Experimental Procedures of Accelerated Aging and Evaluation of Effectiveness of Nanostructured Products for the Protection of Volterra (Italy) Panchina Stone

Abstract

:1. Introduction

2. Materials and Methods

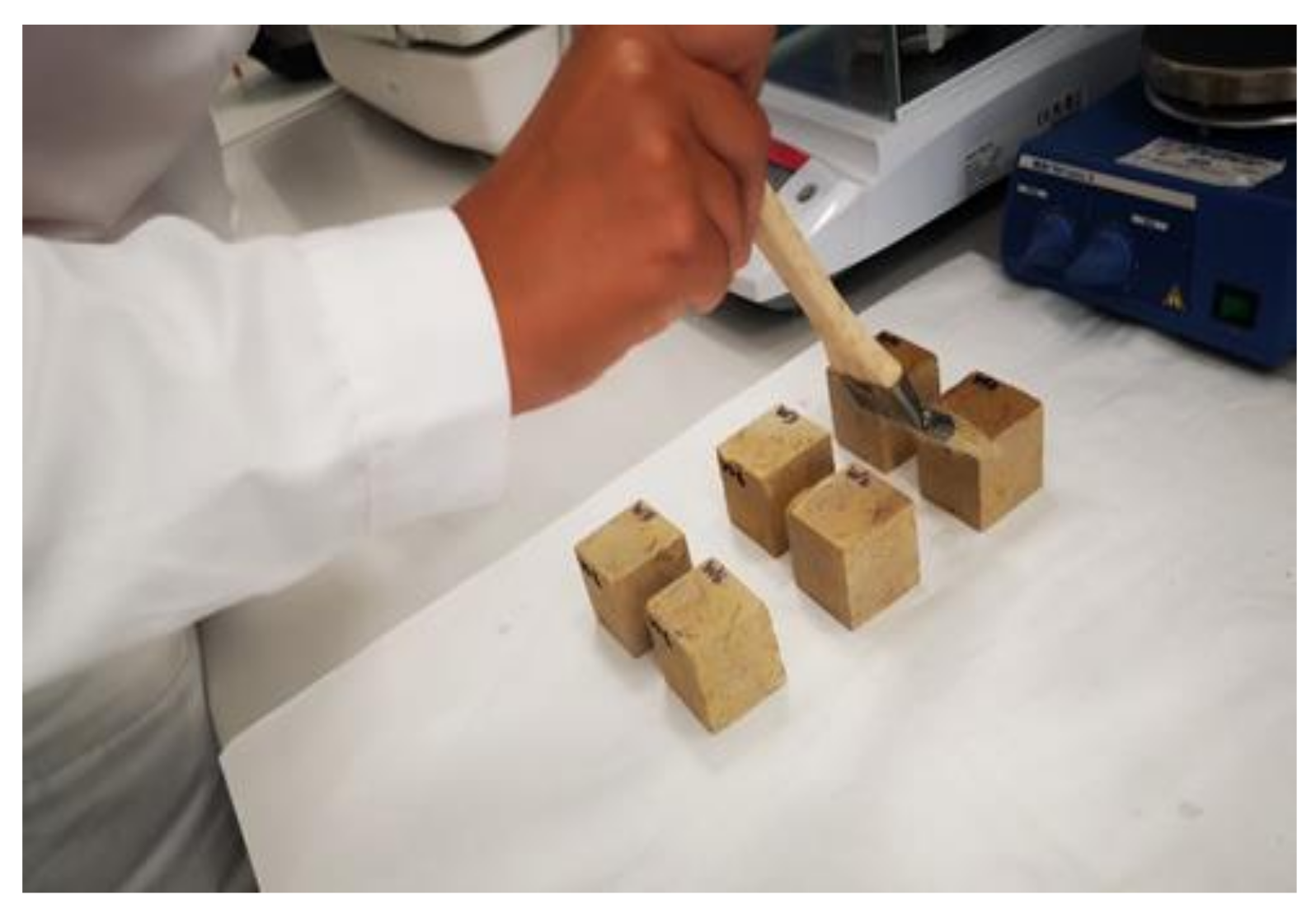

