Advanced Composite Materials: A Panacea for Improved Electricity Transmission

Abstract

1. Introduction

2. Strength and Challenges of Transmission Conductors

3. Further Challenges of Electricity Transmission Grids

4. Robust Composite Materials for Transmission Conductors

4.1. Al-CNTs

4.2. Al-BN

4.3. Al-TiC

4.4. Al-SiC

5. Future Work

- (i)

- Production of the suggested Al composites with an improved powder technology technique such as spark plasma sintering. The fabrication would involve optimization of the process parameters and the reinforcement weight fraction. All the composites should be subjected to the same fabrication and testing conditions. Properties to be tested include mechanical, physical, electrochemical, tribological, and thermal properties. These tests would be able to confirm the composite with the best characteristics.

- (ii)

- The best performing composite should be produced and drawn into wire for onward characterization and testing. Properties to be tested on the drawn wire include ampacity, CTE, and tensile strength tests.

- (iii)

- Comparative analysis of the developed transmission conductor and the existing conductors on the basis of their properties and cost must be conducted.

6. Conclusions and Recommendations

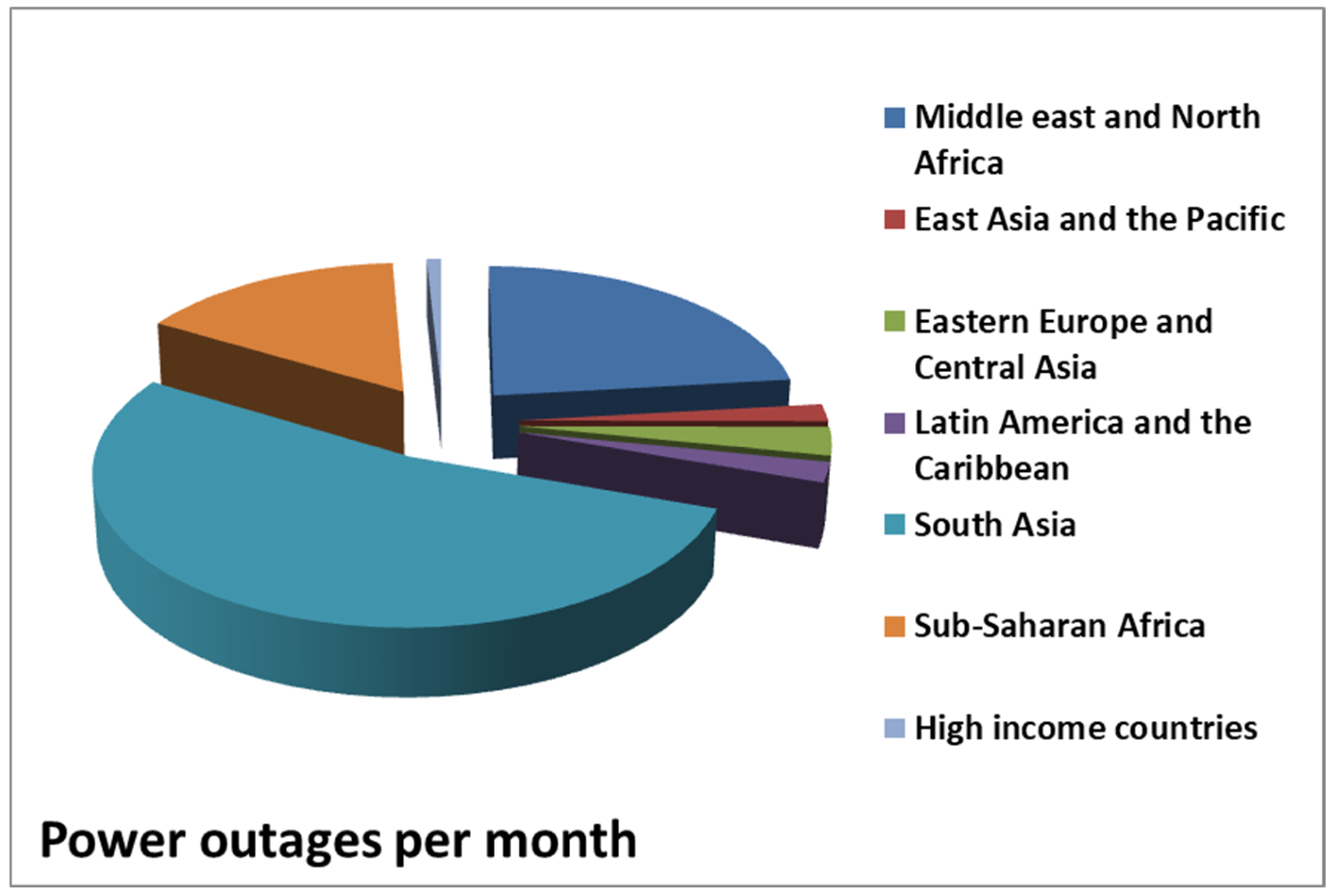

- South Asia, Middle East/North Africa, and sub-Saharan Africa are the three major regions mostly hit by frequent power outages.

