Supply Chain Management for Improved Energy Efficiency: Review and Opportunities

Abstract

1. Introduction

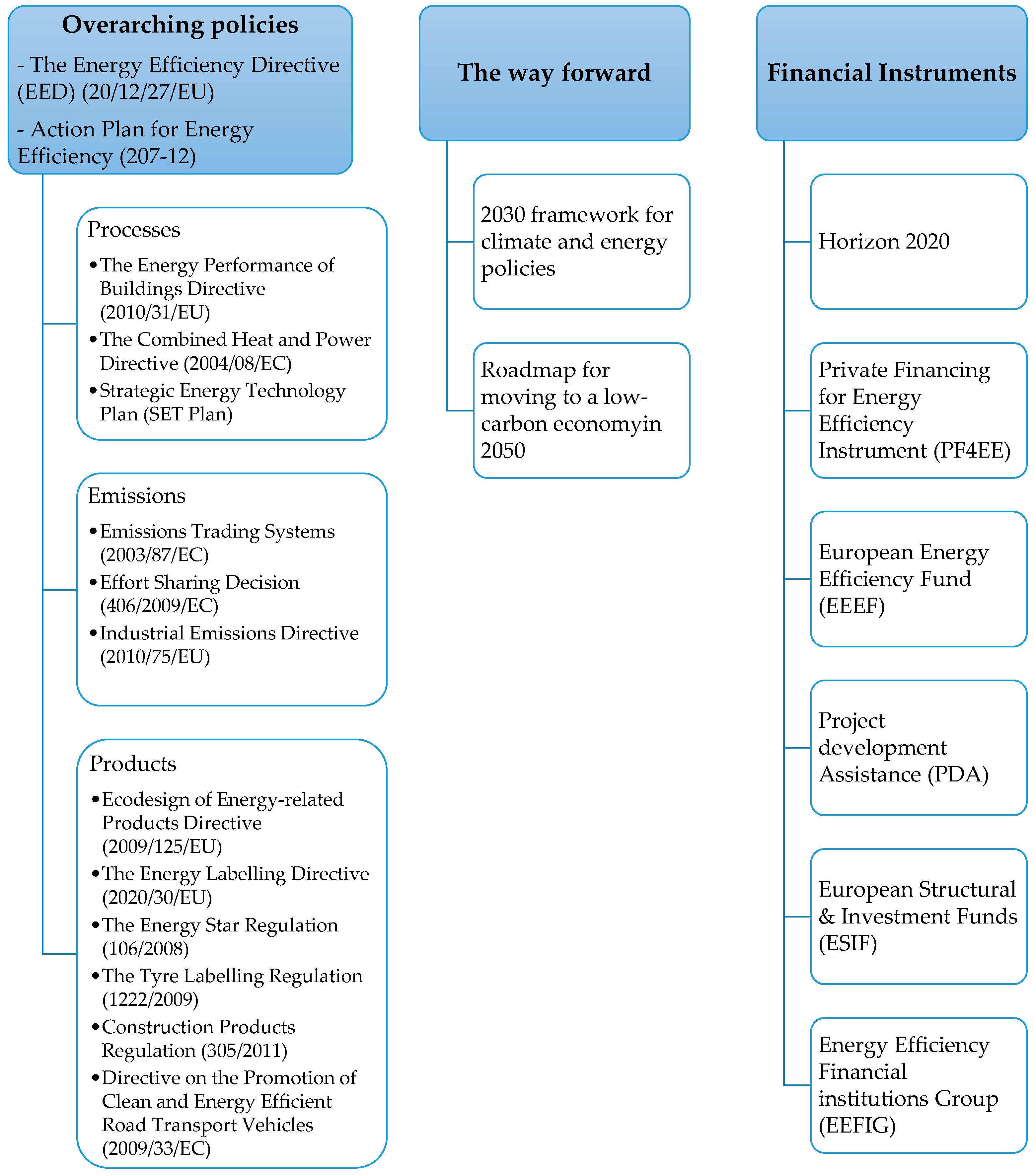

1.1. Background

- (i)

- Production machines: measures concerning the design and control of machines as well as process parameters.

- (ii)

- Production planning and control (PPC): actions for improved energy and resource efficiency ranging from the avoidance of consumption peaks (e.g., through orders balancing) to the optimal usage of equipment, especially for those machines with low shares of non-value adding idling wastes.

- (iii)

- Technical building services (TBS): measures responsible for an efficient supply of required forms of energy and resources (e.g., compressed air) for ensuring production and optimal environment conditions. For instance, these measures may concern the technical configuration of the equipment, the control of processes as well as the avoidance of losses.

1.2. Motivations

- Experts may use this review as an inspiring overview on how supply chain perspective may support the energy efficiency challenge and as a guideline to identify a specific practical intervention;

- Researchers may use this review to get an overview of supply chain contributions that have already accounted in different ways the energy efficiency issues and the gaps that still exist in the literature, moreover they may use our discussion to identify the most promising research opportunities.

