1. Introduction

Lightweight design is becoming increasingly important, especially in the transport and mobility sector, due to the goals of the Green Deal [

1] passed by the European Union. The target is to achieve climate neutrality in Europe by 2050. One aspect of this is to reduce emissions from the transport and mobility sector by 90%. For car manufacturers, in particular, the fleet emission targets will therefore become significantly stricter and from 2025 onwards, the already low emission limits of 95 g CO

2/km for cars are to be further reduced by 15% and from 2030 onwards by 37.5% [

2]. For this reason, high-strength steel and aluminium materials as well as fibre-reinforced plastics are used to reduce vehicle weight through multi-material systems in order to decrease emissions. A challenge in the production of lightweight structures from these materials is conventional joining processes, which reach their process limits due to different mechanical properties and chemical incompatibilities as well as deviating thermal expansion coefficients. For this reason, research is being conducted into innovative and versatile mechanical joining processes [

3], which are able to join dissimilar materials and react to changing process boundary conditions and variations of the joining partners. Pin joining is one process with the potential to join dissimilar metals as well as metals and fibre-reinforced plastics. Pin structures are already being used to strengthen joints between metals and continuous fibre-reinforced plastics [

4]. However, processes such as cold metal transfer (CMT) [

5], metal injection moulding (MIM) [

6], COMELD

TM [

7] or additive manufacturing processes such as powder bed fusion (PBF-LB) [

8] or direct energy deposition (DED) [

9] are used to produce pins on the surfaces of sheet metal components. These processes often have limitations in the area of process speed or maximum component size. For this reason, research effort is put into the production of pin structures by cold extrusion from the sheet metal plane. This offers the advantages that the process can be integrated into existing process chains with little effort, the components have good dimensional accuracy as well as good surface quality, in addition, the material in the forming zone increases in strength due to the strain hardening during the extrusion process. The fundamental feasibility of bulk-forming pins from the sheet metal plane has already been demonstrated by Ghassemali et al. [

10] for copper, Hirota [

11] for aluminium and Kraus et al. [

12] for DC04. Currently, however, only a few works are known that use cold extruded metallic pins for joining dissimilar metals. The general feasibility was demonstrated by Kraus et al. [

13] using DC04 and EN AW-6016. Two different joining strategies are usually investigated in which pins are used for joining. One is the direct pin pressing [

14], where the pin is pressed directly into an unperforated joining partner, causing the pin to be upset inside the joining partner, thus forming an undercut and consequently a form and force-fit joint. On the other hand, caulking is investigated [

13], in which the pin is first inserted through a pre-punched joining partner and subsequently upset on the pin head side, which also results in an undercut and thus in a form and force-fit joint. Due to the requirement that the pin has a greater height than the sheet thickness of the joining partner when caulking, in some cases large punch penetration depths during pin extrusion are necessary in order to achieve the required pin height. This leads to a strong sheet thinning in the forming zone and therefore to a weakening of the sheet material. In previous investigations, this has led to the failure of pin joints under shear load at high penetration depths and low residual sheet thicknesses, not due to the shearing of the pins, but due to the failure of the thinned sheet.

In order to meet the challenge of a limiting compromise between a maximum pin height and still maintaining a sufficient residual sheet thickness, measures have to be investigated to avoid thinning on the one hand and to increase the material available on the other hand. One approach is to provide the required material as a local distribution manufacturer in a prior conducted orbital forming process [

15].

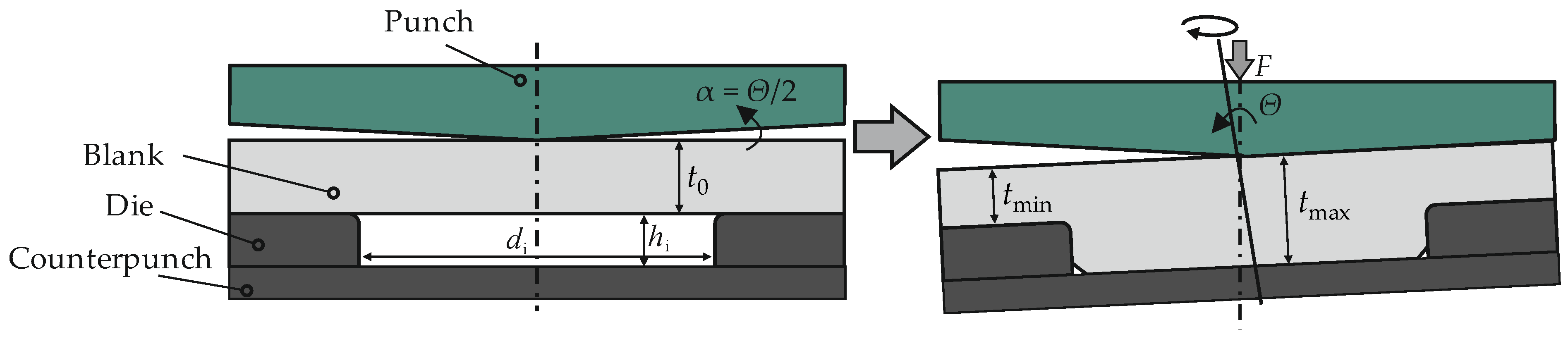

The process of orbital forming is derived from conventional upsetting by tilting one tool component around the angle

Θ [

16], which is typically chosen between 1–2° [

17]. Maximum values of 10° are investigated by Standring [

18]. Consequently, the contact zone between the tool and workpiece is reduced significantly, resulting in reduced required forming forces of 10%, compared to conventional upsetting [

19]. Due to the quasi-rolling movement of the punch, the material is pushed radially outside into the desired cavities, which can be applied either into the punch or the counterpunch or both-sided, depending on the desired geometry [

20]. Due to the radial material flow, a characteristic process effect is a so-called centre thinning, explaining the local thinning in the component centre [

