A Wind Power Plant with Thermal Energy Storage for Improving the Utilization of Wind Energy

Abstract

1. Introduction

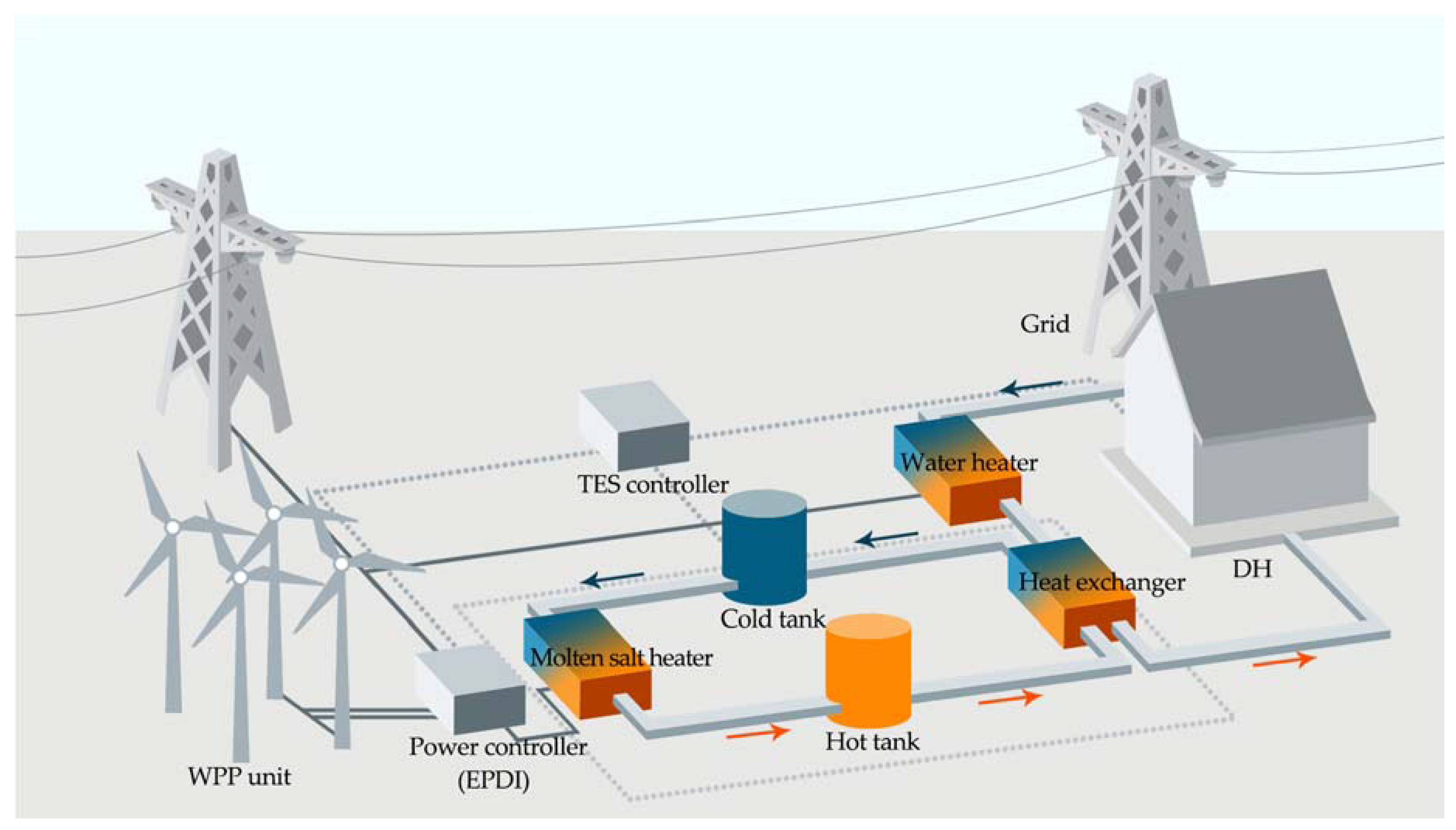

2. System Description

3. Mathematical Model

3.1. Modelica Model Library

3.2. Components Models

3.2.1. Wind Power Unit Module

3.2.2. Heater Modules

3.2.3. Two-Tank Storage Module

3.2.4. Heat Exchanger Module

3.2.5. Heating Loop Module

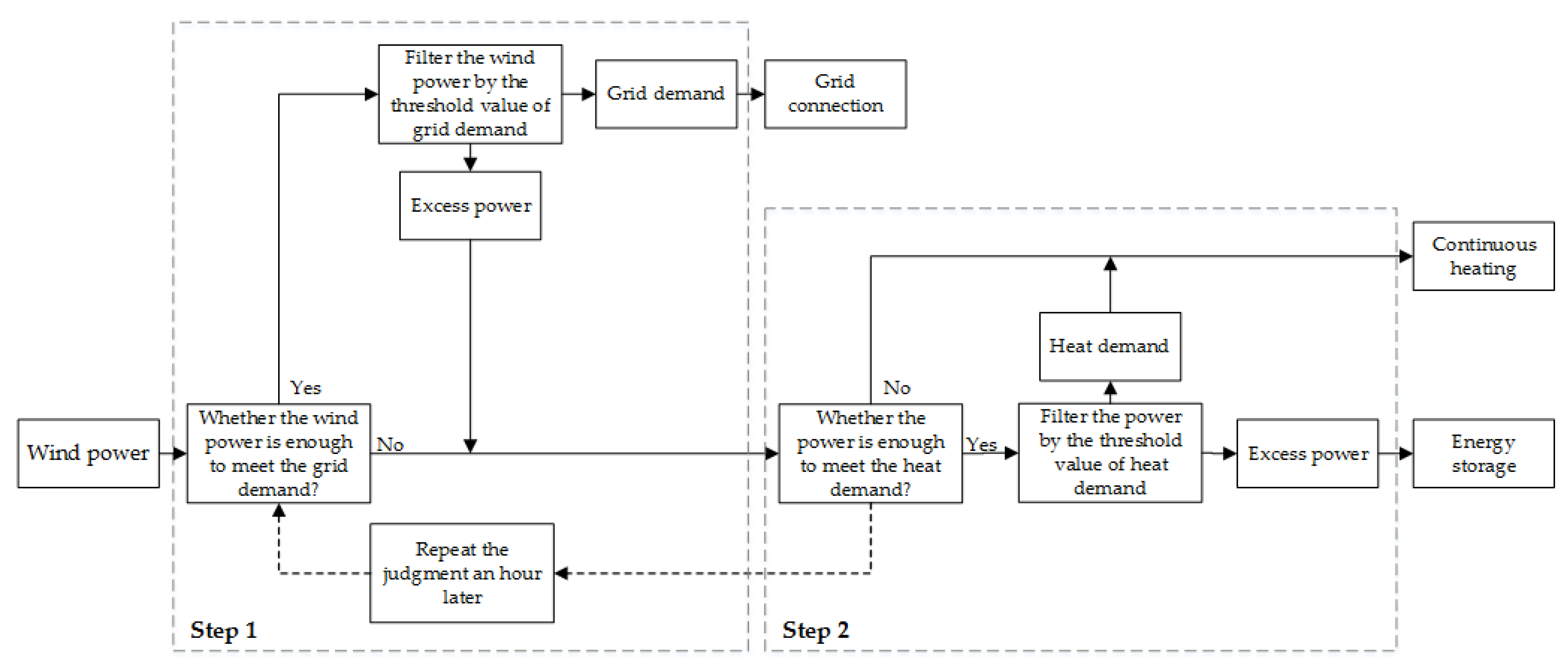

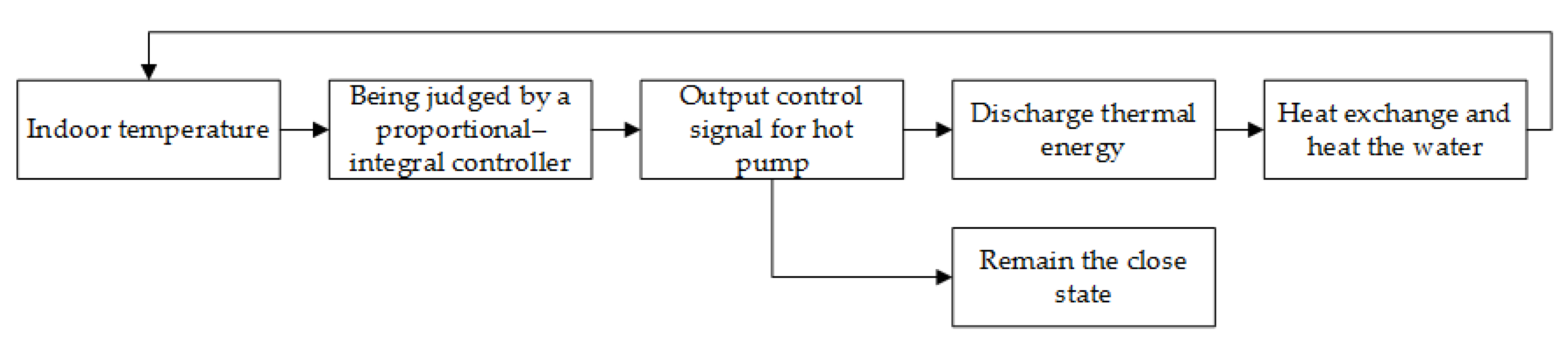

3.2.6. Controller Modules

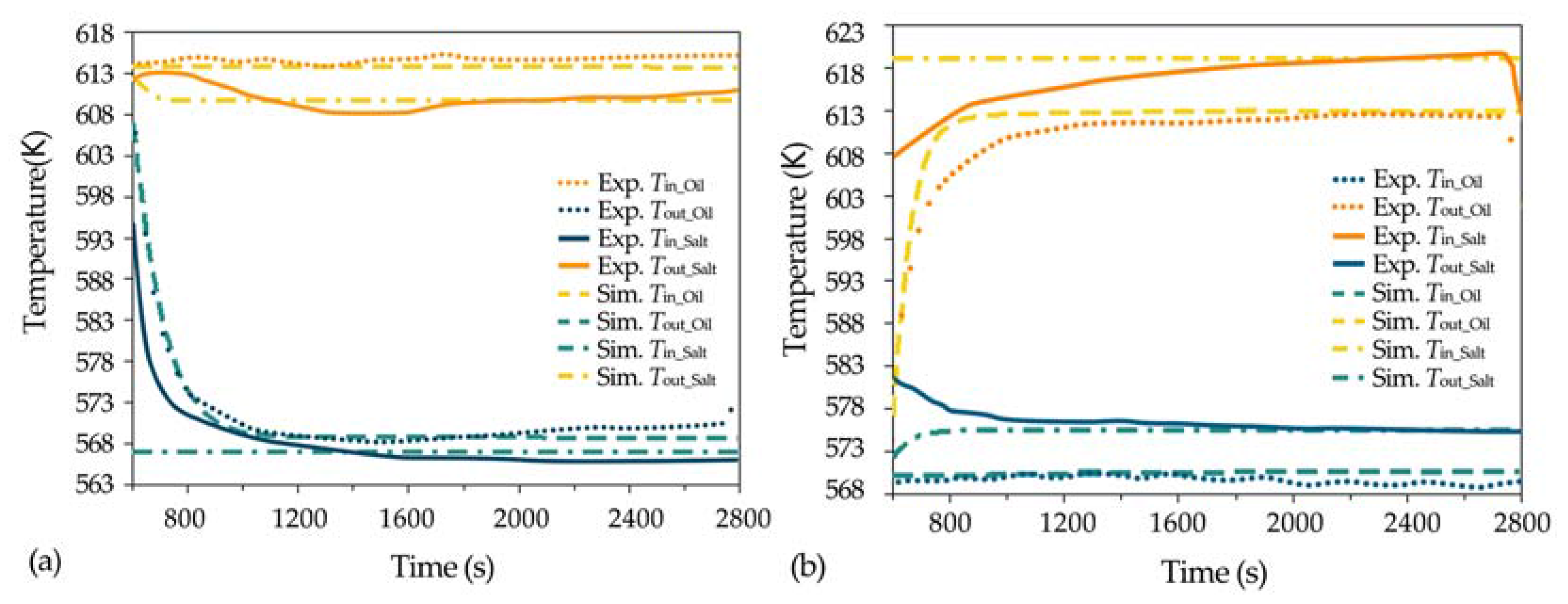

3.3. Model Validation

3.4. Model Assumptions

4. Results and Discussion

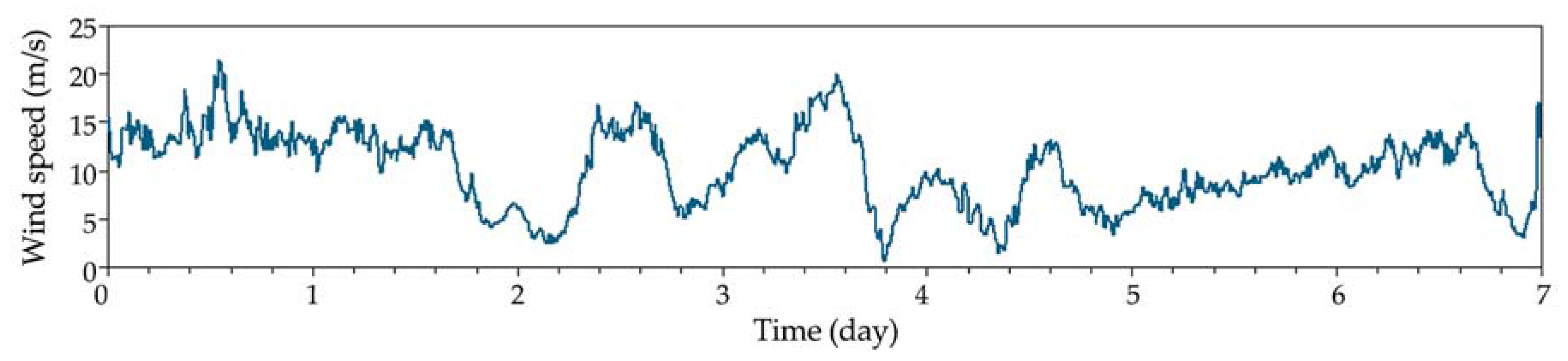

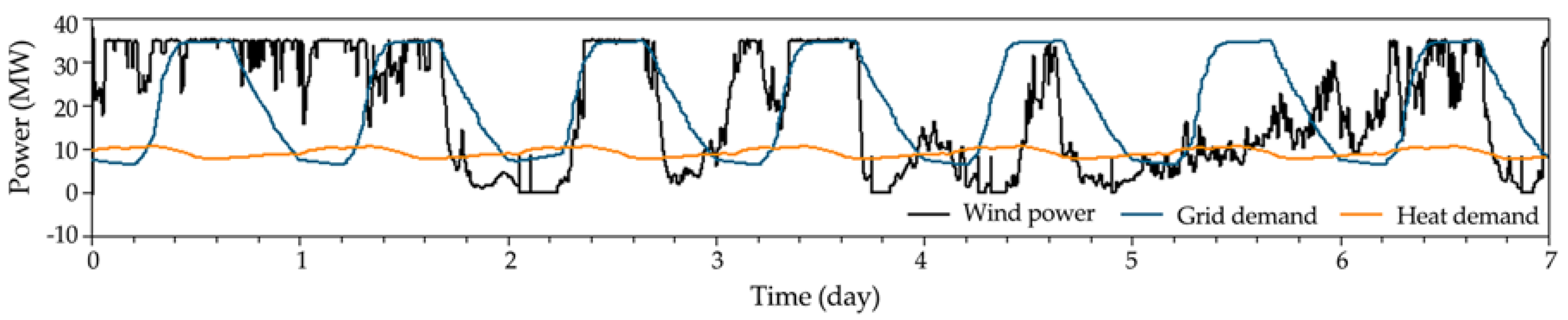

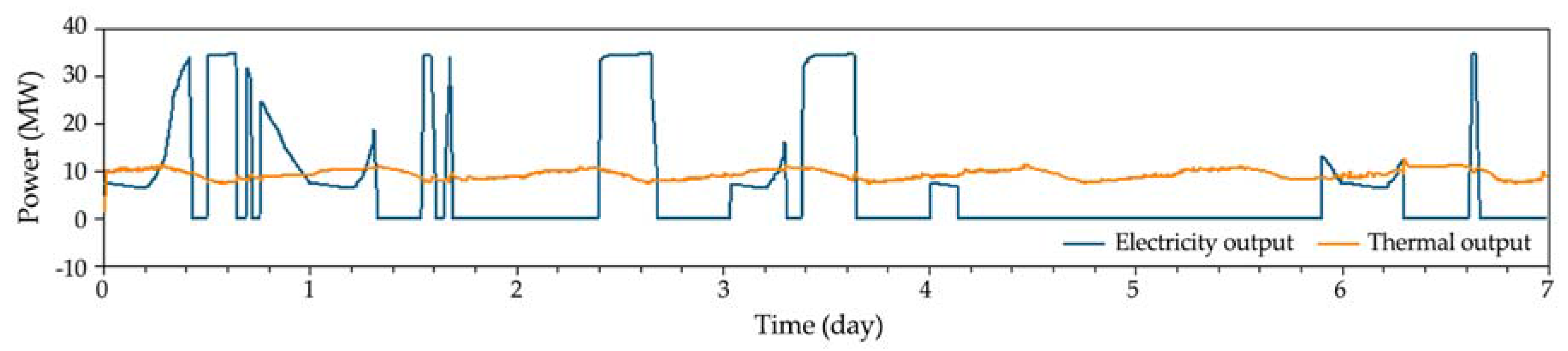

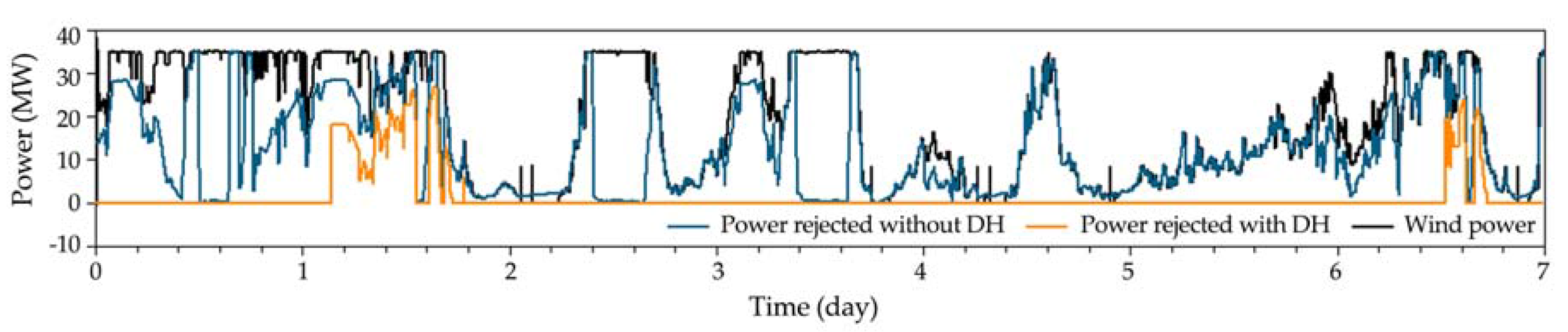

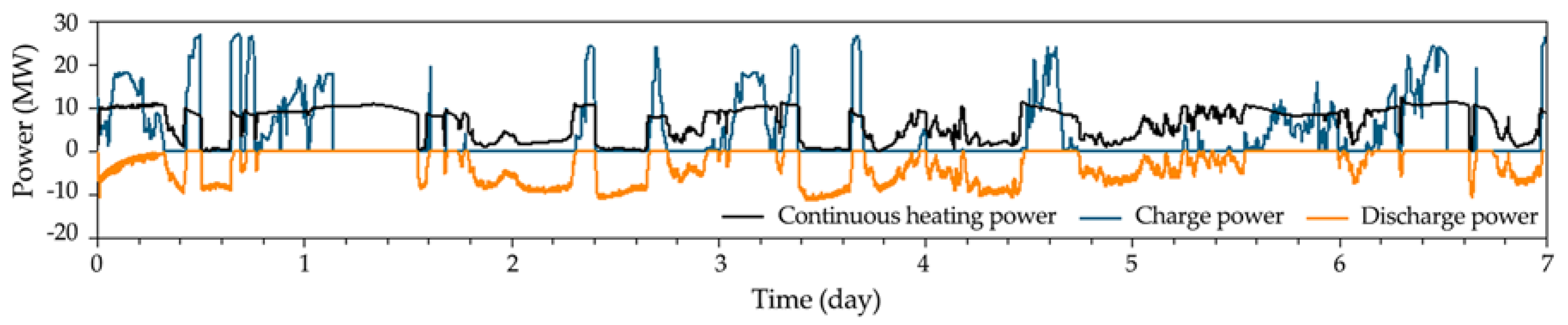

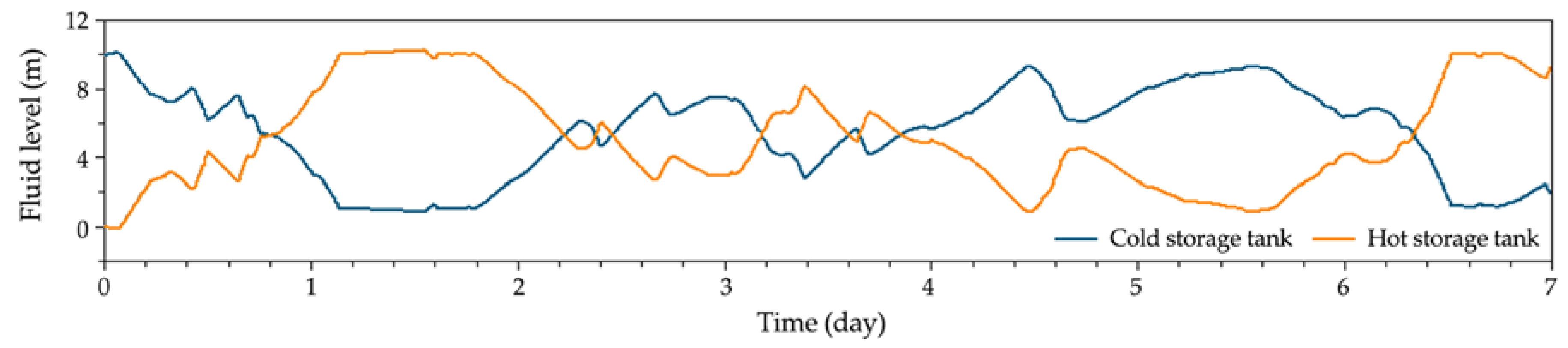

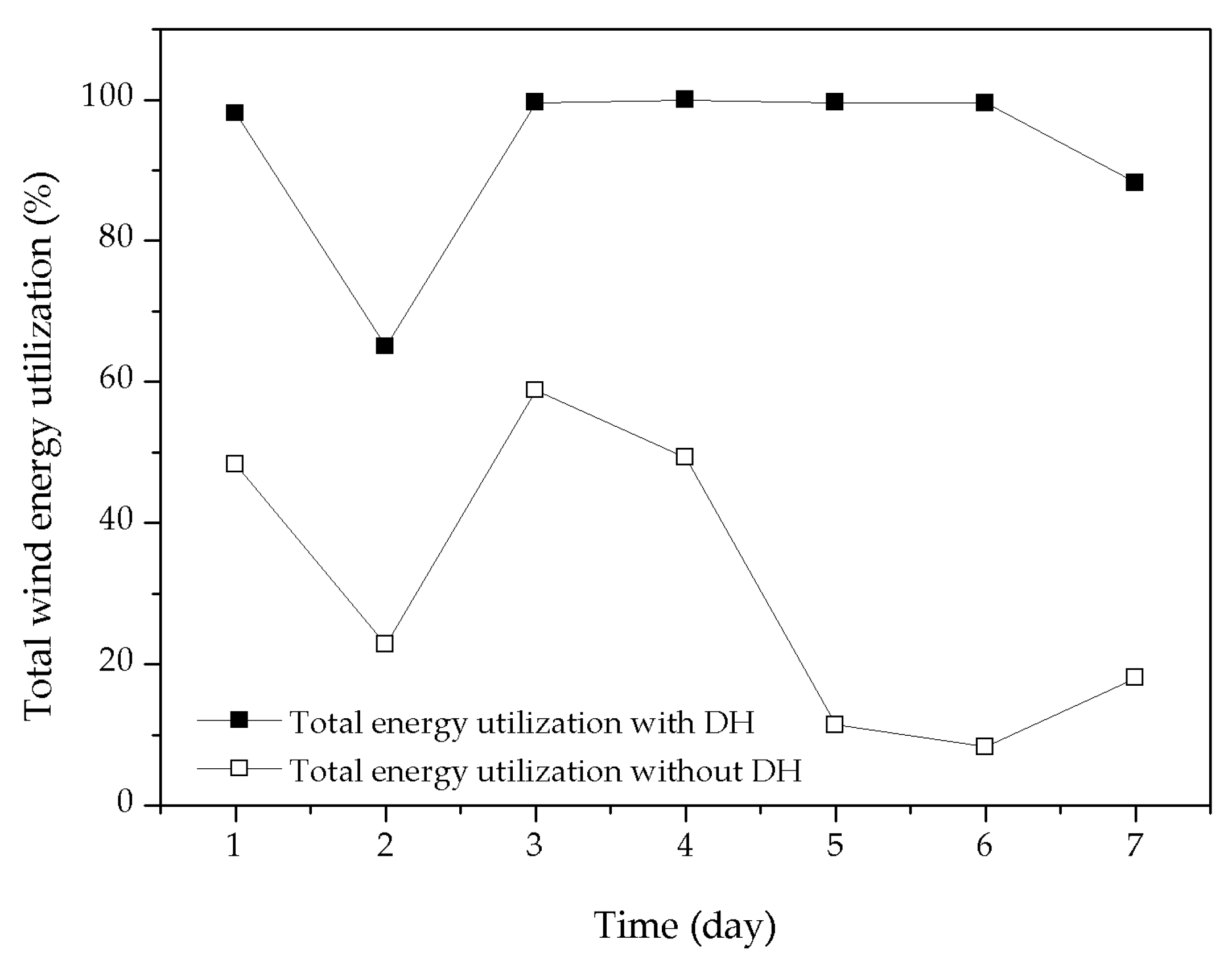

4.1. Operation and Performance of the Integrated System

4.2. The Influence of the System Configuration on the Performance of the Integrated System

5. Conclusions

- (1)

