Smart Sustainable Production Management for City Multifloor Manufacturing Clusters: An Energy-Efficient Approach to the Choice of Ceramic Filter Sintering Technology

Abstract

:1. Introduction

2. Literature Review

2.1. Smart Sustainable Production Management of Ceramic Materials within CMFMCs

2.2. Ceramic Filter Sintering Processes: An Energy-Efficient Approach

- -

- To develop a model and indicators to assess the energy efficiency of the choice of sintering technology for foam ceramic filters for smart sustainable CMFMCs.

- -

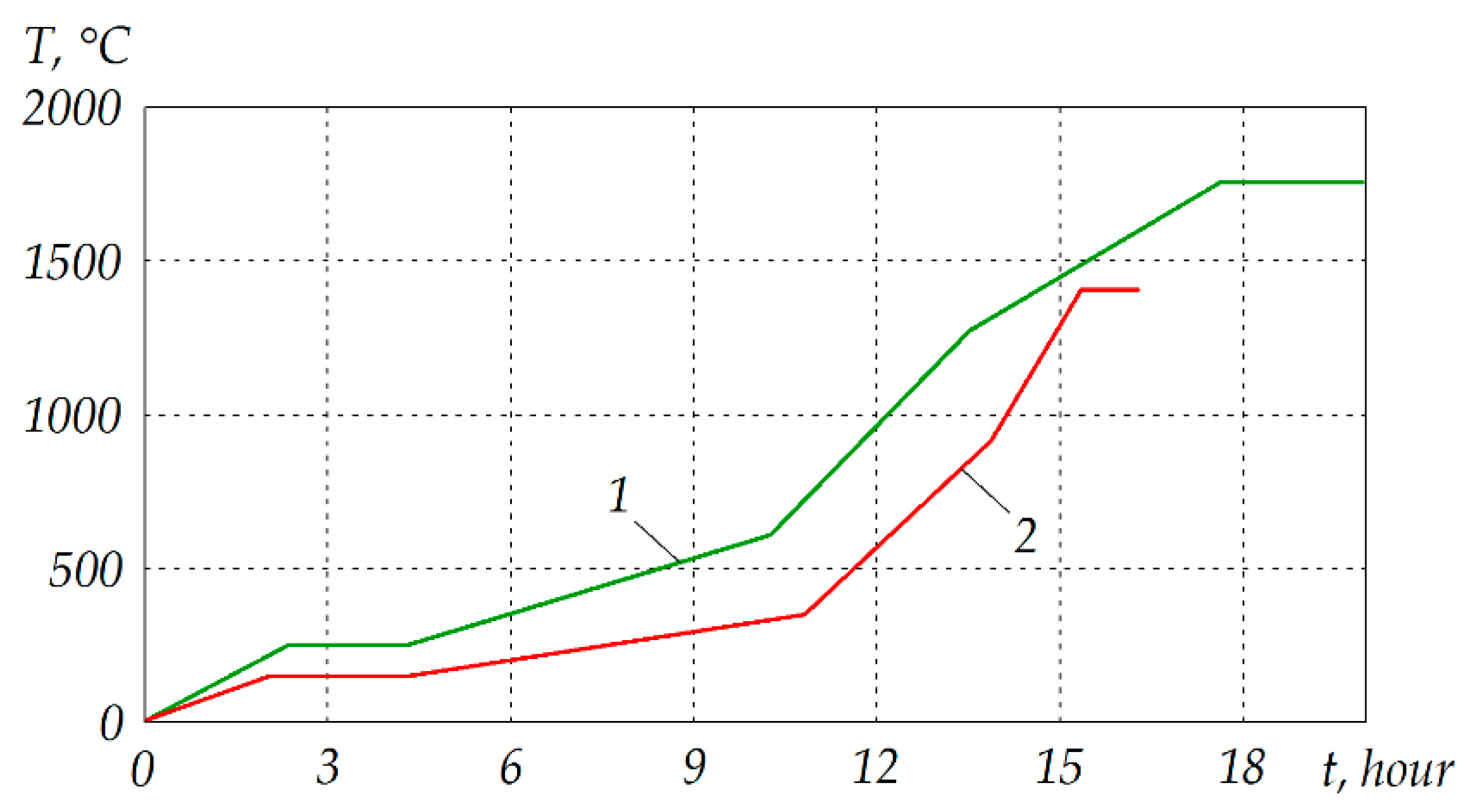

- To investigate the possibilities of relatively low-temperature technology using two percent additives of titanium and manganese dioxides before the technology of monoxide corundum ceramics in terms of time and energy intensity of heating and high-temperature holding.

- -

- To offer recommendations for operators/managers of production of foam composite filters on the choice of energy-efficient technologies and appropriate equipment for their application within the framework of smart sustainable CMFMCs.

3. Materials and Methods

- Each variant of the thermal cycle was considered as a set of stages of heating and high-temperature holding (the cooling stage together with the furnace or outside it was not considered, as either not needing electric power support at all or carried out with a relatively small energy intensity of such support);

- The sequence of stages corresponded to a nondecreasing sequence of values of the heating temperature and high-temperature holding, specified in a certain way by the regulations of the technological process;

- The energy consumption of thermal equipment was proportional to its installed capacity.