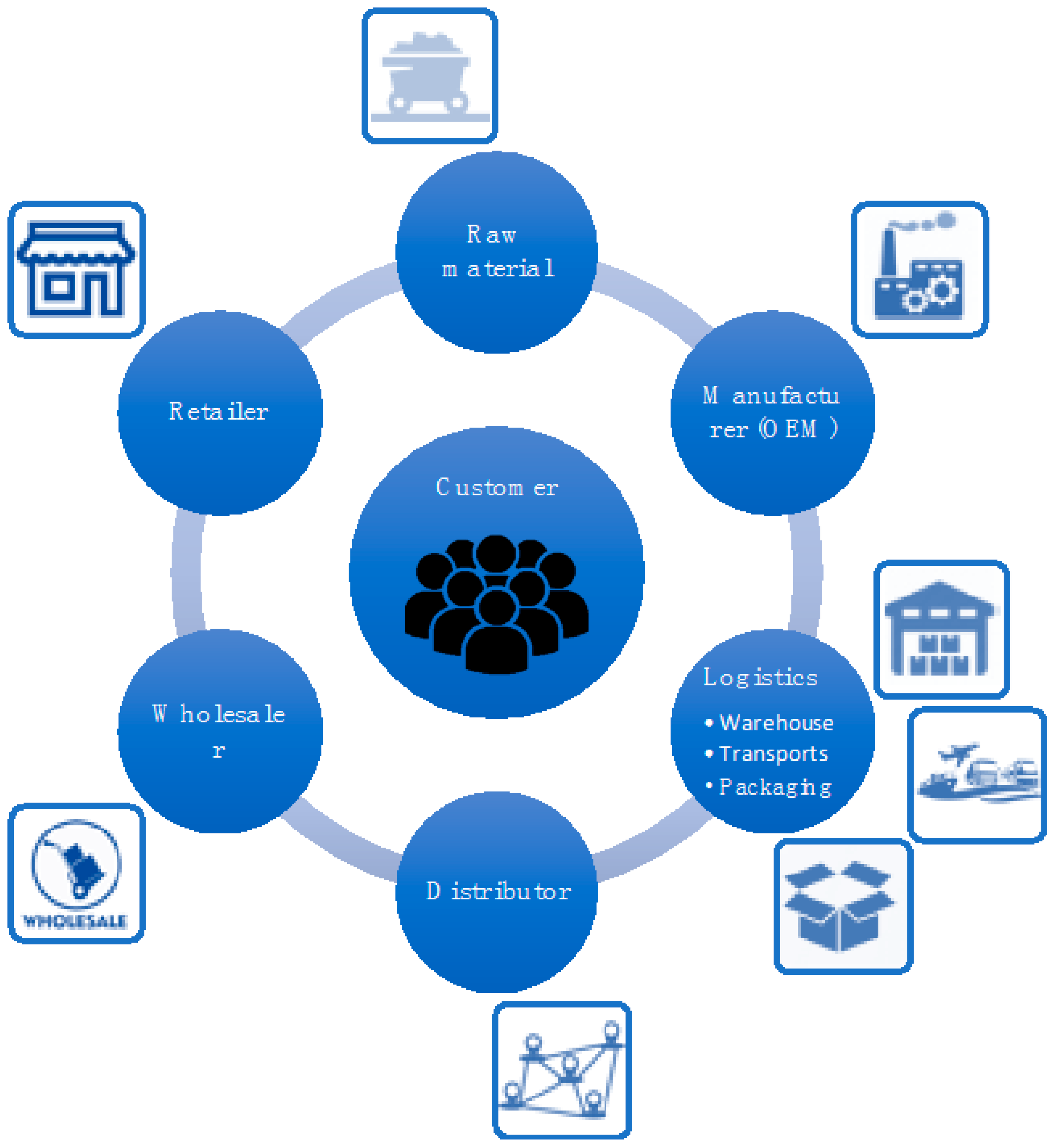

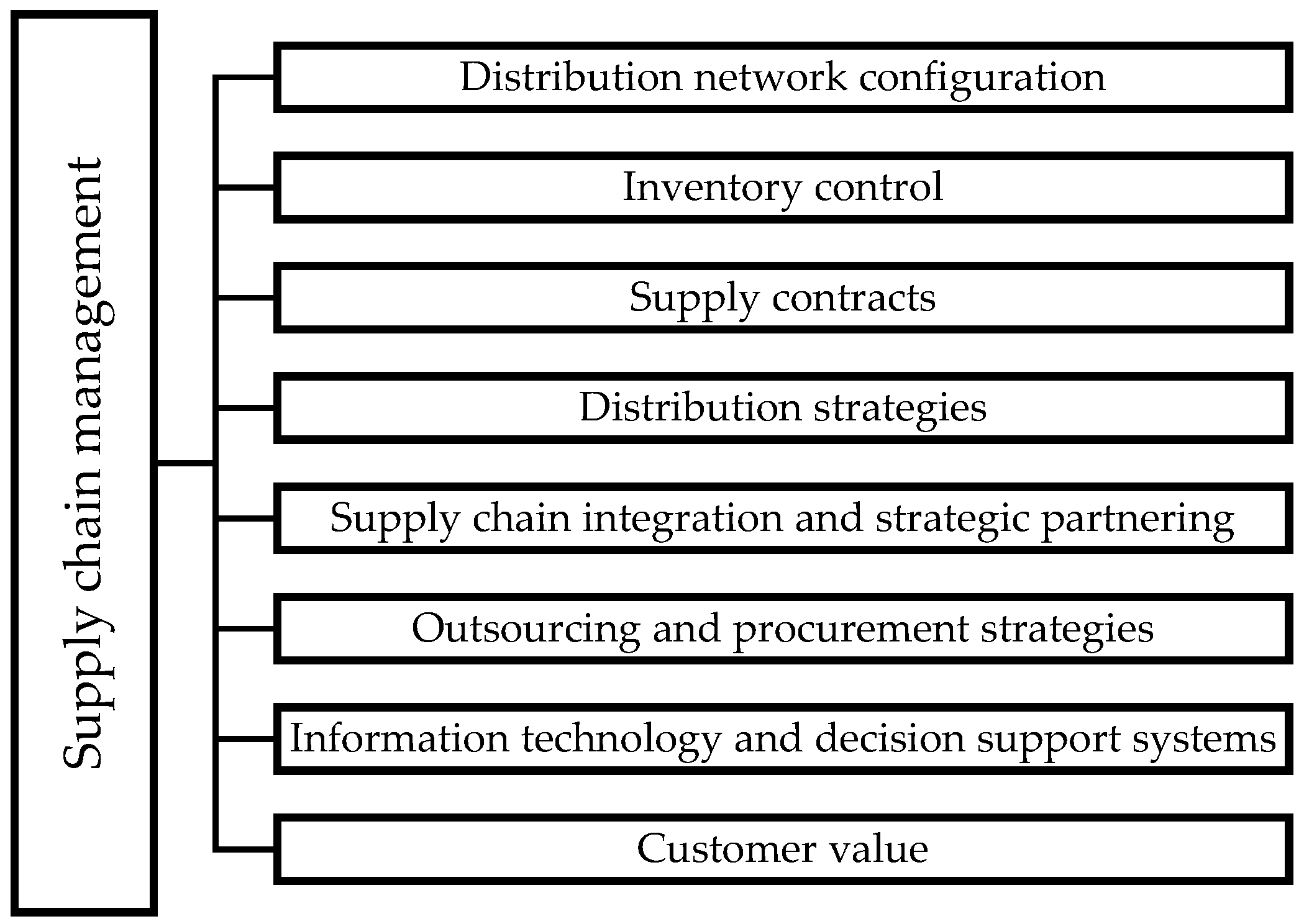

2. Conceptual Framework

- RQ1.

- Are any energy efficiency measures assessed or defined? Which kind of measures are mainly considered (i.e., production machines, production planning, auxiliary services and/or logistic activities)?

- RQ2.

- Are the benefits introduced through energy efficiency measures in the supply chain quantitatively and/or qualitatively evaluated? If they are quantitatively evaluated, which model types (such as optimization models, heuristic models, multi-criteria decision-making) and solution approaches (such as linear, non-linear, integer, stochastic and dynamic programming, fuzzy logic, analytical hierarchy process and so on) are used? Are NEBs also considered?

- RQ3.

- Which area of the supply chain are interested by the coordination and integration of the energy-related decision-making process (e.g., inventory, production process, etc.)?

- RQ4.

- Are the effects of the uncertain and variable background investigated?

- RQ5.

- Are case studies presented? Which is the context of application (i.e., industrial sector considered, location)?

3. Review Methodology

- Energy sources mix

- Energy or RES supply chains and not production system

- Energy impacts on a single entity instead of the whole supply chain

- Effects only on environmental performances and reduction of emissions.