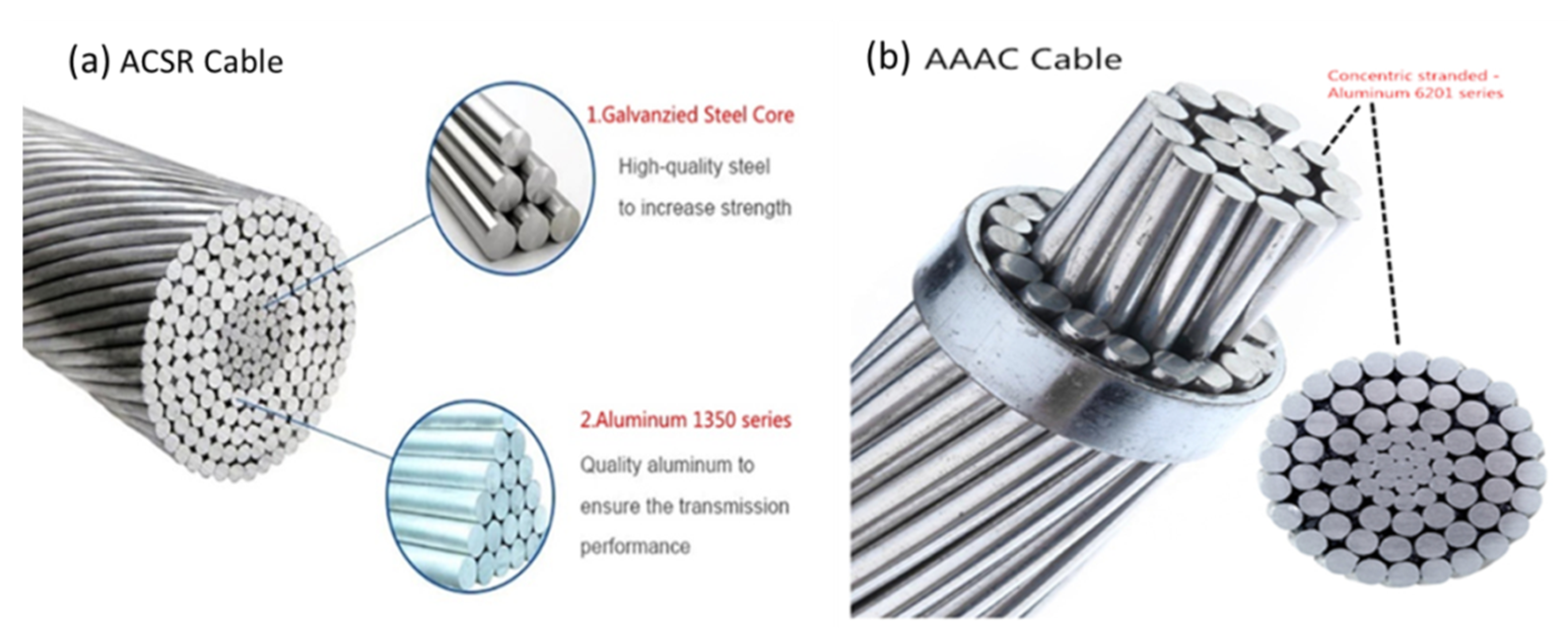

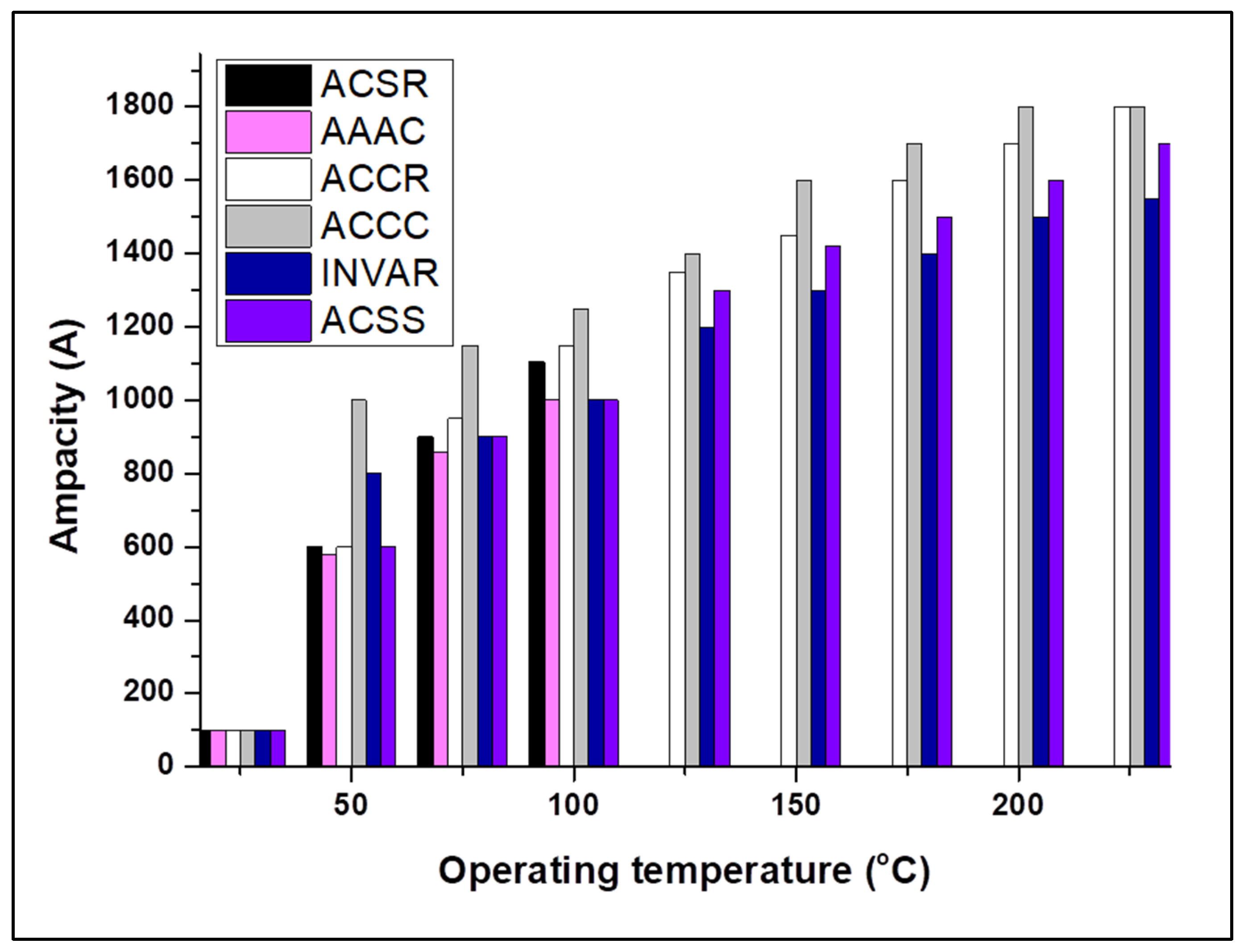

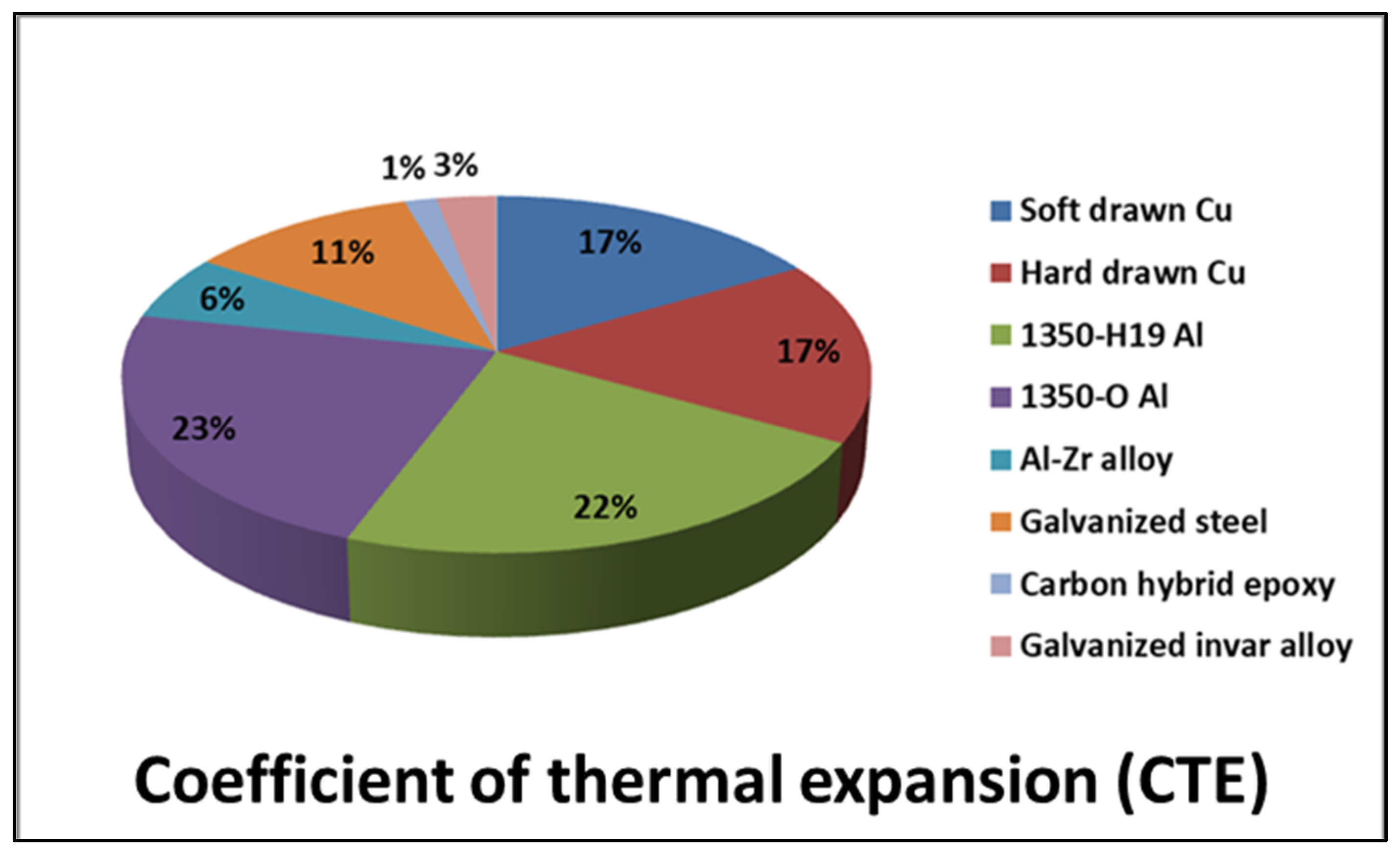

- AAAC and ACSR are challenged by a low operating temperature of 95 °C. HTLS conductors can withstand a temperature of 200 °C, above which makes them possess higher ampacity than the conventional conductors. However, ACCC and ACCR, being the best performing, are still challenged by low strength (for ACCC) and relatively high CTE (for ACCR). Hence, this is the imperativeness of this research.

- Monolithic Al lacks mechanical and tribological properties that are requisite of transmission conductors. So, it is recommended that it should be reinforced with nanoparticles of CNTs, BN, TiC, and SiC in binary and ternary composite systems, produced with SPS, that are characterized and tested. The obtained results should be used to confirm the best composite to be used for further studies.

- Lightning, bushfire, harsh weather, short circuit, and overloading also contribute to frequent power outages. These are natural environmental hazards that can hardly be avoided. So, to cushion their effects, flame- and heat-resistant nanomaterials are recommended to be used for reinforcing Al alloy that will be used in developing a robust transmission conductor.

- It is recommended that the best composite should be drawn into a wire and tested. The tests to be conducted should include ampacity, coefficient of thermal expansion (CTE), and tensile strength.

- Cost and property comparison of the developed conductor and the existing conductors should be conducted. It is expected that the proposed Al nanocomposites would have more ampacity, higher thermal conductivity, lower CTE, and better strength than the existing transmission conductors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Emetere, M.; Agubo, O.; Chikwendu, L. Erratic electric power challenges in Africa and the way forward via the adoption of human biogas resources. Energy Explor. Exploit. 2021, 39, 1349–1377. [Google Scholar] [CrossRef]

- Blimpo, M.P.; Cosgrove-Davies, M. Electricity Access in Sub-Saharan Africa: Uptake, Reliability, and Complementary Factors for Economic Impact; World Bank Publications: Washington, DC, USA, 2019. [Google Scholar]

- Padma, T. Biomass fuels blamed for premature deaths in rural settings. Nat. Med. 2007, 13, 112. [Google Scholar] [CrossRef] [PubMed]

- Trace, S. South Africa’s Crippling Electricity Problem; Oxford Policy Management: Oxford, UK, 2020. [Google Scholar]

