Direct Digital Manufacturing of a Customized Face Mask

Abstract

:1. Introduction

2. Previous Work

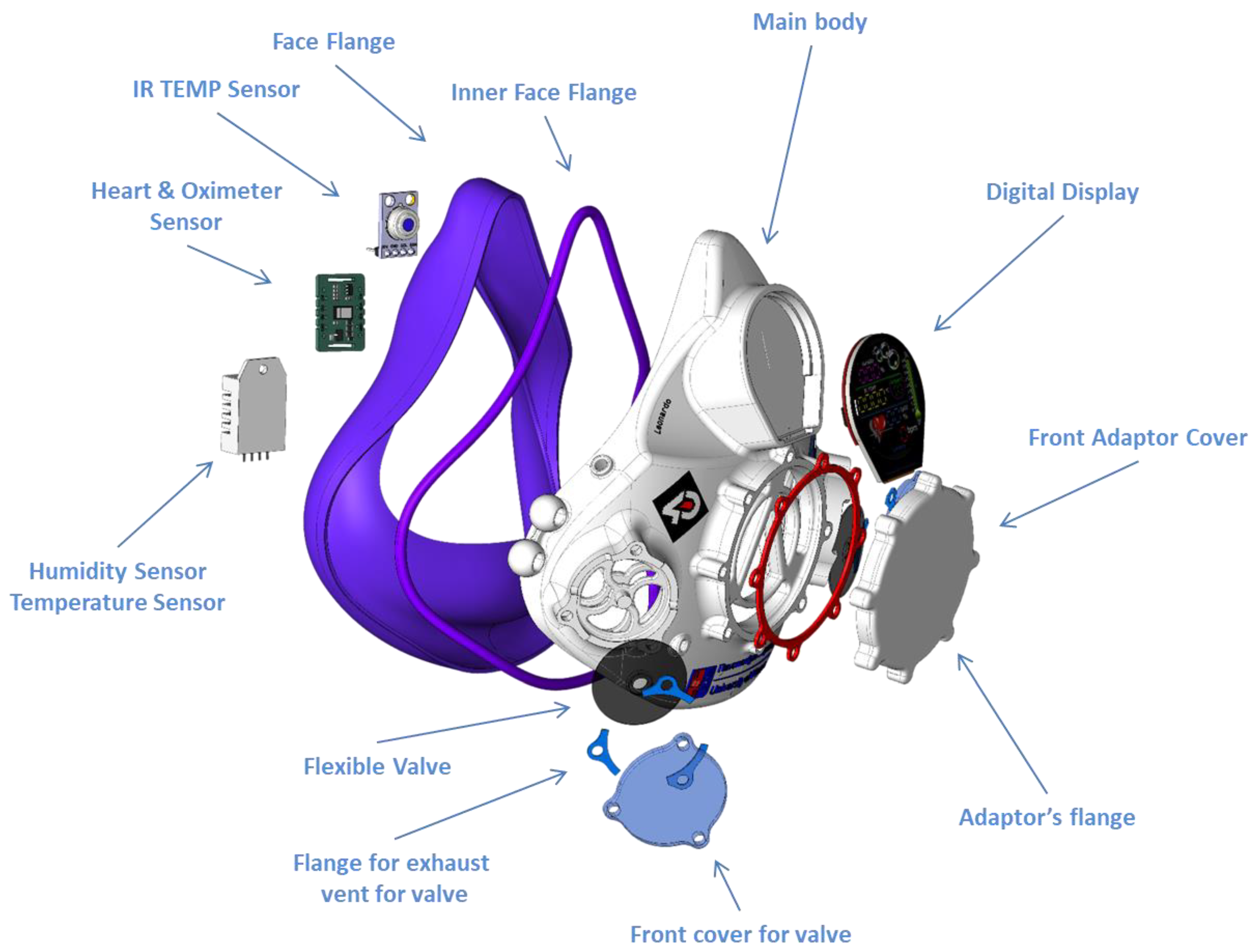

3. Mask Design Features and Fabrication Process

- The face mask must cover the area of the nose and the mouth,

- The best possible fitting between the mask and the facial geometry should be achieved,

- The mask must be easy to use and comfortable in breathing,

- Non-allergenic materials must be used, and

- The mask must have the highest possible filtering capacity to achieve the required protection level.

