Rooftop Greenhouse: (1) Design and Validation of a BES Model for a Plastic-Covered Greenhouse Considering the Tomato Crop Model and Natural Ventilation Characteristics

Abstract

:1. Introduction

2. Materials and Methods

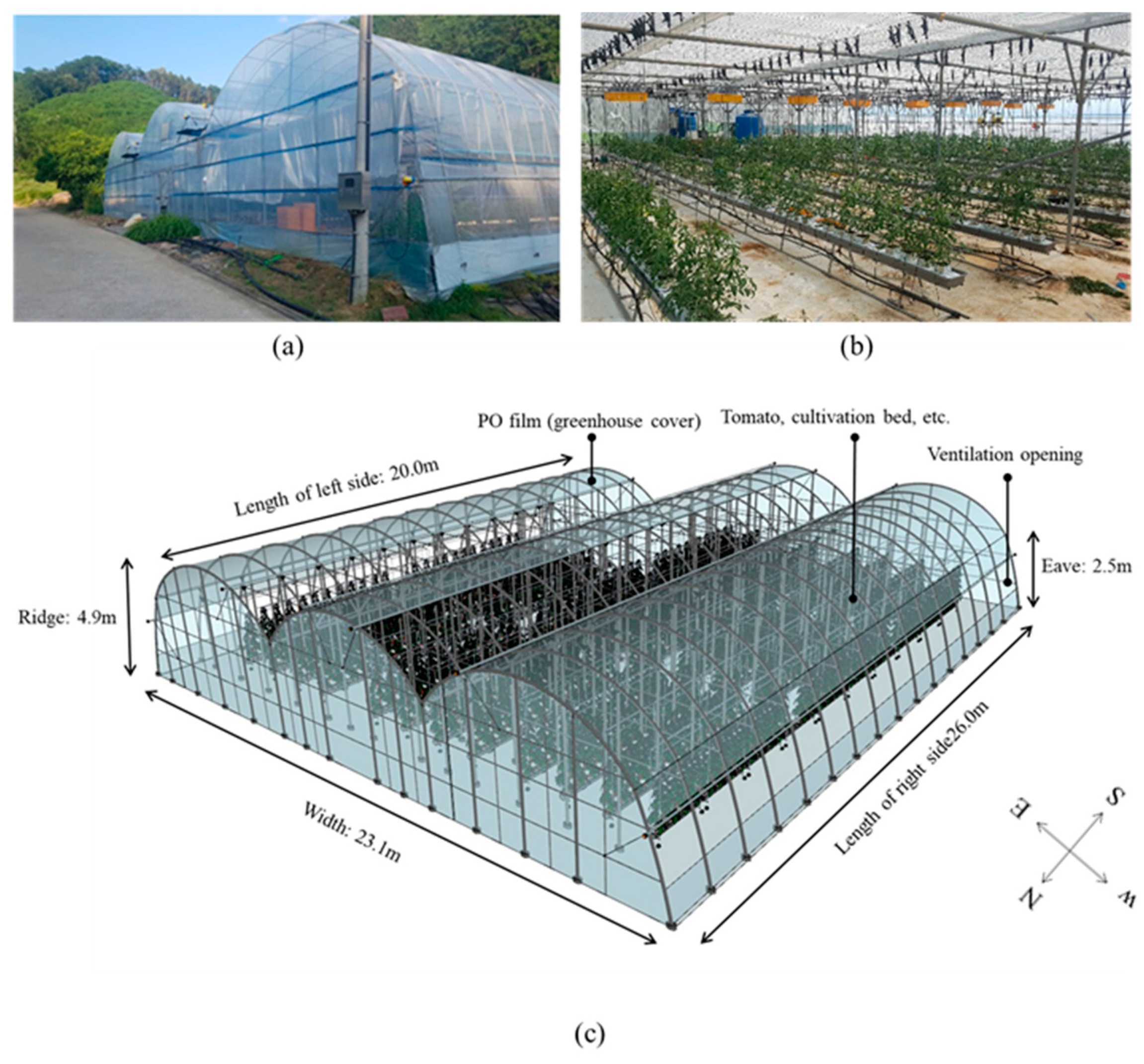

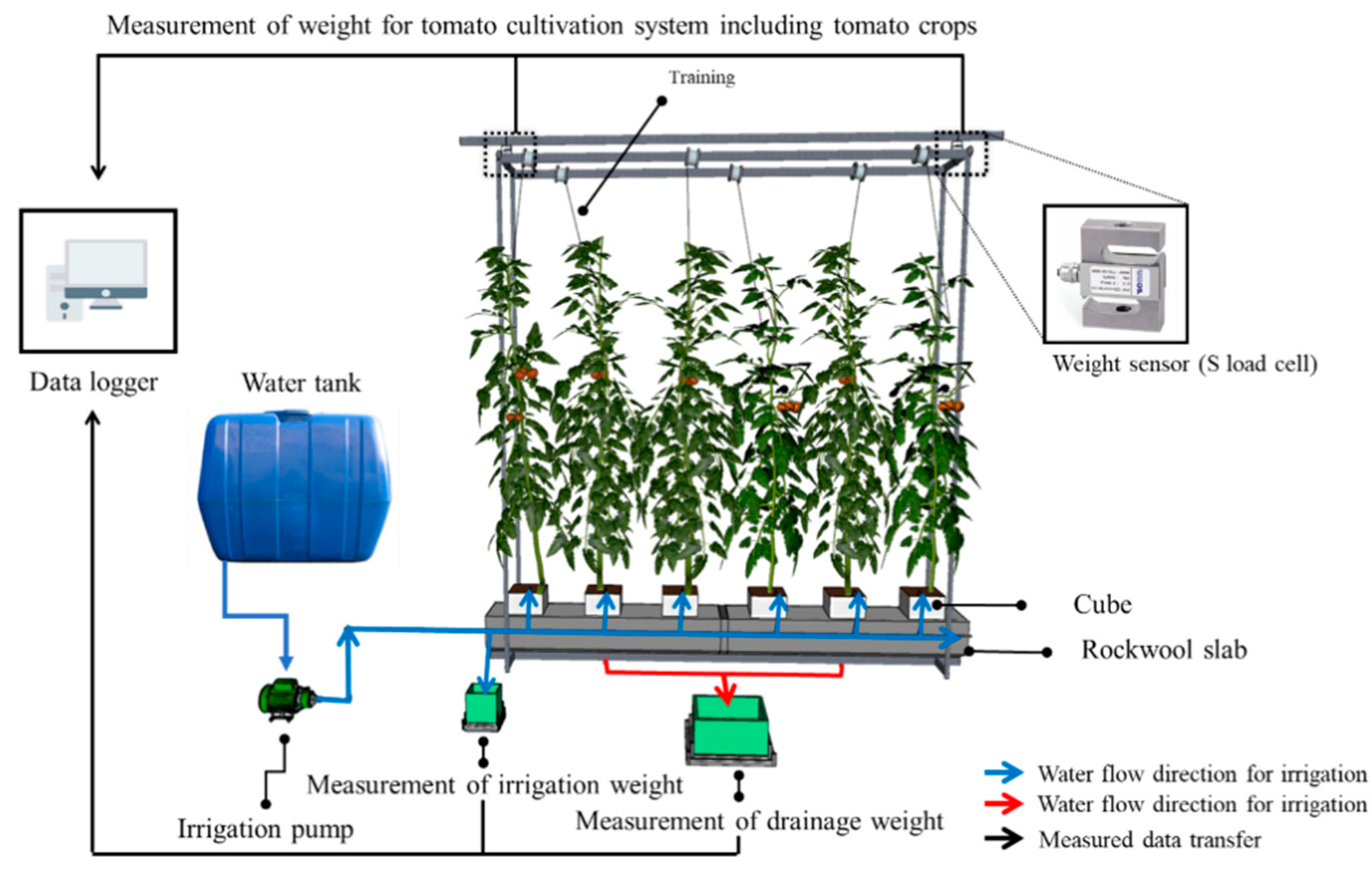

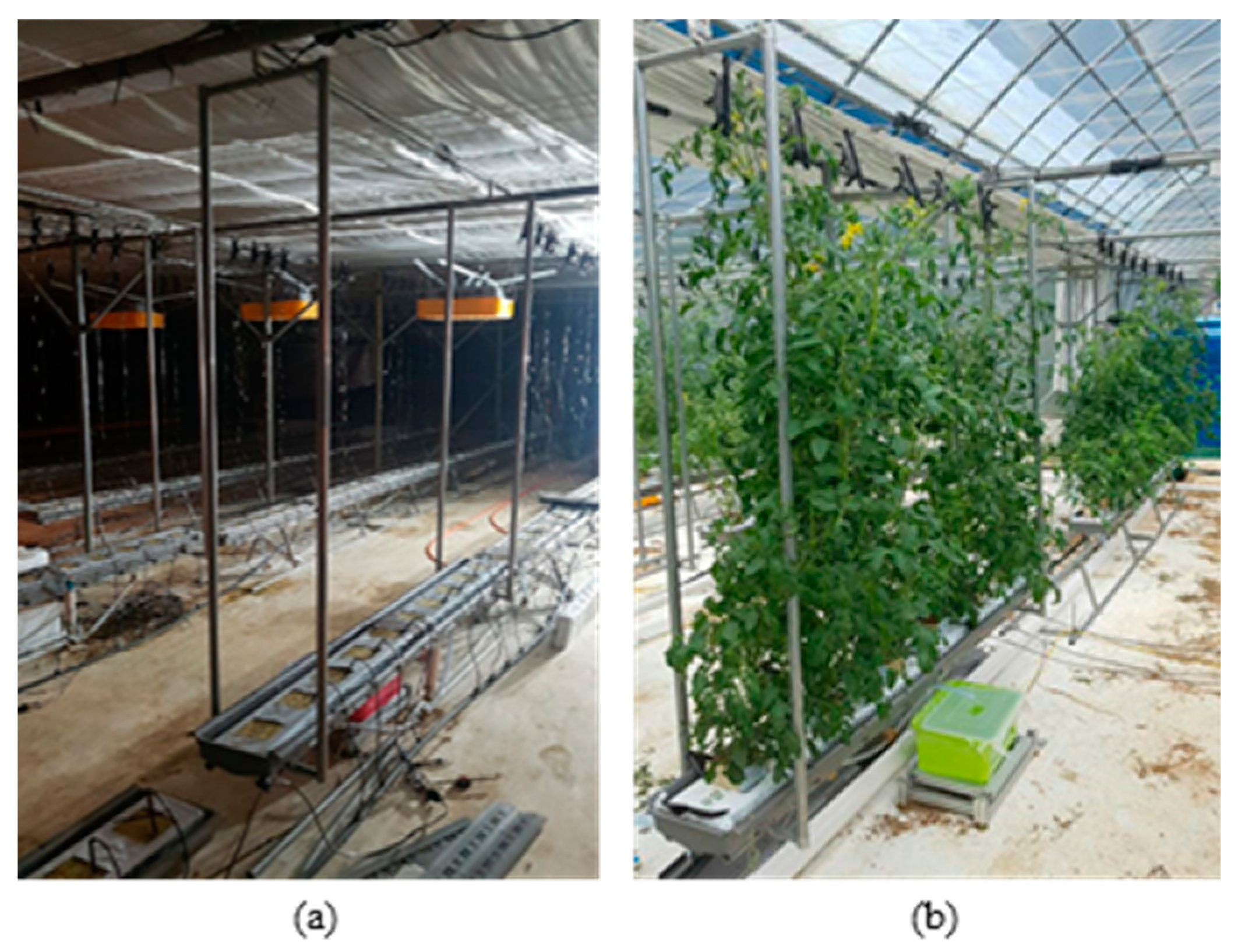

2.1. Experimental Greenhouse

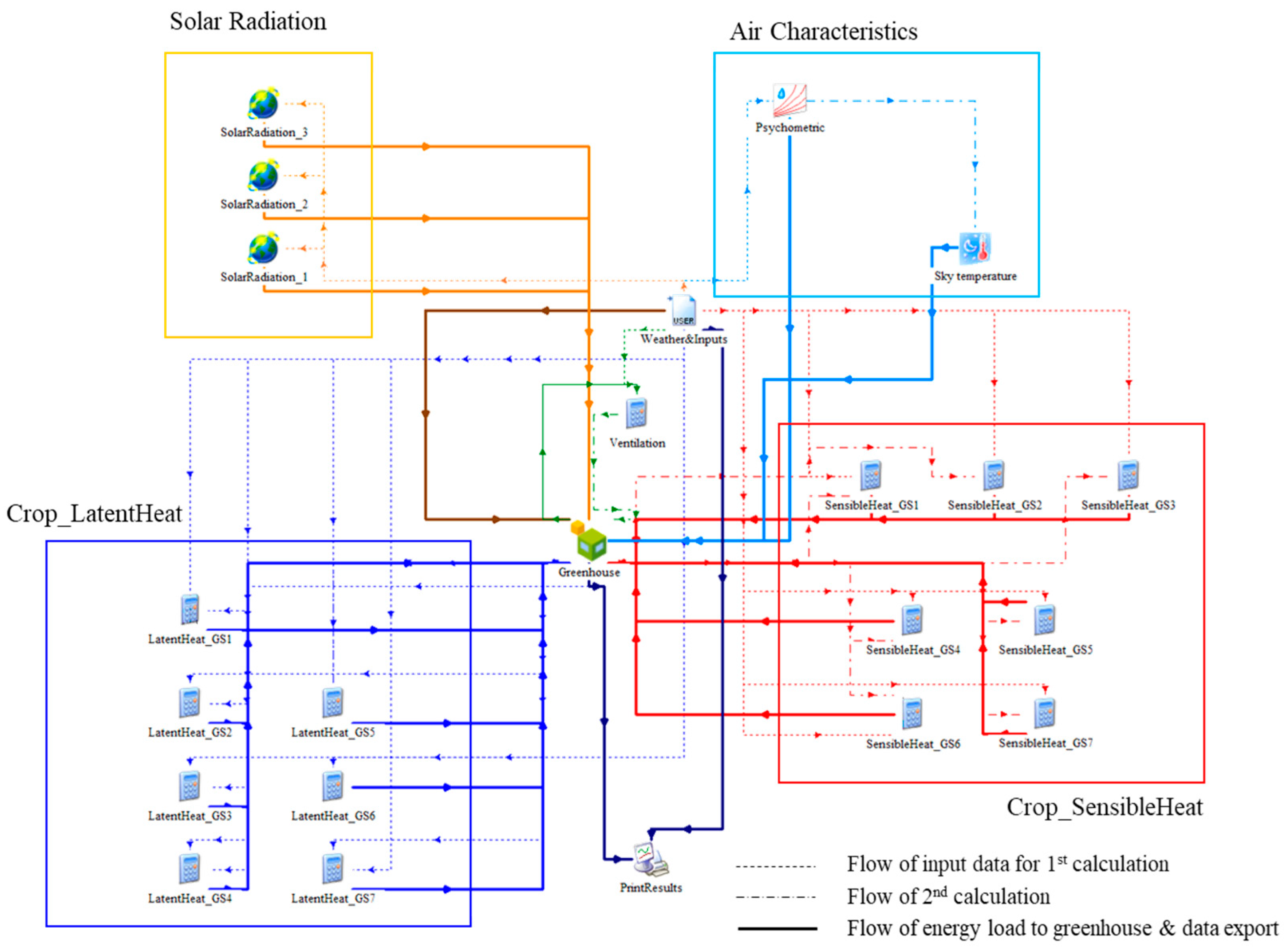