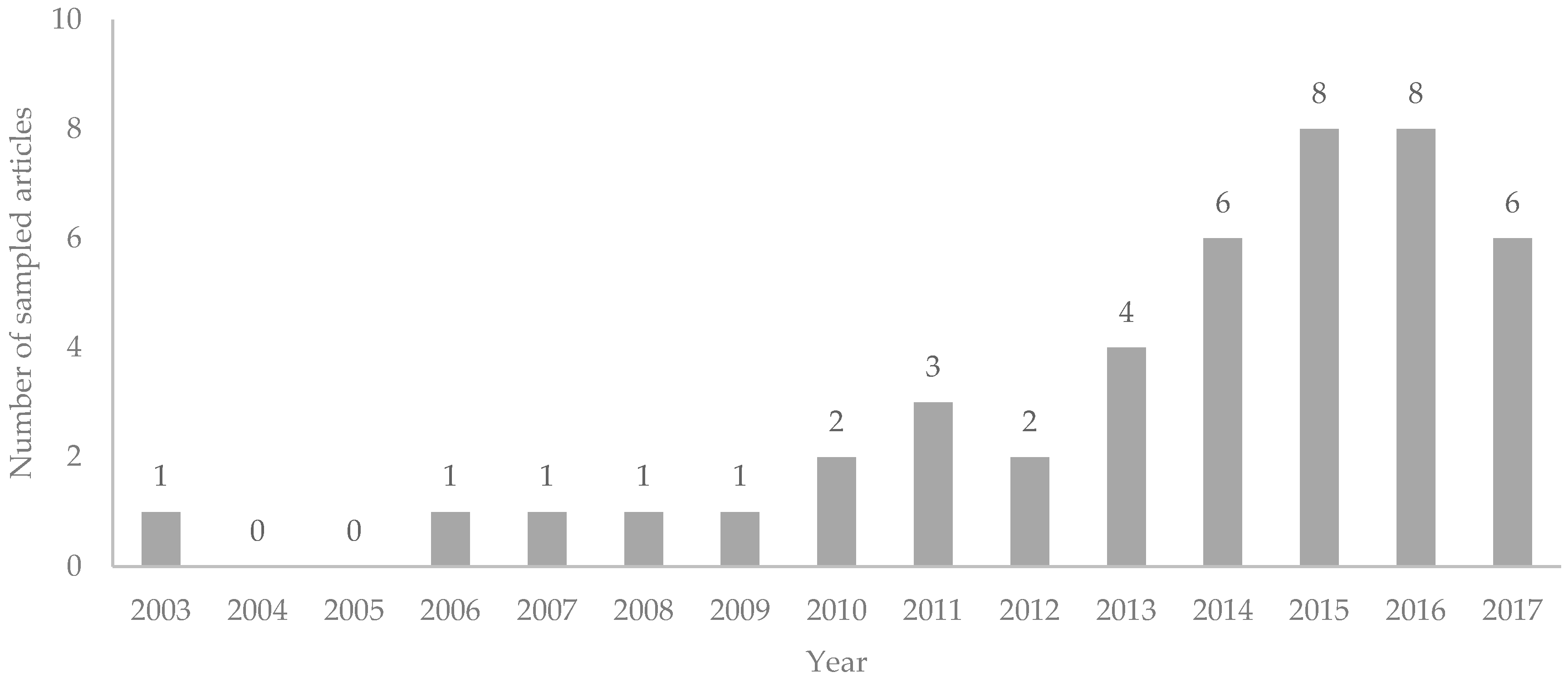

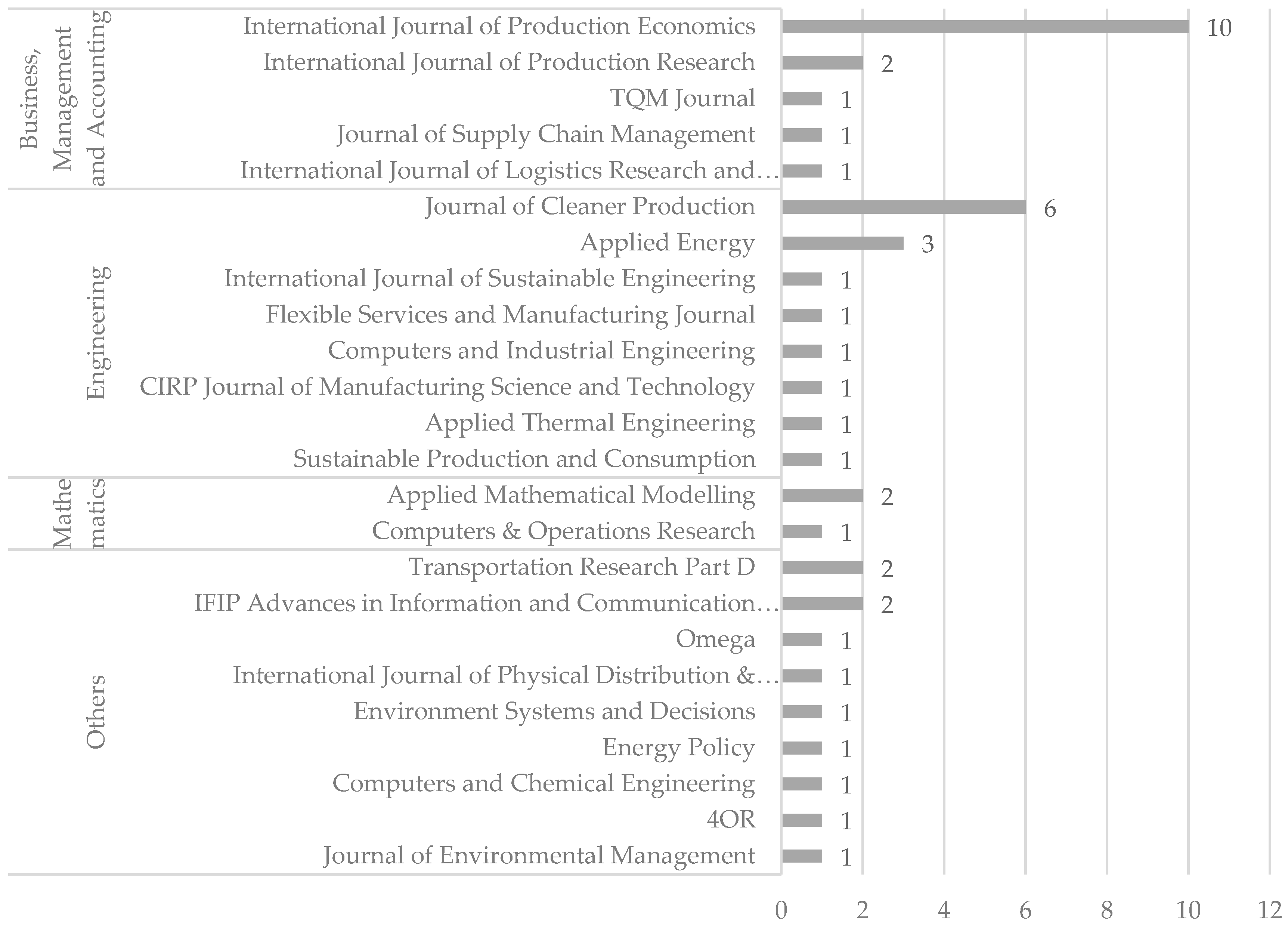

4. Descriptive Analysis

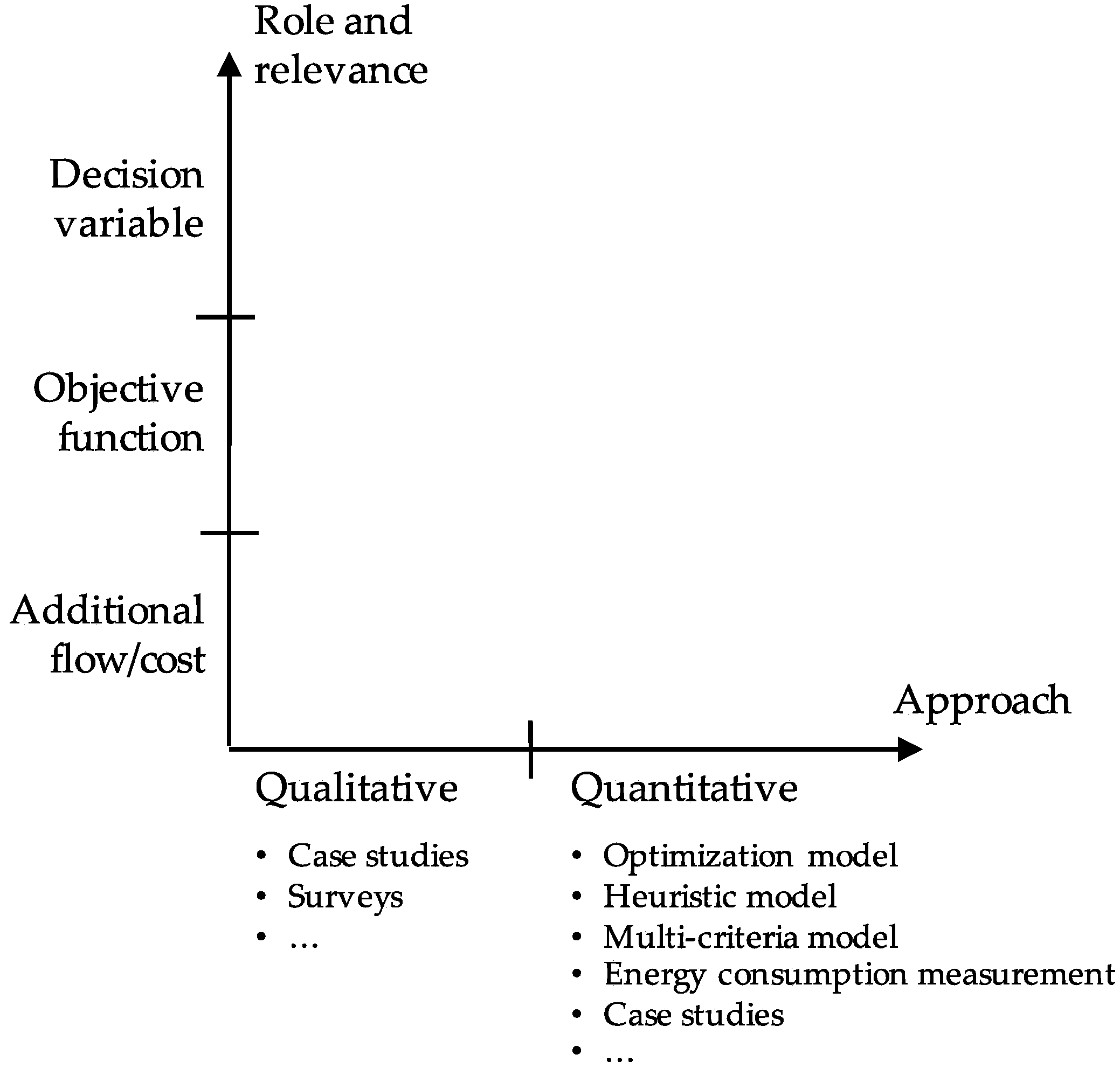

5. Content Analysis

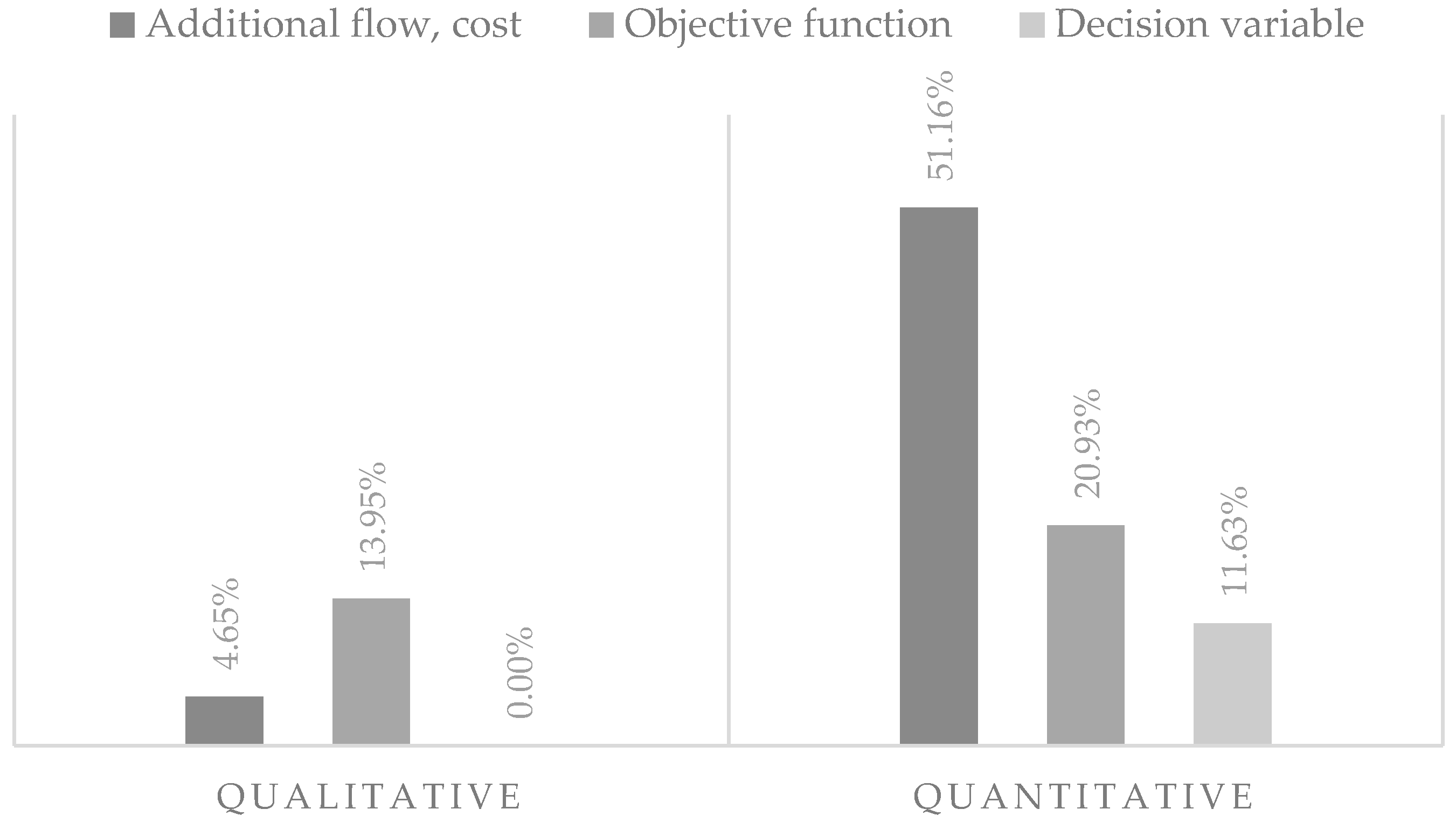

5.1. Qualitative Approach

5.2. Quantitative Approach

5.2.1. Additional Flow and Cost

5.2.2. Objective Function

5.2.3. Decision Variables

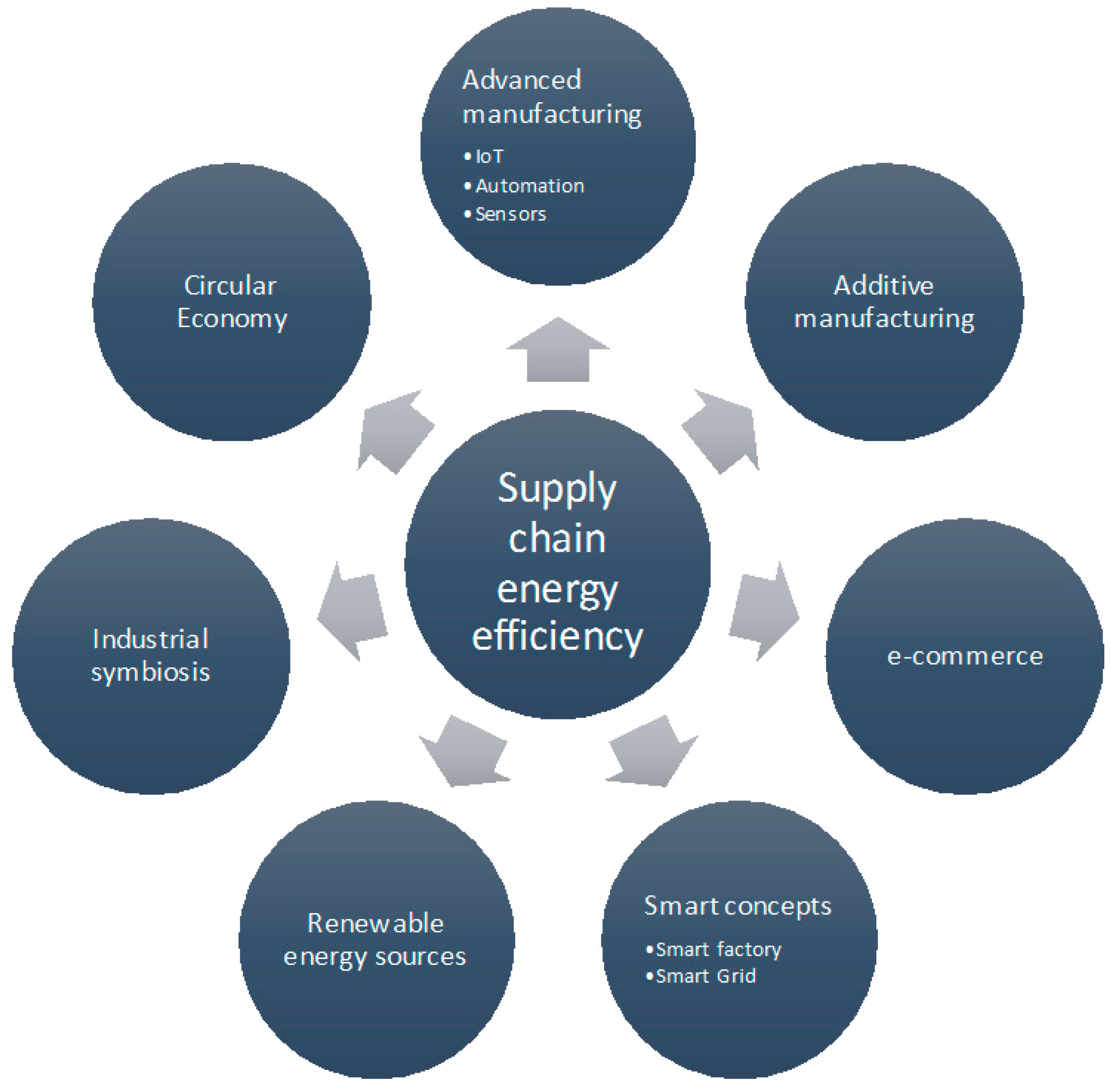

6. Discussion and Insights for Future Research Streams

- the increased use of RES in substitution to both traditional uses of biomass and conventional fuels leads to relevant energy savings, since renewables introduce more energy efficient technologies compared to their traditional alternatives;

- the combination of accelerated deployment of renewable energy technologies and energy efficiency measures has the potential to further contribute to raising renewable energy shares and accelerating energy intensity improvements.

7. Conclusions

- (i)

- The effects that the introduction of the energy topic have on the supply chain economic and environmental results and on the form of cooperation;

- (ii)

- How supply chain management can support the development of energy efficient measures to overcome existing barriers;

- (iii)

- How different learning curves and knowledge of participants along the supply chain can influence the outcomes;

- (iv)

- The effects introduced by considering risks and uncertainties that characterise the current environment.

Author Contributions

Conflicts of Interest

Appendix A

| ID | Reference | Solution Technique | EEMs | Case Studies | Coordinated Decisions | Uncertainty | NEBs | Life Cycle Perspective | Approach | Relevance |

|---|---|---|---|---|---|---|---|---|---|---|

| [21] | Kalenoja et al., 2011 | Case study | Logistic activities | Paper and metal industries | Raw material procurement, inbound logistics, production and outbound logistics | - | - | ✓ | QN | AF |

| [22] | Hasanov et al., 2013 | Optimization model | - | - | Production, inventory, transportation and waste disposal | - | - | ✓ | QN | AF |

| [34] | Wu et al., 2014 | Case study | Auxiliary services | Apparel and kitchenware production industries | Energy consumption | - | - | - | QL | OF |

| [48] | Cosimato and Troisi, 2015 | Case study | Logistic activities | Logistic company | Sustainable practices | - | - | - | QL | AF |

| Auxiliary services | ||||||||||

| [49] | Ahi et al., 2016 | Literature review | - | - | Sustainable practices | - | - | ✓ | QL | OF |