- The seven-day simulation results showed that the daily utilization of wind energy of the WTES system is much higher than that of the WPP system (without DH and TES). Meanwhile, the normal operation of the WTES system is under a simple and automatic control scheme, by which the electricity supplying and the DH form integrated dispatching and command.

- (2)

- The integrated system with a larger scale of TES can provide larger capacity to utilize the rejected wind energy, thus resulting in a higher total energy utilization. Parametric analysis reveals that the WTES system performance in the case of a given scale of the wind farm mainly depends on the configuration of the TES system and heat demand from users. The optimal design of the system can be carried out by giving the actual conditions of each wind farm and user demand.

- (3)

- In summary, the integrated WTES system is considered to be effective on enhancing the utilization of wind energy under great wind rejection.

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Notations | |

| A | Cross-sectional area of the flow component (m2) |

| ADH | Heat transfer surface (m2) |

| cp | Specific heat (J/kg/K) |

| C | Experimental coefficients |

| CP | Performance coefficient of wind turbine |

| E | Energy (MWh) |

| F | Friction force (kg/m/s2) |

| g | Constant of gravity (m/s2) |

| h | Specific enthalpy (J/kg) |

| J | Moment of inertia (kg∙m2) |

| k | Heat exchanger coefficient (W/m2/K) |

| Mass flow rate (kg/s) | |

| p | Pressure (Pa) |

| P | Power (W) |

| Pe | Electrical power input of electric heater (W) |

| PW | Wind power generated by wind turbine (W) |

| ΔQ | Energy variation (J) |

| R | Radius of wind turbine blade (m) |

| S | Effective area swept by wind turbine blades (m2) |

| t | Time (s) |

| T | Temperature (K) |

| Td | Test duration (s) |

| ΔTf | Temperature difference of fluid (K) |

| u | Internal specific energy of fluid (J/kg) |

| v | Wind speed (m/s) |

| WDH | Heat transfer rate of user side in DH sector (W) |

| Ws | Heat transfer rate of molten salt (W) |

| Wt | Heat flow rate (W) |

| Ww | Heat transfer rate of water (W) |

| x | Position (m) |

| Δx | Position variation (m) |

| z | Elevation (m) |

| Subscripts | |

| a | Air |

