Development of a Real-Time Virtual Nitric Oxide Sensor for Light-Duty Diesel Engines

Abstract

:1. Introduction

2. Experimental Setup and Conditions

2.1. Test Engine

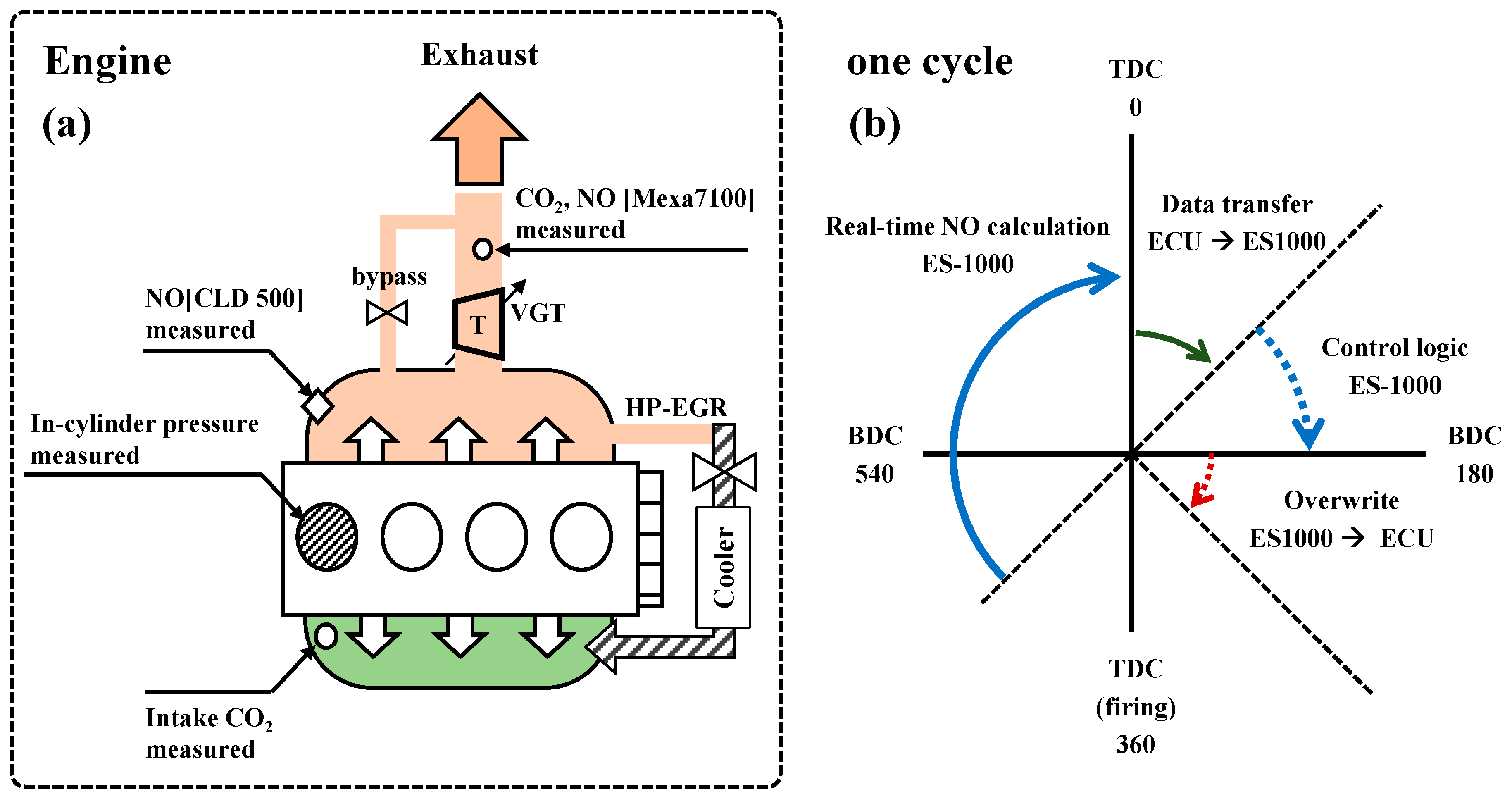

2.2. Experimental Setup

2.2.1. Engine-Out NO Measurement

2.2.2. Real-Time Calculation and Control of Engine-Out NO

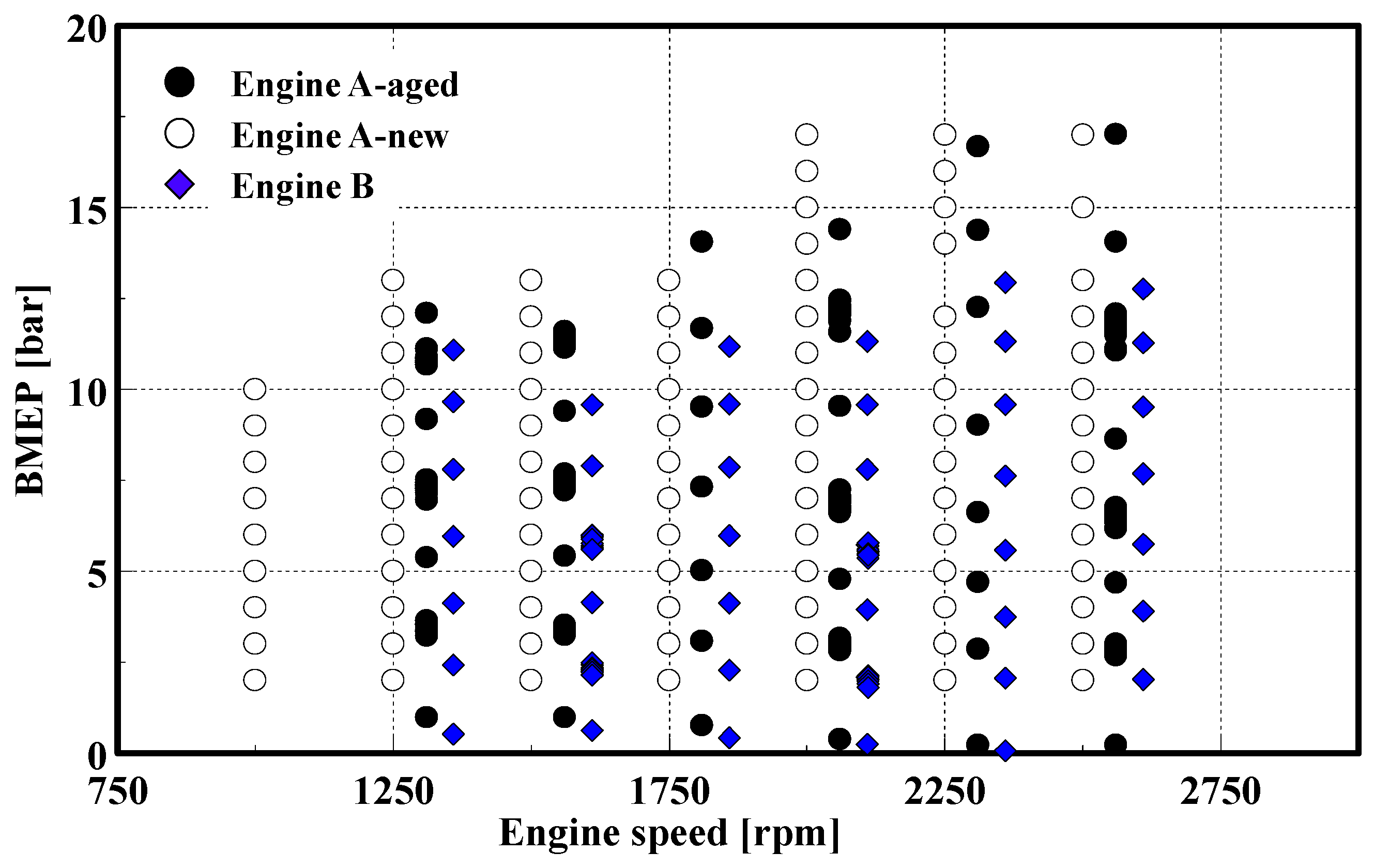

2.2.3. Experimental Conditions

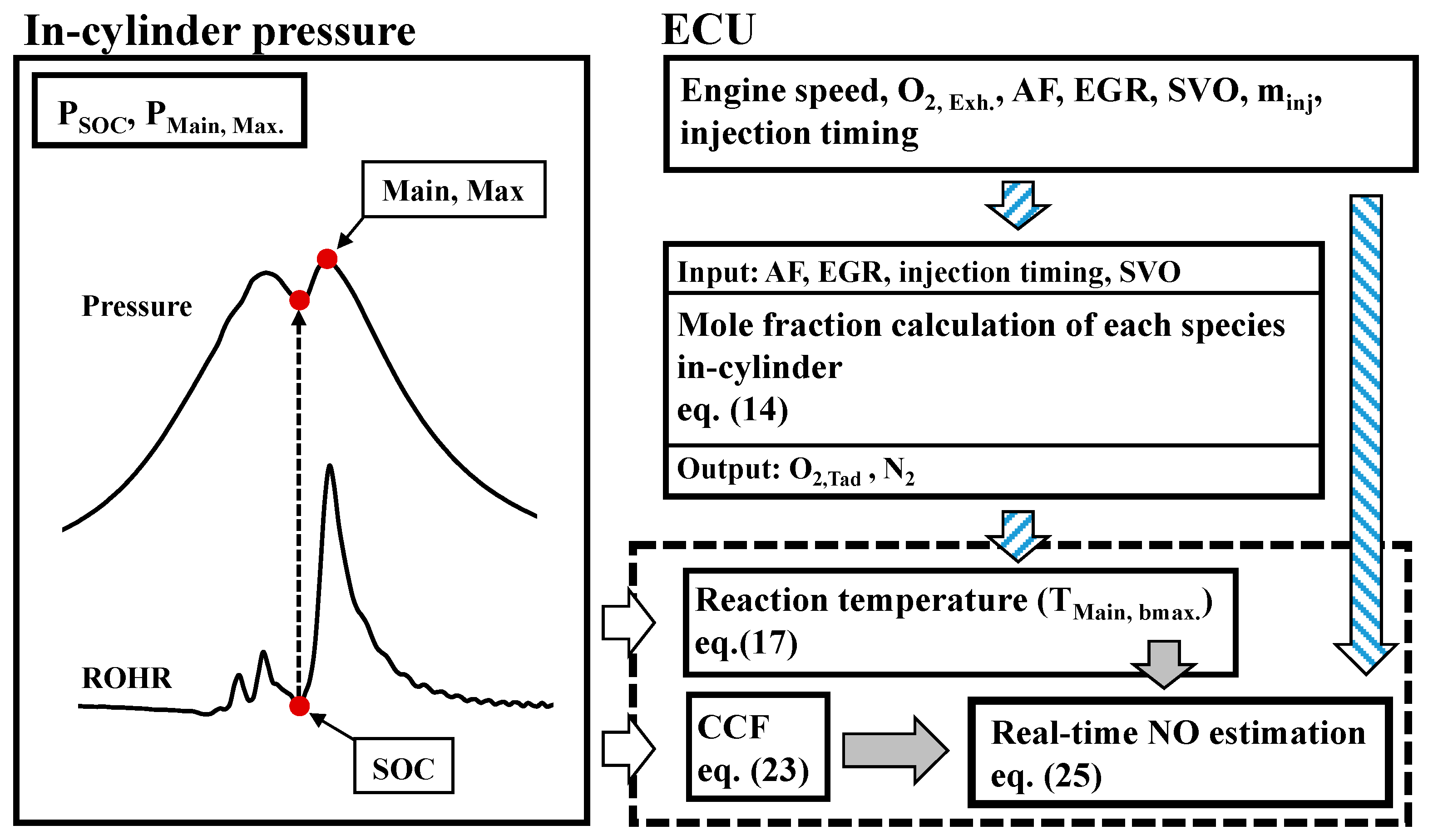

3. Description of the Real-Time NO Estimation Model

