On the Energy Efficiency of Dual Clutch Transmissions and Automated Manual Transmissions

Abstract

1. Introduction

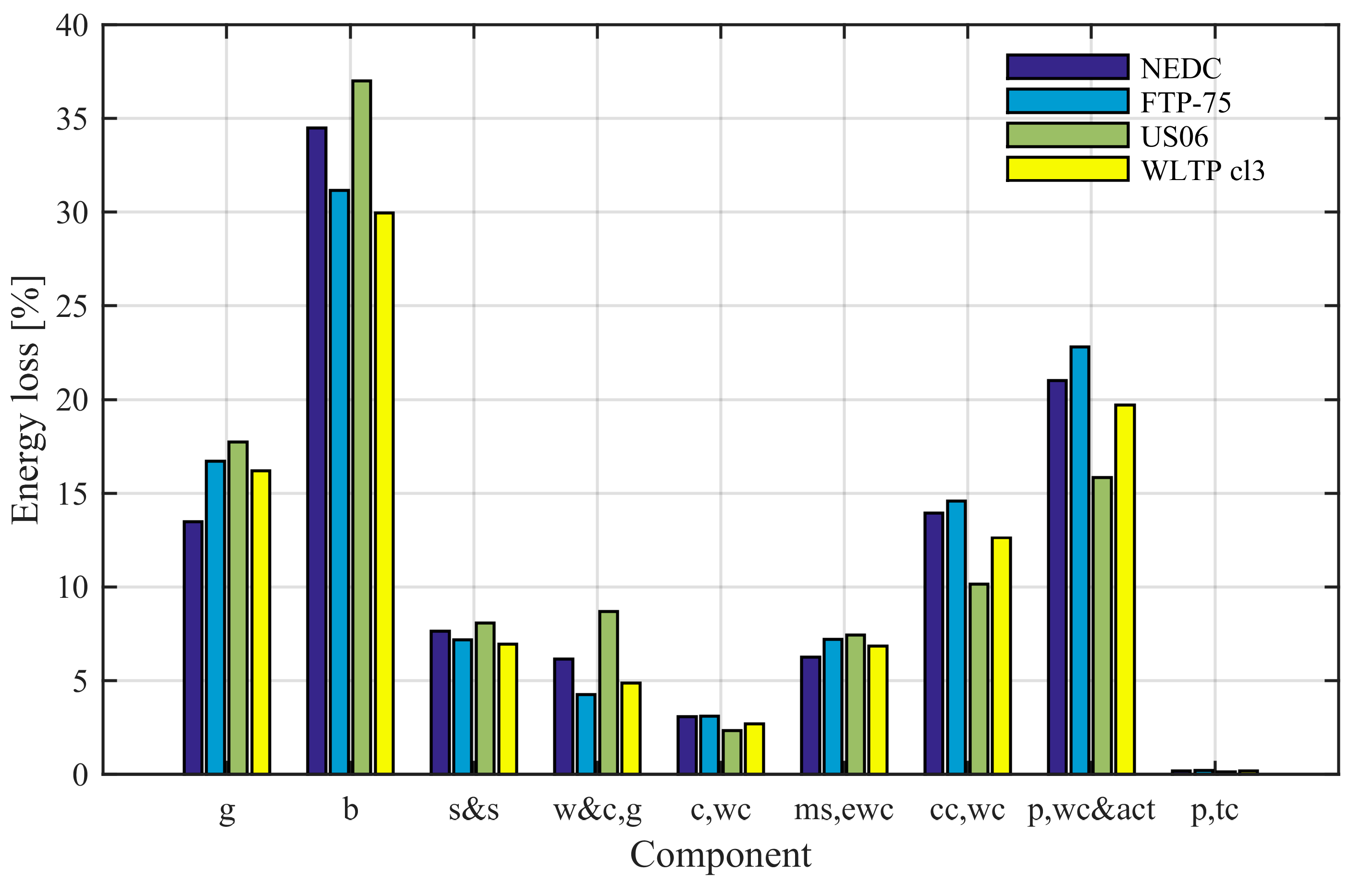

- The discussion of the relative significance of the individual power loss contributions of a specific DCT with wet clutches, through the analysis of simulation-based power loss maps and energy losses along driving cycles.

- The description of a novel hybridised AMT layout, referred to as HAMT in the remainder, designed with the scope of eliminating the energy efficiency shortcomings of the DCT.

- The experimental measurement and comparison of the efficiency maps of the case study DCT and HAMT.

- The analysis of the fuel savings along driving cycles, achievable with the HAMT operating in its internal combustion engine (ICE) mode.

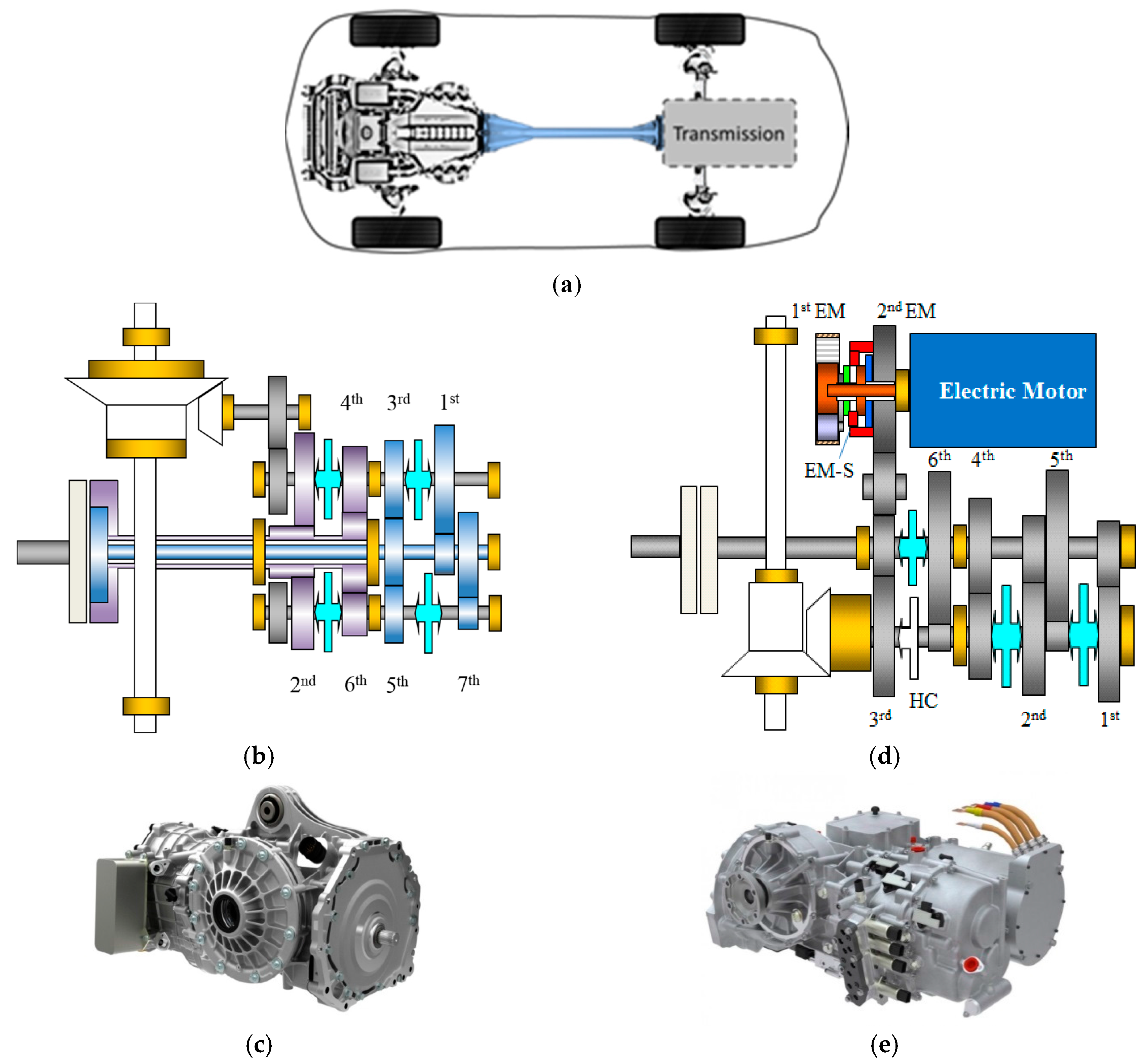

2. Case Study Vehicle and Transmissions

- ICE mode: the ICE provides the traction torque, and the EM is optionally used only for torque-fill during gear shifts. If the electric motor drive has a failure, the HAMT operates like a common AMT.

- Fully electric mode: the EM provides the entire wheel torque, with the exclusion of the friction brake contribution. This mode is suitable for urban driving and low-speed vehicle operation, e.g., initial launch at low torque demands in the first EM gear.