| c | Cold tank |

| CH | Continuous heating |

| charge | Charge mode |

| DH | District heating |

| discharge | Discharge mode |

| e | Electric |

| e-t | Thermo-electric conversion |

| ED | Electrical energy demand |

| ES | Electrical power supply |

| f | Fluid |

| G | Generator |

| HE | Heat exchanger |

| in | Inlet |

| N | Net storage (thermal energy) |

| out | Outlet |

| r | Power rejected |

| s | Molten salt |

| S | Storage |

| t | Thermal energy |

| TD | Thermal energy demand |

| u | Utilizing |

| w | Water |

| W | Wind turbine |

| Greek symbols | |

| β | Pitch angle (rad) |

| γ | Transmission ratio |

| δ | Completion rate (%) |

| η | Efficiency (%) |

| ζ | Total available energy utilization (%) |

| λ | Tip speed ratio of wind turbine blade |

| ρ | Density of air (kg/m3) |

| τ | Torque (N∙m) |

| ω | Angular velocity of turbine (rad/s) |

| Abbreviations | |

| CSP | Concentrating solar power |

| DH | District heating |

| EPDI | Electric power dispatching institution |

| HE | Heat exchanger |

| HTF | Heat transfer fluid |

| MSTES | Molten salt TES |

| NCT | Comfort temperature of norm |

| PI | Proportional-intergral |

| TES | TES |

| WPP | Wind power plant |

| WTES | Wind-TES system |

References

- Zhao, X.; Li, S.; Zhang, S.; Yang, R.; Liu, S. The effectiveness of China’s wind power policy: An empirical analysis. Energy Policy 2016, 95, 269–279. [Google Scholar] [CrossRef]

- Global wind Energy Outlook Scenarios. Global Wind Energy Outlook 2016; Fried, L., Shukla, S., Eds.; Global Wind Energy Council: Brussels, Belgium, 2016; pp. 15–30. [Google Scholar]

- Albadi, M.H.; El-Saadany, E.F. Overview of wind power intermittency impacts on power systems. Electr. Power Syst. Res. 2010, 80, 627–632. [Google Scholar] [CrossRef]

- Zhang, Y.; Tang, N.; Niu, Y.; Du, X. Wind energy rejection in China: Current status, reasons and perspectives. Renew. Sustain. Energy Rev. 2016, 66, 322–344. [Google Scholar] [CrossRef]

- Cochran, J.; Miller, M.; Zinaman, O.; Milligan, M.; Arent, D.; Palmintier, B.; O’Malley, M.; Mueller, S.; Lannoye, E.; Tuohy, A.; et al. Flexibility in 21st Century Power Systems; National Renewable Energy Lab.: Golden, CO, USA, 2014. [Google Scholar]