21]. Different measures can be taken into account to control the material flow during the process. One way to increase the radial material flow is the application of a higher forming force. This results in a reduced thickness in the centre of the component, consequently pushing more material towards the outside [

20]. Another possible approach is the adaption of the process kinematic, which can be either linear, circular, spiral or leaf [

22] and contributes differently to the indicated material flow, as shown by Calmano et al. in [

23]. The setup can furthermore be adapted with a varying number of tumbling cycles during which the tumbling angle

Θ is ramped up (

Uu), held constant (

Uc) and reduced to the initial position (

Ur). Hildenbrand [

24] could demonstrate a positive influence on the radial material flow in the first phase

Uu and an increased tangential material flow in the second phase

Uc. One significant influencing factor on the material flow could additionally be identified as the tumbling angle

Θ itself [

25]. When increasing this angle, compared to the angle of the conical punch

α, the contact area is reduced locally and is wandering on top of the workpiece surface on the outer edge, thus initiating a backward radial material flow as a result of compressive stresses in the sheet plane [

17]. Furthermore, orbital forming is investigated in combination with a semi-tubular self-piercing riveting process in order to increase the material flow control during joining [

26]. In conclusion, the orbital forming process is qualified to manufacture specimens with a local material pre-distribution [

20]. Nevertheless, these specimens were not used for a subsequent pin extrusion process so far.

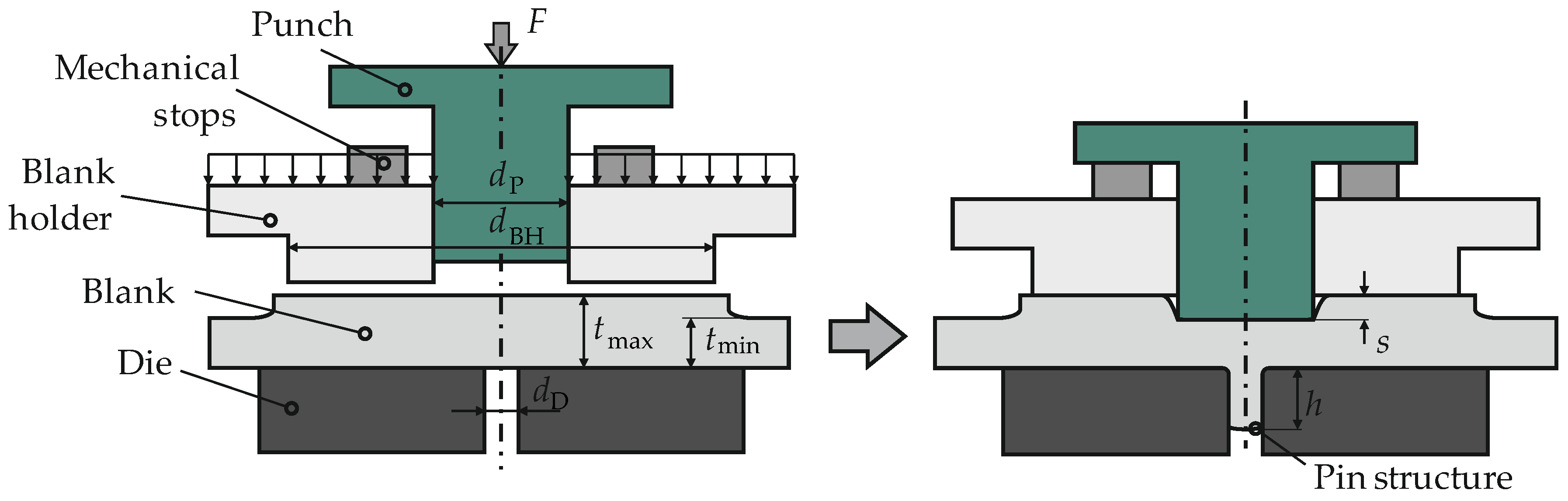

For this reason, a combination of a local material pre-distribution by orbital forming and a subsequent pin extrusion process is investigated in this contribution. The aim is to increase the residual sheet thickness and the pin height, thus extending the process limits of the pin extrusion and subsequent joining operation as well as the versatility of the process. Therefore, pins are extruded out of a conventional blank of DC04 (1.0338) with the initial thickness of t0 = 2.0 mm. In parallel, a circular local material pre-distribution in the direct vicinity of the later extrusion zone is manufactured by orbital forming and is subsequently applied within the pin extrusion process. In order to ensure comparability between both approaches, an identical punch penetration depth and process parameters, in general, are chosen. Furthermore, the diameter of the thickened area is defined as 25 mm in comparison to the diameter of the blank holder of 20 mm to realise a full surface contact as in the conventional process. These components are directly compared with regard to geometrical parameters and the mechanical properties of the part to evaluate the quality of the later joint as well as the resulting punch force as an indicator of the influence on the process. The potential is revealed by a direct comparison of the conventionally extruded pin with the pin extruded from a local material pre-distribution, manufactured in an orbital forming operation.

3. Results

In this chapter, the experimental results are evaluated. Therefore, a conventionally extruded pin structure is analysed, regarding its geometrical properties in form of pin height and residual sheet thickness. Furthermore, the mechanical properties of the part are evaluated in form of a micro-hardness plot and the calculation of the average hardness values directly in the pin. These characteristics are of significant importance for the subsequent joining operation and joint strength and are thus taken into account for a qualitative as well as a quantitative statement of the potential of a local material pre-distribution for the extrusion of pin structures for joining purposes. The potential is revealed by directly comparing these results to the pin extrusion from a component with local material pre-distribution.

3.1. Pin Extrusion from Conventional Blank

Conventional pin extrusion, particularly for use in subsequent joining, has already been investigated in other works [

27], but serves as a comparison for this work to investigate the influence of local material pre-distribution by orbital forming on the pin extrusion process and the properties of the formed pin.