2.2. Bilding Energy Simulation (BES)

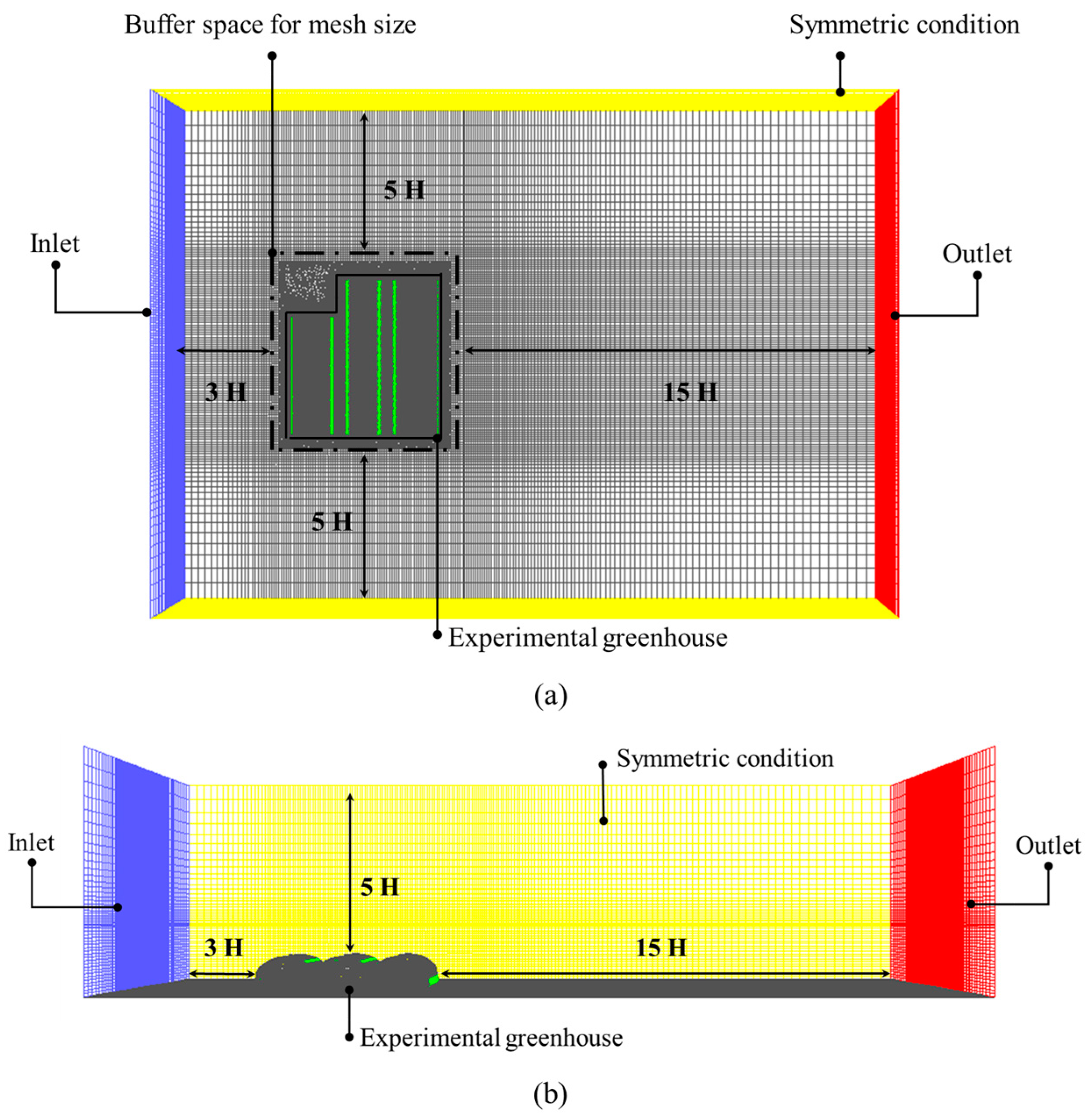

2.3. Computational Fluid Dynamics (CFD)

2.4. Experimental Procedures

2.4.1. Monitoring of the Environmental Variables

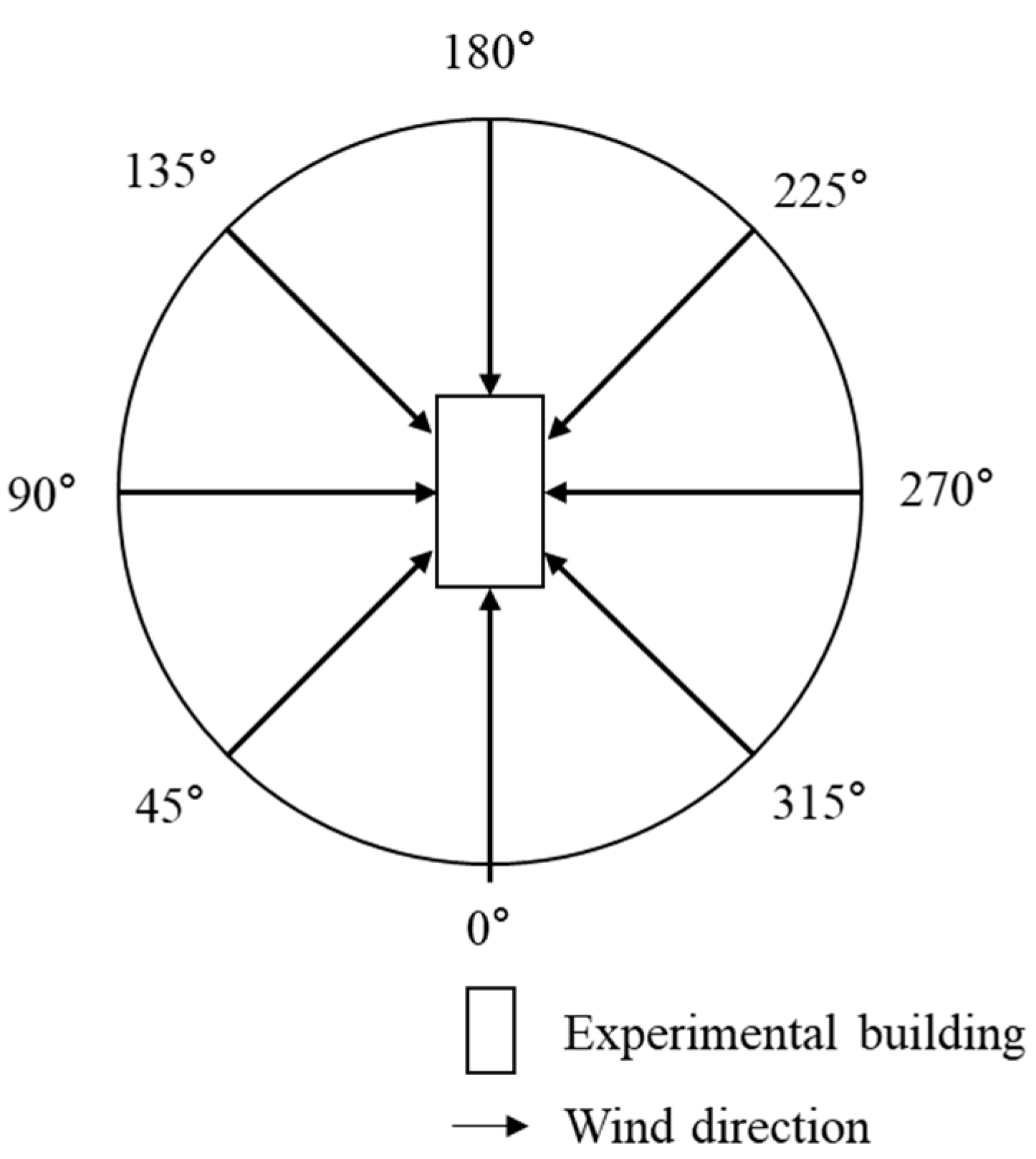

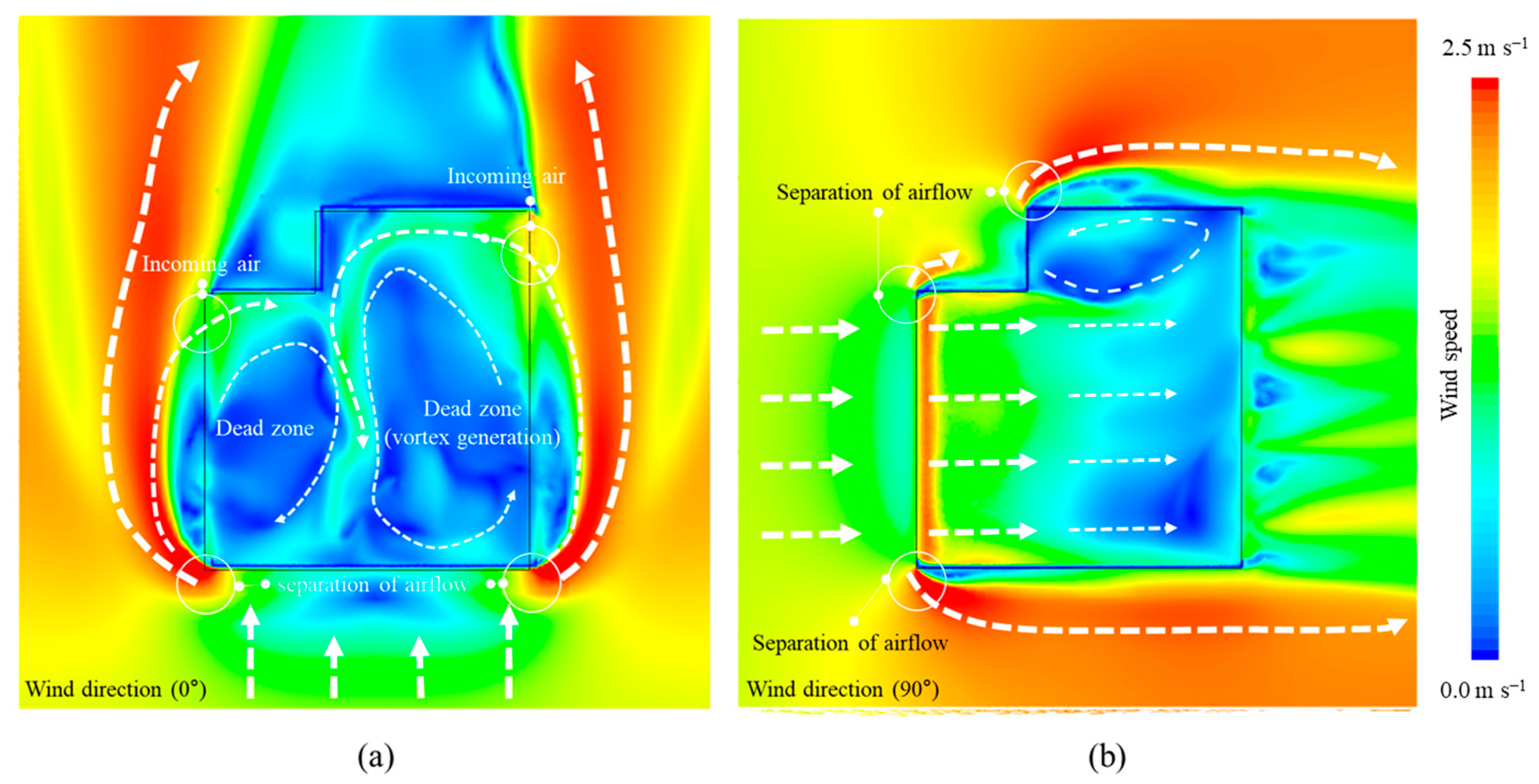

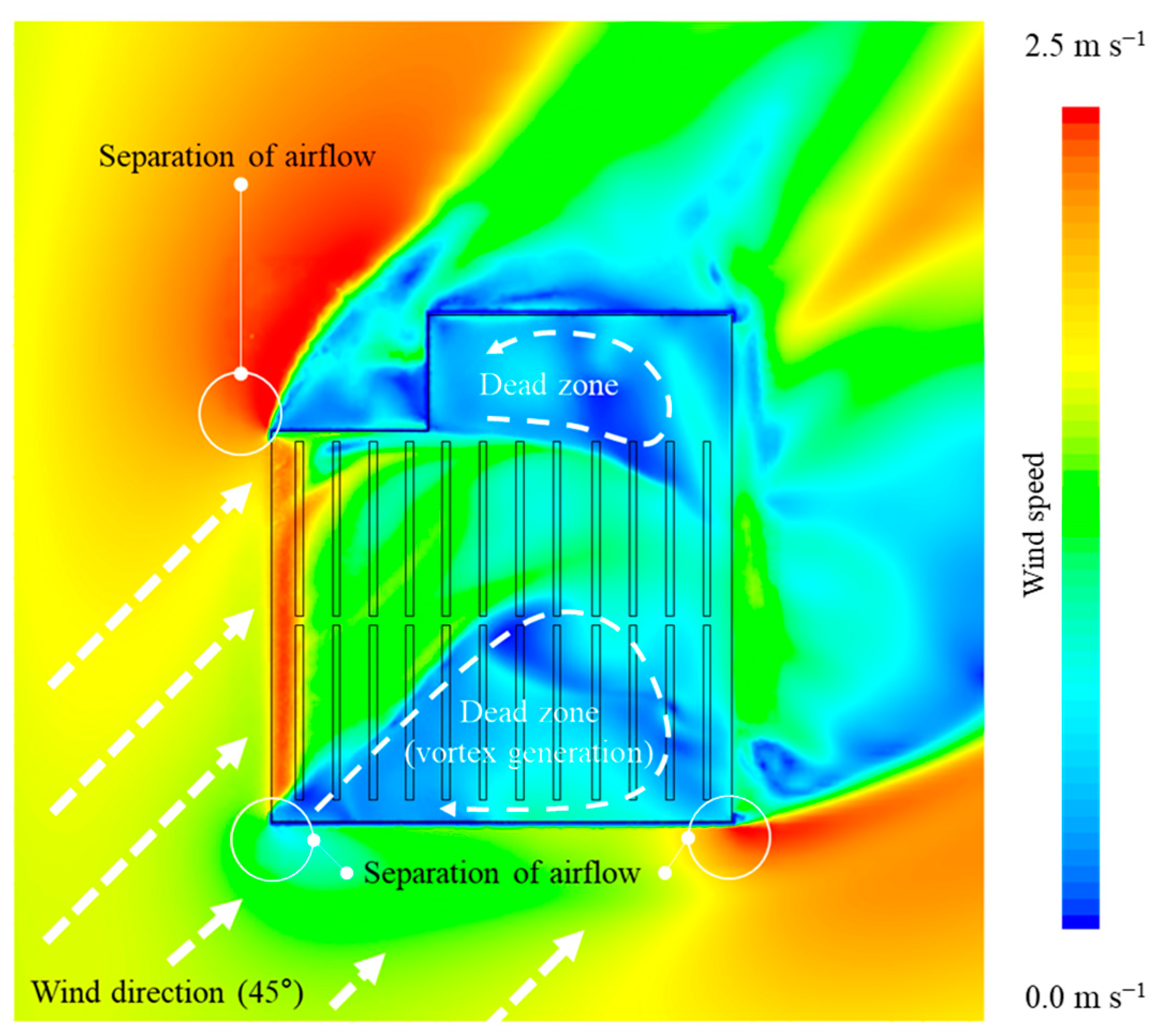

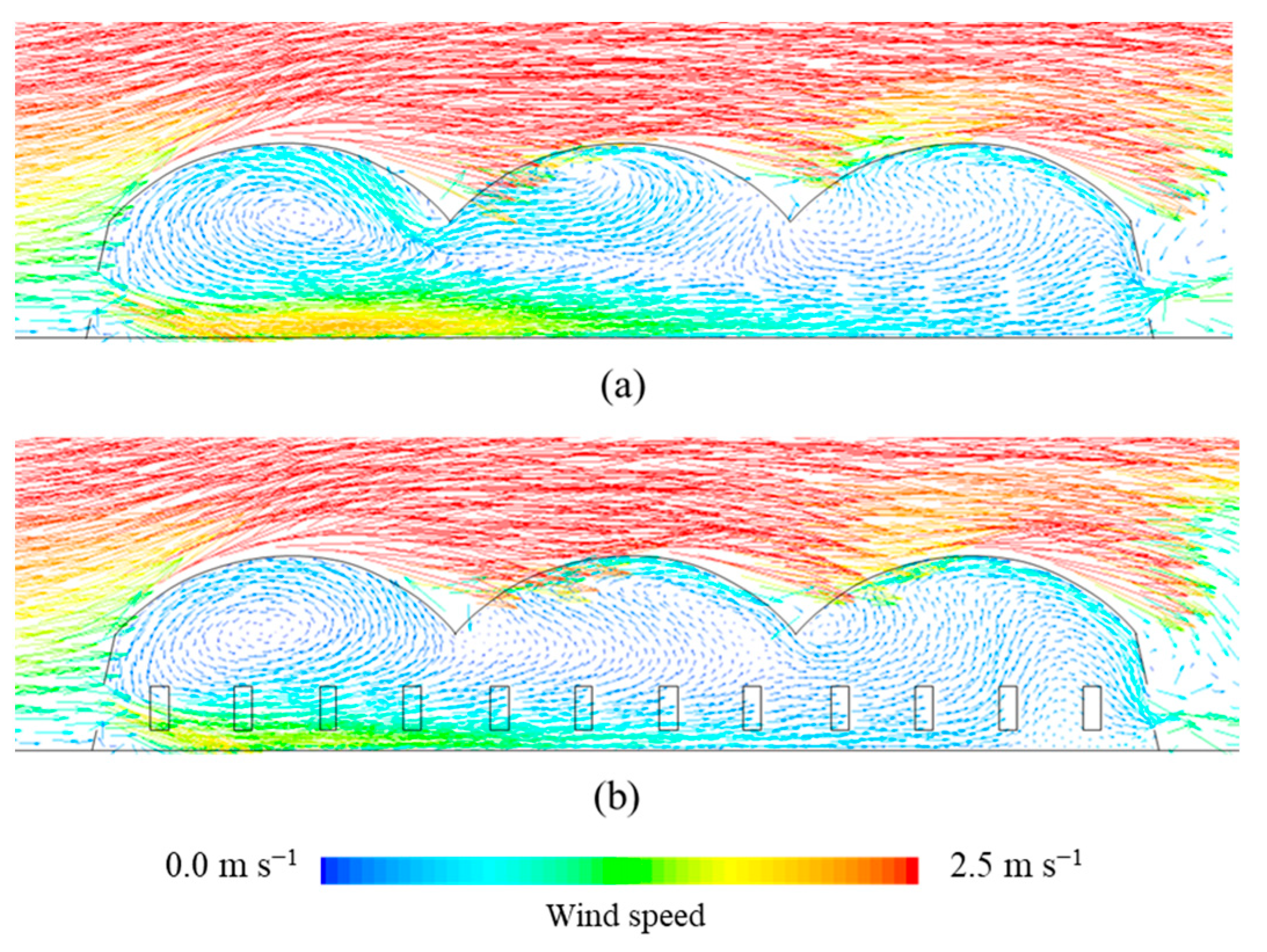

2.4.2. Design of CFD Model to Analyse Ventilation Characteristics of the Experimental Greenhouse

