Abstract

In the wake of Industry 4.0, circular supply chain management has undergone radical transformations. Organizations have been able to boost their efficiency thanks to incorporating Industry 4.0 technologies such as big data analytics, the internet of things (IoT), blockchain, cloud computing, artificial intelligence, etc., into various supply chain functions. Since circular procurement (CP) is an essential part of circular supply chain management, it can provide fresh chances for organizations to become more efficient and sustainable. With the support of Industry 4.0 technologies, CP can provide extra opportunities for accelerating the shift to the circular economy. Although research into the intersection of procurement and Industry 4.0 continues to advance, no review study has examined the implications of Industry 4.0 in CP. Therefore, this research aims to address this knowledge gap by systematically reviewing the existing literature about the applications of Industry 4.0 technologies in CP. A total of 89 journal articles were selected from Scopus and Web of Science databases to identify the themes discussed and set an agenda for future research. A conceptual framework is also developed to evaluate the antecedents, enablers, and performance outcomes of Industry-4.0-enabled CP. Finally, the review concludes by highlighting the theoretical and practical implications.

1. Introduction

The concept of a circular economy (CE) has gained traction during the last several decades [1,2,3]. As an industrial economy, the goal of the CE is to achieve sustainability via restorative designs and objects [4]. The foundation of CE is a closed-loop cycle of resource reuse, remanufacturing, recycling, and recovery that improves both economic and environmental outcomes [5].

With the emergence of the CE, circular procurement (CP) emerged. It represents the incorporation of circularity in the procurement function, in which businesses aim to acquire regenerated biological resources in pursuit of a zero end-of-life philosophy [6]. Ref. [7] argue that CP can be a tool to advance the CE agenda since resource efficiency, durability, reuse, refurbishment, recyclability, and purchasing recycled materials are all aspects of the CP framework. Leveraging the natural environment, CP allows for the recycling of materials and the creation of new resources from by-products [8]. As a result, CP can contribute to achieving zero waste by fostering reuse, reduce, recycle, remanufacture, and repair activities. This CE practice also seeks to revitalize materials and create new industrial relationships across various supply chains [6,9,10].

Recent research has shown that the emergence of Industry 4.0 technologies (e.g., the internet of things (IoT), blockchain technology, big data analytics, artificial intelligence, etc.) plays a significant role in easing the implementation of CP [5,11,12]. Unlike conventional procurement models, which hamper certain product or service acquisitions (e.g., product-service software systems), the development of new procurement processes based on Industry 4.0 technologies can facilitate the agile relational orientation necessary for the digital transition of industrial organizations [13]. By automating procurement processes, Industry 4.0 technologies connect the firm with its suppliers and support dynamic coordination and cooperation of the procurement function [14].

While the literature on the nexus of procurement and Industry 4.0 is constantly progressing, it remains scattered, with no review examining the role of new technologies in the transition toward CP. For example, [15] conducted a systematic literature review on the applications of Industry 4.0 technologies in procurement processes and reveal nine value propositions of procurement 4.0. The authors of [16] studied the impact of digitalization on procurement and the barriers hampering the implementation of procurement 4.0. The research shows that digitizing the procurement process can lead to many positive outcomes, such as improved daily administrative and business operations, effective decision-making procedures, high organizational efficiency, better productivity, and new business models. While these studies offer a starting point for comprehending the impact of Industry 4.0 on procurement, there is a need for additional research to clarify how Industry 4.0 technologies accelerate the transition toward CP. Motivated by this knowledge gap, the current article integrates the literature on CP and Industry 4.0. This research aims to provide a comprehensive overview of the state-of-the-art literature on the role of Industry 4.0 technologies in the transition toward CP and set an agenda for future research. A systematic review’s fundamental goal is to analyze the issue at hand and pinpoint potential new avenues of research by methodically collecting evidence from a wide range of relevant publications. In this study, the following research question will be addressed:

- -

- What is the role of Industry 4.0 technologies in the transition toward CP?

This study makes significant contributions and adds insights in several areas. First, it helps advance the state of the knowledge in the CP field, which represents a transformative sustainability tool that goes beyond the frameworks of conventional procurement and sustainability approaches. Second, the study suggests a conceptual framework by outlining the antecedents in implementing Industry 4.0, the procurement practices shaped by new technologies, and the performance outcomes of the integration of CP and Industry 4.0. Third, to the authors’ best knowledge, this is the first comprehensive effort to explore the role of Industry 4.0 in the CP field. Fourth, the answers to the abovementioned study question would assist academics and managers in understanding and adopting Industry 4.0 technologies in CP.

2. Theoretical Background

2.1. Circular Procurement (CP)

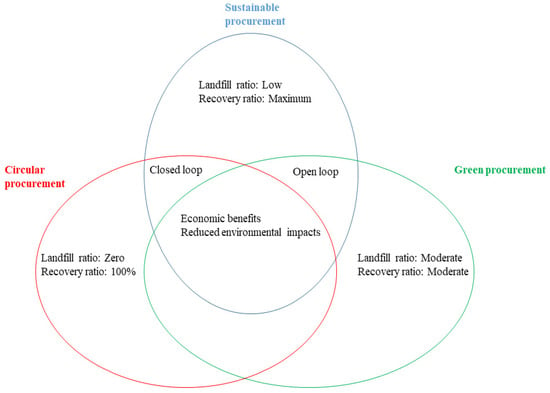

According to the European Commission [17], CP is the process by which government agencies acquire products or services with the goal of reducing or eliminating their negative impacts on the environment and the amount of waste generated across the course of their entire useful life. CP also represents the practice of using purchasing as a tool to advance the CE [9]. As such, the acquisition of competitively priced goods, services, or systems that contribute to longer lifetime, value retention, and/or notably enhanced and safe cycling of technical or biological material constitutes another description of CP [6]. CP can be advanced through other procurement initiatives, namely, green procurement and sustainable procurement [18]. The former refers to the practice of purchasing products or services that help minimize environmental effects in comparison to alternatives that serve the same function or products that fulfill specific predetermined environmental standards [19]. Green procurement is also defined by [20] as the incorporation of environmental factors into purchasing policies, programs, and activities. The procurement department may help promote recycling, reuse, and resource conservation by participating in green or environmental practices such as life-cycle analysis and environment design, which are all part of supply chain management [21]. Unlike green procurement, sustainable procurement applies a wider focus on sustainability by encompassing additional elements, including safety, health, and social equity [19]. In general, high wastages were observed beyond the products’ useful life in green and sustainable procurement, despite the fact that these initiatives were designed to save society, the environment, and the economy [22,23]. Nonetheless, CP is committed to the zero-waste principle even after a product’s lifespan has ended. This implies that cross-sector cooperation can maximize the value of products and services. The authors of [7] note that three factors should be prioritized in order to encourage CP: (1) services rather than products (servitization), (2) product conception, operation, and disposal, and (3) market dialogue. Figure 1 depicts the differences between CP, green procurement, and sustainable procurement.

Figure 1.

The differences between CP, green procurement, and sustainable procurement.

2.2. Industry 4.0

In 2011, the German government launched an initiative to encourage digitalization in manufacturing via the implementation of a strategic roadmap, marking the beginning of the fourth industrial revolution. At the 2011 Hannover fair, the concept of Industry 4.0 was officially announced. As a result of Industry 4.0, most factories now use highly developed information systems [24,25,26]. The shift from traditional production systems to digital manufacturing necessitates the development of smart factories and advanced technologies in order to improve operational efficiencies throughout the value chain [5]. Using state-of-the-art technologies, Industry 4.0 digitally transforms production networks [27,28,29]. Moreover, the goal of Industry 4.0 is to improve managerial decision-making via the use of real-time data related to energy consumption, production status, machines, customer orders, and material flows using technologies such as artificial intelligence, the IoT, big data analytics, and robotics [5,30,31,32]. There is a lack of consensus in the existing literature on the technologies that fall within the Industry 4.0 umbrella [33]. In order to determine which technologies are most applicable to Industry 4.0, this research draws on the most commonly referenced works in the field (see Table 1).

Table 1.

Main Industry 4.0 technologies.

In the context of procurement, the adoption of Industry 4.0 can fundamentally alter the direction of organizations’ sustainable procurement processes [68,69,70]. Industry 4.0 can contribute to the automation of procurement processes, offering firms higher productivity, enhanced efficiency, effective decision-making, and optimal organizational profitability [16]. Furthermore, Industry 4.0 technologies establish robust links between the supply chain team and the procurement department and increase the firm’s access to all essential data, including inventory levels, costs, delivery lead times, and any potential operational hazards [71]. As a result, Industry 4.0 technologies can enhance trust and transparency in buyer–supplier relationships to transform the procurement function into a hub for strategic networking. While the literature on the impact of Industry 4.0 technologies on procurement is increasing, there is still a paucity of review studies focusing on the interplay between Industry 4.0 and CP. Therefore, the current study aims to fill this knowledge gap and contribute to an understanding of the role of Industry 4.0 in the transition toward CP.