4. Results and Discussion

5. Managerial Implications

- -

- This research could help managers in organizing the production of foam ceramic filters within CMFMCs, providing the smart management of production and supply chains in real time and avoiding negative economic, social and environmental consequences [1,3,4,5]. At the same time, this paper focused on issues related to decision making on energy reduction at the stage of choosing the technology and equipment for the production of foam ceramic filters.

- -

- The main purpose of this study was to develop the model and indicators to assess the energy efficiency of the choice of foam ceramic filter sintering technology, which are necessary tools for making managerial production and technological decisions within the framework of smart sustainable CMFMCs.

- -

- The choice of technological equipment is also related to the possibility of their delivery and placement on the appropriate production floors of CMFMC buildings. The overall dimensions and weight of the technological equipment must satisfy the capabilities of the freight elevators the CMFMC buildings [1,3,27]. The use of large-sized technological equipment is possible only in a modular design with the possibility of modular delivery to production facilities, as well as a frame, lightweight design [25,26]. At the same time, it should be borne in mind that furnaces with large dimensions of working chambers for the implementation of thermal sintering processes and, consequently, large overall dimensions are more productive due to the simultaneous manufacture of a larger number of products.

- -

- The assessment of technologies, the choice of technological equipment and its placement in the cluster’s manufacturing building should be carried out considering the residual capabilities of its electrical network and the planned electricity costs for production needs for a certain period of time.

- -

- The choice of sintering technology for foam ceramic filters is based on the proposed model and indicators for assessing the energy efficiency of the manufacturing process. In addition, when choosing a technology for sintering foam ceramic filters, the dimensions of products and production volumes are considered. Realtime production planning should consider the residual capacity of the electrical network of each manufacturing building of the cluster.

- -

- The planning of operational and long-term schedules of electricity consumption by manufacturing enterprises in cases of using energy-intensive technological equipment in CMFMC buildings helps to prevent peak overloads of the electrical grid.

- -

- The uniform distribution of energy-intensive technological equipment between the manufacturing buildings of the cluster and its alternation with less energy-intensive technological processes and equipment at enterprises helps to reduce peak loads in the electrical grid due to the uniform redistribution of orders during the operational planning of the manufacture of energy-intensive products.

- -

- The use of a daily time fund with the lowest electricity tariffs for energy-intensive production and alternative renewable energy sources.

- -

- It should be noted that the high energy consumption for the process under consideration imposes the need for high-power medium voltage power lines. The action of such lines on building structures, especially those of steel or reinforced concrete construction, under the conditions of industrial environments may result in the development of corrosion or degradation processes. The important role of capacitive currents was indicated, as well as the role of stray currents generated as a result of asymmetrical loading of phases. Long-term exposure of facilities to such activities can, in turn, threaten their structural integrity [55].

- -

- The organization of production using high-temperature furnaces within the framework of CMFMCs was carried out on the basis of international standards, among which the following could be distinguished: ISO 50001:2018 Energy management systems—Requirements with guidance for use; ISO 23932-1:2018 Fire safety engineering; ISO 14006:2020 Environmental management systems—Guidelines for incorporating ecodesign; ISO 16890:2016 Air filters for general ventilation; ISO 45001:2018 Occupational health and safety management systems—Requirements with guidance for use [56].

6. Conclusions

- -

- The need to improve sintering technologies to obtain products with the necessary physical and mechanical properties at lower temperatures;

- -

- The possibility of organizing the production of various ceramic products within smart and sustainable CMFMCs considering the established restrictions on power consumption, overall dimensions and weight of the furnaces used.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Indexes | |

| I | Number of stages in the thermal cycle of heating and high-temperature holding in the sintering process of the foam ceramic filter, i = 1, 2, 3, …, n. |

