Combustion Characteristics and Slagging during Co-Combustion of Rice Husk and Sewage Sludge Blends

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Ultimate and Proximate Analysis

2.3. Methods and Apparatus

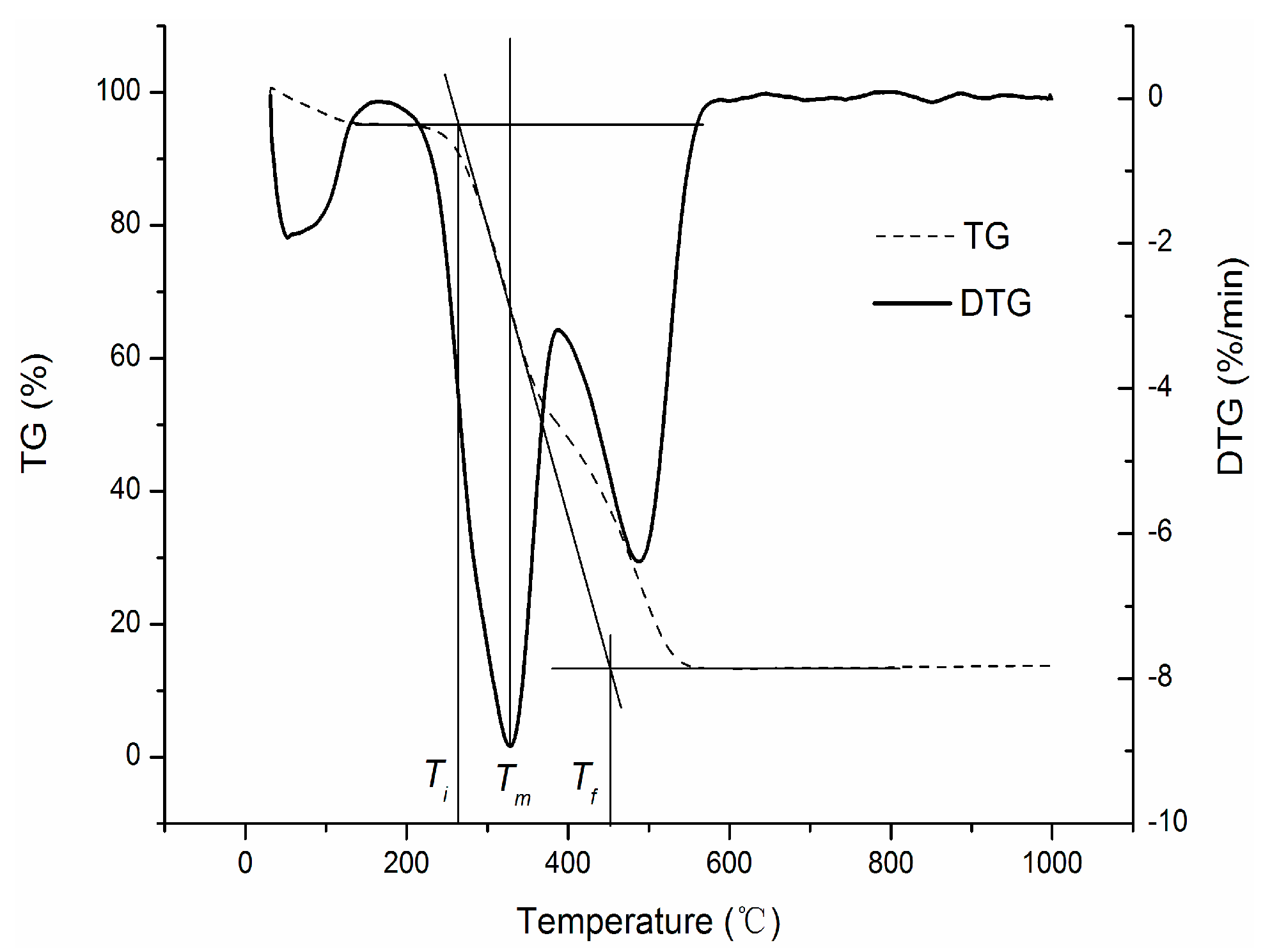

2.4. Characterizations of Ignition and Burnout

2.5. Ash Elemental Analysis

2.6. Characteristics of Ash Melting

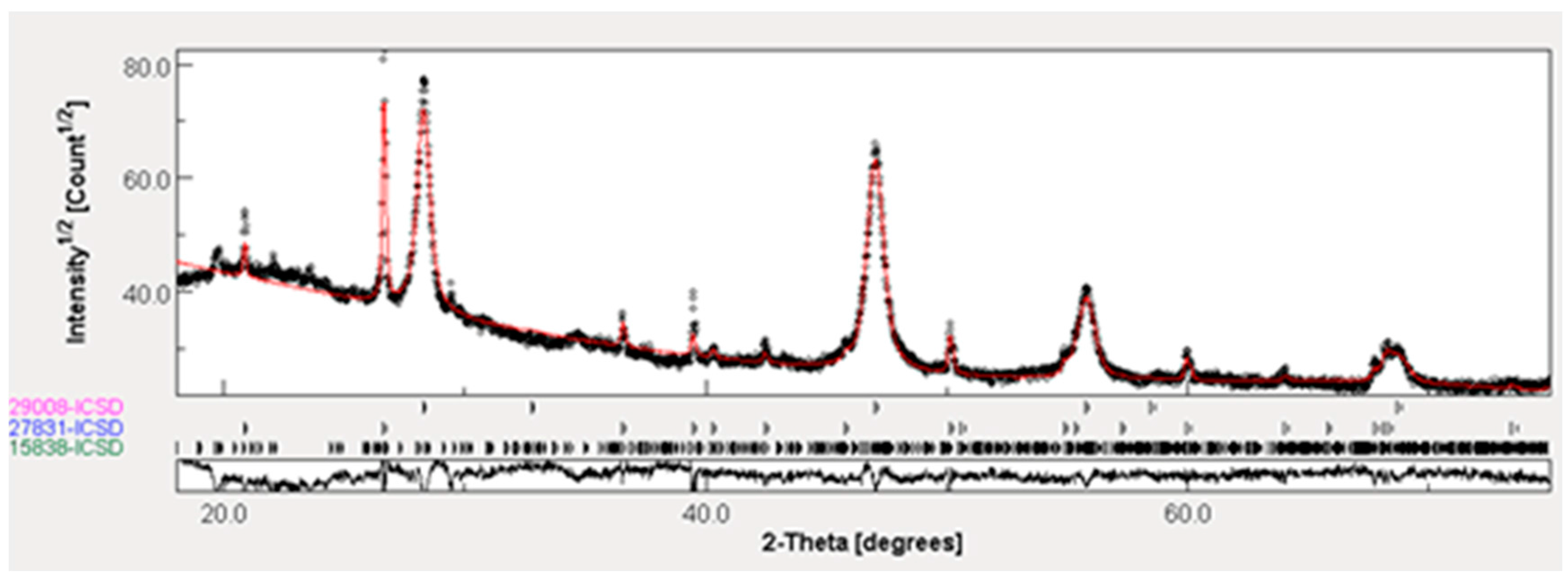

2.7. X-ray Diffraction (XRD) Quantitative Phase Analysis

3. Results and Discussion

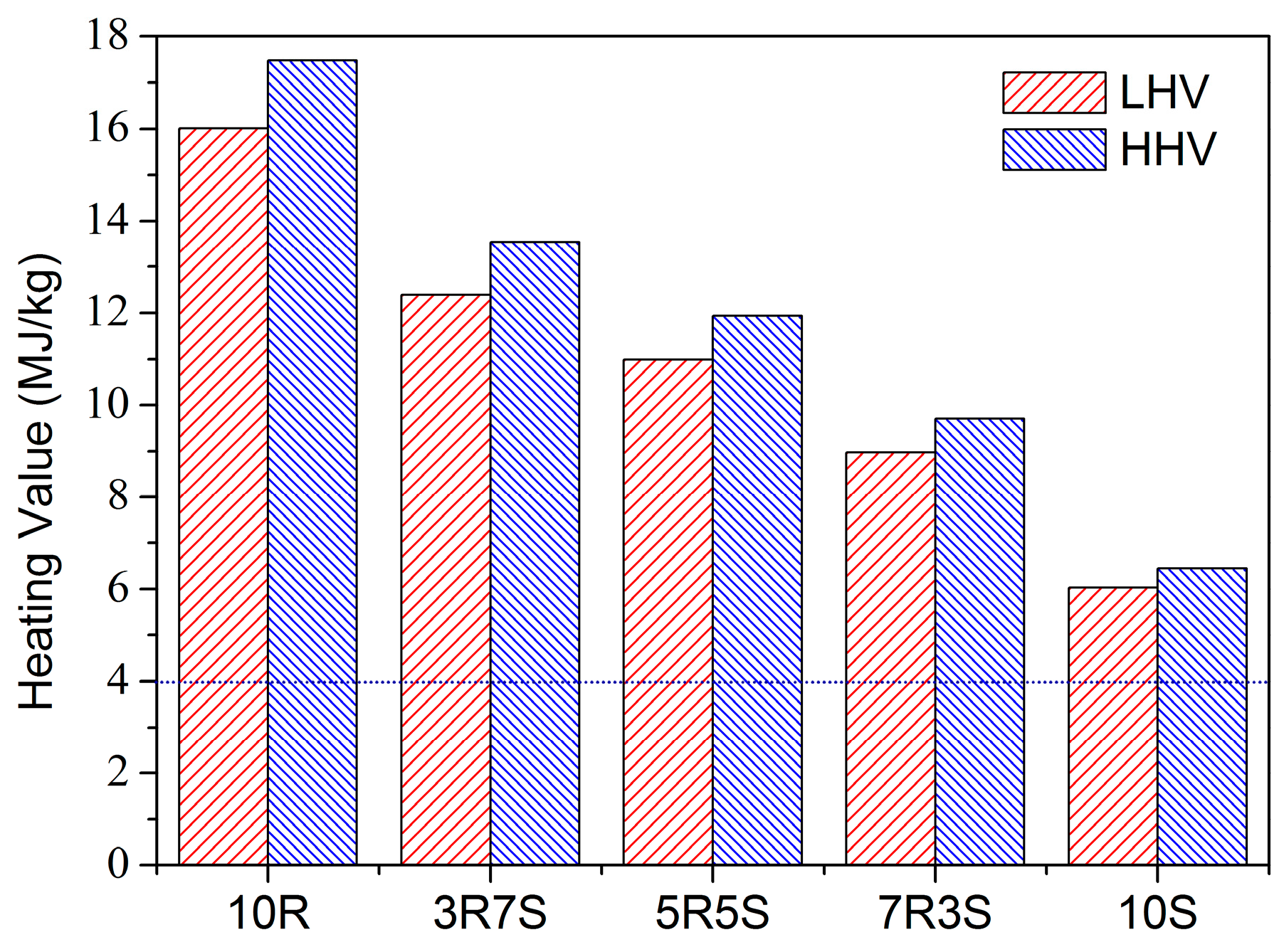

3.1. Proximate and Ultimate Analysis of Rice Husk and Sewage Sludge

3.2. Mono-Combustion Behavior of Rice Husk and Sewage Sludge

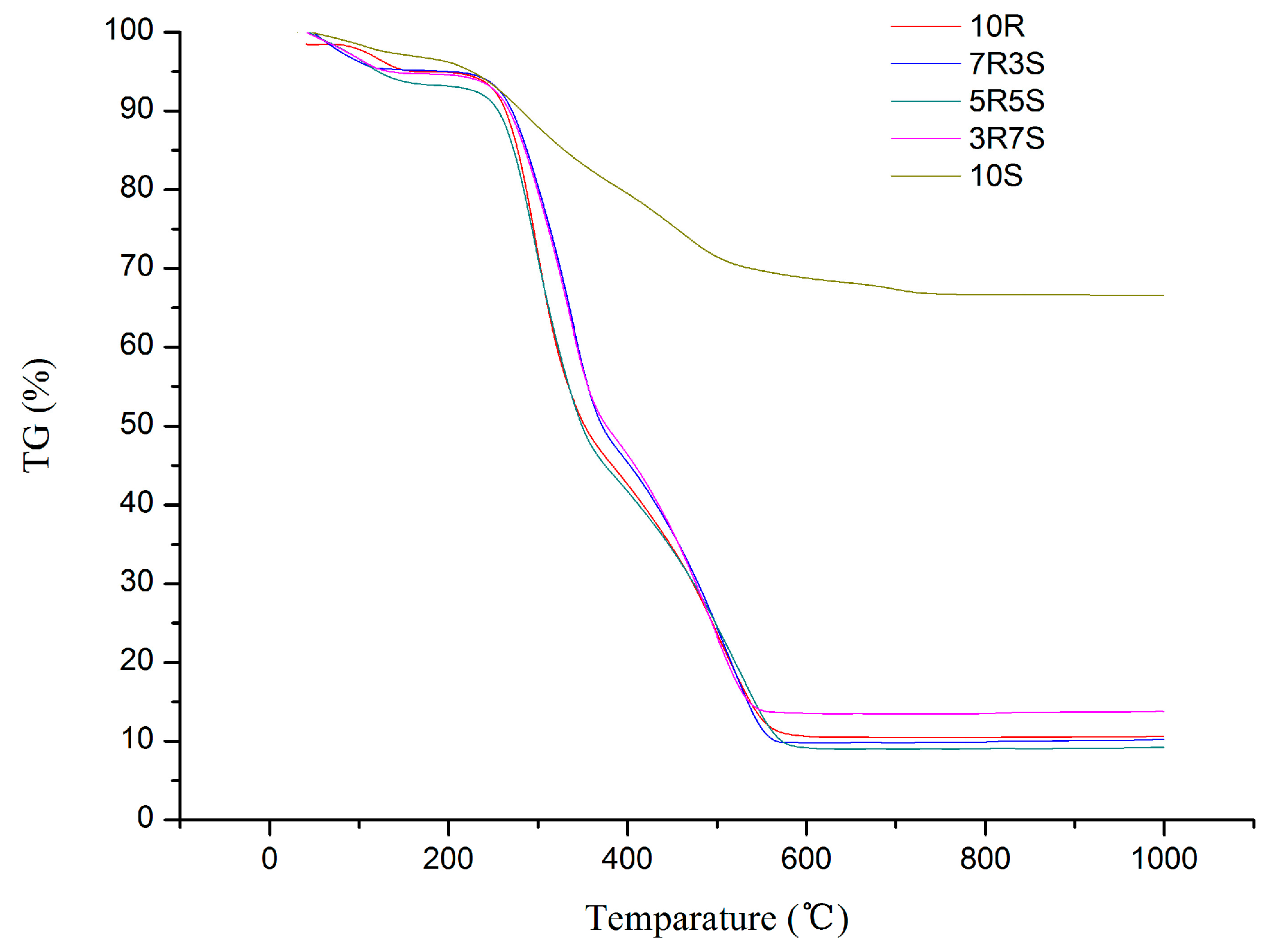

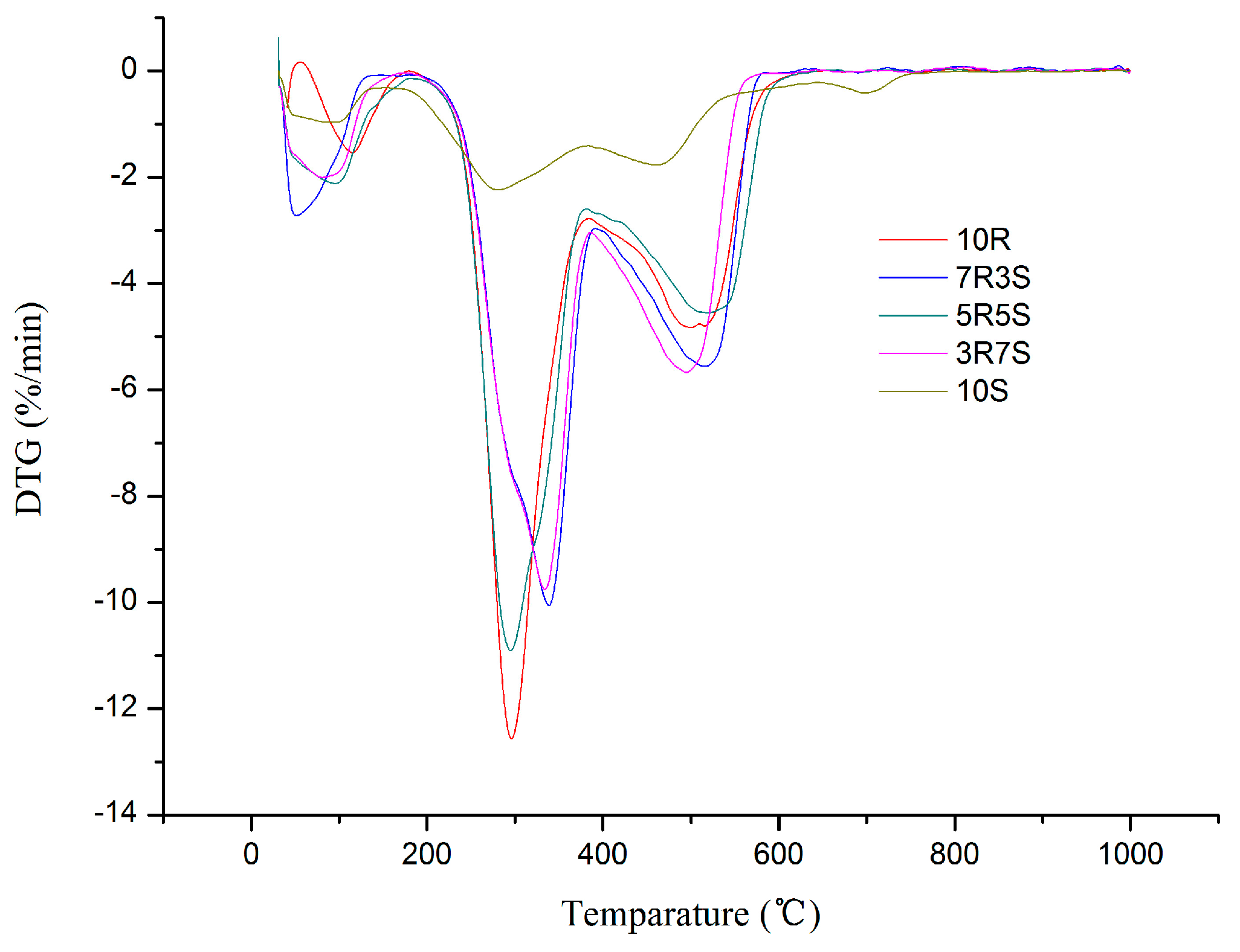

3.3. Co-Combustion Behavior of Rice Husk and Sewage Sludge Blends