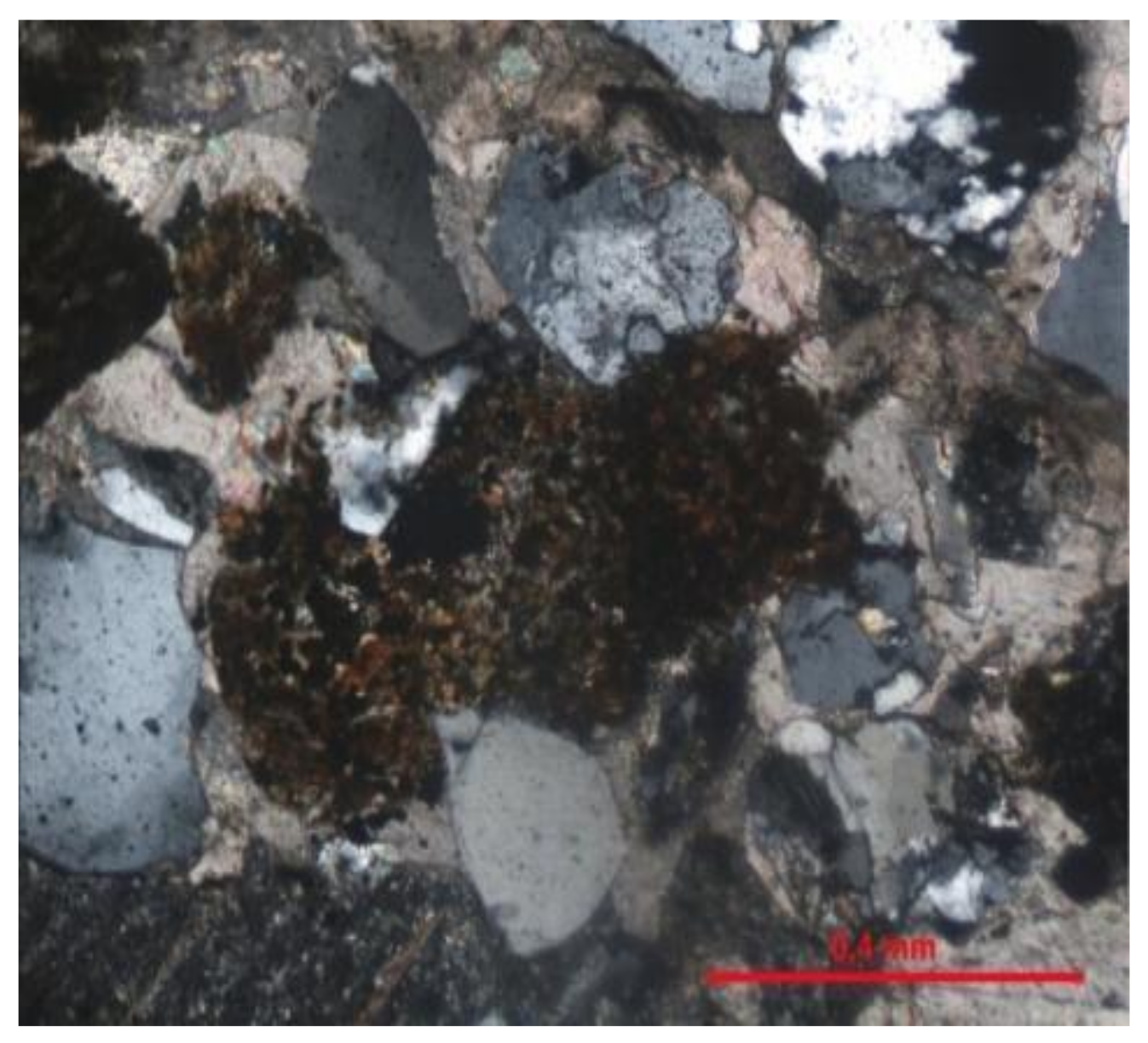

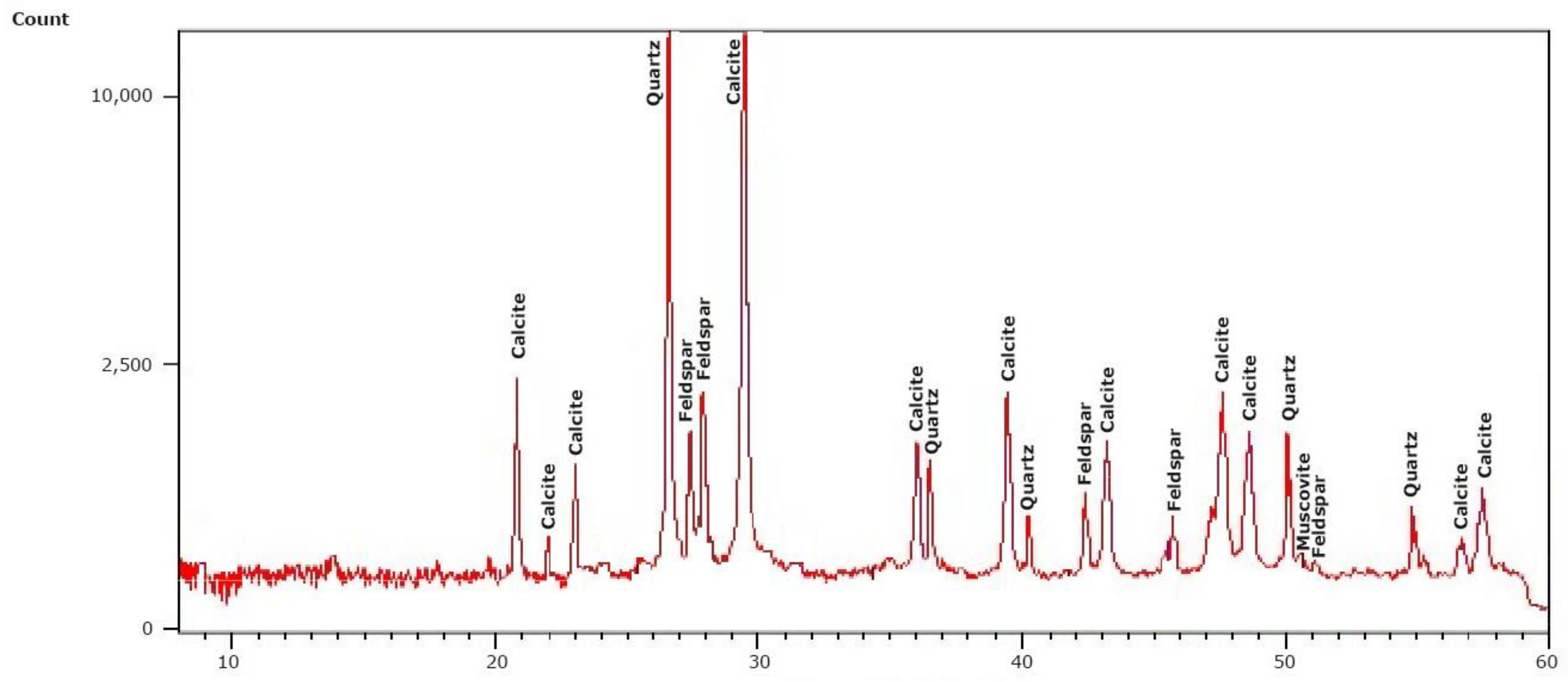

2.1. Stone Characterization

2.2. Applied Products

- Monodisperse (with a very narrow particle-size distribution);

- Polydisperse (with a wider dimensional distribution).