- Hybrid electric mode: the wheel torque is provided by the ICE and EM working in parallel (parallel hybrid electric layout). Reduced fuel consumption and emissions are achieved with an appropriate power split strategy (not covered by this study) aimed at minimising the average ICE brake specific fuel consumption in traction. At the moment, the EM gear shifts are limited to this mode, with the upshifts being actuated at a vehicle speed of ~100 km/h. Future developments will include the implementation of EM gearshift maps, e.g., based on energy efficiency considerations, such as those proposed by the same authors elsewhere [17].

- Reverse gear mode: the EM applies a negative torque through the first EM gear ratio, for the reverse gear operation of the vehicle.

- Cranking from stop and recharge mode: the HC is disengaged and the EM is used either to crank the engine or as an ICE-driven generator to recharge the battery.

- Cranking from EM mode: the clutch is used to crank the engine from an initial condition in which the vehicle is in fully electric mode.

3. DCT Power Loss Analysis

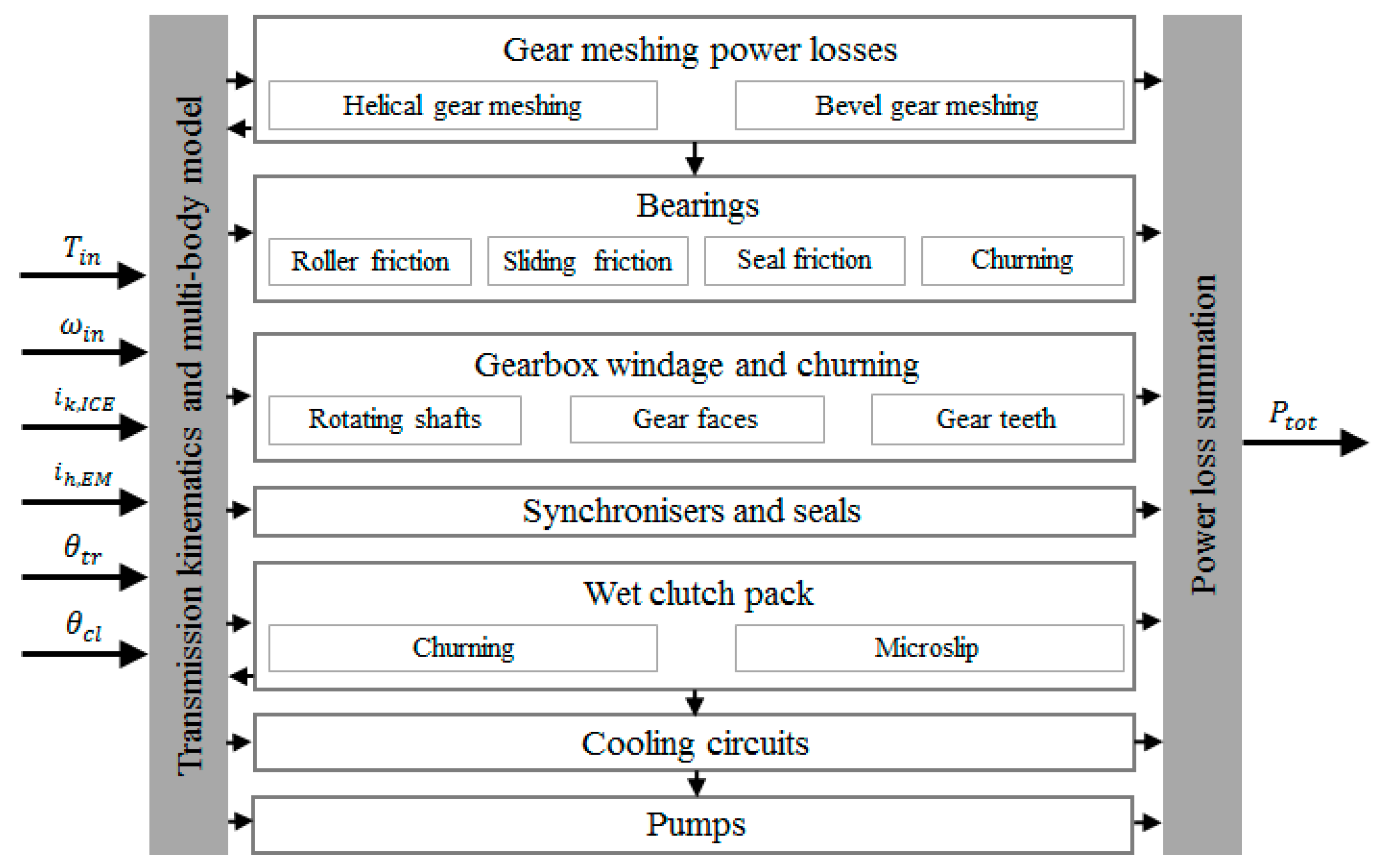

3.1. Transmission Power Loss Model

- Bearing power losses, . These losses are caused by load-independent and load-dependent friction torque contributions. This study uses the model of SKF [22] to calculate the friction torque, , of the -th bearing (in the remainder the subscript indicates a generic transmission component):where is the roller friction torque, is the sliding friction torque, is the bearing seal friction torque, and is the churning friction torque. Since the transmission shafts are often statically indeterminate, and the stiffness of the bearings is rarely provided by the manufacturers, a specific multibody software tool was developed by Oerlikon Graziano SpA to estimate the axial bearing load and stiffness, depending on the installation set-up on the transmission shafts (see also Sorniotti et al. [23]). The tool outputs are used for the calculation of the load-dependent bearing friction losses. Similar tools are available from bearing manufacturers [24].

- Synchroniser and seal power losses, . The synchroniser power loss values, , are based on the experimentally measured drag torque characteristics of the specific synchronisers. The power loss of the –th oil seal, , facing the respective rotating part of the transmission [25], is modelled as:where is the seal drag torque, linearly proportional to the corresponding shaft diameter, . The coefficient depends on the seal material [26].

- Gearbox windage and churning losses, . In accordance with the British Standard [20], these are modelled as the sum of: (i) the power losses associated with the rotating shafts, ; (ii) the power losses associated with the faces of the gears, , which are assumed to behave like discs; and (iii) the power losses associated with the teeth of the gears, . In practice, only the availability of previous experimental results, as is the case in this study, allows for accurate model parameterisation.

- Wet clutch churning power losses, [27,28]. During the engaged gear operation of the DCT, either clutch (i.e., the disengaged one) is characterised by a slip condition. This generates a drag torque, which is caused by the shear associated with the oil between the plates. The drag torque increases with the number, radius, lubrication flow rate of the clutch discs, and decreases with disc clearance and lubricant viscosity. Kitabayashi et al. [27] provide a surface tension model that matches well with the experimentally measured drag torque at low slip speeds. In these conditions, the centrifugal force is negligible with respect to the viscous effects, and the drag torque linearly increases with slip speed. For high speeds, the thickness of the oil film is reduced by the centrifugal effect, which decreases the drag torque [29], thus making it a non-linear function of slip speed. A model formulation for high-speed operation is presented Yuan et al. [30]. In this study, the churning power loss map of the wet clutch assembly is based on the experimental data from the component supplier.

- Microslip power losses of the engaged wet clutch, . Microslip is the angular speed difference, , between the plates of the wet clutch of the engaged gear. In a wet clutch system, the engaged clutch microslip is often continuously regulated by the transmission control unit, which dampens the torsional dynamics of the drivetrain, and thus improves vehicle drivability. In the usual operating conditions of the specific DCT, is of 5–20 rpm, and the associated power loss is:where is the engaged clutch torque.

- Cooling circuit power losses, . These are calculated as the product of the oil flow rate and the respective pressure drop through the cooling circuit, where the latter is experimentally measured.

- Pump power losses, . In general, the efficiency of a pump can be expressed as the product of its volumetric and mechanical efficiencies [31]. However, in practice, transmission pumps are often continuously mechanically driven. They produce a significant power loss even when they generate low or even zero hydraulic power. For this reason, rather than using efficiencies, the model directly calculates the pump power losses from experimental maps provided by the respective suppliers.