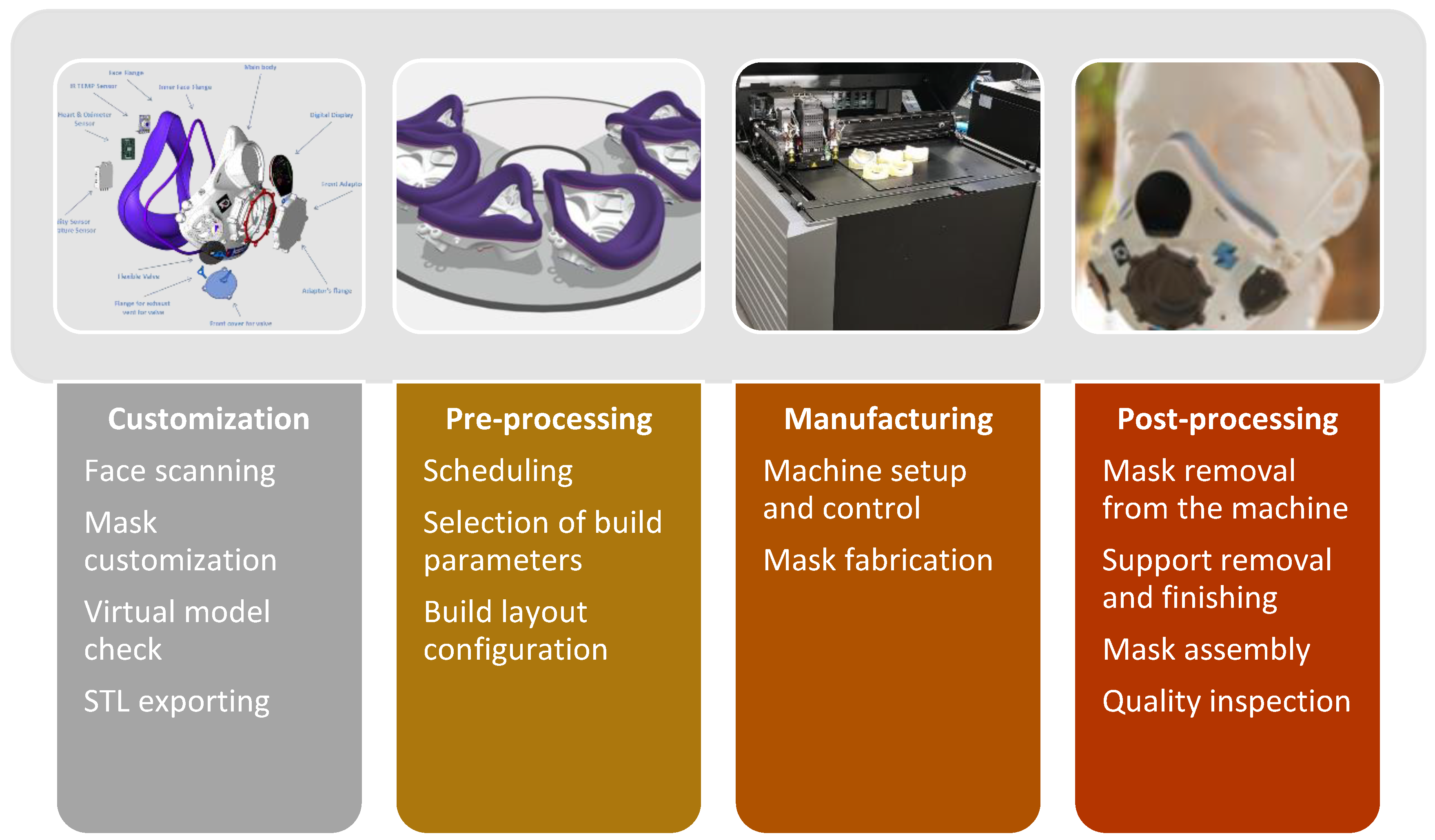

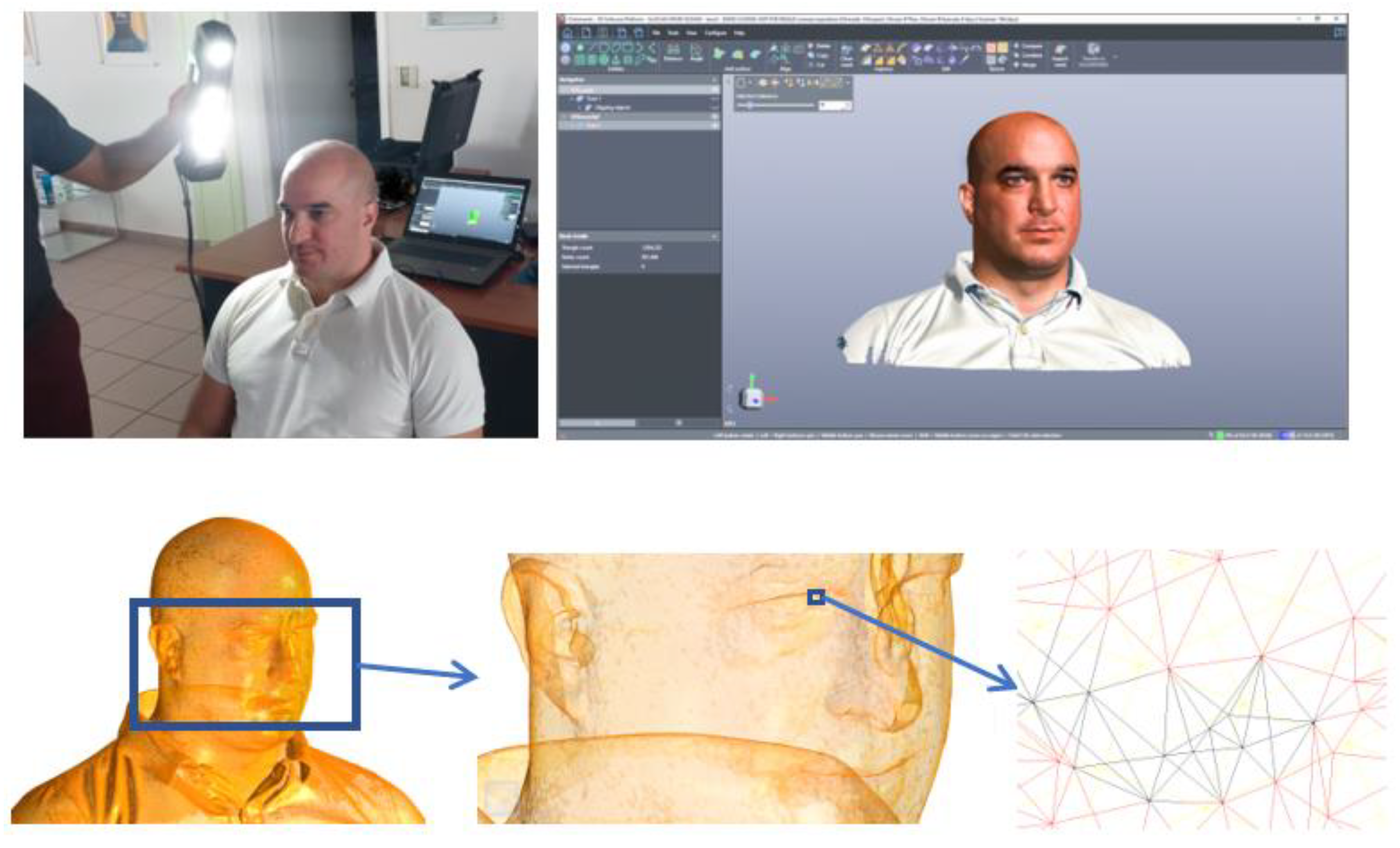

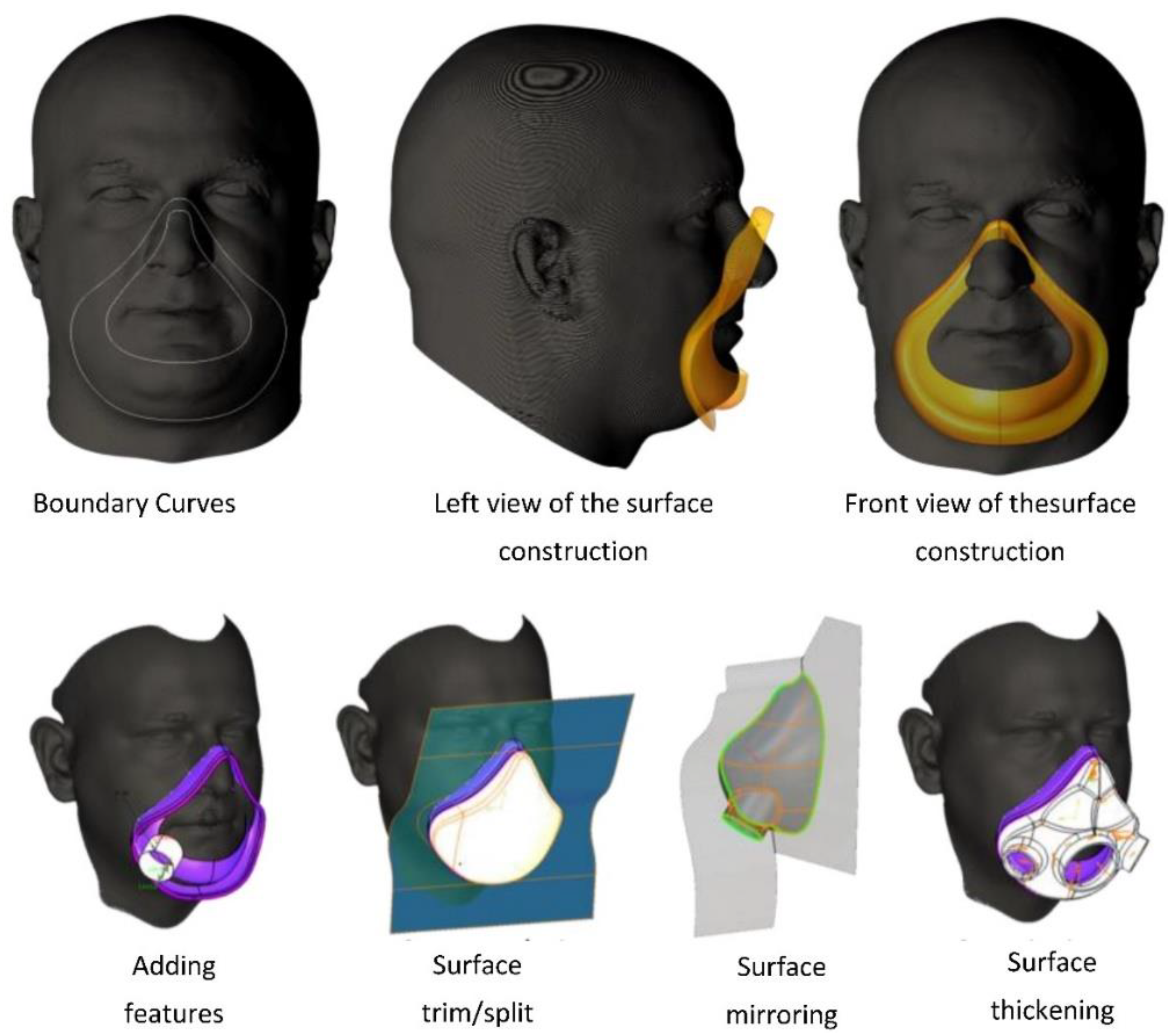

3.1. Design and Customization Phase

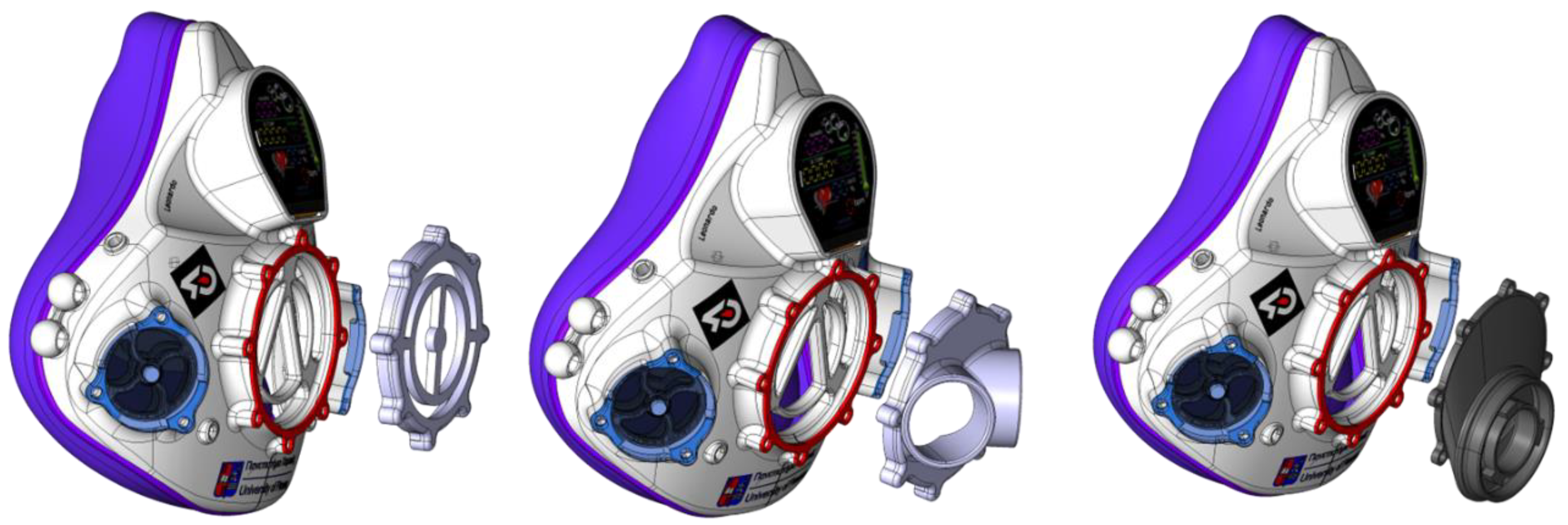

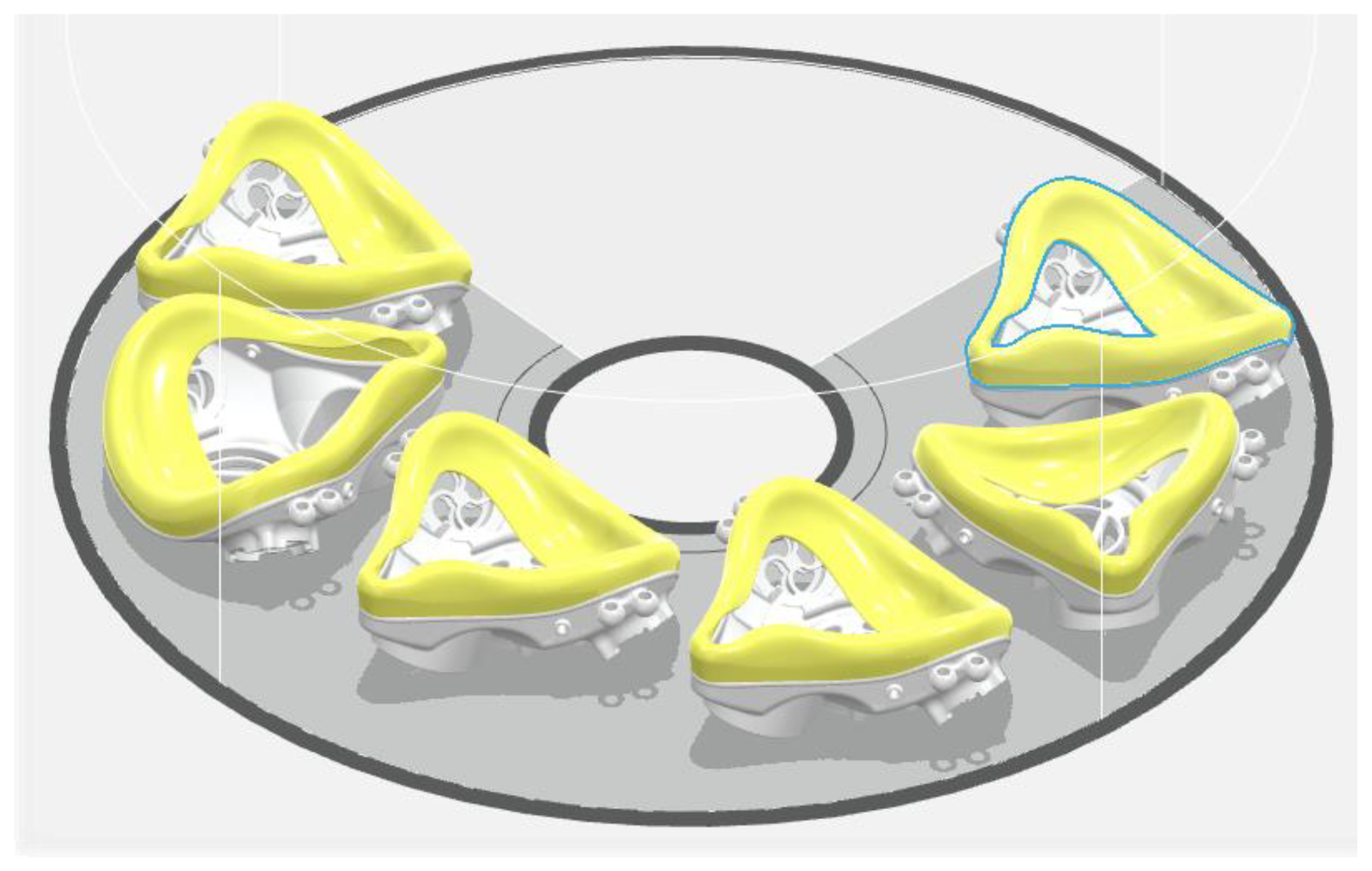

3.2. Process Planning and Fabrication

3.3. Post-Processing and Assembly

4. Throughput, Cost and Facilities Analysis

4.1. Throughput Analysis

4.2. Cost Analysis

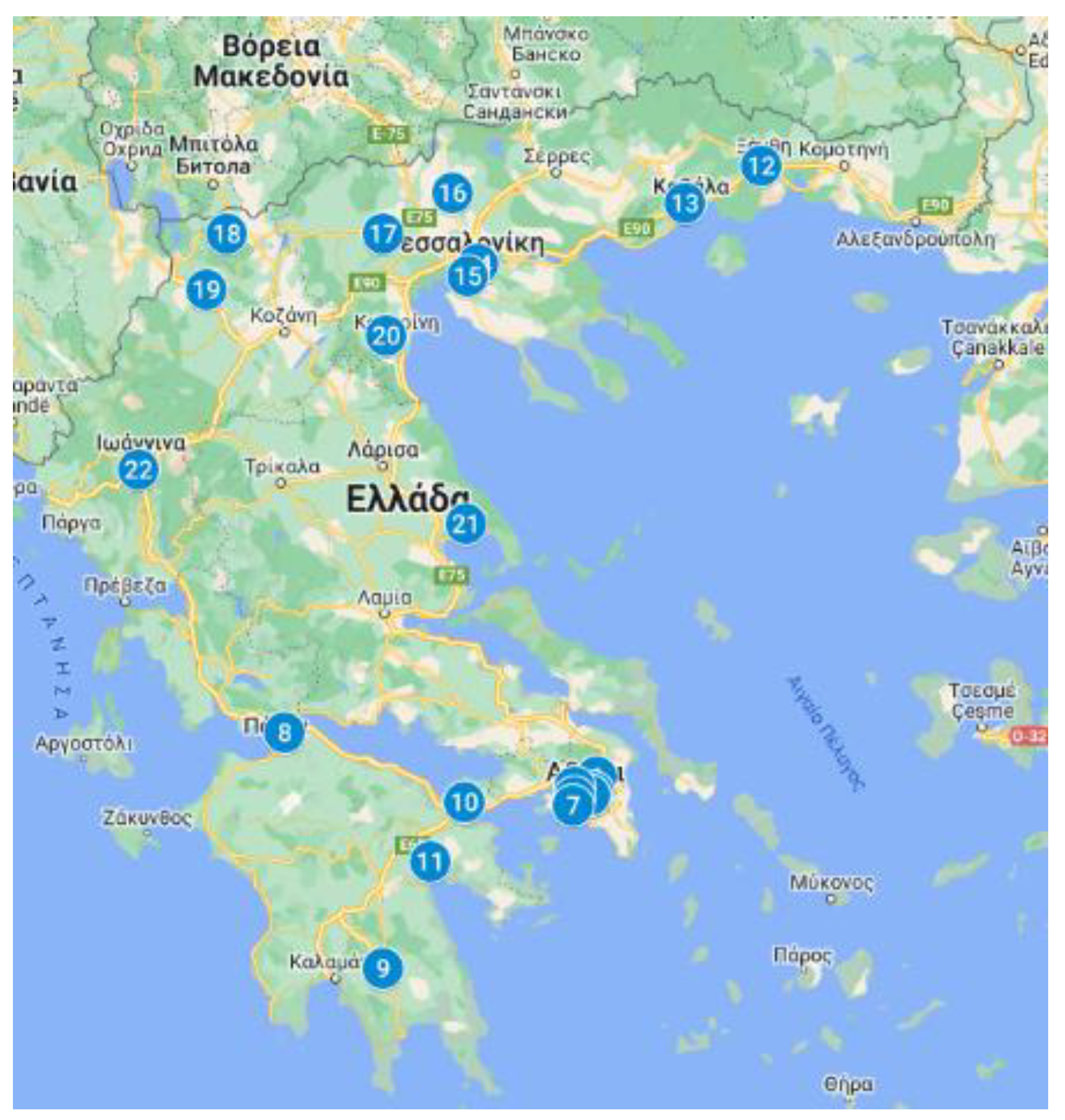

4.3. Facility Analysis

5. Discussion

6. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Levy, G.N.; Schindel, R.; Kruth, J.P. Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann. 2003, 52, 589–609. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Development of Additive Manufacturing Technology. In Additive Manufacturing Technologies, 2nd ed.; Springer: New York, NY, USA, 2015; pp. 19–42. [Google Scholar]

- Chen, D.; Heyer, S.; Ibbotson, S.; Salonitis, K.; Steingrímsson, J.G.; Thiede, S. Direct digital manufacturing: Definition, evolution, and sustainability implications. J. Clean. Prod. 2015, 107, 615–625. [Google Scholar] [CrossRef]

- Cerdas, F.; Juraschek, M.; Thiede, S.; Herrmann, C. Life cycle assessment of 3D printed products in a distributed manufacturing system. J. Ind. Ecol. 2017, 21, S80–S93. [Google Scholar] [CrossRef]

- Manero, A.; Smith, P.; Koontz, A.; Dombrowski, M.; Sparkman, J.; Courbin, D.; Chi, A. Leveraging 3D printing capacity in times of crisis: Recommendations for COVID-19 distributed manufacturing for medical equipment rapid response. Int. J. Environ. Res. Public Health 2020, 17, 4634. [Google Scholar] [CrossRef] [PubMed]

- Wan, J.; Cai, H.; Zhou, K. Industrie 4.0: Enabling technologies. In Proceedings of the 2015 International Conference on Intelligent Computing and Internet of Things, Harbin, China, 17–18 January 2015. [Google Scholar]

