Studies on Cup Anemometer Performances Carried out at IDR/UPM Institute. Past and Present Research

Abstract

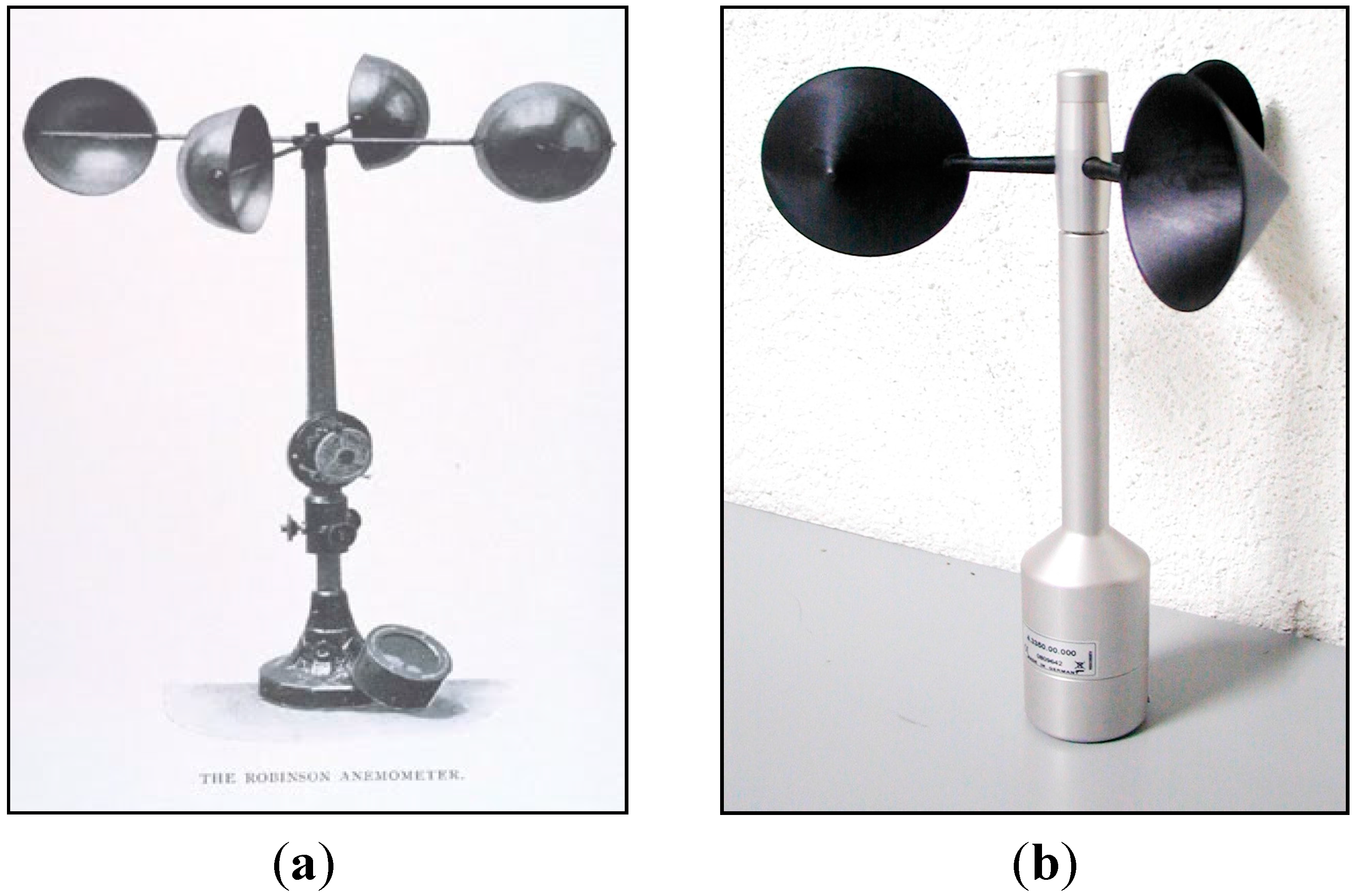

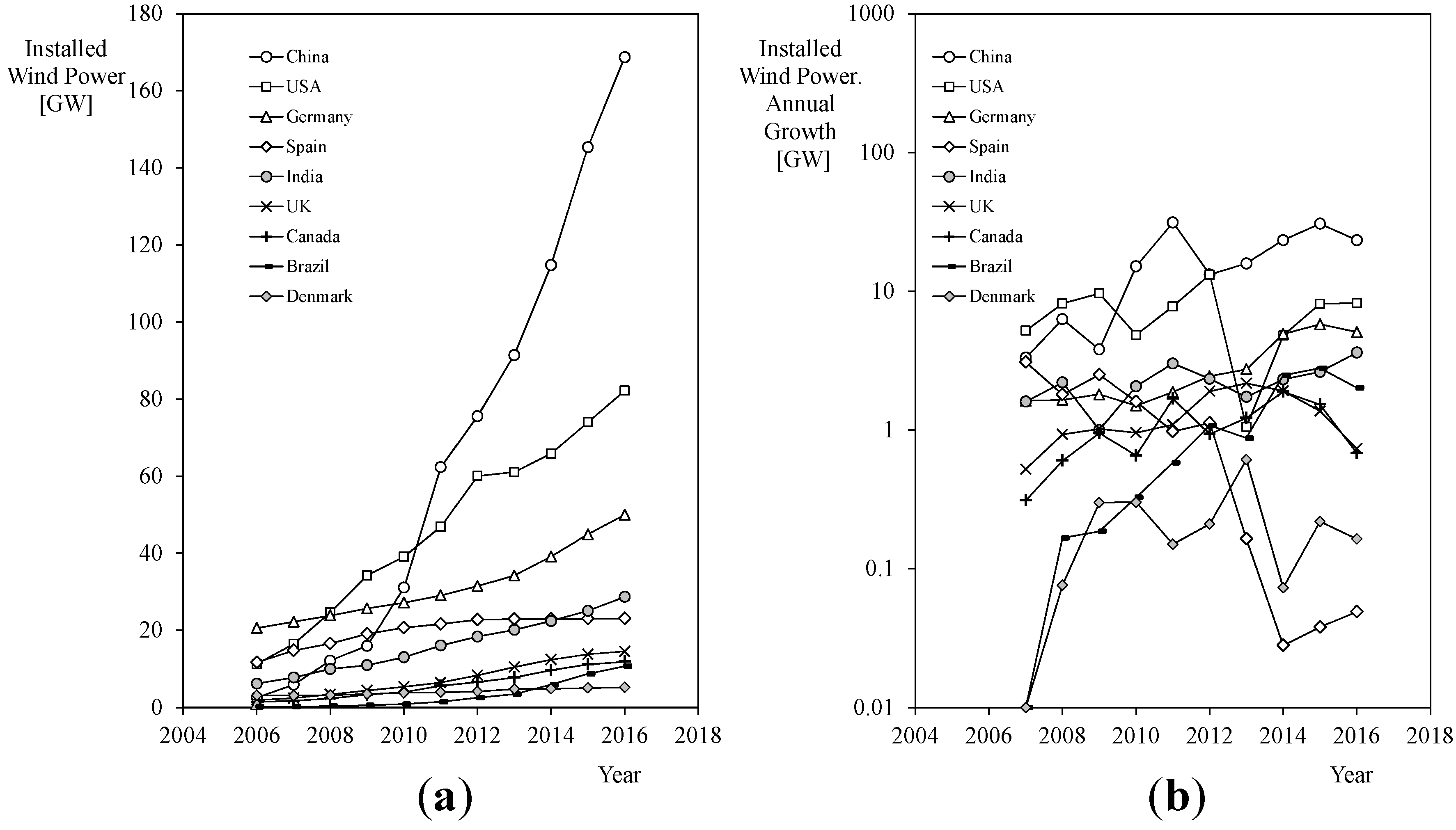

1. Introduction

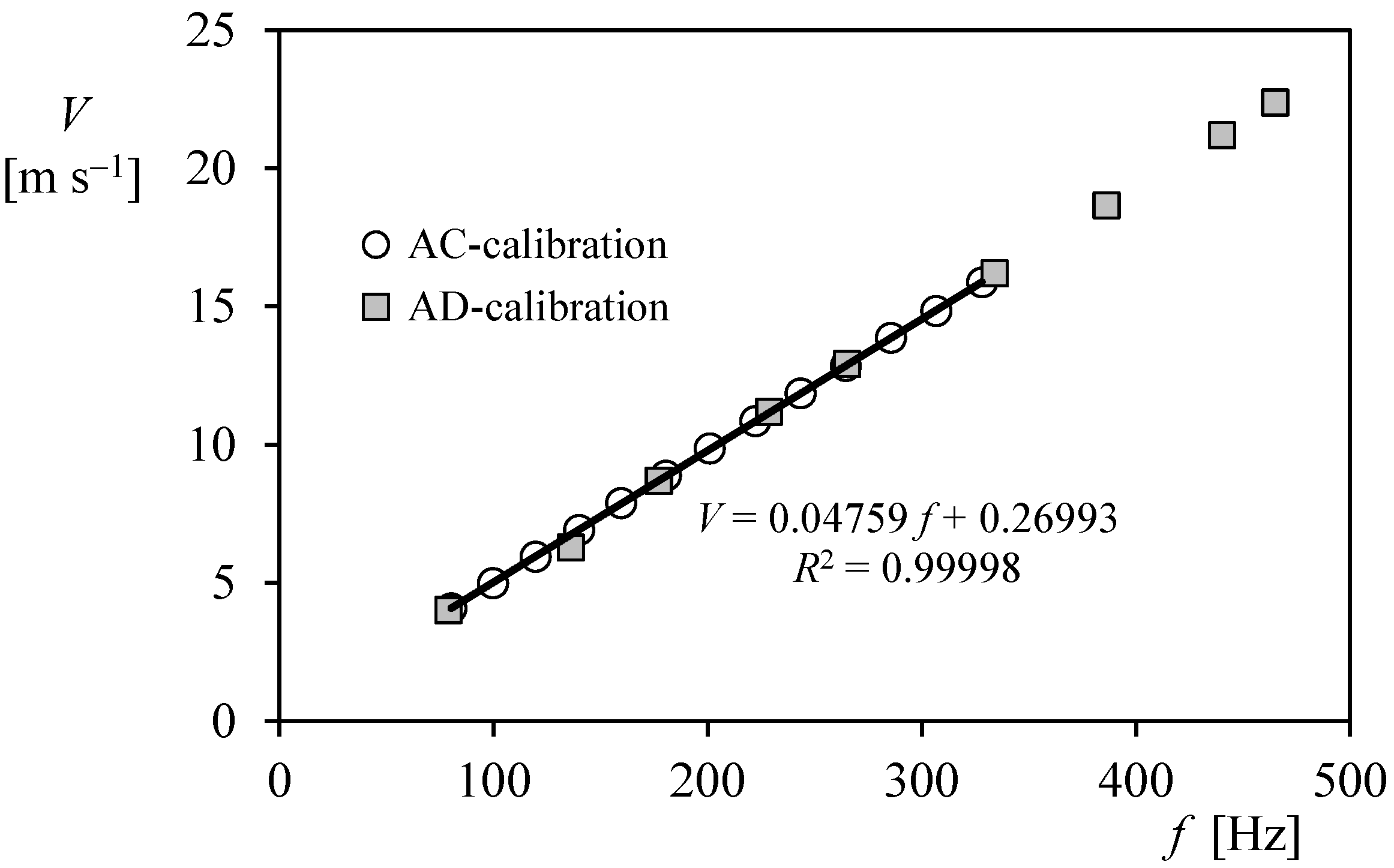

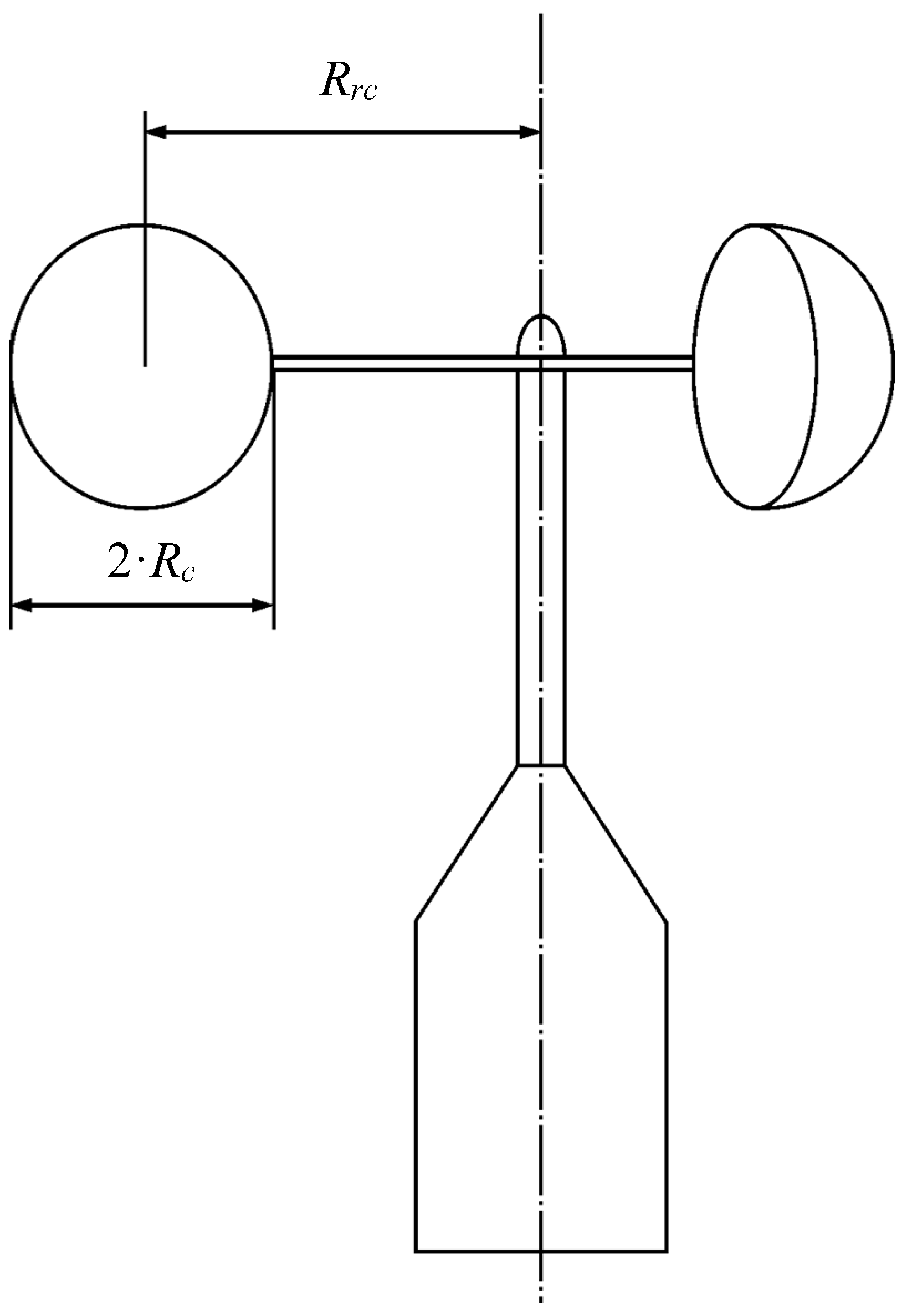

2. Experimental Analyses of Cup Anemometer Performances

- The differences between the AC and AD calibration procedures were negligible in terms of both wind speed (with 2.6%, 0.88%, and 0.31% deviation at 5 m·s−1, 10 m·s−1, and 15 m·s−1 wind speed for the Thies anemometer referred in Figure 3) and wind power generator Annual Energy Production (AEP);