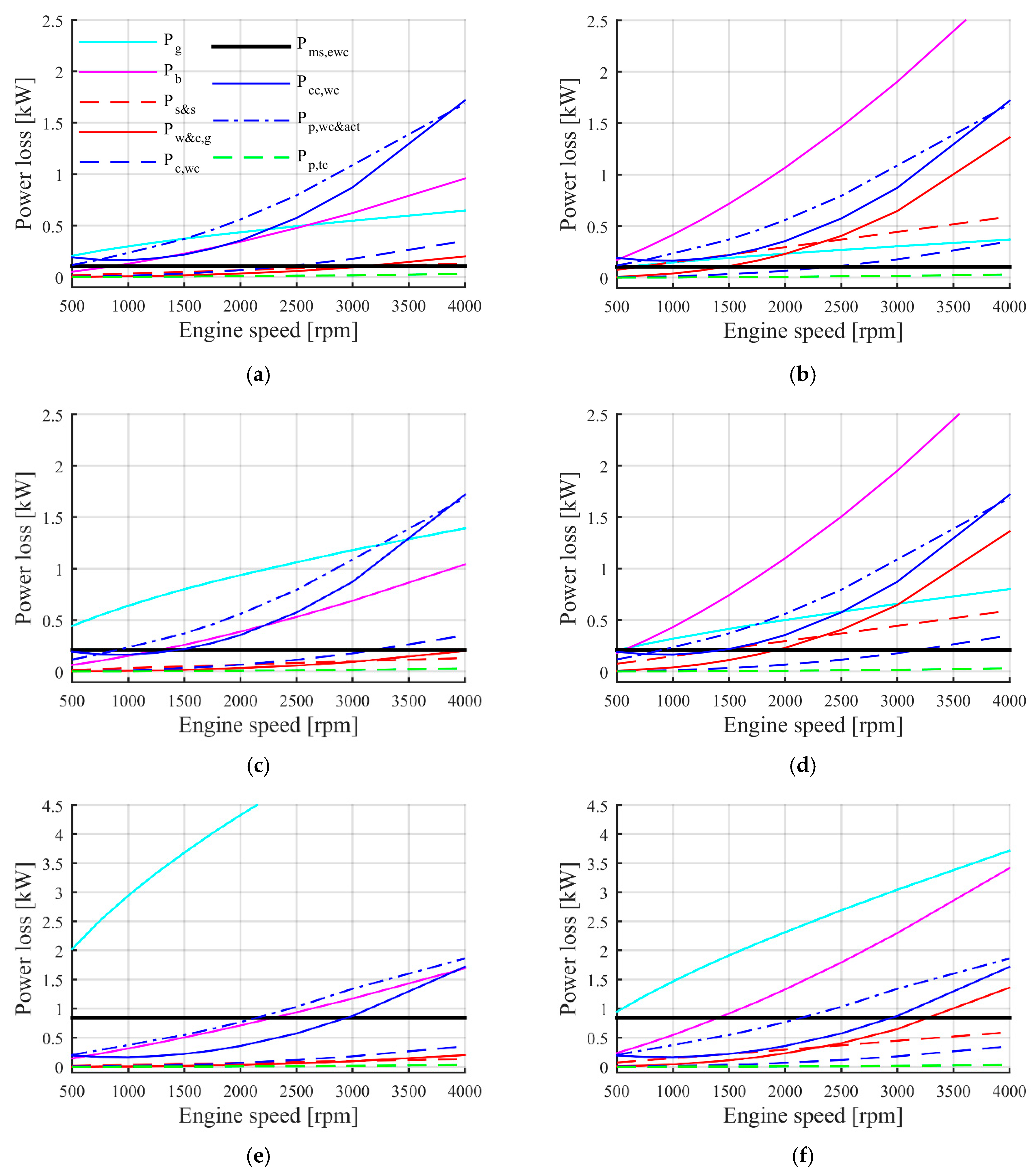

3.2. DCT Power Loss Maps

3.3. DCT Power Loss Contributions during Driving Cycles

4. Experimental Transmission Tests

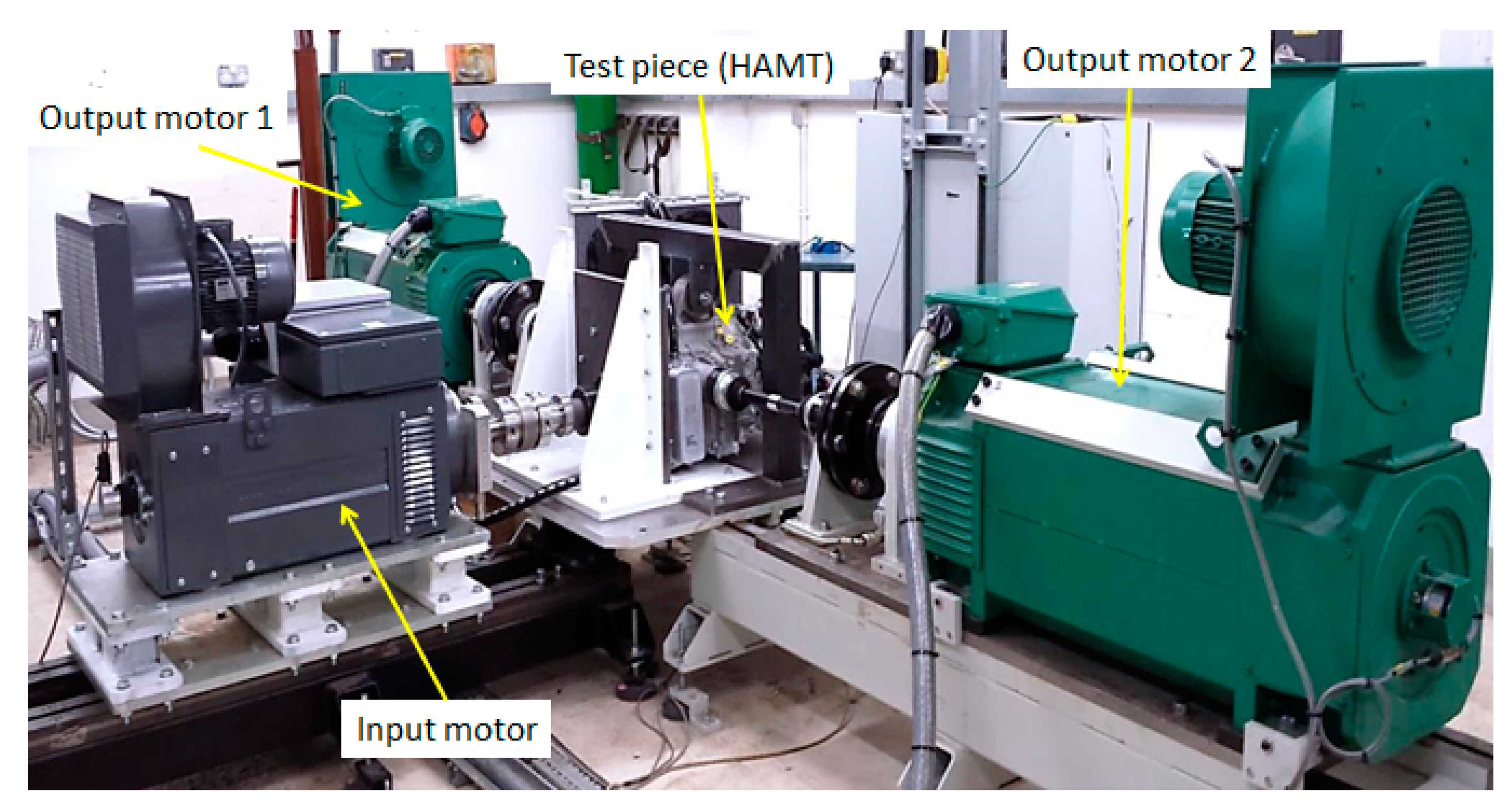

4.1. Experimental Set-up

- The test piece, i.e., the DCT or the HAMT, including constant velocity joints, half-shafts, and the Transmission Control Unit (TCU).

- The electric motor drives of the rig. The test rig includes a 160 kW/550 Nm electric motor and two 90 kW/1925 Nm electric motors, which are mechanically connected to the transmission input and outputs, respectively, to emulate the ICE and the road load. The input and output torques and speeds are measured by torque sensors and encoders located at each motor interface.

- The cooling and heating system for the thermal control of the test piece. The system includes a pump, two resistive water heaters with a total power of 9 kW, a low-power radiator with two fans, a larger deionised water-to-water heat exchanger connected to a 45 kW water chiller, and two on/off valves, one of which controls the water flow rate to the heating devices, and the other one controls the flow rate to the cooling devices. The water chiller and the heat exchanger are used to cool down the water during the tests at particularly low temperature (down to 20 °C). The cooling system pumps deionised water directly into the transmission heat exchanger. The transmission lubricant temperature is controlled through the pump flow rate, while the heaters are regulated by an on/off control strategy.

- A DC power supply for the inverter of the HAMT EM, used during the efficiency tests of the electric part of the HAMT.

- A real-time control system, including a dSPACE MicroAutoBox DS1401 (dSPACE GmbH, Paderborn, Germany) board and a STARS/SPARC system by Horiba (Horiba, Kyoto, Japan). In the specific tests of this study, the input motor, i.e., either the electric motor of the rig or the HAMT EM, was controlled in torque, and the output motors were controlled in speed.