3.4. Slagging Characteristics and Evaluation

3.4.1. Slagging Index Evaluation of Ash from Co-Combustion

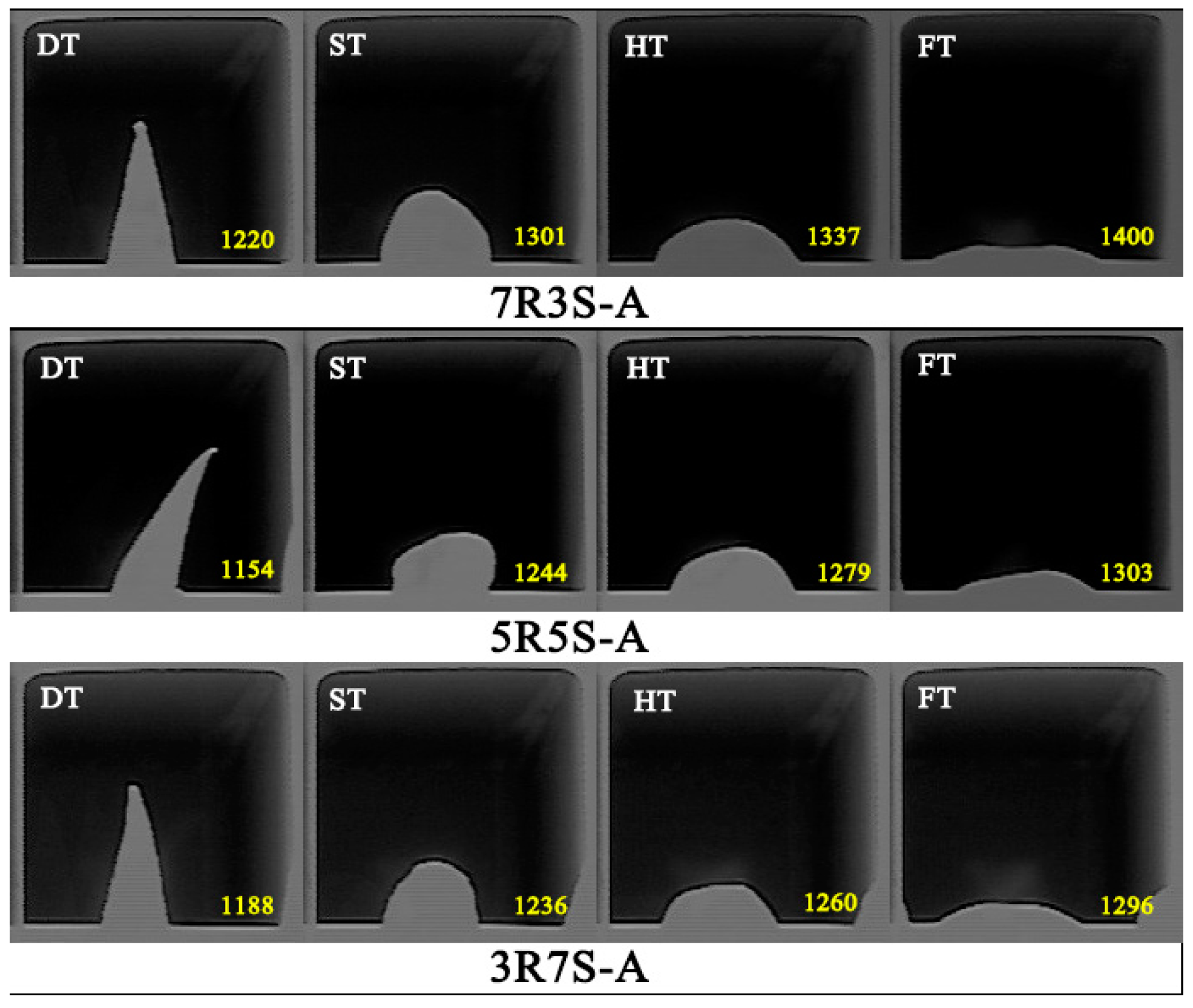

3.4.2. Melting Characteristics of Ash from Co-Combustion

3.5. Influencing Factors of Slagging Characteristics

4. Conclusions

- (1)

- The blends of rice husk and sewage sludge had high volatile matter content, low ash content. In addition, they had high hydrogen content and low contents of sulfur and nitrogen. These advantages mean that the blended fuel can provide clean and efficient energy.

- (2)

- There are four main stages of the material burning processes: dehydration, volatile oxidation, and decomposition/oxidation.

- (3)