- Ibrahim, I.; Hamam, Y.; Alayli, Y.; Jamiru, T.; Sadiku, E.; Kupolati, W.; Ndambuki, J.; Eze, A. A review on Africa energy supply through renewable energy production: Nigeria, Cameroon, Ghana and South Africa as a case study. Energy Strat. Rev. 2021, 38, 100740. [Google Scholar] [CrossRef]

- Sarkodie, S.A.; Adams, S. Electricity access and income inequality in South Africa: Evidence from Bayesian and NARDL analyses. Energy Strat. Rev. 2020, 29, 100480. [Google Scholar] [CrossRef]

- Arnold, J.M.; Mattoo, A.; Narciso, G. Services Inputs and Firm Productivity in Sub-Saharan Africa: Evidence from Firm-Level Data. J. Afr. Econ. 2008, 17, 578–599. [Google Scholar] [CrossRef]

- Fisher-Vanden, K.; Mansur, E.T.; Wang, Q.J. Electricity shortages and firm productivity: Evidence from China’s industrial firms. J. Dev. Econ. 2015, 114, 172–188. [Google Scholar] [CrossRef]

- Fakih, A.; Ghazalian, P.; Ghazzawi, N. The Effects of Power Outages on the Performance of Manufacturing Firms in the MENA Region. Rev. Middle East Econ. Financ. 2020, 16, 1–28. [Google Scholar] [CrossRef]

- Sule, A. Major factors affecting electricity generation, transmission and distribution in Nigeria. Int. J. Eng. Math. Intell. 2010, 1, 159–164. [Google Scholar]

- Alawar, A.; Bosze, E.; Nutt, S. A Composite Core Conductor for Low Sag at High Temperatures. IEEE Trans. Power Deliv. 2005, 20, 2193–2199. [Google Scholar] [CrossRef]

- Abbass, M.K.M.K.; Anaee, R.A.; Jabar, M.M. Corrosion Behavior of Friction Stir Welded of Similar and Dissimilar Al2024-T3 and Al7075-T73 Alloys. Int. J. Ser. Eng. Sci. (IJSES) 2016, 2, 1–15. [Google Scholar]

- Ma, X.; Gao, L.; Zhang, J.; Zhang, L.-C. Fretting Wear Behaviors of Aluminum Cable Steel Reinforced (ACSR) Conductors in High-Voltage Transmission Line. Metals 2017, 7, 373. [Google Scholar] [CrossRef]

- Ujah, C.O.; Popoola, A.P.I.; Popoola, O.M. Review on materials applied in electric transmission conductors. J. Mater. Sci. 2022, 57, 1581–1598. [Google Scholar] [CrossRef]

- Zheng, X.; Chen, G. Propagation mechanism of electrical tree in XLPE cable insulation by investigating a double electrical tree structure. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 800–807. [Google Scholar] [CrossRef]

- Arif, A.; Arif, A.F.M.; Sheikh, A.K.; Qamar, S.Z.; Raza, M.K.; Al-Fuhaid, K.M. Product defects in aluminum extrusion and its impact on operational cost. In Proceedings of the 6th Saudi Engineering Conference, KFUPM, Dhahran, Saudi Arabia, 14–17 December 2002. [Google Scholar]

- Krasnovskii, A.; Kazakov, I. Determination of the Optimal Speed of Pultrusion for Large-Sized Composite Rods. J. Encapsulation Adsorpt. Sci. 2012, 2, 21–26. [Google Scholar] [CrossRef][Green Version]