2.3. Comparative Testing of Treatments

3. Results and Discussion

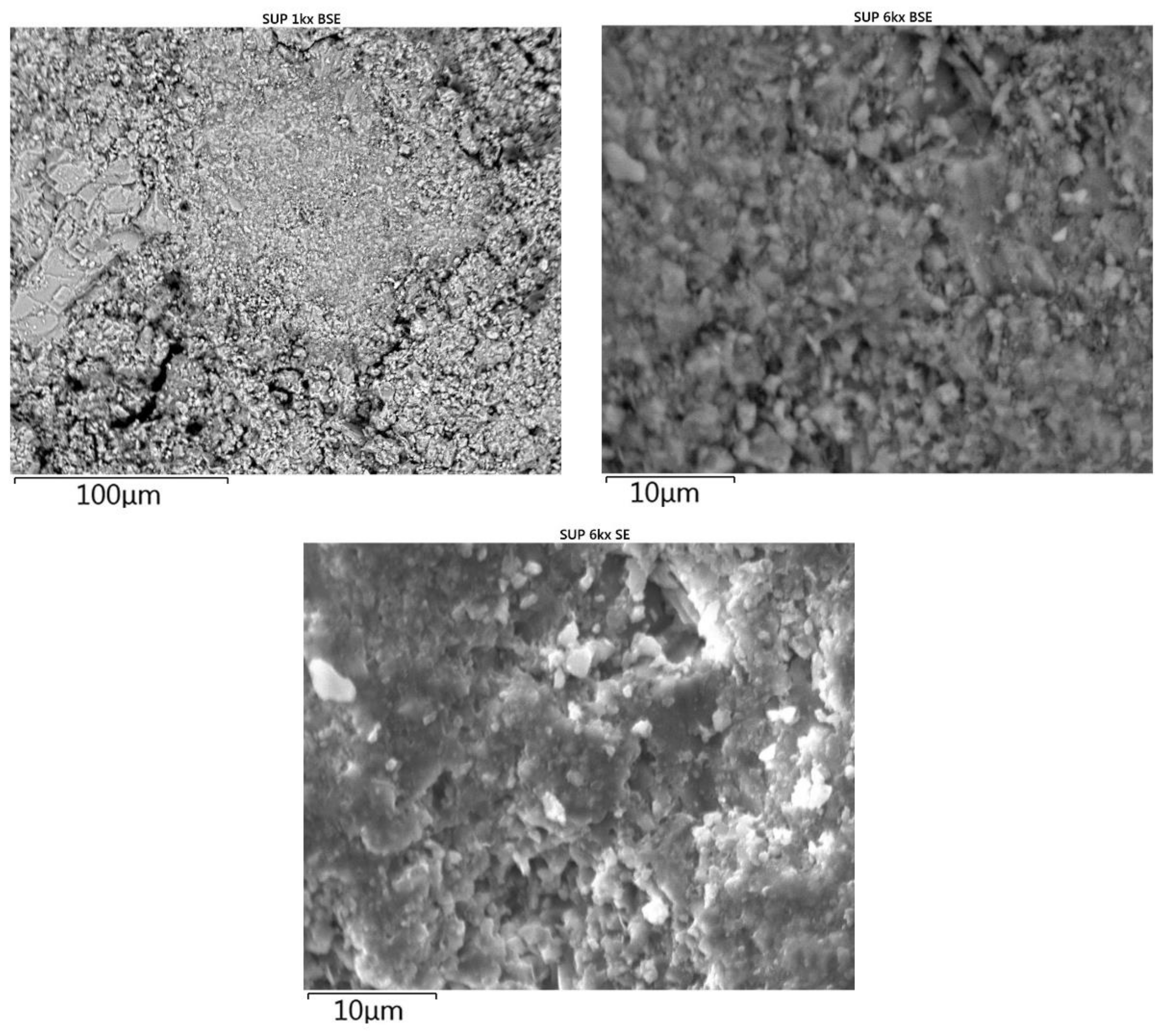

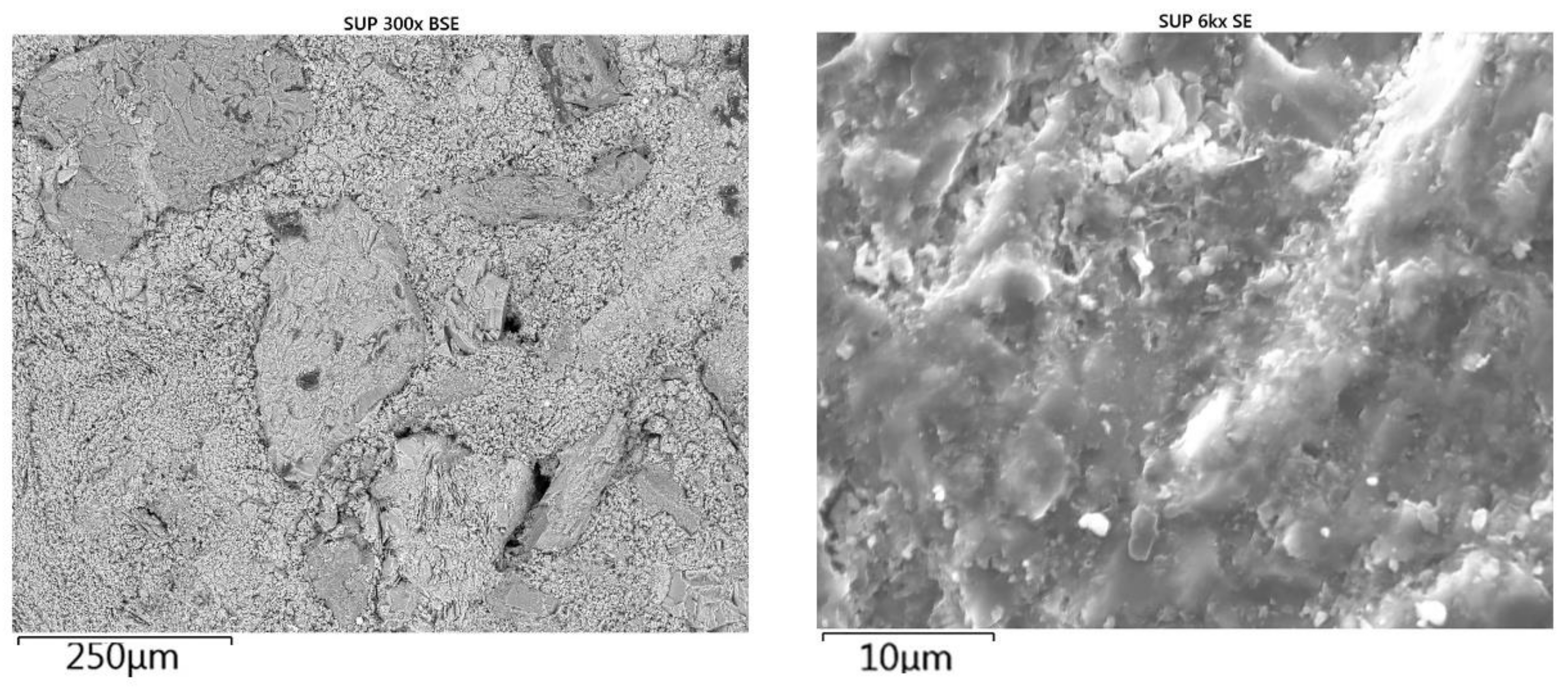

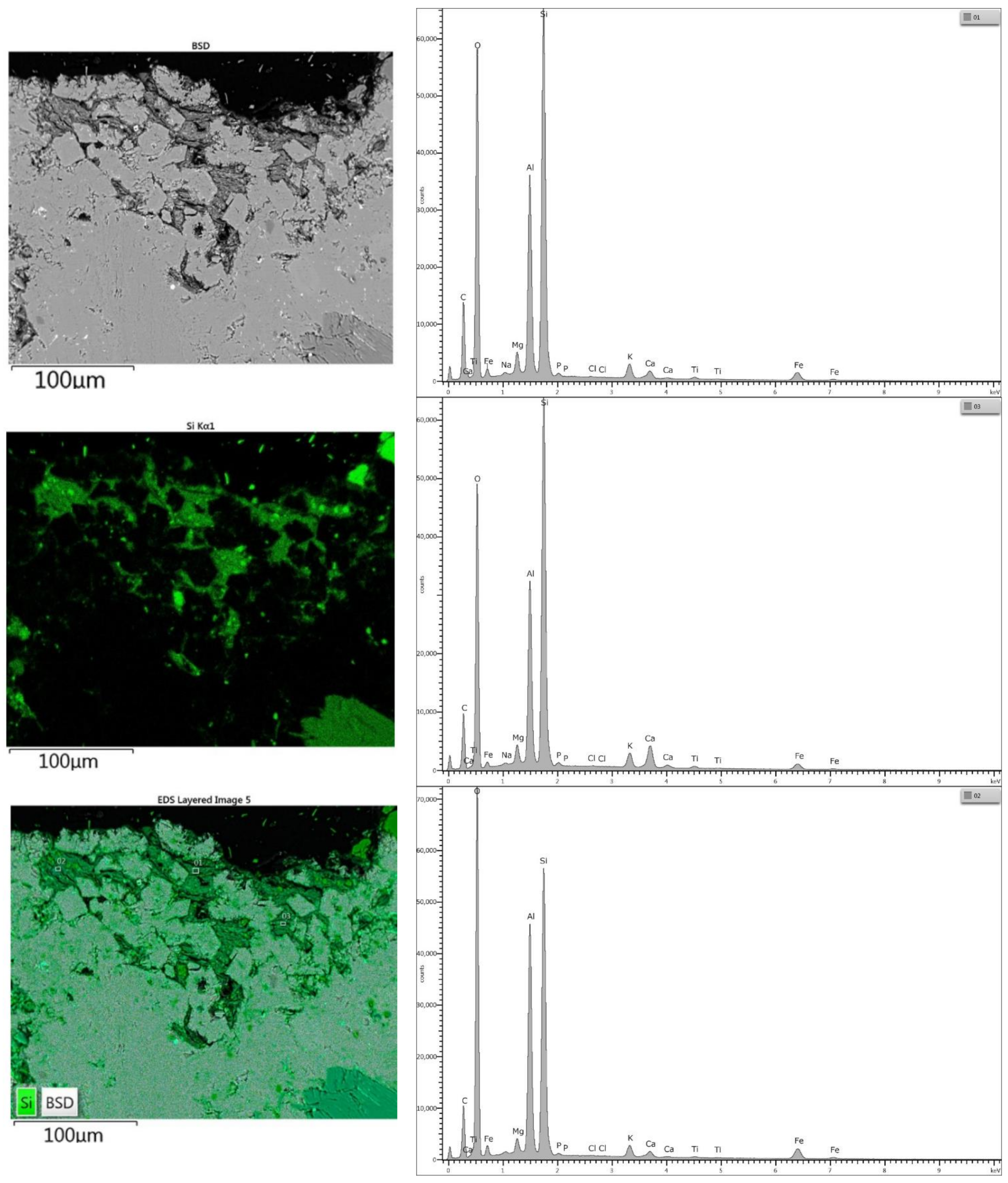

3.1. Stone Characterization

3.2. Comparative Testing of Treatments

3.3. Contact Angle Measurement

3.4. Durability Characteristics

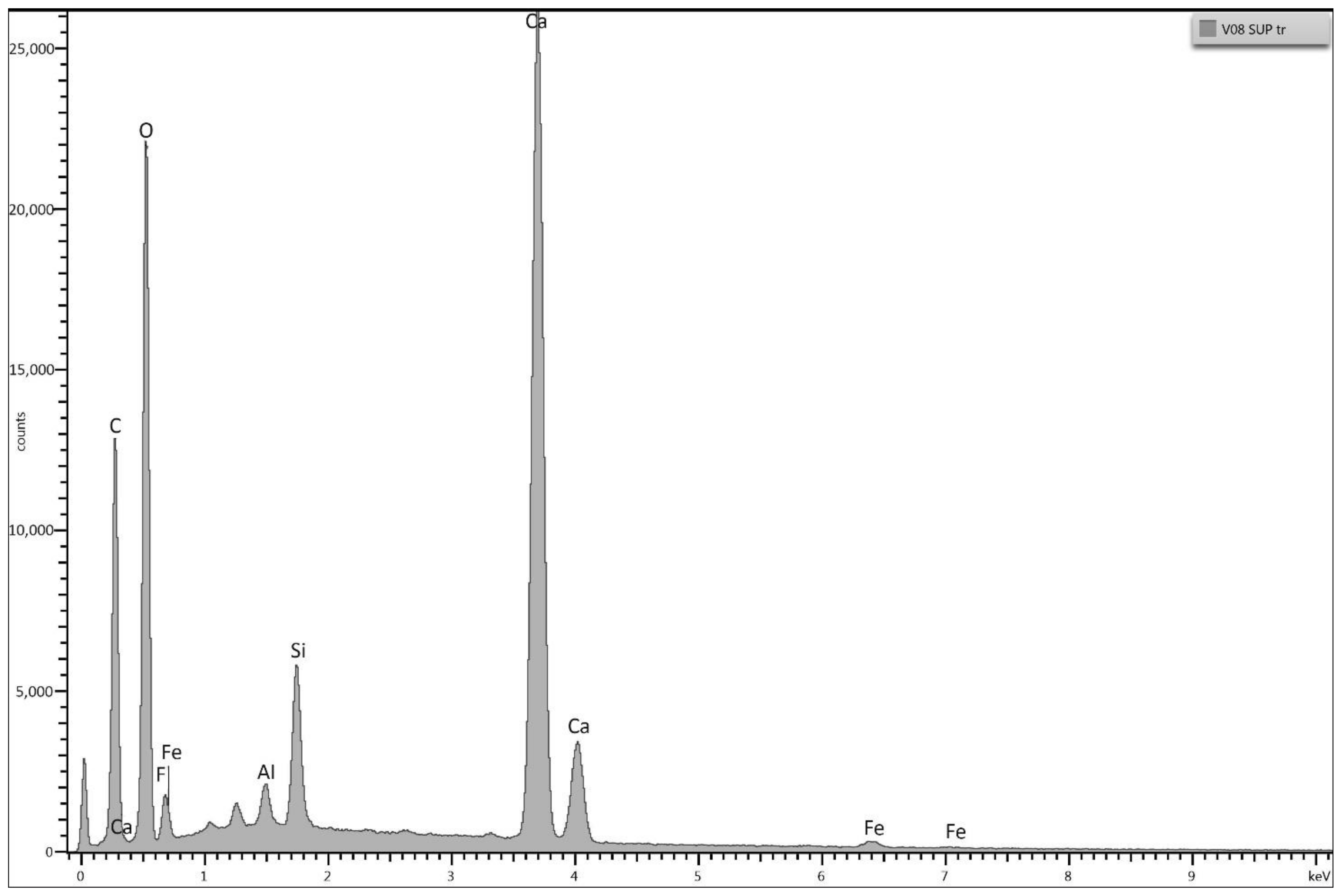

3.5. SEM-EDS Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cristofani, M. Volterra. Scavi 1969–1971. Not. Scavi Antich. 1973, 28, 13–245. [Google Scholar]

- Cristofani, M. Volterra. Scavi nella necropoli del Portone. NS 1955, 29, 114–181. [Google Scholar]

- Cristofani, M. L’Acropoli di Volterra: Nascita e Sviluppo di Una Città; Pacini Editore: Pisa, Italy, 1981. [Google Scholar]

- Dennis, G. Volterra: Città e Necropoli d’Etruria. A Cura di G. Cateni; NIE Editore: Siena, Italy, 1986. [Google Scholar]

- Fiumi, E. Contributo alla datazione del materiale volterrano: Gli scavi della necropoli del Portone negli anni 1873–1874. Stud. Etruschi 1957, 25, 367–415. [Google Scholar]

- Bruun, P. Studies in de romanisation of Etruria. Acta Inst. Rom. Finl. Bardi Ed. Roma 1975, 5, 518. [Google Scholar]

- Rodolico, F. Le Pietre delle Città d’Italia; Le Monnier: Firenze, Italy, 1953. [Google Scholar]