| Parameters | |

| Heating time of item i (h); | |

| Heating intensity of item i (°C/h); | |

| Temperature of the high-temperature holding stage of item i (°C); | |

| Current time (h); | |

| Heat during reversible thermal processes of the system (kJ); | |

| Temperature of the system (°C); | |

| Entropy of the system (kJ/°C); | |

| Equivalent temperature of item i (°C); | |

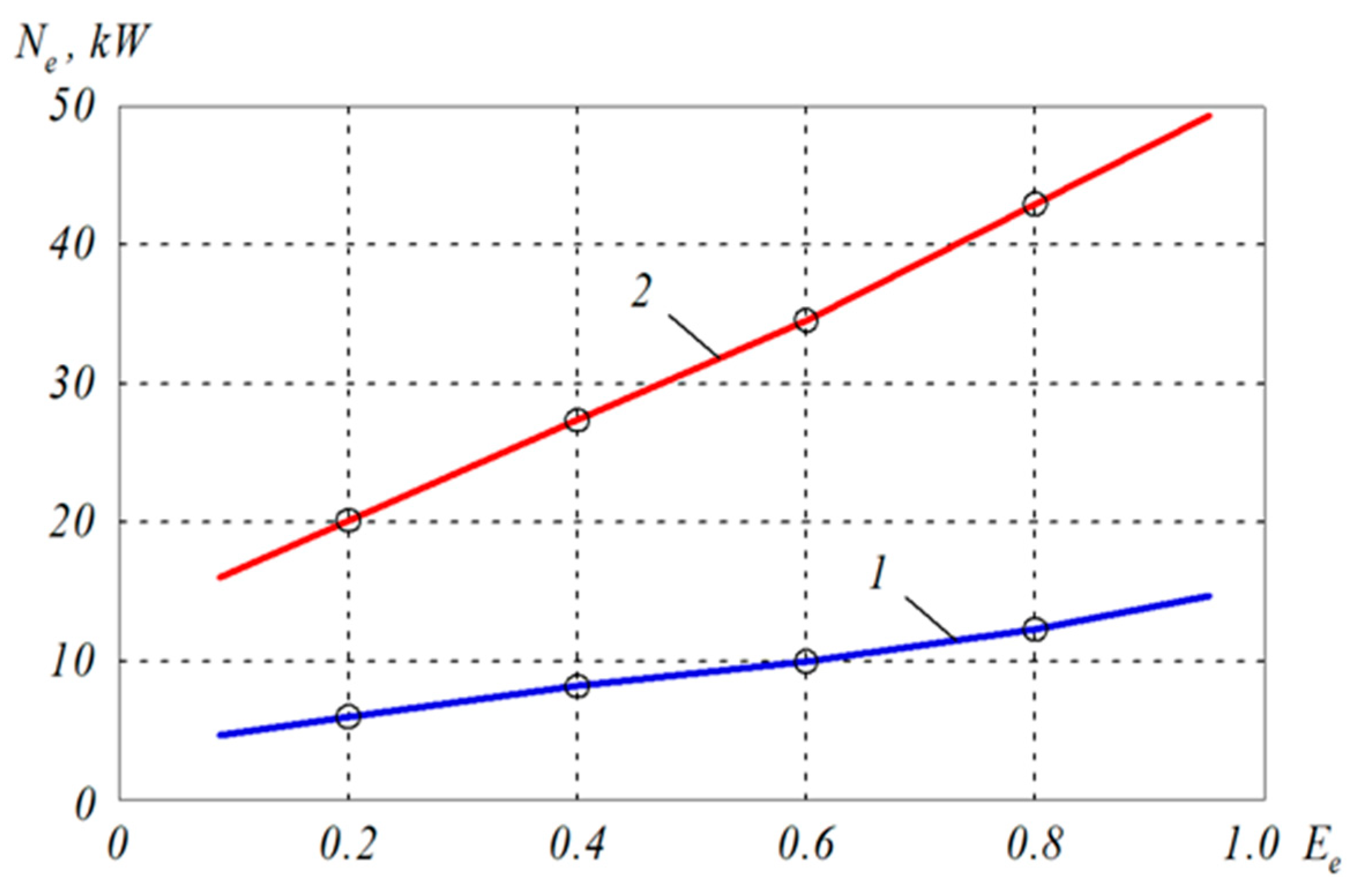

| Equivalent power of item i (kW); | |

| Maximum power during sintering process (kW); | |