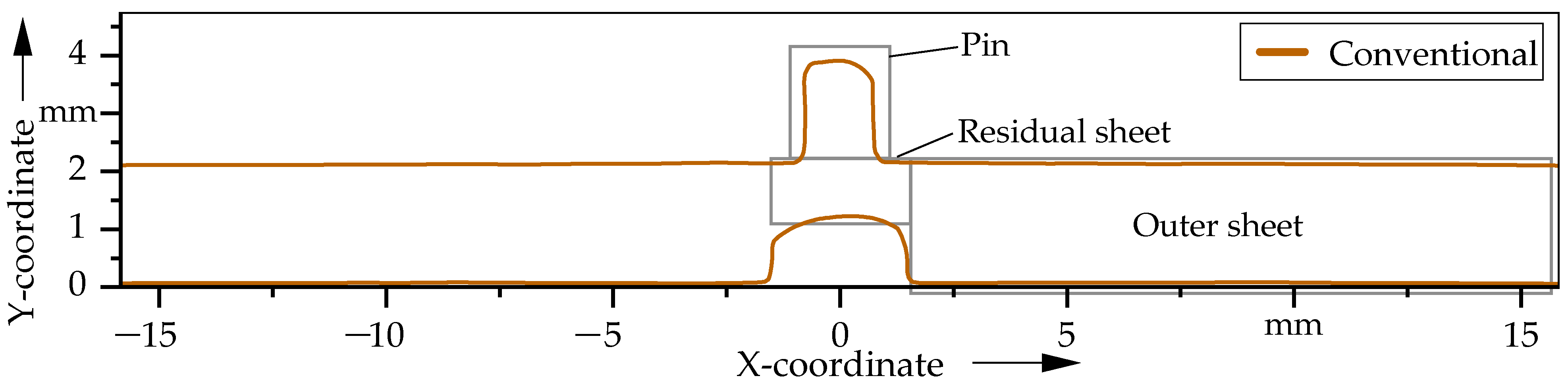

Figure 3 shows the surface contour of the conventional sample made of DC04 with a sheet thickness

t0 = 2 mm with an extruded pin.

Examining the geometric properties of the pin and the forming zone for the produced specimen, an average punch penetration depth

s of 0.98 ± 0.01 mm leads to a pin height

h of 1.85 ± 0.02 mm. This results in a residual sheet thickness of 1.02 ± 0.01 mm.

Figure 4 additionally shows the microhardness of a conventional specimen. The hardness distribution is very similar to a conventional full forward extrusion process [

28]. Here, a strong increase in hardness can be seen, primarily in the direct forming zone below the punch, due to work hardening during the extrusion process. Especially in the area of the neutral flow plane, which extends in a ribbon between the outer edge of the punch and the edge of the die, a strong increase in hardness can be measured. In this region, hardness values of up to 351.6 HV 0.015 are achieved directly under the punch.

Additionally, in the indirect forming zone around the punch, a hardening of the material occurs due to the radial material flow into the sheet metal plane. However, in this zone hardness values between approximately 145 and 190 HV 0.015 are reached, thus lying below the hardness in the direct forming zone. When examining the hardness characteristics of the pin structure, it can be seen that the pin head has a similar hardness to the base material, as there is only a slight plastic deformation in this area due to a mainly axial displacement of the material. However, this increases towards the edge of the pin due to the wall friction and the higher plastic deformation of the material in the edge area of the pin. An analysis of the pin foot shows a significantly increased hardness compared to the base material. Especially in the edge area of the pin, strain hardening due to the lateral flow of the material inwards into the die occurs. The hardness in the pin foot ranges from approximately 200 HV 0.015 in the centre of the pin to about 280 HV 0.015 at the edge of the pin.

3.2. Pin Extrusion from Orbital Formed Tailored Blanks with Local Material Pre-Distribution

In the following, the results of the investigation on the process chain of pin extrusion with prior orbital formed, locally thickened and subsequently calibrated sheets are presented and discussed.