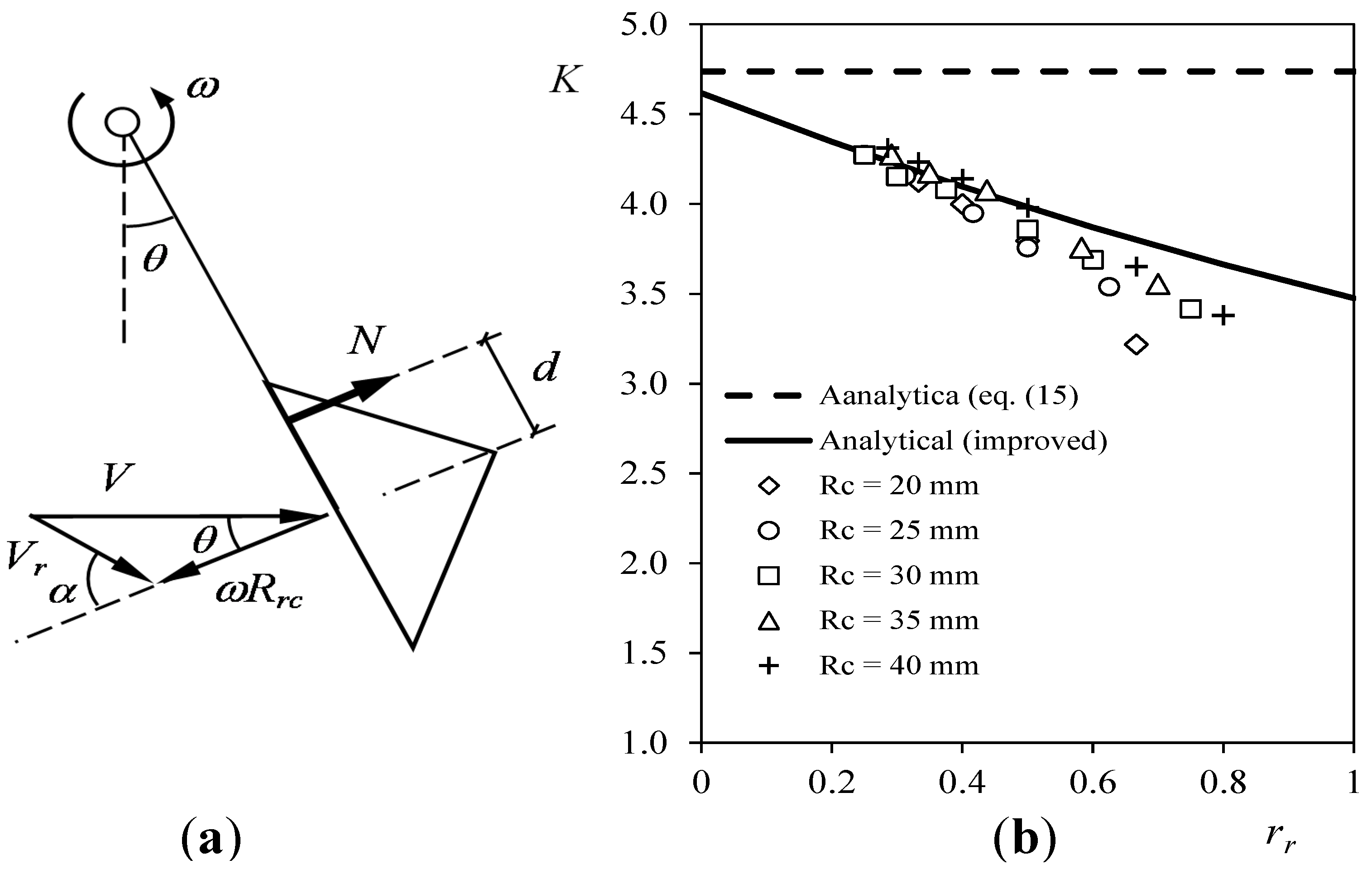

- The slope of the calibration curve, Ar, seemed (in that work) to have a direct relationship with the cups’ center rotation radius, Rrc, (that is, with the anemometer’s rotor radius). This relationship was also proven with an analytical model of the cup anemometer performance.

- Calibration constants, A and B, are affected by changes in air density, which, on the other hand, is driven mostly by changes in air temperature;

- These changes have a quite relevant impact on Annual Energy Production (AEP) estimations, depending on the selected wind sensor. Deviations of AEP up to 18% and 8% at 4 m·s−1, and 7 m·s−1 wind speeds were calculated for 0.1 kg·m−3 air density variations and first class anemometers;

- The anemometers degrade in large storage periods;

- Even showing a quite high level of wear and tear, it is quite difficult to establish degradation patterns of anemometers working on the field.

3. Modeling Cup Anemometer Performances

4. Conclusions

- The analysis of the performance based on experimental results as follows:

- ○

- Force on isolated cups;

- ○

- Calibrations performed on both commercial anemometers and anemometers equipped with special-design rotors;

- ○

- The output signal of the cup anemometers.

- The analytical study of the cup anemometer performances with a new methodology developed consequently. All expertise gained with the analysis of testing results was a fundamental basis for this analytical work. It should be underlined the importance of analytical models in order to produce better sensors in the future, as by using these models, a reduction of costs (measured in time and calculation resources) can be achieved in the first stages of the designing process.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sanz-Andrés, A.; Meseguer, J. El satélite español UPM-Sat 1. Mundo Científico 1996, 169, 560–567. [Google Scholar]

- Meseguer, J.; Sanz, A.; Lopez, J. Liquid bridge breakages aboard spacelab-D1. J. Cryst. Growth 1986, 78, 325–334. [Google Scholar] [CrossRef]

- Sanz-Andrés, A.; Meseguer, J.; Perales, J.M.; Santiago-Prowald, J. A small platform for astrophysical research based on the UPM-Sat 1 satellite of the Universidad Politécnica de Madrid. Adv. Space Res. 2003, 31, 375–380. [Google Scholar] [CrossRef]

- Sanz-Andrés, A.; Rodríguez-De-Francisco, P.; Santiago-Prowald, J. The Experiment CPLM (Comportamiento De Puentes Líquidos En Microgravedad) on Board MINISAT 01. In Science with Minisat 01; Springer: Dordrecht, The Netherlands, 2001; pp. 97–121. [Google Scholar]

- Neefs, E.; Vandaele, A.C.; Drummond, R.; Thomas, I.R.; Berkenbosch, S.; Clairquin, R.; Delanoye, S.; Ristic, B.; Maes, J.; Bonnewijn, S.; et al. NOMAD spectrometer on the ExoMars trace gas orbiter mission: Part 1—Design, manufacturing and testing of the infrared channels. Appl. Opt. 2015, 54, 8494–8520. [Google Scholar] [CrossRef] [PubMed]

- Fernández Rico, G.; Perez-Grande, I. Diseño térmico preliminar del Instrumento PHI de Solar Orbiter. In Actas del VII Congreso Nacional de Ingeniería Termodinámica—CNIT7; Universidad del País Vasco: Bilbao, España, 2011. [Google Scholar]

- Patel, M.R.; Antoine, P.; Mason, J.; Leese, M.; Hathi, B.; Stevens, A.H.; Dawson, D.; Gow, J.; Ringrose, T.; Holmes, J.; et al. NOMAD spectrometer on the ExoMars trace gas orbiter mission: Part 2—Design, manufacturing, and testing of the ultraviolet and visible channel. Appl. Opt. 2017, 56, 2771–2782. [Google Scholar] [CrossRef] [PubMed]

- Abdellaoui, G.; Abe, S.; Acheli, A.; Adams, J.H.; Ahmad, S.; Ahriche, A.; Albert, J.N.; Allard, D.; Alonso, G.; Anchordoqui, L.; et al. Meteor studies in the framework of the JEM-EUSO program. Planet. Space Sci. 2017, 143, 245–255. [Google Scholar] [CrossRef]