| Maximum temperature during sintering process (°C); | |

| Proportionality factor (kW/°C); | |

| Initial temperature of furnace (°C); | |

| Increasing the initial temperature of furnace (°C); | |

| Reduction in heating time (h); | |

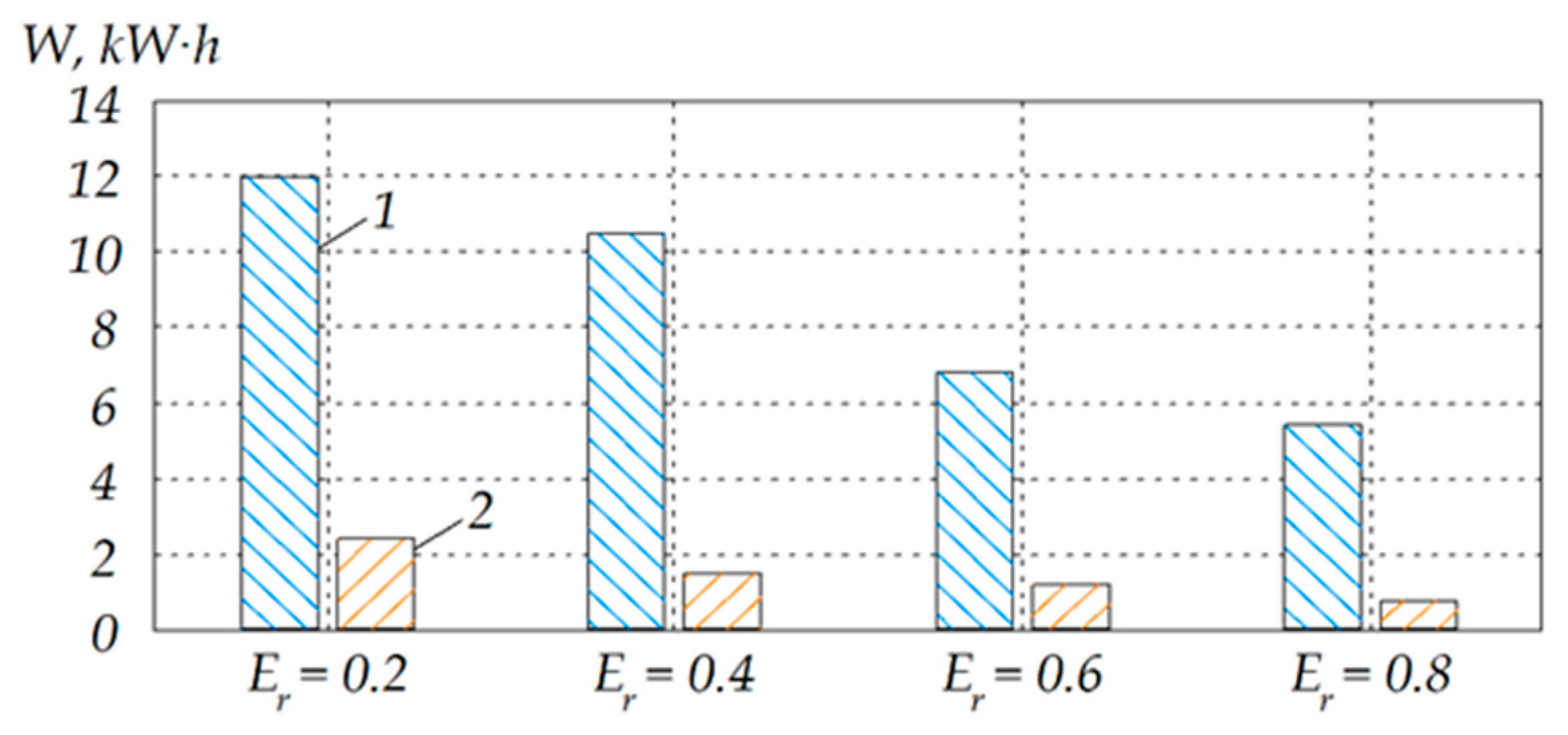

| Energy consumption (kW h); | |

| Indicator to assess the energy efficiency of thermal cycles during sintering process of the foam ceramic filter; | |

| Relative indicator to assess the energy efficiency of thermal cycles during sintering process of the foam ceramic filter; | |