- Di, Df, Rm of the blends increased with increasing rice husk ratio. The results not only show that the reactivity of the blends was improved by increasing the amount of rice husk, but also suggest synergistic interactions between rice husk and sewage sludge during the co-combustion process.

- (4)

- According to BAI, there was no slagging tendency in the blended fuel, but according to B/A, ST, and DT, the slagging potential of the blends increased with increasing sewage sludge content. Hence, the ratio of sewage sludge in the blends should not exceed 30%.

- (5)

- Thus far, experimental studies have been conducted at the laboratory scale. Future studies are aimed at investigating combustion characteristics and slagging during co-combustion of the blends in a pilot scale fluidized bed incinerator, as well as fly ash proposal and pollutant emission (SOx and NOx).

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the chemical composition of biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Kastanaki, E.; Vamvuka, D. A Comparative reactivity and kinetic study on the combustion of coal-biomass char blends. Fuel 2006, 85, 1186–1193. [Google Scholar] [CrossRef]

- Lo, K.-C.; Wu, K.-T.; Chyang, C.-S.; Ting, W.-T. A new study on combustion behavior of pine sawdust characterized by the Weibull distribution. Chin. J. Chem. Eng. 2009, 17, 860–868. [Google Scholar]

- Werther, J.; Ogada, T. Sewage sludge combustion. Prog. Energy Combust. Sci. 1999, 25, 55–116. [Google Scholar] [CrossRef]

- Werle, S.; Wilk, R.K. A review of methods for the thermal utilization of sewage sludge: The Polish perspective. Renew. Energy 2010, 35, 1914–1919. [Google Scholar] [CrossRef]