- Abdellaoui, G.; Abe, S.; Acheli, A.; Adams, J.H.; Ahmad, S.; Ahriche, A.; Albert, J.-N.; Allard, D.; Alonso, G.; Anchordoqui, L.; et al. Cosmic ray oriented performance studies for the JEM-EUSO first level trigger. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrom. Detect. Assoc. Equip. 2017, 866, 150–163. [Google Scholar] [CrossRef]

- Cubas, J.; Farrahi, A.; Pindado, S. Magnetic Attitude Control for Satellites in Polar or Sun-Synchronous Orbits. J. Guid. Control Dyn. 2015, 38, 1947–1958. [Google Scholar] [CrossRef]

- Roibás-Millán, E.; Alonso-Moragón, A.; Jiménez-Mateos, A.; Pindado, S. On solar panels testing for small-size satellites. The UPMSAT-2 mission. Meas. Sci. Technol. 2017. [Google Scholar] [CrossRef]

- Pindado, S.; Meseguer, J. Wind tunnel study on the influence of different parapets on the roof pressure distribution of low-rise buildings. J. Wind Eng. Ind. Aerodyn. 2003, 91, 1133–1139. [Google Scholar] [CrossRef]

- Franchini, S.; Pindado, S.; Meseguer, J.; Sanz-Andrés, A. A parametric, experimental analysis of conical vortices on curved roofs of low-rise buildings. J. Wind Eng. Ind. Aerodyn. 2005, 93, 639–650. [Google Scholar] [CrossRef]

- Pindado, S.; Meseguer, J.; Franchini, S. The influence of the section shape of box-girder decks on the steady aerodynamic yawing moment of double cantilever bridges under construction. J. Wind Eng. Ind. Aerodyn. 2005, 93, 547–555. [Google Scholar] [CrossRef]

- Pindado, S.; Meseguer, J.; Franchini, S. Influence of an upstream building on the wind-induced mean suction on the flat roof of a low-rise building. J. Wind Eng. Ind. Aerodyn. 2011, 99, 889–893. [Google Scholar] [CrossRef]

- Sanz-Andrés, A.; Santiago-Prowald, J. Train-induced pressure on pedestrians. J. Wind Eng. Ind. Aerodyn. 2002, 90, 1007–1015. [Google Scholar] [CrossRef]

- Sanz-Andrés, A.; Santiago-Prowald, J.; Baker, C.; Quinn, A. Vehicle-induced loads on traffic sign panels. J. Wind Eng. Ind. Aerodyn. 2003, 91, 925–942. [Google Scholar] [CrossRef]

- Pindado, S.; Sanz, A.; Sebastian, F.; Perez-grande, I.; Alonso, G.; Perez-Alvarez, J.; Sorribes-Palmer, F.; Cubas, J.; Garcia, A.; Roibas, E.; Fernandez, A. Master in Space Systems, an Advanced Master’s Degree in Space Engineering. In ATINER’S Conference Paper Series, No: ENGEDU2016-1953; Athens Institute for Education and Research: Athens, Greece, 2016; pp. 1–16. [Google Scholar]

- Pindado Carrion, S.; Roibás-Millán, E.; Cubas Cano, J.; García, A.; Sanz Andres, A.P.; Franchini, S.; Pérez Grande, M.I.; Alonso, G.; Pérez-Álvarez, J.; Sorribes-Palmer, F.; et al. The UPMSat-2 Satellite: An academic project within aerospace engineering education. In ATINER’S Conference Paper Series. Working Paper; Athens Institute for Education and Research: Athens, Greece, 2017. [Google Scholar]

- Pindado, S.; Roibas, E.; Cubas, J.; Sorribes-Palmer, F.; Sanz-Andrés, A.; Franchini, S.; Perez-Grande, I.; Zamorano, J.; De La Puente, J.A.; Perez-Alvarez, J.; et al. MUSE. Master in Space Systems at Universidad Politécnica de Madrid (UPM). Available online: https://www.researchgate.net/project/MUSE-Master-in-Space-Systems-at-Universidad-Politecnica-de-Madrid-UPM (accessed on 12 November 2017).

- Cubas, J.; Sorribes-Palmer, F.; Pindado, S. The use of STK as educational tool in the MUSE (Master in Space Systems), an Advanced Master’s Degree in Space. In Proceedings of the AGI’s 2nd International Users Conference: Ciao Roma, Roma, Italy, 6–18 November 2016. [Google Scholar]

- Pindado, S.; Vega, E.; Martínez, A.; Meseguer, E.; Franchini, S.; Pérez, I. Analysis of calibration results from cup and propeller anemometers. Influence on wind turbine Annual Energy Production (AEP) calculations. Wind Energy 2011, 14, 119–132. [Google Scholar] [CrossRef]

- Pindado, S.; Barrero-Gil, A.; Sanz, A. Cup Anemometers’ Loss of Performance Due to Ageing Processes, and Its Effect on Annual Energy Production (AEP) Estimates. Energies 2012, 5, 1664–1685. [Google Scholar] [CrossRef]

- Pindado, S.; Pérez, J.; Avila-Sanchez, S. On cup anemometer rotor aerodynamics. Sensors 2012, 12, 6198–6217. [Google Scholar] [CrossRef] [PubMed]

- Pindado, S.; Sanz, A.; Wery, A. Deviation of Cup and Propeller Anemometer Calibration Results with Air Density. Energies 2012, 5, 683–701. [Google Scholar] [CrossRef]

