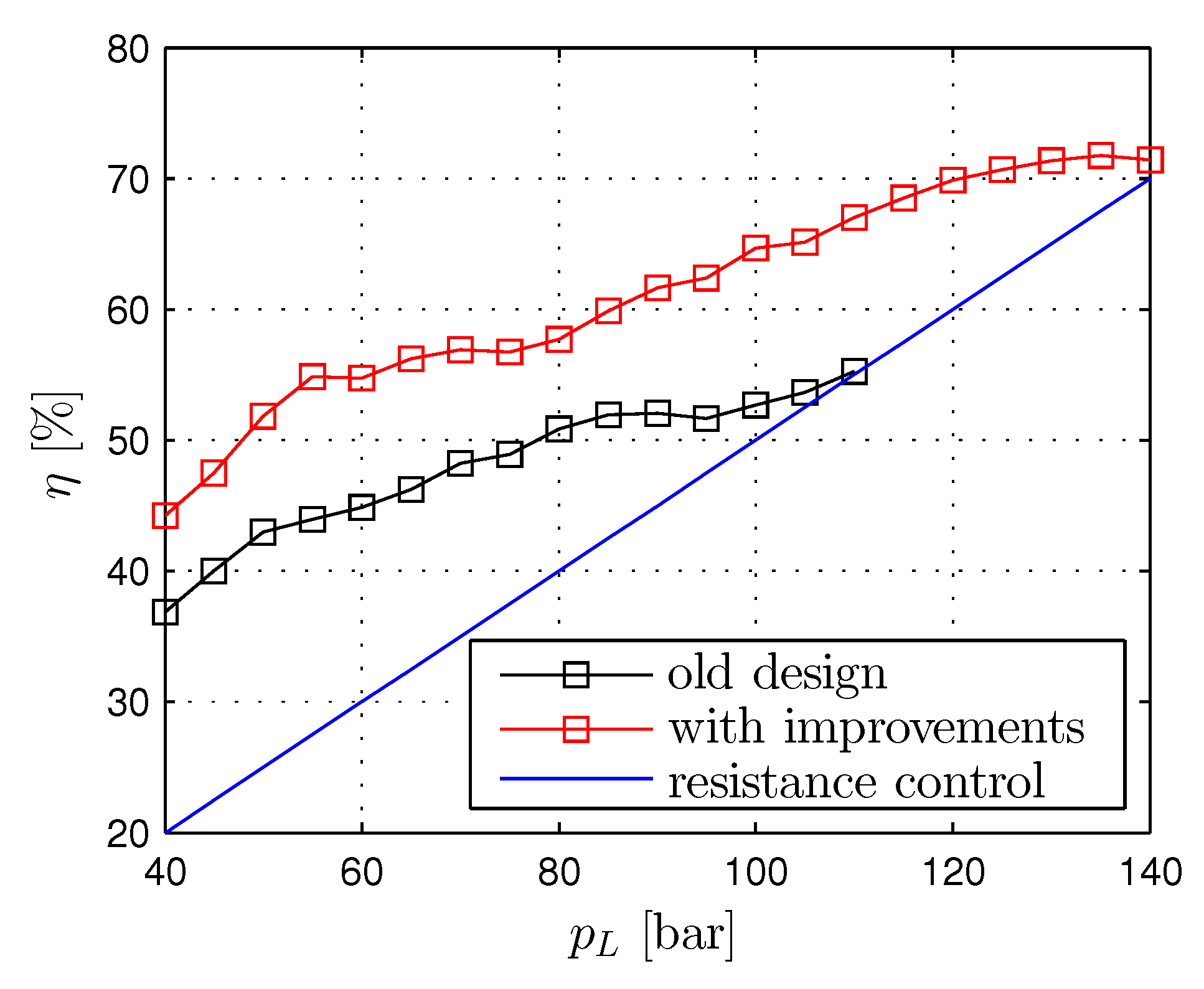

The resulting gap geometry results in a destabilizing behaviour of the piston and leads to an increased friction force. As consequence, the energy efficiency is drastically reduced as reported in

Figure 8. Hence, an improved guidance system based on elastic deformation was developed. A hydrostatic difference pressure or/and a hydrodynamic pressure deforms a PEEK piston such that a conical stabilizing sealing gap is created. The concept and further details can be found in [

30].