- Aziz, M.; Budianto, D.; Oda, T. Computational fluid dynamic analysis of co-firing of palm kernel shell and coal. Energies 2016, 9, 137. [Google Scholar] [CrossRef]

- Kalembkiewicz, J.; Chmielarz, U. Ashes from co-combustion of coal and biomass: New industrial wastes. Resour. Conserv. Recycl. 2012, 69, 109–121. [Google Scholar] [CrossRef]

- Liu, Z.; Quek, A.; Hoekman, S.K.; Srinivasan, M.P.; Balasubramanian, R. Thermogravimetric investigation of hydrochar-lignite co-combustion. Bioresour. Technol. 2012, 123, 646–652. [Google Scholar] [CrossRef] [PubMed]

- Varol, M.; Atimtay, A.T.; Bay, B.; Olgun, H. Investigation of co-combustion characteristics of low quality lignite coals and biomass with thermogravimetric analysis. Thermochim. Acta 2010, 510, 195–201. [Google Scholar] [CrossRef]

- Fernandes, I.J.; Calheiro, D.; Kieling, A.G.; Moraes, C.A.M.; Rocha, T.L.A.C.; Brehm, F.A.; Modolo, R.C.E. Characterization of rice husk ash produced using different biomass combustion techniques for energy. Fuel 2016, 165, 351–359. [Google Scholar] [CrossRef]

- Jiang, J.; Du, X.; Yang, S. Analysis of the combustion of sewage sludge-derived fuel by a thermogravimetric method in China. Waste Manag. 2010, 30, 1407–1413. [Google Scholar] [CrossRef] [PubMed]

- Magdziarz, A.; Wilk, M. Thermogravimetric study of biomass, sewage sludge and coal combustion. Energy Convers. Manag. 2013, 75, 425–430. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, J.; Preto, F.; Zhu, J.; Xu, C. Ash deposition in biomass combustion or co-firing for power/heat generation. Energy 2012, 5, 5171–5189. [Google Scholar] [CrossRef]