3.1. Determination of the Adiabatic Flame Temperature

3.2. Calculation of the Engine-Out NO

3.2.1. Calculation of the Cycle-Averaged NO Formation Rate

3.2.2. Determination of the NO Formation Area and Duration

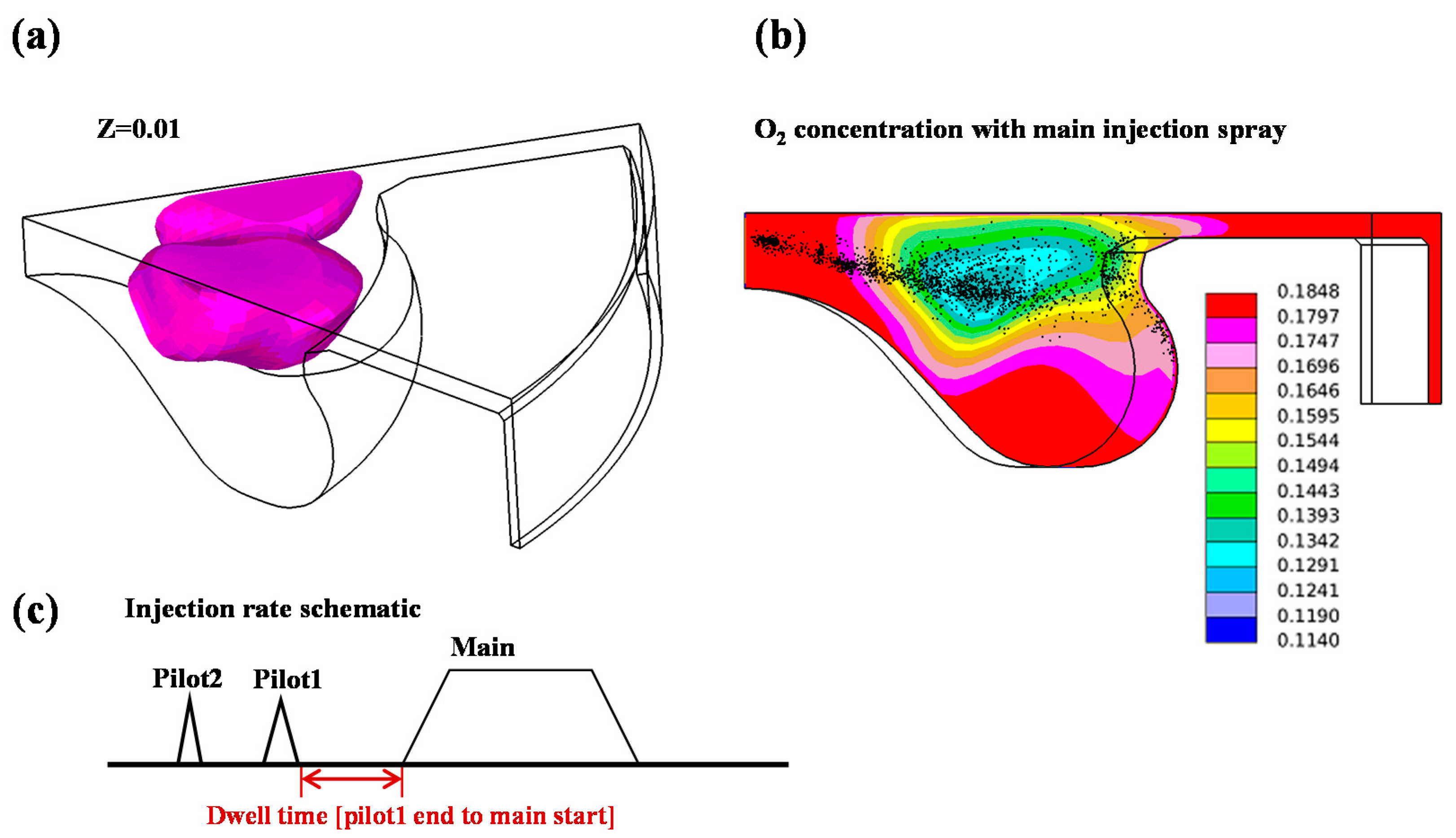

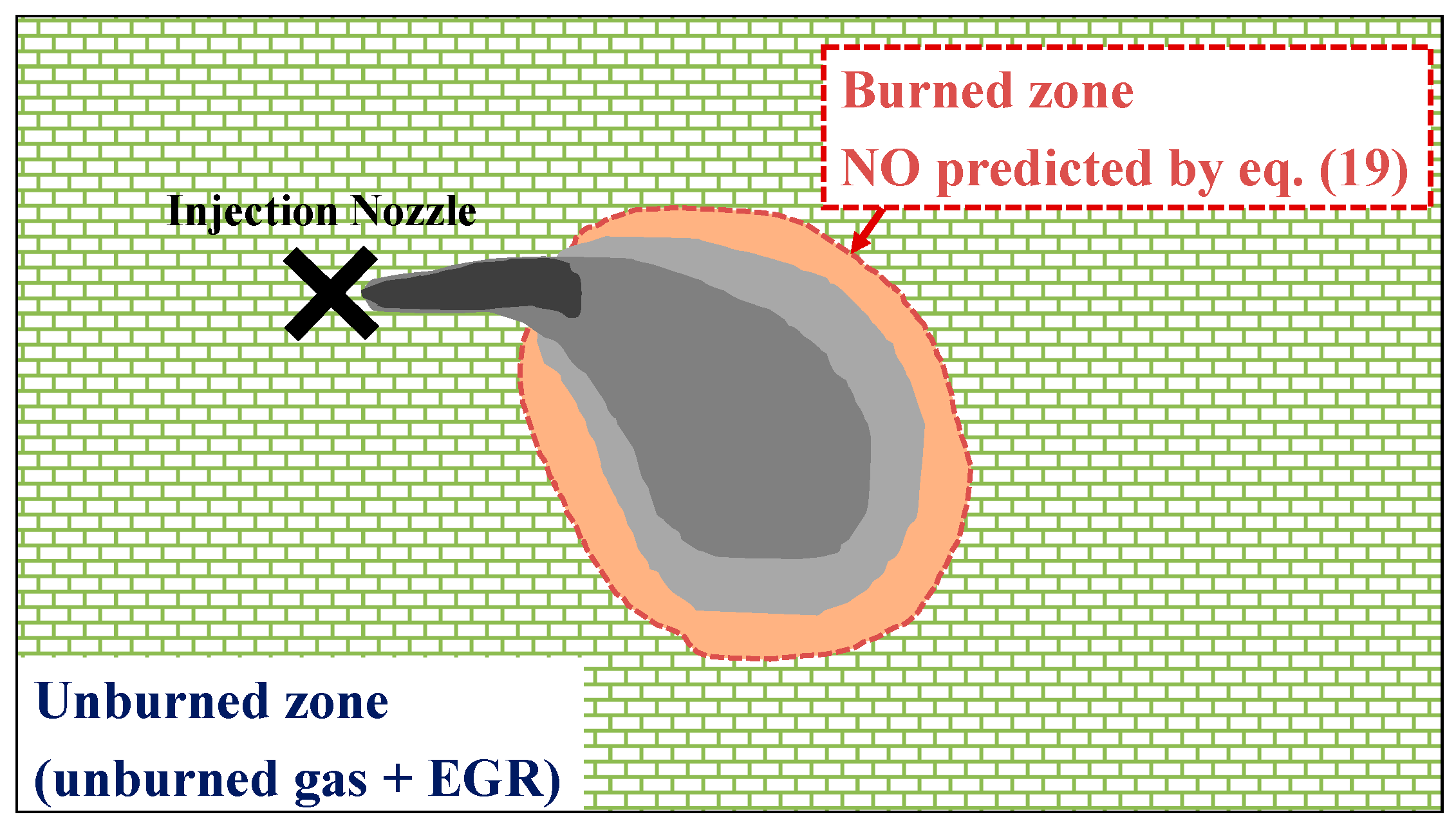

3.3. Spatial Concentration Correction of the Calculated NO

- (1)

- Pressure in the burned zone and the unburned zone are identical. (Pbunred = Punburned)

- (2)

- The mass ratio of the burned to the unburned can be expressed as the global equivalent ratio (Φ) divided by (1 − Φ).

- (3)

- The temperature in the burned zone (Tburned) is treated as the maximum burned gas temperature (Tmax).

- (4)

- The temperature in the unburned zone can be calculated using the isentropic compression and expansion relationship:where the letters indicate the temperature in the unburned zone, the temperature of the main SOC, the maximum pressure, the pressure at SOC, and the specific heat ratio, respectively.

