Abstract

Nowadays, in Europe, several infrastructures, such as bridges, viaducts, and maritime structures, are in an advanced state of degradation. Therefore, novel repair/rehabilitation techniques are sought. Recent advances in ultra-high-performance fibre-reinforced cement-based composites (UHPFRC) represent a significant step towards resilient structures. In addition to their remarkable mechanical properties (compressive strength > 150 MPa), they present extremely low permeability and, as a premise, very high durability. Despite their relatively high cost, UHPFRC can be a competitive solution for rehabilitation/strengthening applications where smaller volumes are needed. UHPFRC applied in thin layers (with or without reinforcement) can replace carbonated and/or cracked concrete acting as a protective watertight and/or strengthening layer. The structural capacity increases (stiffness, ultimate strength), and the durability is expected to improve significantly while keeping cross-sectional dimensions. Additional advantages are expected, such as reduced intervention time, fewer maintenance routines, reduced life-cycle cost, and longer service life. Although much of the focus on UHPFRC has centred on mechanical and/or structural performance, durability is inevitably linked with mechanical properties. The current work evaluated the durability of non-property and greener UHPC concerning expansive reactions, alkali-silica reactions and expansion due to external sulphates, by macro and micro-scale integrative study. Linear expansion tests were performed in UHPC specimens according to ASTM C 1260 and LNEC E−364. At the macro level, no deleterious expansion due to ASR or external sulphate occured. Expansion due to ASR was 0.0018% after 14 days of immersion in an alkali-rich environment, and no expansion was recorded regarding sulphate attack. However, SEM analysis reveals reactive products of ASR and sulphate attack, namely, ASR gel and ettringite, respectively, in UHPC specimens.

1. Introduction

The Portland cement (PC) patent in 1824 revolutionised the construction industry, and PC based concretes are the most used manufactured materials worldwide. With the substantial growth of the ready-mixed and precast concrete sectors over the past 60 years, concrete performance requirements have become very demanding, such as higher early strength, flowability, durability, and, more recently, ecological footprint concerns. The unsatisfactory durability performance of several concrete/reinforced concrete structures has provoked more concern among the construction stakeholders and the scientific community [1]. Thus, concrete materials have accomplished several technological evolutions, such as self-compacting concrete and high and ultra-high performance. These features were possible due to the emergency of superlasticizers, providing PC composites with very low water content and maintaining desirable fresh workability and high compressive strength.

Ultra-high-performance cement-based composites (UHPC) are the new generation of “concretes”. A major driver for the development of UHPC generations was reactive powder concrete (RPC) [2], with compressive strengths over 200 MPa; it is, however, quite fragile. Thus, employing fibres fulfils two important functions: providing ductility and improving tensile strength. The academy, the technical community, and industries worldwide have made significant research efforts to manufacture ultra-high-performance fibre-reinforced cement-based composites (UHPRC). Additionally, private companies and governmental figures are increasing their attention and initiatives toward the performance advantages of UHPFRC as a solution for more sustainable and resilient construction [3,4,5,6,7]. Most UHPFRC advances have been performed in Japan, France, Switzerland, Germany, Denmark, and the USA. Some of them give rise to commercial UHPFRC blended mixtures, as presented in Appendix A. Usually, UHPFRC tensile strength exceeds 10 MPa, such as DUCTAL® (12 MPa) [8], the “High-Performance Hybrid-Fibre Concrete” (12 MPa) [3], and, more recently, the “Ultra-High Performance Fiber Reinforced Concrete with Low Fiber Contents” (13 MPa) [9]. In Europe, UHPFRC has been used in bridges in Germany, Austria, Croatia, France, Italy, The Netherlands, Spain, and Switzerland [3,10]. Using UHPFRC for architectonic purposes can also be seen in facades of MuCEM in France, Centre bus RATP de Thiais, Jean Bouin Stadium, and SWATCH Building in Swiss. In the USA, UHPFRC has been applied in precast concrete deck panels, pre-stressed concrete girder simple-span bridges, and cast “in-situ” UHPC to connect prefabricated bridge components [11]. An exhaustive list of UHPFRC applications worldwide can be found elsewhere [12,13].