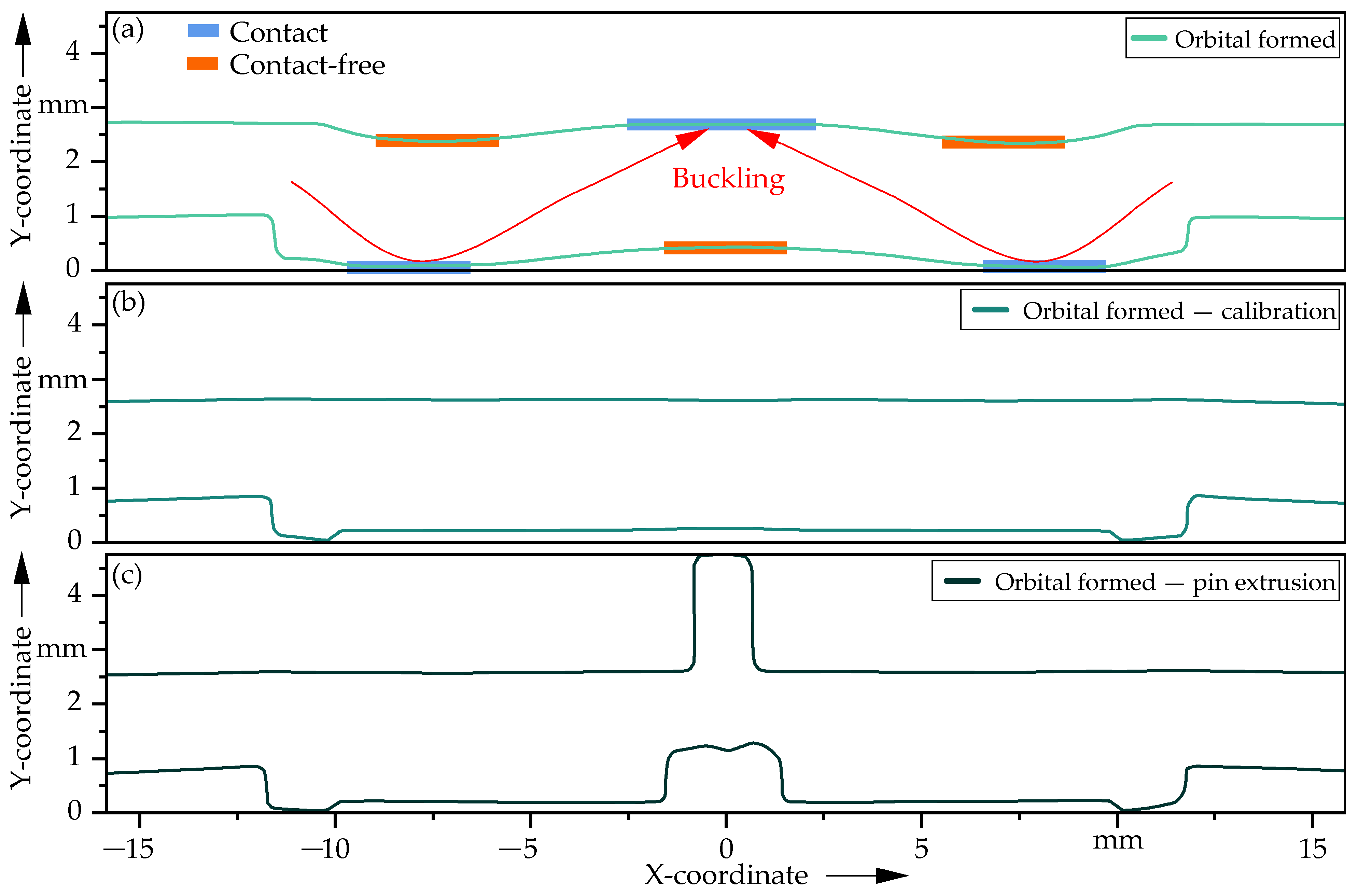

Figure 5 shows the surface contour of the three process steps, which were measured in 3D using a GOM Atos system. Looking at the contour of the orbital formed sample (cf.

Figure 5a), the buckled surface is prominent in the thickened area. This is caused by a double Eulerian buckling due to the resulting stresses during the orbital forming process. The high local stresses that occur in the contact area between the punch and the sheet cause an inward-directed radial material flow, as the material is prevented from flowing radially outwards by the tool design. This initially results in a single buckling of the sheet into the die cavity. As the process progresses and the axial displacement of the forming punch and thus the radial compressive stresses in the sheet metal plane increase, the sheet buckles again in the reverse direction in the centre of the specimen, resulting in the geometry shown in

Figure 5a in the thickened area. Additionally, due to the increasing contact pressure and consequently higher friction forces, different local material flow velocities occur across the sheet thickness, which leads to discontinuities in the flow field. Thus, the effect of buckling is increased. As a result, the sheet comes into contact with both the bottom of the tool and the punch at the outer area of the sheet deformation. The contact areas are marked in red in

Figure 5a. Due to the tumbling movement and the resulting inward material flow, there is nevertheless also a thinning of the sheet in the transition area to the die, respectively, to the thickened area. Here, a sheet thickness of 1.68 mm could be measured, which, however, increases again towards the outer edge of the blank.

To ensure comparability between the conventional and the thickened specimens, the thickened specimens were calibrated in the subsequent step by upsetting the thickened area with the blank holder with a diameter of 20 mm and a force of 150 kN. In this way, the surface buckling is levelled and parallelism of the two sheet surfaces is ensured.

Figure 5b shows a contour of the surface of an initially orbital formed and subsequently calibrated sample of DC04, which was measured using a GOM Atos system. Here, it is apparent, that the calibration step reduces the surface buckling in the forming zone and ensures planar surfaces. This is important for the subsequent pin extrusion, as the buckled surface of the orbital formed sample would lead to a reduced pin height since the radial material flow rate would increase due to the reduced deformation resistance of the surrounding material and less material would flow into the die. Additionally, the blank holder would not be in full contact, which would lead to a reduced contact and friction surface and thus also promote the radial material flow. Furthermore, the calibration step leads to an increase in sheet thickness in the centre and thus the forming zone of the sample. The orbital formed sample (

Figure 5a) has a sheet thickness of 2.26 mm in the forming zone, which corresponds to an increase of 13% compared to the initial sheet thickness of

t0 = 2 mm. In contrast, a sheet thickness of 2.35 mm can be measured for the calibrated sample (cf.

Figure 5b) in the same area, which represents a 17.5% increase compared to the initial sheet thickness. This increase can be explained by the fact that the material flows radially inwards from the edge areas below the blank holder and fills the contact-free areas shown in yellow in

Figure 5a, thus levelling them.

For the final process step,

Figure 5c shows the contour of a sample where a pin is extruded from the sheet metal following the calibration step. When examining the geometric characteristics, a punch penetration depth of 0.96 ± 0.00 mm and a resulting pin height of 2.12 ± 0.05 mm could be measured for the samples. The residual sheet thickness could be measured as 1.40 ± 0.02 mm, which in combination with the punch penetration depth leads to a total sheet thickness in the forming zone of 2.36 mm and agrees very well with the measured values for the sheet thickness in the forming zone for the calibrated sample from

Figure 5b. Based on the results presented, it is possible to see the potential of the process combination compared to conventional forming, resulting from the material pre-distribution and associated work hardening of the material for reduced sheet thinning. This is discussed in more detail in

Section 3.3.

In addition to the geometric investigation of the conventional samples and the process chain of pin extrusion with material pre-distribution, the hardness distribution of the components is investigated.