4.2. Test Procedure

- The temperature of the transmission lubricant is initially set to the reference value through the heating/cooling system of the test rig and a pre-defined heating routine. Then, the lubricant temperature is kept approximately constant (in a range of ±5 °C with respect to the reference value) for the whole duration of the test.

- The appropriate ICE gear or EM gear is selected.

- The appropriate clutch (odd or even for the DCT) is engaged.

- The output motor speeds are set to their target value, and then kept constant by a feedback controller.

- The input motor torque, i.e., either the torque of the electric motor of the test rig emulating the ICE, or the torque of the HAMT EM, is applied in steps up to its maximum value of interest for the specific speed.

- Each measurement condition is kept for 30 s, during which the torque and speed values at the drivetrain input and outputs, or the EM drive input power when relevant, are collected through the dSPACE ControlDesk software (dSPACE GmbH, Paderborn, Germany).

- The input torque is gradually removed.

- The output speed is progressively decreased to zero.

5. DCT and HAMT Comparison

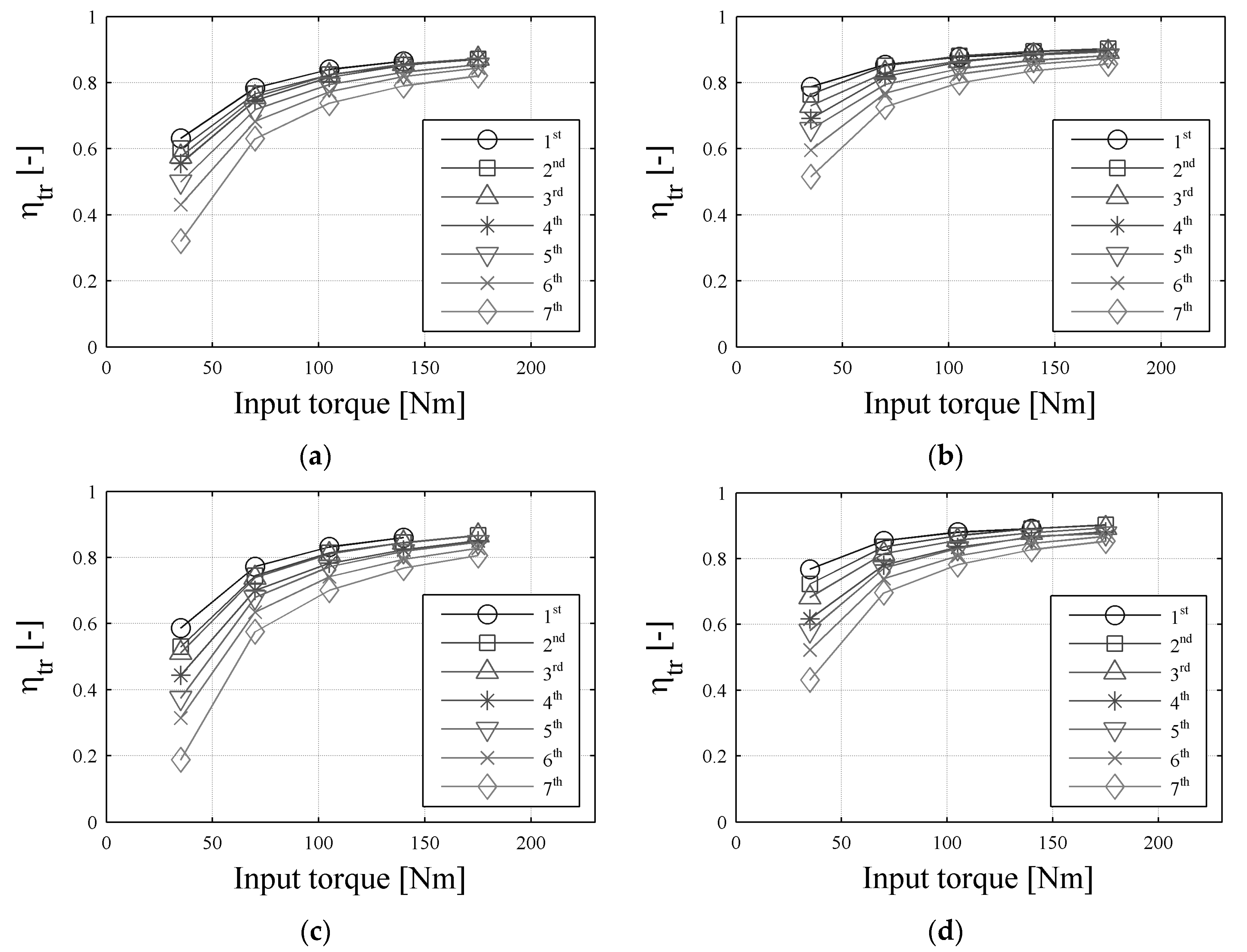

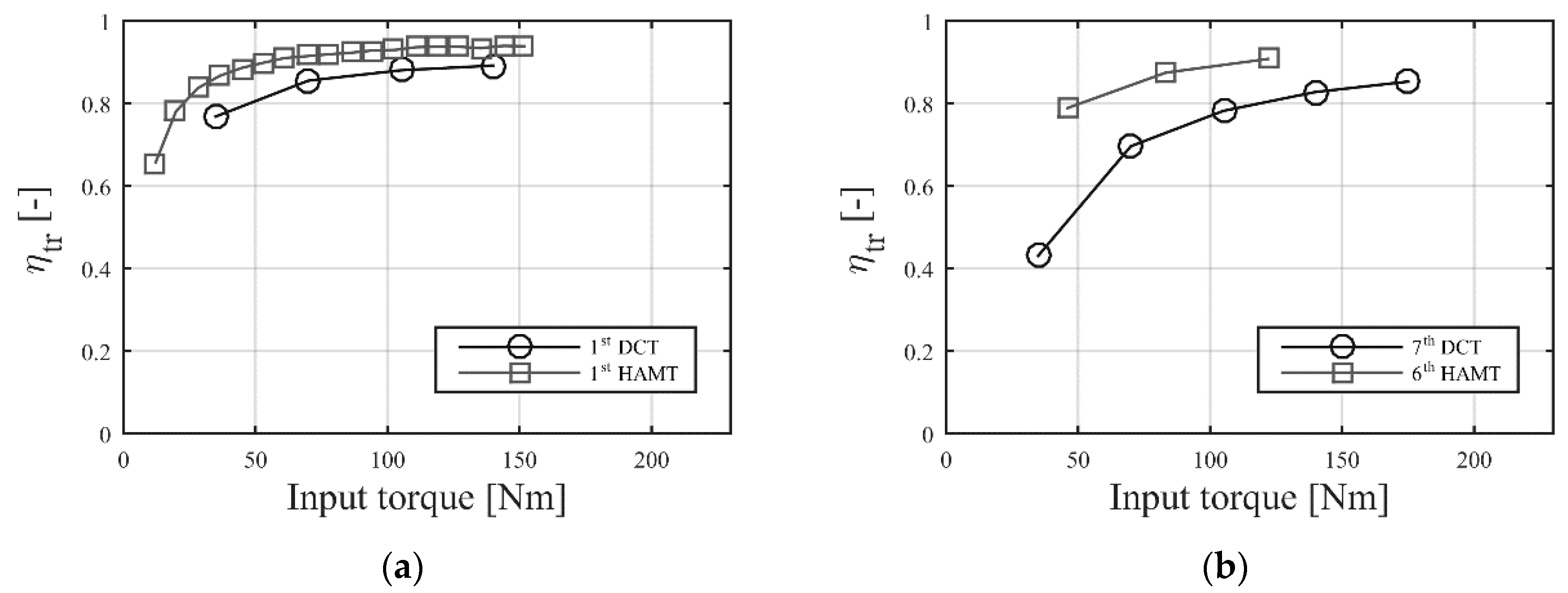

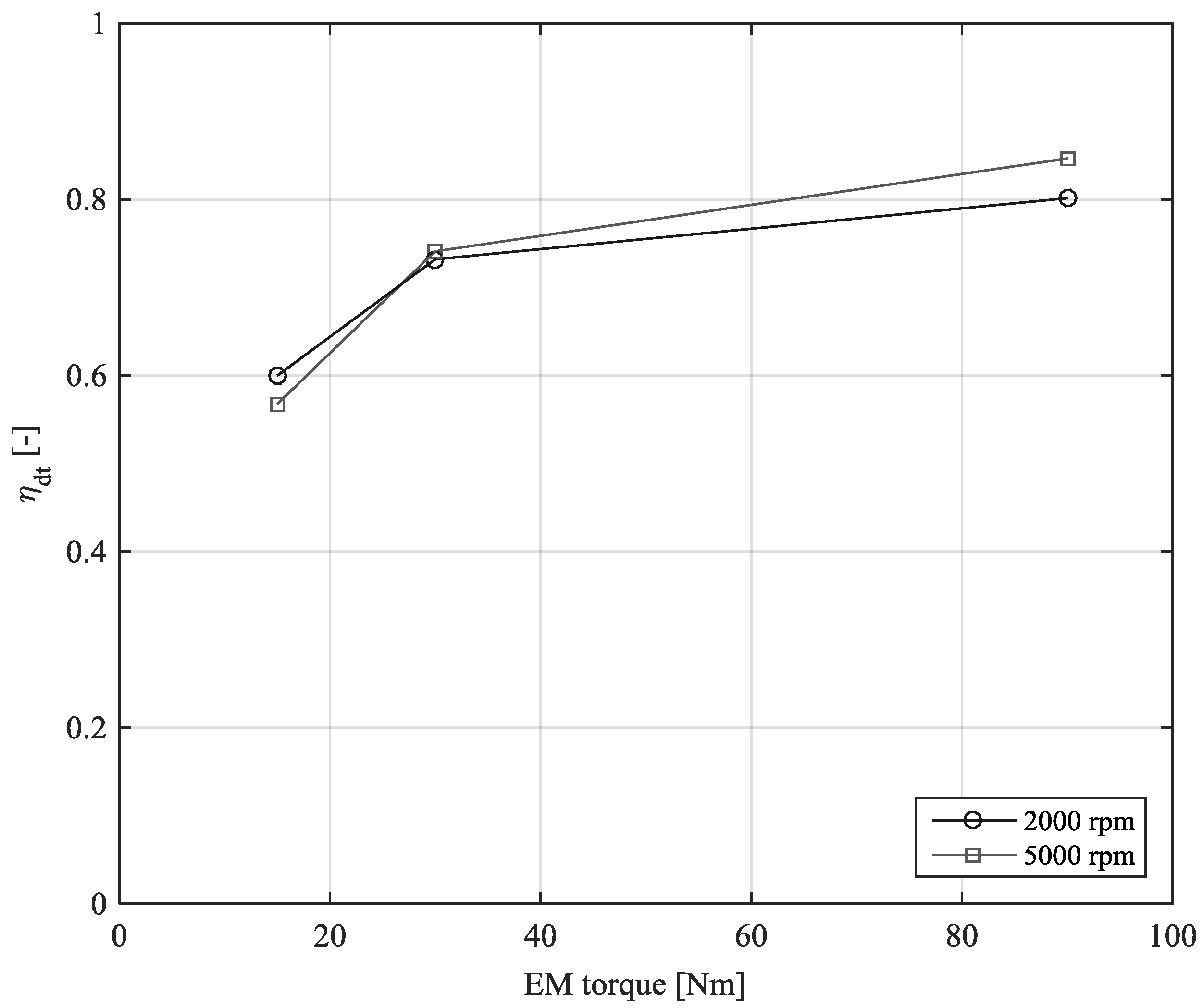

5.1. Experimental Efficiency Maps

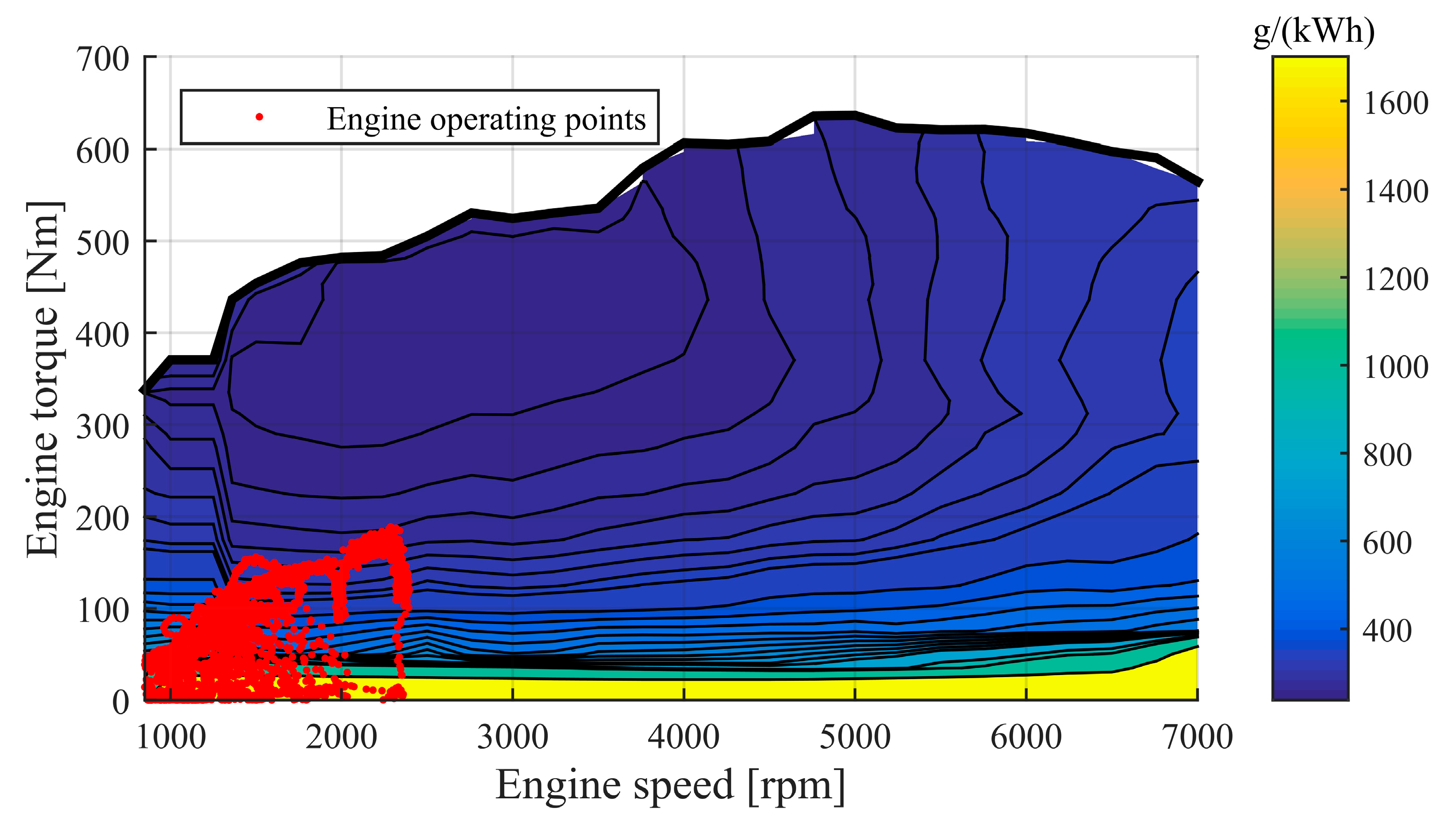

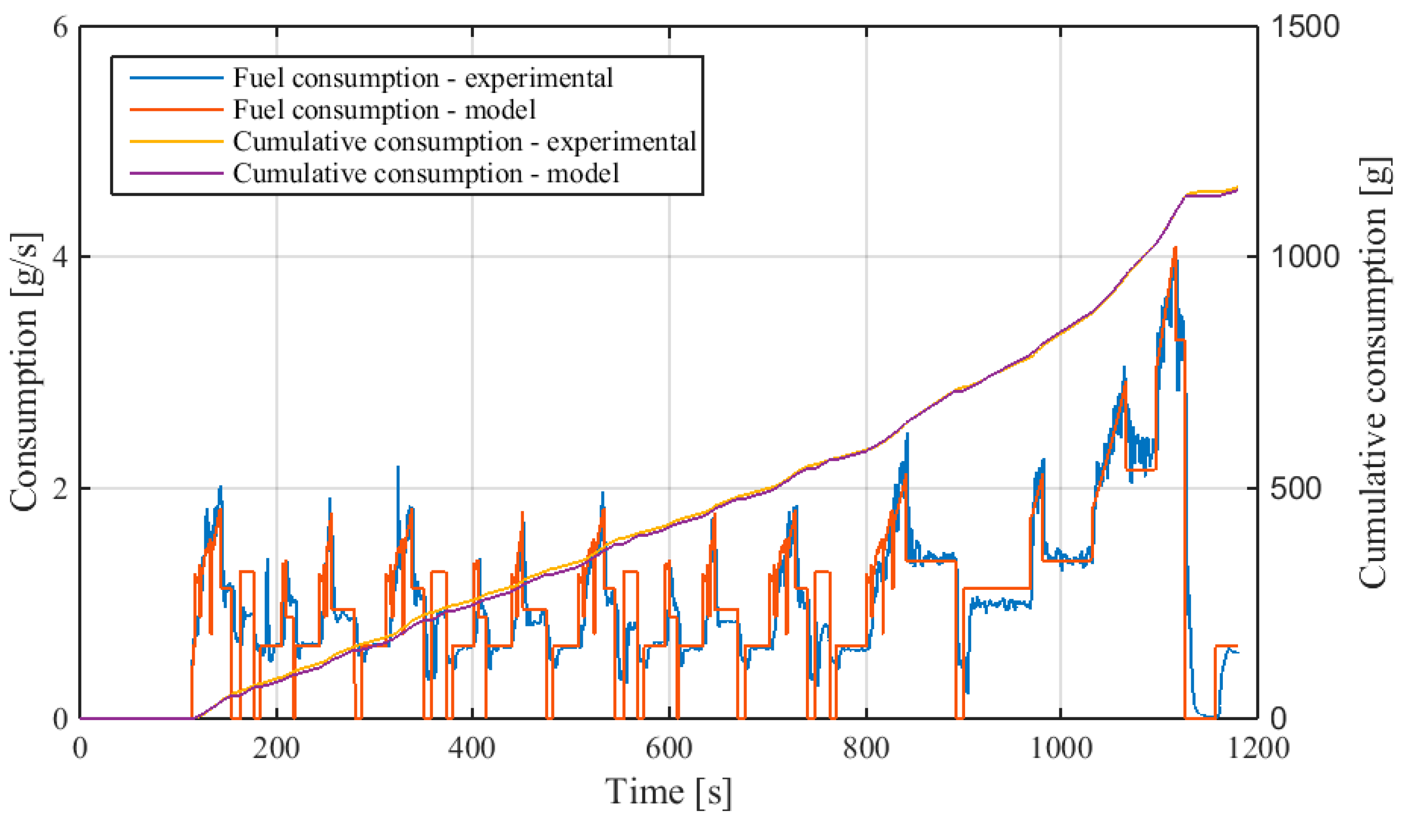

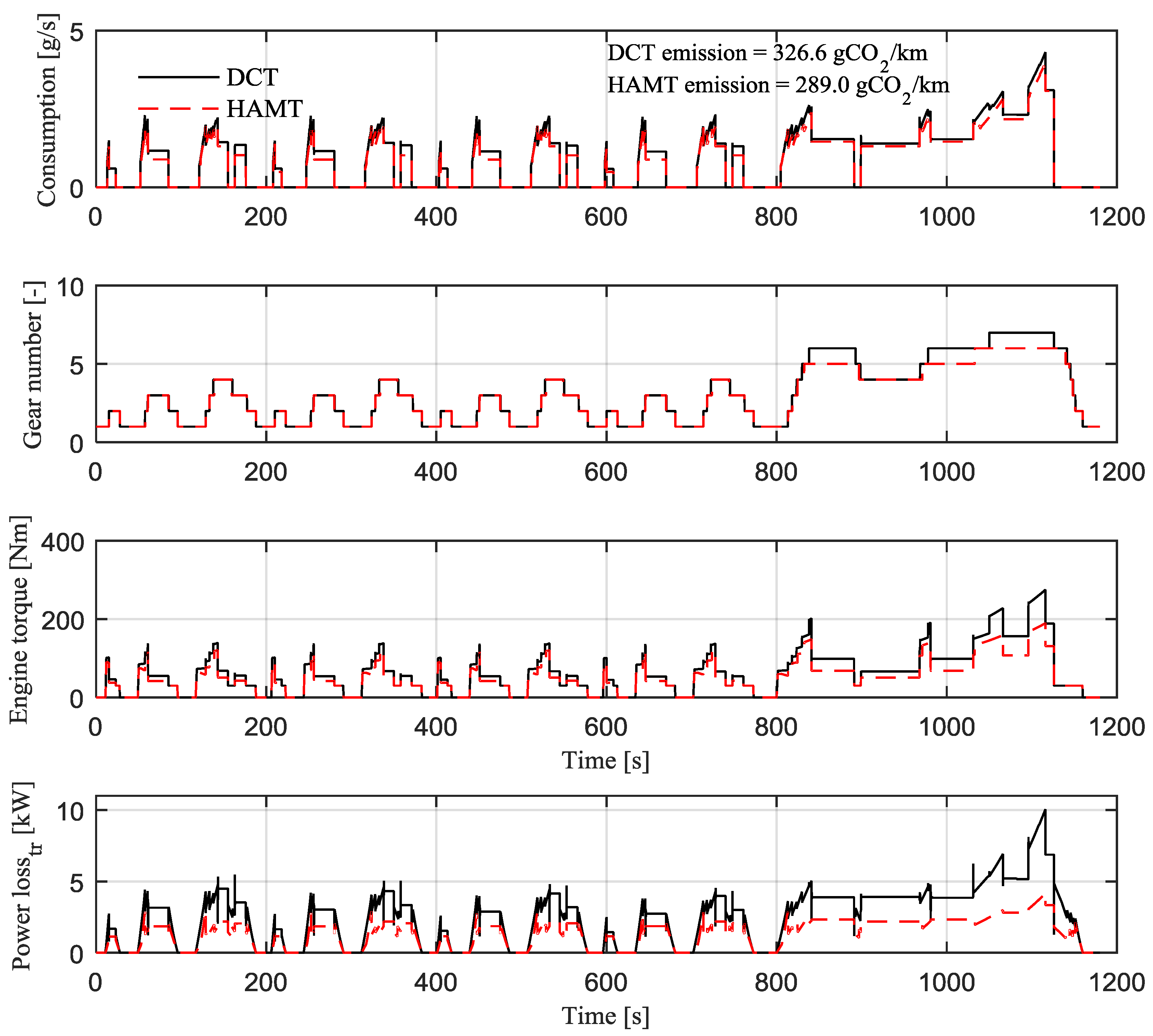

5.2. Driving Cycle Simulation Results

6. Conclusions