3.4. Fitting of the Constant in the NO Estimation Model

4. Results and Discussion

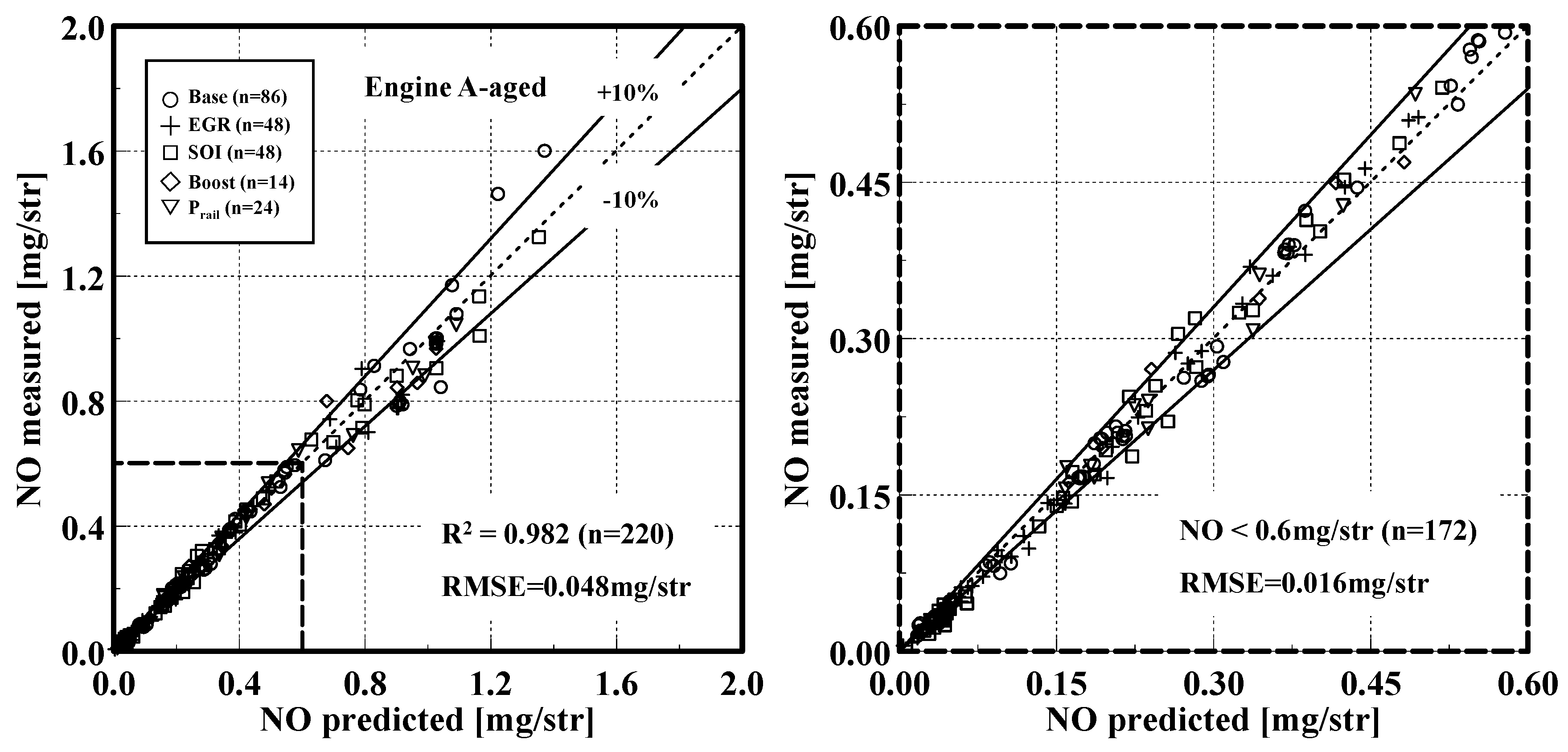

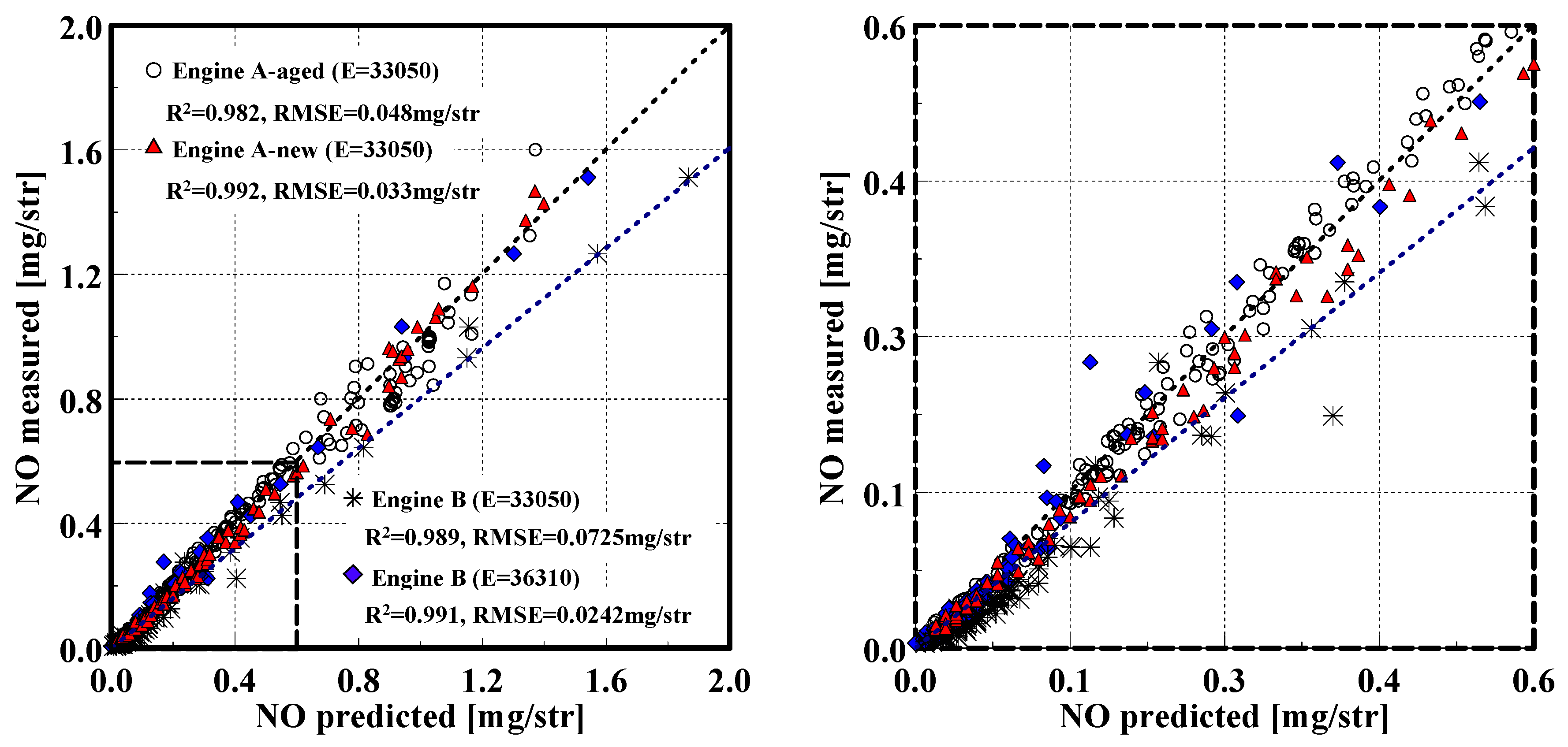

4.1. Model Application in Steady-State Operation Conditions

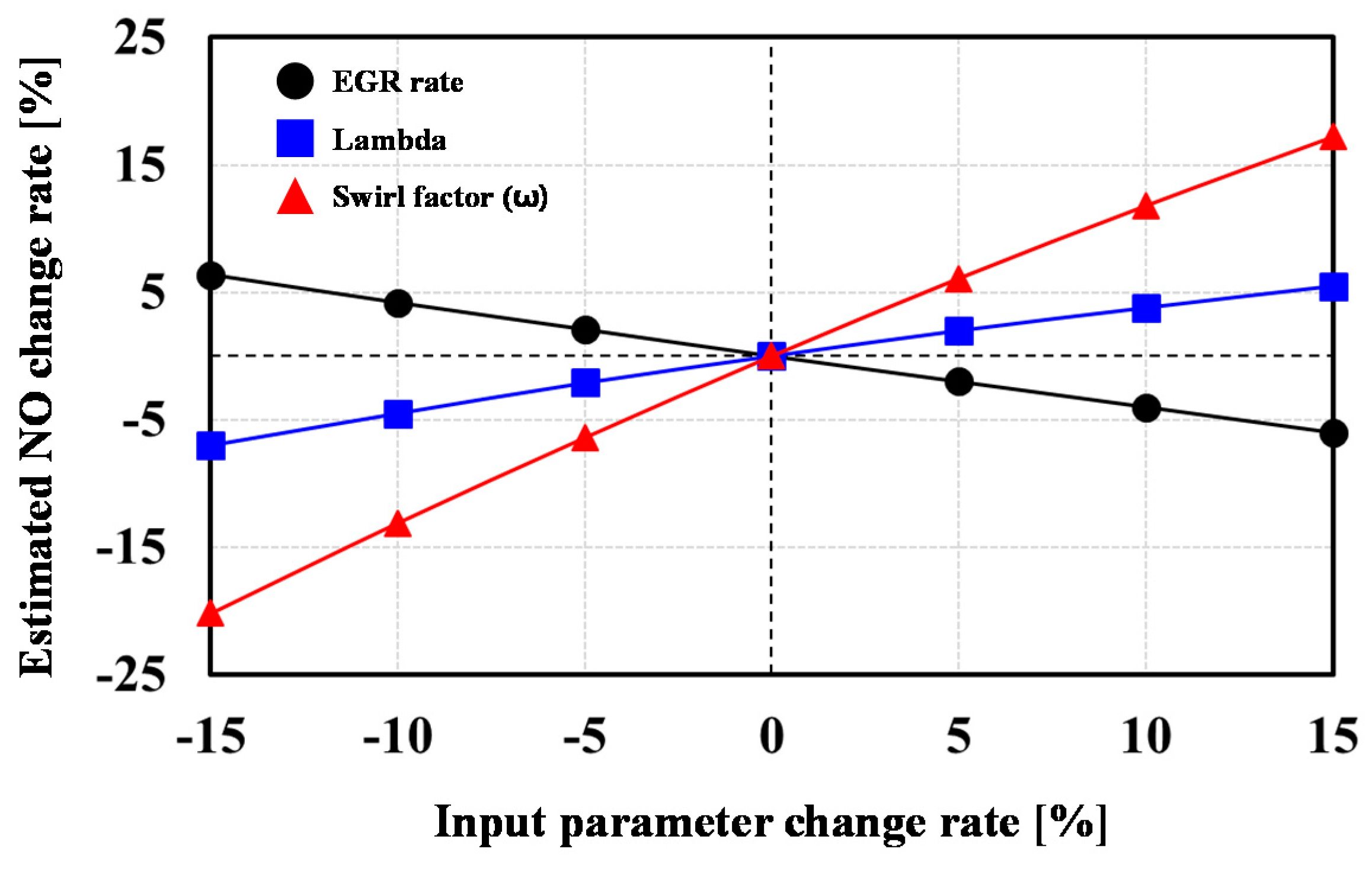

4.2. Evaluation of the Model Input Parameter Sensitivity Analysis

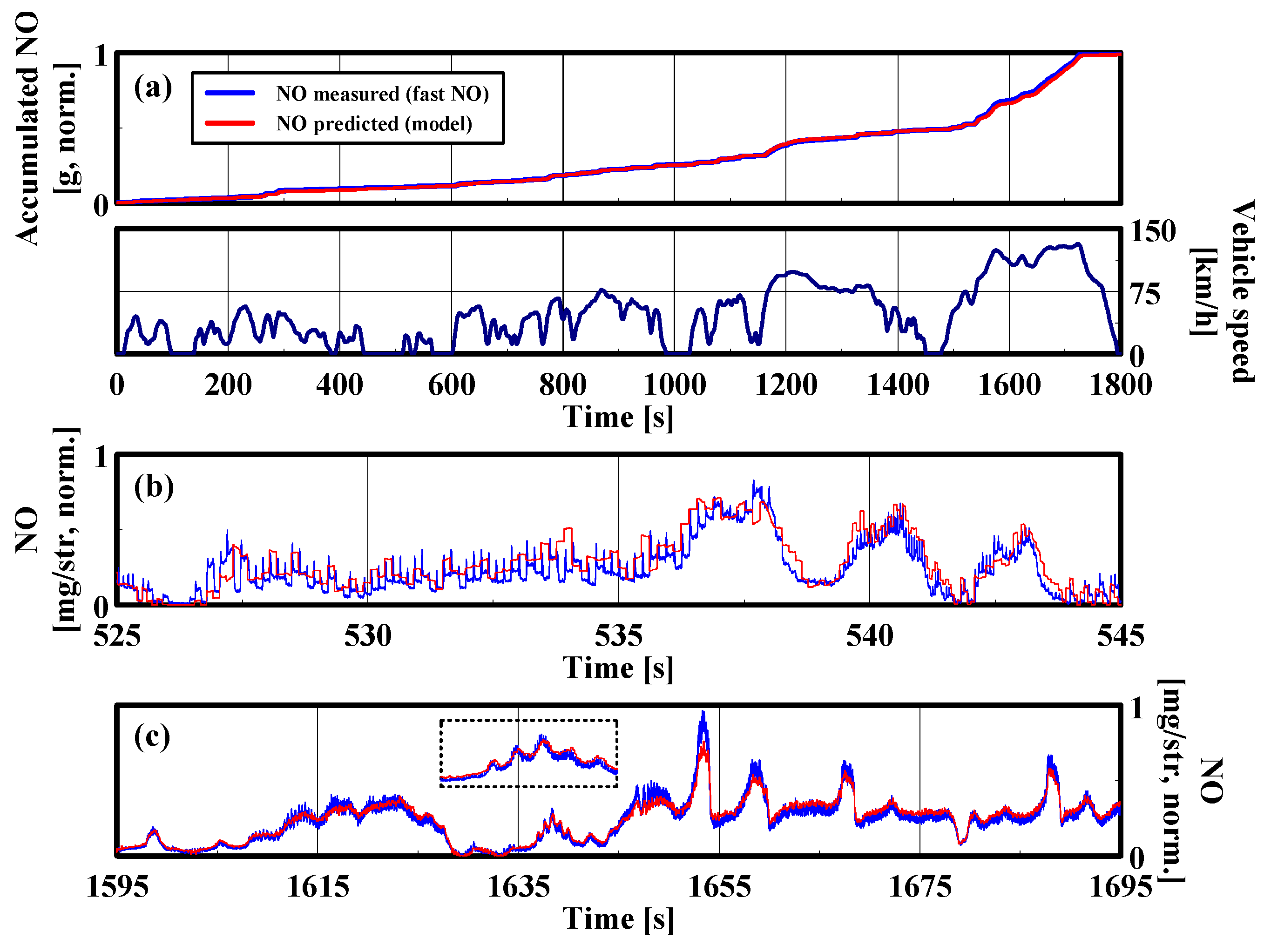

4.3. Model Application in Transient Operation Conditions over a WLTC

4.4. Model Robustness Validation

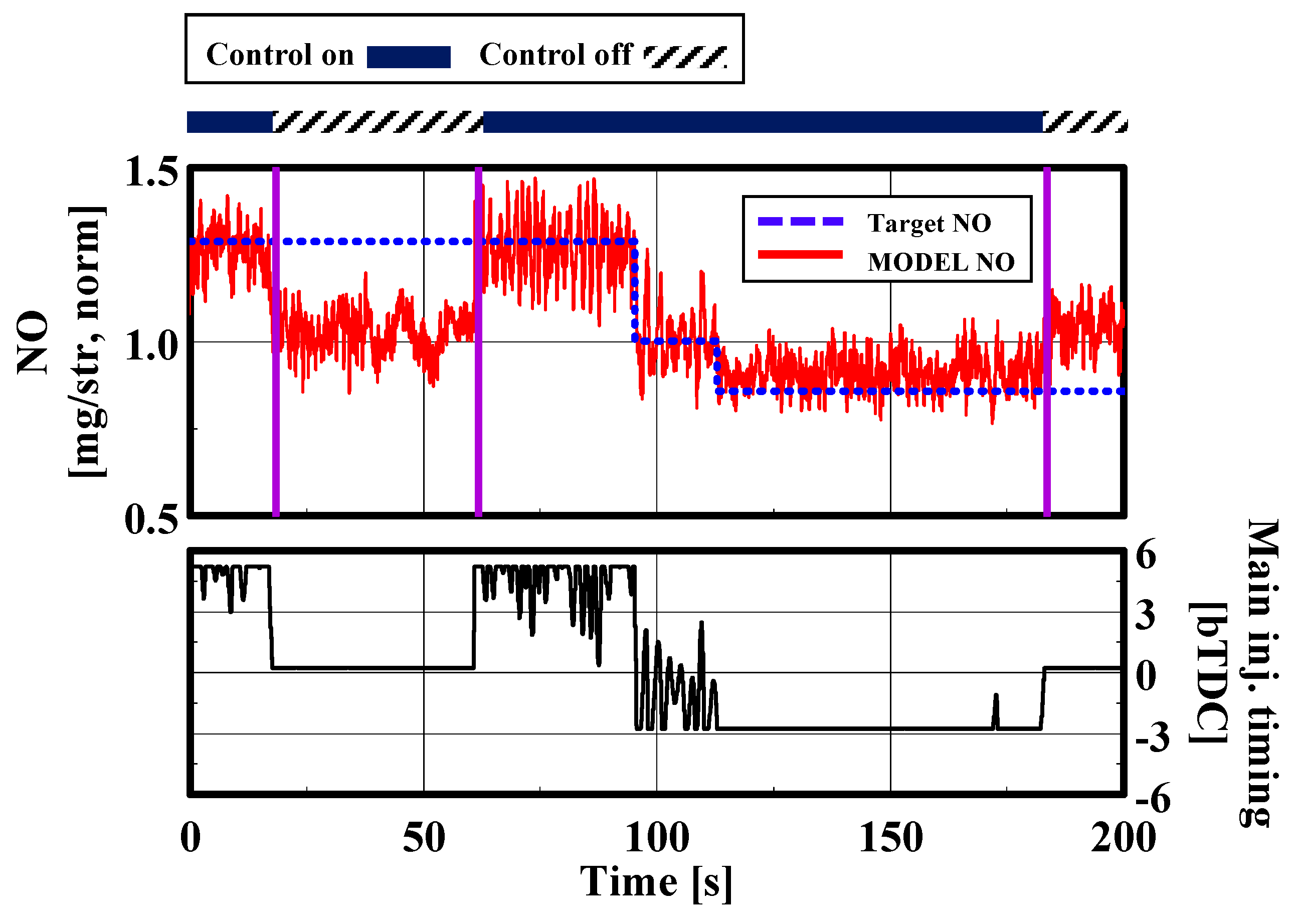

4.5. Real-Time NO Emission Control during Steady-State Operating Conditions

5. Conclusions

- (1)

- as an engine emission calibrator in the engine development stage

- (2)

- for the real-time management of exhaust NO emissions

- (3)

- as an alerting system for physical NOx sensor failure

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| A | a constant in Equation (18) |

| a | a constant in Equation (2) |