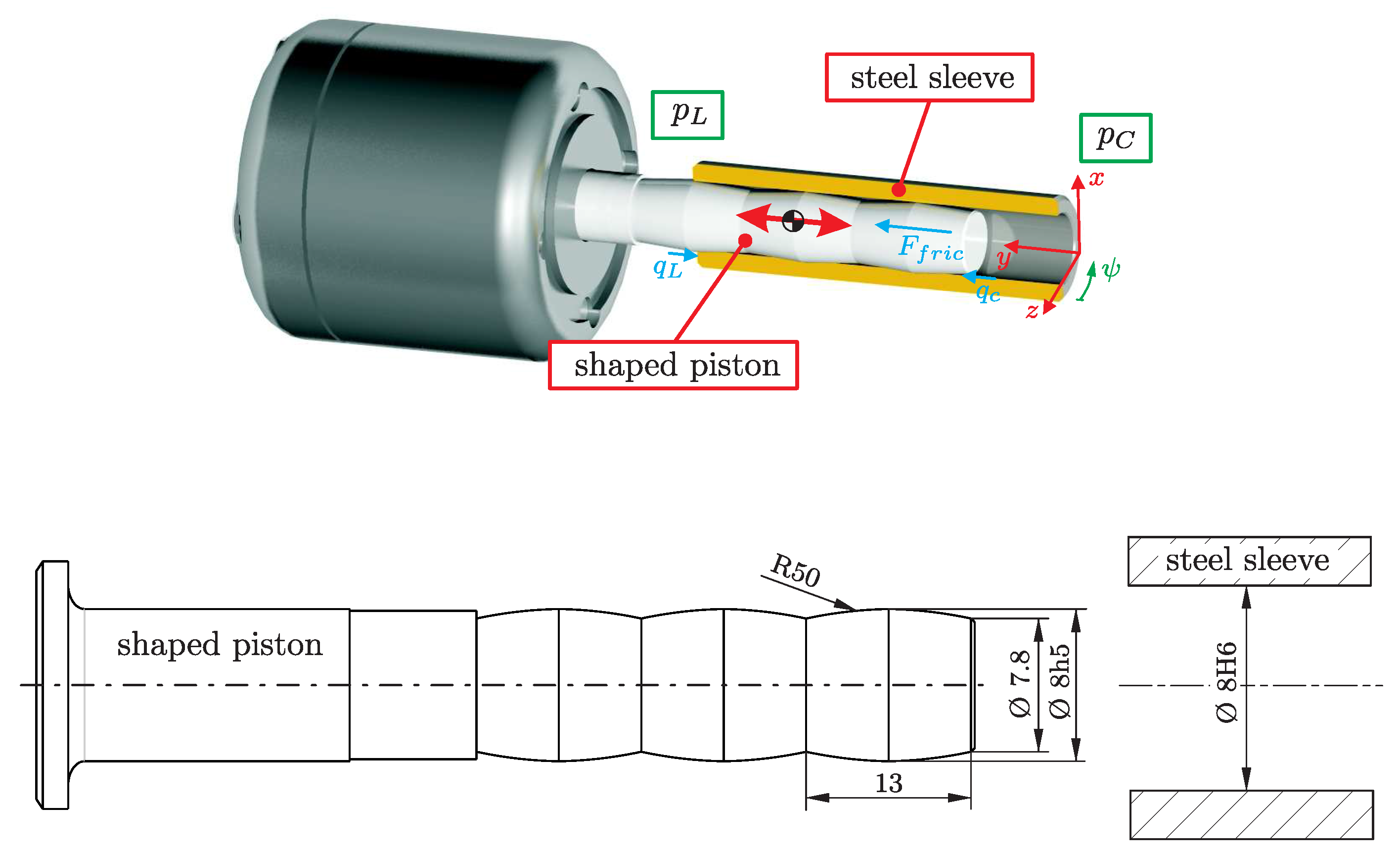

The investigated bearing sleeve cannot be used without small modifications of the HSD. Both steel sleeves and the position sensor are replaced by only one but longer steel sleeve which guides the shaped piston made of PEEK. The chosen concept is depicted in

Figure 16.

The diameter of the steel sleeve is specified as . This sleeve can be manufactured by reaming. The maximum diameter of the piston is which is reduced to . The length of one bearing segment is . According to the fitting tolerances the minimum gap height is between 0 and .

To study the characteristics of the bearing system the finite element suite Abaqus was used. A Reynolds User Element was developed and included into Abaqus for the simulation of the fluid structure interaction. The Reynolds equation is discretised by finite elements and solved simultaneously with the mechanical model.