- Wang, D.; Xu, Y.; Duan, B.; Wang, Y.; Song, M.; Yu, H.; Liu, H. Intelligent Recognition Model of Hot Rolling Strip Edge Defects Based on Deep Learning. Metals 2021, 11, 223. [Google Scholar] [CrossRef]

- Giordano, M.; Nicolais, L. Resin flow in a pultrusion process. Polym. Compos. 1997, 18, 681–686. [Google Scholar] [CrossRef]

- Khan, J.; Dalu, R.; Gadekar, S. Defects in extrusion process and their impact on product quality. Int. J. Mech. Eng. Robot. Res. 2014, 3, 187. [Google Scholar]

- Khorasani, M.; Ghasemi, A.; Rolfe, B.; Gibson, I. Additive manufacturing a powerful tool for the aerospace industry. Rapid Prototyp. J. 2022, 28, 87–100. [Google Scholar] [CrossRef]

- Wang, R.; Chen, Y.; Peng, X.; Cong, N.; Fang, D.; Liang, X.; Shang, J. Topological design of the hybrid structure with high damping and strength efficiency for additive manufacturing. Rapid Prototyp. J. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Lovo, J.F.P.; Neto, V.G.; Piedade, L.P.; Massa, R.C.; Pintão, C.A.; Foschini, C.R.; Fortulan, C.A. Mechanical properties assessment of a 3D printed composite under torsional and perpendicular stress. Rapid Prototyp. J. 2022. ahead-of-print. [Google Scholar] [CrossRef]

- Fayomi, O.; Aigbodion, V.; Abdulwahab, M. Surface modification, strengthening effect and electrochemical comparative study of Zn-Al2O3-CeO3 and Zn-TiO2-CeO3 coating on mild steel. Int. J. Adv. Manuf. Technol. 2016, 85, 1419–1427. [Google Scholar]

- Glover, J.D.; Sarma, M.S.; Overbye, T. Power System Analysis & Design; SI Version; Cengage Learning: Boston, MA, USA, 2012. [Google Scholar]

- Thrash, F.R. Transmission Conductors—A Review of the Design and Selection Criteria, Technical Support Article, Southwire Company. 2014. Available online: http://www.southwire.com/support/TransmissionConductoraReviewOfTheDesignandSelectionCriteria.htm (accessed on 9 June 2022).

- Banerjee, K. Making the Case for High Temperature Low Sag (htls) Overhead Transmission Line Conductors; Arizona State University: Tempe, AZ, USA, 2014. [Google Scholar]

- Huang, Y.; Kormakov, S.; He, X.; Gao, X.; Zheng, X.; Liu, Y.; Sun, J.; Wu, D. Conductive Polymer Composites from Renewable Resources: An Overview of Preparation, Properties, and Applications. Polymers 2019, 11, 187. [Google Scholar] [CrossRef] [PubMed]

- Blume, S.W. Electric Power System Basics for the Nonelectrical Professional; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Chen, G.; Wang, X.; Wang, J.; Liu, J.; Zhang, T.; Tang, W. Damage investigation of the aged aluminium cable steel reinforced (ACSR) conductors in a high-voltage transmission line. Eng. Fail. Anal. 2012, 19, 13–21. [Google Scholar] [CrossRef]

- Qiao, K.; Zhu, A.; Wang, B.; Di, C.; Yu, J.; Zhu, B. Characteristics of Heat Resistant Aluminum Alloy Composite Core Conductor Used in overhead Power Transmission Lines. Materials 2020, 13, 1592. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Wang, H.; Liu, C.; Liu, Y.; Guo, C. Experimental Analysis on Mechanical Properties of Aluminum Conductor Steel-reinforced for Transmission Line. J. Phys. Conf. Ser. 2021, 2108, 012099. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, P.; Popoola, O.; Aigbodion, V. Enhanced mechanical, electrical and corrosion characteristics of Al-CNTs-Nb composite processed via spark plasma sintering for conductor core. J. Compos. Mater. 2019, 53, 3775–3786. [Google Scholar] [CrossRef]

- Nakada, Y. Thermal Oxidation Behavior of Magnesium Silicide with Added Alumina or Aluminum. Mater. Trans. 2021, 62, 871–879. [Google Scholar] [CrossRef]

- Mohtar, S.N.; Jamal, N.; Sulaiman, M. Analysis of all aluminum conductor (AAC) and all aluminum alloy conductor (AAAC). In Proceedings of the 2004 IEEE Region 10 Conference TENCON 2004, Chiang Mai, Thailand, 24 November 2004; IEEE: Manhattan, NY, USA, 2004. [Google Scholar]

- Kühnel, C.; Bardl, R.; Stengel, D.; Kiewitt, W.; Grossmann, S. Investigations on the mechanical and electrical behaviour of HTLS conductors by accelerated ageing tests. CIRED-Open Access Proc. J. 2017, 2017, 273–277. [Google Scholar] [CrossRef]

- Nuchprayoon, S.; Chaichana, A. Cost evaluation of current uprating of overhead transmission lines using ACSR and HTLS conductors. In Proceedings of the 2017 IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Milan, Italy, 6–9 June 2017; IEEE: Manhattan, NY, USA, 2017. [Google Scholar]

- Tokombayev, A.; Heydt, G.T. High temperature low sag (HTLS) technologies as upgrades for overhead transmission systems. In Proceedings of the 2013 North American Power Symposium (NAPS), Manhattan, KS, USA, 22–24 September 2013; IEEE: Manhattan, NY, USA, 2013. [Google Scholar]

- Zainuddin, N.M.; Rahman, M.S.A.; Kadir, M.Z.A.A.; Ali, N.H.N.; Ali, Z.; Osman, M.; Mansor, M.; Ariffin, A.M.; Nor, S.F.M.; Nasir, N.A.F.M. Review of Thermal Stress and Condition Monitoring Technologies for Overhead Transmission Lines: Issues and Challenges. IEEE Access 2020, 8, 120053–120081. [Google Scholar] [CrossRef]

- Reddy, B.S.B.; Das, K.; Das, S. A review on the synthesis of in situ aluminum based composites by thermal, mechanical and mechanical–thermal activation of chemical reactions. J. Mater. Sci. 2007, 42, 9366–9378. [Google Scholar] [CrossRef]

- Reddy, B.S.; Chatterjee, D. Analysis of High Temperature Low Sag Conductors Used for High Voltage Transmission. Energy Procedia 2016, 90, 179–184. [Google Scholar] [CrossRef]

- Ippolito, M.G.; Massaro, F.; Cassaro, C. HTLS Conductors: A Way to Optimize RES Generation and to Improve the Competitiveness of the Electrical Market—A Case Study in Sicily. J. Electr. Comput. Eng. 2018, 2018, 2073187. [Google Scholar] [CrossRef]

- Weyer, D.F. Material Evaluation: Self Damping Wire SD/ACSR Conductor Failures. Master’s Thesis, University of Nebraska-Lincoln, Lincoln, NE, USA, 2016. [Google Scholar]

- Shivashankar, G. Overview of different overhead transmission line conductors. Mater. Today Proc. 2017, 4, 11318–11324. [Google Scholar] [CrossRef]