- Rauch, E.; Dallasega, P.; Matt, D.T. Distributed manufacturing network models of smart and agile mini-factories. Int. J. Agil. Syst. Manag. 2017, 10, 185–205. [Google Scholar] [CrossRef]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Attaran, M. Additive Manufacturing: The Most Promising Technology to Alter the Supply Chain and Logistics. J. Serv. Sci. Manag. 2017, 10, 189–205. [Google Scholar] [CrossRef] [Green Version]

- Azarian, M.; Yu, H.; Solvang, W.D. Integrating Additive Manufacturing into a Virtual Industry 4.0 Factory. In Lecture Notes in Electrical Engineering; Wang, Y., Martinsen, K., Yu, T., Wang, K., Eds.; Springer: Singapore, 2021; Volume 737, pp. 587–594. [Google Scholar]

- Mellor, S.; Hao, L.; Zhang, D. Additive manufacturing: A framework for implementation. Int. J. Prod. Econ. 2014, 149, 194–201. [Google Scholar] [CrossRef] [Green Version]

- Gaub, H. Customization of mass-produced parts by combining injection molding and additive manufacturing with Industry 4.0 technologies. Reinf. Plast. 2016, 60, 401–404. [Google Scholar] [CrossRef]

- Srinivasan, R.; Giannikas, V.; McFarlane, D.; Thorne, A. Customising with 3D printing: The role of intelligent control. Comput. Ind. 2018, 103, 38–46. [Google Scholar] [CrossRef]

- Kreiger, M.; Pearce, J.M. Environmental life cycle analysis of distributed three-dimensional printing and conventional manufacturing of polymer products. ACS Sustain. Chem. Eng. 2013, 1, 1511–1519. [Google Scholar] [CrossRef]

- Laskurain-Iturbe, I.; Arana-Landín, G.; Landeta-Manzano, B.; Uriarte-Gallastegi, N. Exploring the influence of industry 4.0 technologies on the circular economy. J. Clean. Prod. 2021, 321, 128944. [Google Scholar] [CrossRef]

- Hettiarachchi, B.D.; Brandenburg, M.; Seuring, S. Connecting additive manufacturing to circular economy implementation strategies: Links, contingencies and causal loops. Int. J. Prod. Econ. 2022, 246, 108414. [Google Scholar] [CrossRef]