2.4.3. Analysis of CFD-Computed Ventilation Characteristics

2.4.4. Design and Validation of the Greenhouse BES Model Integrated with the Tomato Crop Model and Ventilation Characteristics

3. Results and Discussion

3.1. Environmental Monitoring Inside and Outside the Greenhouse

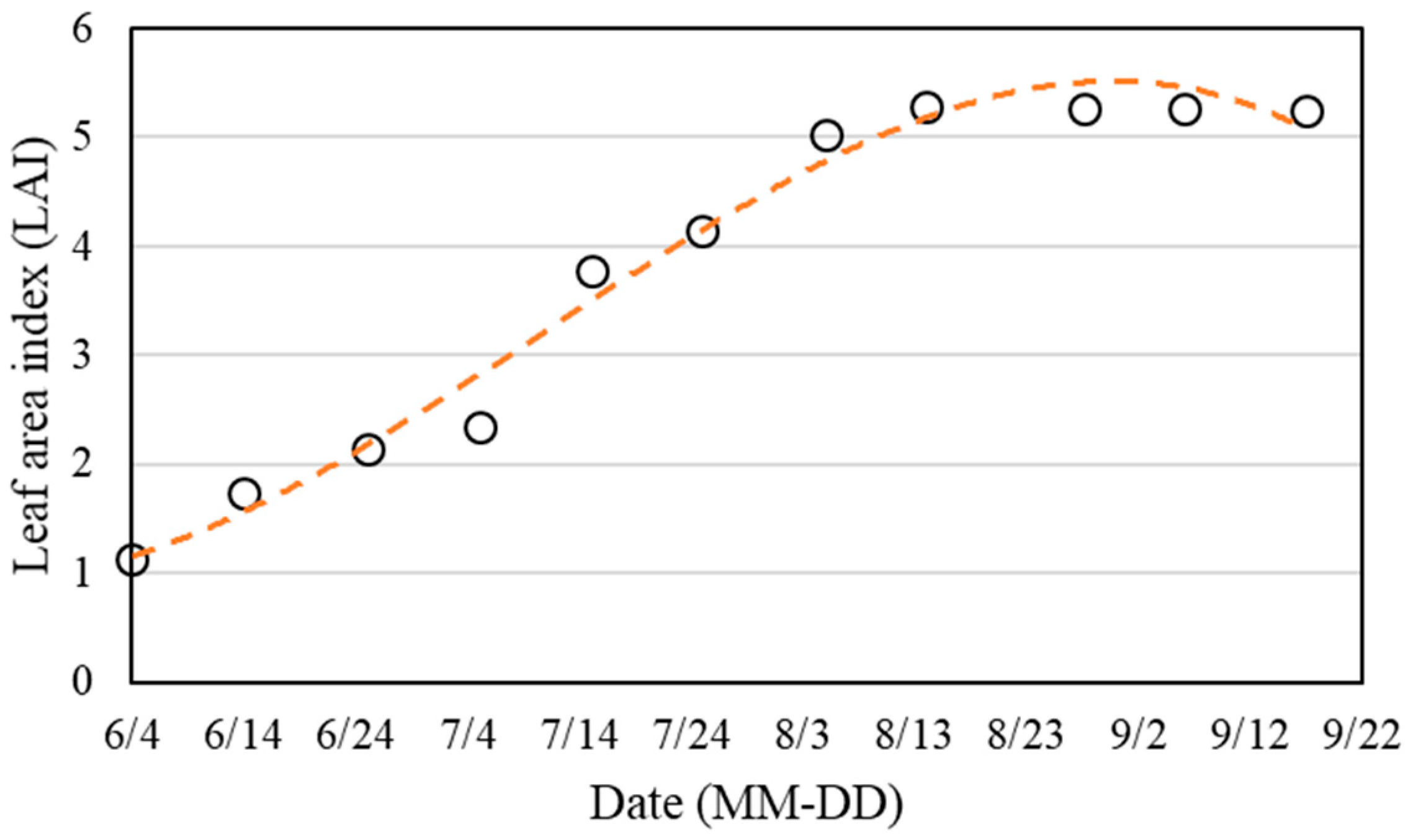

3.2. Design and Validation of Crop Model

| Stage | The Equation for Estimating ET of Tomato | Adjusted R2 | Pr > |t| | Equations |

|---|---|---|---|---|

| 1 | 0.909 | <0.001 | (23) | |

| 2 | 0.876 | <0.001 | (24) | |

| 3 | 0.886 | <0.001 | (25) | |

| 4 | 0.719 | <0.001 | (26) | |

| 5 | 0.833 | <0.001 | (27) | |

| 6 | 0.878 | <0.001 | (28) | |

| 7 | 0.974 | <0.001 | (29) |

| Stage | The Equation for Estimating TL of Tomato | Adjusted R2 | Pr > |t| | Equations |