- Thrash, F. ACSS/TW-An improved high temperature conductor for upgrading existing lines or new construction. In Proceedings of the 2001 Power Engineering Society Summer Meeting. Conference Proceedings (Cat. No. 01CH37262), Vancouver, BC, Canada, 15–19 July 2001; IEEE: Manhattan, NY, USA, 2001. [Google Scholar]

- Reddy, B.S.; Chatterjee, D. Performance evaluation of high temperature high current conductors. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1570–1579. [Google Scholar] [CrossRef]

- Morgan, V. Effect of elevated temperature operation on the tensile strength of overhead conductors. IEEE Trans. Power Deliv. 1996, 11, 345–352. [Google Scholar] [CrossRef]

- Johnson, D.; Anderson, T.; Deve, H. A new generation of high performance conductors. In Proceedings of the 2001 Power Engineering Society Summer Meeting. Conference Proceedings (Cat. No. 01CH37262), Vancouver, BC, Canada, 15–19 July 2001; IEEE: Manhattan, NY, USA, 2001. [Google Scholar]

- Beryozkina, S. Evaluation Study of Potential Use of Advanced Conductors in Transmission Line Projects. Energies 2019, 12, 822. [Google Scholar] [CrossRef]

- Ujah, C.O. Development and modelling of aluminium-carbon nanotubes-niobium composite conductor for high voltage transmission networks. In Chemical, Metallurgical and Materials Engineering; Tshwane University of Technology: Pretoria, South Africa, 2020; p. 340. [Google Scholar]

- Nawi, N.D.; Phang, F.A.; Yusof, K.M.; Rahman, N.F.A.; Zakaria, Z.Y.; Hassan, S.A.H.S.; Musa, A.N. Instilling Low Carbon Awareness through Technology-Enhanced Cooperative Problem Based Learning. Int. J. Emerg. Technol. Learn. 2019, 14, 152–166. [Google Scholar] [CrossRef]

- Atanasovski, M.; Arapinoski, B.; Kostov, M.; Trpezanovski, L. Comparison of ACSR, AAAC and ACCC Conductors for Transmission Overhead Lines. In Proceedings of the International Scientific Conference on Information, Communication and Energy Systems and Technologies, Ohrid, North Macedonia, 27–29 June 2019. [Google Scholar]

- Youcan, Y.; Yugang, D. A finite element method of modelling and designing of an ACCC conductor. MATEC Web Conf. 2018, 153, 01005. [Google Scholar] [CrossRef][Green Version]

- Chan, J.; Clairmont, B.; Rueger, D.; Childs, D.; Karki, S. Demonstration of Advanced Conductors for Overhead Transmission Lines; CEC-500-2013-030; Electric Power Research Institute: Palo Alto, CA, USA, 2008. [Google Scholar]

- Burks, B.; Armentrout, D.; Kumosa, M. Failure prediction analysis of an ACCC conductor subjected to thermal and mechanical stresses. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 588–596. [Google Scholar] [CrossRef]

- Slegers, J. Transmission Line Loading: Sag Calculations and High-Temperature Conductor Technologies; Iowa State University: Ames, IA, USA, 2011; pp. 1–24. [Google Scholar]

- Kotaka, S.; Itou, H.; Matsuura, T.; Yonezawa, K.; Morikawa, H. Applications of gap-type small-sag conductors for overhead transmission lines. Sei Tech. Rev.-Engl. Ed. 2000, 6, 64–72. [Google Scholar]

- Yang, C.; Zheng, Y.; Yang, F.; Fu, Z.; Xu, C.; Duo, J. Characteristics of the gap-type up-rating conductor used in overhead power transmission lines. J. Phys. Conf. Ser. 2021, 1965, 012082. [Google Scholar] [CrossRef]

- Mazon, A.; Zamora, I.; Eguía, P.; Torres, E.; Migudlez, S.; Medina, R.; Saenz, J. Gap-type conductors: Influence of high temperature in the compression clamp systems. In Proceedings of the 2003 IEEE Bologna Power Tech Conference Proceedings: Bologna, Italy, 23–26 June 2003; IEEE: Manhattan, NY, USA, 2003. [Google Scholar]

- Ishihara, H.; Okada, H.; Shinoda, A.; Nagano, K.; Shimada, N. Development of new type up-rating conductors with low sag. In Proceedings of the 2003 IEEE PES Transmission and Distribution Conference and Exposition (IEEE Cat. No. 03CH37495), Dallas, TX, USA, 7–12 September 2003; IEEE: Manhattan, NY, USA, 2003. [Google Scholar]

- Ujah, C.O.; Popoola, A.P.I.; Popoola, O.M.; Aigbodion, V.S. Enhanced tribology, thermal and electrical properties of Al-CNT composite processed via spark plasma sintering for transmission conductor. J. Mater. Sci. 2019, 54, 14064–14073. [Google Scholar] [CrossRef]

- Ujah, C.; Popoola, A.P.; Popoola, O.M. Thermal conductivity improvement of Al alloy with Nb nanopowder using SPS for transmission conductor. IOP Conf. Ser. Mater. Sci. Eng. 2019, 689, 012004. [Google Scholar] [CrossRef]

- Ujah, C.O.; Popoola, A.P.I.; Popoola, O.M.; Aigbodion, V.S. Electrical conductivity, mechanical strength and corrosion characteristics of spark plasma sintered Al-Nb nanocomposite. Int. J. Adv. Manuf. Technol. 2018, 101, 2275–2282. [Google Scholar] [CrossRef]

- Pawlak, U.; Pawlak, M. Type of Material in the Pipes Overhead Power Lines Impact on the Distribution on the Size of the Overhang and the Tension. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 022058. [Google Scholar] [CrossRef]

- Haghighi, M.; Shaeri, M.H.; Sedghi, A.; Djavanroodi, F. Effect of Graphene Nanosheets Content on Microstructure and Mechanical Properties of Titanium Matrix Composite Produced by Cold Pressing and Sintering. Nanomaterials 2018, 8, 1024. [Google Scholar] [CrossRef] [PubMed]

- Alaneme, K.K.; Okotete, E.A.; Fajemisin, A.V.; Bodunrin, M.O. Applicability of metallic reinforcements for mechanical performance enhancement in metal matrix composites: A review. Arab J. Basic Appl. Sci. 2019, 26, 311–330. [Google Scholar] [CrossRef]

- Hayat, M.D.; Singh, H.; He, Z.; Cao, P. Titanium metal matrix composites: An overview. Compos. Part A Appl. Sci. Manuf. 2019, 121, 418–438. [Google Scholar] [CrossRef]

- Meir, S.; Kalabukhov, S.; Frage, N.; Hayun, S. Mechanical properties of Al2O3\Ti composites fabricated by spark plasma sintering. Ceram. Int. 2015, 41, 4637–4643. [Google Scholar] [CrossRef]

- Chen, Y.-T. The Factors Affecting Electricity Consumption and the Consumption Characteristics in the Residential Sector—A Case Example of Taiwan. Sustainability 2017, 9, 1484. [Google Scholar] [CrossRef]