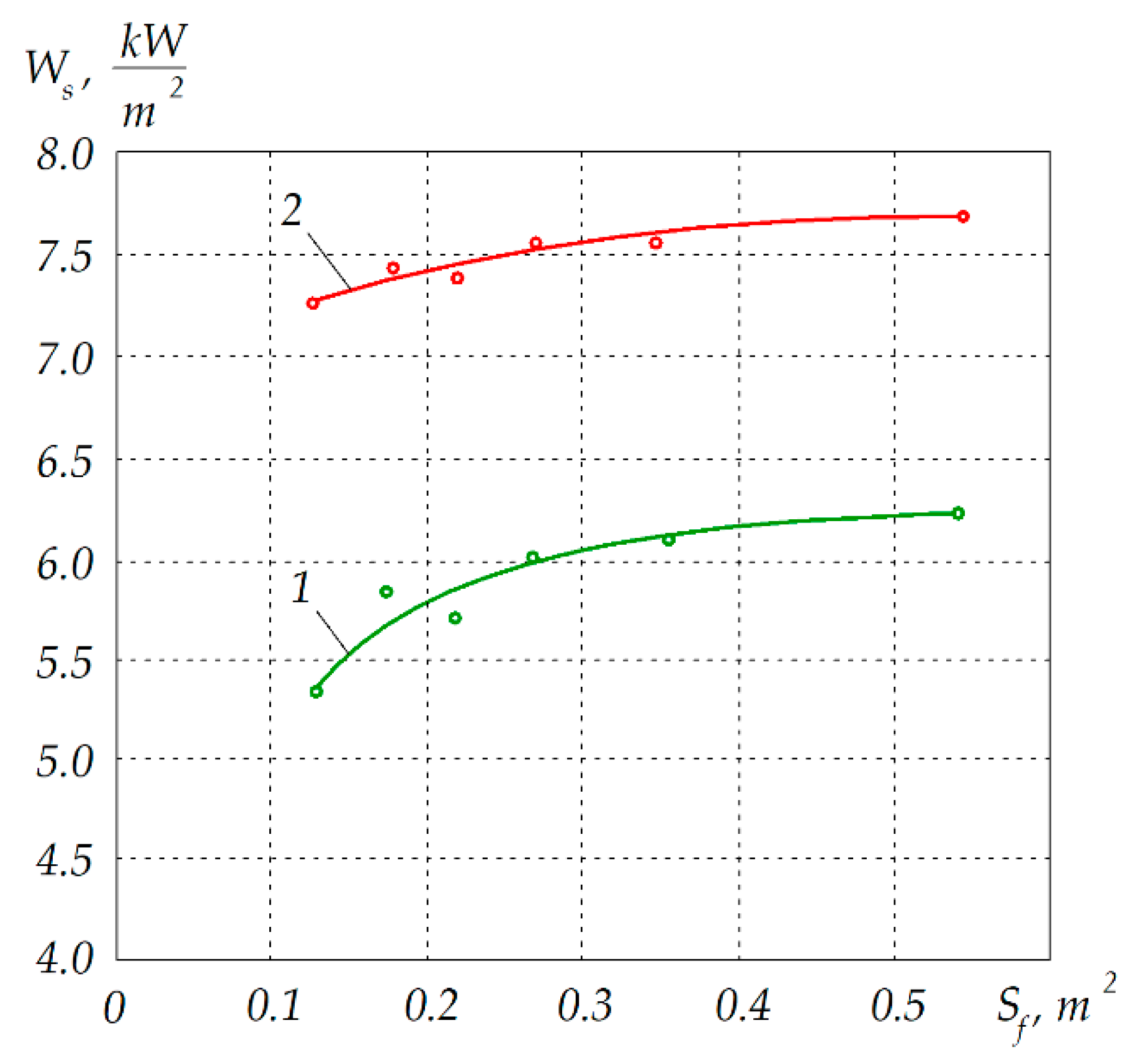

| Furnace hearth area (m2); | |

| Power distributed over the hearth area (kW/m2). | |

References

- Deja, A.; Dzhuguryan, T.; Dzhuguryan, L.; Konradi, O.; Ulewicz, R. Smart sustainable city manufacturing and logistics: A framework for city logistics node 4.0 operations. Energies 2021, 14, 8380. [Google Scholar] [CrossRef]

- Dzhuguryan, T.; Jóźwiak, Z.; Deja, A.; Semenova, A. Infrastructure and functions of a city logistics node for multi-floor manufacturing cluster. In Proceedings of the 8th International Scientific Conference CMDTUR, Žilina, Slovakia, 4–5 October 2018; pp. 196–201. [Google Scholar]

- Ingaldi, M.; Ulewicz, R. Problems with the implementation of industry 4.0 in enterprises from the SME sector. Sustainability 2020, 12, 217. [Google Scholar] [CrossRef]

- Dudek, T.; Dzhuguryan, T.; Wiśnicki, B.; Pędziwiatr, K. Smart Sustainable Production and Distribution Network Model for City Multi-Floor Manufacturing Clusters. Energies 2022, 15, 488. [Google Scholar] [CrossRef]

- Gevorkyan, E.S.; Gutsalenko, Y.G.; Litovchenko, S.V.; Chishkala, V.A. Development of alumina filtering ceramics using refractory water-soluble salt additives. Newsl. NTU KhPI 2003, 11, 39–44. (In Russian) [Google Scholar]

- Gevorkyan, E.S.; Gutsalenko, Y.G.; Litovchenko, S.V.; Chishkala, V.A. Development of Alum-oxide Filtering Ceramic with the Use of Burnable Additives. Newsl. NTU KhPI 2003, 11, 15–23. (In Russian) [Google Scholar]

- Thuault, A.; Savary, E.; Hornez, J.-C.; Moreau, G.; Descamps, M.; Marinel, S.; Leriche, A. Improvement of the hydroxyapatite mechanical properties by direct microwave sintering in single mode cavity. J. Eur. Ceram. Soc. 2014, 34, 1865–1871. [Google Scholar] [CrossRef]

- Rohit, S.; Varun, S. Experimental investigation for cutting performance of cemented carbide cutting insert developed through microwave sintering. Int. J. Refract. Met. Hard Mater. 2022, 106, 105867. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Hasan, A.S.M.M.; Trianni, A. A Review of Energy Management Assessment Models for Industrial Energy Efficiency. Energies 2020, 13, 5713. [Google Scholar] [CrossRef]

- Davydenko, L.; Davydenko, N.; Bosak, A.; Bosak, A.; Deja, A.; Dzhuguryan, T. Smart Sustainable Freight Transport for a City Multi-Floor Manufacturing Cluster: A Framework of the Energy Efficiency Monitoring of Electric Vehicle Fleet Charging. Energies 2022, 15, 3780. [Google Scholar] [CrossRef]

- Brunke, J.C.; Johansson, M.; Thollander, P. Empirical investigation of barriers and drivers to the adoption of energy conservation measures, energy management practices and energy services in the Swedish iron and steel industry. J. Clean. Prod. 2014, 84, 509–525. [Google Scholar] [CrossRef]

- Soepardi, A.; Thollander, P. Analysis of Relationships among Organizational Barriers to Energy Efficiency Improvement: A Case Study in Indonesia’s Steel Industry. Sustainability 2018, 10, 216. [Google Scholar] [CrossRef] [Green Version]

- Trianni, A.; Cagno, E.; Thollander, P.; Backlund, S. Barriers to industrial energy efficiency in foundries: A European comparison. J. Clean. Prod. 2013, 40, 161–176. [Google Scholar] [CrossRef]

- Trianni, A.; Cagno, E.; Farné, S. Barriers, drivers and decision-making process for industrial energy efficiency: A broad study among manufacturing small and medium-sized enterprises. Appl. Energy 2016, 162, 1537–1551. [Google Scholar] [CrossRef]

- Frazzon, E.M.; Agostino, I.R.S.; Broda, E.; Freitag, M. Manufacturing networks in the era of digital production and operations: A socio-cyber-physical perspective. Annu. Rev. Control 2020, 49, 288–294. [Google Scholar] [CrossRef]

- Kusiak, A. Smart manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q. Environmental sustainability and production: Taking the road less travelled. Int. J. Prod. Res. 2018, 56, 743–759. [Google Scholar] [CrossRef]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart manufacturing and intelligent manufacturing: A comparative Review. Engineering 2020, 7, 738–757. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency (LAST UPDATED ON JANUARY 31, 2022), Sustainable Manufacturing. Available online: https://www.epa.gov/sustainability/sustainable-manufacturing (accessed on 18 July 2022).