- Wohlers, T.; Tim Caffrey, T. 3D Printing and Additive Manufacturing State of the Industry; Wohlers Associates, Inc.: Fort Collins, CO, USA, 2014. [Google Scholar]

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3-D printing: Creating a map of additive manufacturing products and services. Addit. Manuf. 2014, 1, 64–76. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Froes, F., Boyer, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar]

- Simons, M. Additive manufacturing—a revolution in progress? Insights from a multiple case study. Int. J. Adv. Manuf. Technol. 2018, 96, 735–749. [Google Scholar] [CrossRef]

- Kretzschmar, N.; Chekurov, S.; Salmi, M.; Tuomi, J. Evaluating the readiness level of additively manufactured digital spare parts: An industrial perspective. Appl. Sci. 2018, 8, 1837. [Google Scholar] [CrossRef] [Green Version]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- Eyers, D.R.; Potter, A.T. Industrial Additive Manufacturing: A manufacturing systems perspective. Comput. Ind. 2017, 92, 208–218. [Google Scholar] [CrossRef]

- Salmi, M.; Akmal, J.S.; Pei, E.; Wolff, J.; Jaribion, A.; Khajavi, S.H. 3D printing in COVID-19: Productivity estimation of the most promising open source solutions in emergency situations. Appl. Sci. 2020, 10, 4004. [Google Scholar] [CrossRef]

- Durão, L.F.C.; Christ, A.; Anderl, R.; Schützer, K.; Zancul, E. Distributed manufacturing of spare parts based on additive manufacturing: Use cases and technical aspects. Procedia CIRP 2016, 57, 704–709. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Holmström, J.; Partanen, J. Additive manufacturing in the spare parts supply chain: Hub configuration and technology maturity. Rapid Prototyp. J. 2018, 24, 1178–1192. [Google Scholar] [CrossRef] [Green Version]

- Kostidi, E.; Nikitakos, N.; Progoulakis, I. Additive Manufacturing and Maritime Spare Parts: Benefits and Obstacles for the End-Users. J. Mar. Sci. Eng. 2021, 9, 895. [Google Scholar] [CrossRef]