| [50] | Glover et al., 2014 | Institutional theory | - | Dairy supply chain | Sustainable practices | - | - | - | QL | OF |

| [51] | Winkler, 2011 | Qualitative analysis | Logistic activities | - | Waste, energy consumption, transport processes and packaging | - | - | ✓ | QL | AF |

| [52] | Halldórsson and Kovács, 2010 | Conceptual framework | Logistic activities | - | Sustainable practices | - | - | - | QL | OF |

| [53] | Denham et al., 2015 | Literature review | Logistic activities | Seafood industry | Sustainable practices | - | - | ✓ | QL | OF |

| Auxiliary services | ||||||||||

| [54] | Mulhall and Bryson, 2014 | Case study | - | Intermediate metal processing industry | Purchasing | ✓ | - | - | QL | OF |

| [55] | Sundarakani et al., 2010 | Optimization model | Logistic activities | - | Logistic | - | - | - | QN | AF |

| [56] | Kannegiesser and Günther, 2013 | Optimization model | Logistic activities | - | Production and logistic | - | - | - | QN | AF |

| [57] | Zamarripa et al., 2014 | Optimization model | - | Polystyrene production-distribution and energy generation supply chain | Resources procurement, production, inventory, transportation | ✓ | - | - | QN | AF |

| [58] | Rizet et al., 2012 | Case study | - | Yogurt, jeans, fruits and furniture supply chains | Transportation and storage | - | - | - | QN | AF |

| [59] | Ferretti et al., 2007 | Optimization model | Logistic activities | Aluminium supply chain | Production, inventory, transportation and green practices | - | - | - | QN | AF |

| [60] | Meneghetti and Monti, 2014 | Optimization model | Logistic activities | Food supply chain | Production, inventory and transportation | - | - | - | QN | AF |

| [61] | Waldemarsson et al., 2013 | Optimization model | Production planning | Pulp industry | Raw materials purchasing, production, inventory, transportation and energy consumption | - | - | - | QN | AF |

| [62] | Marimin et al., 2014 | Multi-criteria decision making | Production planning | Natural rubber supply chain | Sustainable practices | - | - | - | QN | AF |

| [63] | Krikke et al., 2003 | Case study | Logistic activities | Refrigerators closed-loop supply chain | Transportation, waste and energy consumption | - | - | ✓ | QN | AF |

| [64] | Cholette and Venkat, 2009 | Case study | Logistic activities | Wine industry | Transportation and storage | - | - | - | QN | AF |