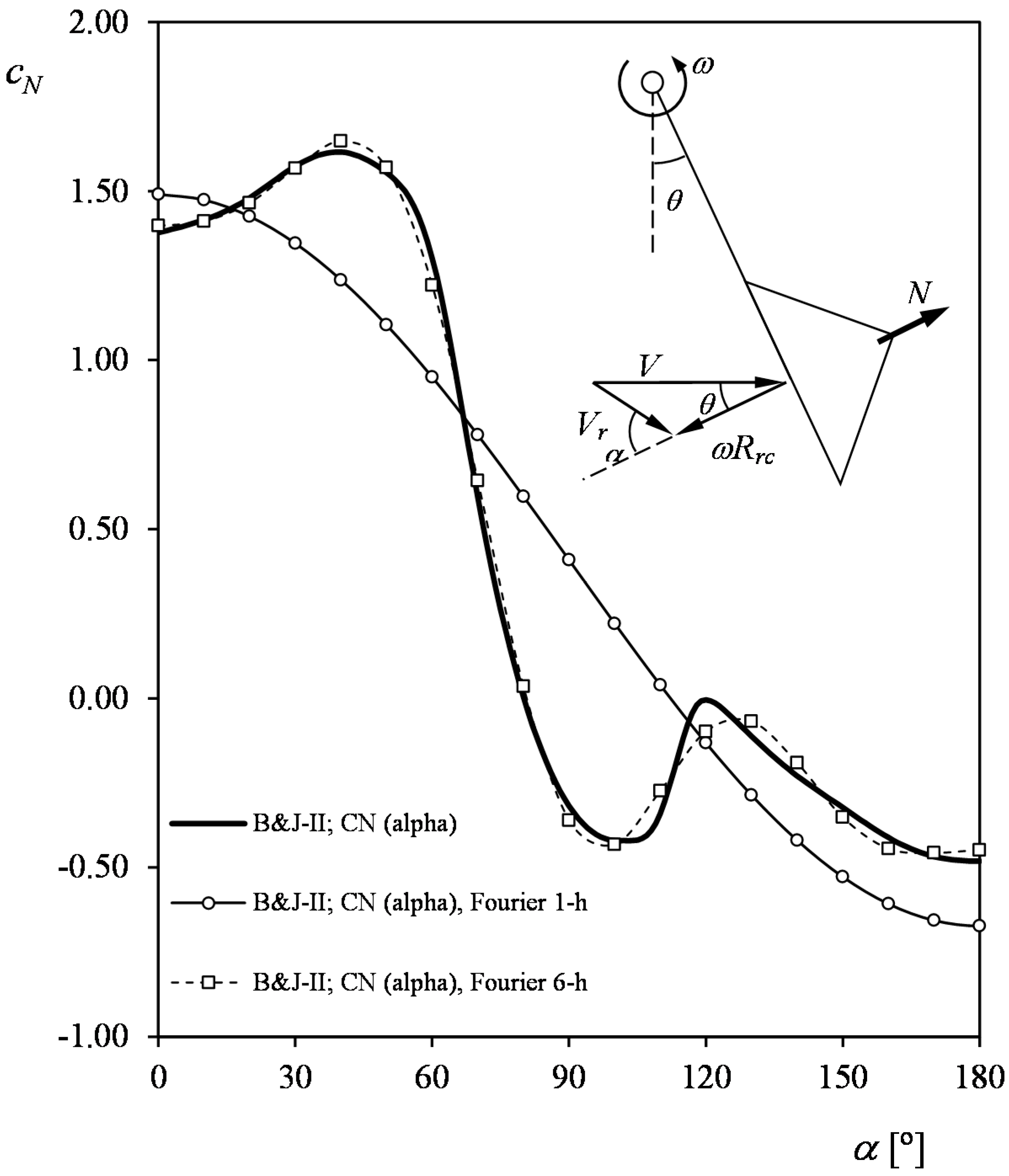

- Pindado, S.; Cubas, J.; Sanz-Andrés, A. Aerodynamic analysis of cup anemometers performance. The stationary harmonic response. Sci. World J. 2013, 2013, 197325. [Google Scholar] [CrossRef] [PubMed]

- Pindado, S.; Pérez, I.; Aguado, M. Fourier analysis of the aerodynamic behavior of cup anemometers. Meas. Sci. Technol. 2013, 24, 065802. [Google Scholar] [CrossRef]

- Pindado, S.; Cubas, J.; Sorribes-Palmer, F. The Cup Anemometer, a Fundamental Meteorological Instrument for the Wind Energy Industry. Research at the IDR/UPM Institute. Sensors 2014, 14, 21418–21452. [Google Scholar] [CrossRef] [PubMed]

- Sanz-Andrés, A.; Pindado, S.; Sorribes, F. Mathematical analysis of the effect of the rotor geometry on cup anemometer response. Sci. World J. 2014, 2014, 537813. [Google Scholar] [CrossRef] [PubMed]

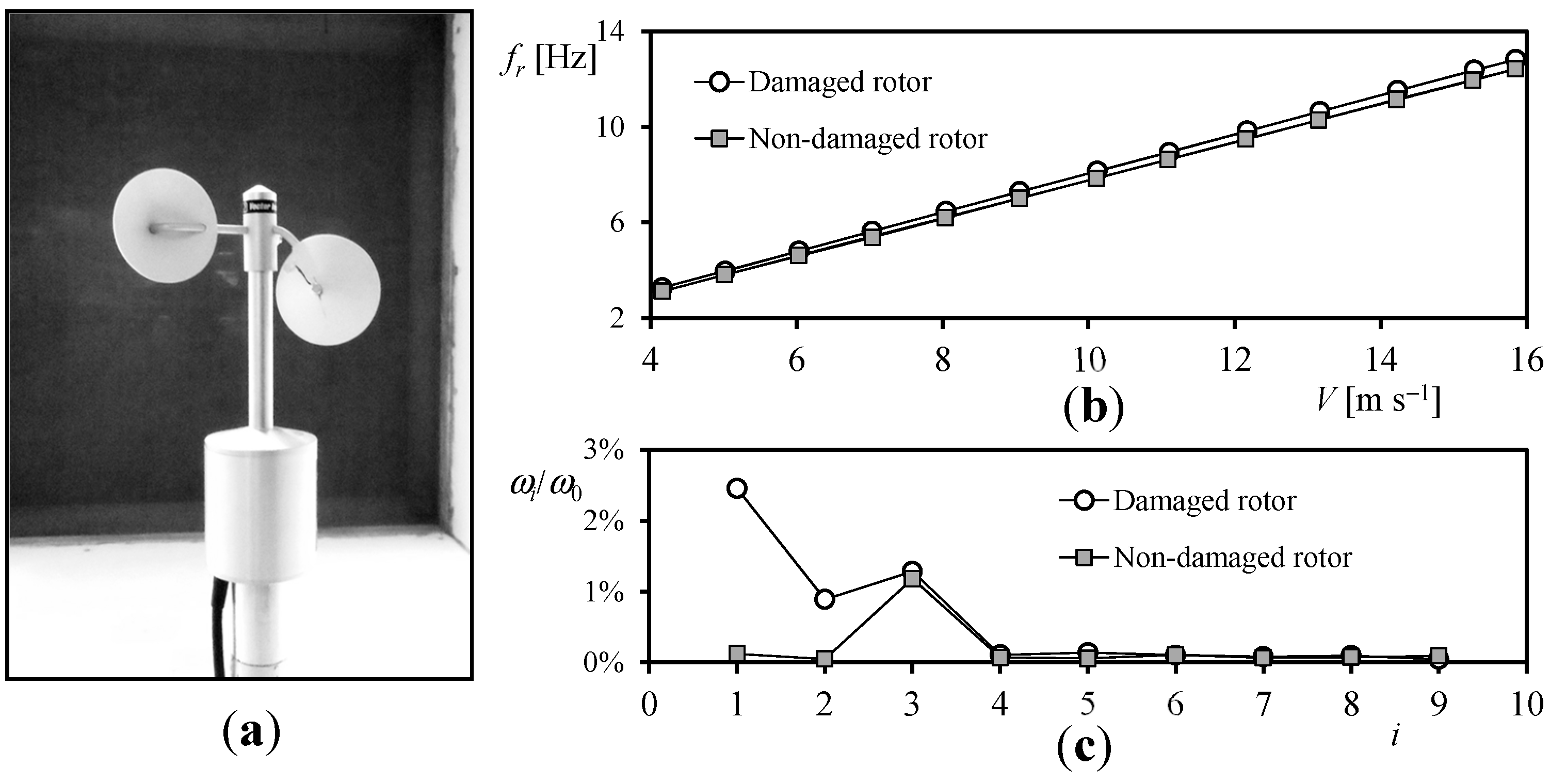

- Vega, E.; Pindado, S.; Martínez, A.; Meseguer, E.; García, L. Anomaly detection on cup anemometers. Meas. Sci. Technol. 2014, 25, 127002. [Google Scholar] [CrossRef]