3. Research Method

The systematic literature review (SLR) is a methodology that allows for an in-depth examination of the present status of any given research field while simultaneously identifying knowledge gaps that can be filled by future studies and research [72,73]. In order to comprehensively assess and summarize the current research on the role of Industry 4.0 in the transition toward CP, this work applies the SLR technique used by previous studies [74,75]. First, the studies were identified; next, the relevant studies were determined; third, information was retrieved; fourth, data were synthesized and reported; and lastly, the results were discussed. Two academics formed a review panel to set the conceptual boundaries of the study. At each stage, from the first identification to the final culling of the pertinent articles, three experts including two professors in the SCM field and one senior industry practitioner were consulted to enhance the search strategy and the search terms [76]. These discussions allowed the authors to resolve any disagreement and reach a final decision to continue with the research. Finally, the study pursues standard procedures [74] to assure the accuracy and replicability of the results:

- (1)

- Planning the review by developing selection criteria to locate the relevant publications;

- (2)

- Screening the publications to evaluate their suitability by outlining the exclusion and inclusion criteria;

- (3)

- Analyzing material and retrieving data by examining the prior publications while applying several filters;

- (4)

- Data execution by summarizing the study results.

3.1. Planning the Review

First, the research question for this SLR was developed. In line with previous research [77,78], two prestigious academic databases (Scopus and Web of Science) were consulted in search of answers to the research question. The authors began database exploration by looking for the keywords “Industry 4.0” and “circular procurement” and then expanded the search terms from there. The review criteria included all relevant publications, regardless of publication date. Although the concept of Industry 4.0 was coined in 2011, the literature prior to this year was also reviewed because most Industry 4.0 technologies (e.g., artificial intelligence, the IoT, machine learning, etc.) were available since the turn of the millennium, but their usage was limited before 2011 [79].

3.2. Research Screening Criteria

For the current SLR, the authors decided that scholarly articles would be the appropriate unit of analysis [80]. Then, the research team determined which research articles would be considered for inclusion and which would be disqualified (see Table 2). After scouring the chosen databases for relevant publications, an extensive list was obtained. So, peer-reviewed publications were hand-selected, and all non-peer-reviewed documents (e.g., books, chapters, editorials) were eliminated. In general, quantitative and qualitative publications alike were taken into account as long as they were united in their emphasis on Industry 4.0 and CP. The research team ignored the gray literature, which includes working papers, white papers, theses, project reports, and conference proceedings. Furthermore, journal articles written in English were included, and works that focus on the applications of Industry 4.0 in business while ignoring the procurement aspect were disregarded.

Table 2.

Inclusion and exclusion criteria.

3.3. Data Extraction

To begin, Google Scholar was used to look for any relevant publications that would help develop the search query. The list of keywords was refined and the search strings were finalized by analyzing the titles, abstracts, and keywords of the top 100 publications retrieved in this first search. In the end, the initial string—“Industry 4.0” AND “circular procurement”—was adjusted to include the following terms: (“Additive manufacturing” OR “3D Printing” OR “Artificial intelligence” OR “Artificial neural network*” OR “Augmented reality” OR “Big data” OR “Blockchain” OR “Cloud computing” OR “Cloud Manufacturing” OR “Collaborative robot*” OR “CPS” OR “cyber-physical system*” OR “Cybersecurity” OR “Data mining” OR “Digitalisation technolog*” OR “fourth industrial revolution” OR “Industrial Internet” OR “Industrial revolution” OR “Industry 4.0” OR “Internet of thing*” OR “IoT” OR “Machine intelligence” OR “Machine learning” OR “Smart Factory” OR “Smart Manufacturing” OR “Smart Production” OR “Virtual reality” OR “Web intelligence” OR simulation) AND (procurement OR purchas* OR sourcing) AND (circular* OR sustainab* OR “circular economy” OR “circular business” OR “circular supply chain*” OR green OR “closed loop*”). The searches in Scopus and Web of Science were conducted 20 September 2022. In total, the research team found 294, 167 from Scopus and 127 from Web of Science. The team limited the selection of publications to the subject of business and management, without specifying any time period. The abstract of each publication was also taken into account in the screening process, in addition to the usual bibliographic data such as journal title, publication date, and authors. The screening process consisted of four phases. Each step was completed independently by two authors who conferred afterward to choose whether or not to advance to the next step.

Since certain publications in Scopus were also found on the Web of Science, the authors removed the duplicates first. After eliminating the duplicates, a total of 253 publications were retained. Second, the authors reviewed all 253 publications against inclusion and exclusion criteria. The remaining number of publications was 132. Third, the authors excluded papers that discussed Industry 4.0 technologies without a specific focus on CP. After this process, 100 publications were still available for the analysis. At last, the research team looked through the remaining 100 publications and kept only those that addressed the role of Industry 4.0 in facilitating the CP transition. This resulted in a total of 83 studies for the analysis. Moreover, backward and forward citation chaining was applied to guarantee the inclusion of all pertinent publications. This step resulted in the inclusion of 6 additional publications, bringing the total number of studies to 89.

3.4. Data Execution

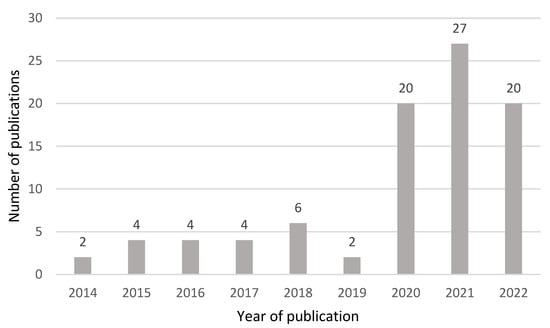

The applications of Industry 4.0 have recently seen a resurgence in popularity as academics and practitioners realized their potential as useful tools in enabling novel purchasing and supply capability management [81]. As can be seen in Figure 2, the relationship between Industry 4.0 and CP was a relatively new area of study prior to 2020 [82]. Even while most Industry 4.0 technologies like blockchain, the IoT, and big data analytics are still in their infancy and have not yet seen widespread adoption in CP, the number of publications in this area has grown dramatically between 2020 and 2022, demonstrating the growing importance of Industry 4.0 for CP.

Figure 2.

Year-wise distribution of selected publications.

The geographical spread of the selected papers was examined by retrieving all authors’ affiliations. Table 3 displays the top ten most productive countries that have contributed to the literature at the intersection of Industry 4.0 and CP. Researchers in the United Kingdom produced the most publications (17), followed by China, the USA, and India, with 15 papers each. Overall, research at the convergence of Industry 4.0 and CP has been rapidly progressing, and academics from both developed and developing nations have contributed significantly to this field.

Table 3.

Country-wise distribution of selected publications.

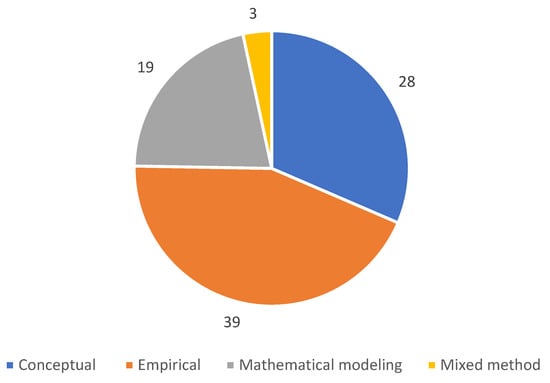

Table 4 shows the breakdown of publications by journal. The fact that the 89 articles were published in 51 journals is indicative of the topic’s widespread significance. Journal of Cleaner Production led in the number of papers published, followed by Journal of Enterprise Information Management, Technological Forecasting and Social Change, International Journal of Production Research, and International Journal of Production Economics, all of which had four papers. In conclusion, the results show that the literature pertaining to Industry 4.0 and CP is advanced by a couple of influential outlets, but there is a broad interest in issues of digitalization, sustainability, resource circularity, and procurement. Figure 3 depicts the distribution of the selected publications according to the research approach used. Most previous studies have applied different empirical methods to examine the role of Industry 4.0 technologies in the transition toward CP. Conceptual studies are also shown to be a common approach, which is the case for any developing field of study.

Table 4.

Journal-wise distribution of publications.

Figure 3.

Distribution of publications according to research methods.

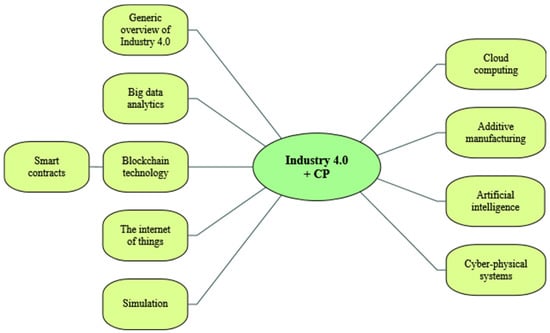

4. Thematic Analysis

To properly synthesize the findings of the literature, the research team analyzed all 89 articles for recurring themes. This method is consistent with recent systematic reviews [83,84]. To aggregate data from the existing literature, a content analysis strategy was adopted. Textual data can be analyzed using the popular content analysis technique, which involves carefully categorizing, coding, and finding the themes present in the data [85]. The examined material was summarized in an unbiased and understandable manner using a rigorous three-step process. The specifics of the three steps are the following: (1) open codes were assigned by the lead author to each publication, (2) inductive and deductive methods were applied to categorize the open codes into axial codes and acknowledge the associations between the open codes, and (3) discussion of the axial codes was held to reach a consensus on the classification of the themes. Overall, the thematic analysis sheds light on how the various Industry 4.0 technologies can facilitate the transition toward CP. To keep this view, a distinct collection of microtopics was found, and publications were analyzed in accordance with these themes (see Figure 4).