|---|---|---|---|---|

| 1 | 0.963 | <0.001 | (30) | |

| 2 | 0.968 | <0.001 | (31) | |

| 3 | 0.972 | <0.001 | (32) | |

| 4 | 0.977 | <0.001 | (33) | |

| 5 | 0.992 | <0.001 | (34) | |

| 6 | 0.995 | <0.001 | (35) | |

| 7 | 0.993 | <0.001 | (36) |

3.3. Evaluation of Ventilation Rate According to Wind Environment and Crops

3.4. Evaluation of Cd of the Greenhouse

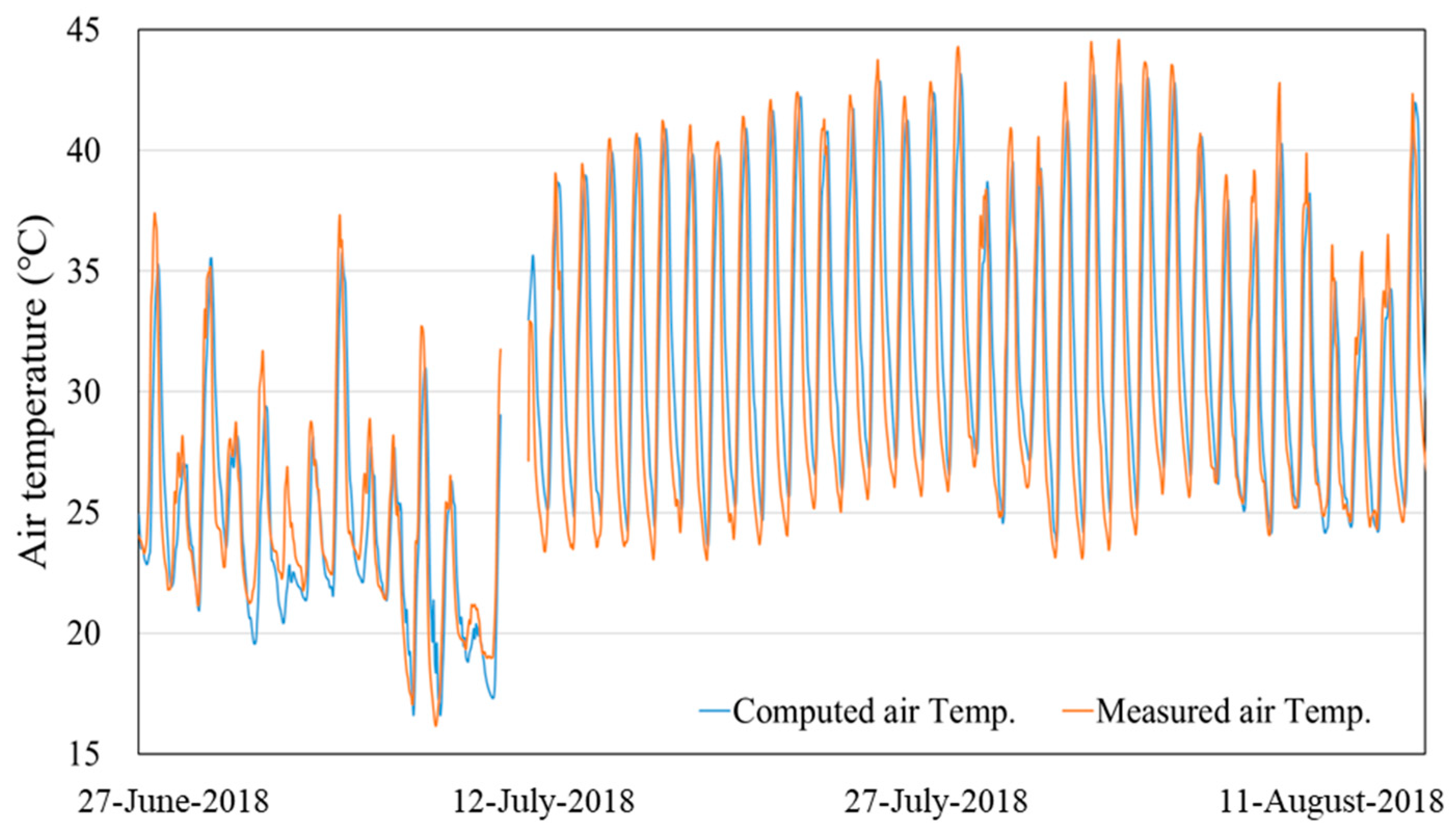

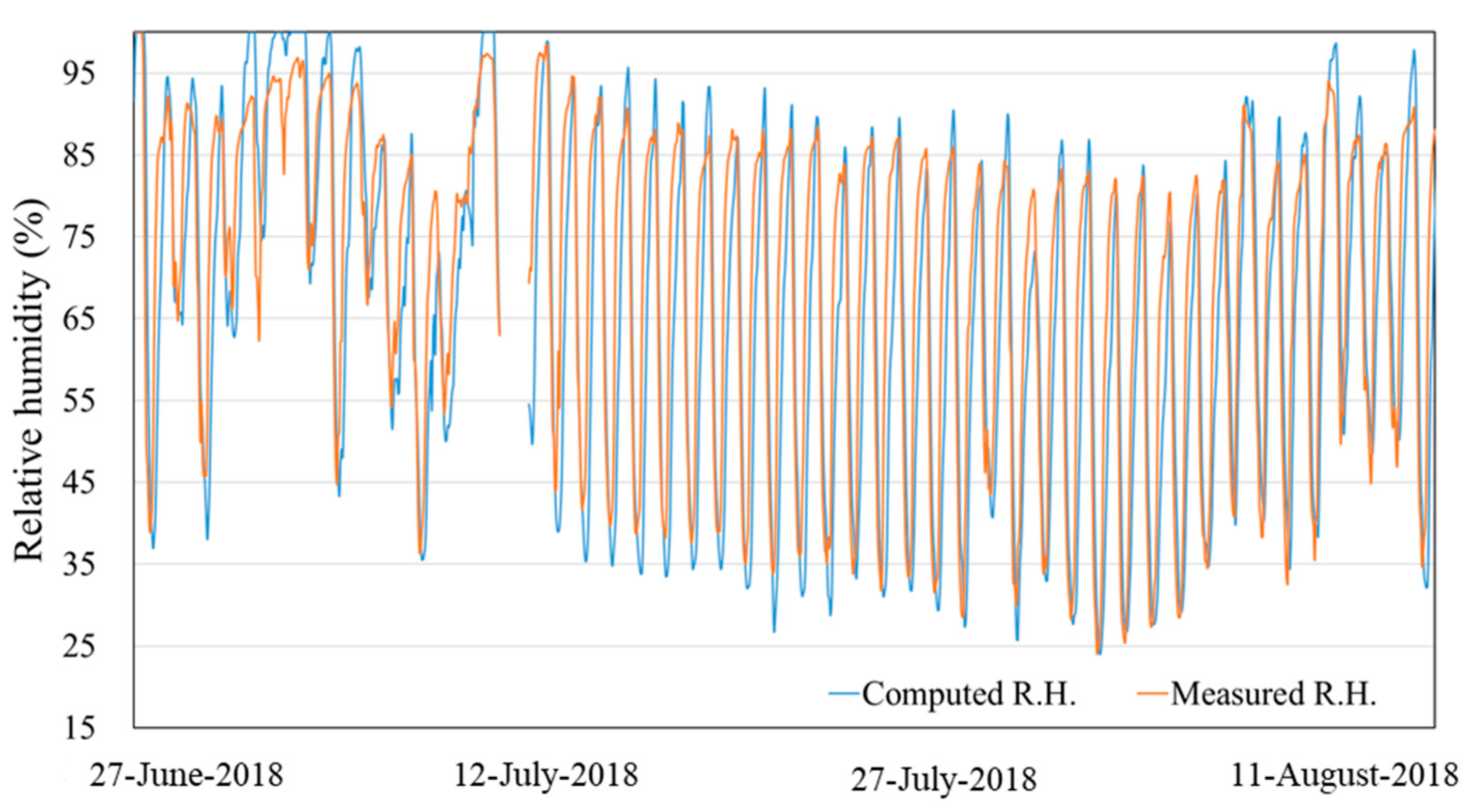

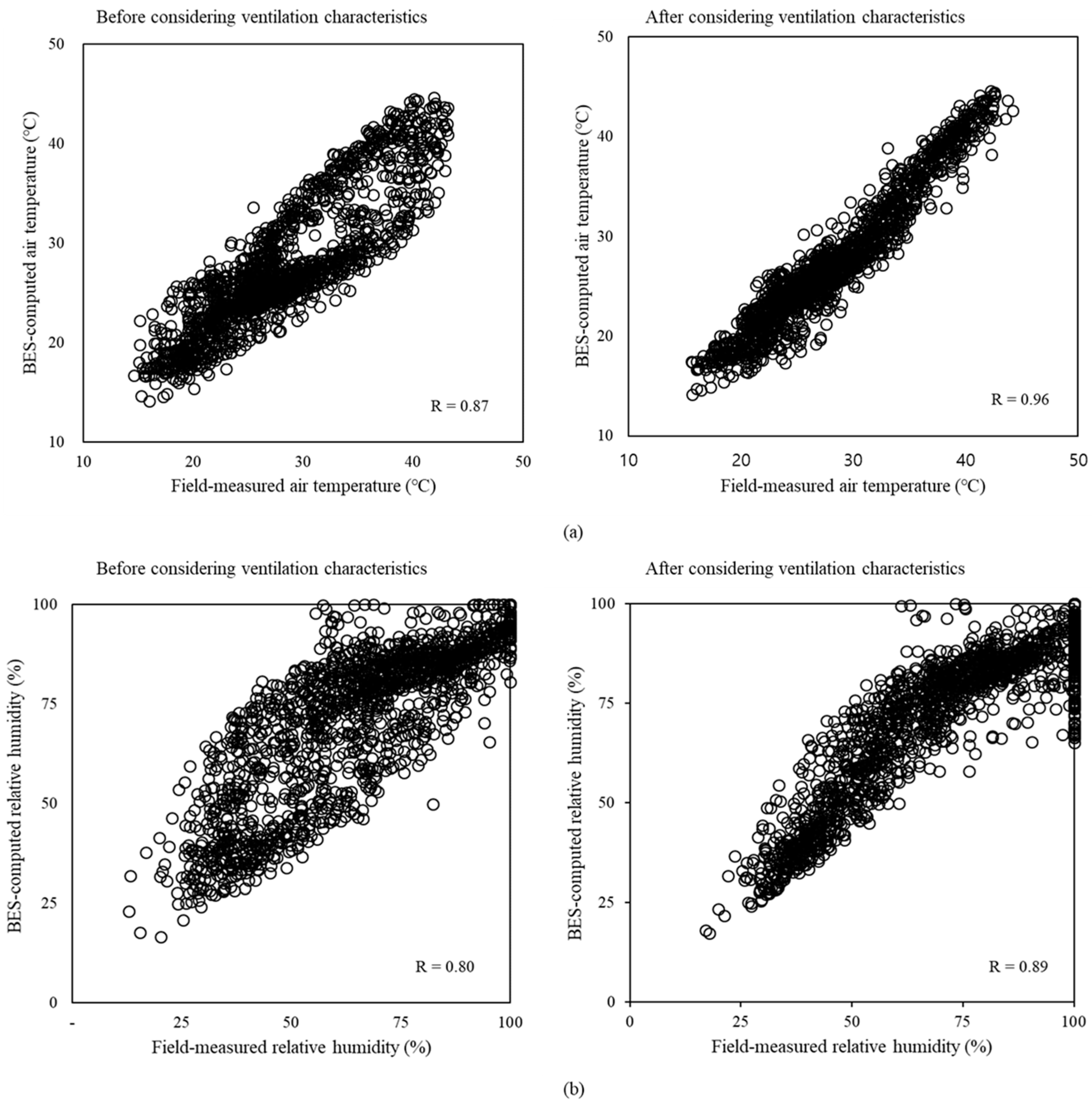

3.5. Design and Validation of a BES Model for Greenhouse

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Moon, J.; Shim, C.; Jung, O.; Hong, J.-W.; Han, J.; Song, Y.-I. Characteristics in Regional Climate Change over South Korea for Regional Climate Policy Measures: Based on Long-Term Observations. J. Clim. Chang. Res. 2020, 11, 755–770. [Google Scholar] [CrossRef]