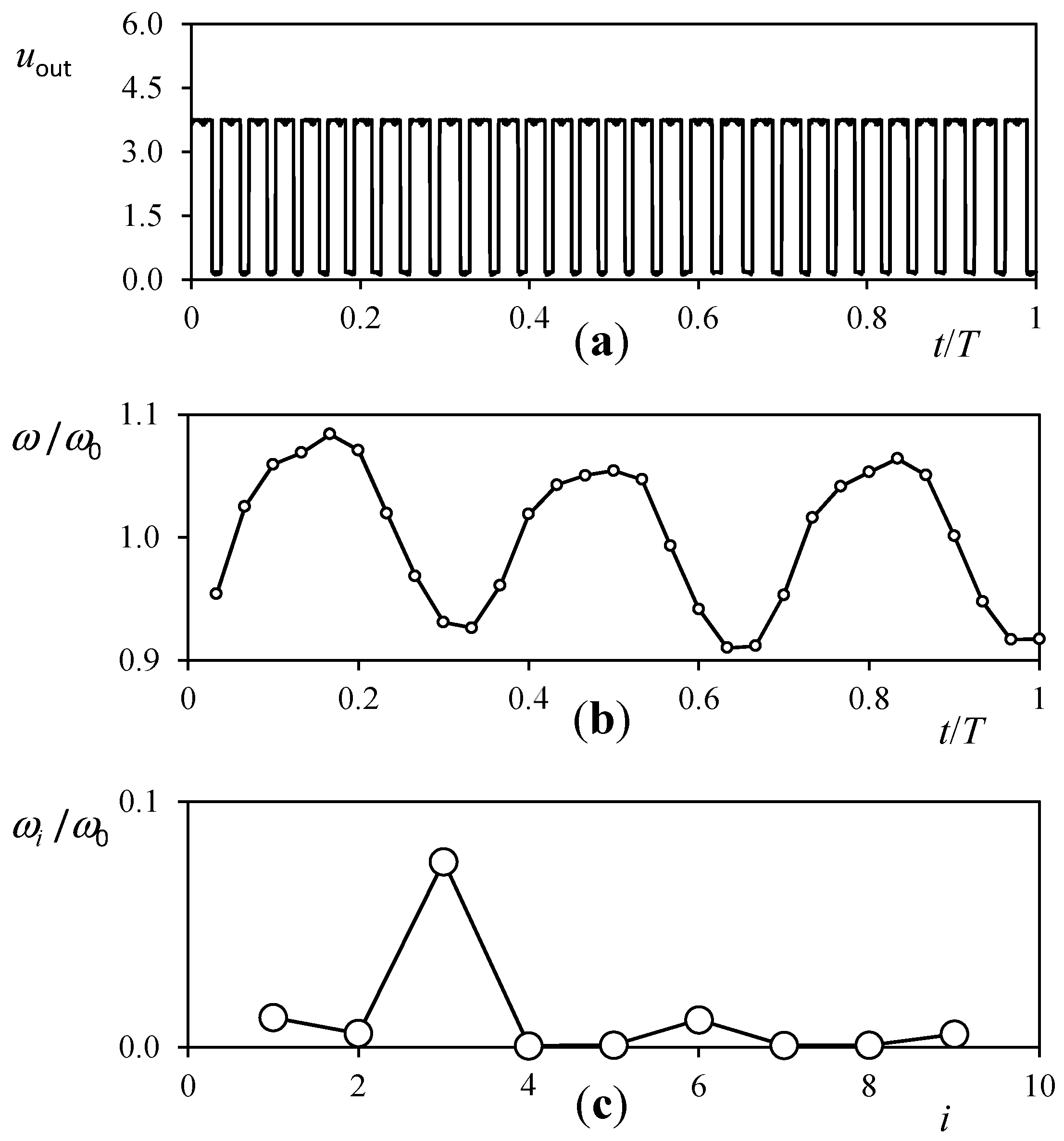

- Pindado, S.; Cubas, J.; Sorribes-Palmer, F. On the harmonic analysis of cup anemometer rotation speed: A principle to monitor performance and maintenance status of rotating meteorological sensors. Measurement 2015, 73, 401–418. [Google Scholar] [CrossRef]

- Pindado, S.; Cubas, J.; Sorribes-Palmer, F. On the Analytical Approach to Present Engineering Problems: Photovoltaic Systems Behavior, Wind Speed Sensors Performance, and High-Speed Train Pressure Wave Effects in Tunnels. Math. Probl. Eng. 2015, 2015, 897357. [Google Scholar] [CrossRef]

- Pindado, S.; Ramos-Cenzano, A.; Cubas, J. Improved analytical method to study the cup anemometer performance. Meas. Sci. Technol. 2015, 26, 1–6. [Google Scholar] [CrossRef]

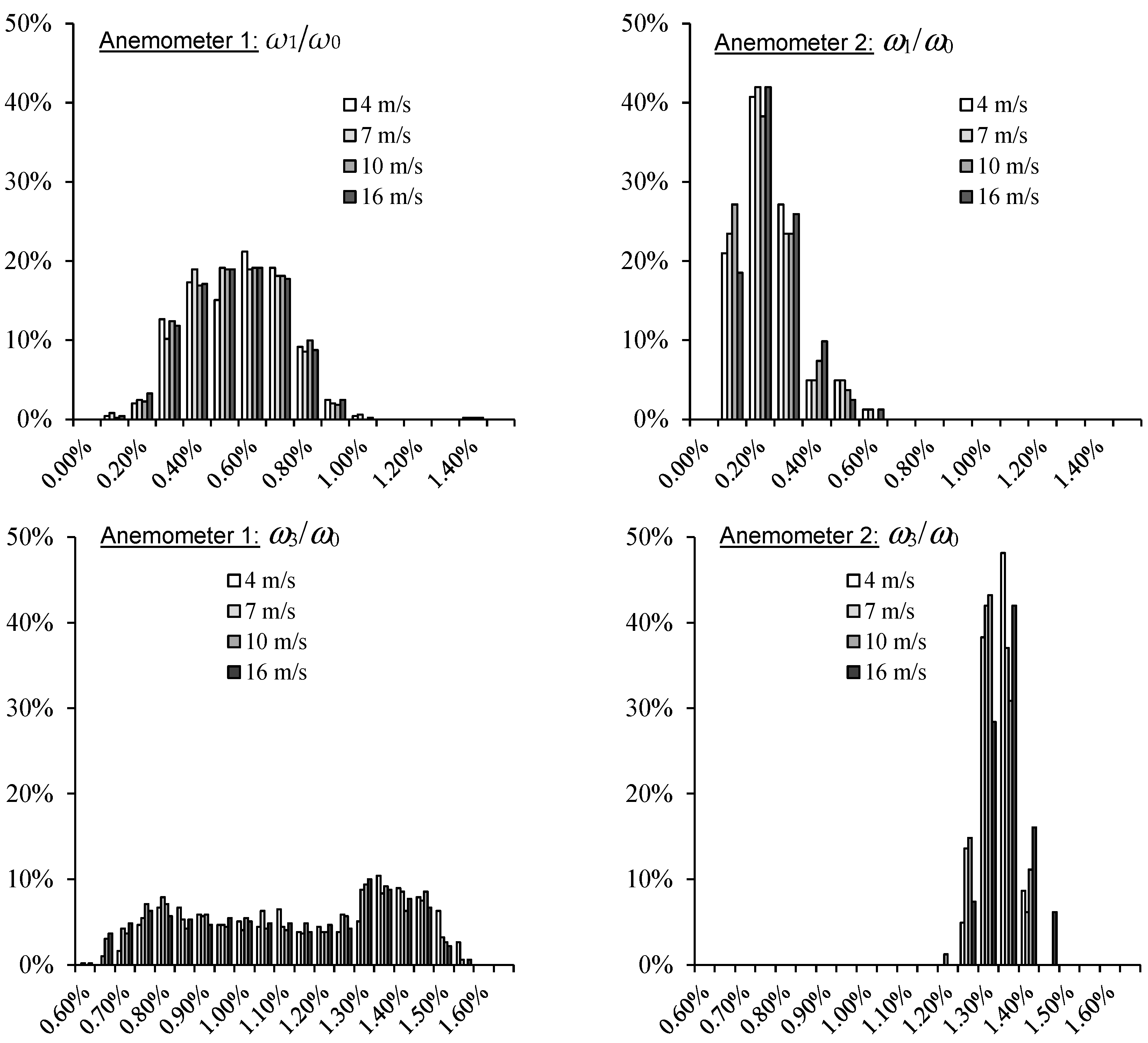

- Martínez, A.; Vega, E.; Pindado, S.; Meseguer, E.; García, L. Deviations of cup anemometer rotational speed measurements due to steady state harmonic accelerations of the rotor. Measurement 2016, 90, 483–490. [Google Scholar] [CrossRef]

- Cuerva, A.; Sanz-Andrés, A. On sonic anemometer measurement theory. J. Wind Eng. Ind. Aerodyn. 2000, 88, 25–55. [Google Scholar] [CrossRef]

- Cuerva, A.; Sanz-Andrés, A.; Navarro, J. On multiple-path sonic anemometer measurement theory. Exp. Fluids 2003, 34, 345–357. [Google Scholar] [CrossRef]

