Study on Quantitative Correlations between the Ageing Condition of Transformer Cellulose Insulation and the Large Time Constant Obtained from the Extended Debye Model

Abstract

1. Introduction

2. Preparation of Oil-Impregnated Pressboard Specimens

- (1)

- The pressboards and insulation oil are dried in a vacuum-thermal tank at 105 °C/50 Pa for two days.

- (2)

- The dried and degassed insulation oil is heated to 40 °C/50 Pa.

- (3)

- The dried pressboards are quickly put into the dried and degassed insulation oil with vacuum impregnation for two days under the condition of 40 °C/50 Pa.

2.1. Preparation of Oil-Paper Insulation Specimens with Different Ageing Conditions

- (1)

- The pretreated oil-impregnated pressboard specimens are divided into five equal groups. Thus these oil-impregnated pressboard specimens are put into five ageing steel cans numbered No. 1, No. 2, No. 3, No. 4 and No. 5, respectively.

- (2)

- Appropriate copper bars are put into the steel cans, numbered No. 2–No. 5 (No. 1 is used for storing the unaged specimen). All steel cans are sealed and then treated using vacuum pumping and nitrogen charging techniques.

- (3)

- The steel cans (No. 2–No. 5) are put into the thermal ageing oven for accelerating thermal ageing under 130 °C.

- (4)

- After ageing for 8 days (No. 2), 21 days (No. 3), 32 days (No. 4) and 42 days (No. 5), respectively, these steel cans are taken out and placed at room temperature for 48 h. Then, the DP values of cellulose pressboard specimens are measured in order to obtain the degradation degree of aged and unaged cellulose pressboard specimens according to IEC 60450.