- Bag, S.; Pretorius, J.H.C. Relationships between industry 4.0, sustainable manufacturing and circular economy: Proposal of a research framework. Int. J. Organ. Anal. 2020, 30, 1934–8835. [Google Scholar] [CrossRef]

- Dzhuguryan, T.; Deja, A.; Wiśnicki, B.; Jóźwiak, Z. The Design of sustainable city multi-floor manufacturing processes under uncertainty in supply chains. Sustainability 2020, 12, 9439. [Google Scholar] [CrossRef]

- Westkämper, E. Towards the Re-Industrialization of Europe: A Concept for Manufacturing for 2030; Springer Science and Business Media LLC: Berlin, Germany, 2014. [Google Scholar]

- Dzhuguryan, T.; Deja, A. Sustainable waste management for a city multifloor manufacturing cluster: A framework for designing a smart supply chain. Sustainability 2021, 13, 1540. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Gilka, N.; Grigoryan, G.; Dzhuguryan, T.; Linchevski, P.; Markarov, G.; Pupin, A. Flexible Manufacturing. Module. Patent SU 1380915A1, 21 November 1988. [Google Scholar]

- Dzhuguryan, T.; Wiśnicki, B.; Dudek, T. Concept of intelligent reconfigurable trolleys for city multi-floor manufacturing and logistics system. In Proceedings of the 8th Carpathian Logistics Congress (CLC2018), Prague, Czech Republic, 3–5 December 2018; pp. 254–259. [Google Scholar]

- Ye, F.; Zhang, J.; Liu, L.; Zhan, H. Effect of solid content on pore structure and mechanical properties of porous silicon nitride ceramics produced by freeze casting. Mater. Sci. Eng. 2011, 528, 1421–1424. [Google Scholar]

- Zhaoping, H.; Feng, Y.; Limeng, L.; Qiang, L.; Haijiao, Z. Effects of solid content on the phase assemblages, mechanical and dielectric properties of porous a-SiAlON ceramics fabricated by freeze casting. Ceram. Int. 2013, 39, 1075–1079. [Google Scholar]

- Jung-Hye, E.; Young-Wook, K.; Chul, P.; Chunmin, W. Effect of forming methods on porosity and compressive strength of polysiloxane-derived porous silicon carbide ceramics. J. Ceram. Soc. Jpn. 2012, 120, 199–203. [Google Scholar]

- Heness, G.; Booth, N.; Ben-Nissan, B. Specimen size effects on the compressive strength of porous, open cell ceramics-size matters. J. Aust. Ceram. Soc. 2014, 50, 176–179. [Google Scholar]

- Babafemi, A.; Yinusa, D. Formulation of ceramic water filter composition for the treatment of heavy metals and correction of physiochemical parameters in household water. Art and Design Rev. 2015, 3, 94–100. [Google Scholar]

- Gevorkyan, E.; Nerubatskyi, V.; Gutsalenko, Y.; Melnik, O.; Voloshyna, L. Examination of patterns in obtaining porous structures from submicron aluminum oxide powder and its mixtures. East. Eur. J. Enterp. Technol. 2020, 6, 41–49. [Google Scholar] [CrossRef]

- Nair, C.S.; Kani, K.M. Evaluating the performance of locally made ceramic filters for household water treatment. Int. J. Res. Technol. Stud. 2017, 4, 40–45. [Google Scholar]

- Enyew, A.Z.; Tesfaye, B.B. Clay ceramic filter for water treatment. Mater. Sci. Appl. Chem. 2017, 34, 69–74. [Google Scholar]

- Jackson, K.N.; Smith, J.A. A new method for the deposition of metallic silver on porous ceramic water filters. J. Nanotechnol. 2018, 2018, 2573015. [Google Scholar] [CrossRef]

- Andrievski, R.A. In Processing and properties of nanocrystalline materials. J. Mater. Sci. 2003, 38, 1367–1380. [Google Scholar] [CrossRef]

- Gevorkyan, E.S.; Rucki, M.; Kagramanyan, A.A.; Nerubatskiy, V.P. Composite material for instrumental applications based on micro powder Al2O3 with additives nano-powder SiC. Int. J. Refract. Met. Hard Mater. 2019, 82, 336–339. [Google Scholar] [CrossRef]

- Gevorkyan, E.; Mamalis, A.; Vovk, R.; Semiatkowski, Z.; Morozow, D.; Nerubatskyi, V.; Morozova, O. Special features of manufacturing cutting inserts from nanocomposite material Al2O3-SiC. J. Instrum. 2021, 16, 10015. [Google Scholar] [CrossRef]

- Gevorkyan, E.; Nerubatskyi, V.; Chyshkala, V.; Gutsalenko, Y.; Morozova, O. Determining the influence of ultra-dispersed aluminum nitride impurities on the structure and physical-mechanical properties of tool ceramics. East. Eur. J. Enterp. Technol. 2021, 6, 40–52. [Google Scholar] [CrossRef]