- Jiang, Y.; Xu, J.; Sun, Y.; Wei, C.; Wang, J.; Ke, D.; Li, X.; Yang, J.; Peng, X.; Tang, B. Day-ahead stochastic economic dispatch of wind integrated power system considering demand response of residential hybrid energy system. Appl. Energy 2017, 190, 1126–1137. [Google Scholar] [CrossRef]

- Lund, P.D.; Lindgren, J.; Mikkola, J.; Salpakari, J. Review of energy system flexibility measures to enable high levels of variable renewable electricity. Renew. Sustain. Energy Rev. 2015, 45, 785–807. [Google Scholar] [CrossRef]

- Sullivan, P.; Short, W.; Blair, N. Modelling the benefits of storage technologies to wind power. In Proceedings of the American Wind Energy Association Wind Power 2008 Conference, Golden, CO, USA, 1–4 June 2008. [Google Scholar]

- Díaz-González, F.; Sumper, A.; Gomis-Bellmunt, O.; Villafáfila-Robles, R. A review of energy storage technologies for wind power applications. Renew. Sustain. Energy Rev. 2012, 16, 2154–2171. [Google Scholar] [CrossRef]

- Yuan, Y.; Zhang, X.; Ju, P.; Fu, Z. Determination of economic dispatch of wind farm-battery energy storage system using genetic algorithm. Int. Trans. Electr. Energy Syst. 2014, 24, 264–280. [Google Scholar] [CrossRef]

- Zahedi, A. Sustainable power supply using solar energy and wind power combined with energy storage. Energy Procedia 2014, 52, 642–650. [Google Scholar] [CrossRef][Green Version]

- Monroy, C.A.S.; Christie, R.D. Energy storage effects on day-ahead operation of power systems with high wind penetration. In Proceedings of the North American Power Symposium 2011, Boston, MA, USA, 4–6 August 2011. [Google Scholar]

- Amrouche, S.O.; Rekioua, D.; Rekioua, T.; Bacha, S. Overview of energy storage in renewable energy systems. Int. J. Hydrogen Energy 2016, 41, 20914–20927. [Google Scholar] [CrossRef]

- Zhang, Y.; Ding, W. Increasing Wind Power Consumption & Absorbability, Solving Grid Connection Issue by Use of Thermal Energy Storage Technology. In Proceedings of the Chinese Society for Electrical Engineering Annual Meeting 2012, Beijing, China, 21–24 November 2012. [Google Scholar]

- Li, G. Sensible heat thermal storage energy and exergy performance evaluations. Renew. Sustain. Energy Rev. 2016, 53, 897–923. [Google Scholar] [CrossRef]

- Tyner, C.E.; Sutherland, J.P.; Gould, W.R. Solar Two: A Molten Salt Power Tower Demonstration; Sandia National Laboratories: Albuquerque, NM, USA, 1995. [Google Scholar]

- Pacheco, J.E.; Reilly, H.E.; Kolb, G.J.; Tyner, C.E. Summary of the Solar Two Test and Evaluation Program; Sandia National Laboratories: Albuquerque, NM, USA, 2000. [Google Scholar]

- Hasnain, S.M. Review on sustainable thermal energy storage technologies, part I: Heat storage materials and techniques. Energy Convers. Manag. 1998, 39, 1127–1138. [Google Scholar] [CrossRef]

- Herrmann, U.; Kelly, B.; Price, H. Two-tank molten salt storage for parabolic trough solar power plants. Energy 2004, 29, 883–893. [Google Scholar] [CrossRef]

- Parrado, C.; Marzo, A.; Fuentealba, E.; Fernández, A.G. 2050 LCOE improvement using new molten salts for thermal energy storage in CSP plants. Renew. Sustain. Energy Rev. 2016, 57, 505–514. [Google Scholar] [CrossRef]

- Glatzmaier, G. Developing a Cost Model and Methodology to Estimate Capital Costs for Thermal Energy Storage; NREL/TP-5500-53066; National Renewable Energy Laboratory: Golden, CO, USA, 2011. [Google Scholar]

- Okazaki, T.; Shirai, Y.; Nakamura, T. Concept study of wind power utilizing direct thermal energy conversion and thermal energy storage. Renew. Energy 2015, 83, 332–338. [Google Scholar] [CrossRef]

- Xinhuanet. State Grid Corporation of China Published the “White Paper for Promoting the Development of New Energy (2016)”. Available online: http://news.xinhuanet.com/2016-03/11/c_1118307562.htm (accessed on 11 March 2016).

- State Grid Corporation of China. The Means to Capture the Wind. Available online: http://www.sgcc.com.cn/xwzx/gsyw/2017/03/338555.shtml (accessed on 16 March 2017).

- ZhongTouYiXing New Energy Investment Co. Ltd. Zhong Tou Yi Xing New Energy Investment Corporation Employs the Electrical Heated Molten Salt Thermal Energy Storage Technology for Domestic Heating. Available online: http://www.ztyxxny.com/newsdetail/91.html (accessed on 22 April 2016).

- Xinhuanet. The Technology of Molten Salt Thermal Energy Storage by Utilizing Valley Electricity for Heat Helps Realize the Heating Reform Project. Available online: http://news.xinhuanet.com/2016-01/25/c_1117885895.htm (accessed on 25 January 2016).

- Martin, M.; Thornley, P. The Potential for Thermal Storage to Reduce the Overall Carbon Emissions from District Heating Systems; The Tyndall Centre: Tyndall Manchester, UK, 2012; pp. 4–8. [Google Scholar]

- Arabkoohsar, A.; Andresen, G.B. Design and analysis of the novel concept of high temperature heat and power storage. Energy 2017, 126, 21–33. [Google Scholar] [CrossRef]

- Lidegaard, M. District heating-Danish and Chinese Experience; Danish Board of District Heating & Danish Energy Agency: Frederiksberg, Denmark, 2013; pp. 5–14. [Google Scholar]

- Wu, Y.; Zhang, X.; Wang, H.; Sun, J. Molten salt heat storage and supply technology based on heating using abandoned wind power, PV power or off-peak power. Sino-Glob. Energy 2017, 22, 93–99. [Google Scholar]

- Tian, Y.; Zhao, C.Y. A review of solar collectors and thermal energy storage in solar thermal applications. Appl. Energy 2013, 104, 538–553. [Google Scholar] [CrossRef]