2.2. Preparation of Oil-Paper Insulation Specimens with Different Water Contents

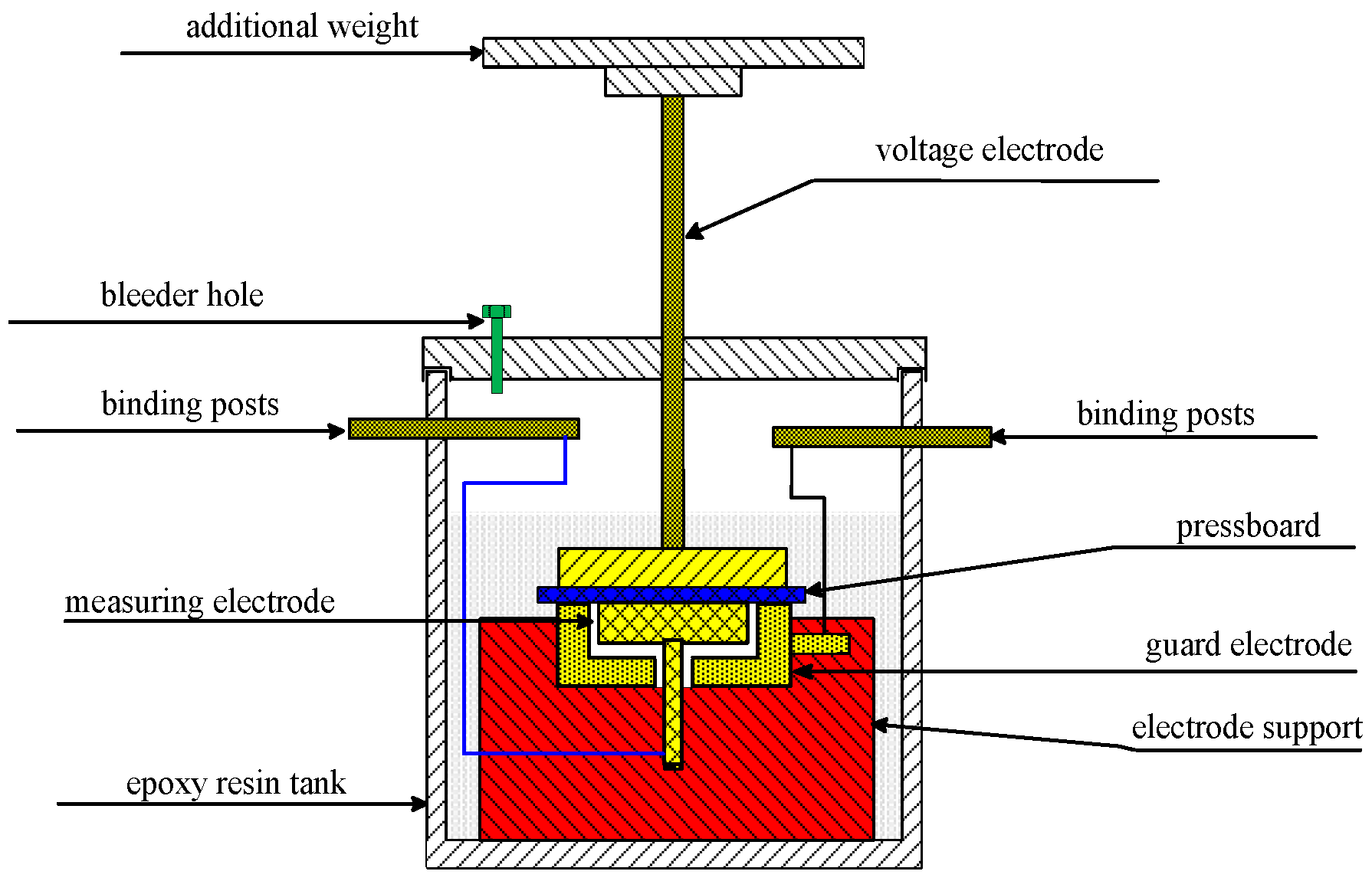

3. Introduction of the PDC Test Platform

3.1. Three-Electrode Test Cell

3.2. DIRANA

4. PDC Results and Analysis

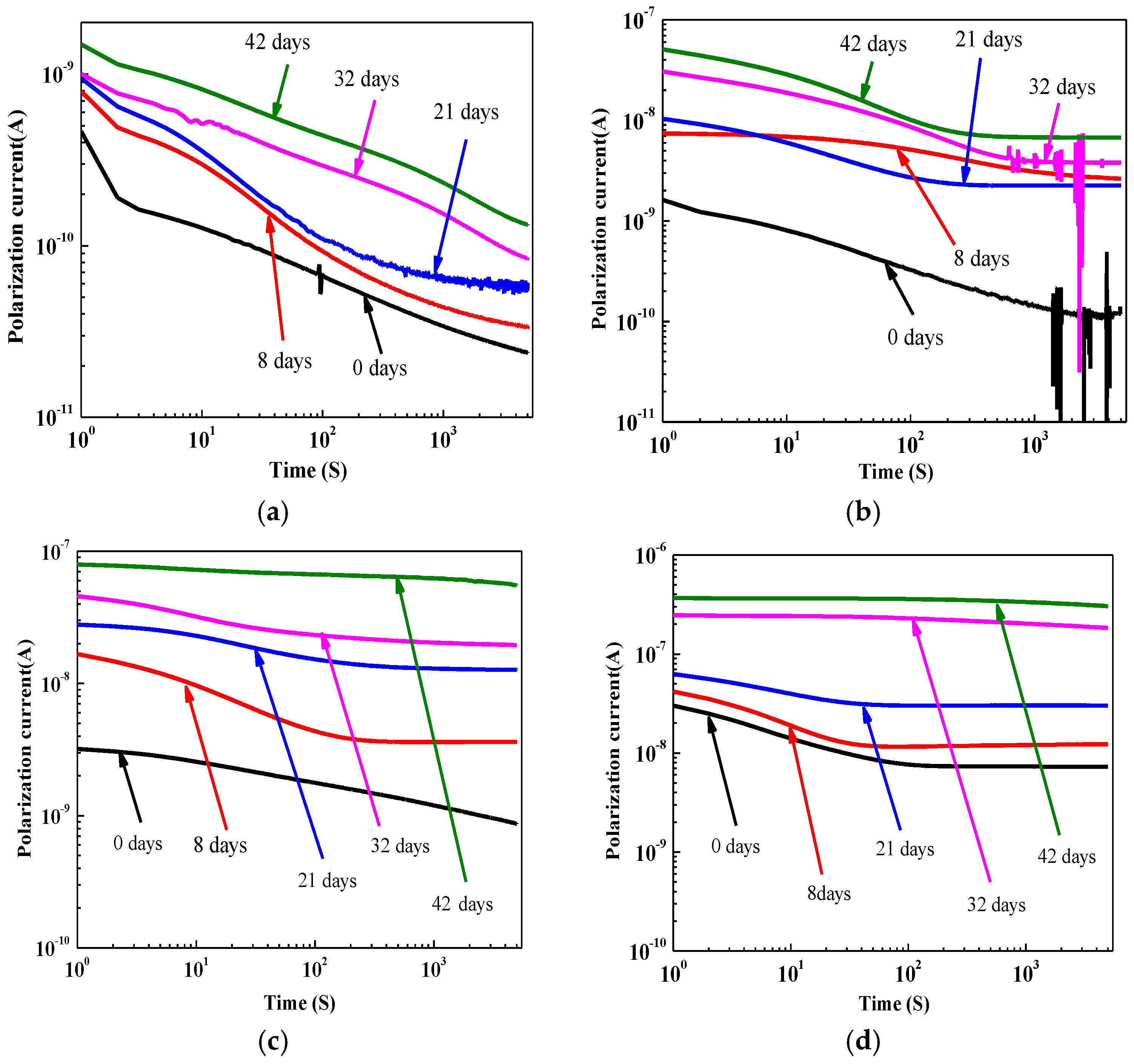

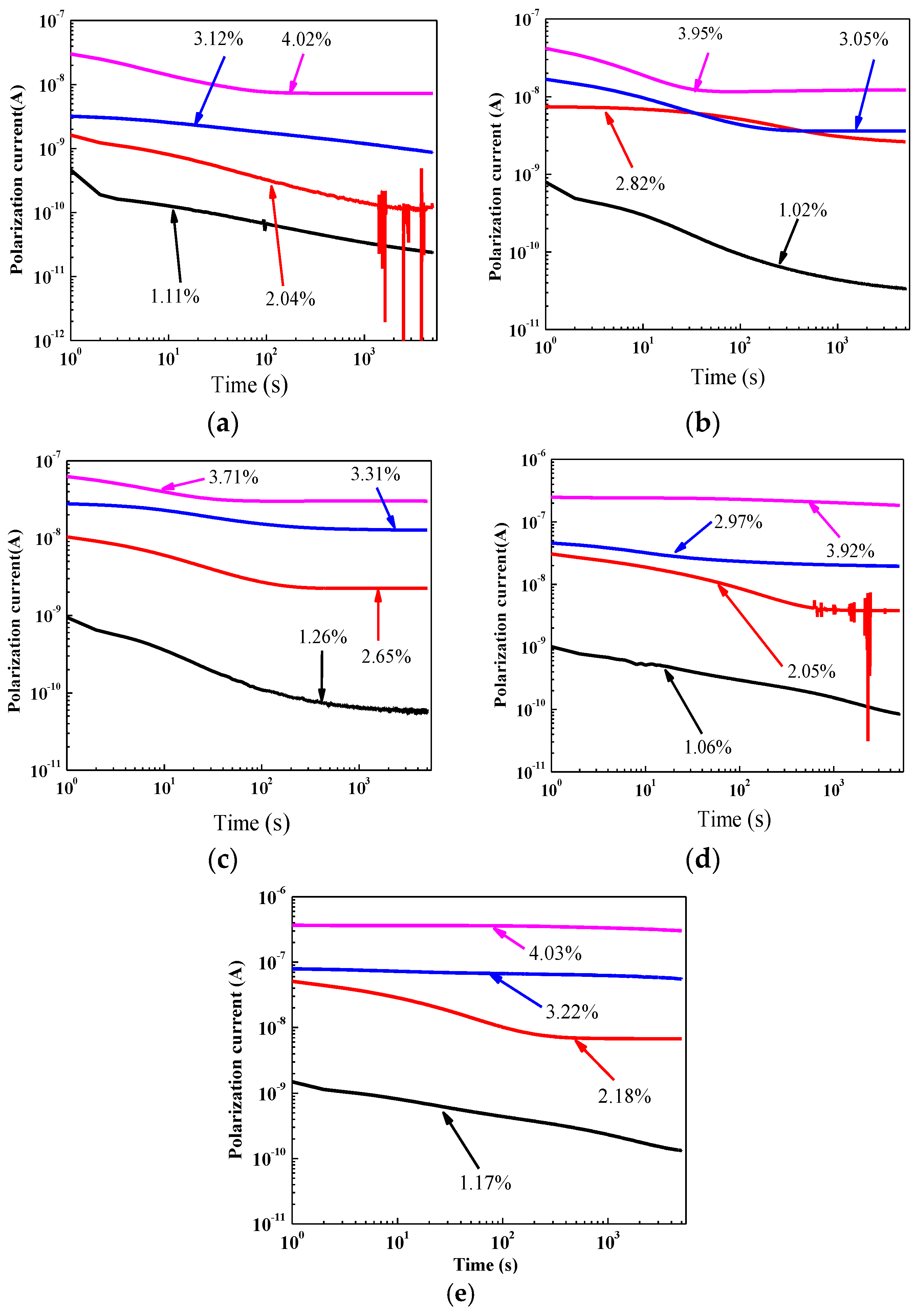

4.1. Ageing Effect on Polarization Current

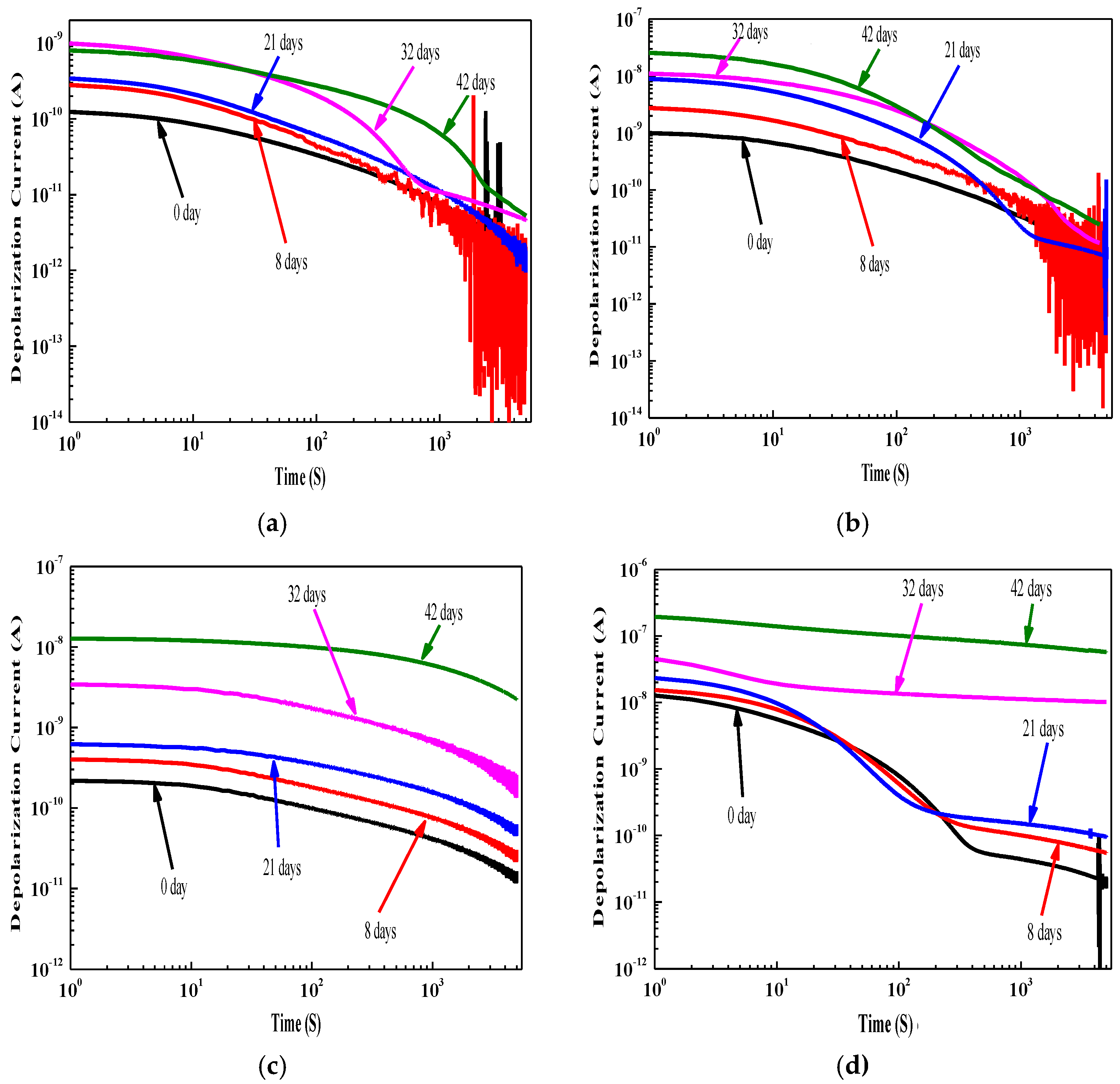

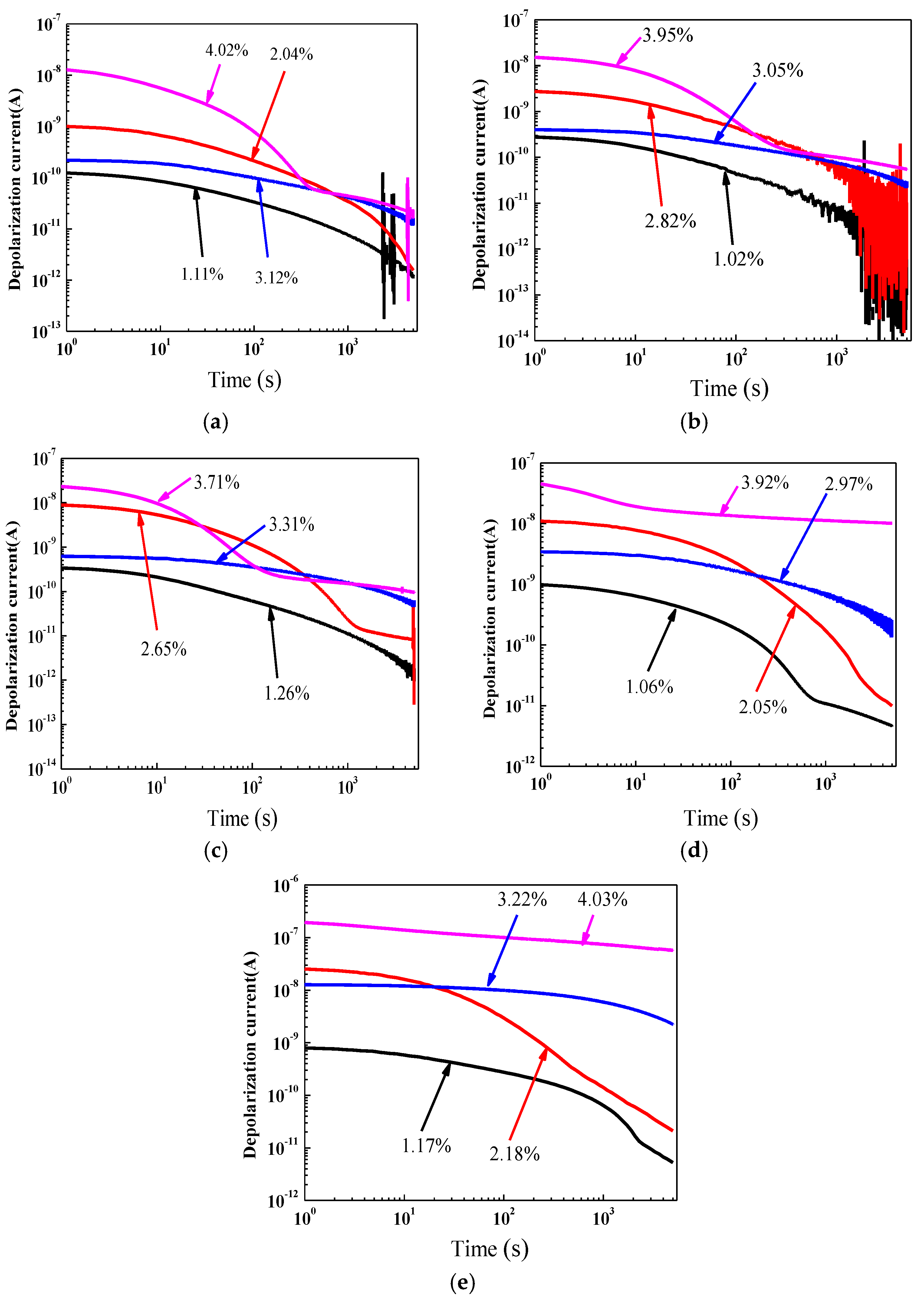

4.2. Ageing Effect on Depolarization Current

5. Quantifying the Ageing Condition of Transformer Cellulose Insulation Using Large Time Constant

5.1. Large Time Constant Technique

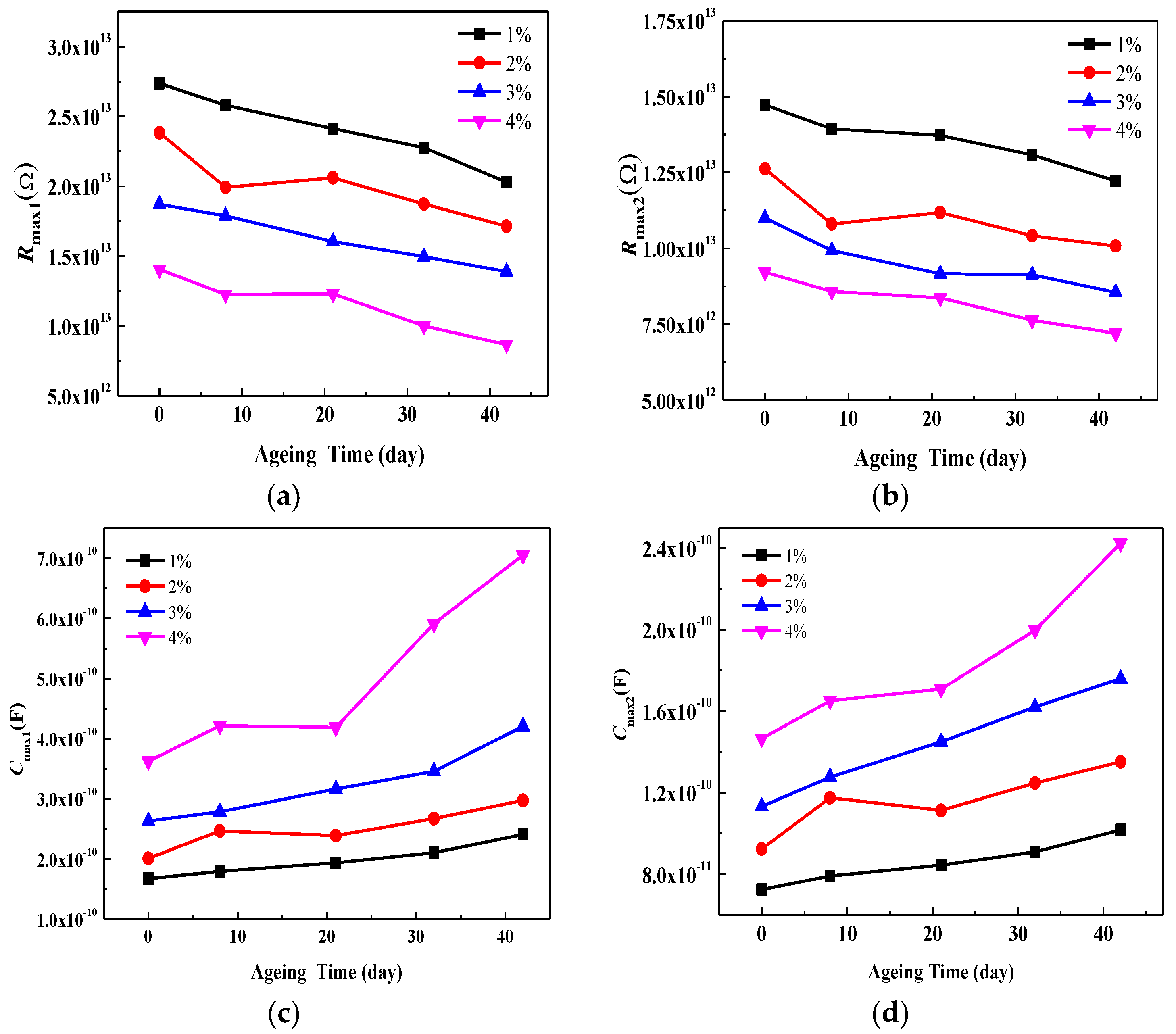

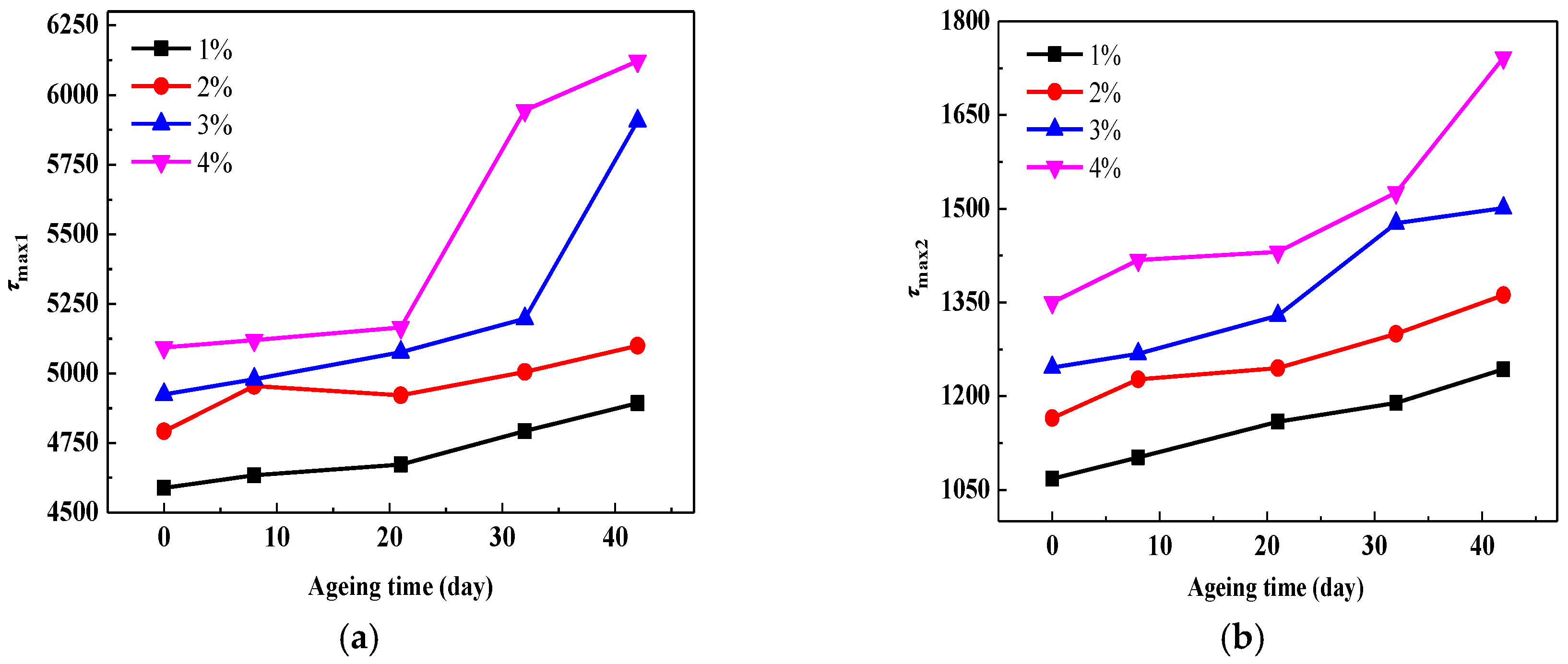

5.2. Ageing Effect on Resistances, Capacitances and Large Time Constant of Maximum and Second Maximum R-C Branches

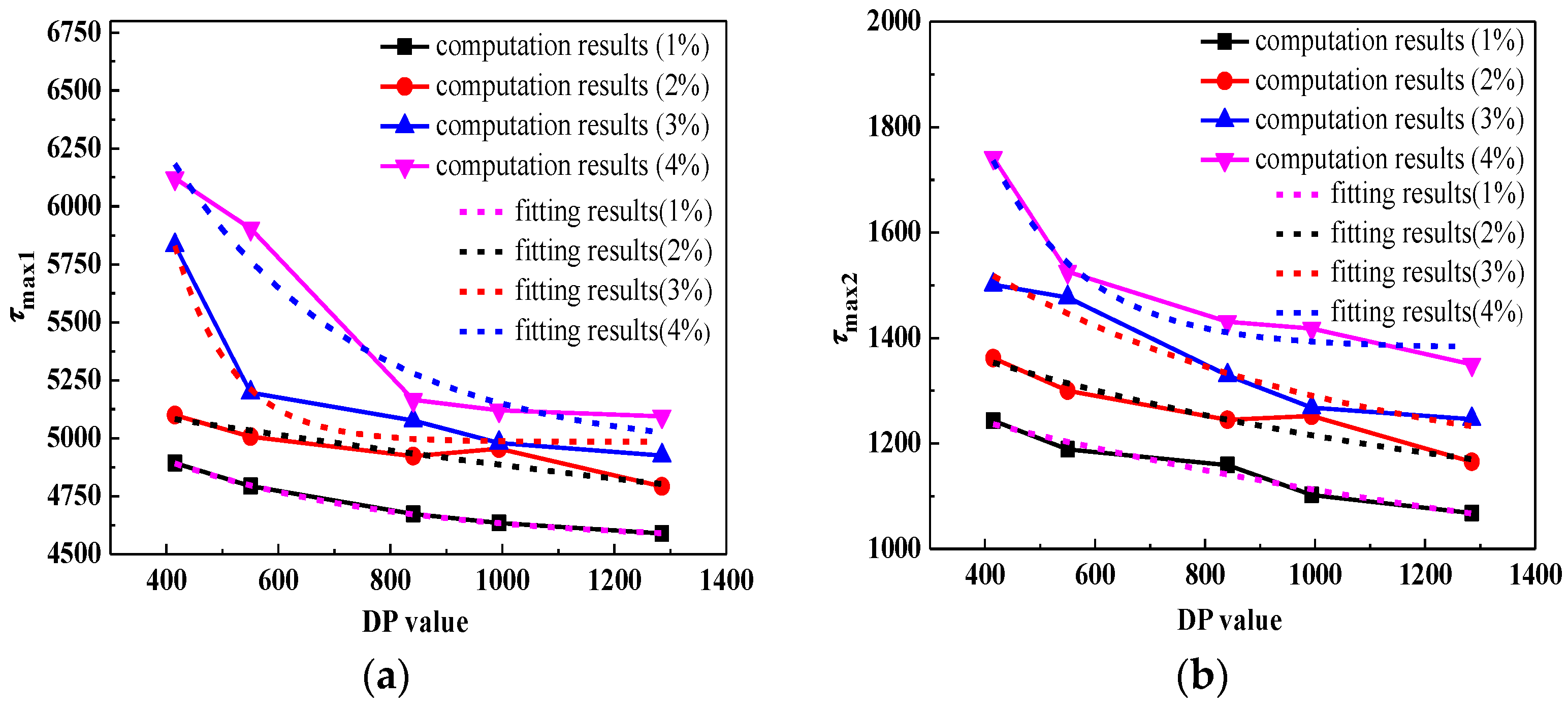

5.3. Quantitative Relationship between Large Time Constant and DP Value

5.4. Case Verification