- Malatesta, A. Le formazioni pleistocenice del Livornese. Atti. Soc. Tosc. Sci. Nat. Mem. Ser. A 1942, 51, 145–206. [Google Scholar]

- Barsotti, G.; Federici, P.R.; Antonioli, F.; Silenzi, S.; Vittori, E.; Villani, C. Sea level changes and tectonic mobility. Precise measurements in three coastlines of Italy considered stable during the last 125 ky. Phys. Chem. Earth Part A Solid Earth Geod. 1999, 24, 337–342. [Google Scholar]

- Giannelli, L.; Mazzanti, R.; Salvatorini, G. Studio del Quaternario Livornese, con particolare riferimento alla stratigrafia e alle faune delle formazioni del bacino di carenaggio della Torre del Fanale. Mem. Soc. Geol. Ital. 1974, 13, 425–495. [Google Scholar]

- Aquino, A.; Pagnotta, S.; Polese, S.; Tamponi, M.; Lezzerini, M. Panchina Calcarenite: A Building Material from Tuscany Coast. Earth Environ. Sci. 6th World Multidiscip. Earth Sci. 2020, 5, 609. [Google Scholar] [CrossRef]

- Price, C.A.; Doehne, E. Stone Conservation: An Overview of Current Research; Getty Conservation Institute: Los Angeles, LA, USA, 2011. [Google Scholar]

- Manoudis, P.N.; Papadopoulou, S.; Karapanagiotis, I.; Tsakalof, A.; Zuburtikudis, I.; Panayiotou, C. Polymer-Silica nanoparticles composite films as protective coatings for stone-based monuments. J. Phys. Conf. Ser. 2007, 61, 1361–1365. [Google Scholar] [CrossRef]

- Delgado-Rodriguez, J. Consolidation of decayed stone. A delicate problem with few practical solutions, Historical constructions. In Proceedings of the International Seminar on Historical Constructions, Guimarães, Portugal, 7–9 November 2001. [Google Scholar]

- Rizzarelli, P.; La Rosa, C.; Torrisi, A. Testing a fluorinated compound as a protective material for calcarenite. J. Cult. Herit. 2001, 2, 55–62. [Google Scholar] [CrossRef]

- Poli, T.; Toniolo, L.; Chiantore, O. The protection of different Italian marbles with two partially fluorinated acrylic copolymers. Appl. Phys. A 2004, 79, 347–351. [Google Scholar] [CrossRef]

- Lazzari, M.; Chiantore, O. Thermal-ageing of paraloid acrylic protective polymers. Polymer 2000, 41, 6447–6455. [Google Scholar] [CrossRef]

- Chiantore, O.; Lazzari, M. Photo-oxidative stability of paraloid acrylic protective polymers. Polymer 2001, 42, 17–27. [Google Scholar] [CrossRef]

- Lazzarini, L.; Laurenzi Tabasso, M. Il Restauro della Pietra; CEDAM: Padova, Italy, 1994. [Google Scholar]

- Aglietto, M.; Passaglia, E.; Taburoni, E.; Ciardelli, F.; Botteghi, C.; Matteoli, U. A new class of fluorinated acrylic polymers: Protective materials for stone. In Proceedings of the ICOM Commitee for Conservation: 10th Triennal Meeting, Washington, DC, USA, 20–27 August 1993; Volume 2, pp. 553–558. [Google Scholar]

- Gu, J.-D. Microbiological deterioration and degradation of synthetic polymeric materials: Recent research advances. Int. Biodeterior. Biodegrad. 2003, 52, 69–91. [Google Scholar] [CrossRef]

- Sabatini, V.; Farina, H.; Montarsolo, A.; Pargoletti, E.; Ortenzi, M.A.; Cappelletti, G. Fluorinated polyacrylic resins for the protection of cultural heritages: The effect of fluorine on hydrophobic properties and photochemical stability. Chem. Lett. 2018, 47, 280–283. [Google Scholar] [CrossRef]

- Ruffolo, S.A.; La Russa, M.F. Nanostructured Coatings for Stone Protection: An Overview. Front. Mater. 2019, 6, 147. [Google Scholar] [CrossRef]

- Baglioni, P.; Giorgi, R. Soft and hard nanomaterials for restoration and conservation of cultural heritage. Soft Matter 2006, 2, 293–303. [Google Scholar] [CrossRef]

- Rodriguez-Navarro, C.; Ruiz-Agudo, E. Nanolimes: From synthesis to application. Pure Appl. Chem. 2017, 90, 523–550. [Google Scholar] [CrossRef]

- Pozo-Antonio, J.S.; Otero, J.; Alonso, P.; Barberà, X. Nanolime- and nanosilica-based consolidants applied on heated granite and limestone: Effectiveness and durability. Constr. Build. Mater. 2019, 201, 852–870. [Google Scholar] [CrossRef]

- Ruffolo, S.A.; La Russa, M.F.; Malagodi, M.; Oliviero Rossi, C.; Palermo, A.M.; Crisci, G.M. ZnO and ZnTiO3 nanopowders for antimicrobial stone coating. Appl. Phys. A Mater. Sci. Process. 2010, 100, 829–834. [Google Scholar] [CrossRef]

- La Russa, M.F.; Rovella, N.; De Buergo, M.A.; Belfiore, C.M.; Pezzino, A.; Crisci, G.M. Nano-TiO2 coatings for cultural heritage protection: The role of the binder on hydrophobic and self-cleaning efficacy. Prog. Org. Coat. 2016, 91, 1–8. [Google Scholar] [CrossRef]

- Bergamonti, L.; Predieri, G.; Paz, Y.; Fornasini, L.; Lottici, P.P.; Bondioli, F. Enhanced self-cleaning properties of N-doped TiO2 coating for Cultural Heritage. Microchem. J. 2017, 133, 1–12. [Google Scholar] [CrossRef]