Figure 4.

Themes at the intersection of Industry 4.0 and CP.

4.1. Generic Overview of Industry 4.0′s Potential for CP

The publications discussing the connection between Industry 4.0 and CP were evaluated to obtain a high-level summary of the literature. In general, a common assertion among academics is that Industry 4.0 can serve as a catalyst for CP. A firm that wishes to achieve circularity should consider the uptake of Industry 4.0 in its procurement function. Numerous works concentrated on this direction [14,15,16]. For example, [16] argues that firms can use Industry 4.0 technologies to streamline their operations in areas such as spare parts procurement, inventory control, and manufacturing. As a result, this improves the openness and efficiency of the value-generation process while minimizing resource consumption [82]. At an operational level, Industry 4.0 technologies can effectively integrate CP processes because they have the potential to improve productivity and efficiency, support lifelong learning, and alter the nature of work by freeing up time and enabling a variety of flexible career paths [81]. By fully automating CP, Industry 4.0 ensures seamless integration of purchasing processes, efficient traceability, and forecasting of circular resources [6,86]. The authors of [87] note that the integration of Industry 4.0 in procurement presents a plethora of digital tools designed to offer new value propositions, establish trust in buyer–supplier relationships, and support innovative procurement data utilization. Moreover, the potential for Industry 4.0 technologies to facilitate circular business models was also a point of agreement in the literature [12,41,88]. In circular business models, an audit of all procurement transactions is challenging and costly because manufacturing systems and raw material monitoring are required to calculate and verify emissions [89]. However, with the support of Industry 4.0 technologies, organizations can efficiently audit their circular purchasing transactions, track the consumption of raw materials, and monitor the entire life cycle of products [90,91,92].

4.2. Big Data Analytics

The applications of big data analytics have been frequently considered by scholars, and several perspectives on leveraging this technology for supporting CP were prevalent [93,94,95]. For example, the authors of [96] point out that big data analytics can assist firms in optimizing their supplier selection, purchasing strategies, and logistic plans. The authors of [97] state that big data analytics can provide a significant contribution to raw materials pricing, lead-time reduction, and minimization of business and environmental risks facing suppliers, thus allowing for significant improvements in CP. Big data can also aid in the management of supplier-related risks if CP indicators are established, which leads to the identification of appropriate and sustainable sourcing [15]. By capitalizing on this technology, the procurement department can swiftly collect more data and communicate with other firm units to make better and more informed green procurement decisions over the course of a product lifecycle [97]. Access to big data can greatly support CP strategies and the prediction of disruptions by facilitating the assessment of suppliers and market trends. Automating the process of selecting a sustainable supplier is possible with the help of big data, as the technology can optimize the purchasing operations of standardized and circular parts and components [98].

4.3. Blockchain Technology

According to [99], blockchain can aid the organization, its suppliers, customers, partners, and if required, regulatory bodies—all of which have an interest in a trustworthy and seamless CP process. A decentralized strategy for purchase order processes makes it possible for suppliers without established business relationships to participate in the procurement process without delay using data from blockchain technology [100]. Furthermore, the introduction of blockchain significantly improves several CE practices, particularly CP [101], because the technology strengthens information security, ensures transparency, and boosts traceability across the full product life cycle [12]. As a result, this could bring a dramatic improvement to CP and the supply chain as a whole.

The Increased transparency and visibility of blockchain can be useful in sourcing strategies that prioritize speed and deal with bottleneck suppliers [81]. With blockchain, various sustainability issues across supply chains, such as transactional inefficiencies, theft, poor management, fraud, and lack of trust, can be overcome [102]. The fundamental advantages of blockchain in CP are connected to its ability to enhance data integrity, authenticate transactions, and eliminate corruption and fraud [86]. By increasing traceability and transparency in CP, blockchain can promote more responsible sourcing plans and guarantee compliance with environmental requirements [92]. The authors of [103] highlight that the speedy verification of documents from suppliers, such as licenses, certifications, and record proofs, is a direct result of blockchain’s role in fostering the development of robust integration ties between supply chain partners.

CP managers can have timely access to and monitor transaction histories for suppliers by using blockchain, which can integrate features of decentralization, streamline global-scale procurement transactions, and drive process disintermediation [104]. Additionally, the circular supply chain’s competitiveness, energy efficiency, and waste management can all be improved with the use of blockchain in resource allocation and scheduling [41,81].

Smart Contracts

Smart contracts are lauded for their potential to improve CP in a number of ways [86,105,106]. The smart-contract capability provided by blockchain technology to circular organizations [107] can boost the effectiveness of procurement activities while reducing their costs [40]. Automation via smart contracts can help an organization fix current weaknesses in CP processes and transform the whole supplier selection process into a flexible smart contract [105]. The benefits of smart contracts in CP also include reduced costs, faster transactions, increased competitiveness, and less bureaucracy [108]. Moreover, auditing CP processes can be efficiently carried out with smart contracts as they represent a legal fundament that can ensure information traceability and auditability [102]. Corruption, sustainability concerns, and social issues like sub-contracting can be monitored closely throughout the execution of smart contracts. As a result, this would make CP more transparent and traceable [109]. Although smart contracts coded on the top of a blockchain system can perform repetitive tasks between buyers and suppliers in regard to payments and the terms of contracts, new regulations should be specified before they can be treated as binding contracts [105].

4.4. The Internet of Things

The internet of things (IoT) is essential to CP because it automates data collection and transmission, allowing for a constant, unrestricted data flow and a unified interface for collaboration [86,95,110]. Similarly, the widespread use of the IoT can make it easier for organizations to interconnect and share relevant information. With the use of internet connection protocols, Wi-Fi, and Bluetooth, the IoT facilitates communication between buying entities and the exchange of information. In an IoT ecosystem, suppliers can alter previously static data by assigning a unique identifier to products sold at various locations. As a result, the IoT system can then support appropriate supplier selection for collaboration based on parameters such as pricing, materials, and quality changes [111]. Moreover, the CP department can leverage the IoT to track products with the use of tags [112]. In this intelligent system, machines and computers can solve problems, determine priorities, and communicate results to every part of the business network [48]. The impact of market uncertainty can be mitigated through the IoT as the technology facilitates enhanced human–machine interaction, leading to more tailored product purchases. Metrics for assessing CP processes can be derived using IoT techniques, including meta-heuristic networks, operations research models, and supported vector machines, hence reducing the opportunity for corruption [15]. Furthermore, the IoT has the potential to improve demand forecasting, resource allocation, inventory visibility, and sustainable supplier relationship management for businesses. In order to better manage logistics and maintain positive relationships with suppliers, the IoT can be used to increase transparency in the purchasing process [5]. Trucks’ fuel consumption, emissions, and mileage can be monitored by the IoT to enhance the transportation infrastructure and routing strategies [113]. Through the IoT, CP data is created in real-time and made available to buyers and suppliers. IoT networks allow for tracking suppliers’ past performance and their associated environmental effects. With the use of the IoT, organizations can monitor their suppliers’ environmental performance throughout the course of a long-term partnership. Overall, the usage of IoT technology in CP can improve contracting, ordering, pricing, and auditing [114].

4.5. Simulation

In procurement, the earnings and operating expenses can be modeled to account for the impact of random factors such as order volumes and delivery times via the use of simulation [115]. Simulation models can accurately portray system dynamics and assess process changes based on their own algorithms. Smart supply chain implementation relies on technologies such as simulation to enable digital platforms with suppliers and customers to optimize green performance (by, for example, conducting tests virtually rather than on physical prototypes). Furthermore, modeling tools assist in defining supplier demand and minimizing logistics movements that result in higher emissions, energy consumption, and transportation impacts in shipping [116]. Simulation can also support workers in enhancing decision-making concerning supply certification and identifying possible recycling wastes from operations [116]. The use of simulations can reveal where each procurement system falls short in terms of green projects [117]. By allowing engineers and designers to swiftly analyze and evaluate design choices with live data, digital simulation aims to promote effective innovation [48]. Alternative approaches to product remanufacturing can leverage simulation to support procurement-related decision-making processes, boost resource use efficiency, and allow for the delivery of new services, particularly those with a focus on maintenance [12]. Ref. [118] argues that statistical analysis provided by simulations can enhance the responsiveness of wood-procurement systems. As a result, the testing and optimization of procurement processes through simulation enables an organization to reduce risks, business changeover, and setup time while improving quality control [113].