- Rupp, M.; Buck, M.; Klink, R.; Merkel, M.; Harrison, D.K. Additive manufacturing of steel for digital spare parts–A perspective on carbon emissions for decentral production. Clean. Environ. Syst. 2022, 4, 100069. [Google Scholar] [CrossRef]

- González-Varona, J.M.; Poza, D.; Acebes, F.; Villafáñez, F.; Pajares, J.; López-Paredes, A. New business models for sustainable spare parts logistics: A case study. Sustainability 2020, 12, 3071. [Google Scholar] [CrossRef] [Green Version]

- Ballardini, R.M.; Ituarte, I.F.; Pei, E. Printing spare parts through additive manufacturing: Legal and digital business challenges. J. Manuf. Technol. Manag. 2018, 29, 958–982. [Google Scholar] [CrossRef] [Green Version]

- Heinen, J.J.; Hoberg, K. Assessing the potential of additive manufacturing for the provision of spare parts. J. Oper. Manag. 2019, 65, 810–826. [Google Scholar] [CrossRef] [Green Version]

- Eyers, D.R.; Potter, A.T.; Gosling, J.; Naim, M.M. The flexibility of industrial additive manufacturing systems. Int. J. Oper. Prod. Manag. 2018, 38, 2313–2343. [Google Scholar] [CrossRef] [Green Version]

- Basak, S.; Baumers, M.; Holweg, M.; Hague, R.; Tuck, C. Reducing production losses in additive manufacturing using overall equipment effectiveness. Addit. Manuf. 2022, 56, 102904. [Google Scholar] [CrossRef]

- Achillas, C.; Aidonis, D.; Iakovou, E.; Thymianidis, M.; Tzetzis, D. A methodological framework for the inclusion of modern additive manufacturing into the production portfolio of a focused factory. J. Manuf. Syst. 2015, 37, 328–339. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P.; Papacharalampopoulos, A.; Bikas, H. Addressing the challenges for the industrial application of additive manufacturing: Towards a hybrid solution. Int. J. Lightweight Mater. Manuf. 2018, 1, 157–168. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Design for additive manufacturing. In Additive Manufacturing Technologies, 2nd ed.; Springer: New York, NY, USA, 2015; pp. 399–435. [Google Scholar]

- Doubrovski, Z.; Verlinden, J.C.; Geraedts, J.M.P. Optimal design for additive manufacturing: Opportunities and challenges. In Proceedings of the 16th Design for Manufacturing and the Life Cycle Conference, Washington, DC, USA, 28–31 August 2011; ASME: New York, NY, USA; pp. 635–646. [Google Scholar]

- Yang, S.; Zhao, Y.F. Additive manufacturing-enabled design theory and methodology: A critical review. Int. J. Adv. Manuf. Technol. 2015, 80, 327–342. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Wiberg, A.; Persson, J.; Ölvander, J. Design for additive manufacturing–a review of available design methods and software. Rapid Prototyp. J. 2019, 25, 1080–1094. [Google Scholar] [CrossRef] [Green Version]

- Plocher, J.; Panesar, A. Review on design and structural optimisation in additive manufacturing: Towards next-generation lightweight structures. Mater. Des. 2019, 183, 108164. [Google Scholar] [CrossRef]

- Alfaify, A.; Saleh, M.; Abdullah, F.M.; Al-Ahmari, A.M. Design for additive manufacturing: A systematic review. Sustainability 2020, 12, 7936. [Google Scholar] [CrossRef]

- Strong, D.; Kay, M.; Conner, B.; Wakefield, T.; Manogharan, G. Hybrid manufacturing–integrating traditional manufacturers with additive manufacturing (AM) supply chain. Addit. Manuf. 2018, 21, 159–173. [Google Scholar] [CrossRef]

- Strong, D.; Kay, M.; Conner, B.; Wakefield, T.; Manogharan, G. Hybrid manufacturing—Locating AM hubs using a two-stage facility location approach. Addit. Manuf. 2019, 25, 469–476. [Google Scholar] [CrossRef]

- Verboeket, V.; Khajavi, S.H.; Krikke, H.; Salmi, M.; Holmström, J. Additive manufacturing for localized medical parts production: A case study. IEEE Access 2021, 9, 25818–25834. [Google Scholar] [CrossRef]

- Emelogu, A.; Marufuzzaman, M.; Thompson, S.M.; Shamsaei, N.; Bian, L. Additive manufacturing of biomedical implants: A feasibility assessment via supply-chain cost analysis. Addit. Manuf. 2016, 11, 97–113. [Google Scholar] [CrossRef]

- Emelogu, A.; Chowdhury, S.; Marufuzzaman, M.; Bian, L. Distributed or centralized? A novel supply chain configuration of additively manufactured biomedical implants for southeastern US States. CIRP J. Manuf. Sci. Technol. 2019, 24, 17–34. [Google Scholar] [CrossRef]

- Chowdhury, S.; Francis, J.; Marufuzzaman, M.; Bian, L. Supply chain cost analysis for additively manufactured biomedical implants. Int. J. Syst. Sci. Oper. Logist. 2020, 7, 275–290. [Google Scholar] [CrossRef]

- Chowdhury, S.; Shahvari, O.; Marufuzzaman, M.; Francis, J.; Bian, L. Sustainable design of on-demand supply chain network for additive manufacturing. IISE Trans. 2019, 51, 744–765. [Google Scholar] [CrossRef]

- Rinaldi, M.; Caterino, M.; Fera, M.; Manco, P.; Macchiaroli, R. Technology selection in green supply chains-the effects of additive and traditional manufacturing. J. Clean. Prod. 2021, 282, 124554. [Google Scholar] [CrossRef]

- Jimo, A.; Braziotis, C.; Rogers, H.; Pawar, K. Additive manufacturing: A framework for supply chain configuration. International J. Prod. Econ. 2022, 253, 108592. [Google Scholar] [CrossRef]

- Singh, S.; Prakash, C.; Ramakrishna, S. Three-dimensional printing in the fight against novel virus COVID-19: Technology helping society during an infectious disease pandemic. Technol. Soc. 2020, 62, 101305. [Google Scholar] [CrossRef] [PubMed]

- Advincula, R.C.; Dizon, J.R.C.; Chen, Q.; Niu, I.; Chung, J.; Kilpatrick, L.; Newman, R. Additive manufacturing for COVID-19: Devices, materials, prospects, and challenges. MRS Commun. 2020, 10, 413–427. [Google Scholar] [CrossRef] [PubMed]

- Choong, Y.Y.C.; Tan, H.W.; Patel, D.C.; Choong, W.T.N.; Chen, C.H.; Low, H.Y.; Tan, M.J.; Patel, C.D.; Chua, C.K. The global rise of 3D printing during the COVID-19 pandemic. Nat. Rev. Mater. 2020, 5, 637–639. [Google Scholar] [CrossRef]

- Larrañeta, E.; Dominguez-Robles, J.; Lamprou, D.A. Additive manufacturing can assist in the fight against COVID-19 and other pandemics and impact on the global supply chain. 3d Print. Addit. Manuf. 2020, 7, 100–103. [Google Scholar] [CrossRef]

- Vordos, N.; Gkika, D.A.; Maliaris, G.; Tilkeridis, K.E.; Antoniou, A.; Bandekas, D.V.; Mitropoulos, A.C. How 3D printing and social media tackles the PPE shortage during COVID-19 pandemic. Saf. Sci. 2020, 130, 104870. [Google Scholar] [CrossRef] [PubMed]

- AMCPR—Assessing the Role of Additive Manufacturing in Support of the U.S. COVID-19 Response. Available online: https://www.americamakes.us/wp-content/uploads/2021/12/Full-Report-Assessing-the-Role-of-AM-in-Support-of-the-US-COVID-19-Response.pdf (accessed on 27 July 2022).

- Colorado, H.A.; Mendoza, D.E.; Lin, H.T.; Gutierrez-Velasquez, E. Additive manufacturing against the Covid-19 pandemic: A technological model for the adaptability and networking. J. Mater. Res. Technol. 2021, 16, 1150. [Google Scholar] [CrossRef] [PubMed]

- Davies, S.; O’Connor, D.; Griffiths, L. The Latest 3D Printing Efforts against COVID-19. Available online: https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/live-blog-how-the-3d-printing-industry-fighting-covid-19/ (accessed on 25 July 2022).