- Sethi, V.P.; Sumathy, K.; Lee, C.; Pal, D. Thermal modeling aspects of solar greenhouse microclimate control: A review on heating technologies. Sol. Energy 2013, 96, 56–82. [Google Scholar] [CrossRef]

- De Zwart, H.F. Analyzing Energy-Saving Potentials in Greenhouse Cultivation Using a Simulation Model; University & Research Centre: Wageningen, The Netherlands, 1996. [Google Scholar]

- Luo, W.; de Zwart, H.F.; DaiI, J.; Wang, X.; Stanghellini, C.; Bu, C. Simulation of Greenhouse Management in the Subtropics, Part I: Model Validation and Scenario Study for the Winter Season. Biosyst. Eng. 2005, 90, 307–318. [Google Scholar] [CrossRef]

- Fabrizio, E. Energy reduction measures in agricultural greenhouses heating: Envelope, systems and solar energy collection. Energy Build. 2012, 53, 57–63. [Google Scholar] [CrossRef]

- Joudi, K.A.; Farhan, A.A. A dynamic model and an experimental study for the internal air and soil temperatures in an innovative greenhouse. Energy Convers. Manag. 2015, 91, 76–82. [Google Scholar] [CrossRef]

- Mohammadi, B.; Ranjbar, S.F.; Ajabshirchi, Y. Application of dynamic model to predict some inside environment variables in a semi-solar greenhouse. Inf. Process. Agric. 2018, 5, 279–288. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Tanino, K. Modeling heating demands in a Chinese-style solar greenhouse using the transient building energy simulation model TRNSYS. J. Build. Eng. 2020, 29, 101114. [Google Scholar] [CrossRef]

- Rasheed, A.; Kwak, C.S.; Kim, H.T.; Lee, H.W. Building Energy an Simulation Model for Analyzing Energy Saving Options of Multi-Span Greenhouses. Appl. Sci. 2020, 10, 6884. [Google Scholar] [CrossRef]

- Chahidi, L.O.; Fossa, M.; Priarone, A.; Mechaqrane, A. Energy saving strategies in sustainable greenhouse cultivation in the mediterranean climate—A case study. Appl. Energy 2021, 282, 116156. [Google Scholar] [CrossRef]

- Shin, H.; Kwak, Y.; Jo, S.-K.; Kim, S.-H.; Huh, J.-H. Applicability evaluation of a demand-controlled ventilation system in livestock. Comput. Electron. Agric. 2022, 196, 106907. [Google Scholar] [CrossRef]

- Zhang, Y.; Gauthier, L.; de Halleux, D.; Dansereau, B.; Gosselin, A. Effect of covering materials on energy consumption and greenhouse microclimate. Agric. For. Meteorol. 1996, 82, 227–244. [Google Scholar] [CrossRef]

- Boulard, T.; Wang, S. Greenhouse crop transpiration simulation from external climate conditions. Agric. For. Meteorol. 2000, 100, 25–34. [Google Scholar] [CrossRef]

- Zhao, Y.; Teitel, M.; Barak, M. SE—Structures and Environment: Vertical Temperature and Humidity Gradients in a Naturally Ventilated Greenhouse. J. Agric. Eng. Res. 2001, 78, 431–436. [Google Scholar] [CrossRef]

- Gupta, M.J.; Chandra, P. Effect of greenhouse design parameters on conservation of energy for greenhouse environmental control. Energy 2002, 27, 777–794. [Google Scholar] [CrossRef]

- Luo, W.; Stanghellini, C.; Dai, J.; Wang, X.; de Zwart, H.F.; Bu, C. Simulation of Greenhouse Management in the Subtropics, Part II: Scenario Study for the Summer Season. Biosyst. Eng. 2005, 90, 433–441. [Google Scholar] [CrossRef]

- Taki, M.; Ajabshirchi, Y.; Ranjbar, S.F.; Rohani, A.; Matloobi, M. Modeling and experimental validation of heat transfer and energy consumption in an innovative greenhouse structure. Inf. Process. Agric. 2016, 3, 157–174. [Google Scholar] [CrossRef] [Green Version]

- Misra, D.; Ghosh, S. Microclimatic Modeling and Analysis of a Fog-Cooled Naturally Ventilated Greenhouse. Int. J. Environ. Agric. Biotechnol. 2017, 2, 997–1001. [Google Scholar] [CrossRef]

- Rasheed, A.; Lee, J.W.; Lee, H.W. Development of a model to calculate the overall heat transfer coefficient of greenhouse covers. Span. J. Agric. Res. 2018, 15, e0208. [Google Scholar] [CrossRef] [Green Version]

- Reyes-Rosas, A.; Molina-Aiz, F.D.; Valera, D.L.; López, A.; Khamkure, S. Development of a single energy balance model for prediction of temperatures inside a naturally ventilated greenhouse with polypropylene soil mulch. Comput. Electron. Agric. 2017, 142, 9–28. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Tanino, K. Development of a thermal model for simulation of supplemental heating requirements in Chinese-style solar greenhouses. Comput. Electron. Agric. 2018, 150, 235–244. [Google Scholar] [CrossRef]

- Singh, M.C.; Singh, J.P.; Singh, K.G. Development of a microclimate model for prediction of temperatures inside a naturally ventilated greenhouse under cucumber crop in soilless media. Comput. Electron. Agric. 2018, 154, 227–238. [Google Scholar] [CrossRef]

- Mobtaker, H.G.; Ajabshirchi, Y.; Ranjbar, S.F.; Matloobi, M. Simulation of thermal performance of solar greenhouse in north-west of Iran: An experimental validation. Renew. Energy 2019, 135, 88–97. [Google Scholar] [CrossRef]

- Semple, L.; Carriveau, R.; Ting, D. Assessing heating and cooling demands of closed greenhouse systems in a cold climate. Int. J. Energy Res. 2017, 41, 1903–1913. [Google Scholar] [CrossRef]

- Shakir, S.M.; Farhan, A.A. Movable thermal screen for saving energy inside the greenhouse. Assoc. Arab. Univ. J. Eng. Sci. 2019, 26, 106–112. [Google Scholar] [CrossRef]

- Lee, S.B.; Lee, I.B.; Homg, S.W.; Seo, I.H.; Bitog, P.J.; Kwon, K.S.; Ha, T.H.; Han, C.-P. Prediction of Greenhouse Energy Loads using Building Energy Simulation (BES). J. Korean Soc. Agric. Eng. 2012, 54, 113–124. [Google Scholar] [CrossRef]

- Hassanien, R.H.E.; Li, M.; Lin, W.D. Advanced applications of solar energy in agricultural greenhouses. Renew. Sustain. Energy Rev. 2015, 54, 989–1001. [Google Scholar] [CrossRef]

- Barichello, J.; Vesce, L.; Mariani, P.; Leonardi, E.; Braglia, R.; Di Carlo, A.; Canini, A.; Reale, A. Stable Semi-Transparent Dye-Sensitized Solar Modules and Panels for Greenhouse Application. Energies 2021, 14, 6393. [Google Scholar] [CrossRef]

- Hamdi, I.; Kooli, S.; Elkhadraoui, A.; Azaizia, Z.; Abdelhamid, F.; Guizani, A. Experimental study and numerical modeling for drying grapes under solar greenhouse. Renew. Energy 2018, 127, 936–946. [Google Scholar] [CrossRef]

- Thomas, Y.; Wang, L.; Denzer, A. Energy savings analysis of a greenhouse heated by waste heat. In Proceedings of the 15th IBPSA Conference, San Francisco, CA, USA, 7–9 August 2017; pp. 2512–2517. [Google Scholar]

- Ha, T.; Lee, I.B.; Kwon, K.S.; Hong, S.W. Computation and field experiment validation of greenhouse energy load using Building Energy Simulation model. Int. J. Agric. Biol. Eng. 2015, 8, 116–127. [Google Scholar]

- Lee, S.N. Design of a Greenhouse Energy Model Including Energy Exchange of Internal Plants and Its Application for Energy Loads Estimation. Master’s Dissertation, College of Agriculture and Life Sciences, Seoul National University, Seoul, Korea, 2017. [Google Scholar]

- Lee, M.; Lee, I.-B.; Ha, T.-H.; Kim, R.-W.; Yeo, U.-H.; Lee, S.-Y.; Park, G.; Kim, J.-G. Estimation on Heating and Cooling Loads for a Multi-Span Greenhouse and Performance Analysis of PV System using Building Energy Simulation. Prot. Hortic. Plant Fact. 2017, 26, 258–267. [Google Scholar] [CrossRef]

- Semple, L.; Carriveau, R.; Ting, D.S.K. A techno-economic analysis of seasonal thermal energy storage for greenhouse applications. Energy Build. 2017, 154, 175–187. [Google Scholar] [CrossRef]

- Rasheed, A.; Lee, J.W.; Lee, H.W. Development and Optimization of a Building Energy Simulation Model to Study the Effect of Greenhouse Design Parameters. Energies 2018, 11, 2001. [Google Scholar] [CrossRef] [Green Version]

- Alinejad, T.; Yaghoubi, M.; Vadiee, A. Thermo-environomic assessment of an integrated greenhouse with an adjustable solar photovoltaic blind system. Renew. Energy 2020, 156, 1–13. [Google Scholar] [CrossRef]

- Cossu, M.; Murgia, L.; Ledda, L.; Deligios, P.A.; Sirigu, A.; Chessa, F.; Pazzona, A. Solar radiation distribution inside a greenhouse with south-oriented photovoltaic roofs and effects on crop productivity. Appl. Energy 2014, 133, 89–100. [Google Scholar] [CrossRef]

- Marucci, A.; Zambon, I.; Colantoni, A.; Monarca, D. A combination of agricultural and energy purposes: Evaluation of a prototype of photovoltaic greenhouse tunnel. Renew. Sustain. Energy Rev. 2018, 82, 1178–1186. [Google Scholar] [CrossRef]

- Shukla, A.; Tiwari, G.N.; Sodha, M. Thermal modeling for greenhouse heating by using thermal curtain and an earthair heat exchanger. Build. Environ. 2006, 41, 843–850. [Google Scholar] [CrossRef]

- Cuce, E.; Harjunowibowo, D.; Cuce, P.M. Renewable and sustainable energy saving strategies for greenhouse systems: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 64, 34–59. [Google Scholar] [CrossRef]