4.6. Cloud Computing

Through the use of cloud computing, buyer–supplier relationships and value chains can be optimized by linking together various businesses, factories, and procedures [16]. Through its ability to store massive amounts of data and provide tools for processing, managing, and extracting insights from data, cloud computing provides several answers to the challenges faced by sustainable smart systems. By using cloud computing, organizations can transform their supply chains into value networks [96]. As such, cloud computing greatly simplifies collaboration and coordination between buyers and suppliers. It also enables agility and flexibility, which are the hallmarks of procurement in the Industry 4.0 era. In order to manage upstream suppliers for green purchasing and eco-design for products, a firm can use cloud computing to carry out several planning and execution operations, streamline business processes, achieve cost savings, and facilitate information sharing. Collaboration between the firm and its suppliers using a cloud-based solution is recognized as an essential backbone of physical and business production [96]. By promoting cooperation across all network partners, cloud computing systems can shorten product design time and synchronize all manufacturing processes. Orders placed by customers are processed and carried out more quickly when they are digitalized through cloud computing [48]. For better energy efficiency, cloud computing can also be used to calculate the whole carbon footprint of a product during its lifetime, thereby accelerating the transition toward CP [90].

4.7. Additive Manufacturing

Considering that procurement occurs early in a product’s life cycle, it makes sense to include additive manufacturing in the supply chain at this point to build a robust network. When additive manufacturing is used during the procurement phase, the supplier of components provides the firm with the design file, and the components are made in the factories in response to orders for finished goods [119]. Given that on-shoring is an objective of additive manufacturing, its implementation in the procurement phase is expected to result in a new supply network for the logistical activities related to sourcing and distribution [119]. The use of additive manufacturing can eliminate further stages of manufacturing and result in fully functional, unified products’ features. The other advantages of incorporating additive manufacturing in CP are the reduction of supply-related risks through its in-house production of components, the decentralization of manufacturing locations in areas close to customers, the decrease in waste, inventory, and transportation, and the promotion of sustainable green ecosystems [56,120,121]. After taking additive manufacturing into account throughout the sourcing process, the authors of [122] recommend that the procurement department employ additive manufacturing to lower the supply risk of bottleneck items. In this manner, organizations can incorporate additive manufacturing into their CP activities to reduce supply-side risks and coordinate both established and new business models.

4.8. Artificial Intelligence

Artificial intelligence (AI) adds smartness to the supplier selection choices of procurement managers via its amazing capacity to gather and evaluate market data [123]. The research of [124] suggests that AI has the potential to replace manual jobs and tasks within business processes thanks to recent advances in autonomous decision-making and algorithmic machine learning. Particularly for ambiguous activities, CP managers can capitalize on AI to support decision-making processes. According to [125], the widespread adoption of AI in supply chain activities, including procurement, has the potential to have a positive impact on the environment by lowering pollution levels, reducing energy consumption, and decreasing greenhouse gas emissions, all while boosting business profits. Increased traceability and transparency throughout a product’s life cycle are made possible by the usage of AI in CP. As a means of reducing pollution, firms can use AI in remanufacturing operations by using data collected at the product’s end of life to inform the processing of remanufacturing parameters [126]. AI also aids CP endeavors by facilitating activities, enhancing workforce automation skills, and optimizing production planning [90,111].

CP data can be analyzed by AI techniques such as machine learning and deep learning so that better pricing is set in order to discourage wasteful behavior and safeguard against economic and ecological harms [87]. In addition, this information can be processed and analyzed through the use of AI techniques to determine the possible options for all involved parties and the environment, thereby revealing new avenues for improving environmental sustainability. The authors of [127] indicate that AI can aid in pattern analysis, leading to a deeper comprehension of particular supplier behaviors that, in turn, can aid CP managers in identifying suitable potential suppliers. With the use of AI, the process of determining pricing from various suppliers can be sped up and made more accurate by means of various methods, such as multiple regression, metaheuristic algorithms, and case-based reasoning models [123]. AI’s ability to learn from data and compare historical and real-time data makes it a potent tool for solving several complicated issues in CP, including the estimation of optimal prices in procurement contracts and bidding decisions. Finally, AI can be used to eliminate service processing and ordering faults and improve service providers’ ex ante and ex post performance. The technology can shorten the time it takes for engineers to respond to the procurement hub and develop automated decision-making systems for supplier risk management and supplier contract negotiations [128].

4.9. Cyber-Physical Systems

Cyber-physical systems (CPS) often involve several computational platforms that interact through communication networks. These systems can solicit bids and notify the procurement department when they are received. Based on the data that the system provides, the procurement department can choose the best offer [129]. Incorporating cyber-physical systems in the firm can also improve production and maintenance planning and allow the firm to more efficiently collect, manage, and use waste as a resource [130]. Because of their ability to automate resource management, CPS can advance CP by helping firms achieve cost savings and supporting their circular business models [5]. Similarly, CPS can play a critical role in automating the demand-generation of CP systems [131]. For example, CPS can establish the link between the real world and the virtual one by promoting the use of devices like sensor-driven shelves and smart bins that detect when a stockpile of physical objects is running low. Additionally, integrating services and suppliers can be made easier with the introduction of CPS. Therefore, process and collaboration competencies—as well as abilities in areas such as radio, network, and transmission technologies, rapid information procurement, material control, and optimization—are likely to grow in significance in the future of CP.

5. Discussion: Toward the Development of a Conceptual Framework

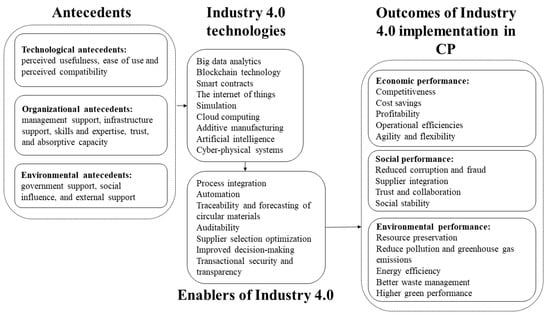

The implementation of Industry 4.0 in the transition toward CP offers an adaptive and flexible capability that brings several benefits to the procurement function. This can help overcome the challenging decisions about the ramifications of Industry 4.0 technologies by demonstrating how they can add value to the procurement process of organizations. On the basis of the literature assessment and the thematic analysis in the preceding sections, the study suggests a conceptual framework for the interplay between Industry 4.0 and CP, synthesizing four key themes for future research of this nexus: antecedents, Industry 4.0 technologies, enablers of Industry 4.0 for CP, and outcomes of Industry 4.0 implementation in CP (see Figure 5). This framework is an effort to clarify the role of Industry 4.0 in the CP transition and shed light on the relationship between the interrelated themes. The framework depicts the requirements and expectations of incorporating Industry 4.0 in CP.

Figure 5.

Conceptual framework for the adoption of Industry 4.0 technologies in CP.

Derived from the well-established technology–organization–environment framework, the antecedents of adopting Industry 4.0 in CP are classified into three categories. Technological antecedents refer to a set of characteristics that describe how technological structures and practices affect the adoption of emerging technologies [132,133,134]. As such, technological aspects, including software and hardware, are required to adopt new technologies. Moreover, Industry 4.0 implementation in CP depends on ease of use, that is, managers’ expectations of how simple it will be to implement new technology into their procurement operations [135,136]. In the context of CP, ease-of-use can improve the adoption of Industry 4.0 technologies since it lessens the mental strain placed on procurement managers. All these factors point to the fact that Industry 4.0 technologies are likely to be adopted in CP if they are simpler to use. During their transition toward Industry 4.0-enabled CP, firms can encounter a number of compatibility difficulties, including those related to connecting the new system with the current procurement infrastructure [137]. As a result, Industry 4.0 technologies should be congruent with the firm’s existing processes, structure, and culture [138].

The organizational antecedents relate to the firm readiness to adopt Industry 4.0 technologies and their willingness to devote resources to their integration in CP. As a critical antecedent, management support is crucial to mobilize resources when introducing new technologies in CP. In addition, adopting Industry 4.0 requires new types of infrastructure support. For example, the IoT, a building block of Industry 4.0, cannot function without industrial sensors. The data generated by Industry 4.0 systems are substantial, necessitating both ample storage space and the ability to use machine learning techniques to analyze the information. Furthermore, skills and expertise are needed to perform reliable analyses and exploit knowledge. Adopting Industry 4.0 also requires a high level of trust among all parties involved because information flows more smoothly between trusted business partners. In addition, firms with a high absorptive capacity can be better equipped to absorb new information and spread it across employees. To be more precise, the adoption of Industry 4.0 in CP can be correlated with the absorptive capacity of the firm.

The final category of antecedents concerns the factors external to the firm, including government support, social influence, and external support. The assistance offered by regulatory bodies to enable the adoption of Industry 4.0 technologies in CP is essential [101]. Similarly, the pressure put by suppliers and customers and other supply chain partners can force the firm to adopt Industry 4.0 technologies in its CP [10,94]. For instance, if a sizable portion of firms in a certain sector decide to invest in cutting-edge technologies in their operations, it is eventually expected that all firms will implement the new technology. Finally, the support that the firm receives from outside its walls is critical for the implementation of Industry 4.0 technologies in CP. When it comes to establishing an Industry 4.0 infrastructure, local universities and labs may aid in the cultivation of abilities and research and development activities that boost the rate of learning [139].