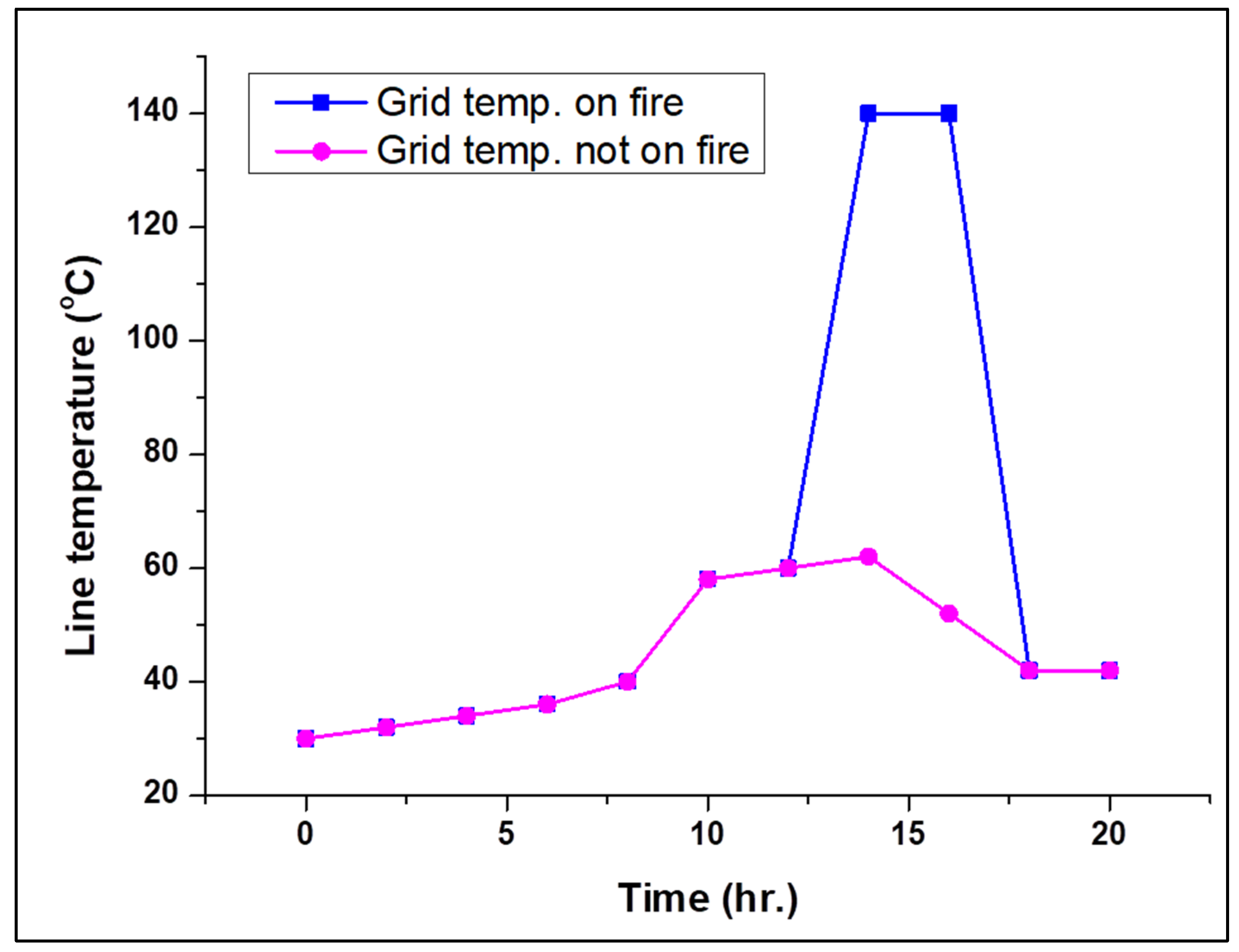

- Mitchell, J.W. Power line failures and catastrophic wildfires under extreme weather conditions. Eng. Fail. Anal. 2013, 35, 726–735. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, R.; Shi, J.; Wan, J.; Yi, H.; Zhong, J. Determination of the power transmission line ageing failure probability due to the impact of forest fire. IET Gener. Transm. Distrib. 2018, 12, 3812–3819. [Google Scholar] [CrossRef]

- Anagnostatos, S.D.; Halevidis, C.D.; Polykrati, A.D.; Koufakis, E.I.; Bourkas, P.D. High-Voltage Lines in Fire Environment. IEEE Trans. Power Deliv. 2011, 26, 2053–2054. [Google Scholar] [CrossRef]