- Peiró, G.; Gasia, J.; Miró, L.; Prieto, C.; Cabeza, L.F. Experimental analysis of charging and discharging processes, with parallel and counter flow arrangements, in a molten salts high temperature pilot plant scale setup. Appl. Energy 2016, 178, 294–403. [Google Scholar] [CrossRef]

- Li, X.; Xu, E.; Song, S.; Wang, X.; Yuan, G. Dynamic simulation of two-tank indirect thermal energy storage system with molten salt. Renew. Energy 2017, 113, 1311–1319. [Google Scholar] [CrossRef]

- Powell, K.M.; Edgar, T.F. Control of a large scale solar thermal energy storage system. In Proceedings of the 2011 American Control Conference, San Francisco, CA, USA, 29 June–1 July 2011. [Google Scholar]

- Zhao, Z.; Arif, M.T.; Oo, A.M.T. Solar thermal energy with molten-salt storage for residential heating application. Energy Procedia 2017, 110, 243–249. [Google Scholar] [CrossRef]

- Green, M.; Sabharwall, P.; Yoon, S.J.; Bragg-Sitton, S.B.; Stoot, C. Nuclear Hybrid Energy System: Molten Salt Energy Storage; INL/EXT-13-31768; Idaho National Laboratory: Idaho Falls, ID, USA, 2013. [Google Scholar]

- Ma, Z.; Glatzmaier, G.C.; Kutscher, C.F. Thermal energy storage and its potential applications in solar thermal power plants and electricity storage. In Proceedings of the ASME 2011 5th International Conference on Energy Sustainability, Washington, DC, USA, 7–10 August 2011. [Google Scholar]

- Mowers, M.; Helm, C.; Blair, N.; Short, W. Correlations between geographically dispersed concentrating solar power and demand in the United States. In Proceedings of the ASME 2010 4th International Conference on Energy Sustainability, Phoenix, AZ, USA, 17–22 May 2010. [Google Scholar]

- Shropshire, D.; Purvins, A.; Papaioannou, I.; Maschio, I. Benefits and cost implications from integrating small flexible nuclear reactors with off-shore wind farms in a virtual power plant. Energy Policy 2012, 46, 558–573. [Google Scholar] [CrossRef]

- Eberhar, P.; Chung, T.S.; Haumer, A.; Kra, C. Open source library for the simulation of Wind Power Plants. In Proceedings of the 11th International Modelica Conference, Versailles, France, 21–23 September 2015. [Google Scholar]

- Petersson, J.; Isaksson, P.; Tummescheit, H.; Ylikiiskil, J. Modeling and Simulation of a Vertical Wind Power Plant in Dymola/Modelica. In Proceedings of the 9th International Modelica Conference, Munich, Germany, 3–5 September 2012. [Google Scholar]

- Hefni, B.E.; Soler, R. Dynamic multi-configuration model of a 145 MWe concentrated solar power plant with the ThermoSysPro library (tower receiver, molten salt storage and steam generator). Energy Procedia 2015, 69, 1249–1258. [Google Scholar] [CrossRef][Green Version]

- Hefni, B.E. Dynamic modeling of concentrated solar power plants with the ThermoSysPro library (Parabolic Trough collectors, Fresnel reflector and Solar-Hybrid). Energy Procedia 2014, 49, 1127–1137. [Google Scholar] [CrossRef]

- Zaversky, F.; Rodríguez-García, M.M.; García-Barberena, J.; Sánchez, M.; Astrain, D. Transient behavior of an active indirect two-tank thermal energy storage system during changes in operating mode—An application of an experimentally validated numerical model. Energy Procedia 2014, 49, 1078–1087. [Google Scholar] [CrossRef]

- Faille, D.; Liu, S.; Wang, Z.; Yang, Z. Control design model for a solar tower plant. Energy Procedia 2014, 49, 2080–2089. [Google Scholar] [CrossRef]

- Stiebler, M. Wind Energy System for Electric Power Generation; Springer: Berlin/Heidelberg, Germany, 2008; pp. 11–12. [Google Scholar]

- Heier, S. Grid Integration of Wind Energy: Onshore and Offshore Conversion Systems, 3rd ed.; John Wiley & Sons Ltd.: Chichester, UK, 2014; pp. 32–44. [Google Scholar]

- Catană, I.; Safta, C.; Panduru, V. Power optimization control system of wind turbines by changing the pitch angle. UPB Sci. Bull. Ser. D 2010, 72, 140–148. [Google Scholar]

- Shao, B.; Sun, C.; Qi, C. Building thermal characteristic simulation under heating condition. Heat. Vent. Air Cond. 2017, 47, 124–128. [Google Scholar]

- Zhang, X.; Yang, L.; He, B.; Zhang, A.; Wang, F. Calculation method of auxiliary power consumption rate for combined heating cooling and power distributed energy system. Therm. Power Gen. 2017, 46, 88–92. [Google Scholar]

| Parameter | Unit | Value |

|---|---|---|

| Diameter of blades | m | 90 |

| Density of air | kg/m3 | 1.2 |

| Initial temperature of molten salt | K | 563 |

| Operating temperature of cold tank | K | 563 |

| Operating temperature of hot tank | K | 838 |

| Efficiency of pumps | - | 70% |

| Density of molten salt | kg/m3 | 2089.905 − 0.636 T (°C) |

| Specific heat of molten salt | J/(kg∙K) | 1443 + 0.172 T (°C) |

| Thermal conductivity of molten salt | W/(m∙K) | 1.9 × 10−4 T (°C) + 0.443 |

| Kinematic viscosity of molten salt | m2/s | −6.557 × 10−14 T3 (°C) + 1.05 × 10−10 T2 (°C) − 5.706 × 10−8 T (°C) + 1.112 × 10−5 |

| Height of cold tank | M | 10 |

| Height of hot tank | m | 10 |

| Diameter of cold tank | m | 10 |

| Diameter of hot tank | m | 10 |

| Initial temperature of water | K | 273 |

| NCT | K | 298 |

| Heat transfer area of salt-water HE | m2 | 50.2 |

| Heat transfer surface of air-water HE | m2 | 50,000 |

| Heat exchange coefficient of air-water HE | W/(m2∙K) | 10 |

| Parameter | Unit | Value | |

|---|---|---|---|

| Validation a | Validation b | ||

| Process | - | Charge | Discharge |

| HTF | - | Therminol VP-1 | |

| TES medium | - | Solar salt | |

| Flow arrangement | - | Counter flow | |

| Density of TES medium | kg/m3 | 2089.905 − 0.636 T (°C) | |

| Specific heat of TES medium | J/(kg∙K) | 1443 + 0.172 T (°C) | |

| Thermal conductivity of TES medium | W/(m∙K) | 1.9 × 10−4 T (°C) + 0.443 | |

| Kinematic viscosity of TES medium | m2/s | −6.557 × 10−14 T3 (°C) + 1.05 × 10−10 T2 (°C) −5.706 × 10−8 T (°C) + 1.112 × 10−5 | |