| A/D | analog/digital |

| AF | air-fuel ratio |

| aTDC | after top dead center |

| b | a constant in Equation (2) |

| bTDC | before top dead center |

| BMEP | Brake Mean Effective Pressure (bar) |

| c | a constant in Equation (2) |

| CA | Crank Angle (degree) |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| CRDI | common rail direct injection |

| d | a constant in Equation (2) |

| DPF | Diesel Particulate Filter |

| DT | Dwell Time (time interval between the end of pilot1 injection and start of main injection, s) |

| ECU | Engine Control Unit |

| EGR | Exhaust Gas Recirculation (-) |

| EMS | Engine Management System |

| EVC | exhaust valve close |

| EVO | exhaust valve open |

| IVC | intake valve close |

| IVO | intake valve open |

| k | specific heat ratio |

| LNT | Lean NOx Trap |

| RMSE | Root mean square error (mg/str) |

| ROHR | Rate of Heat Release |

| M | mass (kg) |

| NO | nitric monoxide |

| NO2 | nitrogen dioxide |

| NOx | nitric oxides |

| P | pressure (bar) |

| SCR | selective catalytic reduction |

| SVO | Swirl Valve Opening (%) |

| T | temeperature (K) |

| V | volume (m3) |

| VGT | variable geometry turbine |

| WLTC | worldwide harmonized light vehicles test cycle |

| Z | mixture fraction (-) |

| Greek Symbols | |

| α | air availability (-) |

| δ | a constant in Equation (11) (-) |

| λ | air-excess ratio (-) |

| ψ | molar N/O ratio (-) |

| Φ | Equivalence ratio (-) |

| ω | Swirl factor (-) |

| Subscripts | |

| ad | adiabatic |

| e | equilibrium concentration |

| max | maximum |

| SOC | start of combustion |

| ub | unburned |

References

- Mauzerall, D.L.; Sultan, B.; Kim, N.; Bradford, D.F. NOx emissions from large point sources: Variability in ozone production, resulting health damages and economic costs. Atmos. Environ. 2005, 39, 2851–2866. [Google Scholar] [CrossRef]