- Niihara, K. New design concept of structural ceramics. Ceram. Nanocomposites 1991, 82, 974–982. [Google Scholar] [CrossRef]

- Gevorkyan, E.; Rucki, M.; Krzysiak, Z.; Chishkala, V.; Zurowski, W.; Kucharczyk, W.; Barsamyan, V.; Nerubatskyi, V.; Mazur, T.; Morozow, D.; et al. Analysis of the electroconsolidation process of fine-dispersed structures out of hot pressed Al2O3–WC nanopowders. Materials. 2021, 14, 6503. [Google Scholar] [CrossRef]

- Gevorkyan, E.S.; Nerubatskyi, V.P.; Vovk, R.V.; Morozova, O.M.; Chyshkala, V.O.; Gutsalenko, Y.G. Revealing thermomechanical properties of Al2O3–C–SiC composites at sintering. Funct. Mater. 2022, 29, 193–201. [Google Scholar] [CrossRef]

- Semchenko, G.D. Structural Ceramics and Refractories. Shtrich 2000, 304. (In Russian). Available online: https://scholar.google.com.ua/citations?view_op=view_citation&hl=ru&user=OSsE_qgAAAAJ&cstart=200&pagesize=100&sortby=pubdate&citation_for_view=OSsE_qgAAAAJ:u-x6o8ySG0sC (accessed on 1 August 2022).

- Polyakov, A.A. Technology of ceramic radioelectronic materials. Radio Commun. 1989, 200, 212–214. (In Russian) [Google Scholar]

- Chyshkala, V.O.; Lytovchenko, S.V.; Nerubatskyi, V.P.; Vovk, R.V.; Gevorkyan, E.S.; Morozova, O.M. Detection of regularities of Y2Zr2O7 pyrochlor phase formation during the reaction of solid-phase synthesis under different temperature-time conditions. Funct. Mater. 2022, 29, 30–38. [Google Scholar] [CrossRef]

- Gevorkyan, E.; Nerubatskyi, V.; Chyshkala, V.; Morozova, O. Revealing specific features of structure formation in composites based on nanopowders of synthesized zirconium dioxide. East. Eur. J. Enterp. Technol. 2021, 5, 6–19. [Google Scholar] [CrossRef]

- Stanciu, L.A.; Kodash, V.Y.; Groza, J.R. Effects of heating rate on densification and grain growth during field-assisted sintering of Al2O3 and MoSi2. Mat. Metal. Trans. 2001, 32, 2633–2638. [Google Scholar] [CrossRef]

- Peng, H.X.; Fan, Z.; Evans, J.R.G.; Busfield, J.J.C. Microstructure of ceramic foam. Eur. Ceram. Soc. 2000, 20, 807–813. [Google Scholar] [CrossRef]

- Ding, X.J.; Zhang, J.Z.; Wang, R.D.; Feng, C.D. A novel preparation of porous alumina with parallel channels. Mater. Lett. 2001, 51, 429–433. [Google Scholar] [CrossRef]

- Čápek, V.; Sheehan, D.P. Challenges to the Second Law of Thermodynamics: Theory and Experiment; Springer: Berlin, Germany, 2005. [Google Scholar]

- Zhang, Y.; Li, Q.; Zhou, H. Theory and Calculation of Heat Transfer in Furnaces; Academic Press: New York, NY, USA, 2016. [Google Scholar]

- Gevorkyan, E.S.; Gutsalenko, Y.G.; Litovchenko, S.V.; Chishkala, V.A. Intensification of sintering of corundum ceramics by titanium and manganese dioxides additives. Newsl. NTU KhPI 2003, 9, 55–63. [Google Scholar]

- Saggio-Woyansky, J.; Scott, C.E.; Minnear, W.P. Processing of Porous Ceramics. Am. Ceram. Soc. 1992, 71, 1674–1682. [Google Scholar]

- Kozak, M.; Chmiel, J. Cold ironing galvanic corrosion issues with regard to a shore-to-ship medium voltage connection. Energies 2020, 13, 5372. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). 2019. Available online: https://www.iso.org/home.html (accessed on 18 July 2022).

| N/N | Name of Characteristics | Percentage (%) |

|---|---|---|

| Fractional composition: | ||

| 0.3…0.4 (μm) | 50.0 | |

| 1 | 0.2…0.3 (μm) | 30.0 |

| 0.1…0.2 (μm) | 14.0 | |

| Less than 1 (μm) | 6.0 | |

| Content of the main impurities: | ||

| Fe2O3 | 0.003 | |

| 2 | Na2O | 0.001 |

| SiO2 | 0.010 | |

| TiO2 | 0.002 |

| N/N | Name of Characteristics | Percentage (%) |

|---|---|---|

| Fractional composition: | ||

| 0.3…0.4 (μm) | 45.0 | |

| 1 | 0.2…0.3 (μm) | 25.0 |

| 0.1…0.2 (μm) | 23.0 | |

| Less than 1 (μm) | 7.0 | |

| Content of the main impurities: | ||

| Fe2O3 | 0.003 | |

| 2 | Na2O | 0.001 |

| SiO2 | 0.011 | |

| TiO2 | 0.002 |

| Model | Outer Dimensions (mm) | Inner Dimensions (mm) | Power (kW) | Weight (kg) |