- Equbal, A.; Akhter, S.; Sood, A.K.; Equbal, I. The usefulness of additive manufacturing (AM) in COVID-19. Ann. 3d Print. Med. 2021, 2, 100013. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Nachtane, M.; Goda, I.; Qureshi, Y.; Benyahia, H. Additive manufacturing in fighting against novel coronavirus COVID-19. Int. J. Adv. Manuf. Technol. 2020, 110, 2913–2927. [Google Scholar] [CrossRef]

- Naghshineh, B.; Carvalho, H. The implications of additive manufacturing technology adoption for supply chain resilience: A systematic search and review. Int. J. Prod. Econ. 2021, 247, 108387. [Google Scholar] [CrossRef]

- Bharti, N.; Singh, S. COVID-19: The use of 3D printing to address PPE shortage during a pandemic—A safety perspective. ACS Chem. Health Saf. 2020, 27.6, 335–340. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.M. Distributed manufacturing of open source medical hardware for pandemics. J. Manuf. Mater. Processing 2020, 4, 49. [Google Scholar] [CrossRef]

- Clifton, W.; Damon, A.; Martin, A.K. Considerations and cautions for three-dimensional-printed personal protective equipment in the COVID-19 crisis. 3d Print. Addit. Manuf. 2020, 7, 97–99. [Google Scholar] [CrossRef]

- Novak, J.I.; Loy, J. A quantitative analysis of 3D printed face shields and masks during COVID-19. Emerald Open Res. 2020, 2, 42. [Google Scholar] [CrossRef]

- Amin, D.; Nguyen, N.; Roser, S.M.; Abramowicz, S. 3D printing of face shields during COVID-19 pandemic: A technical note. J. Oral Maxillofac. Surg. 2020, 78, 1275–1278. [Google Scholar] [CrossRef] [PubMed]

- Armijo, P.R.; Markin, N.W.; Nguyen, S.; Ho, D.H.; Horseman, T.S.; Lisco, S.J.; Schiller, A.M. 3D printing of face shields to meet the immediate need for PPE in an anesthesiology department during the COVID-19 pandemic. Am. J. Infect. Control. 2021, 49, 302–308. [Google Scholar] [CrossRef] [PubMed]

- Lemarteleur, V.; Fouquet, V.; Le Goff, S.; Tapie, L.; Morenton, P.; Benoit, A.; Vennat, E.; Zamansky, B.; Guilbert, T.; Depil-Duval, A.; et al. 3D-printed protected face shields for health care workers in Covid-19 pandemic. Am. J. Infect. Control. 2021, 49, 389–391. [Google Scholar] [CrossRef]

- Neijhoft, J.; Viertmann, T.; Meier, S.; Söhling, N.; Wicker, S.; Henrich, D.; Marzi, I. Manufacturing and supply of face shields in hospital operation in case of unclear and confirmed COVID-19 infection status of patients. Eur. J. Trauma Emerg. Surg. 2020, 46, 743–745. [Google Scholar] [CrossRef]

- Celik, H.K.; Kose, O.; Ulmeanu, M.E.; Rennie, A.E.; Abram, T.N.; Akinci, I. Design and additive manufacturing of medical face shield for healthcare workers battling coronavirus (COVID-19). Int. J. Bioprinting 2020, 6, 286. [Google Scholar] [CrossRef] [PubMed]

- Lindsley, W.G.; Noti, J.D.; Blachere, F.M.; Szalajda, J.V.; Beezhold, D.H. Efficacy of face shields against cough aerosol droplets from a cough simulator. J. Occup. Environ. Hyg. 2014, 11, 509–518. [Google Scholar] [CrossRef] [PubMed]

- Salimnia, H.; Meyer, M.P.; Mitchell, R.; Fairfax, M.R.; Gundel, A.; Guru, N.; Chopra, T. A laboratory model demonstrating the protective effects of surgical masks, face shields, and a combination of both in a speaking simulation. Am. J. Infect. Control. 2021, 49, 409–415. [Google Scholar] [CrossRef] [PubMed]

- Swennen, G.R.; Pottel, L.; Haers, P.E. Custom-made 3D-printed face masks in case of pandemic crisis situations with a lack of commercially available FFP2/3 masks. Int. J. Oral Maxillofac. Surg. 2020, 49, 673–677. [Google Scholar] [CrossRef] [PubMed]

- Cai, M.; Li, H.; Shen, S.; Wang, Y.; Yang, Q. Customized design and 3D printing of face seal for an N95 filtering facepiece respirator. J. Occup. Environ. Hyg. 2018, 15, 226–234. [Google Scholar] [CrossRef]

- Piombino, P.; Committeri, U.; Norino, G.; Vaira, L.A.; Troise, S.; Maglitto, F.; Mariniello, D.; De Riu, G.; Califano, L. Facing COVID-19 pandemic: Development of custom-made face mask with rapid prototyping system. J. Infect. Dev. Countries 2021, 15, 51–57. [Google Scholar] [CrossRef]

- Thomas, C.N.; Schroder, L.K.; Cole, P.A. Ten days to implementation of 3D-printed masks for a level-I orthopaedic trauma practice during the COVID-19 pandemic. JBJS 2020, 102, e95. [Google Scholar] [CrossRef]

- Tino, R.; Moore, R.; Antoline, S.; Ravi, P.; Wake, N.; Ionita, C.N.; Morris, J.M.; Decker, S.J.; Sheikh, A.; Rybicki, F.J.; et al. COVID-19 and the role of 3D printing in medicine. 3d Print. Med. 2020, 6, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Moretti, F. MY FACE MASK: 3D Printed Face Mask with a Replaceable Filter. Available online: https://www.3dwasp.com/en/3d-printed-mask-from-3d-scanning/ (accessed on 25 July 2022).

- Arezki, A.; Melega, T.; Nussbaum, J. A Mask for All. Available online: https://www.amaskforall.com/index.html (accessed on 25 July 2022).

- Longhitano, G.A.; Nunes, G.B.; Candido, G.; da Silva, J.V.L. The role of 3D printing during COVID-19 pandemic: A review. Prog. Addit. Manuf. 2021, 6, 19–37. [Google Scholar] [CrossRef]

- Gierthmuehlen, M.; Kuhlenkoetter, B.; Parpaley, Y.; Gierthmuehlen, S.; Köhler, D.; Dellweg, D. Evaluation and discussion of handmade face-masks and commercial diving-equipment as personal protection in pandemic scenarios. PLoS ONE 2020, 15, e0237899. [Google Scholar] [CrossRef] [PubMed]

- Bezek, L.B.; Pan, J.; Harb, C.; Zawaski, C.E.; Molla, B.; Kubalak, J.R.; Marr, L.C.; Williams, C.B. Additively manufactured respirators: Quantifying particle transmission and identifying system-level challenges for improving filtration efficiency. J. Manuf. Syst. 2021, 60, 762–773. [Google Scholar] [CrossRef] [PubMed]

- WHO—Mask Use in the Context of COVID-19. Available online: https://www.who.int/publications/i/item/advice-on-the-use-of-masks-in-the-community-during-home-care-and-in-healthcare-settings-in-the-context-of-the-novel-coronavirus-(2019-ncov)-outbreak (accessed on 26 July 2022).

- FDA—3D Printing of Medical Devices, Accessories, Components, and Parts during the COVID-19 Pandemic. Available online: https://www.fda.gov/medical-devices/coronavirus-covid-19-and-medical-devices/3d-printing-medical-devices-accessories-components-and-parts-during-covid-19-pandemic (accessed on 26 July 2022).

- Stratasys—Materials Catalogue, Polyjet Biocompatible Materials. Available online: https://www.stratasys.com/materials/search/biocompatible (accessed on 26 July 2022).