| [65] | Waldemarsson et al., 2017 | Optimization model | Production planning | Pulp industry | Raw materials, production, storage, distribution and transportation | - | - | - | QN | AF |

| [66] | Zanoni et al., 2013 | Optimization model | Production planning | - | Production, inventory and energy consumption | - | - | - | QN | AF |

| [67] | Zanoni and Zavanella, 2012 | Optimization model | Production planning | Food supply chain | Production, inventory, transportation and energy consumption | - | - | - | QN | AF |

| [68] | Bazan et al., 2015a | Optimization model | Production planning | - | Production, inventory, transportation and emissions | - | - | - | QN | AF |

| [69] | Bazan et al., 2015b | Optimization model | Production planning | - | Production, inventory, transportation, waste disposal and emissions | - | - | - | QN | AF |

| [70] | Bazan et al., 2017 | Optimization model | Production planning | - | Production, inventory, transportation, waste disposal, energy consumption and emissions | - | - | - | QN | AF |

| [71] | Bazan et al., 2016 | Literature review | - | - | Production, inventory, transportation, waste disposal, energy consumption and emissions | - | - | - | QN | AF |

| [72] | Chung and Wee, 2011 | Optimization model | Production planning | - | Production, inventory and remanufacturing | - | - | ✓ | QN | AF |

| Logistic activities | ||||||||||

| [73] | Biel and Glock, 2016 | Optimization model | Production planning | - | Production, inventory and energy consumption | - | - | - | QN | AF |

| [74] | Marchi et al., 2017 | Optimization model | Production planning | - | Production, inventory and energy consumption | - | - | - | QN | AF |

| [75] | Hanes and Carpenter, 2017 | Case study | Production machines | Light-weight vehicle supply chain | energy consumption | - | - | ✓ | QN | OF |

| [76] | Michelsen et al., 2006 | Case study | Production planning | Furniture industry | Eco-efficiency decisions | - | - | ✓ | QN | OF |

| [77] | Tsoulfas and Pappis, 2008 | Multi-criteria decision making | Logistic activities | - | Sustainable practices | - | - | ✓ | QN | OF |

| [78] | Fahimnia et al., 2015 | Optimization model | Logistic activities | - | Production, inventory, transportation and environmental performance | ✓ | - | - | QN | OF |

| [79] | Jain et al., 2013 | Case study | Production planning | Forklift brake supply chain | Raw materials purchasing, production, inventory, transportation and energy consumption | - | - | ✓ | QN | OF |