- Meszler, D.; German, J.; Mock, P.; Bandivadekar, A. CO2 Reduction Technologies for the European Car and Van Fleet, A 2025–2030 Assessment; The International Council on Clean Transportation (ICCT): Berlin, Germany, 2016. [Google Scholar]

- Yang, Z. Improving the Conversions between the Various Passenger Vehicle Fuel Economy/CO2 Emission Standards Around the World; The International Council on Clean Transportation (ICCT): Berlin, Germany, 2014. [Google Scholar]

- Sarangi, A.K.; McTaggart-Cowan, G.P.; Garner, C.P. The Effects of Intake Pressure on High EGR Low Temperature Diesel Engine Combustion; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Kimura, S.; Aoki, O.; Kitahara, Y.; Aiyoshizawa, E. Ultra-Clean Combustion Technology Combining a Low-Temperature and Premixed Combustion Concept for Meeting Future Emission Standards; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Colban, W.F.; Miles, P.C.; Oh, S. Effect of Intake Pressure on Performance and Emissions in an Automotive Diesel Engine Operating in Low Temperature Combustion Regimes; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Alriksson, M.; Denbratt, I. Low Temperature Combustion in a Heavy Duty Diesel Engine Using High Levels of EGR; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Forzatti, P.; Lietti, L.; Nova, I.; Tronconi, E. Diesel Nox aftertreatment catalytic technologies: Analogies in lnt and scr catalytic chemistry. Catal. Today 2010, 151, 202–211. [Google Scholar] [CrossRef]

- Theis, J.; Gulari, E. A LNT + SCR System for Treating the NOx Emissions from a Diesel Engine; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Curran, S.; Hanson, R.; Wagner, R.; Reitz, R.D. Efficiency and Emissions Mapping of RCCI in a Light-Duty Diesel Engine; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Kihas, D.; Uchanski, M.R. Engine-Out NOx Models for On-Ecu Implementation: A Brief Overview; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- D’Ambrosio, S.; Finesso, R.; Fu, L.; Mittica, A.; Spessa, E. A control-oriented real-time semi-empirical model for the prediction of NOx emissions in diesel engines. Appl. Energy 2014, 130, 265–279. [Google Scholar] [CrossRef]

- Asprion, J.; Chinellato, O.; Guzzella, L. A fast and accurate physics-based model for the Nox emissions of diesel engines. Appl. Energy 2013, 103, 221–233. [Google Scholar] [CrossRef]

- Andersson, M.; Johansson, B.; Hultqvist, A.; Noehre, C. A predictive Real Time NOx Model for Conventional and Partially Premixed Diesel Combustion; 01-3329, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2006. [Google Scholar]

- Egnell, R. Combustion diagnostics by means of multizone heat release analysis and No calculation. SAE Trans. J. Engines 1998, 107. [Google Scholar] [CrossRef]

- Del Re, L.; Allgöwer, F.; Glielmo, L.; Guardiola, C.; Kolmanovsky, I. Automotive Model Predictive Control: Models, Methods and Applications; Springer: Berlin, Germany, 2010. [Google Scholar]

- Arrègle, J.; López, J.J.; Guardiola, C.; Monin, C. Sensitivity Study of a NOx Estimation Model for On-Board Applications; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2008. [Google Scholar]

- Seykens, X.; Baert, R.; Somers, L.; Willems, F. Experimental validation of extended no and soot model for advanced hd diesel engine combustion. SAE Int. J. Engines 2009, 2, 606–619. [Google Scholar] [CrossRef]

- Willems, F.; Doosje, E.; Engels, F.; Seykens, X. Cylinder Pressure-Based Control in Heavy-Duty EGR Diesel Engines Using a Virtual Heat Release and Emission Sensor; SAE Paper; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Hegarty, K.; Favrot, R.; Rollett, D.; Rindone, G. Semi-Empiric Model Based Approach for Dynamic Prediction of NOx Engine Out Emissions on Diesel Engines; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Finesso, R.; Spessa, E. Real-Time Predictive Modeling of Combustion and Nox Formation in Diesel Engines under Transient Conditions; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Eriksson, L.; Nielsen, L. Modeling and Control of Engines and Drivelines; John Wiley & Sons: New York, NY, USA, 2014. [Google Scholar]

- Schejbal, M.; Štěpánek, J.; Marek, M.; Kočí, P.; Kubíček, M. Modelling of soot oxidation by NO2 in various types of diesel particulate filters. Fuel 2010, 89, 2365–2375. [Google Scholar] [CrossRef]

- Zhang, Z.-S.; Crocker, M.; Chen, B.-B.; Wang, X.-K.; Bai, Z.-F.; Shi, C. Non-thermal plasma-assisted Nox storage and reduction over cobalt-containing lnt catalysts. Catal. Today 2015, 258, 386–395. [Google Scholar] [CrossRef]

- Iwasaki, M.; Shinjoh, H. A comparative study of “standard”,“fast” and “NO2” scr reactions over fe/zeolite catalyst. Appl. Catal. A Gen. 2010, 390, 71–77. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Finesso, R.; Misul, D.; Spessa, E. Estimation of the Engine-Out NO2/NOx Ratio in a Euro vi Diesel Engine; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Hernandez, J.; Lapuerta, M.; Perez-Collado, J. A combustion kinetic model for estimating diesel engine Nox emissions. Combust. Theory Model. 2006, 10, 639–657. [Google Scholar] [CrossRef]

- Liu, S.; Li, H.; Liew, C.; Gatts, T.; Wayne, S.; Shade, B.; Clark, N. An experimental investigation of NO2 emission characteristics of a heavy-duty h 2-diesel dual fuel engine. Int. J. Hydrog. Energy 2011, 36, 12015–12024. [Google Scholar] [CrossRef]

- Lee, J.; Lee, S.; Park, W.; Min, K.; Song, H.H.; Choi, H.; Yu, J.; Cho, S.H. The Development of Real-Time NOx Estimation Model and Its Application; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- ISO/IEC Guide 98-3:2008. Guide to the Expression of Uncertainty in Measurement, ISO: Geneva, Switzerland, 1995.