- Solís, G.J.; Alonso, E.; Riesco, P. Distribution of metal extractable fractions during anaerobic sludge treatment in southern Spain WWTPs. J. Water Air Soil Pollut. 2002, 140, 139–156. [Google Scholar] [CrossRef]

- Seggiani, M.; Vitolo, S.; Pastorelli, M.; Ghetti, P. Combustion reactivity of different oil-fired fly ashes as received and leached. Fuel 2007, 86, 1885–1891. [Google Scholar] [CrossRef]

- Zhang, D.K.; Wall, T.F. Ignition of coal particles: The influence of experimental technique. Fuel 1994, 73, 1114–1119. [Google Scholar] [CrossRef]

- Altun, N.E.; Kök, M.V.; Hicyilmaz, C. Effect of different binders on the combustion properties of lignite. Part II. Effect on kinetics. J. Therm. Anal. Calorim. 2001, 65, 797–804. [Google Scholar] [CrossRef]

- Cheng, J.; Zhou, J.H.; Liu, J.Z.; Zhou, Z.J.; Cao, X.Y.; Cen, K.F. University, Hangzhou, Chi, Catalysis effect of carbide lime on various coal combustion. J. Fuel Chem. Technol. 2004, 32, 37–42. [Google Scholar]

- Hurt, R.H.; Gibbins, J.R. Residual carbon from pulverized coal fired boilers: 1. Size distribution and combustion reactivity. Fuel 1995, 74, 471–480. [Google Scholar] [CrossRef]

- Proximate Analysis of Coal; Chinese Standard: GB/T 212-2008; Standards Press of China: Beijing, China, 2008.

- Fernández-Jimenez, A.; de la Torre, A.G.; Palomo, A.; López-Olmo, G.; Alonso, M.M.; Aranda, M.A.G. Quantitative determination of phases in the alkali activation of fly ash. Part I: Potential ash reactivity. Fuel 2006, 85, 625–634. [Google Scholar] [CrossRef]

- Fernández-Jimenez, A.; de la Torre, A.G.; Palomo, A.; López-Olmo, G.; Alonso, M.M.; Aranda, M.A.G. Quantitative determination of phases in the alkaline activation of fly ash. Part II: Degree of reaction. Fuel 2006, 85, 1960–1969. [Google Scholar] [CrossRef]

- Determination of Calorific Value of Coal; Chinese Standard: GB/T 213-2003; China Standards Press: Beijing, China, 2003.

- Liu, L.; Zhang, C. Pyrolysis Characteristics and Incineration Technique during Combustion of Sludge; Central South University Press: Changsha, China, 2006. [Google Scholar]

- Wang, C.; Wang, F.; Yang, Q.; Liang, R. Thermogravimetric studies of the behavior of wheat straw with added coal during combustion. Biomass Bioenergy 2009, 33, 50–56. [Google Scholar] [CrossRef]

- Zhao, P.; Ge, S.; Yoshikawa, K. An orthogonal experimental study on solid fuel production from sewage sludge by employing steam explosion. Appl. Energy 2013, 112, 1213–1221. [Google Scholar] [CrossRef]

- Sait, H.H.; Hussain, A.; Salema, A.A.; Ani, F.N. Pyrolysis and combustion kinetics of date palm biomass using thermogravimetric analysis. Bioresour. Technol. 2012, 118, 382–389. [Google Scholar] [CrossRef] [PubMed]

- Vamvuka, D.; Zografos, D. Predicting the behaviour of ash from agricultural wastes during combustion. Fuel 2004, 83, 2051–2057. [Google Scholar] [CrossRef]

- Bapat, D.W.; Kulkarni, S.V.; Bhandarkar, V.P. Design and operating experience on fluidized bed boiler burning biomass fuels with high alkali ash. In Proceedings of the 14th International Conference on Fluidized Bed Combustion, Vancouver, BC, Canada, 11–16 May 1997. [Google Scholar]

- Singh, S.; Nimmo, W.; Williams, P.T. An experimental study of ash behaviour and the potential fate of ZnO/Zn in the co-combustion of pulverised South African coal and waste tyre rubber. Fuel 2013, 111, 269–279. [Google Scholar] [CrossRef]