| [80] | Das and Posinasetti, 2015 | Optimization model | Logistic activities | - | Production, inventory, transportation and energy consumption | - | - | ✓ | QN | OF |

| [81] | Kadambala et al., 2017 | Multi-criteria decision making | Logistic activities | - | Purchasing, production, inventory, transportation, remanufacturing and energy consumption | - | - | ✓ | QN | OF |

| [82] | Wang et al., 2016 | Case study | Production planning | China’s consumer goods retail system | Energy consumption | - | - | ✓ | QN | OF |

| [83] | McBrien et al., 2016 | Case study | Auxiliary services | Steel supply chain | Energy consumption and heat recovery | - | - | ✓ | QN | OF |

| [84] | Zhang et al., 2016a | Optimization model | - | - | Prices and energy efficiency levels | - | - | - | QN | DV |

| [85] | Zhang et al., 2016b | Optimization model | - | - | Prices and energy efficiency levels | - | - | - | QN | DV |

| [86] | Xie, 2015 | Optimization model | - | - | Prices and energy saving level | - | - | - | QN | DV |

| [87] | Xie, 2016 | Optimization model | - | - | Prices and energy saving level | - | - | - | QN | DV |

| [88] | Xie et al., 2017 | Optimization model | Production machines | Shipbuilding supply chain | Prices and energy saving level | ✓ | - | - | QN | DV |

References

- BP Statistical Review of World Energy. Available online: https://www.bp.com/content/dam/bp/pdf/energy-economics/statistical-review-2016/bp-statistical-review-of-world-energy-2016-full-report.pdf (accessed on 12 October 2017).

- Kesicki, F.; Yanagisawa, A. Modelling the potential for industrial energy efficiency in IEA’s World Energy Outlook. Energy Effic. 2014, 8, 155–169. [Google Scholar] [CrossRef]

- Jayaram, J.; Avittathur, B. Green supply chains: A perspective from an emerging economy. Int. J. Prod. Econ. 2015, 164, 234–244. [Google Scholar] [CrossRef]

- Deloitte. Energy Efficiency in Europe: The Levers to Deliver the Potential. Available online: https://www2.deloitte.com/content/dam/Deloitte/global/Documents/Energy-and-Resources/energy-efficiency-in-europe.pdf (accessed on 12 October 2017).

- ISO. ISO 50001: 2011, Energy Management Systems—Requirements with Guidance for Use; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- Backlund, S.; Thollander, P.; Palm, J.; Ottosson, M. Extending the energy efficiency gap. Energy Policy 2012, 51, 392–396. [Google Scholar] [CrossRef]

- Tanaka, K. Review of policies and measures for energy efficiency in industry sector. Energy Policy 2011, 39, 6532–6550. [Google Scholar] [CrossRef]

- Biel, K.; Glock, C.H. Systematic literature review of decision support models for energy-efficient production planning. Comput. Ind. Eng. 2016, 101, 243–259. [Google Scholar] [CrossRef]

- Thiede, S.; Posselt, G.; Herrmann, C. SME appropriate concept for continuously improving the energy and resource efficiency in manufacturing companies. CIRP J. Manuf. Sci. Technol. 2013, 6, 204–211. [Google Scholar] [CrossRef]

- IEA. Capturing the Multiple Benefits of Energy Efficiency; International Energy Agency: Paris, France, 2014; pp. 18–25. [Google Scholar]

- Department of Energy & Climate Change (DECC). What Are the Factors Influencing Energy Behaviours and Decision-Making in the Non-Domestic Sector? A Rapid Evidence Assessment; DECC: Aberdeen, UK, 2012.

- Cagno, E.; Trianni, A. Evaluating the barriers to specific industrial energy efficiency measures: An exploratory study in small and medium-sized enterprises. J. Clean. Prod. 2014, 82, 70–83. [Google Scholar] [CrossRef]

- DeCanio, S.J. The efficiency paradox: Bureaucratic and organizational barriers to profitable energy-saving investments. Energy Policy 1998, 26, 441–454. [Google Scholar] [CrossRef]

- De Groot, H.L.F.; Verhoef, E.T.; Nijkamp, P. Energy saving by firms: Decision-making, barriers and policies. Energy Econ. 2001, 23, 717–740. [Google Scholar] [CrossRef]

- Thollander, P.; Palm, J. An Interdisciplinary Perspective on Barriers, Energy Audits, Energy Management, Policies, and Programs. In Improving Energy Efficiency in Industrial Energy Systems; Springer: London, UK, 2013; p. 151. [Google Scholar]

- Trianni, A.; Cagno, E. Dealing with barriers to energy efficiency and SMEs: Some empirical evidences. Energy 2012, 37, 494–504. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Worrell, E.; Pugliese, G. Empirical investigation of energy efficiency barriers in Italian manufacturing SMEs. Energy 2013, 49, 444–458. [Google Scholar] [CrossRef]

- ECB. Survey on the Access to Finance of Enterprises in the Euro Area (October 2014 to March 2015); European Central Bank: Frankfurt am Main, Germany, 2015. [Google Scholar]

- Wehinger, G. SMEs and the credit crunch: Current financing difficulties, policy measures and a review of literature. OECD J. Financ. Mark. Trends 2014, 2013, 115–148. [Google Scholar] [CrossRef]

- Hale, G.; Arteta, C. Currency crises and foreign credit in emerging markets: Credit crunch or demand effect? Eur. Econ. Rev. 2009, 53, 758–774. [Google Scholar] [CrossRef]

- Kalenoja, H.; Kallionpaa, E.; Rantala, J. Indicators of energy efficiency of supply chains. Int. J. Logist. Res. Appl. 2011, 14, 77–95. [Google Scholar] [CrossRef]

- Hasanov, P.; Jaber, M.Y.; Zanoni, S.; Zavanella, L.E. Closed-loop supply chain system with energy, transportation and waste disposal costs. Int. J. Sustain. Eng. 2013, 6, 352–358. [Google Scholar] [CrossRef]

- Jansen, J.H. Supply Chain Finance Management; HAN Business Publications: Nijmegen, The Netherlands, 2014; pp. 1–36. [Google Scholar]

- Jaber, M.Y.; Goyal, S.K. Coordinating a three-level supply chain with multiple suppliers, a vendor and multiple buyers. Int. J. Prod. Econ. 2008, 116, 95–103. [Google Scholar] [CrossRef]

- O’Keeffe, J.M.; Gilmour, D.; Simpson, E. A network approach to overcoming barriers to market engagement for SMEs in energy efficiency initiatives such as the Green Deal. Energy Policy 2016, 97, 582–590. [Google Scholar] [CrossRef]

- Roehrich, J.K.; Grosvold, J.; Hoejmose, S.U. Reputational risks and sustainable supply chain management. Int. J. Oper. Prod. Manag. 2014, 34, 695–719. [Google Scholar] [CrossRef]

- Parry, P.; Martha, J.; Grenon, G. The Energy-Efficient Supply Chain. Strategy+Bus. 2007, 47, 1–8. [Google Scholar]

- Zanoni, S.; Mazzoldi, L.; Zavanella, L.E.; Jaber, M.Y. A joint economic lot size model with price and environmentally sensitive demand. Prod. Manuf. Res. 2014, 2, 341–354. [Google Scholar] [CrossRef]

- Marchi, B.; Ries, J.M.; Zanoni, S.; Glock, C.H. A joint economic lot size model with financial credits and uncertain investment opportunities. Int. J. Prod. Econ. 2016, 176, 170–182. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Ferretti, I.; Zavanella, L.E. Learning curves in energy efficiency investments: The effects of supply chain integration. In Proceedings of the Nineteenth International Working Seminar on Production Economics, Innsbruck, Austria, 22–26 February 2016; pp. 211–222. [Google Scholar]

- Nguyen, J.Q.; Donohue, K.; Mehrotra, M. The Buyer’s Role in Improving Supply Chain Energy Efficiency. Available online: https://ssrn.com/abstract=2564287 (accessed on 11 October 2017).