6. Water Effect on PDC Results and Branch Parameters Obtained from the Extended Debye Model

6.1. Water Effect on Polarization Current

6.2. Water Effect on Depolarization Current

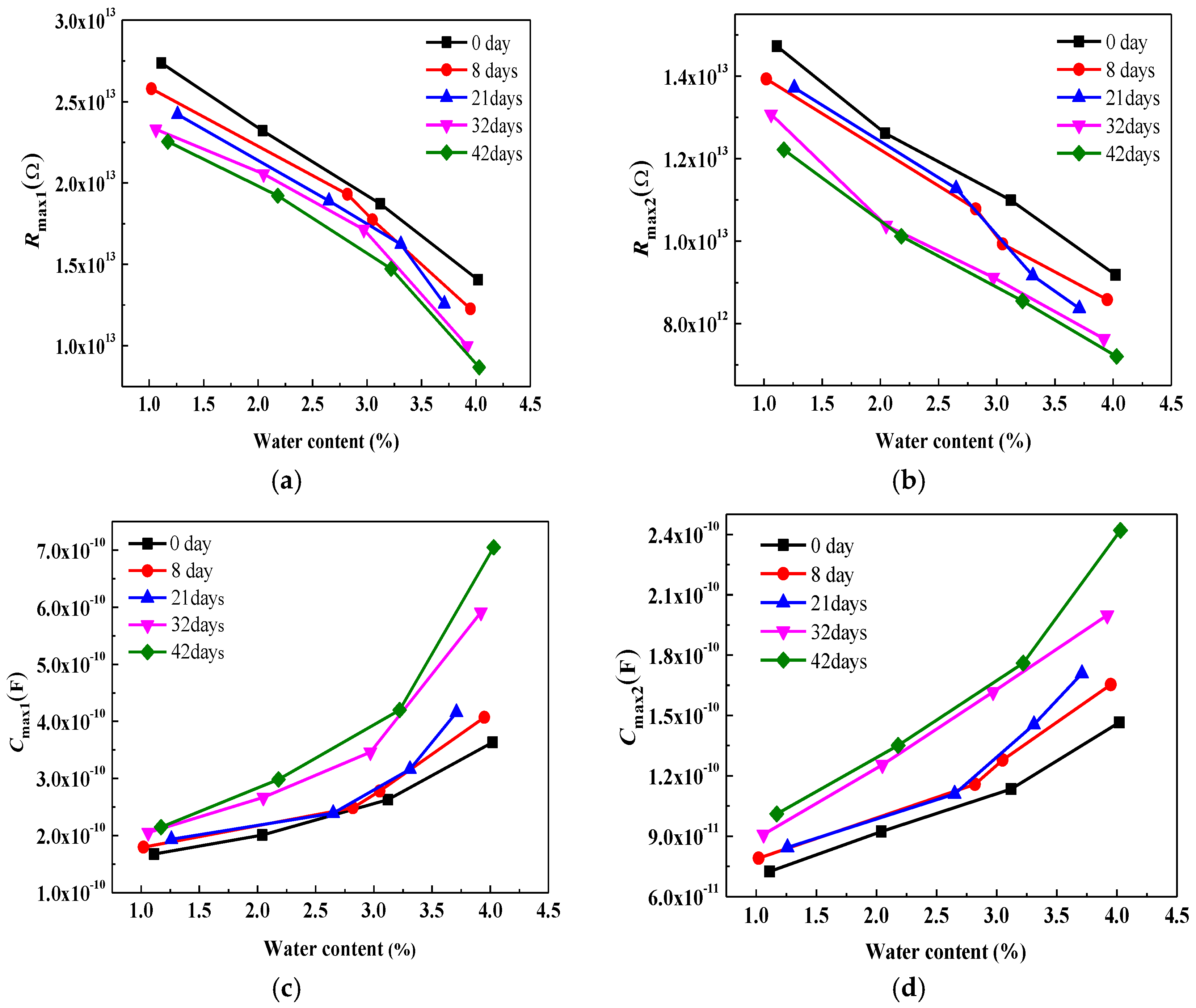

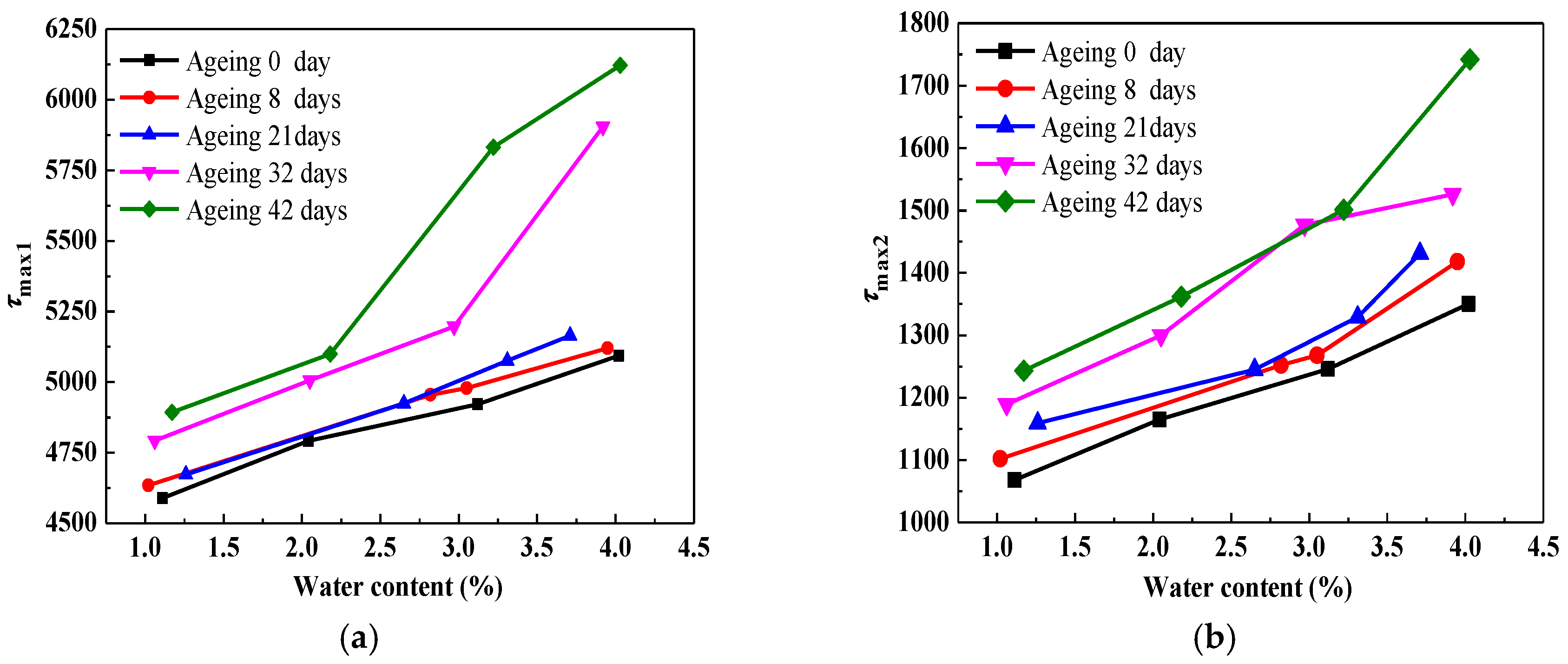

6.3. Water Effect on Resistances, Capacitances and Large Time Constant of Maximum and Second Maximum R-C Branches

7. Conclusions

- (1)

- The water effect on resistance values and capacitance values of maximum and second maximum R-C branches is more predominant than the ageing effect. However, in contrast to the ageing effect, this change of resistance and capacitance values does not indicate permanent degradation of the cellulose insulation due to the fact the water effect is inverted when the water content decreases.

- (2)

- The large time constants obtained from the maximum and second maximum R-C branches are geometry independent. It has been observed that the large time constants show a total trend of