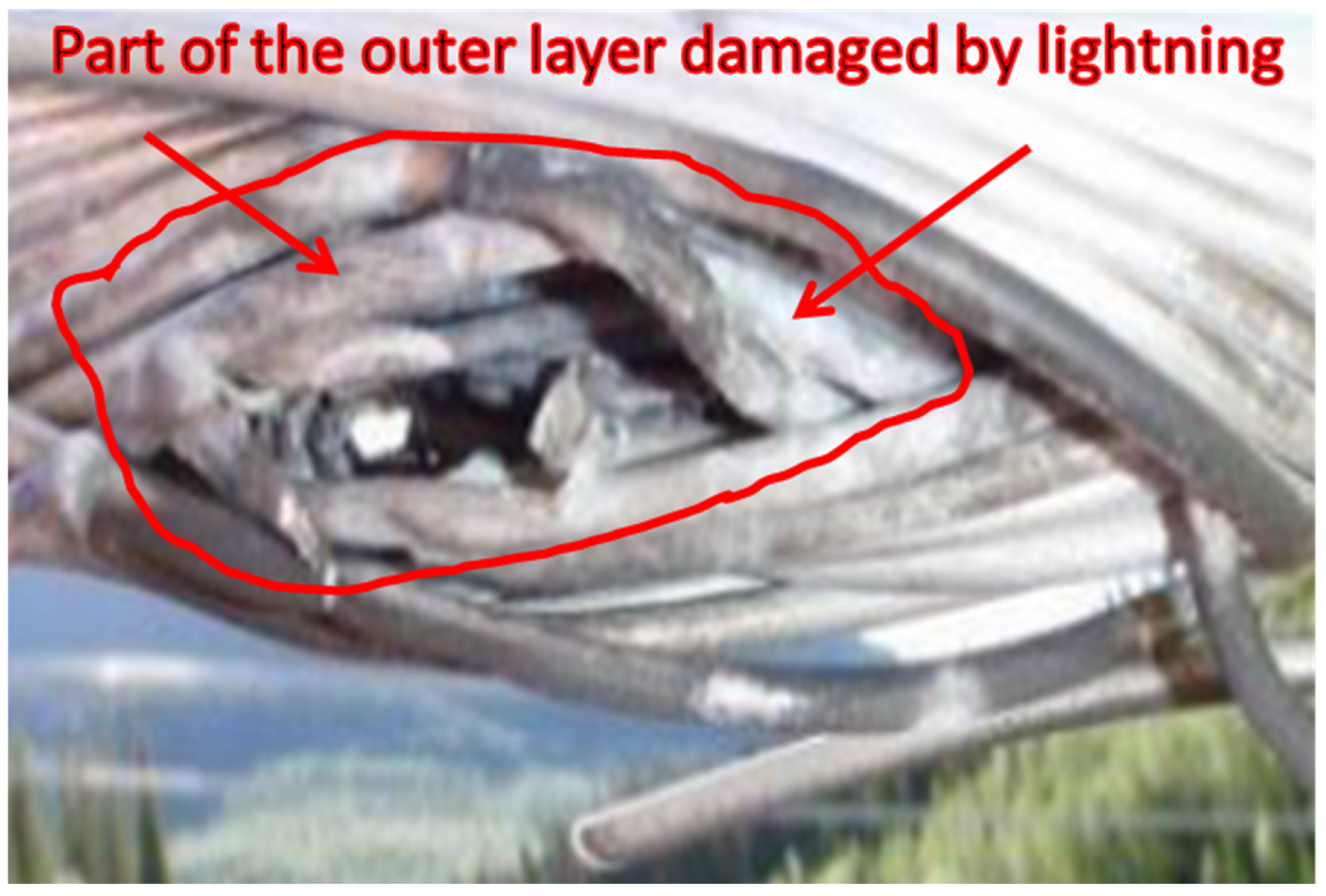

- CIGRE. WG C4.407. Lightning Parameters for Engineering Applications; Technol. Brouchre-549; CIGRE: Paris, France, 2013. [Google Scholar]

- Abdelal, G.; Murphy, A. Nonlinear numerical modelling of lightning strike effect on composite panels with temperature dependent material properties. Compos. Struct. 2014, 109, 268–278. [Google Scholar] [CrossRef]

- Takami, J.; Narita, T.; Okabe, S. Characteristics of Direct Lightning Strokes to Phase Conductors on UHV Designed Transmission Lines. IEEJ Trans. Power Energy 2002, 122, 436–441. [Google Scholar] [CrossRef]

- Lönnermark, A.; Ingason, H. The Effect of Cross-sectional Area and Air Velocity on the Conditions in a Tunnel during a Fire. 2007. SP Technical Research Institute of Sweden. Technical Report. Available online: http://www.sp.se.1-94 (accessed on 5 July 2022).

- Villars, P.; Cenzual, K. Pearson’s Crystal Data®: Crystal Structure Database for Inorganic Compounds; ASM International Materials Park: Geauga County, OH, USA, 2007. [Google Scholar]

- Schmid, R.; Miah, A.M. The Strength of the Hydrohalic Acids. J. Chem. Educ. 2001, 78, 116. [Google Scholar] [CrossRef]

- Malaki, M.; Xu, W.; Kasar, A.K.; Menezes, P.L.; Dieringa, H.; Varma, R.S.; Gupta, M. Advanced Metal Matrix Nanocomposites. Metals 2019, 9, 330. [Google Scholar] [CrossRef]

- Paisios, M.; Karagiannopoulos, C.; Bourkas, P. Estimation of the temperature rise in cylindrical conductors subjected to heavy 10/350 μs lightning current impulses. Electr. Power Syst. Res. 2008, 78, 80–87. [Google Scholar] [CrossRef]

- Heckenbergerova, J.; Musilek, P.; Filimonenkov, K. Assessment of seasonal static thermal ratings of overhead transmission conductors. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–28 July 2011; IEEE: Manhattan, NY, USA, 2011. [Google Scholar]

- Bartos, M.; Chester, M.; Johnson, N.; Gorman, B.; Eisenberg, D.; Linkov, I.; Bates, M. Impacts of rising air temperatures on electric transmission ampacity and peak electricity load in the United States. Environ. Res. Lett. 2016, 11, 114008. [Google Scholar] [CrossRef]

- Fernandez, E.; Albizu, I.; Bedialauneta, M.; Mazon, A.; Leite, P. Review of dynamic line rating systems for wind power integration. Renew. Sustain. Energy Rev. 2016, 53, 80–92. [Google Scholar] [CrossRef]

- Douglass, D.; Chisholm, W.; Davidson, G.; Grant, I.; Lindsey, K.; Lancaster, M.; Lawry, D.; McCarthy, T.; Nascimento, C.; Pasha, M.; et al. Real-Time Overhead Transmission-Line Monitoring for Dynamic Rating. IEEE Trans. Power Deliv. 2014, 31, 921–927. [Google Scholar] [CrossRef]

- Stephen, R.; Lilien, J.-L.; Seppa, T.; Douglass, D.; Lancaster, M.; Biedenbach, G.; Watt, G.; Pestana, R.; Ferrières, P.; Schmale, M. Guide for Application of Direct Real-Time Monitoring Systems; CIGRE: Paris, France, 2012. [Google Scholar]

- Ghannoum, E. Structural and Mechanical Design. In Overhead Lines; Springer: Berlin/Heidelberg, Germany, 2017; pp. 191–276. [Google Scholar]

- Soulinaris, G.; Halevidis, C.; Polykrati, A.; Bourkas, P. Evaluation of the thermal stresses and dielectric phenomena in the investigation of the causes of wildfires involving distribution power lines. Electr. Power Syst. Res. 2014, 117, 76–83. [Google Scholar] [CrossRef]

- Yumurtaci, M.; Gökmen, G.; Kocaman, Ç.; Ergin, S.; Kiliç, O. Classification of short-circuit faults in high-voltage energy transmission line using energy of instantaneous active power components-based common vector approach. Turk. J. Electr. Eng. Comput. Sci. 2016, 24, 1901–1915. [Google Scholar] [CrossRef]

- Huang, N.; Qi, J.; Li, F.; Yang, D.; Cai, G.; Huang, G.; Zheng, J.; Li, Z. Short-Circuit Fault Detection and Classification Using Empirical Wavelet Transform and Local Energy for Electric Transmission Line. Sensors 2017, 17, 2133. [Google Scholar] [CrossRef]

- Research. Bird Caging. 2022. Available online: https://cr4.globalspec.com/thread/63445/Infromation-Needed-About-Bird-Caging-in-ACSR-Conductors (accessed on 5 July 2022).

- Lloyd, J.; Clement, J. Electromigration in copper conductors. Thin Solid Films 1995, 262, 135–141. [Google Scholar] [CrossRef]

- Ali, M.H.; Rubel, R.I. A comparative review of Mg/CNTs and Al/CNTs composite to explore the prospect of bimetallic Mg-Al/CNTs composites. AIMS Mater. Sci. 2020, 7, 217–243. [Google Scholar]

- Kumar, P.S.R.; Smart, D.R.; Alexis, S.J. Corrosion behaviour of Aluminium Metal Matrix reinforced with Multi-wall Carbon Nanotube. J. Asian Ceram. Soc. 2017, 5, 71–75. [Google Scholar] [CrossRef]

- Chunfeng, D.; Zhang, X.; Yanxia, M.A.; Dezun, W. Fabrication of aluminum matrix composite reinforced with carbon nanotubes. Rare Met. 2007, 26, 450–455. [Google Scholar]

- He, C.; Zhao, N.; Shi, C.; Du, X.; Li, J.; Li, H.; Cui, Q. An Approach to Obtaining Homogeneously Dispersed Carbon Nanotubes in Al Powders for Preparing Reinforced Al-Matrix Composites. Adv. Mater. 2007, 19, 1128–1132. [Google Scholar] [CrossRef]