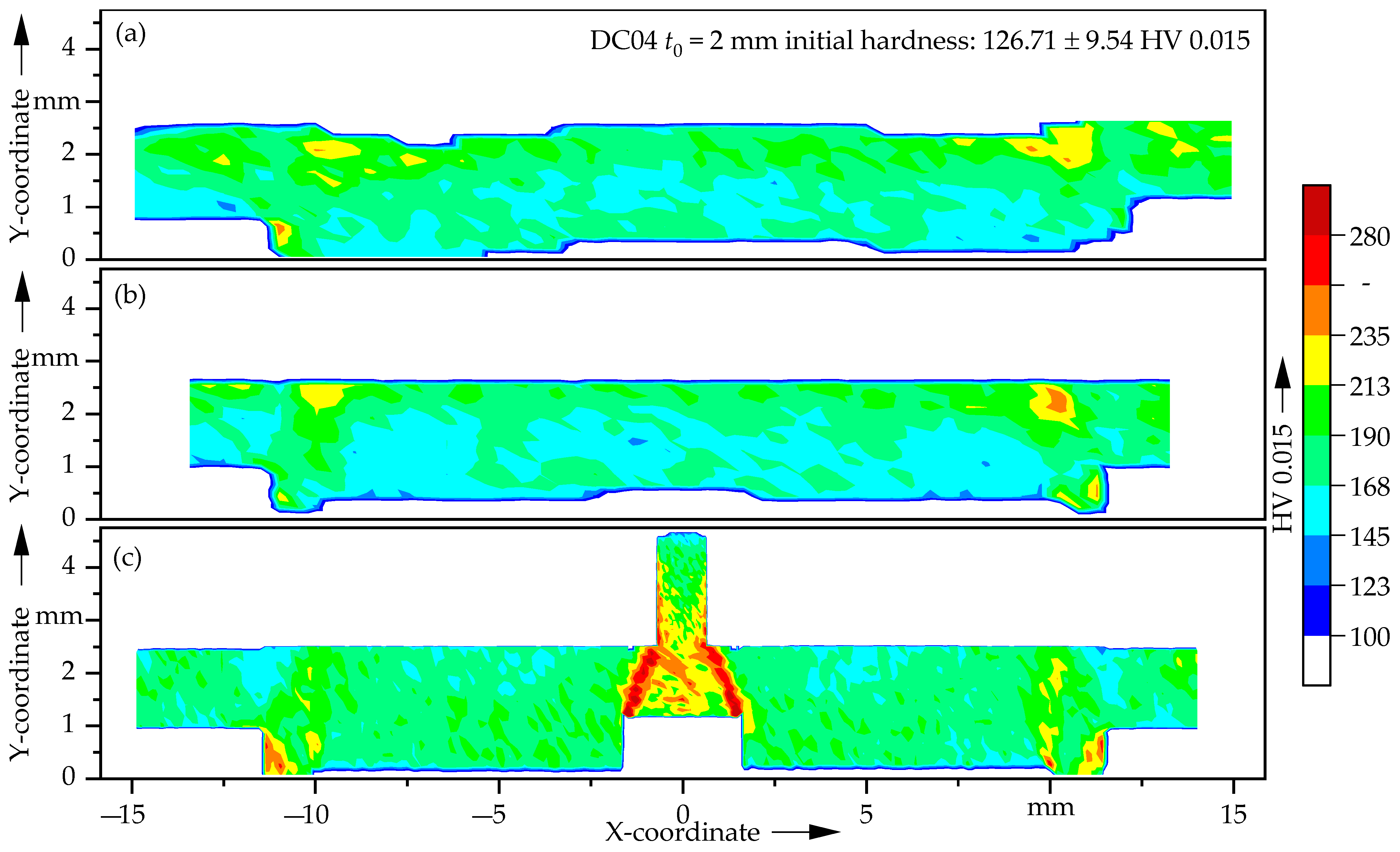

Figure 6 shows the results of the microhardness measurements of the individual process steps in the process chain with local material thickening.

Figure 6a shows, analogous to

Figure 5, first the process step of tumbling followed by the calibration step (cf.

Figure 6b) and then pin extrusion (cf.

Figure 6c).

Examining the hardness profile of the orbital formed sample, the significantly increased hardness with an average of 177.61 ± 17.35 HV 0.015 compared to the base material with 126.71 ± 9.54 HV 0.015 can be seen. Especially in the area of the die entry and the buckling resulting from the forming, hardness values of up to 250 HV 0.015 can be measured. This occurs due to the high plastic deformation and buckling of the sheet caused by the inward flow of material. However, if the subsequently calibrated sample in

Figure 6b is analysed, it can be seen that no significant increase in hardness resulted from the calibration compared to the orbital formed sample and that it, therefore, has a minor influence on the hardness. Here, the mean value of the hardness of the examined component is 174.24 ± 19.31 HV 0.015 and thus in a comparable range to the orbital formed sample. When examining the hardness of the pin extrusion sample, a significant increase in hardness can be measured, especially due to the pin extrusion in the forming zone. This is not surprising, since the pin extrusion results in significant plastic deformation of the material, especially at the neutral flow plane of the material. This can be seen very clearly in

Figure 6c on the ribbon with high hardness between the outer edge of the punch and the edge of the die. Here, hardness values of up to 372.40 HV 0.015 are reached below the punch indentation. In addition, an increase in the hardness values in the pin itself can be seen due to the initial hardness during the orbital forming. Thus, especially in the pin base, the hardness increases compared to the conventional sample, which can also have a positive effect on the load-bearing capacity, especially for pin joints. The rest of the pin structure also has a higher hardness due to the pre-hardening of the preceding process steps, which can be seen especially in the pin head, since the material usually has the lowest hardness here, due to the fact that this area only experiences minor deformation during pin extrusion.

3.3. Potential of a Local Material Pre-Distribution for Pin Extrusion

Comparing the results presented in

Section 3.1 and

Section 3.2, a conclusion can be drawn about the potential of local material pre-distribution by means of orbital forming for pin extrusion. Therefore, characteristic process parameters as well as the resulting part properties are directly compared.