- Cuerva, A.; Sanz-Andrés, A.; Lorenz, R.D. Sonic anemometry of planetary atmospheres. J. Geophys. Res. Planets 2003, 108, 1–7. [Google Scholar] [CrossRef]

- Franchini, S.; Sanz-Andrés, A.; Cuerva, A. Measurement of velocity in rotational flows using ultrasonic anemometry: The flowmeter. Exp. Fluids 2007, 42, 903–911. [Google Scholar] [CrossRef]

- Franchini, S.; Sanz-Andrés, A.; Cuerva, A. Effect of the pulse trajectory on ultrasonic fluid velocity measurement. Exp. Fluids 2007, 43, 969–978. [Google Scholar] [CrossRef]

- Wagner, R.; Courtney, M.; Gottschall, J.; Lindelöw-Marsden, P. Accounting for the speed shear in wind turbine power performance measurement. Wind Energy 2011, 14, 993–1004. [Google Scholar] [CrossRef]

- Lang, S.; McKeogh, E. LIDAR and SODAR measurements of wind speed and direction in upland terrain for wind energy purposes. Remote Sens. 2011, 3, 1871–1901. [Google Scholar] [CrossRef]

- Bradley, S. Aspects of the Correlation between Sodar and Mast Instrument Winds. J. Atmos. Ocean. Technol. 2013, 30, 2241–2247. [Google Scholar] [CrossRef]

- Sanz Rodrigo, J.; Borbón Guillén, F.; Gómez Arranz, P.; Courtney, M.S.; Wagner, R.; Dupont, E. Multi-site testing and evaluation of remote sensing instruments for wind energy applications. Renew. Energy 2013, 53, 200–210. [Google Scholar] [CrossRef]

- Hasager, C.; Stein, D.; Courtney, M.; Peña, A.; Mikkelsen, T.; Stickland, M.; Oldroyd, A. Hub Height Ocean Winds over the North Sea Observed by the NORSEWInD Lidar Array: Measuring Techniques, Quality Control and Data Management. Remote Sens. 2013, 5, 4280–4303. [Google Scholar] [CrossRef]

- Hobby, M.; Gascoyne, M.; Marsham, J.H.; Bart, M.; Allen, C.; Engelstaedter, S.; Fadel, D.M.; Gandega, A.; Lane, R.; McQuaid, J.B.; et al. The Fennec Automatic Weather Station (AWS) Network: Monitoring the Saharan Climate System. J. Atmos. Ocean. Technol. 2013, 30, 709–724. [Google Scholar] [CrossRef]

- Mikkelsen, T. Lidar-based Research and Innovation at DTU Wind Energy—A Review. J. Phys. Conf. Ser. 2014, 524, 12007. [Google Scholar] [CrossRef]

- Serrano González, J.; Burgos Payán, M.; Santos, J.M.R.; González-Longatt, F. A review and recent developments in the optimal wind-turbine micro-siting problem. Renew. Sustain. Energy Rev. 2014, 30, 133–144. [Google Scholar] [CrossRef]

- Bradley, S.; Strehz, A.; Emeis, S. Remote sensing winds in complex terrain—A review. Meteorol. Z. 2015, 24, 547–555. [Google Scholar] [CrossRef]

- Kim, D.; Kim, T.; Oh, G.; Huh, J.; Ko, K. A comparison of ground-based LiDAR and met mast wind measurements for wind resource assessment over various terrain conditions. J. Wind Eng. Ind. Aerodyn. 2016, 158, 109–121. [Google Scholar] [CrossRef]

- Kang, D.; Hyeon, J.; Yang, K.; Huh, J.; Ko, K. Analysis and Verification of Wind Data from Ground-based LiDAR. Int. J. Renew. Energy Res. 2017, 7, 937–945. [Google Scholar]

- Cheynet, E.; Jakobsen, J.B.; Snæbjörnsson, J.; Reuder, J.; Kumer, V.; Svardal, B. Assessing the potential of a commercial pulsed lidar for wind characterisation at a bridge site. J. Wind Eng. Ind. Aerodyn. 2017, 161, 17–26. [Google Scholar] [CrossRef]

- Li, J.; Yu, X. (Bill) LiDAR technology for wind energy potential assessment: Demonstration and validation at a site around Lake Erie. Energy Convers. Manag. 2017, 144, 252–261. [Google Scholar] [CrossRef]

- Khan, K.S.; Tariq, M. Wind resource assessment using SODAR and meteorological mast—A case study of Pakistan. Renew. Sustain. Energy Rev. 2017. [Google Scholar] [CrossRef]

- Dubov, D.; Aprahamian, B.; Aprahamian, M. Comparison between Conventional Wind Measurement Systems and SODAR Systems for Remote Sensing Including Examination of Real Wind Data. In Proceedings of the 2017 15th International Conference on Electrical Machines, Drives and Power Systems (ELMA), Sofia, Bulgaria, 1–3 June 2017; pp. 106–109. [Google Scholar]

- Pedersen, B.M.; Hansen, K.S.; Øye, S.; Brinch, M.; Fabian, O. Some experimental investigations on the influence of the mounting arrangements on the accuracy of cup-anemometer measurements. J. Wind Eng. Ind. Aerodyn. 1992, 39, 373–383. [Google Scholar] [CrossRef]

- Pedersen, T.F.; Sørensen, N.N.; Madsen, H.A.; Courtney, M.; Møller, R.; Enevoldsen, P.; Egedal, P. Spinner anemometry—An innovative wind measurement concept. In Proceedings of the 2007 European Wind Energy Conference and Exhibition (EWEC 2007), Milan, Italy, 7–10 May 2007. [Google Scholar]

- Wagner, R.; Pedersen, T.F.; Courtney, M.; Antoniou, I.; Davoust, S.; Rivera, R.L. Power curve measurement with a nacelle mounted lidar. Wind Energy 2014, 17, 1441–1453. [Google Scholar] [CrossRef]

- Pedersen, T.F.; Demurtas, G.; Zahle, F. Calibration of a spinner anemometer for yaw misalignment measurements. Wind Energy 2015, 18, 1933–1952. [Google Scholar] [CrossRef]

- Demurtas, G.; Pedersen, T.F.; Zahle, F. Calibration of a spinner anemometer for wind speed measurements. Wind Energy 2016, 19, 2003–2021. [Google Scholar] [CrossRef]

- Robinson, T.R. On a New Anemometer. Proc. R. Ir. Acad. 1847, 4, 566–572. [Google Scholar]

- Robinson, T.R. On the Determination of the Constants of the Cup Anemometer by Experiments with a Whirling Machine. Philos. Trans. R. Soc. Lond. 1878, 169, 777–822. [Google Scholar] [CrossRef]

- Robinson, T.R. On the Constants of the Cup Anemometer. Proc. R. Soc. Lond. 1880, 30, 572–574. [Google Scholar] [CrossRef]

- Robinson, T.R. On the Determination of the Constants of the Cup Anemometer by Experiments with a Whirling Machine. Part II. Philos. Trans. R. Soc. Lond. 1880, 171, 1055–1070. [Google Scholar] [CrossRef]

- Brazier, M.C.-E. Sur la variation des indications des anémomètres Robinson et Richard en fonction de l’inclinaison du vent. C. R. Séances Acad. Sci. 1920, 170, 610–612. [Google Scholar]

- Brazier, M.C.-E. Sur la comparabilité des anémomètres. C. R. Séances Acad. Sci. 1921, 172, 843–845. [Google Scholar]

- Brazier, M.C.-E. On the Comparability of Anemometers. Mon. Weather Rev. 1921, 49, 575. [Google Scholar] [CrossRef]

- Marvin, C.F. Recent Advances in Anemometry. Mon. Weather Rev. 1934, 62, 115–120. [Google Scholar] [CrossRef]

- Patterson, J. The cup anemometer. Trans. R. Soc. Can. Ser. III 1926, 20, 1–54. [Google Scholar]