- Schulze, M.; Nehler, H.; Ottosson, M.; Thollander, P. Energy management in industry—A systematic review of previous findings and an integrative conceptual framework. J. Clean. Prod. 2016, 112, 3692–3708. [Google Scholar] [CrossRef]

- Pons, M.; Bikfalvi, A.; Llach, J.; Palcic, I. Exploring the impact of energy efficiency technologies on manufacturing firm performance. J. Clean. Prod. 2013, 52, 134–144. [Google Scholar] [CrossRef]

- Wu, Z.; Ellram, L.M.; Schuchard, R. Understanding the role of government and buyers in supplier energy efficiency initiatives. J. Supply Chain Manag. 2014, 50, 84–105. [Google Scholar] [CrossRef]

- Hoejmose, S.U.; Roehrich, J.K.; Grosvold, J. Is doing more doing better? The relationship between responsible supply chain management and corporate reputation. Ind. Mark. Manag. 2014, 43, 77–90. [Google Scholar] [CrossRef]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K.H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Grosvold, J.; Hoejmose, S.; Roehrich, J. Squaring the circle: Management, measurement and performance of sustainability in supply chains. Supply Chain Manag. Int. J. 2014, 19, 292–305. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Sarode, A.; Kole, S. A Literature Overview on Green Supply Chain Management and Critical Factors. Available online: http://www.ijaeit.com/LCE%20FINAL%20PUB/IJAEIT%202016%2029.pdf (accessed on 12 Ocotober 2017).

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of sustainability in supply chain management: A literature review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Reim, W.; Parida, V.; Örtqvist, D. Product–Service Systems (PSS) business models and tactics—A systematic literature review. J. Clean. Prod. 2015, 97, 61–75. [Google Scholar] [CrossRef]

- Roehrich, J.K.; Lewis, M.A.; George, G. Are public-private partnerships a healthy option? A systematic literature review. Soc. Sci. Med. 2014, 113, 110–119. [Google Scholar] [CrossRef] [PubMed]

- Patterson, M.G. What is energy efficiency? Concepts, indicators and methodological issues. Energy Policy 1996, 24, 377–390. [Google Scholar] [CrossRef]

- Herring, H. Energy efficiency—A critical view. Energy 2006, 31, 10–20. [Google Scholar] [CrossRef]

- Cosimato, S.; Troisi, O. Green supply chain management. TQM J. 2015, 27, 256–276. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C.; Jaber, M.Y. Energy-related performance measures employed in sustainable supply chains: A bibliometric analysis. Sustain. Prod. Consum. 2016, 7, 1–15. [Google Scholar] [CrossRef]

- Glover, J.L.; Champion, D.; Daniels, K.J.; Dainty, A.J.D. An Institutional Theory perspective on sustainable practices across the dairy supply chain. Int. J. Prod. Econ. 2014, 152, 102–111. [Google Scholar] [CrossRef]

- Winkler, H. Closed-loop production systems—A sustainable supply chain approach. CIRP J. Manuf. Sci. Technol. 2011, 4, 243–246. [Google Scholar] [CrossRef]

- Halldórsson, Á.; Kovács, G. The sustainable agenda and energy efficiency: Logistics solutions and supply chains in times of climate change. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 5–13. [Google Scholar] [CrossRef]

- Denham, F.C.; Howieson, J.R.; Solah, V.A.; Biswas, W.K. Environmental supply chain management in the seafood industry: Past, present and future approaches. J. Clean. Prod. 2015, 90, 82–90. [Google Scholar] [CrossRef]

- Mulhall, R.A.; Bryson, J.R. Energy price risk and the sustainability of demand side supply chains. Appl. Energy 2014, 123, 327–334. [Google Scholar] [CrossRef]

- Sundarakani, B.; de Souza, R.; Goh, M.; Wagner, S.M.; Manikandan, S. Modeling carbon footprints across the supply chain. Int. J. Prod. Econ. 2010, 128, 43–50. [Google Scholar] [CrossRef]

- Kannegiesser, M.; Günther, H.-O. Sustainable development of global supply chains—Part 1: Sustainability optimization framework. Flex. Serv. Manuf. J. 2013, 26, 24–47. [Google Scholar] [CrossRef]

- Zamarripa, M.; Hjaila, K.; Silvente, J.; Espuña, A. Tactical management for coordinated supply chains. Comput. Chem. Eng. 2014, 66, 110–123. [Google Scholar] [CrossRef]

- Rizet, C.; Browne, M.; Cornelis, E.; Leonardi, J. Assessing carbon footprint and energy efficiency in competing supply chains: Review—Case studies and benchmarking. Transp. Res. Part D Transp. Environ. 2012, 17, 293–300. [Google Scholar] [CrossRef]

- Ferretti, I.; Zanoni, S.; Zavanella, L.; Diana, A. Greening the aluminium supply chain. Int. J. Prod. Econ. 2007, 108, 236–245. [Google Scholar] [CrossRef]

- Meneghetti, A.; Monti, L. Greening The Food Supply Chain: An optimisation model for sustainable design of refrigerated automated warehouses. Int. J. Prod. Res. 2015, 53, 6567–6587. [Google Scholar] [CrossRef]

- Waldemarsson, M.; Lidestam, H.; Rudberg, M. Including energy in supply chain planning at a pulp company. Appl. Energy 2013, 112, 1056–1065. [Google Scholar] [CrossRef]

- Marimin; Darmawan, M.A.; Islam Fajar Putra, M.P.; Wiguna, B. Value chain analysis for green productivity improvement in the natural rubber supply chain: A case study. J. Clean. Prod. 2014, 85, 201–211. [Google Scholar] [CrossRef]

- Krikke, H.; Bloemhof-Ruwaard, J.; Van Wassenhove, L.N. Concurrent product and closed-loop supply chain design with an application to refrigerators. Int. J. Prod. Res 2003, 41, 3689–3719. [Google Scholar] [CrossRef]

- Cholette, S.; Venkat, K. The energy and carbon intensity of wine distribution: A study of logistical options for delivering wine to consumers. J. Clean. Prod. 2009, 17, 1401–1413. [Google Scholar] [CrossRef]

- Waldemarsson, M.; Lidestam, H.; Karlsson, M. How energy price changes can affect production-and supply chain planning—A case study at a pulp company. Appl. Energy 2017, 203, 333–347. [Google Scholar] [CrossRef]

- Zanoni, S.; Bettoni, L.; Glock, C.H. Energy implications in the single-vendor single-buyer integrated production inventory model. IFIP Adv. Inf. Commun. Technol. 2013, 397, 57–64. [Google Scholar] [CrossRef]

- Zanoni, S.; Zavanella, L. Chilled or frozen? Decision strategies for sustainable food supply chains. Int. J. Prod. Econ. 2012, 140, 731–736. [Google Scholar] [CrossRef]

- Bazan, E.; Jaber, M.Y.; Zanoni, S. Supply chain models with greenhouse gases emissions, energy usage and different coordination decisions. Appl. Math. Model. 2015, 39, 5131–5151. [Google Scholar] [CrossRef]

- Bazan, E.; Jaber, M.Y.; El Saadany, A.M.A. Carbon Emissions and Energy Effects on Manufacturing-Remanufacturing Inventory Models. Comput. Ind. Eng. 2015, 88, 307–316. [Google Scholar] [CrossRef]

- Bazan, E.; Jaber, M.Y.; Zanoni, S. Carbon emissions and energy effects on a two-level manufacturer- retailer closed-loop supply chain model with remanufacturing subject to different coordination mechanisms. Int. J. Prod. Econ. 2017, 183, 394–408. [Google Scholar] [CrossRef]

- Bazan, E.; Jaber, M.Y.; Zanoni, S. A review of mathematical inventory models for reverse logistics and the future of its modeling: An environmental perspective. Appl. Math. Model. 2016, 40, 4151–4178. [Google Scholar] [CrossRef]