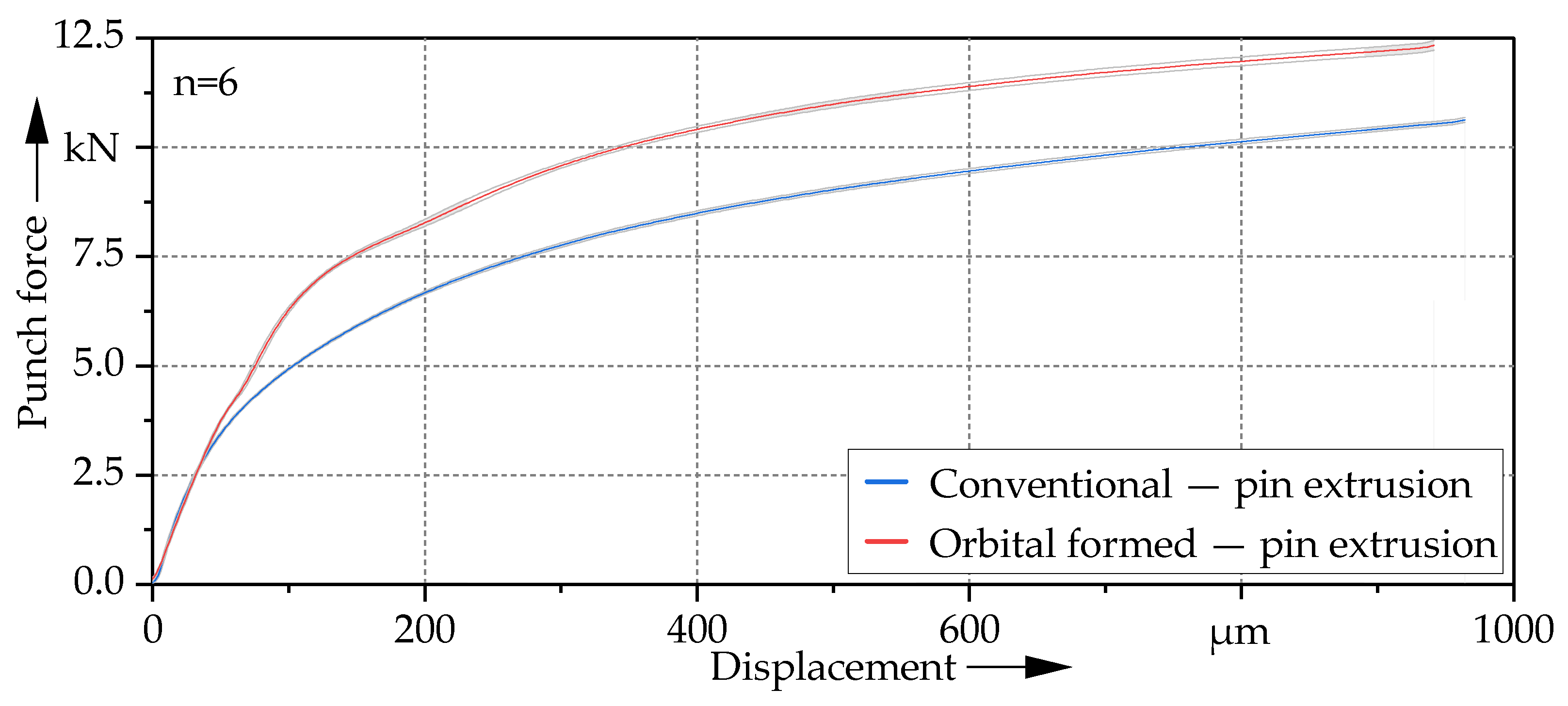

In order to reveal the influence of a local material pre-distribution by orbital forming on the process parameters of a subsequent pin extrusion, the characteristic force-displacement curves as an indicator for the influence of the varying material properties on the process are compared in

Figure 7. When analysing the diagram, the characteristic force–displacement curve for conventional pin extrusion processes can be observed [

14]. After the contact between the punch and workpiece is established, the material is deformed elastically until reaching the initial yield stress of the respective materials. This specific point is directly at the transition from the elastic linear area of the curve to the area of plastic deformation. Due to the strain hardening effect from the orbital forming process, the material strength is increased and consequently, the yield strength is increased as well.

This results in an estimated required punch force of 3.1 kN compared to 5.0 kN, showing an increase of 61.3% for the samples with material pre-distribution. The visible deviation from the linear behaviour at around 4.5 kN can be explained by the compensation of the remaining unevenness of the surface, resulting from the orbital forming process. In the section on plastic deformation, the increase in the forming force can as well be explained by the strain-hardening effect during pin extrusion. This effect is not depending on the initial material strength but on the strain hardening exponent, which is a constant material characteristic. Therefore, the increase in both curves is parallel to each other. The maximum required punch forces differ by 16.0% due to a higher resistance against forming due to strain hardening with values of Fmax,c = 10.63 ± 0.06 kN compared to Fmax,o = 12.33 ± 0.11 kN.