- Spilhaus, A.F.; Rossby, C. Analysis of the Cup Anemometer (Meteorological Course. Professional Notes—No. 7); Massachusetts Institute of Technology: Cambridge, MA, USA, 1934. [Google Scholar]

- Fergusson, S.P. Harvard Meteorological Studies No. 4. Experimental Studies of Cup Anemometers; Harvard University Press: Cambridge, MA, USA, 1939. [Google Scholar]

- Sheppard, P.A. An improved design of cup anemometer. J. Sci. Instrum. 1940, 17, 218–221. [Google Scholar] [CrossRef]

- MEASNET. Cup Anemometer Calibration Procedure, Version 1 (September 1997, Updated 24/11/2008); MEASNET: Madrid, Spain, 1997. [Google Scholar]

- MEASNET. Cup Anemometer Calibration Procedure, Version 2 (October 2009); MEASNET: Madrid, Spain, 2009. [Google Scholar]

- Stefanatos, N.; Papadopoulos, P.; Binopoulos, E.; Kostakos, A.; Spyridakis, G. Effects of long term operation on the performance characteristics of cup anemometers. In Proceedings of the European Wind Energy Conference and Exhibition (EWEC 2007), Milan, Italy, 7–10 May 2007; pp. 1–6. [Google Scholar]

- Chree, C. Contribution to the Theory of the Robinson Cup-Anemometer. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1895, 40, 63–90. [Google Scholar] [CrossRef]

- Schrenk, O. Über die Trägheitsfehler des Schalenkreuz-Anemometers bei schwankender Windstärke. Z. Tech. Phys. 1929, 10, 57–66. [Google Scholar]

- Brevoort, M.J.; Joyner, U.T. Experimental Investigation of the Robinson-Type Cup Anemometer; NACA TN-513; Government Printing Office: Washington, DC, USA, 1935.

- Ramos Cenzano, A. Análisis Mediante Cálculo Numérico (CFD) del Comportamiento de Anemómetros de Cazoletas; Universidad Politécnica de Madrid: Madrid, Spain, 2014. [Google Scholar]

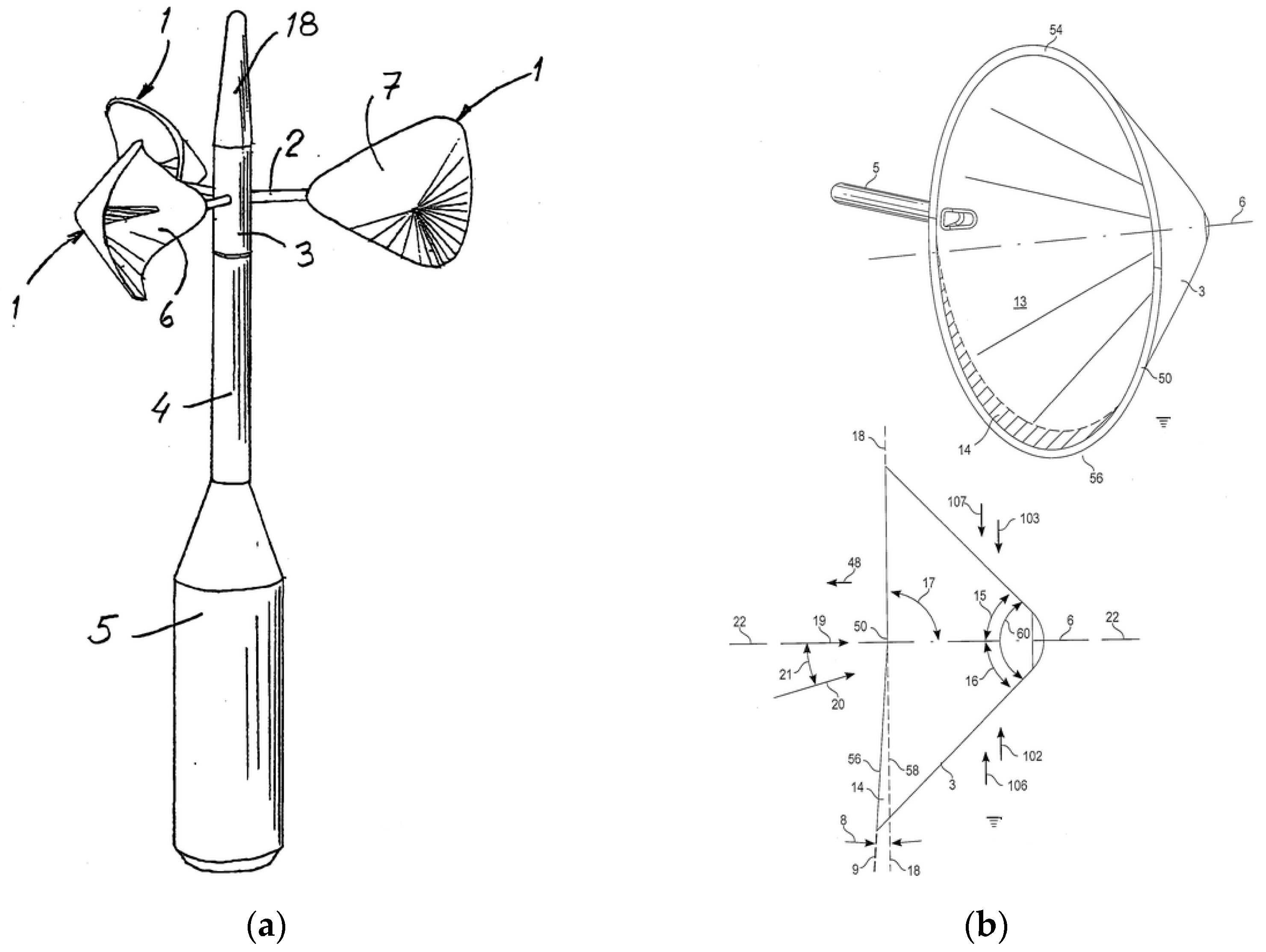

- Dahlberg, J.-Å.; Gustavsson, J.; Ronsten, G.; Pedersen, T.F.; Paulsen, U.S.; Westermann, D. Development of a Standardised Cup Anemometer Suited to Wind Energy Applications—(Classcup); Contract JOR3-C T98-0263; Publishable Final Report; Aeronautical Research Institute of Sweden: Ulvsunda, Sweden, 2001; pp. 1–37. [Google Scholar]

- Dahlberg, J.-A. Cup Anemometer. U.S. Patent 2004/0083806 A1, 6 May 2017. [Google Scholar]

- Westermann, D. Selektives Messen einer Richtungskomponente der Strömungsgeschwindigkeit mit einem Schalensternanemometer. EP 1489427 B1, 12 November 2008. [Google Scholar]

- Hong, S.-H. Asymmetric-Cup Anemometer. U.S. Patent 2012/0266692 A1, 25 October 2012. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roibas-Millan, E.; Cubas, J.; Pindado, S. Studies on Cup Anemometer Performances Carried out at IDR/UPM Institute. Past and Present Research. Energies 2017, 10, 1860. https://doi.org/10.3390/en10111860

Roibas-Millan E, Cubas J, Pindado S. Studies on Cup Anemometer Performances Carried out at IDR/UPM Institute. Past and Present Research. Energies. 2017; 10(11):1860. https://doi.org/10.3390/en10111860

Chicago/Turabian StyleRoibas-Millan, Elena, Javier Cubas, and Santiago Pindado. 2017. "Studies on Cup Anemometer Performances Carried out at IDR/UPM Institute. Past and Present Research" Energies 10, no. 11: 1860. https://doi.org/10.3390/en10111860

APA StyleRoibas-Millan, E., Cubas, J., & Pindado, S. (2017). Studies on Cup Anemometer Performances Carried out at IDR/UPM Institute. Past and Present Research. Energies, 10(11), 1860. https://doi.org/10.3390/en10111860