- The DCT driving cycle simulation results show that the energy losses caused by the wet clutch related components can exceed 40% of the total transmission energy dissipations. This share is particularly high because of the low torque operation of the specific drivetrain during the schedules, with respect to its maximum design values.

- The described HAMT layout with a single dry clutch avoids most of the clutch power losses because of the absence of clutch churning, clutch microslip, a clutch cooling circuit and a dedicated pump.

- The experimental efficiency measurements of the two transmissions on a test rig confirmed the higher efficiency of the HAMT with respect to the DCT. In particular, the efficiency increases between 5% and 9% at medium–high input torque values, depending on the selected gear. Larger efficiency improvements are achieved at low torque demands, which are typical of the selected driving cycles because of the reduction of the power losses associated with the ancillary systems in the HAMT. As expected, transmission efficiency increases with temperature for both transmission layouts.

- The fuel consumption benefit of the HAMT along the selected driving cycles ranges from 9.2% to 11.5% in the ICE mode. Hence, the appropriate energy efficiency-oriented design of the transmission system should become an important point in the drivetrain development process.

Acknowledgments

Author Contributions

Conflicts of Interest

List of Symbols

| Brake specific fuel consumption of the internal combustion engine | |

| Aerodynamic drag coefficient | |

| Diameter of the -th seal | |

| Energy related to the power loss contribution | |

| Rolling resistance coefficient (part independent of vehicle speed) | |

| Rolling resistance coefficient (part to be multiplied by the square of vehicle speed) | |

| Gravity | |

| Inverter input current | |

| Internal combustion engine related transmission ratio for the -th gear | |

| , …, | Internal combustion engine related transmission ratios for the 1st gear, …, 7th gear, i.e., the ratios between the ICE speed and the differential case speed |

| Electric motor related transmission ratio for the -th gear | |

| , | 1st and 2nd electric motor related gear ratios |

| Mass moment of inertia of the rotating components of the clutch assembly | |

| Mass moment of inertia of the rotating parts of the internal combustion engine | |

| Wheel mass moment of inertia | |

| Coefficient of the hyperbolic tangent function for modelling tyre rolling resistance at low speed | |

| Vehicle mass | |

| Apparent vehicle mass | |

| Total resistance torque of the -th bearing | |

| Churning friction torque of the -th bearing | |

| DCT mass | |

| HAMT EM mass | |

| HAMT energy storage mass | |

| HAMT mass (transmission only) | |

| Fuel mass flow rate | |

| HAMT inverter mass | |

| Roller resistance torque of the of the -th bearing | |

| Friction torque of the seals of the -th bearing | |

| Sliding friction torque of the -th bearing | |

| Index of a measured point | |

| Number of measurement points during a steady-state efficiency measurement phase | |