Once the antecedents of Industry 4.0 implementation are recognized, organizations can reap several benefits from embracing new technologies in their CP activities, including better process integration [48], automation [140], and effective supplier selection strategies [94]. These enablers can lead to several economic, social, and environmental outcomes (see Figure 5).

6. Conclusions

The current study represents the first attempt to analyze the interplay between Industry 4.0 and CP. A well-established research protocol was applied to collect relevant studies from well-recognized databases, Scopus and Web of Science. As a result, the study’s research question was answered by clarifying the role of Industry 4.0 technologies in CP. The research profile includes analysis of the annual scholarly output, geographical coverage, publication sources, and research approaches applied. The thorough analysis of the selected publications reveals ten themes. Research into the interplay between Industry 4.0 and CP is an important area of research, and the results of this study have important implications for both academics and practitioners.

6.1. Future Research Agenda

As a result of this contribution, future researchers may examine several directions. For instance, the impact of Industry-4.0-enabled CP on other circular supply chain processes (e.g., inventory management, transportation, logistics) can be studied. Although Industry 4.0 applications have been widely investigated, nothing is known about the role of some technologies—such as augmented reality, virtual reality, and 5G telecommunications—in advancing CP. Moreover, the degree of Industry 4.0 implementation in CP and its impact on business processes and integration (taking into account all functions) have been ignored in previous studies. Considering the identified enablers of Industry 4.0 for CP, it is advised that further research is needed to determine how to evaluate circular manufacturing planning in the era of Industry 4.0. The lack of empirical evidence for the impact of Industry 4.0 technologies on the optimization of CP processes may be attributable to the maturity level of Industry 4.0 implementation; this should be kept in mind for future research.

6.2. Theoretical Implications

The concepts of Industry 4.0 and CP are essential not only for firms and their suppliers but also for the whole circular supply chain, the environment, and society at large. This review finds that big data analytics, blockchain technology, the IoT, and AI help firms automate and improve CP processes, which in turn accelerates the smart transformation of firms. Thus, organizations should set up an adequate internal environment to accommodate new technologies before rolling the results out of their supply chains. Additionally, the research profile of the extant literature is provided in terms of yearly publication trends, geographical distribution, publication sources, and research approaches applied to uncover the role of Industry 4.0 technology in the transition toward CP. This effort can help researchers in the future to better understand the current state of knowledge and develop novel research questions.

This study stands out among prior reviews since it explicitly focuses on the nexus of Industry 4.0 and CP. While previous research has looked at the applications of Industry 4.0 in procurement [14,16], their limited focus only serves to highlight the need for a more detailed understanding of the role of new technologies in fostering CE practices in procurement activities. To fill this void, the authors conducted an extensive literature analysis to identify and summarize the contributions of Industry 4.0 to CP. This systematic review also captures the limited nature of research on the interplay between Industry 4.0 and CP, from the broad classification to the narrow insights. In addition, the study provides researchers with several pending issues that deserve further attention to unlock the potential of Industry 4.0 in CP. Finally, based on the prior, the authors provide a conceptual framework for Industry 4.0 implementation in CP considering the antecedents, the enablers, and the performance outcomes of Industry-4.0-enabled CP. The elements of the framework provide future researchers with more avenues of inquiry into the necessary capabilities to acquire, thus helping to further define the nature of the bond between Industry 4.0 and CP.

6.3. Practical Implications

Recently, procurement professionals have faced a deluge of information on emerging technologies with varying degrees of relevance to their work. Practitioners in the field of purchasing and supply management are motivated to embark on CP and Industry 4.0 to generate more value. This review proposes a conceptual framework to assist practitioners in determining the antecedents, enablers, and performance outcomes of Industry 4.0 technologies in CP. This framework identifies the main technologies contributing to the advancement of CP. As a result, the practitioners should scrutinize how these technologies can be applicable to areas beyond CP, such as circular manufacturing. Moreover, the roadmap of managers in the CP field should address several questions, including: How far along is the organization’s preparation for incorporating Industry 4.0 technologies in CP?; How can Industry-4.0-enabled CP contribute to the development of circular supply chains and the realization of the CE agenda?; Which of the Industry 4.0 technologies has the most influence on CP, given the challenges faced by supply chain partners? From this review, four major takeaways can be addressed by managers. First, it is the responsibility of managers to invest in their organizations’ technology infrastructure to sustain their CP activities. Second, implementing Industry 4.0 technologies is a great way to boost operations productivity and achieve higher circularity performance. Third, this review recommends that organizations assess the technical and socio-economic feasibility of adopting Industry 4.0 technologies in CP. Managers should be equipped with the appropriate resources and capabilities to facilitate the integration of emerging technologies and achieve CE goals. Finally, practitioners must place emphasis on the adoption of Industry 4.0 in CP to balance the power between the buying firm and its suppliers.

6.4. Limitations

This study acknowledges the transformative potential of Industry 4.0 technologies in CP without focusing on a specific industrial context. Despite its contributions, the current review has certain limitations. To begin, only two scientific databases were consulted for the review, namely, Scopus and Web of Science. While these databases are known for their widespread coverage, it is possible that certain publications not indexed in Scopus and the Web of Science were omitted. Moreover, the analysis of interplay between Industry 4.0 and CP was confined by applying strict selection criteria for the relevant literature without considering conference papers, books, and chapters. As a result, future studies can include these potentially valuable knowledge sources and refine the keyword selection to broaden the scope of their investigation. Finally, the conclusions of the present review need empirical support, which can be supplied by future academics.

Author Contributions

Conceptualization, A.R.; methodology, A.R.; software, A.R.; validation, A.R. and A.A.; formal analysis, A.R.; investigation, A.R.; resources, A.R.; data curation, A.R.; writing—original draft preparation, A.R.; writing—review and editing, A.A.; visualization, A.R.; supervision, A.A.; project administration, A.A.; funding acquisition, A.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available upon request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Heshmati, A. A Review of the Circular Economy and Its Implementation. Int. J. Green Econ. 2017, 11, 251–288. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular Economy—From Review of Theories and Practices to Development of Implementation Tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A. How Do Scholars Approach the Circular Economy? A Systematic Literature Review. J. Clean. Prod. 2018, 178, 703–722. [Google Scholar] [CrossRef]

- Mboli, J.S.; Thakker, D.; Mishra, J.L. An Internet of Things-Enabled Decision Support System for Circular Economy Business Model. Softw. Pract. Exp. 2022, 52, 772–787. [Google Scholar] [CrossRef]

- Rejeb, A.; Suhaiza, Z.; Rejeb, K.; Seuring, S.; Treiblmaier, H. The Internet of Things and the Circular Economy: A Systematic Literature Review and Research Agenda. J. Clean. Prod. 2022, 350, 131439. [Google Scholar] [CrossRef]

- Qazi, A.A.; Appolloni, A. A Systematic Review on Barriers and Enablers toward Circular Procurement Management. Sustain. Prod. Consum. 2022, 33, 343–359. [Google Scholar] [CrossRef]

- Al-Sinan, M.A.; Bubshait, A.A. The Procurement Agenda for the Transition to a Circular Economy. Sustainability 2022, 14, 11528. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K. Circular Economy Practices among Chinese Manufacturers Varying in Environmental-Oriented Supply Chain Cooperation and the Performance Implications. J. Environ. Manag. 2010, 91, 1324–1331. [Google Scholar] [CrossRef]

- Sönnichsen, S.D.; Clement, J. Review of Green and Sustainable Public Procurement: Towards Circular Public Procurement. J. Clean. Prod. 2020, 245, 118901. [Google Scholar] [CrossRef]

- Xu, L.; Jia, F.; Yan, F.; Chen, L. Circular Procurement: A Systematic Literature Review. J. Clean. Prod. 2022, 365, 132845. [Google Scholar] [CrossRef]

- Awan, U.; Sroufe, R.; Shahbaz, M. Industry 4.0 and the Circular Economy: A Literature Review and Recommendations for Future Research. Bus. Strategy Environ. 2021, 30, 2038–2060. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Piprani, A.Z.; Yu, Z. Digital Technology and Circular Economy Practices: Future of Supply Chains. Oper. Manag. Res. 2022, 15, 676–688. [Google Scholar] [CrossRef]

- Sjödin, D.; Kamalaldin, A.; Parida, V.; Islam, N. Procurement 4.0: How Industrial Customers Transform Procurement Processes to Capitalize on Digital Servitization. IEEE Trans. Eng. Manag. 2021, 1–16. [Google Scholar] [CrossRef]

- Glas, A.H.; Kleemann, F.C. The Impact of Industry 4.0 on Procurement and Supply Management: A Conceptual and Qualitative Analysis. Int. J. Bus. Manag. Invent. 2016, 5, 55–66. [Google Scholar]