- Ujah, C.O.; Popoola, A.P.I.; Popoola, O.M.; Aigbodion, V.S. Influence of CNTs addition on the mechanical, microstructural, and corrosion properties of Al alloy using spark plasma sintering technique. Int. J. Adv. Manuf. Technol. 2020, 106, 2961–2969. [Google Scholar] [CrossRef]

- Ertug, B. Sintering Applications; BoD–Books on Demand: Norderstedt, Germany, 2013. [Google Scholar]

- Firestein, K.L.; Steinman, A.E.; Golovin, I.S.; Cifre, J.; Obraztsova, E.A.; Matveev, A.T.; Kovalskii, A.M.; Lebedev, O.I.; Shtansky, D.V.; Golberg, D. Fabrication, characterization, and mechanical properties of spark plasma sintered Al–BN nanoparticle composites. Mater. Sci. Eng. A 2015, 642, 104–112. [Google Scholar] [CrossRef]

- Gostariani, R.; Ebrahimi, R.; Asadabad, M.A.; Paydar, M.H. Mechanical Properties of Al/BN Nanocomposites Fabricated by Planetary Ball Milling and Conventional Hot Extrusion. Acta Met. Sin. (Engl. Lett.) 2017, 31, 245–253. [Google Scholar] [CrossRef]

- Xue, Y.; Jiang, B.; Bourgeois, L.; Dai, P.; Mitome, M.; Zhang, C.; Yamaguchi, M.; Matveev, A.; Tang, C.; Bando, Y.; et al. Aluminum matrix composites reinforced with multi-walled boron nitride nanotubes fabricated by a high-pressure torsion technique. Mater. Des. 2015, 88, 451–460. [Google Scholar] [CrossRef]

- Firestein, K.; Corthay, S.; Steinman, A.; Matveev, A.; Kovalskii, A.; Sukhorukova, I.; Golberg, D.; Shtansky, D. High-strength aluminum-based composites reinforced with BN, AlB2 and AlN particles fabricated via reactive spark plasma sintering of Al-BN powder mixtures. Mater. Sci. Eng. A 2016, 681, 1–9. [Google Scholar] [CrossRef]

- Raviraj, M.; Sharanprabhu, C.; Mohankumar, G. Experimental analysis on processing and properties of Al-TiC metal matrix composites. Procedia Mater. Sci. 2014, 5, 2032–2038. [Google Scholar] [CrossRef]

- Bauri, R.; Yadav, D.; Suhas, G. Effect of friction stir processing (FSP) on microstructure and properties of Al–TiC in situ composite. Mater. Sci. Eng. A 2011, 528, 4732–4739. [Google Scholar] [CrossRef]

- Agrawal, E.; Tungikar, V. Study on tribological properties of Al-TiC composites by Taguchi method. Mater. Today Proc. 2020, 26, 2242–2247. [Google Scholar] [CrossRef]

- Wang, Z.J.; Qiu, Z.X.; Sun, H.Y.; Liu, W.C. Effect of TiC content on the microstructure, texture and mechanical properties of 1060/Al–TiC/1060 laminated composites. J. Alloys Compd. 2019, 806, 788–797. [Google Scholar] [CrossRef]

- Porter, L.M.; Davis, R.F. A critical review of ohmic and rectifying contacts for silicon carbide. Mater. Sci. Eng. B 1995, 34, 83–105. [Google Scholar] [CrossRef]

- Yaghobizadeh, O.; Baharvandi, H.R.; Ahmadi, A.R.; Aghaei, E. Development of the Properties of Al/SiC Nano-Composite Fabricated by Stir Cast Method by Means of Coating SiC Particles with Al. Silicon 2018, 11, 643–649. [Google Scholar] [CrossRef]

- Karvanis, K.; Fasnakis, D.; Maropoulos, A.; Papanikolaou, S. Production and mechanical properties of Al-SiC metal matrix composites. In IOP Conference Series: Materials Science and Engineering, 20th Innovative Manufacturing Engineering and Energy Conference (IManEE 2016), Kozani, Greece, 23–25 September 2016; IOP Publishing: Bristol, UK, 2016. [Google Scholar]

- Shaikh, M.B.N.; Aziz, T.; Arif, S.; Ansari, A.H.; Karagiannidis, P.G.; Uddin, M. Effect of sintering techniques on microstructural, mechanical and tribological properties of Al-SiC composites. Surf. Interfaces 2020, 20, 100598. [Google Scholar] [CrossRef]

- Kamrani, S.; Riedel, R.; Reihani, S.S.; Kleebe, H. Effect of Reinforcement Volume Fraction on the Mechanical Properties of Al—SiC Nanocomposites Produced by Mechanical Alloying and Consolidation. J. Compos. Mater. 2009, 44, 313–326. [Google Scholar] [CrossRef]

| HTLS Conductors | Conductor Picture | Advantages | Weaknesses | Ref. |

|---|---|---|---|---|

| (i) ACSS |  |

|

| [42,43,44,45] |

| (ii) ACCR |  |

|

| [46,47,48,49,50] |

| (iii) ACCC |  |

|

| [11,51,52,53,54,55,56] |

| (iv) G-TACSR |  |

|

| [50,57,58,59,60] |

| Properties/Types | ACSR | ACCR | ACCC | Al-CNTs-Nb |

|---|---|---|---|---|

| Thermal conductivity (W/mK) | 54 | 30 | 1.2 | 128 |

| Maximum operating temperature (°C) | 95 | 180 | 125 | 400 |

| Core density (g/cm3) | 8.05 | 3.00 | 1.94 | 2.72 |

| Transmission Grid Challenges | Manifestation/Damage | Prevention/Control |

|---|---|---|

| Conductor defects |

|

|

| Overloading |

| Reinforcing Al alloy with thermally stable materials such as CNTs, BN, and TiC |

| Bushfire |

| Fire resistant nanomaterials should be alloyed to Al alloy in order to withstand high temperature of flames |

| Lightning |

| Use of high thermal conductive nanomaterials in alloying of Al to induce speedy heat conduction |

| Extreme weather |

| Use of nanomaterials with very low CTE such as CNTs in reinforcing Al alloy as the conductor material |

| Short circuit |

| Use of refractory material that would withstand very high temperatures of over 200 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ujah, C.O.; Kallon, D.V.V.; Aikhuele, D.O.; Aigbodion, V.S. Advanced Composite Materials: A Panacea for Improved Electricity Transmission. Appl. Sci. 2022, 12, 8291. https://doi.org/10.3390/app12168291

Ujah CO, Kallon DVV, Aikhuele DO, Aigbodion VS. Advanced Composite Materials: A Panacea for Improved Electricity Transmission. Applied Sciences. 2022; 12(16):8291. https://doi.org/10.3390/app12168291

Chicago/Turabian StyleUjah, Chika Oliver, Daramy Vandi Von Kallon, Daniel O. Aikhuele, and Victor Sunday Aigbodion. 2022. "Advanced Composite Materials: A Panacea for Improved Electricity Transmission" Applied Sciences 12, no. 16: 8291. https://doi.org/10.3390/app12168291

APA StyleUjah, C. O., Kallon, D. V. V., Aikhuele, D. O., & Aigbodion, V. S. (2022). Advanced Composite Materials: A Panacea for Improved Electricity Transmission. Applied Sciences, 12(16), 8291. https://doi.org/10.3390/app12168291