| Total transmission bearing power loss | |

| Cooling circuit power loss | |

| Power loss of the cooling circuit of the wet clutch pack | |

| Churning power loss of the wet clutch pack | |

| Drivetrain power | |

| Peak power of the HAMT EM | |

| Nominal power of the HAMT EM | |

| Total transmission gear meshing power loss | |

| Bevel gear power loss | |

| Helical gear power loss | |

| Power output of the internal combustion engine | |

| Maximum power of the internal combustion engine | |

| Transmission input power | |

| Average transmission input power during a steady-state efficiency measurement phase | |

| Inverter input power | |

| -th transmission power loss contribution | |

| Microslip power loss of the engaged wet clutch | |

| Transmission output power | |

| Average transmission output power during a steady-state efficiency measurement phase | |

| Pump power loss | |

| Power loss of the transmission cooling circuit pump | |

| Power loss of the pump for wet clutch cooling and transmission system actuation | |

| Total transmission seal power loss | |

| Power loss of the -th seal | |

| Total transmission seal and synchroniser power loss | |

| Total synchroniser power loss (outside the synchronisation phases) | |

| Power loss of the -th synchroniser (outside the synchronisation phases) | |

| Total power loss of a generic transmission | |

| Total DCT power loss | |

| Total DCT power loss, with the exclusion of the clutch microslip power loss | |

| Total gearbox windage and churning power loss | |

| Windage and churning power loss associated with the faces of the gears | |

| Windage and churning power loss associated with the teeth of the gears | |

| Windage and churning power loss associated with the rotating shafts | |

| Wheel radius | |

| Frontal area of the vehicle | |

| Coefficient for the estimation of the -th seal friction torque | |

| Time | |

| Required drivetrain torque at the wheel | |

| Peak torque of the HAMT EM | |

| Nominal torque of the HAMT EM | |

| Engaged wet clutch torque | |

| , | Final and initial times of the driving cycle simulation |

| Internal combustion engine torque | |

| Maximum torque of the internal combustion engine | |

| Transmission input torque | |

| Time of corresponding to the -th measured point | |

| , | Left and right drivetrain output torques |

| Drag torque of the -th seal | |

| Instantaneous volume fuel consumption per unit distance | |

| Inverter voltage | |

| Vehicle speed | |

| Slip speed of the engaged wet clutch | |

| Electric drivetrain efficiency (from the inverter to the wheels) | |

| Transmission efficiency | |

| Wet clutch oil temperature | |

| Coolant temperature of the ICE | |

| Transmission lubricant temperature | |

| Air density | |

| Fuel density | |

| Angular speed of the electric motor | |

| Angular speed of the internal combustion engine | |

| Transmission input speed | |

| , | Angular speeds at the left and right wheel hubs |

| Relative angular speed between the -th seal and the corresponding transmission component | |

| Angular wheel speed |

References

- National Research Council. Cost, Effectiveness, and Deployment of Fuel Economy Technologies for Light-Duty Vehicles; The National Academies Press: Washington, DC, USA, 2015. [Google Scholar]

- Johnson, T.V. Diesel emissions in review. SAE Int. J. Engines 2011, 4, 143–157. [Google Scholar] [CrossRef]

- Mueller, N.; Strauss, S.; Tumback, S.; Goh, G.C.; Christ, A. Next generation engine start/stop systems: “Free-wheeling”. SAE Int. J. Engines 2011, 4, 874–887. [Google Scholar] [CrossRef]

- National Research Council. Assessment of Fuel Economy Technologies for Light-Duty Vehicles; The National Academies Press: Washington, DC, USA, 2011. [Google Scholar]

- Tribioli, L. Energy-Based Design of Powertrain for a Re-Engineered Post-Transmission Hybrid Electric Vehicle. Energies 2017, 10, 918. [Google Scholar] [CrossRef]

- De Cauwer, C.; Verbeke, V.; Coosemans, T.; Faid, S.; Van Mierlo, J. A Data-Driven Method for Energy Consumption Prediction and Energy-Efficient Routing of Electric Vehicles in Real-World Conditions. Energies 2017, 10, 608. [Google Scholar] [CrossRef]

- Bottiglione, F.; De Pinto, S.; Mantriota, G.; Sorniotti, A. Energy Consumption of a Battery Electric Vehicle with Infinitely Variable Transmission. Energies 2014, 7, 8317–8337. [Google Scholar] [CrossRef]

- Kulkarni, M.; Shim, T.; Zhang, Y. Shift dynamics and control of dual-clutch transmissions. Mech. Mach. Theory 2007, 42, 168–182. [Google Scholar] [CrossRef]

- Schaeffler Automotive Aftermarket GmbH & Co. KG. The Dry Double Clutch. 2014. Available online: http://www.schaeffler.com/remotemedien/media/_shared_media/08_media_library/01_publications/automotiveaftermarket/brochure_1/downloads_5/luk_5/LuK_TecBr_2CT_Basis_LowRes_GB.pdf (accessed on 28 July 2017).

- Webster, H. A fully automatic vehicle transmission using a layshaft type gearbox. SAE Int. 1981, 810104. [Google Scholar] [CrossRef]

- Van Dongen, L.A.M. Efficiency characteristics of manual and automatic passenger car transaxles. SAE Int. 1982. [Google Scholar] [CrossRef]

- Greenbaum, J.; Kluger, M.; Westmoreland, B. Manual transmission efficiency trends and characteristics. SAE Int. 1994. [Google Scholar] [CrossRef]

- Hohn, B.R.; Michaelis, K.; Hinterstoißer, M. Optimization of gearbox efficiency. Goriva i Maziva 2009, 48, 462–480. [Google Scholar]

- Falzoni, F. Seven-Gear Gearbox for a Motorcar Double Clutch Transmission. U.S. Patent 7,562,598, 21 July 2009. [Google Scholar]

- Liu, H.; Lee, J.C.; Yoon, A.; Kim, S.-T. Profile design and numerical calculation of instantaneous flow rate of a gerotor pump. J. Appl. Math. Phys. 2015, 3, 92–97. [Google Scholar] [CrossRef]

- De Pinto, S.; Camocardi, P.; Sorniotti, A.; Gruber, P.; Perlo, P.; Viotto, F. Torque-Fill Control and Energy Management for a Four-Wheel-Drive Electric Vehicle Layout with Two-Speed Transmissions. IEEE Trans. Ind. Appl. 2017, 53, 447–458. [Google Scholar] [CrossRef]

- Sorniotti, A.; Boscolo, M.; Turner, A.; Cavallino, C. Optimisation of a 2-Speed Gearbox for an Electric Vehicle. In Proceedings of the 2010 Symposium on Advanced Vehicle Control (AVEC), Loughborough, UK, 22–26 August 2010. [Google Scholar]

- Gavgani, A.M.; Bingham, T.; Sorniotti, A.; Doherty, J.; Cavallino, C.; Fracchia, M. A parallel hybrid electric drivetrain layout with torque-fill capability. SAE Int. J. Passeng. Cars Mech. Syst. 2015, 8, 767–778. [Google Scholar]

- Gavgani, A.M.; Sorniotti, A.; Doherty, J.; Cavallino, C. Optimal gearshift control for a novel hybrid electric drivetrain. Mech. Mach. Theory 2016, 105, 352–368. [Google Scholar] [CrossRef]

- British Standards Institute (BSI). ISO/TR 14179–1:2001: Gears—Thermal Capacity—Part 1: Rating Gear Drives with Thermal Equilibrium at 95 °C Sump Temperature; British Standards Institute: London, UK, 2001. [Google Scholar]

- Fernandes, C.; Marques, P.M.T.; Martins, R.C.; Seabra, J.H.O. Gearbox power loss. Part II: Friction losses in gears. Tribol. Int. 2015, 88, 309–316. [Google Scholar] [CrossRef]

- SKF. I Cuscinetti Volventi, Quaderni di Formazione; Gruppo SKF: Airasca, Italy, 2008. [Google Scholar]

- Sorniotti, A.; Sampo’, E.; Velardocchia, M.; Bonisoli, E.; Galvagno, E. Friction inside Wheel Hub Bearings: Evaluation through Analytical Models and Experimental Methodologies. SAE Int. 2007. [Google Scholar] [CrossRef]

- Schaeffler Technologies. Bearinx, Herzogenaurach, Germany. Available online: http://www.schaeffler.com/remotemedien/media/_shared_media/08_media_library/01_publications/schaeffler_2/brochure/downloads_1/pbo_de_us.pdf (accessed on 28 July 2017).