increase but there is a little fluctuation as the DP values decrease due to the fact that the rate of change of Cmax1 and Cmax2 values is higher than that of the Rmax1 and Rmax2 values. It also has been shown that there is a good exponential relationship between large time constants and DP values.

- (3)

- The large time constants obtained from maximum and second maximum R-C branches show a total trend of increase with the water content increase but there is a little fluctuation due to the fact that the rate of change of Cmax1 and Cmax2 values is higher than that of the Rmax1 and Rmax2 values.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Liao, R.; Zheng, H.; Grzybowski, S.; Yang, L.; Tang, C.; Zhang, Y. Fuzzy information granulated particle swarm optimisation-support vector machine regression for the trend forecasting of dissolved gases in oil-filled transformers. IET Electr. Power Appl. 2011, 5, 230–237. [Google Scholar] [CrossRef]

- Koch, M.; Prevost, T. Analysis of dielectric response measurements for condition assessment of oil-paper transformer insulation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1908–1915. [Google Scholar] [CrossRef]

- Muthann, K.T.; Sarka, A.; Da, K.; Waldner, K. Transformer insulation life assessment. IEEE Trans. Power Deliv. 2006, 21, 150–156. [Google Scholar] [CrossRef]

- Wang, M.; Vandermaar, A.J.; Srivastava, K.D. Review of condition assessment of power transformers in service. IEEE Electr. Insul. Mag. 2002, 18, 12–15. [Google Scholar] [CrossRef]

- Liao, R.; Liang, S.; Sun, C.; Yang, L.; Sun, H. A comparative study of thermal aging of transformer insulation paper impregnated in natural ester and in mineral oil. Eur. Trans. Electr. Power 2010, 20, 518–533. [Google Scholar] [CrossRef]

- Tenbohlen, S.; Coenen, S.; Djamali, M.; Müller, A.; Samimi, M.H.; Siegel, M. Diagnostic measurements for power transformers. Energies 2016, 9, 347. [Google Scholar] [CrossRef]