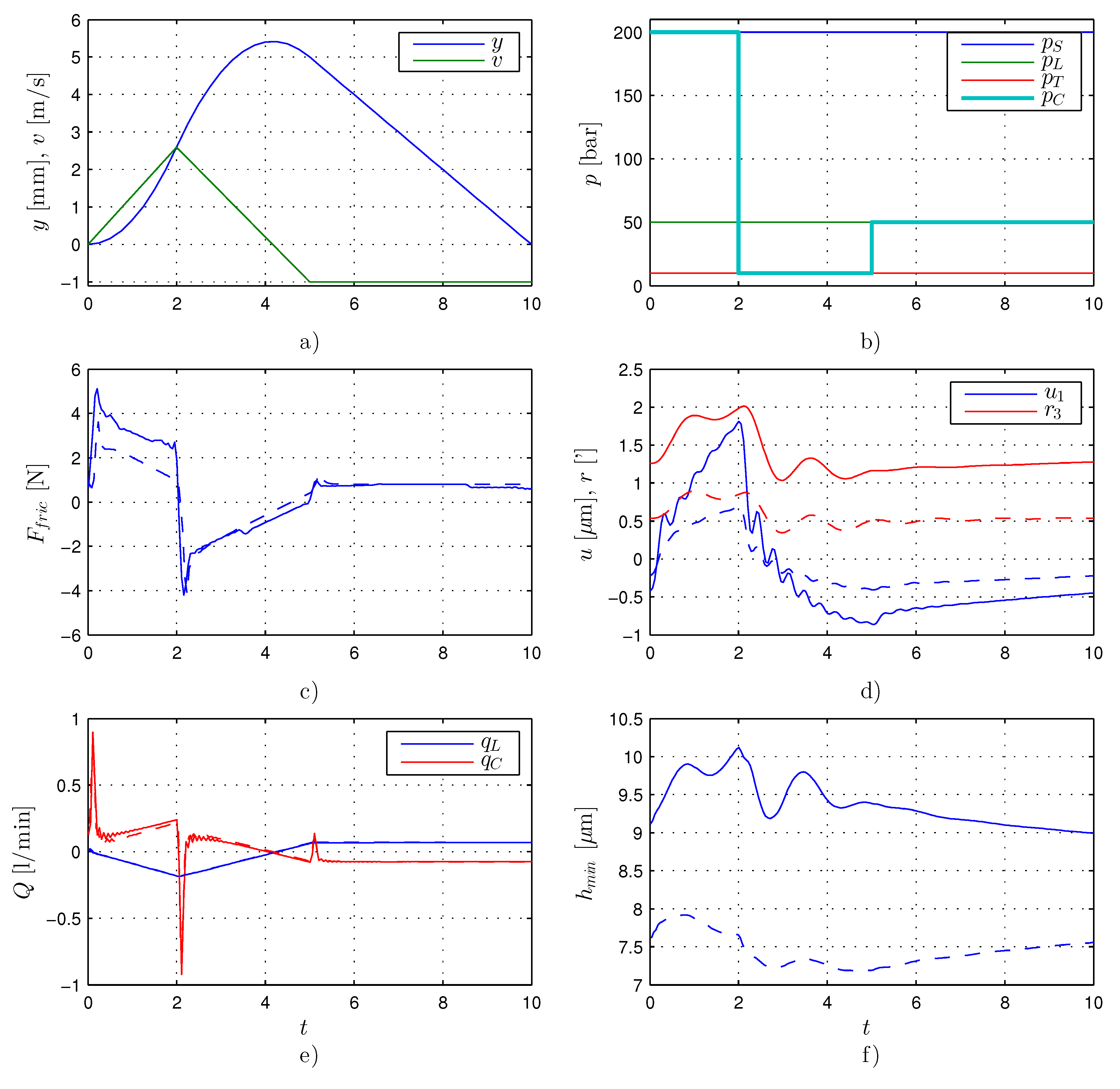

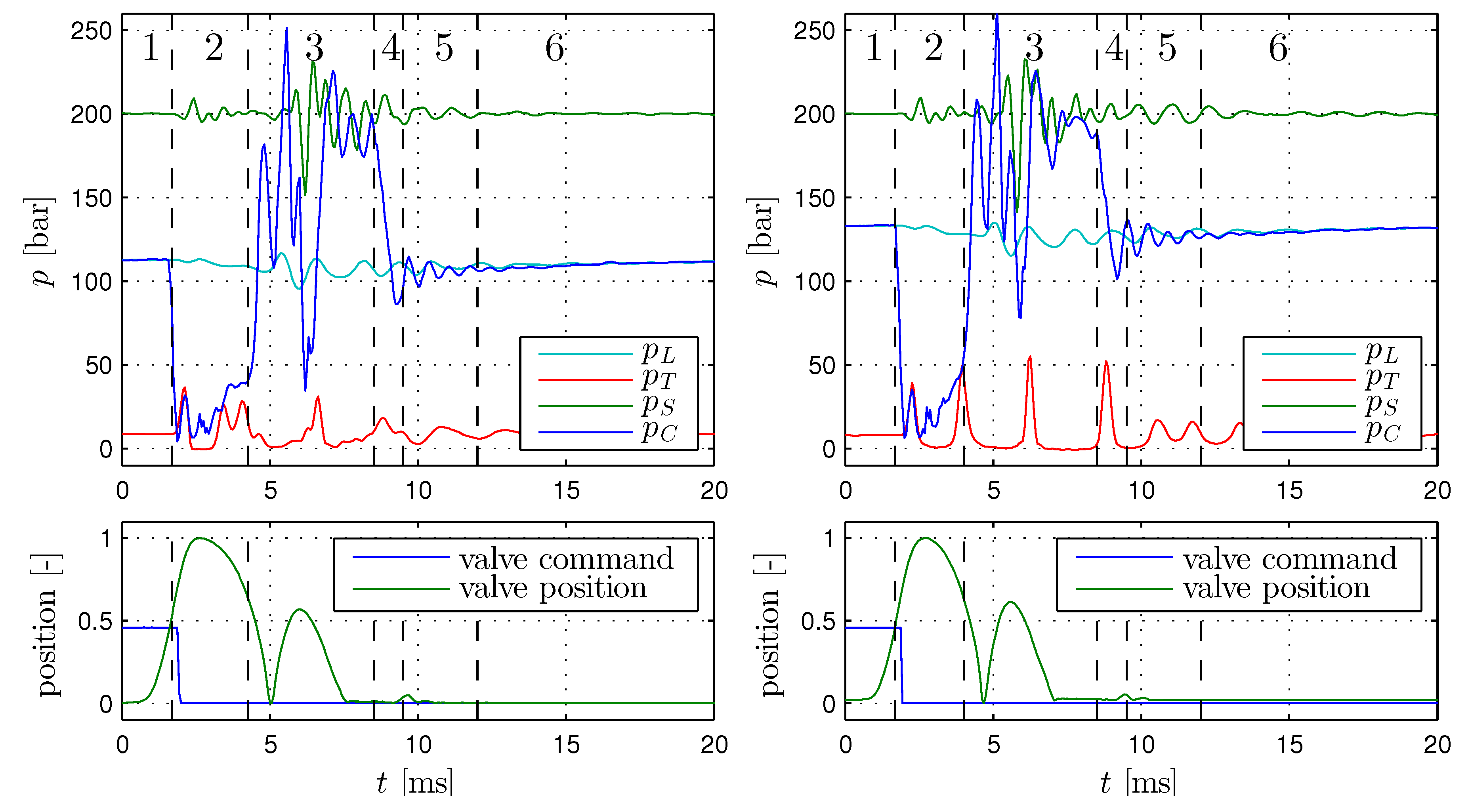

The purpose of the numerical analysis of one operation cycle is to demonstrate the behaviour of the bearing system for variable pressure boundary conditions under normal HSD operation conditions. Simplified position, velocity and boundary pressure profiles as depicted in

Figure 17a,b were used for the following Abaqus simulations. The system pressure

, tank pressure

and load pressure

are set to

,

and

, respectively. The chamber pressure

is switched between these values.

In

Figure 17c–f the simulation results for two values of the minimal nominal fluid gap (solid lines for

and dashed lines for

) can be seen. The friction force

has its maximum with ≈

near the point of the maximum velocity of the piston as illustrated in

Figure 17c. A smaller nominal gap height leads to a reduction of the friction force. Compared to the estimated friction forces of the previous bearing concept (see

Figure 15) this is a significant improvement. It should be mentioned that

summarizes the Couette and Poiseuille contributions of the shear forces. The results for the eccentricity

and tilt

in

Figure 17d show that the piston is stabilized in an appropriate manner.

The boundary flows

and

, depicted in

Figure 17e, show the influence of the elastic deformation of the piston. The flow rate peaks are at the pressure build up and pressure reduction phases. For the HSD application the elasticity of the pistons acts as additional dead volume. The mean leakage flows through the bearing are a few millilitres per minute. Friction forces and leakages through the gap between piston and sleeve represent the two main sources of energy dissipation.

The minimum fluid film height

is for the whole cycle above

for the nominal gap height of

and above

for a nominal gap height of

as shown in

Figure 17f.