- Naunheimer, H.; Bertsche, B.; Ryborz, J.; Novak, W. Automotive Transmissions, 2nd ed.; Springer Science & Business Media: Berlin, Germany, 2011; pp. 115–139. [Google Scholar]

- Niemann, G.; Winter, H.; Höhn, B.R. Manuale Degli Organi Delle Macchine; Tecniche Nuove: Milan, Italy, 2006. [Google Scholar]

- Kitabayashi, H.; Li, C.Y.; Hiraki, H. Analysis of the various factors affecting drag torque in multiple-plate wet clutches. SAE Int. 2003. [Google Scholar] [CrossRef]

- Li, H.; Jing, Q.; Ma, B. Modeling and parametric study on drag torque of wet clutch. In Proceedings of the FISITA 2012 World Automotive Congress: Volume 5: Advanced Transmission System and Driveline; Springer: Berlin, Germany, 2013; pp. 21–30. [Google Scholar]

- Sung, I.H.; Ryu, J.S. Computational simulation study on the viscous drag of the automotive wet clutch for prediction and control. In Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 13–19 November 2015; Advances in Multidisciplinary Engineering. ASME: New York, NY, USA, 2015; Volume 15, p. V015T19A035. [Google Scholar]

- Yuan, Y.; Liu, E.A.; Hill, J.; Zou, Q. An improved hydrodynamic model for open wet transmission clutches. J. Fluids Eng. 2007, 129, 333–337. [Google Scholar] [CrossRef]

- Bucciarelli, A.; Speich, H. Manuale di Oleodinamica; Tecniche Nuove: Milan, Italy, 2002. [Google Scholar]

- Townsend, D. Dudley’s Gear Handbook, 2nd ed.; McGraw Hill: New York, NY, USA, 1992. [Google Scholar]

- Schlegel, C.; Hosl, A.; Diel, S. Detailed loss modelling of vehicle gearboxes. In Proceedings of the 7th Modelica Conference, Como, Italy, 20–22 September 2009. [Google Scholar]

- Inaguma, Y.; Yoshida, N. Mathematical analysis of influence of oil temperature on efficiencies in hydraulic pumps for automatic transmissions. SAE Int. J. Passeng. Cars Mech. Syst. 2013, 6, 786–797. [Google Scholar] [CrossRef]

- Hibi, A.; Ichikawa, T. Mathematical model of the torque characteristics for hydraulic motors. Bull. JSME 1977, 20, 616–621. [Google Scholar] [CrossRef]

- Markel, T.; Brooker, A.; Hendricks, T.; Johnson, V.; Kelly, K.; Kramer, B.; O’Keefe, M.; Sprik, S.; Wipke, K. ADVISOR: A systems analysis tool for advanced vehicle modeling. J. Power Sources 2002, 110, 255–266. [Google Scholar] [CrossRef]

- Gao, D.W.; Mi, C.; Emadi, A. Modeling and simulation of electric and hybrid vehicles. Proc. IEEE 2007, 95, 729–745. [Google Scholar] [CrossRef]

- Pennycott, A.; De Novellis, L.; Gruber, P.; Sorniotti, A. Sources of power loss during torque–vectoring for fully electric vehicles. Int. J. Veh. Des. 2015, 67, 157–177. [Google Scholar] [CrossRef]

- De Novellis, L.; Sorniotti, A.; Gruber, P. Wheel torque distribution criteria for electric vehicles with torque-vectoring differentials. IEEE Trans. Veh. Technol. 2014, 63, 1593–1602. [Google Scholar] [CrossRef]

- National Highway Traffic Safety Administration. Light-Duty Vehicle Greenhouse Gas Emission Standards and Corporate Average Fuel Economy Standards; Final Rule, Part 2; United States Government: Washington, DC, USA, 2010.

- Environmental Protection Agency. Greenhouse Gas Emissions from a Typical Passenger Vehicle; EPA-420-F-14-040a; U.S. Environmental Protection Agency: Ann Arbor, MI, USA, 2014.

- SAE International. Manual Transmission and Transaxle Efficiency and Parasitic Loss Measurement; No. J2453; SAE International: Warrendale, PA, USA, 2011. [Google Scholar]

| Symbol | Name | Value | Unit | |

|---|---|---|---|---|

| Vehicle mass with DCT | 1673 | kg | ||

| Maximum ICE torque | 683 | Nm | ||

| Maximum ICE power | 480 | kW | ||

| Wheel radius | 0.33 | m | ||

| Rolling resistance coefficient (speed independent term) | 0.015 | - | ||

| Speed related term of the rolling resistance coefficient | 6.5 × 10−6 | s2/m2 | ||

| Aerodynamic drag coefficient | 0.39 | - | ||

| Frontal area of the vehicle | 1.92 | m2 | ||

| Clutch mass moment of inertia | 0.05 | kg m2 | ||

| Engine mass moment of inertia | 0.12 | kg m2 | ||

| Wheel mass moment of inertia | 0.96 | kg m2 | ||

| DCT mass | 160 | kg | ||

| HAMT mass (transmission only) | 115 | kg | ||

| HAMT EM mass | 25 | kg | ||

| HAMT inverter mass | 10 | kg | ||

| HAMT energy storage mass | 85 | kg | ||

| Peak torque of the HAMT EM | 198 | Nm | ||

| Nominal torque of the HAMT EM | 100 | Nm | ||

| Peak power of the HAMT EM | 120 | kW | ||

| Nominal power of the HAMT EM | 90 | kW | ||

| DCT | HAMT | |||

| 1st ICE gear ratio | 13.169 | 12.647 | [-] | |

| 2nd ICE gear ratio | 8.644 | 8.498 | [-] | |

| 3rd ICE gear ratio | 6.300 | 6.226 | [-] | |

| 4th ICE gear ratio | 4.892 | 4.649 | [-] | |

| 5th ICE gear ratio | 3.841 | 3.545 | [-] | |

| 6th ICE gear ratio | 2.996 | 2.729 | [-] | |

| 7th ICE gear ratio | 2.269 | NA | [-] | |

| 1st EM gear ratio | NA | 13.89 | [-] | |

| 2nd EM gear ratio | NA | 4.54 | [-] | |

| Mode | EM Status | ICE Status | EM Gear | ICE Gear | Hybrid Coupling | Dry Clutch |

|---|---|---|---|---|---|---|

| ICE | OFF | ON | N | 1st–6th | Engaged | Closed |

| Fully electric | ON | OFF | 1st | N | Engaged | Closed |

| Hybrid electric | ON | ON | 1st, 2nd | 1st–6th | Engaged | Closed |

| Reverse gear | ON | OFF | 1st | 1st | Engaged | Open |

| Cranking from stop and recharge | ON | Cranking | 1st | 3rd | Disengaged | Closed |

| Cranking from fully electric mode | ON | Cranking | 1st | 3rd–6th | Engaged | Closing |

| Driving Cycle | Transmission System | Consumption [l/100 km] | CO2 Emission [g/km] | HAMT Emission Reduction w.r.t. DCT [%] |

|---|---|---|---|---|

| NEDC | DCT | 13.9 | 326.6 | 11.5 |

| HAMT | 12.3 | 289.0 | ||

| FTP75 | DCT | 13.5 | 317.2 | 11.1 |

| HAMT | 12.0 | 282.0 | ||

| US06 | DCT | 13.1 | 307.8 | 9.2 |

| HAMT | 11.9 | 279.6 | ||

| WLTP cl3 | DCT | 12.9 | 303.1 | 10.8 |

| HAMT | 11.5 | 270.2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vacca, F.; De Pinto, S.; Hartavi Karci, A.E.; Gruber, P.; Viotto, F.; Cavallino, C.; Rossi, J.; Sorniotti, A. On the Energy Efficiency of Dual Clutch Transmissions and Automated Manual Transmissions. Energies 2017, 10, 1562. https://doi.org/10.3390/en10101562

Vacca F, De Pinto S, Hartavi Karci AE, Gruber P, Viotto F, Cavallino C, Rossi J, Sorniotti A. On the Energy Efficiency of Dual Clutch Transmissions and Automated Manual Transmissions. Energies. 2017; 10(10):1562. https://doi.org/10.3390/en10101562

Chicago/Turabian StyleVacca, Fabio, Stefano De Pinto, Ahu Ece Hartavi Karci, Patrick Gruber, Fabio Viotto, Carlo Cavallino, Jacopo Rossi, and Aldo Sorniotti. 2017. "On the Energy Efficiency of Dual Clutch Transmissions and Automated Manual Transmissions" Energies 10, no. 10: 1562. https://doi.org/10.3390/en10101562

APA StyleVacca, F., De Pinto, S., Hartavi Karci, A. E., Gruber, P., Viotto, F., Cavallino, C., Rossi, J., & Sorniotti, A. (2017). On the Energy Efficiency of Dual Clutch Transmissions and Automated Manual Transmissions. Energies, 10(10), 1562. https://doi.org/10.3390/en10101562