- Godina, R.; Rodrigues, E.M.G.; Matias, J.C.O.; Catalão, J.P.S. Effect of loads and other key factors on oil-transformer ageing: Sustainability benefits and challenges. Energies 2015, 8, 12147–12186. [Google Scholar] [CrossRef]

- Lee, B.E.; Park, J.W.; Crossley, P.A.; Kang, Y.C. Induced voltages ratio-based algorithm for fault detection, and faulted phase and winding identification of a three-winding power transformer. Energies 2014, 7, 6031–6049. [Google Scholar] [CrossRef]

- Wang, C.; Wu, J.; Wang, J.; Zhao, W. Reliability analysis and overload capability assessment of oil-immersed power transformers. Energies 2016, 9, 43. [Google Scholar] [CrossRef]

- Prasojo, A.; Diwyacitta, K.; Gumilang, H. Transformer paper expected life estimation using ANFIS based on oil characteristics and dissolved gases (case study: Indonesian transformers). Energies 2017, 10, 1135. [Google Scholar] [CrossRef]

- Saha, T.K. Review of modern diagnostic techniques for assessing insulation condition in aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 903–917. [Google Scholar] [CrossRef]

- Linhjell, D.; Lundgaard, L.E.; Gafvert, U. Dielectric response of mineral oil impregnated cellulose and the impact of aging. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 156–169. [Google Scholar] [CrossRef]

- Liao, R.; Hao, J.; Chen, G.; Yang, L. Quantitative analysis of ageing condition of oil-Paper insulation by frequency domain spectroscopy. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 821–830. [Google Scholar] [CrossRef]

- Saha, T.K.; Purkait, P. Investigations of temperature effects on the dielectric response measurements of transformer oil-paper insulation system. IEEE Trans. Power Deliv. 2008, 23, 252–260. [Google Scholar] [CrossRef]

- Saha, T.K.; Zheng, T.Y. Experience with return voltage measurements for assessing insulation conditions in service-aged transformers. IEEE Trans. Power Deliv. 2003, 18, 128–135. [Google Scholar] [CrossRef]