| Height of tank | m | 1.2 | |

| Diameter of tank | m | 0.8 | |

| Inlet temperature | K | 567 | 619 |

| Design pressure | bar | 10 | 10 |

| Density of HTF | kg/m3 | −2.835 × 10−6 T3 (°C) + 1.235 × 10−3 T2 (°C) + 1.037 T (°C) + 1094 | |

| Specific heat of HTF | J/(kg∙K) | 4.908 × 10−8 T4 (°C) − 3.960 × 10−5 T3 (°C) + 1.107 × 10−2 T2 (°C) + 1.439 T (°C) + 1556 | |

| Thermal conductivity of HTF | W/(m∙K) | −1.687 × 10−7 T2 (°C) − 8.885 × 10−5 T + 0.138 | |

| Kinematic viscosity of HTF | m2/s | −9.565 × 10−19 T5 (°C) + 1.417 × 10−15 T4 (°C) − 8.435 × 10−13 T3 (°C) + 2.574 × 10−10 T2 (°C) − 4.197 × 10−8 T (°C) + 3.318 × 10−6 | |

| Heating power of electric heater | W | 24,000 | - |

| Heat transfer power of air-HTF HE | W | - | 20,000 |

| Inlet temperature | K | 614 | 570 |

| Design pressure | bar | 20 | 20 |

| Metal material | - | Stainless steel alloy 316 | |

| Mass flow rate of HTF | kg/s | 0.09 | |

| Mass flow rate of TES medium | kg/s | 0.11 | |

| Parameter | Unit | Value | ||||||

|---|---|---|---|---|---|---|---|---|

| Time | day | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Electrical energy demand | MWh | 495.6 | 496.4 | 499.9 | 459.2 | 498.3 | 497.3 | 494.8 |

| Thermal energy demand | MWh | 222.9 | 225.0 | 220.0 | 224.0 | 220.9 | 229.8 | 232.1 |

| Total available wind energy | MWh | 760.6 | 554.3 | 374.3 | 527.1 | 206.5 | 282.0 | 463.5 |

| Output electrical energy | MWh | 367.3 | 126.3 | 220.2 | 260.1 | 23.5 | 23.5 | 83.9 |

| Output thermal energy | MWh | 222.9 | 225.0 | 220.0 | 224.0 | 220.9 | 229.8 | 232.1 |

| Net TES | MWh | 155.6 | 9.0 | −67.4 | 43.0 | −38.8 | 27.2 | 92.9 |

| Power rejected with DH | MWh | 14.8 | 194 | 1.5 | 0 | 0.9 | 1.5 | 54.6 |

| Power rejected without DH | MWh | 393.3 | 428.0 | 154.1 | 267.0 | 183.0 | 258.5 | 379.6 |

| Completion rate of electrical power supply | % | 74.1 | 25.4 | 44.0 | 56.6 | 4.7 | 4.7 | 17.0 |

| Completion rate of DH | % | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 |

| Energy utilization of WTES system (with DH) | % | 98.1 | 65.0 | 99.6 | 100.0 | 99.6 | 99.5 | 88.2 |

| Energy utilization of WPP system (without DH) | % | 48.3 | 22.8 | 58.8 | 49.3 | 11.4 | 8.3 | 18.1 |

| Parameter | Unit | Value | ||||

|---|---|---|---|---|---|---|

| Diameter of storage tanks | m | 6 | 8 | 10 | 12 | 14 |

| Electrical energy demand | MWh | 3475.1 | ||||

| Thermal energy demand | MWh | 1574.7 | ||||

| Output electrical energy | MWh | 1104.8 | ||||

| Output thermal energy | MWh | 1526.8 | 1574.7 | 1574.7 | 1574.7 | 1574.7 |

| Net TES | MWh | 73.6 | 150.2 | 223 | 308 | 431 |

| Power rejected with DH | MWh | 415.2 | 339.0 | 266.1 | 180.6 | 57.0 |

| Power rejected without DH | MWh | 2062.6 | ||||

| Completion rate of electrical power supply | % | 31.8 | ||||

| Completion rate of DH | % | 99.7 | 100 | 100 | 100 | 100 |

| Energy utilization of WTES system (with DH) | % | 86.9 | 89.3 | 91.6 | 94.3 | 98.2 |

| Energy utilization of WPP system (without DH) | % | 34.9 | ||||

| Parameter | Unit | Value | ||

|---|---|---|---|---|

| Area of DH | m2 | 30,000 | 50,000 | 70,000 |

| Thermal energy demand | MWh | 962.1 | 1574.7 | 2156.3 |

| Output thermal energy | MWh | 962.1 | 1574.7 | 1890.5 |

| Power rejected | MWh | 912.2 | 266.1 | 70.5 |

| Completion of DH | % | 100 | 100 | 87.7 |

| Energy utilization of WTES system (with DH) | % | 71.3 | 91.6 | 98.9 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Cheng, M.-S.; Zhao, B.-C.; Dai, Z.-M. A Wind Power Plant with Thermal Energy Storage for Improving the Utilization of Wind Energy. Energies 2017, 10, 2126. https://doi.org/10.3390/en10122126

Liu C, Cheng M-S, Zhao B-C, Dai Z-M. A Wind Power Plant with Thermal Energy Storage for Improving the Utilization of Wind Energy. Energies. 2017; 10(12):2126. https://doi.org/10.3390/en10122126

Chicago/Turabian StyleLiu, Chang, Mao-Song Cheng, Bing-Chen Zhao, and Zhi-Min Dai. 2017. "A Wind Power Plant with Thermal Energy Storage for Improving the Utilization of Wind Energy" Energies 10, no. 12: 2126. https://doi.org/10.3390/en10122126

APA StyleLiu, C., Cheng, M.-S., Zhao, B.-C., & Dai, Z.-M. (2017). A Wind Power Plant with Thermal Energy Storage for Improving the Utilization of Wind Energy. Energies, 10(12), 2126. https://doi.org/10.3390/en10122126