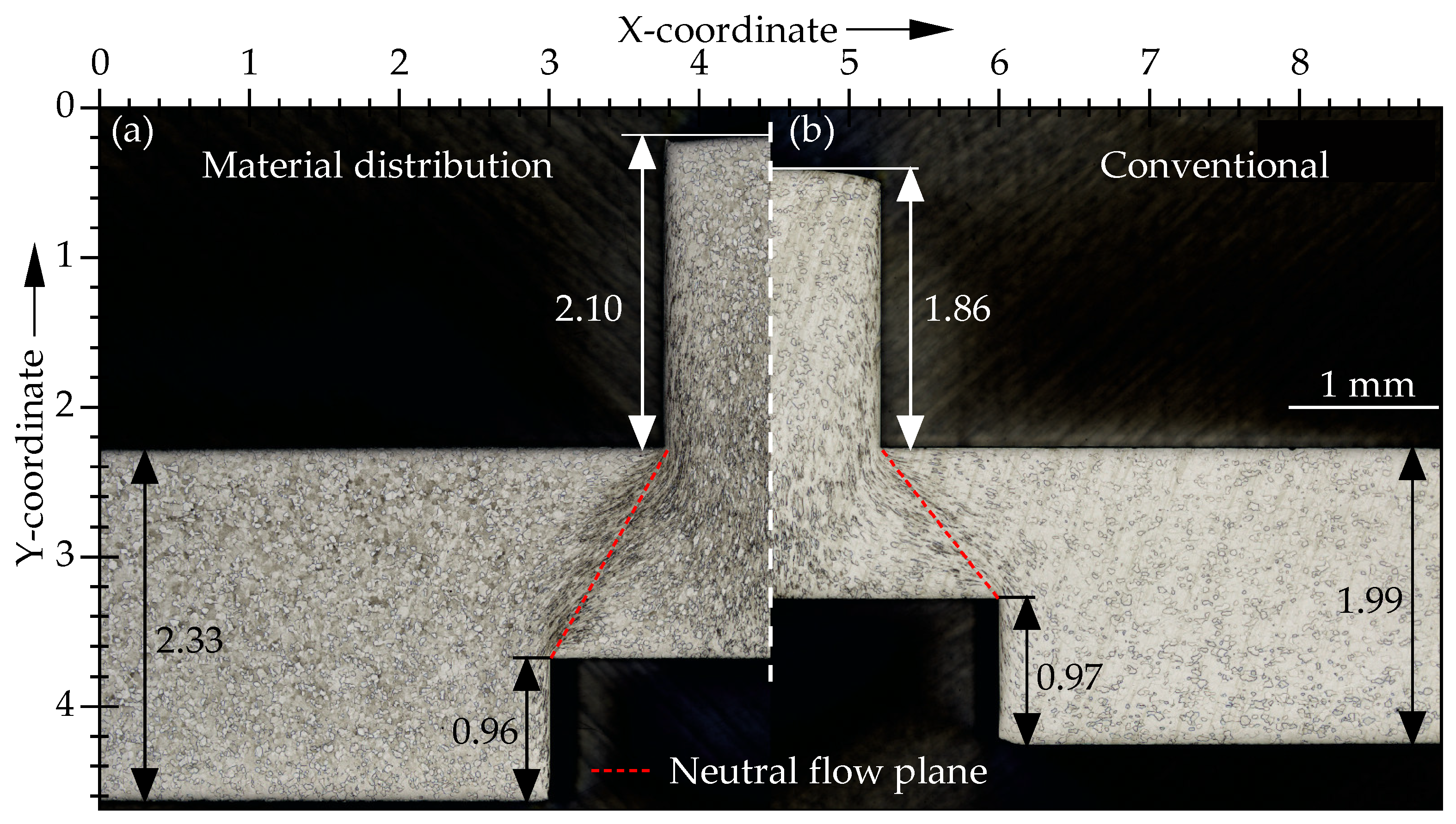

The geometrical properties of the conventional samples and the samples thickened by orbital forming are compared in

Figure 8. To ensure comparability, the same process parameters were selected for pin extrusion. Nevertheless, when investigating the punch penetration depths, it is noticeable that a slightly lower punch penetration depth was achieved with the extrusion of the thickened specimens compared to the conventional specimens. This can be explained by the higher initial strength of the sheet, which results from the orbital forming and calibration step in form of strain hardening. This results in a slightly increased elastic deformation of the punch and, respectively, of the upper tool, thus leading to a lower punch penetration depth.

Nevertheless, even in consideration of the reduced punch penetration depth, a significantly increased pin height could be detected in the thickened samples. Compared to the conventional samples, the measured pin height could be increased by 14.6% from an average of 1.85 mm to 2.12 mm for the thickened samples. The axial material flow is facilitated by the higher strain hardening of the surrounding material through the orbital forming and calibration process, as this consequently has a higher resistance to deformation than the initial material state of the conventional specimens. For this reason, the radial material flow in the sheet plane is reduced in comparison, which leads to the increased pin height in the thickened specimens. This fact was already proven by Hirota and Mitchitsuji [

29] for A1050.

The second relevant parameter for the quality of the pin structure is the average residual sheet thickness of the investigated samples. It can be verified that in addition to an already higher pin structure under the same process parameters, the local material pre-distribution and thickening in the forming zone also results in a 37.3% increase in residual sheet thickness of 1.4 mm, compared to a residual sheet thickness of 1.02 mm for the conventional samples after forming. This is due to the local thickening, which results in an overall higher initial sheet thickness in the forming zone, thus offering more material for the forming process. The potential of a local thickening in the forming zone confirms this, in combination with the higher pin structure due to strain hardening compared to conventional pin extrusion.

In addition, the comparison of the microhardness distribution in the pin shows, that the material pre-distribution through the orbital forming process has a positive effect on the material strength in the pin area. In Römisch et al. [

14] it could already be proven, that the maximum load-bearing capacity of a pin joint under shear load depends on the strain hardening of the pin, especially in the pin foot, since the joint usually fails at this point due to shearing of the pin. The resulting average hardness values for the different specimens and the relevant areas are compared in

Table 2. With average values of 177.61 ± 17.35 HV 0.015 and 174.24 ± 19.31 HV 0.015 of the orbital formed as well as the calibrated specimen, an increase of 40% from the initial hardness of 126.71 ± 9.54 HV 0.015 is resulting from the forming operation. This increase in hardness is the starting point for the subsequent pin extrusion process and manifests itself in an overall higher value of hardness in the pin structure, reaching values of 205.48 ± 25.65 HV 0.015 in comparison to the conventional specimen with an average value of 180.77 ± 35.53 HV 0.015. This resembles an increase of 13.7%, which stands in accordance with the increase in the maximum required forming force, analysed in

Figure 7. As already shown in the previous chapters, the material in the outer sheet is not influenced by the pin extrusion process. Consequently, the material offers the respective initial hardness values before the extrusion, which differ due to the strain hardening in orbital forming operation from 163.56 ± 22.07 HV 0.015 to 181.99 ± 16.34 HV 0.015, showing an increase of 11.3%. When comparing the average values in the residual sheet directly beneath the pin structure, comparable values of 231.32 ± 32.17 HV 0.015 and 229.48 ± 29.18 HV 0.015 could be reached. This fact can be explained by the higher ratio of punch penetration depth to overall thickness for the conventional blank. This ratio of 0.49 indicates an increased degree of forming, thus resulting in a higher strain hardening effect, respectively, higher hardness values during the pin extrusion process. The ratio for the orbital formed component with 0.41 is consequently lower, but with an increased initial hardness due to the prior forming operation, comparable values are reached.