- Jahani, N.; Sepehri, A.; Vandchali, H.R.; Tirkolaee, E.B. Application of Industry 4.0 in the Procurement Processes of Supply Chains: A Systematic Literature Review. Sustainability 2021, 13, 7520. [Google Scholar] [CrossRef]

- Bienhaus, F.; Haddud, A. Procurement 4.0: Factors Influencing the Digitisation of Procurement and Supply Chains. Bus. Process Manag. J. 2018, 24, 965–984. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; Towards a Circular Economy: A Zero Waste Programme for Europe; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- Alhola, K.; Ryding, S.-O.; Salmenperä, H.; Busch, N.J. Exploiting the Potential of Public Procurement: Opportunities for Circular Economy. J. Ind. Ecol. 2019, 23, 96–109. [Google Scholar] [CrossRef]

- Kristensen, H.S.; Mosgaard, M.A. A Review of Micro Level Indicators for a Circular Economy—Moving Away from the Three Dimensions of Sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Large, R.O.; Gimenez Thomsen, C. Drivers of Green Supply Management Performance: Evidence from Germany. J. Purch. Supply Manag. 2011, 17, 176–184. [Google Scholar] [CrossRef]

- Carter, C.R.; Carter, J.R. Interorganizational Determinants of Environmental Purchasing: Initial Evidence from the Consumer Products Industries. Decis. Sci. 1998, 29, 659–684. [Google Scholar] [CrossRef]

- Appolloni, A.; Sun, H.; Jia, F.; Li, X. Green Procurement in the Private Sector: A State of the Art Review between 1996 and 2013. J. Clean. Prod. 2014, 85, 122–133. [Google Scholar] [CrossRef]

- Cheng, W.; Appolloni, A.; D’Amato, A.; Zhu, Q. Green Public Procurement, Missing Concepts and Future Trends—A Critical Review. J. Clean. Prod. 2018, 176, 770–784. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Connecting Circular Economy and Industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113. [Google Scholar] [CrossRef]

- Tseng, M.-L.; Tan, R.R.; Chiu, A.S.F.; Chien, C.-F.; Kuo, T.C. Circular Economy Meets Industry 4.0: Can Big Data Drive Industrial Symbiosis? Resour. Conserv. Recycl. 2018, 131, 146–147. [Google Scholar] [CrossRef]

- Novak, A.; Bennett, D.; Kliestik, T. Product Decision-Making Information Systems, Real-Time Sensor Networks, and Artificial Intelligence-Driven Big Data Analytics in Sustainable Industry 4.0. Econ. Manag. Financ. Mark. 2021, 16, 62–72. [Google Scholar]

- Fragapane, G.; Ivanov, D.; Peron, M.; Sgarbossa, F.; Strandhagen, J.O. Increasing Flexibility and Productivity in Industry 4.0 Production Networks with Autonomous Mobile Robots and Smart Intralogistics. Ann. Oper. Res. 2022, 308, 125–143. [Google Scholar] [CrossRef]

- Lohmer, J.; Lasch, R. Production Planning and Scheduling in Multi-Factory Production Networks: A Systematic Literature Review. Int. J. Prod. Res. 2021, 59, 2028–2054. [Google Scholar] [CrossRef]

- Prause, G.; Atari, S. On Sustainable Production Networks for Industry 4.0. Entrep. Sustain. Issues 2017, 4, 421–431. [Google Scholar] [CrossRef]

- Nagy, M.; Lăzăroiu, G. Computer Vision Algorithms, Remote Sensing Data Fusion Techniques, and Mapping and Navigation Tools in the Industry 4.0-Based Slovak Automotive Sector. Mathematics 2022, 10, 3543. [Google Scholar] [CrossRef]

- Valaskova, K.; Nagy, M.; Zabojnik, S.; Lăzăroiu, G. Industry 4.0 Wireless Networks and Cyber-Physical Smart Manufacturing Systems as Accelerators of Value-Added Growth in Slovak Exports. Mathematics 2022, 10, 2452. [Google Scholar] [CrossRef]

- Zvarikova, K.; Rowland, M.; Krulicky, T. Sustainable Industry 4.0 Wireless Networks, Smart Factory Performance, and Cognitive Automation in Cyber-Physical System-Based Manufacturing. J. Self-Gov. Manag. Econ. 2021, 9, 9–20. [Google Scholar]

- Rosin, F.; Forget, P.; Lamouri, S.; Pellerin, R. Impacts of Industry 4.0 Technologies on Lean Principles. Int. J. Prod. Res. 2020, 58, 1644–1661. [Google Scholar] [CrossRef]

- Bonnard, R.; Arantes, M.D.S.; Lorbieski, R.; Vieira, K.M.M.; Nunes, M.C. Big Data/Analytics Platform for Industry 4.0 Implementation in Advanced Manufacturing Context. Int. J. Adv. Manuf. Technol. 2021, 117, 1959–1973. [Google Scholar] [CrossRef]

- Gokalp, M.O.; Kayabay, K.; Akyol, M.A.; Eren, P.E.; Koçyiğit, A. Big Data for Industry 4.0: A Conceptual Framework. In Proceedings of the 2016 International Conference on Computational Science and Computational Intelligence (CSCI), Las Vegas, NV, USA, 15–17 December 2016; pp. 431–434. [Google Scholar]

- Sahal, R.; Breslin, J.G.; Ali, M.I. Big Data and Stream Processing Platforms for Industry 4.0 Requirements Mapping for a Predictive Maintenance Use Case. J. Manuf. Syst. 2020, 54, 138–151. [Google Scholar] [CrossRef]

- Santos, M.Y.; Oliveira e Sá, J.; Costa, C.; Galvão, J.; Andrade, C.; Martinho, B.; Lima, F.V.; Costa, E. A Big Data Analytics Architecture for Industry 4.0. In Proceedings of the Recent Advances in Information Systems and Technologies, Madeira, Portugal, 11–13 April 2017; Rocha, Á., Correia, A.M., Adeli, H., Reis, L.P., Costanzo, S., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 175–184. [Google Scholar]

- Sharma, A.; Pandey, H. Big Data and Analytics in Industry 4.0. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development; Advances in Science, Technology & Innovation; Nayyar, A., Kumar, A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 57–72. ISBN 978-3-030-14544-6. [Google Scholar]

- Singh, H. Big Data, Industry 4.0 and Cyber-Physical Systems Integration: A Smart Industry Context. Mater. Today Proc. 2021, 46, 157–162. [Google Scholar] [CrossRef]

- Chidepatil, A.; Bindra, P.; Kulkarni, D.; Qazi, M.; Kshirsagar, M.; Sankaran, K. From Trash to Cash: How Blockchain and Multi-Sensor-Driven Artificial Intelligence Can Transform Circular Economy of Plastic Waste? Adm. Sci. 2020, 10, 23. [Google Scholar] [CrossRef]

- Kayikci, Y.; Gozacan-Chase, N.; Rejeb, A.; Mathiyazhagan, K. Critical Success Factors for Implementing Blockchain-Based Circular Supply Chain. Bus. Strategy Environ. 2022, 31, 3595–3615. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Saberi, S.; Sarkis, J. Blockchain Technology and the Sustainable Supply Chain: Theoretically Exploring Adoption Barriers. Int. J. Prod. Econ. 2021, 231, 107831. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of Things and Supply Chain Management: A Literature Review. Int. J. Prod. Res. 2019, 57, 4719–4742. [Google Scholar] [CrossRef]

- Ng, I.C.L.; Wakenshaw, S.Y.L. The Internet-of-Things: Review and Research Directions. Int. J. Res. Mark. 2017, 34, 3–21. [Google Scholar] [CrossRef]

- Rebelo, R.M.L.; Pereira, S.C.F.; Queiroz, M.M. The Interplay between the Internet of Things and Supply Chain Management: Challenges and Opportunities Based on a Systematic Literature Review. Benchmarking Int. J. 2021, 29, 683–711. [Google Scholar] [CrossRef]

- Barari, A.; de Sales Guerra Tsuzuki, M.; Cohen, Y.; Macchi, M. Editorial: Intelligent Manufacturing Systems towards Industry 4.0 Era. J. Intell. Manuf. 2021, 32, 1793–1796. [Google Scholar] [CrossRef]

- De Paula Ferreira, W.; Armellini, F.; De Santa-Eulalia, L.A. Simulation in Industry 4.0: A State-of-the-Art Review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Dutta, G.; Kumar, R.; Sindhwani, R.; Singh, R.K. Digital Transformation Priorities of India’s Discrete Manufacturing SMEs—A Conceptual Study in Perspective of Industry 4.0. Compet. Rev. Int. Bus. J. 2020, 30, 289–314. [Google Scholar] [CrossRef]

- Leng, J.; Wang, D.; Shen, W.; Li, X.; Liu, Q.; Chen, X. Digital Twins-Based Smart Manufacturing System Design in Industry 4.0: A Review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Kim, J.H. A Review of Cyber-Physical System Research Relevant to the Emerging IT Trends: Industry 4.0, IoT, Big Data, and Cloud Computing. J. Ind. Integr. Manag. 2017, 02, 1750011. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X. Industry 4.0 and Cloud Manufacturing: A Comparative Analysis. J. Manuf. Sci. Eng. 2016, 139, 034701. [Google Scholar] [CrossRef]