- Banerjee, S.; Dionysiou, D.D.; Pillai, S.C. Self-cleaning applications of TiO2 by photo-induced hydrophilicity and photocatalysis. Appl. Catal. B Environ. 2015, 176–177, 396–428. [Google Scholar] [CrossRef] [Green Version]

- De Ferri, L.; Lottici, P.P.; Lorenzi, A.; Montenero, A.; Salvioli-Mariani, E. Study of silica nanoparticles—Poly-siloxane hydrophobic treatments for stone-based monument protection. J. Cult. Herit. 2011, 12, 356–363. [Google Scholar] [CrossRef]

- Simpson, J.T.; Hunter, S.R.; Aytug, T. Superhydrophobic materials and coatings: A review. Rep. Prog. Phys. 2015, 78, 8. [Google Scholar] [CrossRef]

- Crupi, V.; Fazio, B.; Gessini, A.; Kis, Z.; La Russa, M.F.; Majolino, D. TiO2-SiO2-PDMS nanocomposite coa-ting with self-cleaning effect for stone material: Finding the optimal amount of TiO2. Constr. Build. Mater. 2018, 166, 464–471. [Google Scholar] [CrossRef]

- UNI EN 1925; Metodi di Prova Per Pietre Naturali—Determinazione del Coefficiente di Assorbimento d’Acqua per Capillarità. Ente Nazionale Italiano di Unificazione: Milano, Italy, 2000.

- Normal 21/85; Permeabilità Al Vapor d’Acqua. CNR-ICR: Rome, Italy, 1987.

- UNI EN 1015-19; Metodi di Prova per Malte per Opere Murarie—Determinazione della Permeabilità Al Vapore d’Acqua delle Malte da Intonaco Indurite. ISO: Geneva, Switzerland.

- UNI 11087; Beni Culturali—Materiali Lapidei Naturali Ed Artificiali—Determinazione del Contenuto di Sali Solubili. ISO: Geneva, Switzerland.

- UNI EN 12087; Isolanti Termici Per Edilizia—Determinazione dell’Assorbimento d’Acqua a Lungo Termine: Prova Attraverso Immersione. ISO: Geneva, Switzerland, 2013.

- UNI EN 15803; Conservazione dei Beni Culturali—Metodi di Prova—Determinazione della Permeabilità Al Vapore d’Acqua (dp). ISO: Geneva, Switzerland, 2010.

- Germinario, S. Analysis of leccese stone decay after laboratory ageing test. In Proceedings of the VIIth Conference Diagnosis, Conservation and Valorization of Cultural Heritage, Napoli, Italy, 15–16 December 2016; pp. 252–258. [Google Scholar]

- Fernandez, F.; Germinario, S. Alteration and deterioration of natural stone materials: Artificial aging as a tool of knowledge. In Proceedings of the VIIIth Conference Diagnosis, Conservation and Valorization of Cultural Heritage, 14–15 December 2017; pp. 324–333. [Google Scholar]

- EN 12370; Metodi di Prova per Pietre Naturali. Determinazione della Resistenza Alla Cristallizzazione dei Sali. CNR-ICR: Rome, Italy, 2001.

- ASTM D724-99; Standard Test Method for Surface Wettability of Paper (Angle-of-Contact Method). ASTM: West Conshohocken, PA, USA, 2003.

- ASTM D5946; Standard Test Method for Corona-Treated Polymer Films Using Water Contact Angle Measurements. ASTM: West Conshohocken, PA, USA, 2004.

- Adams, A.E.; Mackenzie, W.S. A Colour Atlas, Carbonate Sediments and Rocks under the Microscope; CRC Press: Boca Raton, FL, USA, 1998; p. 330. [Google Scholar]

- Chatzigrigoriou, A.; Manoudis, P.N.; Karapanagiotis, I. Fabrication of water repellent coatings using waterborne resins for the protection of the cultural heritage. Macromol. Symp. 2013, 331, 158–165. [Google Scholar] [CrossRef]

- Zornoza-Indart, A.; Paula Lopez-Arce, P. Silica nanoparticles (SiO2): Influence of relative humidity in stone consolidation. J. Cult. Herit. 2016, 18, 258–270. [Google Scholar] [CrossRef]

- Adamopoulos, F.G.; Vouvoudi, E.C.; Achilias, D.S.; Karapanagiotis, I. Fluorosilane Water-Repellent Coating for the Protection of Marble. Wood Other Mater. Herit. 2021, 4, 2668–2675. [Google Scholar]

- Yao, W.; Li, Y.; Huang, X. Fluorinated poly(meth)acrylate: Synthesis and properties. Polymers 2014, 55, 6197–6211. [Google Scholar] [CrossRef] [Green Version]

- Aslanidou, D.; Karapanagiotis, I.; Panayiotou, C. Tuning the wetting properties of siloxane-nanoparticle coatings to induce superhydrophobicity and superoleophobicity for stone protection. Mater. Des. 2016, 108, 736–744. [Google Scholar] [CrossRef]

- Mosquera, M.J.; Carrascosa, L.A.M.; Badreldin, N. Producing superhydrophobic/oleophobic coatings on Cultural Heritage building materials. Pure. Appl. Chem. 2018, 90, 551–561. [Google Scholar] [CrossRef]

- Normal—11:85; Assorbimento d’Acqua per Capillarità Coefficiente d’Assorbimento Capillare. Istituto Centrale del Restauro: Rome, Italy, 1986.

- UNI EN 1926; Metodi di Prova per Pietre Naturali—Determinazione della Resistenza a Compressione Uniassiale. 2007.