- Seykens, X.L.J. Development and Validation of a Phenomenological Diesel Engine Combustion Model. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2010. [Google Scholar]

- Turns, S. An Introduction to Combustion: Concepts and Applications; SAE International: Warrendale, PA, USA, 1996. [Google Scholar]

- Minami, T.; Takeuchi, K.; Shimazaki, N. Reduction of Diesel Engine NOx Using Pilot Injection; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 1995. [Google Scholar]

- Colin, O.; Benkenida, A. The 3-zones extended coherent flame model (ecfm3z) for computing premixed/diffusion combustion. Oil Gas Sci. Technol. 2004, 59, 593–609. [Google Scholar] [CrossRef]

- Kim, G.; Min, K. Numerical Study on the Multiple Injection Strategy in Diesel Engines Using a Modified 2-d Flamelet Model; 0148-7191, SAE Technical Paper; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Peters, N. Turbulent Combustion; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Park, W.; Lee, J.; Min, K.; Yu, J.; Park, S.; Cho, S. Prediction of real-time no based on the in-cylinder pressure in diesel engines. Proc. Combus. Inst. 2013, 34, 3075–3082. [Google Scholar] [CrossRef]

- Finesso, R.; Spessa, E. Ignition delay prediction of multiple injections in diesel engines. Fuel 2014, 119, 170–190. [Google Scholar] [CrossRef]

- Le, M.K.; Kook, S. Injection pressure effects on the flame development in a light-duty optical diesel engine. SAE Int. J. Engines 2015, 8, 609–624. [Google Scholar] [CrossRef]

- Arrègle, J.; López, J.J.; Guardiola, C.; Monin, C. On board NOx prediction in diesel engines: A physical approach. In Automotive Model Predictive Control; Springer: Berlin, Gemany, 2010. [Google Scholar]

- Guardiola, C.; López, J.J.; Martín, J.; García-Sarmiento, D. Semiempirical in-cylinder pressure based model for NOx prediction oriented to control applications. Appl. Therm. Eng. 2011, 31, 3275–3286. [Google Scholar] [CrossRef]

- Mellor, A.M.; Mello, J.; Duffy, K.P.; Easley, W.; Faulkner, J. Skeletal Mechanism for NOx Chemistry in Diesel Engines; SAE Technical Paper; SAE International: Warrendale, PA, USA, 1998. [Google Scholar]

- Plee, S.; Ahmad, T.; Myers, J.; Siegla, D. Effects of flame temperature and air-fuel mixing on emission of particulate carbon from a divided-chamber diesel engine. In Particulate Carbon; Springer: Berlin, Gemany, 1981. [Google Scholar]

- Peckham, M.; Campbell, B.; Finch, A. Measurement of the effects of the exhaust gas recirculation delay on the nitrogen oxide emissions within a turbocharged passenger car diesel engine. J. Automob. Eng. 2011, 225, 1156–1166. [Google Scholar] [CrossRef]

| Engine Type | In-Lined Compression Ignition 4 Cylinders | |

|---|---|---|

| EURO5 (Engine A) | EURO6 (Engine B) | |

| Displaced volume | 1582 cc | 2199 cc |

| Bore × Stroke | 77.2 mm × 84.5 mm | 85.4 mm × 96 mm |

| Compression ratio | 17.3 | 16 |

| Turbocharger type | Single stage VGT | Single stage E-VGT |

| Fuel injection system | CRDI (Solenoid injector) | CRDI (Solenoid injector) |

| Maximum power and torque | 94 kW/260 N.m | 150 kW/440 N.m |

| Valve timing | IVO/IVC (ATDC17/ABDC14) EVO/EVC (BBDC23/BTDC 20) | IVO/IVC (ATDC10/ABDC7) EVO/EVC (BBDC32/BTDC17) |

| Device | Error | Expanded Uncertainty (%) | |

|---|---|---|---|

| Fast NO analyzer | Zero drift | <5 ppm/h | ≤2.1 |

| Span drift | <1% full scale/h | ||

| Exhaust gas analyzer | Zero drift | <1% full scale/24 h | ≤4.5 |

| Span drift | <1% full scale/24 h | ||

| Noise | <2% full scale | ||

| Linearity | <1% full scale | ||

| Piezo electric sensor | Linearity | <0.3% full scale | ≤5.7 |

| Sensitivity shift | <2% (at 23–350 °C) | ||

| <0.5% (at 200 ± 50 °C) | |||

| Short term drift (Thermal shock) | <2% for minimum pressure (9 bar) | ||

| <1% for maximum pressure (250 bar) | |||

| Charge amplifier | ≤0.2 | ||

| Analog/digital error | A/D conversion linearity | ≤0.024 | |

| Experimental Conditions | Engine A | Engine B | Sweep Interval (Based on Typical) |

|---|---|---|---|

| EGR (%) | 0 to 40 | 0 to 56 | 5 Steps between min/max |

| Minimum: −10% | |||

| Maximum: 20% | |||

| Rail pressure (bar) | 300 to 1400 | ±100 | |

| Boost pressure (bar) | 1 to 2.3 | ±0.1 | |

| Main injection timing (aTDC) | −6 to 2 | ±2, 4 | |

| Equivalence ratio (Φ) | 0.2 to 0.9 | ||

| Injection per cycle | 3 (pilot2, pilot1, main) or 4 (pilot2, pilot1, main, post) | ||

| Pilot + Pre injection (mg/str) | 1 to 3 | ||

| Engine A-Aged | Measured | Estimated | Error (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Air map offset | −3% | general | +3% | −3% | general | +3% | −3% | general | +3% |

| Total NO (g, norm.) | 0.904 | 1.000 | 1.123 | 0.883 | 0.985 | 1.095 | −2.3 | −1.5 | −2.5 |

| Total NO_bypassed (g, norm.) | 0.738 | 0.698 | −5.4 | ||||||

| Engine Speed | BMEP_General (bar) | BMEP_Bypassed (bar) | ∆ Boost Pressure (hPa) | ∆ EGR (%) | ∆ φ (-) |

|---|---|---|---|---|---|

| 1500 | 9.4 | 7.0 | −141.9 | 16.9 | 0.31 |

| 1500 | 11.4 | 8.6 | −138.1 | 16.8 | 0.29 |

| 2000 | 6.9 | 5.2 | −71.9 | 15.1 | 0.27 |

| 2000 | 9.5 | 6.8 | −112.4 | 15.8 | 0.32 |

| 2000 | 12.1 | 8.4 | −116.8 | 15.4 | 0.33 |

| 2000 | 14.4 | 10.6 | −80.6 | 17.0 | 0.32 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Lee, Y.; Kim, G.; Min, K. Development of a Real-Time Virtual Nitric Oxide Sensor for Light-Duty Diesel Engines. Energies 2017, 10, 284. https://doi.org/10.3390/en10030284

Lee S, Lee Y, Kim G, Min K. Development of a Real-Time Virtual Nitric Oxide Sensor for Light-Duty Diesel Engines. Energies. 2017; 10(3):284. https://doi.org/10.3390/en10030284

Chicago/Turabian StyleLee, Seungha, Youngbok Lee, Gyujin Kim, and Kyoungdoug Min. 2017. "Development of a Real-Time Virtual Nitric Oxide Sensor for Light-Duty Diesel Engines" Energies 10, no. 3: 284. https://doi.org/10.3390/en10030284

APA StyleLee, S., Lee, Y., Kim, G., & Min, K. (2017). Development of a Real-Time Virtual Nitric Oxide Sensor for Light-Duty Diesel Engines. Energies, 10(3), 284. https://doi.org/10.3390/en10030284