- We, J.; Zhang, G.; Xu, H.; Peng, H.; Wang, S.; Dong, M. Novel characteristic parameters for oil-paper insulation assessment from differential time-domain spectroscopy based on polarization and depolarization current measurement. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1918–1928. [Google Scholar] [CrossRef]

- Saha, T.K.; Purkait, P. Investigation of polarization and depolarization current measurements for the assessment of oil-paper insulation of aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2004, 11, 144–154. [Google Scholar] [CrossRef]

- Zaengl, W.S. Dielectric spectroscopy in time and frequency domain for HV power equipment, Part I: Theoretical considerations. IEEE Electr. Insul. Mag. 2003, 19, 9–22. [Google Scholar] [CrossRef]

- Liao, R.; Liu, J.; Yang, L.; Gao, J.; Zhang, Y.; Lv, Y.; Zheng, H. Understanding and analysis on frequency dielectric parameter for quantitative diagnosis of water content in paper-oil insulation system. IET Electr. Power Appl. 2015, 9, 213–222. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, L.; Chen, X.; Jiang, J.; Wang, L. Modelling the low-frequency dielectric response test of insulation oil. IET Electr. Power Appl. 2017, 11, 323–330. [Google Scholar] [CrossRef]

- Farahani, M.; Borsi, H.; Gockenbach, E. Dielectric response studies on insulating system of high voltage rotating machines. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 383–393. [Google Scholar] [CrossRef]

- Hadjadj, Y.; Meghnefi, F.; Fofana, I.; Ezzaidi, H. On the feasibility of using poles computed from frequency domain spectroscopy to assess oil impregnated paper insulation conditions. Energies 2013, 6, 2204–2220. [Google Scholar] [CrossRef]

- Fofana, I.; Hemmatjou, H.; Meghnefi, F.; Farzaneh, M.; Setayeshmehr, A.; Borsi, H.; Gockenbach, E. On the frequency domain dielectric response of oil-paper insulation at low Temperatures. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 799–807. [Google Scholar] [CrossRef]

- Baral, A.; Chakravorti, S. Assessment of non-uniform aging of cellulose dielectric using system Poles of a modified extended Debye model for oil-paper insulation of transformers. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1922–1933. [Google Scholar] [CrossRef]

- Baral, A.; Chakravorti, S. Prediction of water present in cellulosic part of power transformer insulation using transfer function of modified extended Debye model. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1368–1375. [Google Scholar] [CrossRef]

- Hao, J.; Liao, R.; Chen, G.; Ma, Z.; Yang, L. Quantitative analysis ageing condition of natural ester-paper insulation and mineral oil-paper insulation by polarization/depolarization current. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 188–199. [Google Scholar]

- Liu, J.; Zheng, H.; Zhang, Y.; Wei, H.; Liao, R. Grey relational analysis for insulation condition assessment of power transformers based upon conventional dielectric response measurement. Energies 2017, 10, 1526. [Google Scholar] [CrossRef]

- Jonscher, A.K. Dielectric Relaxation in Celluloses; Chelsea Dielectrics Press: London, UK, 1983. [Google Scholar]

- Saha, T.K.; Purkait, P.; Müller, F. Deriving an equivalent circuit of transformers insulation for understanding the dielectric response measurements. IEEE Trans. Power Deliv. 2005, 20, 149–157. [Google Scholar] [CrossRef]

- Liu, J.; Liao, R.; Zhang, Y.; Gong, C.; Wang, C.; Gao, J. Condition evaluation for aging state of transformer oil-paper insulation based on time-frequency domain dielectric characteristics. Electr. Power Compon. Syst. 2015, 43, 759–769. [Google Scholar] [CrossRef]

- Fofana, I.; Hemmatjoua, H.; Farzaneh, M. Low temperature and water effects on polarization and depolarization currents of oil-paper insulation. Electr. Power Compon. Syst. 2010, 80, 91–97. [Google Scholar] [CrossRef]

| Water | Fitting Equation τmax1 = A + B × exp(C × DP) | R2 |

|---|---|---|

| 1% | τmax1 = 4548.317 + 932.157 exp(−0.0024 × DP) | 0.99 |

| 2% | τmax1 = −33049.599 + 38257.396 exp(−8.0977 × DP) | 0.80 |

| 3% | τmax1 = 4984.090 + 48336.764 exp(−0.0098 × DP) | 0.96 |

| 4% | τmax1 = 4934.992 + 4360.154 exp(−0.0030 × DP) | 0.91 |

| Water | Fitting Equation τmax1 = A + B × exp(C × DP) | R2 |

|---|---|---|

| 1% | τmax2 = 852.655 + 506.382 exp(−0.0007 × DP) | 0.92 |

| 2% | τmax2 = 1028.678 + 482.556 exp(−0.0010 × DP) | 0.96 |

| 3% | τmax2 = 1126.325 + 728.836 exp(−0.0015 × DP) | 0.93 |

| 4% | τmax2 = 1381.403 + 4040.509 exp(−0.0059 × DP) | 0.95 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Liu, J.; Zheng, H.; Wei, H.; Liao, R. Study on Quantitative Correlations between the Ageing Condition of Transformer Cellulose Insulation and the Large Time Constant Obtained from the Extended Debye Model. Energies 2017, 10, 1842. https://doi.org/10.3390/en10111842

Zhang Y, Liu J, Zheng H, Wei H, Liao R. Study on Quantitative Correlations between the Ageing Condition of Transformer Cellulose Insulation and the Large Time Constant Obtained from the Extended Debye Model. Energies. 2017; 10(11):1842. https://doi.org/10.3390/en10111842

Chicago/Turabian StyleZhang, Yiyi, Jiefeng Liu, Hanbo Zheng, Hua Wei, and Ruijin Liao. 2017. "Study on Quantitative Correlations between the Ageing Condition of Transformer Cellulose Insulation and the Large Time Constant Obtained from the Extended Debye Model" Energies 10, no. 11: 1842. https://doi.org/10.3390/en10111842

APA StyleZhang, Y., Liu, J., Zheng, H., Wei, H., & Liao, R. (2017). Study on Quantitative Correlations between the Ageing Condition of Transformer Cellulose Insulation and the Large Time Constant Obtained from the Extended Debye Model. Energies, 10(11), 1842. https://doi.org/10.3390/en10111842