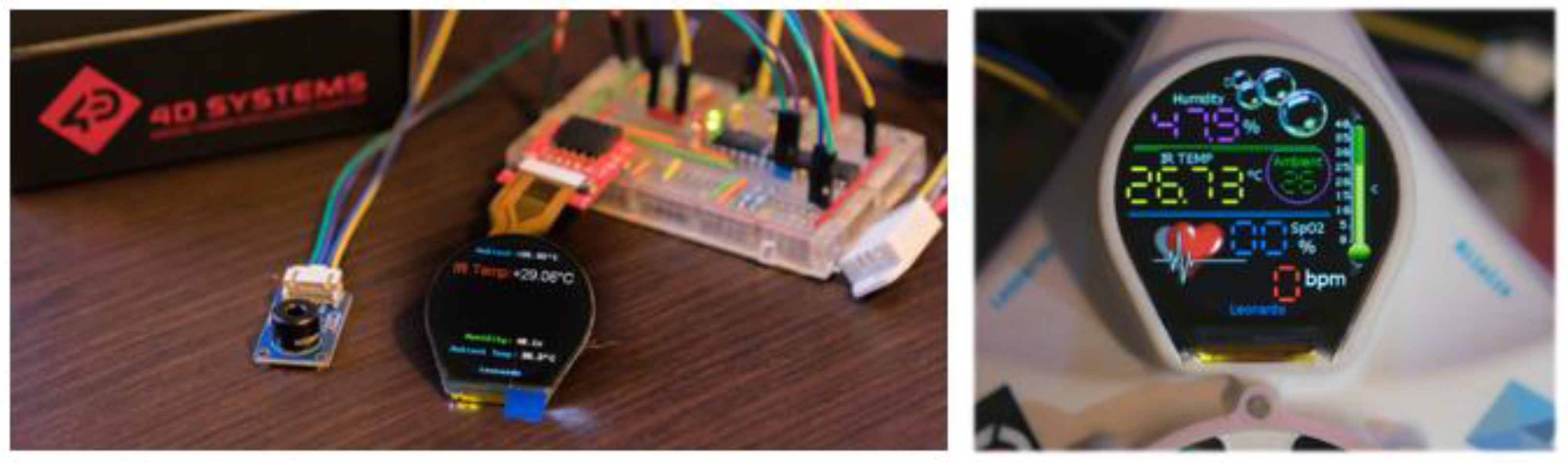

- Vourvoulakis, J.; Bilalis, L. Real-time pulse oximetry extraction using a lightweight algorithm and a task pipeline scheme. In Proceedings of the 10th International Conference on Modern Circuits and Systems Technologies (MOCAST), Thessaloniki, Greece, 5–7 July 2021; IEEE: Piscataway, NJ, USA. [Google Scholar]

- Ruffo, M.; Tuck, C.; Hague, R. Cost estimation for rapid manufacturing-laser sintering production for low to medium volumes. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1417–1427. [Google Scholar] [CrossRef] [Green Version]

- Lindermann, C.; Jahnke, U.; Moi, M.; Koch, R. Analyzing product lifecycle costs for a better understanding of cost drivers in additive manufacturing. In Proceedings of the 2012 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; Beaman, J., Bourell, D., Crawford, R., Marcus, H., Conner Seepersad, C., Eds.; University of Texas at Austin: Austin, TX, USA, 2012; pp. 177–188. [Google Scholar]

- Rickenbacher, L.; Spierings, A.; Wegener, K. An integrated cost-model for selective laser melting (SLM). Rapid Prototyp. J. 2013, 19, 208–214. [Google Scholar] [CrossRef]

- Schröder, M.; Falk, B.; Schmitt, R. Evaluation of cost structures of additive manufacturing processes using a new business model. Procedia CIRP 2015, 30, 311–316. [Google Scholar] [CrossRef] [Green Version]

- Thomas, D.S.; Gilbert, S.W. Costs and cost effectiveness of additive manufacturing. NIST Spec. Publ. 2014, 1176, 12. [Google Scholar]

- Baumers, M.; Dickens, P.; Tuck, C.; Hague, R. The cost of additive manufacturing: Machine productivity, economies of scale and technology-push. Technol. Forecast. Soc. Change 2016, 102, 193–201. [Google Scholar] [CrossRef]

- Charalambis, A.; Davoudinejad, A.; Tosello, G.; Pedersen, D.B. Cost estimation of a specifically designed direct light processing (DLP) additive manufacturing machine for precision printing. In Proceedings of the 17th EUSPEN International Conference & Exhibition, Hannover, Germany, 29 May–2 June 2017; Bosse, H., Denkena, B., Dröder, K., Hoffmeister, H.-W., Eds.; EUSPEN: Hannover, Germany, 2017. [Google Scholar]

- Costabile, G.; Fera, M.; Fruggiero, F.; Lambiase, A.; Pham, D. Cost models of additive manufacturing: A literature review. Int. J. Ind. Eng. Comput. 2017, 8, 263–283. [Google Scholar] [CrossRef]

- Tosello, G.; Charalambis, A.; Kerbache, L.; Mischkot, M.; Pedersen, D.B.; Calaon, M.; Hansen, H.N. Value chain and production cost optimization by integrating additive manufacturing in injection molding process chain. Int. J. Adv. Manuf. Technol. 2019, 100, 783–795. [Google Scholar] [CrossRef] [Green Version]

- Ding, J.; Baumers, M.; Clark, E.A.; Wildman, R.D. The economics of additive manufacturing: Towards a general cost model including process failure. Int. J. Prod. Econ. 2021, 237, 108087. [Google Scholar] [CrossRef]

- Stratasys—J5 series User Guide. Available online: https://support.stratasys.com/SupportCenter/HTML5UserGuides/J5-Series_UG_Jul_2022/Content/3_Topics_Introducing/Electrical%20Specifications.htm?Highlight=power%20consumption (accessed on 25 July 2022).

- Klose, A.; Drexl, A. Facility location models for distribution system design. Eur. J. Oper. Res. 2005, 162, 4–29. [Google Scholar] [CrossRef]

- Melo, M.T.; Nickel, S.; Saldanha-Da-Gama, F. Facility location and supply chain management–A review. Eur. J. Oper. Res. 2009, 196.2, 401–412. [Google Scholar] [CrossRef]

- Ballou, R.H. Business Logistics/Supply Chain Management: Planning, Organizing, and Controlling the Supply Chain, 5th ed.; Pearson: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

- Daskin, M.S.; Maass, K.L. The p-median problem. In Location Science; Laporte, G., Nickel, S., Saldanha da Gama, F., Eds.; Springer: Cham, Switzerland, 2015; pp. 21–45. [Google Scholar]

| Component | Material |

|---|---|

| Face Flange | MED625FLX |

| Inner Flange | MED625FLX |

| Main Body | MED610 |

| Adaptors | MED610 |

| Adaptor for 3M Filter | MED610 |

| Front Valve Cover | MED610 |

| Flexible Valve Leaf | MED625FLX |

| Front adaptor flange | MED625FLX |

| Flange for exhaust vent | MED625FLX |

| Number of Parts per Job | Job Build Time (h) | Build Time per Part (h) | Job Materials Cost (€) | Materials Cost per Part (€) |

|---|---|---|---|---|

| 1 | 23.5 | 23.50 | 101 | 101 |

| 2 | 26 | 13.00 | 164 | 82 |

| 3 | 26 | 8.67 | 225 | 75 |

| 4 | 26 | 6.50 | 288 | 72 |

| 5 | 26 | 5.20 | 340 | 68 |

| 6 | 26 | 4.33 | 384 | 64 |

| System Configurations | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Operational period (years) | 5 | 5 | 5 | 5 | 5 | 5 |

| Number of designers/operators | 1 | 2 | 2 | 3 | 3 | 4 |

| Designers/Operators annual salary (€) | 35,000 | 35,000 | 35,000 | 35,000 | 35,000 | 35,000 |

| Number of MJ machines | 1 | 1 | 2 | 2 | 3 | 3 |

| MJ machine purchase cost (€) | 100,000 | 100,000 | 100,000 | 100,000 | 100,000 | 100,000 |

| MJ machine annual maintenance cost (€) | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 | 10,000 |