|---|---|---|---|---|

| Top 60/L | 600 × 890 × 850 | 410 × 410 × 340 | 29 | 72 |

| Top 100 | 660 × 960 × 970 | 480 × 480 × 570 | 126 | 102 |

| Top 140 | 750 × 1040 × 990 | 550 × 550 × 570 | 168 | 124 |

| Technology | Characteristics of Furnace | Characteristics of Technology Stages | Sequence of Stages of Heating and High-Temperature Holding | ||||||

|---|---|---|---|---|---|---|---|---|---|

| I | II | III | IV | V | VI | ||||

| Typical with additive 13% Cr2O3 | 1400 | 2.5 | Duration of the stage (h) | 1.75 | 1.0 | 12.5 | 1.0 | 14.15 | 5.0 |

| Average temperature (°C) | 72.5 | 125 | 312.5 | 500 | 925 | 1350 | |||

| Average power (kW) | 0.10 | 0.19 | 0.53 | 0.87 | 1.64 | 2.41 | |||

| Energy consumption (kW h) | 0.17 | 0.19 | 6.62 | 0.87 | 23.2 | 12.05 | |||

| Intensified without metal oxide additives | 2500 | 35 | Duration of the stage (h) | 2.3 | 2.0 | 5.8 | 3.25 | 4.15 | 2.5 |

| Average temperature (°C) | 135 | 250 | 425 | 925 | 1500 | 1750 | |||

| Average power (kW) | 1.62 | 3.25 | 5.72 | 12.77 | 20.89 | 24.42 | |||

| Energy consumption (kW h) | 3.73 | 6.49 | 33.15 | 4.51 | 86.68 | 61.04 | |||

| Intensified with additives 2% TiO2 + 2% MnO2 | 1400 | 2.5 | Duration of the stage (h) | 2.15 | 2.0 | 6.65 | 3.05 | 1. 35 | 1.0 |

| Average temperature (°C) | 85 | 150 | 250 | 625 | 1150 | 1400 | |||

| Average power (kW) | 0.12 | 0.24 | 0.42 | 1.10 | 2.05 | 2.50 | |||

| Energy consumption (kW h) | 0.25 | 0.47 | 2.77 | 3.34 | 2.76 | 2.50 | |||

| Technology | Furnace Characteristics | Initial Temperature T0 (°C) | Estimated Estimates | ||||

|---|---|---|---|---|---|---|---|

(°C) | (kW) | Te (°C) | (kW) | W (kW h) | (h) | ||

| Intensified without metal oxide additives | 2500 | 35 | 20 | 835.8 | 11.70 | 236.37 | 20.2 |

| 40 | 844.1 | 11.63 | 232.61 | 20.0 | |||

| Intensified with additives 2% TiO2 + 2% MnO2 | 1400 | 2.5 | 20 | 423.5 | 0.76 | 12.52 | 16.55 |

| 40 | 432.3 | 0.75 | 12.10 | 16.2 | |||

| Technology | Characteristics | |||

|---|---|---|---|---|

| Density (g/cm3) | Flexural Strength (MPa) | Porosity (%) | Air Permeability (nPa) | |

| Intensified without metal oxide additives | 1.20 | 10.5 | 63 | 200 |

| Intensified with additives 2%TiO2 + 2% MnO2 | 1.35 | 25 | 70 | 250 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gevorkyan, E.; Chmiel, J.; Wiśnicki, B.; Dzhuguryan, T.; Rucki, M.; Nerubatskyi, V. Smart Sustainable Production Management for City Multifloor Manufacturing Clusters: An Energy-Efficient Approach to the Choice of Ceramic Filter Sintering Technology. Energies 2022, 15, 6443. https://doi.org/10.3390/en15176443

Gevorkyan E, Chmiel J, Wiśnicki B, Dzhuguryan T, Rucki M, Nerubatskyi V. Smart Sustainable Production Management for City Multifloor Manufacturing Clusters: An Energy-Efficient Approach to the Choice of Ceramic Filter Sintering Technology. Energies. 2022; 15(17):6443. https://doi.org/10.3390/en15176443

Chicago/Turabian StyleGevorkyan, Edwin, Jarosław Chmiel, Bogusz Wiśnicki, Tygran Dzhuguryan, Mirosław Rucki, and Volodymyr Nerubatskyi. 2022. "Smart Sustainable Production Management for City Multifloor Manufacturing Clusters: An Energy-Efficient Approach to the Choice of Ceramic Filter Sintering Technology" Energies 15, no. 17: 6443. https://doi.org/10.3390/en15176443

APA StyleGevorkyan, E., Chmiel, J., Wiśnicki, B., Dzhuguryan, T., Rucki, M., & Nerubatskyi, V. (2022). Smart Sustainable Production Management for City Multifloor Manufacturing Clusters: An Energy-Efficient Approach to the Choice of Ceramic Filter Sintering Technology. Energies, 15(17), 6443. https://doi.org/10.3390/en15176443