- O’Donovan, P.; Gallagher, C.; Leahy, K.; O’Sullivan, D.T.J. A Comparison of Fog and Cloud Computing Cyber-Physical Interfaces for Industry 4.0 Real-Time Embedded Machine Learning Engineering Applications. Comput. Ind. 2019, 110, 12–35. [Google Scholar] [CrossRef]

- Velásquez, N.; Estévez, E.C.; Pesado, P.M. Cloud Computing, Big Data and the Industry 4.0 Reference Architectures. J. Comput. Sci. Technol. 2018, 18, 258–266. [Google Scholar] [CrossRef]

- Yen, C.-T.; Liu, Y.-C.; Lin, C.-C.; Kao, C.-C.; Wang, W.-B.; Hsu, Y.-R. Advanced Manufacturing Solution to Industry 4.0 Trend through Sensing Network and Cloud Computing Technologies. In Proceedings of the 2014 IEEE International Conference on Automation Science and Engineering (CASE), Shanghai, China, 18–21 August 2014; pp. 1150–1152. [Google Scholar]

- Attaran, M. Additive Manufacturing: The Most Promising Technology to Alter the Supply Chain and Logistics. J. Serv. Sci. Manag. 2017, 10, 189. [Google Scholar] [CrossRef]

- Boer, J.D.; Lambrechts, W.; Krikke, H. Additive Manufacturing in Military and Humanitarian Missions: Advantages and Challenges in the Spare Parts Supply Chain. J. Clean. Prod. 2020, 257, 120301. [Google Scholar] [CrossRef]

- Florén, H.; Barth, H.; Gullbrand, J.; Holmén, M. Additive Manufacturing Technologies and Business Models—A Systematic Literature Review. J. Manuf. Technol. Manag. 2021, 32, 136–155. [Google Scholar] [CrossRef]

- Hohn, M.M.; Durach, C.F. Additive Manufacturing in the Apparel Supply Chain—Impact on Supply Chain Governance and Social Sustainability. Int. J. Oper. Prod. Manag. 2021, 41, 1035–1059. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive Manufacturing in the Spare Parts Supply Chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Oettmeier, K.; Hofmann, E. Impact of Additive Manufacturing Technology Adoption on Supply Chain Management Processes and Components. J. Manuf. Technol. Manag. 2016, 27, 944–968. [Google Scholar] [CrossRef]

- Cheah, C.G.; Chia, W.Y.; Lai, S.F.; Chew, K.W.; Chia, S.R.; Show, P.L. Innovation Designs of Industry 4.0 Based Solid Waste Management: Machinery and Digital Circular Economy. Environ. Res. 2022, 213, 113619. [Google Scholar] [CrossRef]

- Pietronudo, M.C.; Croidieu, G.; Schiavone, F. A Solution Looking for Problems? A Systematic Literature Review of the Rationalizing Influence of Artificial Intelligence on Decision-Making in Innovation Management. Technol. Forecast. Soc. Change 2022, 182, 121828. [Google Scholar] [CrossRef]

- Bagheri, B.; Yang, S.; Kao, H.-A.; Lee, J. Cyber-Physical Systems Architecture for Self-Aware Machines in Industry 4.0 Environment. IFAC-Pap. 2015, 48, 1622–1627. [Google Scholar] [CrossRef]

- Mueller, E.; Chen, X.-L.; Riedel, R. Challenges and Requirements for the Application of Industry 4.0: A Special Insight with the Usage of Cyber-Physical System. Chin. J. Mech. Eng. 2017, 30, 1050–1057. [Google Scholar] [CrossRef]

- O’Donovan, P.; Gallagher, C.; Bruton, K.; O’Sullivan, D.T.J. A Fog Computing Industrial Cyber-Physical System for Embedded Low-Latency Machine Learning Industry 4.0 Applications. Manuf. Lett. 2018, 15, 139–142. [Google Scholar] [CrossRef]

- Pivoto, D.G.S.; de Almeida, L.F.F.; da Rosa Righi, R.; Rodrigues, J.J.P.C.; Lugli, A.B.; Alberti, A.M. Cyber-Physical Systems Architectures for Industrial Internet of Things Applications in Industry 4.0: A Literature Review. J. Manuf. Syst. 2021, 58, 176–192. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Joseph Jerome, J.J.; Saxena, D.; Sonwaney, V.; Foropon, C. Procurement 4.0 to the Rescue: Catalysing Its Adoption by Modelling the Challenges. Benchmarking Int. J. 2021, 29, 217–254. [Google Scholar] [CrossRef]

- Mavidis, A.; Folinas, D. From Public E-Procurement 3.0 to E-Procurement 4.0; A Critical Literature Review. Sustainability 2022, 14, 11252. [Google Scholar] [CrossRef]

- Tripathi, S.; Gupta, M. A Framework for Procurement Process Re-Engineering in Industry 4.0. Bus. Process Manag. J. 2020, 27, 439–458. [Google Scholar] [CrossRef]

- Schiele, H. Supply-Management Maturity, Cost Savings and Purchasing Absorptive Capacity: Testing the Procurement–Performance Link. J. Purch. Supply Manag. 2007, 13, 274–293. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a Systematic Review. In The Sage Handbook of Organizational Research Methods; Sage Publications Ltd.: Thousand Oaks, CA, USA, 2009; pp. 671–689. ISBN 978-1-4129-3118-2. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Chauhan, C.; Dhir, A.; Akram, M.U.; Salo, J. Food Loss and Waste in Food Supply Chains. A Systematic Literature Review and Framework Development Approach. J. Clean. Prod. 2021, 295, 126438. [Google Scholar] [CrossRef]

- Talwar, S.; Kaur, P.; Fosso Wamba, S.; Dhir, A. Big Data in Operations and Supply Chain Management: A Systematic Literature Review and Future Research Agenda. Int. J. Prod. Res. 2021, 59, 3509–3534. [Google Scholar] [CrossRef]

- Roehrich, J.K.; Selviaridis, K.; Kalra, J.; Van der Valk, W.; Fang, F. Inter-Organizational Governance: A Review, Conceptualisation and Extension. Prod. Plan. Control 2020, 31, 453–469. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Mustapha, K.B.; Godsell, J.; Adamu, Z.; Babatunde, K.A.; Akintade, D.D.; Acquaye, A.; Fujii, H.; Ndiaye, M.M.; Yamoah, F.A.; et al. A Critical Analysis of the Impacts of COVID-19 on the Global Economy and Ecosystems and Opportunities for Circular Economy Strategies. Resour. Conserv. Recycl. 2021, 164, 105169. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Simske, S.; Treiblmaier, H. Blockchain Technologies in Logistics and Supply Chain Management: A Bibliometric Review. Logistics 2021, 5, 72. [Google Scholar] [CrossRef]

- Krishnan, S.; Gupta, S.; Kaliyan, M.; Kumar, V.; Garza-Reyes, J.A. Assessing the Key Enablers for Industry 4.0 Adoption Using MICMAC Analysis: A Case Study. Int. J. Product. Perform. Manag. 2021, 70, 1049–1071. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Abdollahi, A.; Treiblmaier, H. The Big Picture on Instagram Research: Insights from a Bibliometric Analysis. Telemat. Inform. 2022, 73, 101876. [Google Scholar] [CrossRef]

- Van Hoek, R.; Sankararaman, V.; Udesen, T.; Geurts, T.; Palumbo-Miele, D. Where We Are Heading and the Research That Can Help Us Get There—Executive Perspectives on the Anniversary of the Journal of Purchasing and Supply Management. J. Purch. Supply Manag. 2020, 26, 100621. [Google Scholar] [CrossRef]

- Veile, J.W.; Schmidt, M.-C.; Müller, J.M.; Voigt, K.-I. Relationship Follows Technology! How Industry 4.0 Reshapes Future Buyer-Supplier Relationships. J. Manuf. Technol. Manag. 2020, 32, 1245–1266. [Google Scholar] [CrossRef]

- Hina, M.; Chauhan, C.; Kaur, P.; Kraus, S.; Dhir, A. Drivers and Barriers of Circular Economy Business Models: Where We Are Now, and Where We Are Heading. J. Clean. Prod. 2022, 333, 130049. [Google Scholar] [CrossRef]

- Zhang, Q.; Dhir, A.; Kaur, P. Circular Economy and the Food Sector: A Systematic Literature Review. Sustain. Prod. Consum. 2022, 32, 655–668. [Google Scholar] [CrossRef]

- Hsieh, H.-F.; Shannon, S.E. Three Approaches to Qualitative Content Analysis. Qual. Health Res. 2005, 15, 1277–1288. [Google Scholar] [CrossRef]

- Asante, M.; Epiphaniou, G.; Maple, C.; Al-Khateeb, H.; Bottarelli, M.; Ghafoor, K.Z. Distributed Ledger Technologies in Supply Chain Security Management: A Comprehensive Survey. IEEE Trans. Eng. Manag. 2021, 1–27. [Google Scholar] [CrossRef]