- Chen, J.; Yang, J.; Zhao, J.; Xu, F.; Shen, Z.; Zhang, L. Energy demand forecasting of the greenhouses using nonlinear models based on model optimized prediction method. Neurocomputing 2016, 174, 1087–1100. [Google Scholar] [CrossRef]

- Graamans, L.; van den Dobbelsteen, A.; Meinen, E.; Stanghellini, C. Plant factories; crop transpiration and energy balance. Agric. Syst. 2017, 153, 138–147. [Google Scholar] [CrossRef]

- Majdoubi, H.; Boulard, T.; Fatnassi, H.; Senhaji, A.; Elbahi, S.; Demrati, H.; Mouqallid, M.; Bouirden, L. Canary Greenhouse CFD Nocturnal Climate Simulation. Open J. Fluid Dyn. 2016, 6, 88–100. [Google Scholar] [CrossRef] [Green Version]

- Talbot, M.-H.; Monfet, D. Estimating the impact of crops on peak loads of a Building-Integrated Agriculture space. Sci. Technol. Built Environ. 2020, 26, 1448–1460. [Google Scholar] [CrossRef]

- Li, B.; Shi, B.J.; Yao, Z.Z.; Shukla, M.K.; Du, T.S. Energy partitioning and microclimate of solar greenhouse under drip and furrow irrigation systems. Agric. Water Manag. 2020, 234, 106096. [Google Scholar] [CrossRef]

- Boulard, T.; Baille, A. Analysis of thermal performance of a greenhouse as a solar collector. Energy Agric. 1987, 6, 17–26. [Google Scholar] [CrossRef]

- Eumorfopoulou, E.; Aravantinos, D. The contribution of a planted roof to the thermal protection of buildings in Greece. Energy Build. 1998, 27, 29–36. [Google Scholar] [CrossRef]

- Henshaw, P. Modelling changes to an unheated greenhouse in the Canadian subarctic to lengthen the growing season. Sustain. Energy Technol. Assess. 2017, 24, 31–38. [Google Scholar] [CrossRef]

- Attar, I.; Naili, N.; Khalifa, N.; Hazami, M.; Farhat, A. Parametric and numerical study of a solar system for heating a greenhouse equipped with a buried exchanger. Energy Convers. Manag. 2013, 70, 163–173. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, P.; Mao, J.; Tang, X.; Li, Z.; Shi, J. A low cost seasonal solar soil heat storage system for greenhouse heating: Design and pilot study. Appl. Energy 2015, 156, 213–222. [Google Scholar] [CrossRef]

- Vadiee, A.; Martin, V. Energy analysis and thermoeconomic assessment of the closed greenhouse—The largest commercial solar building. Appl. Energy 2013, 102, 1256–1266. [Google Scholar] [CrossRef]

- Bournet, P.-E.; Boulard, T. Effect of ventilator configuration on the distributed climate of greenhouses: A review of experimental and CFD studies. Comput. Electron. Agric. 2010, 74, 195–217. [Google Scholar] [CrossRef]

- Piscia, D.; Montero, J.I.; Baeza, E.; Bailey, B.J. A CFD greenhouse night-time condensation model. Biosyst. Eng. 2012, 111, 141–154. [Google Scholar] [CrossRef]

- Bartzanas, T.; Kacira, M.; Zhu, H.; Karmakar, S.; Tamimi, E.; Katsoulas, N.; In BokLeef, C.; Kittas, C. Computational fluid dynamics applications to improve crop production systems. Comput. Electron. Agric. 2013, 93, 151–167. [Google Scholar] [CrossRef]

- Boulard, T.; Roy, J.C.; Pouillard, J.B.; Fatnassi, H.; Grisey, A. Modelling of micrometeorology, canopy transpiration and photosynthesis in a closed greenhouse using computational fluid dynamics. Biosyst. Eng. 2017, 158, 110–133. [Google Scholar] [CrossRef]

- Kim, M.-H.; Lee, D.-W.; Yun, R.; Heo, J. Operational Energy Saving Potential of Thermal Effluent Source Heat Pump System for Greenhouse Heating in Jeju. Int. J. Air-Cond. Refrig. 2017, 25, 1750030. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Lee, I.-B.; Kim, R.-W. Evaluation of wind-driven natural ventilation of single-span greenhouses built on reclaimed coastal land. Biosyst. Eng. 2018, 171, 120–142. [Google Scholar] [CrossRef]

- Klein, S.A. TRNSYS 18: A Transient System Simulation Program, Solar Energy Laboratory, University of Wisconsin, Madison, WI, USA. 2017. Available online: https://sel.me.wisc.edu/trnsys (accessed on 3 September 2020).

- Fatnassi, H.; Boulard, T.; Poncet, C.; Katsoulas, N.; Bartzanas, T.; Kacira, M.; Giday, H.; Lee, I.B. Computational fluid dynamics modelling of the microclimate within the boundary layer of leaves leading to improved pest control management and low-input greenhouse. Sustainability 2021, 13, 8310. [Google Scholar] [CrossRef]

- Yeo, U.H.; Lee, I.B.; Kim, R.W.; Lee, S.Y.; Kim, J.G. Computational fluid dynamics evaluation of pig house ventilation systems for improving the internal rearing environment. Biosyst. Eng. 2019, 186, 259–278. [Google Scholar] [CrossRef]

- Kim, R.W.; Kim, J.G.; Lee, I.B.; Yeo, U.H.; Lee, S.Y.; Decano-Valentin, C. Development of three-dimensional visualisation technology of the aerodynamic environment in a greenhouse using CFD and VR technology, part 1: Development of VR a database using CFD. Biosyst. Eng. 2021, 207, 33–58. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, J.G.; Kim, R.W.; Yeo, U.H.; Lee, I.B. Development of three-dimensional visualisation technology of aerodynamic environment in fattening pig house using CFD and VR technology. Comput. Electron. Agric. 2022, 194, 106709. [Google Scholar] [CrossRef]

- Teitel, M.; Ozer, S.; Mendelovich, V. Airflow temperature and humidity patterns in a screenhouse with a flat insect-proof screen roof and impermeable sloping walls–Computational fluid dynamics (CFD) results. Biosyst. Eng. 2022, 214, 165–176. [Google Scholar] [CrossRef]

- Norton, T.; Sun, D.-W.; Grant, J.; Fallon, R.; Dodd, V. Applications of computational fluid dynamics (CFD) in the modelling and design of ventilation systems in the agricultural industry: A review. Bioresour. Technol. 2007, 98, 2386–2414. [Google Scholar] [CrossRef]

- Monteith, J.L.; Unsworth, M.H. Principles of Environmental Physics; Edward Arnold: London, UK, 1990. [Google Scholar]

- Ortega-Farias, S.O.; Olioso, A.; Fuentes, S.; Valdes, H. Latent heat flux over a furrow-irrigated tomato crop using Penman–Monteith equation with a variable surface canopy resistance. Agric. Water Manag. 2006, 82, 421–432. [Google Scholar] [CrossRef]

- Kim, R.W.; Lee, I.B.; Kwon, K.S. Evaluation of wind pressure acting on multi-span greenhouses using CFD technique, Part 1: Development of the CFD model. Biosyst. Eng. 2017, 164, 235–256. [Google Scholar] [CrossRef]

- Richards, P.J. Computational Modelling of Wind Flow around Low-Rise Buildings Using PHOENICS; AFRC Institute of Engineering Research Wrest Park, Silsoe Research Institute, University of Reading: Bedfordshire, UK, 1989. [Google Scholar]

- Lee, I.-B.; Sase, S.; Sung, S.-H. Evaluation of CFD Accuracy for the Ventilation Study of a Naturally Ventilated Broiler House. Jpn. Agric. Res. Q. JARQ 2007, 41, 53–64. [Google Scholar] [CrossRef] [Green Version]

- Bartzanas, T.; Kittas, C.; Sapounas, A.; Nikita-Martzopoulou, C. Analysis of airflow through experimental rural buildings: Sensitivity to turbulence models. Biosyst. Eng. 2007, 97, 229–239. [Google Scholar] [CrossRef]

- Lee, I.B.; Yun, N.K.; Boulard, T.; Roy, J.C.; Lee, S.H.; Kim, G.W.; Lee, S.; Kwon, S.H. Development of an aerodynamic simulation for studying microclimate of plant canopy in greenhouse-(1) Study on aerodynamic resistance of tomato canopy through wind tunnel experiment. J. Bio-Environ. Control 2006, 15, 289–295. [Google Scholar]

- Lee, I.B.; Yun, N.K.; Boulard, T.; Roy, J.C.; Lee, S.H.; Kim, G.W.; Hong, S.-W.; Sung, S.H. Development of an aerodynamic simulation for studying microclimate of plant canopy in greenhouse-(2) Development of CFD model to study the effect of tomato plants on internal climate of greenhouse. J. Bio-Environ. Control 2006, 15, 296–305. [Google Scholar]

- Kittas, C.; Boulard, T.; Papadakis, G. Natural ventilation of a greenhouse with ridge and side openings: Sensitivity to temperature and wind effects. Trans. ASAE 1997, 40, 415–425. [Google Scholar] [CrossRef]

- Sawachi, T.; Ken-Ichi, N.; Kiyota, N.; Seto, H.; Nishizawa, S.; Ishikawa, Y. Wind Pressure and Air Flow in a Full-Scale Building Model under cross Ventilation. Int. J. Vent. 2004, 2, 343–357. [Google Scholar] [CrossRef]

- Sethi, V.P. On the selection of shape and orientation of a greenhouse: Thermal modeling and experimental validation. Sol. Energy 2009, 83, 21–38. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Fragos, V.P.; Nikita-Martzopoulou, C. Thermal analysis of a hybrid solar energy saving system inside a greenhouse. Energy Convers. Manag. 2014, 81, 428–439. [Google Scholar] [CrossRef]

- Chen, J.; Xu, F.; Tan, D.-P.; Shen, Z.; Zhang, L.; Ai, Q. A control method for agricultural greenhouses heating based on computational fluid dynamics and energy prediction model. Appl. Energy 2015, 141, 106–118. [Google Scholar] [CrossRef]

- Mashonjowa, E.; Ronsse, F.; Milford, J.R.; Pieters, J.G. Modelling the thermal performance of a naturally ventilated greenhouse in Zimbabwe using a dynamic greenhouse climate model. Sol. Energy 2013, 91, 381–393. [Google Scholar] [CrossRef]