The above-mentioned part properties in regard to geometrical characteristics as well as the hardness distribution can furthermore be qualified by analysing microstructural images of a cross-section through the extruded pin, the residual as well as the outer sheet. Therefore, the specimens are prepared by different grinding and polishing operations, followed by chemical edging. Consequently, the grain structure as an indicator for the material flow is visualised. The comparison of the microstructure between the conventional specimen as well as the specimen with local material distribution is depicted in

Figure 9. Since the geometrical parameters were already compared in

Figure 8, this section focuses on the microstructure. The grain orientation and deformation can be evaluated as indicators for the degree of forming and consequently an increased hardening effect. The deformation of the grains is maximum directly in the forming zone beneath the die shoulder as already mentioned in

Section 3.1 and

Section 3.2, showing parallels to a conventional full-forward extrusion process [

28]. Due to the ongoing punch penetration, the material in this area is increasingly pushed into the die, thus redirecting the grain elongation into the pin direction around the die shoulder. Another parallel characteristic to conventional extrusion processes is the unaffected material in the centre of the punch on the top edge due to the missing deformation, which can be validated in the hardness plots from the prior sections. Since the ratio of punch penetration depth in comparison to the overall material thickness is varying for both specimens, the resulting angle of the neutral flow plane differs, as shown in the figure. In general, the grain orientation in the forming zone as well as the pin structure are comparable for both specimens.

Thus, it can be concluded, that the prior orbital forming process not only has a positive effect on the pin height due to the higher material utilisation, but also leads to a greater residual sheet thickness as a result of the local thickening. Furthermore, a higher load-bearing capacity of the subsequent joint is expected due to the increased strain hardening of the pin. However, further research is still necessary to use the pin structures extruded from thickened sheets for joining dissimilar materials.

4. Summary and Outlook

The aim of this contribution was the investigation of the influence of a prior applied local material pre-distribution on a subsequent pin extrusion process, to reduce local sheet thinning and subsequently a weakening of the sheet in the forming zone. Therefore, pins were extruded from a conventional blank and from a blank featuring a local material pre-distribution manufactured by orbital forming, with the same process parameters. In addition, the characteristic geometrical, as well as mechanical properties of the components, and the influence on the process in regard to the required punch force were evaluated. The potential of the material pre-distribution is outlined by a direct comparison of relevant characteristics from the conventional specimen. In doing so, not only the potential of the local material pre-distribution for the investigated subsequent pin extrusion process was demonstrated, but the applicability of orbital forming for a tailored material distribution for various processes could be increased, thus offering new research opportunities. Furthermore, a fundamental process understanding of the novel approach of a process combination combining orbital forming and pin extrusion could be established.

Summarizing the most important results within this investigation, the following conclusions could be derived:

- -

The prior applied forming operation is responsible for an increased strain hardening, thus expecting an increased material strength. The subsequent pin extrusion process increases this hardening as well, resulting in overall higher hardness values, especially in the pin foot area. Consequently, an increased load-bearing capacity of the later joint is expected, as suggested in [

27].

- -

During orbital forming, the complete material inside the thickened area is opposed to strain hardening. This results in an increased flow obstruction in a radial direction from the material next to the forming zone, thereby facilitating the axial material flow into the pin structure. This effect supports on the one hand the maximum resulting pin height and on the other hand, the material utilisation is increased, since less material is pushed radially into the outer sheet area. The strength of the surrounding material is higher and thereby confirming the correlation of increased strength with increased material utilisation in [

29].

- -

The material pre-distribution results in an overall increased material thickness, depending on the orbital forming process. On the one hand, this material allocation can subsequently be used to extrude higher pins while still maintaining a sufficient residual sheet thickness, which positively influences the load-bearing capacity under shear load. On the other hand, the punch penetration depth can be further reduced while still achieving the same pin height as in the conventional approach. Control of the material distribution and the geometrical parameters of pin height as well as residual sheet thickness can be applied in order to tailor desired joint geometries, thereby increasing the versatility of the pin joining process. Nevertheless, the limitations of the proposed process combination regarding a maximum reachable thickness pre-distribution due to the prior orbital forming process have to be mentioned.

- -

Since the component is opposed to radial compression in the sheet plane during orbital forming, the local thickening results in a buckling of the material into the die. Consequently, the geometrical accuracy is reduced. This process limit can be minimised by a subsequent calibration step in form of an upsetting operation. Since the material properties are barely influenced and a sufficient surface flatness can be realised, this calibration step can be transferred onto orbital forming processes in general. By applying this calibration step, process limits in form of buckling could be limited, for example occurring during the process in [

30].

Future research should focus on the establishment of a holistic process understanding on the influence of a local material pre-distribution on the extrusion of pin structures and as well on the subsequent joining operation. The implementation of a numerical model of the process combination would be beneficial to identify phenomena such as material damage or occurring material flow. In doing so, a tailored material distribution depending on the desired extrusion and joining quality should be implemented as a prior orbital forming step. Thereby, process limits in the joint should be eliminated and the versatility of the subsequent pin extrusion and joining processes should be increased. Additionally, an adapted material pre-distribution localised directly beneath the punch could be investigated, to provide exactly the necessary material for the pin extrusion, thus eliminating penetration of the punch into the initial sheet. Different materials should be investigated in order to prove the transferability between different strength classes. Furthermore, the load-bearing capacity of the joint should be compared between conventional extruded pins and pins extruded from a sheet with local material pre-distribution.