- Bostrom, D.; Skoglund, N.; Grimm, A.; Boman, C.; Öhman, M.; Broström, M.; Backman, R. Ash transformation chemistry during combustion of biomass. Energy Fuel 2012, 26, 85–93. [Google Scholar] [CrossRef]

| Analysis | Ultimate Analysis (wt %) | Proximate Analysis (wt %) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | H | O | S | N | Mad | Vad | FCad | Aad | |

| Rice husk | 42.72 | 6.60 | 40.71 | 0.11 | 0.26 | 4.7 | 80.1 | 10.3 | 4.9 |

| Sewage sludge | 12.89 | 1.53 | 13.67 | 0.67 | 2.24 | 4.5 | 25 | 6 | 64.5 |

| Sample | 10R | 7R3S | 5R5S | 3R7S | 10S |

|---|---|---|---|---|---|

| DTGmax (%/min) | 12.56 | 10.05 | 10.90 | 9.75 | 2.24 |

| ti (min) | 14.8 | 16.1 | 15.2 | 16.1 | 12.7 |

| tp (min) | 16.9 | 20.3 | 17.6 | 20.2 | 16.7 |

| tf (min) | 26.2 | 25.9 | 26.5 | 25.2 | 34.7 |

| Δt1/2 (min) | 9.6 | 10.7 | 10.1 | 10.6 | 7.5 |

| Di | 5.02 × 10−2 | 3.08 × 10−2 | 4.07 × 10−2 | 3.00 × 10−2 | 1.06 × 10−2 |

| Df | 2.95 × 10−3 | 1.78 × 10−3 | 2.31 × 10−3 | 1.80× 10−3 | 5.13× 10−4 |

| Ti (°C) | 263.6 | 264.8 | 269.1 | 272.1 | 291.3 |

| Tf (°C) | 553.5 | 547.5 | 559.6 | 532.5 | 721 |

| Tmax (°C) | 295.9 | 338.5 | 295.1 | 333.8 | 281.1 |

| Rm (%/min °C) | 0.042 | 0.03 | 0.037 | 0.029 | 0.008 |

| Total Burnout (%) | 88.06 | 91.45 | 91.01 | 86.87 | 33.76 |

| Sample | Chemical Composition (%) | B/A | BAI | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | MgO | Fe2O3 | Na2O | CaO | Al2O3 | K2O | P2O5 | Cl | TiO2 | |||

| 7R3S-A | 66.23 | 2.00 | 5.57 | 0.71 | 3.96 | 11.58 | 4.26 | 3.74 | 0.09 | 0.48 | 0.21 | 1.12 |

| 5R5S-A | 61.80 | 2.31 | 6.73 | 0.78 | 4.52 | 13.30 | 3.99 | 4.33 | 0.04 | 0.84 | 0.24 | 1.41 |

| 3R7S-A | 55.46 | 2.35 | 8.28 | 0.83 | 5.98 | 14.33 | 3.58 | 4.34 | 0.06 | 0.88 | 0.30 | 1.88 |

| Index | Slagging Level | ||

|---|---|---|---|

| Low | Medium | High | |

| ST (°C) | >1390 | 1390–1260 | <1260 |

| DT (°C) | >1289 | 1108–1288 | <1107 |

| Mineral Phase | Content of Sludge Sewage | ||

|---|---|---|---|

| 30% | 50% | 70% | |

| Quartz | 18.62 | 31.27 | 34.92 |

| Gismondite | 1.09 | 6.54 | 9.34 |

| Amorphous | 80.28 | 62.19 | 55.73 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rong, H.; Wang, T.; Zhou, M.; Wang, H.; Hou, H.; Xue, Y. Combustion Characteristics and Slagging during Co-Combustion of Rice Husk and Sewage Sludge Blends. Energies 2017, 10, 438. https://doi.org/10.3390/en10040438

Rong H, Wang T, Zhou M, Wang H, Hou H, Xue Y. Combustion Characteristics and Slagging during Co-Combustion of Rice Husk and Sewage Sludge Blends. Energies. 2017; 10(4):438. https://doi.org/10.3390/en10040438

Chicago/Turabian StyleRong, Hao, Teng Wang, Min Zhou, Hao Wang, Haobo Hou, and Yongjie Xue. 2017. "Combustion Characteristics and Slagging during Co-Combustion of Rice Husk and Sewage Sludge Blends" Energies 10, no. 4: 438. https://doi.org/10.3390/en10040438

APA StyleRong, H., Wang, T., Zhou, M., Wang, H., Hou, H., & Xue, Y. (2017). Combustion Characteristics and Slagging during Co-Combustion of Rice Husk and Sewage Sludge Blends. Energies, 10(4), 438. https://doi.org/10.3390/en10040438