- Lee, H.W.; Sim, S.Y.; Kim, Y.S. Characteristics of PPF Transmittance and Heat Flow by Double Covering Methods of Plastic Film in Tomato Greenhouse. J. Korean Soc. Agric. Eng. 2010, 52, 11–18. [Google Scholar] [CrossRef] [Green Version]

- Monte, J.A.; De Carvalho, D.F.; Medici, L.O.; da Silva, L.D.B.; Pimentel, C. Growth analysis and yield of tomato crop under different irrigation depths. Rev. Bras. De Eng. Agrícola E Ambient. 2013, 17, 926–931. [Google Scholar] [CrossRef] [Green Version]

- Albright, L.D. Environment Control for Animals and Plants; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1990. [Google Scholar]

- Lindley, J.A.; Whitaker, J.H. Agricultural Buildings and Structures; ASAE: St. Joseph, MI, USA, 1996. [Google Scholar]

- Karava, P.; Stathopoulos, T.; Athienitis, A.K. Wind-induced natural ventilation analysis. Sol. Energy 2007, 81, 20–30. [Google Scholar] [CrossRef]

- Chu, C.R.; Chiu, Y.H.; Chen, Y.J.; Wang, Y.W.; Chou, C.P. Turbulence effects on the discharge coefficient and mean flow rate of wind-driven cross-ventilation. Build. Environ. 2009, 44, 2064–2072. [Google Scholar] [CrossRef]

- Kurabuchi, T.; Ohba, M.; Endo, T.; Akamine, Y.; Nakayama, F. Local Dynamic Similarity Model of Cross-Ventilation Part 1—Theoretical Framework. Int. J. Vent. 2004, 2, 371–382. [Google Scholar] [CrossRef]

- Ohba, M.; Kurabuchi, T.; Tomoyuki, E.; Akamine, Y.; Kamata, M.; Kurahashi, A. Local Dynamic Similarity Model of Cross-Ventilation Part 2—Application of Local Dynamic Similarity Model. Int. J. Vent. 2004, 2, 383–394. [Google Scholar] [CrossRef]

- Carey, P.S.; Etheridge, D.W. Direct wind tunnel modelling of natural ventilation for design purposes. Build. Serv. Eng. Res. Technol. 1999, 20, 131–142. [Google Scholar] [CrossRef]

- Vickery, B.J.; Karakatsanis, C. External wind pressure distributions and induced internal ventilation flow in low-rise industrial and domestic structures. ASHRAE Trans. 1987, 93, 2198–2213. [Google Scholar]

| Boundary conditions of the CFD model | Contents | Input Values |

| Atmospheric pressure | 101,325 Pa | |

| Density of air | 1.225 kg m−3 | |

| Gravitational acceleration | 9.81 m s−2 | |

| Inlet | Wind profile (1, 3, 5 m s−1) | |

| Outlet | Pressure outlet | |

| Coefficient of viscosity | 1.7894 × 10−5 | |

| Drag coefficient of crop | 0.26 | |

| Pressure–velocity coupling | SIMPLE algorithm | |

| Spatial discretization of momentum, volume fraction, turbulent kinetic energy, and turbulence dissipation rate | Second-order upwind | |

| Spatial discretization of gradient | Least squares cell-based | |

| Transient formulation | First-order implicit | |

| Turbulence models | RNG k–ε | |

| Convergence criteria |

| Parameters | Input Values |

|---|---|

| Solar transmittance | 0.862 |

| Solar reflectance (exterior and interior facing side) | 0.105 |

| Visible transmittance | 0.881 |

| Visible reflectance (exterior and interior facing side) | 0.108 |

| Thermal infrared transmittance | 0 |

| Infrared emittance (exterior and interior facing side) | 0.658 |

| Conductivity (W m−1 K−1) | 0.14 |

| U factor (W m−2 K−1) | 5.412 |

| Classification | Average | Highest | Lowest | SD |

|---|---|---|---|---|

| Internal air temperature (°C) | 27.4 | 45.3 | 16.3 | 6.2 |

| External air temperature (°C) | 25.0 | 34.7 | 12.1 | 4.8 |

| Leaf temperature (°C) | 26.8 | 44.1 | 16.6 | 5.7 |

| Internal relative humidity (%) | 91.1 | 100 | 29.3 | 7.5 |

| External relative humidity (%) | 82.6 | 100 | 46.3 | 8.1 |

| Internal solar radiation (W m−2) | – | 629.4 | 0.0 | – |

| External solar radiation (W m−2) | – | 969.4 | 0.0 | – |

| Parameters | ET | Ti | RH | TL | RAD | |

|---|---|---|---|---|---|---|

| ET | Pearson correlation | 1 | 0.611 ** | −0.605 ** | 0.453 ** | 0.729 ** |

| Significance probability | 0.000 | 0.000 | 0.000 | 0.000 | ||

| Ti | Pearson correlation | 0.611 ** | 1 | −0.701 ** | 0.967 ** | 0.671 ** |

| Significance probability | 0.000 | 0.000 | 0.000 | 0.000 | ||

| RH | Pearson correlation | −0.605 ** | −0.701 ** | 1 | −0.681 ** | −0.622 ** |

| Significance probability | 0.000 | 0.000 | 0.000 | 0.000 | ||

| TL | Pearson correlation | 0.453 ** | 0.967 ** | −0.681 ** | 1 | 0.613 ** |

| Significance probability | 0.000 | 0.000 | 0.000 | 0.000 | ||

| RAD | Pearson correlation | 0.729 ** | 0.671 ** | −0.622 ** | 0.613 ** | 1 |

| Significance probability | 0.000 | 0.000 | 0.000 | 0.000 | ||

| Categories | Wind Direction (°) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Wind Speed (m s−1) | Tomato Canopy | 0 | 45 | 90 | 135 | 180 | 225 | 270 | 315 |

| 1.0 | No crop | 6.12 | 15.73 | 18.08 | 14.98 | 5.61 | 16.18 | 18.52 | 17.47 |

| 0.5 m | 6.38 | 14.57 | 15.26 | 13.31 | 5.40 | 15.40 | 17.07 | 16.32 | |

| 1.0 m | 6.51 | 14.55 | 15.01 | 13.27 | 5.64 | 14.73 | 17.02 | 15.89 | |

| 1.6 m | 6.72 | 14.43 | 14.93 | 13.36 | 5.44 | 14.36 | 17.30 | 15.49 | |

| 3.0 | No crop | 11.46 | 43.74 | 50.11 | 43.08 | 13.98 | 46.51 | 54.15 | 48.87 |

| 0.5 m | 10.57 | 42.60 | 47.55 | 41.77 | 10.36 | 44.10 | 54.00 | 46.88 | |

| 1.0 m | 10.24 | 40.63 | 47.25 | 40.84 | 10.49 | 41.27 | 53.86 | 46.99 | |

| 1.6 m | 9.93 | 39.05 | 45.65 | 40.50 | 11.14 | 41.21 | 53.38 | 46.92 | |

| 5.0 | No crop | 16.77 | 73.14 | 82.92 | 72.05 | 26.48 | 78.06 | 94.15 | 82.27 |

| 0.5 m | 15.97 | 71.35 | 80.15 | 70.66 | 23.34 | 74.61 | 91.79 | 79.66 | |

| 1.0 m | 15.30 | 67.76 | 78.77 | 67.69 | 22.65 | 70.80 | 90.36 | 78.98 | |

| 1.6 m | 15.24 | 65.63 | 77.07 | 67.60 | 20.69 | 69.57 | 88.51 | 77.36 | |

| Wind Speed (m s−1) | Tomato Canopy | Wind Direction (°) | |||||

|---|---|---|---|---|---|---|---|

| 45 | 90 | 135 | 225 | 270 | 315 | ||

| 3.0 | without crop | 0.32 | 0.48 | 0.20 | 0.52 | 0.54 | 0.35 |

| 0.5 m | 0.29 | 0.47 | 0.29 | 0.50 | 0.58 | 0.33 | |

| 1.0 m | 0.28 | 0.51 | 0.20 | 0.50 | 0.57 | 0.32 | |

| 1.6 m | 0.26 | 0.54 | 0.19 | 0.47 | 0.58 | 0.31 | |

| 5.0 | without crop | 0.31 | 0.48 | 0.21 | 0.49 | 0.58 | 0.34 |

| 0.5 m | 0.28 | 0.43 | 0.20 | 0.45 | 0.53 | 0.34 | |

| 1.0 m | 0.27 | 0.46 | 0.23 | 0.44 | 0.58 | 0.31 | |

| 1.6 m | 0.25 | 0.45 | 0.19 | 0.43 | 0.55 | 0.28 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeo, U.-H.; Lee, S.-Y.; Park, S.-J.; Kim, J.-G.; Choi, Y.-B.; Kim, R.-W.; Shin, J.H.; Lee, I.-B. Rooftop Greenhouse: (1) Design and Validation of a BES Model for a Plastic-Covered Greenhouse Considering the Tomato Crop Model and Natural Ventilation Characteristics. Agriculture 2022, 12, 903. https://doi.org/10.3390/agriculture12070903

Yeo U-H, Lee S-Y, Park S-J, Kim J-G, Choi Y-B, Kim R-W, Shin JH, Lee I-B. Rooftop Greenhouse: (1) Design and Validation of a BES Model for a Plastic-Covered Greenhouse Considering the Tomato Crop Model and Natural Ventilation Characteristics. Agriculture. 2022; 12(7):903. https://doi.org/10.3390/agriculture12070903

Chicago/Turabian StyleYeo, Uk-Hyeon, Sang-Yeon Lee, Se-Jun Park, Jun-Gyu Kim, Young-Bae Choi, Rack-Woo Kim, Jong Hwa Shin, and In-Bok Lee. 2022. "Rooftop Greenhouse: (1) Design and Validation of a BES Model for a Plastic-Covered Greenhouse Considering the Tomato Crop Model and Natural Ventilation Characteristics" Agriculture 12, no. 7: 903. https://doi.org/10.3390/agriculture12070903

APA StyleYeo, U.-H., Lee, S.-Y., Park, S.-J., Kim, J.-G., Choi, Y.-B., Kim, R.-W., Shin, J. H., & Lee, I.-B. (2022). Rooftop Greenhouse: (1) Design and Validation of a BES Model for a Plastic-Covered Greenhouse Considering the Tomato Crop Model and Natural Ventilation Characteristics. Agriculture, 12(7), 903. https://doi.org/10.3390/agriculture12070903