| Number of 3D scanners | 1 | 1 | 1 | 1 | 1 | 3 |

| 3D scanner purchase cost (€) | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 |

| Number of CAD systems | 1 | 2 | 2 | 3 | 3 | 4 |

| CAD hardware purchase cost (€) | 2000 | 2000 | 2000 | 2000 | 2000 | 2000 |

| CAD software annual license fee (€) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Masks per designer and day | 5 | 5 | 5 | 5 | 5 | 5 |

| Overhead (%) | 20% | 20% | 20% | 20% | 20% | 20% |

| Parts per job | 6 | 6 | 6 | 6 | 6 | 6 |

| Capacity/Throughput | ||||||

| CAD throughput (parts/year) | 1150 | 2300 | 2300 | 3450 | 3450 | 4600 |

| MJ throughput (parts/year) | 1385 | 1385 | 2770 | 2770 | 4154 | 4154 |

| System capacity | 1150 | 1385 | 2300 | 2770 | 3450 | 4154 |

| System Costs | ||||||

| Total machine cost (€) | 150,000 | 150,000 | 300,000 | 300,000 | 450,000 | 450,000 |

| Total scanner cost (€) | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 | 90,000 |

| Total CAD equipment cost (€) | 7000 | 14,000 | 14,000 | 21,000 | 21,000 | 28,000 |

| Total labor cost (€) | 175,000 | 350,000 | 350,000 | 525,000 | 525,000 | 700,000 |

| Total System Costs | 362,000 | 544,000 | 694,000 | 876,000 | 1,026,000 | 1,268,000 |

| Unit Costs | ||||||

| Machine cost/mask (€) | 26.09 | 21.66 | 26.09 | 21.66 | 26.09 | 21.67 |

| Scanner cost/mask (€) | 5.22 | 4.33 | 2.61 | 2.17 | 1.74 | 4.33 |

| CAD cost/mask (€) | 1.22 | 2.02 | 1.22 | 1.52 | 1.22 | 1.35 |

| Labor cost/mask (€) | 30.43 | 50.54 | 30.43 | 37.91 | 30.43 | 33.70 |

| Material cost/mask (€) | 64.00 | 64.00 | 64.00 | 64.00 | 64.00 | 64.00 |

| Overhead (€) | 25.39 | 28.51 | 24.87 | 25.45 | 24.70 | 25.01 |

| Total cost per mask | 152.35 | 171.07 | 149.22 | 152.70 | 148.17 | 150.06 |

| Hospital | Latitude | Longitude | Weighting Factor |

|---|---|---|---|

| Hospital 1 | 38.07 | 23.81 | 6.86 |

| Hospital 2 | 38.00 | 23.78 | 8.35 |

| Hospital 3 | 37.98 | 23.76 | 5.78 |

| Hospital 4 | 37.98 | 23.76 | 4.84 |

| Hospital 5 | 38.02 | 23.67 | 10.23 |

| Hospital 6 | 37.97 | 23.66 | 7.12 |

| Hospital 7 | 37.93 | 23.65 | 5.49 |

| Hospital 8 | 38.30 | 21.79 | 9.65 |

| Hospital 9 | 37.09 | 22.42 | 1.27 |

| Hospital 10 | 37.94 | 22.95 | 2.14 |

| Hospital 11 | 37.64 | 22.73 | 0.45 |

| Hospital 12 | 41.12 | 24.87 | 2.18 |

| Hospital 13 | 40.94 | 24.38 | 3.80 |

| Hospital 14 | 40.64 | 23.04 | 5.52 |

| Hospital 15 | 40.58 | 22.97 | 3.18 |

| Hospital 16 | 40.99 | 22.87 | 1.82 |

| Hospital 17 | 40.79 | 22.42 | 1.27 |

| Hospital 18 | 40.79 | 21.41 | 1.53 |

| Hospital 19 | 40.51 | 21.28 | 1.40 |

| Hospital 20 | 40.29 | 22.45 | 2.34 |

| Hospital 21 | 39.35 | 22.96 | 2.92 |

| Hospital 22 | 39.62 | 20.84 | 11.86 |

| Number of Facilities | Facility Location | Served Hospitals |

|---|---|---|

| 1 | Hospital 2 | 1–22 |

| 2 | Hospital 2 | 1–11 |

| Hospital 16 | 12–22 | |

| 3 | Hospital 2 | 1–2, 5, 8 |

| Hospital 7 | 3–4, 6–7, 9–11 | |

| Hospital 16 | 12–22 | |

| 4 | Hospital 5 | 1–2, 5 |

| Hospital 7 | 3–4, 6–7, 9–11 | |

| Hospital 22 | 8, 22 | |

| Hospital 16 | 1–4, 6, 9–20 | |

| 5 | Hospital 5 | 1–2, 5 |

| Hospital 7 | 3–4, 6–7, 9–11 | |

| Hospital 8 | 8 | |

| Hospital 16 | 12–21 | |

| Hospital 22 | 22 |

| System Configurations | G | H | I | J |

|---|---|---|---|---|

| Number of manufacturing facilities | 2 | 3 | 4 | 5 |

| Designers | 2 | 4 | 5 | 5 |

| MJ Systems | 2 | 3 | 4 | 5 |

| 3D scanners | 2 | 3 | 4 | 5 |

| CAD systems | 2 | 3 | 4 | 5 |

| Overhead (%) | 20% | 20% | 20% | 20% |

| Parts per job | 3 | 3 | 4 | 4 |

| Capacity/Throughput | ||||

| CAD capacity | 2300 | 4600 | 5750 | 5750 |

| MJ capacity | 2770 | 4154 | 5539 | 6924 |

| System capacity | 2300 | 4154 | 5539 | 5750 |

| Actual throughput | 1385 | 2077 | 3692 | 4615 |

| Spare Capacity | 915 | 2077 | 1847 | 1135 |

| System Costs | ||||

| Total machine cost (€) | 300,000 | 450,000 | 600,000 | 750,000 |

| Total scanner cost (€) | 60,000 | 90,000 | 120,000 | 150,000 |

| Total CAD workstation cost (€) | 14,000 | 21,000 | 28,000 | 35,000 |

| Total labor cost (€) | 350,000 | 700,000 | 875,000 | 875,000 |

| Total System Costs (€) | 724,000 | 1,261,000 | 1,623,000 | 1,810,000 |

| Unit Costs | ||||

| Machine cost/mask (€) | 43.33 | 43.33 | 32.50 | 32.50 |

| Scanner cost/mask (€) | 8.67 | 8.67 | 6.50 | 6.50 |

| CAD cost/mask (€) | 2.02 | 2.02 | 1.52 | 1.52 |

| Labor cost/mask (€) | 50.56 | 67.41 | 47.40 | 37.92 |

| Material cost/mask (€) | 75.00 | 75.00 | 72.00 | 72.00 |

| Overhead (€) | 35.92 | 39.29 | 31.98 | 30.09 |

| Total cost per mask (€) | 215.49 | 235.72 | 191.90 | 180.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bilalis, L.; Canellidis, V.; Papatheodorou, T.; Giannatsis, J. Direct Digital Manufacturing of a Customized Face Mask. J. Manuf. Mater. Process. 2022, 6, 126. https://doi.org/10.3390/jmmp6050126

Bilalis L, Canellidis V, Papatheodorou T, Giannatsis J. Direct Digital Manufacturing of a Customized Face Mask. Journal of Manufacturing and Materials Processing. 2022; 6(5):126. https://doi.org/10.3390/jmmp6050126

Chicago/Turabian StyleBilalis, Leonardos, Vassilios Canellidis, Theodore Papatheodorou, and John Giannatsis. 2022. "Direct Digital Manufacturing of a Customized Face Mask" Journal of Manufacturing and Materials Processing 6, no. 5: 126. https://doi.org/10.3390/jmmp6050126

APA StyleBilalis, L., Canellidis, V., Papatheodorou, T., & Giannatsis, J. (2022). Direct Digital Manufacturing of a Customized Face Mask. Journal of Manufacturing and Materials Processing, 6(5), 126. https://doi.org/10.3390/jmmp6050126