- Hofmann, E.; Brunner, J.H.; Holschbach, E. Research in Business Service Purchasing: Current Status and Directions for the Future. Manag. Rev. Q. 2020, 70, 421–460. [Google Scholar] [CrossRef]

- Kamble, S.S.; Belhadi, A.; Gunasekaran, A.; Ganapathy, L.; Verma, S. A Large Multi-Group Decision-Making Technique for Prioritizing the Big Data-Driven Circular Economy Practices in the Automobile Component Manufacturing Industry. Technol. Forecast. Soc. Change 2021, 165, 120567. [Google Scholar] [CrossRef]

- Tura, N.; Hanski, J.; Ahola, T.; Ståhle, M.; Piiparinen, S.; Valkokari, P. Unlocking Circular Business: A Framework of Barriers and Drivers. J. Clean. Prod. 2019, 212, 90–98. [Google Scholar] [CrossRef]

- Feng, Y.; Lai, K.-H.; Zhu, Q. Green Supply Chain Innovation: Emergence, Adoption, and Challenges. Int. J. Prod. Econ. 2022, 248, 108497. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing Relations between Circular Economy and Industry 4.0: A Systematic Literature Review. Int. J. Prod. Res. 2020, 58, 1662–1687. [Google Scholar] [CrossRef]

- Yousefi, S.; Mohamadpour Tosarkani, B. An Analytical Approach for Evaluating the Impact of Blockchain Technology on Sustainable Supply Chain Performance. Int. J. Prod. Econ. 2022, 246, 108429. [Google Scholar] [CrossRef]

- Kusi-Sarpong, S.; Orji, I.J.; Gupta, H.; Kunc, M. Risks Associated with the Implementation of Big Data Analytics in Sustainable Supply Chains. Omega 2021, 105, 102502. [Google Scholar] [CrossRef]

- Mangla, S.K.; Raut, R.; Narwane, V.S.; Zhang, Z. Mediating Effect of Big Data Analytics on Project Performance of Small and Medium Enterprises. J. Enterp. Inf. Manag. 2020, 34, 168–198. [Google Scholar] [CrossRef]

- Nozari, H.; Fallah, M.; Kazemipoor, H.; Najafi, S.E. Big Data Analysis of IoT-Based Supply Chain Management Considering FMCG Industries. Bus. Inform. 2021, 15, 78–96. [Google Scholar] [CrossRef]

- Yang, M.; Fu, M.; Zhang, Z. The Adoption of Digital Technologies in Supply Chains: Drivers, Process and Impact. Technol. Forecast. Soc. Change 2021, 169, 120795. [Google Scholar] [CrossRef]

- AlNuaimi, B.K.; Khan, M.; Ajmal, M.M. The Role of Big Data Analytics Capabilities in Greening E-Procurement: A Higher Order PLS-SEM Analysis. Technol. Forecast. Soc. Change 2021, 169, 120808. [Google Scholar] [CrossRef]

- Gholizadeh, H.; Fazlollahtabar, H.; Khalilzadeh, M. A Robust Fuzzy Stochastic Programming for Sustainable Procurement and Logistics under Hybrid Uncertainty Using Big Data. J. Clean. Prod. 2020, 258, 120640. [Google Scholar] [CrossRef]

- Nicoletti, B. The Future: Procurement 4.0. In Agile Procurement: Volume II: Designing and Implementing a Digital Transformation; Nicoletti, B., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 189–230. ISBN 978-3-319-61085-6. [Google Scholar]

- Härer, F. Decentralized Business Process Modeling and Instance Tracking Secured by a Blockchain. In Proceedings of the 26th European Conference on Information Systems: Beyond Digitization—Facets of Socio-Technical Change, ECIS 2018, AIS Electronic Library, Portsmouth, UK, 23–28 June 2018. [Google Scholar]

- Khan, S.A.R.; Razzaq, A.; Yu, Z.; Miller, S. Industry 4.0 and Circular Economy Practices: A New Era Business Strategies for Environmental Sustainability. Bus. Strategy Environ. 2021, 30, 4001–4014. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain Technology and Its Relationships to Sustainable Supply Chain Management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Rejeb, A.; Sule, E.; Keogh, J. Exploring New Technologies in Procurement. Transp. Logist. Int. J. 2018, 18, 76–86. [Google Scholar]

- Kshetri, N. Blockchain Systems and Ethical Sourcing in the Mineral and Metal Industry: A Multiple Case Study. Int. J. Logist. Manag. 2022, 33, 1–27. [Google Scholar] [CrossRef]

- Dal Mas, F.; Dicuonzo, G.; Massaro, M.; Dell’Atti, V. Smart Contracts to Enable Sustainable Business Models. A Case Study. Manag. Decis. 2020, 58, 1601–1619. [Google Scholar] [CrossRef]

- Sava, N.-A.; Dragoș, D. The legal regime of smart contracts in public procurement. Transylv. Rev. Adm. Sci. 2022, 2022, 99–112. [Google Scholar] [CrossRef]

- Yevu, S.K.; Yu, A.T.W.; Darko, A. Digitalization of Construction Supply Chain and Procurement in the Built Environment: Emerging Technologies and Opportunities for Sustainable Processes. J. Clean. Prod. 2021, 322, 129093. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K. Blockchain and Supply Chain Sustainability [Blockchain i Zrównoważoność Łańcucha Dostaw]. Logforum 2020, 16, 363–372. [Google Scholar] [CrossRef]

- Tiscini, R.; Testarmata, S.; Ciaburri, M.; Ferrari, E. The Blockchain as a Sustainable Business Model Innovation. Manag. Decis. 2020, 58, 1621–1642. [Google Scholar] [CrossRef]

- Parry, G.C.; Brax, S.A.; Maull, R.S.; Ng, I.C.L. Operationalising IoT for Reverse Supply: The Development of Use-Visibility Measures. Supply Chain Manag. 2016, 21, 228–244. [Google Scholar] [CrossRef]

- De Souza, M.; Pereira, G.M.; Lopes de Sousa Jabbour, A.B.; Chiappetta Jabbour, C.J.; Trento, L.R.; Borchardt, M.; Zvirtes, L. A Digitally Enabled Circular Economy for Mitigating Food Waste: Understanding Innovative Marketing Strategies in the Context of an Emerging Economy. Technol. Forecast. Soc. Change 2021, 173, 121062. [Google Scholar] [CrossRef]

- Fang, C.; Liu, X.; Pei, J.; Fan, W.; Pardalos, P.M. Optimal Production Planning in a Hybrid Manufacturing and Recovering System Based on the Internet of Things with Closed Loop Supply Chains. Oper. Res. 2016, 16, 543–577. [Google Scholar] [CrossRef]

- Abideen, A.Z.; Mohamad, F.B.; Fernando, Y. Lean Simulations in Production and Operations Management—A Systematic Literature Review and Bibliometric Analysis. J. Model. Manag. 2020, 16, 623–650. [Google Scholar] [CrossRef]

- Legenvre, H.; Henke, M.; Ruile, H. Making Sense of the Impact of the Internet of Things on Purchasing and Supply Management:A Tension Perspective. J. Purch. Supply Manag. 2020, 26, 100596. [Google Scholar] [CrossRef]

- Alvarez-Palau, E.J.; Calvet-Liñán, L.; Viu-Roig, M.; Gandouz, M.; Juan, A.A. Economic Profitability of Last-Mile Food Delivery Services: Lessons from Barcelona. Res. Transp. Bus. Manag. 2021, 100659. [Google Scholar] [CrossRef]

- Lerman, L.V.; Benitez, G.B.; Müller, J.M.; de Sousa, P.R.; Frank, A.G. Smart Green Supply Chain Management: A Configurational Approach to Enhance Green Performance through Digital Transformation. Supply Chain Manag. 2022, 27, 147–176. [Google Scholar] [CrossRef]

- Tang, Z.W.; Ng, S.T.; Skitmore, M. Influence of Procurement Systems to the Success of Sustainable Buildings. J. Clean. Prod. 2019, 218, 1007–1030. [Google Scholar] [CrossRef]

- Gautam, S.; LeBel, L.; Beaudoin, D. Agility Capabilities in Wood Procurement Systems: A Literature Synthesis. Int. J. For. Eng. 2013, 24, 216–232. [Google Scholar] [CrossRef]

- Muhammad, M.S.; Kerbache, L.; Elomri, A. Potential of Additive Manufacturing for Upstream Automotive Supply Chains. Supply Chain Forum Int. J. 2022, 23, 1–19. [Google Scholar] [CrossRef]

- Garmulewicz, A.; Holweg, M.; Veldhuis, H.; Yang, A. Disruptive Technology as an Enabler of the Circular Economy: What Potential Does 3D Printing Hold? Calif. Manage. Rev. 2018, 60, 112–132. [Google Scholar] [CrossRef]

- Sun, L.; Zhao, L. Envisioning the Era of 3D Printing: A Conceptual Model for the Fashion Industry. Fash. Text. 2017, 4, 1–16. [Google Scholar] [CrossRef]