- UNI EN ISO 7783; Pitture e Vernici—Determinazione delle Proprietà di Trasmissione del Vapore Acqueo—Metodo della Capsula. ISO: Geneva, Switzerland, 2019.

- Franzoni, E.; Fregni, A.; Gabrielli, R.; Graziani, G.; Sassoni, E. Compatibility of photocatalytic TiO2-based finishing for renders in architectural restoration: A preliminary study. Build. Environ. 2014, 80, 125–135. [Google Scholar] [CrossRef]

- Graziani, L.; Quagliarini, E.; Bondioli, F.; D’Orazio, M. Durability of self-cleaning TiO2 coatings on fired clay brick façades: Effects of UV exposure and wet & dry cycles. Build. Environ. 2014, 71, 193–203. [Google Scholar]

- Roveri, M.; Goidanich, S.; Toniolo, L. Artificial Ageing of Photocatalytic Nanocomposites for the Protection of Natural Stones. Coatings 2020, 10, 729. [Google Scholar] [CrossRef]

| FREEZE/THAW | THERMAL SHOCK |

|---|---|

| +22 °C, 1 h −20 °C, 3 h +22 °C, 1 h +70 °C, 3 h | −20 °C, 2 h |

| +22 °C, 2 h | |

| +4 °C, 2 h |

| Sample Name | Applied Product (2 Coats) | Note | Contact Angle 24 h | Contact Angle 48 h | Contact Angle 30 Days |

|---|---|---|---|---|---|

| V01 | NSO | 1F | 81.10 | 90.60 | 85.57 |

| V02 | NSO | 1F | 90.13 | 87.70 | 89.50 |

| V03 | - | REF. SAMPLE | - | - | - |

| V04 | NSO | 1F | 84.40 | 73.80 | 85.60 |

| V05 | NSO | 1F | 89.70 | 90.33 | 88.60 |

| V06 | NSO | 1F | 81.87 | 85.73 | 85.80 |

| V07 | NSO | 1F | 81.33 | 85.60 | 86.70 |

| V08 | NSO | 6F | 78.60 | 91.12 | 90.57 |

| V09 | NSO | 6F | 85.78 | 88.28 | 89.38 |

| V010 | - | REF. SAMPLE | - | - | - |

| V011 | NSO | 6F | 86.60 | 85.32 | 88.08 |

| V012 | NSW | 1F | 76.93 | 69.70 | 83.07 |

| V013 | NSW | 1F | 78.77 | 83.10 | 80.70 |

| V014 | NSW | 1F | 84.83 | 85.87 | 79.30 |

| V015 | NSW | 1F | 63.93 | 85.43 | 84.60 |

| V016 | - | REF. SAMPLE | - | - | - |

| V017 | - | REF. | - | - | - |

| V018 | NSW | 1F | 74.90 | 90.30 | 81.17 |

| V019 | - | REF. SAMPLE | - | - | - |

| V020 | NSW | 1F | 86.00 | 73.50 | 77.70 |

| V021 | NSW | 6F | 75.85 | 79.97 | 83.67 |

| V022 | NSW | 6F | 88.65 | 84.85 | 86.65 |

| V023 | NSW | 6F | 70.47 | 78.64 | 78.98 |

| 1 | NSO | 1F | 86.77 | 86.17 | 85.83 |

| 2 | NSO | 1F | 83.13 | 76.97 | 87.50 |

| 3 | NSW | 1F | 82.53 | 88.63 | 90.87 |

| 4 | NSW | 1F | 83.50 | 83.47 | 84.33 |

| 5 | - | REF. SAMPLE | - | - | - |

| 6 | - | REF. SAMPLE | - | - | - |

| Sample Name | Applied Product (2 Coats) | Average Value 24 h | Average Value 48 h | Average Value 30 Days |

|---|---|---|---|---|

| V01 | NSO | 84.76 | 85.63 | 86.96 |

| V02 | NSO | |||

| V04 | NSO | |||

| V05 | NSO | |||

| V06 | NSO | |||

| V07 | NSO | |||

| V08 | NSO | 83.66 | 88.24 | 89.34 |

| V09 | NSO | |||

| V011 | NSO | |||

| V012 | NSW | 77.56 | 81.32 | 81.09 |

| V013 | NSW | |||

| V014 | NSW | |||

| V015 | NSW | |||

| V018 | NSW | |||

| V020 | NSW | |||

| V021 | NSW | 78.32 | 81.15 | 83.10 |

| V022 | NSW | |||

| V023 | NSW |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandez, F.; Germinario, S.; Montagno, R.; Basile, R.; Borgioli, L.; Laviano, R. Experimental Procedures of Accelerated Aging and Evaluation of Effectiveness of Nanostructured Products for the Protection of Volterra (Italy) Panchina Stone. Buildings 2022, 12, 1685. https://doi.org/10.3390/buildings12101685

Fernandez F, Germinario S, Montagno R, Basile R, Borgioli L, Laviano R. Experimental Procedures of Accelerated Aging and Evaluation of Effectiveness of Nanostructured Products for the Protection of Volterra (Italy) Panchina Stone. Buildings. 2022; 12(10):1685. https://doi.org/10.3390/buildings12101685

Chicago/Turabian StyleFernandez, Federica, Silvia Germinario, Roberta Montagno, Roberta Basile, Leonardo Borgioli, and Rocco Laviano. 2022. "Experimental Procedures of Accelerated Aging and Evaluation of Effectiveness of Nanostructured Products for the Protection of Volterra (Italy) Panchina Stone" Buildings 12, no. 10: 1685. https://doi.org/10.3390/buildings12101685