- Chung, C.J.; Wee, H.M. Short life-cycle deteriorating product remanufacturing in a green supply chain inventory control system. Int. J. Prod. Econ. 2011, 129, 195–203. [Google Scholar] [CrossRef]

- Biel, K.; Glock, C.H. On the use of waste heat in a two-stage production system with controllable production rates. Int. J. Prod. Econ. 2016, 181, 174–190. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Zavanella, L.E. An Integrated Supply Chain Model with Excess Heat Recovery. IFIP Adv. Inf. Commun. Technol. 2017, 514, 479–487. [Google Scholar] [CrossRef]

- Hanes, R.J.; Carpenter, A. Evaluating opportunities to improve material and energy impacts in commodity supply chains. Environ. Syst. Decis. 2017, 37, 6–12. [Google Scholar] [CrossRef]

- Michelsen, O.; Fet, A.M.; Dahlsrud, A. Eco-efficiency in extended supply chains: A case study of furniture production. J. Environ. Manag. 2006, 79, 290–297. [Google Scholar] [CrossRef] [PubMed]

- Tsoulfas, G.T.; Pappis, C.P. A model for supply chains environmental performance analysis and decision making. J. Clean. Prod. 2008, 16, 1647–1657. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Eshragh, A. A tradeoff model for green supply chain planning: A leanness-versus-greenness analysis. Omega 2015, 54, 173–190. [Google Scholar] [CrossRef]

- Jain, S.; Lindskog, E.; Andersson, J.; Johansson, B. A hierarchical approach for evaluating energy trade-offs in supply chains. Int. J. Prod. Econ. 2013, 146, 411–422. [Google Scholar] [CrossRef]

- Das, K.; Rao Posinasetti, N. Addressing environmental concerns in closed loop supply chain design and planning. Int. J. Prod. Econ. 2015, 163, 34–47. [Google Scholar] [CrossRef]

- Kadambala, D.K.; Subramanian, N.; Tiwari, M.K.; Abdulrahman, M.; Liu, C. Closed loop supply chain networks: Designs for energy and time value efficiency. Int. J. Prod. Econ. 2017, 183, 382–393. [Google Scholar] [CrossRef]

- Wang, X.; Cai, H.; Florig, H.K. Energy-saving implications from supply chain improvement: An exploratory study on China’s consumer goods retail system. Energy Policy 2016, 95, 411–420. [Google Scholar] [CrossRef]

- McBrien, M.; Serrenho, A.C.; Allwood, J.M. Potential for energy savings by heat recovery in an integrated steel supply chain. Appl. Therm. Eng. 2016, 103, 592–606. [Google Scholar] [CrossRef]

- Zhang, Q.; Tang, W.; Zhang, J. Green supply chain performance with cost learning and operational inefficiency effects. J. Clean. Prod. 2016, 112, 3267–3284. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.; Tang, W. Coordinating a supply chain with green innovation in a dynamic setting. 4or 2016. [Google Scholar] [CrossRef]

- Xie, G. Modeling decision processes of a green supply chain with regulation on energy saving level. Comput. Oper. Res. 2015, 54, 266–273. [Google Scholar] [CrossRef]

- Xie, G. Cooperative strategies for sustainability in a decentralized supply chain with competing suppliers. J. Clean. Prod. 2016, 113, 807–821. [Google Scholar] [CrossRef]

- Xie, G.; Yue, W.; Wang, S. Energy efficiency decision and selection of main engines in a sustainable shipbuilding supply chain. Transp. Res. Part D 2017, 53, 290–305. [Google Scholar] [CrossRef]

- Saygin, D.; Worrell, E.; Patel, M.K.; Gielen, D.J. Benchmarking the energy use of energy-intensive industries in industrialized and in developing countries. Energy 2011, 36, 6661–6673. [Google Scholar] [CrossRef]

- ISO. ISO 14001: 2015, Environmental Management Systems—Requirements with Guidance for Use; ISO: Geneva, Switzerland, 2015. [Google Scholar]

- Marchi, B.; Zanoni, S.; Mazzoldi, L.; Reboldi, R. Product-service System for Sustainable EAF Transformers: Real Operation Conditions and Maintenance Impacts on the Life-cycle Cost. Procedia CIRP 2016, 47, 72–77. [Google Scholar] [CrossRef]

- ISO. ISO 14044: 2006, Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Electrotechnical Commission (IEC). 60300-3-3 Dependability Management—Part 3-3: Application Guide—Life Cycle Costing; IEC: Geneva, Switzerland, 2004. [Google Scholar]

- Jin, M.; Tang, R.; Ji, Y.; Liu, F.; Gao, L.; Huisingh, D. Impact of advanced manufacturing on sustainability: An overview of the special volume on advanced manufacturing for sustainability and low fossil carbon emissions. J. Clean. Prod. 2017, 161, 69–74. [Google Scholar] [CrossRef]

- Pålsson, H.; Pettersson, F.; Winslott Hiselius, L. Energy consumption in e-commerce versus conventional trade channels Insights into packaging, the last mile, unsold products and product returns. J. Clean. Prod. 2017. [Google Scholar] [CrossRef]

- IRENA. Synergies between Renewable Energy and Energy Efficiency, A Working Paper Based on Remap 2030. Int. Renew. Energy Agency 2015, 1, 1–52. [Google Scholar]

- Chertow, M.R.; Ashton, W.S.; Espinosa, J.C. Industrial Symbiosis in Puerto Rico: Environmentally Related Agglomeration Economies. Reg. Stud. 2008, 42, 1299–1312. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S.; Zavanella, L.E. Symbiosis between industrial systems, utilities and public service facilities for boosting energy and resource efficiency. Energy Procedia 2017, 128C, 544–550. [Google Scholar] [CrossRef]

- Cooper, S.J.G.; Giesekam, J.; Hammond, G.P.; Norman, J.B.; Owen, A.; Rogers, J.G.; Scott, K. Thermodynamic insights and assessment of the “circular economy”. J. Clean. Prod. 2017, 162, 1356–1367. [Google Scholar] [CrossRef]

| Research Area | Keywords | ||

|---|---|---|---|

| Supply chain management | - | “Supply chain” | |

| OR | “Coordinated supply chain” | ||

| OR | “Integrated inventory” | ||

| OR | “Centralized decisions” | ||

| OR | “Integrated supply chain” | ||

| AND | Energy issue | - | “Energy” |

| OR | “Energy efficiency” | ||

| OR | “Energy cost” | ||

| OR | “Energy saving” | ||

| OR | “Energy consumption” | ||

| Step | Description | Total |

|---|---|---|

| Keywords Search | Articles needs to fulfil the search string in their title, abstract, or main text | 4512 |

| Journal Selection | Articles needs to belong to peer-reviewed journals | 2417 |

| Exclusion of journal focused on subject areas not relevant for the literature review | 1343 | |

| Content Analysis and Consolidation | Duplicates were eliminated and relevance ensured by reading the abstract focusing on relevant topics Ensure relevance by reading the title, the abstract and then the entire article | 35 |

| Snowball Search | Forward and backward searches based on articles selected in previous steps | 9 |

| Sample Size | - | 44 |

| Research Stream | Gaps |

|---|---|

|

|

|

|

|

|

|

|

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marchi, B.; Zanoni, S. Supply Chain Management for Improved Energy Efficiency: Review and Opportunities. Energies 2017, 10, 1618. https://doi.org/10.3390/en10101618

Marchi B, Zanoni S. Supply Chain Management for Improved Energy Efficiency: Review and Opportunities. Energies. 2017; 10(10):1618. https://doi.org/10.3390/en10101618

Chicago/Turabian StyleMarchi, Beatrice, and Simone Zanoni. 2017. "Supply Chain Management for Improved Energy Efficiency: Review and Opportunities" Energies 10, no. 10: 1618. https://doi.org/10.3390/en10101618

APA StyleMarchi, B., & Zanoni, S. (2017). Supply Chain Management for Improved Energy Efficiency: Review and Opportunities. Energies, 10(10), 1618. https://doi.org/10.3390/en10101618