Despite its relatively high cost, UHPFRC can be a very competitive solution for the rehabilitation and/or reinforcement of specific areas of reinforced or pre-stressed concrete infrastructures (bridges, viaducts, and maritime structures). This concept was proposed at the Laboratory of Maintenance and Safety of Structures (MCS) in EPFL, by Prof. Dr. E. Bruhwiler, in 1999, in the scope of the project SAMARIS work package 14 “HPFRCC for rehabilitation”, whose contributors included MCS-EPFL [14]. The application of thin layers (20–65 mm) of UHPFRC, which can be bar-reinforced, replacing carbonated and/or cracked-covered conventional concrete, promotes the improvement of the mechanical properties and the waterproofing of (part of) the structural elements exposed to severe environments and/or critical loads. Additionally, increased service life and reduced operations and maintenance costs are expected. This solution has already been applied worldwide with promising results [3,15,16,17,18,19,20,21].

Although much of the focus on UHPFRC has centred on mechanical and/or structural performance, the “in situ” mechanical performance will be inevitably linked with durability against aggressive media. Antagonistically to conventional concrete, the dense microstructure of UHPFRC has almost no capillary pores. The UHPFRC pores are mostly between 0.1–0.001 µm, and thus the pores are mainly located within the calcium silicate hydrate (CSH) gel [22,23,24,25]. Nevertheless, the pores’ size and interconnectivity are dependent on age, heat treatment, the w/b ratio, the type of cement, and the use of supplementary cementitious materials (SCM) or nanomaterials [26,27,28]. The literature survey shows that the average UHPFRC porosity corresponds to 6.4% for a w/b ratio range of 0.13–0.22 and a compressive strength of 100–279 MPa [29]. This compact microstructure is responsible for both mechanical and durability behaviour.

The compact microstructure of UHPFRC is achieved through an adequate raw materials selection and mixture design. In brief, the granular skeleton mix design is optimised by the packing density theory. The first step excludes the coarser aggregate; the fine aggregate usually has a maximum particle size of 1.0 mm [30,31,32]. The coarser aggregate eliminating in UHPFRC has two main purposes: (i) reducing the weaknesses induced by the interfacial transition zone (ITZ) between the cementitious matrix and aggregates [33], and (ii) reducing the overall porosity in the granular matrix. Usually, the total amount of aggregate ranges from 1000–1200 kg/m3, which corresponds to 38–45% of the total volume of the composite [34] and an optimum aggregate to cement ratio between 1.0 and 1.4 is recommended [31,35] depending on performance requirements. The choice of cement is of utmost importance since it is the main ingredient of UHPFRC, accounting for almost 30% of its volume. The cement generally used is Portland cement CEM I 42.5R or 52.5R, and CEM II 42.5R or 52.5R according to EN 197-1, because of their early high strength potential [3]. The binder fraction of a UHPFRC usually contains a substantial amount of silica fume (SF). The primary function of SF is physical, i.e., SF particles fill the spaces between the cement particles, other SCM, and the aggregate. Moreover, SF presents high pozzolanic reactivity, providing additional CSH and decreasing the porosity of the cementitious mixture. A large fraction of silica fume is recommended by some authors, 20 to 35% of cement weight [3], to ensure a dense granular packing.

Nevertheless, SF presents some limitations, such as availability and high cost. Thus, several studies have been conducted on the feasibility of using other supplementary cementing materials (SCM) to partially replace PC and SF in UHPFRC. These include both conventional SCM, such as limestone filler (LF) [36] fly ash or slag [37,38], as well as unconventional, obtained from agricultural or industrial wastes, such as bottom ash [38], sugarcane bagasse ash [39], glass powder [40,41], and RHA [42,43]. The use of alternative SCM reduces the cement dosage and contributes to waste/by-product valorisation and it is an integrated way to promote more sustainable advanced cementitious materials.

Research Significance and Objectives

Alkalis silica reaction (ASR) is a slow, expansive reaction which can take 10–15 years to manifest in concrete structures or elements [44,45]. However, deleterious expansions associated with ASR have been recurrently reported among the main causes of deterioration of important concrete structures and infrastructures, such as dams, nuclear/power plant, pavements, bridges, walls, and barriers. This expansive deleterious reaction can gradually reduce the service life, the load-carrying capacity, and even the safety of the concrete structures, which can lead to high replacement costs or even the structure’s demolition [46,47,48,49,50,51]. Due to the high cement content employed, the equivalent alkali content (Na2Oeq) in UHPFRC mixtures usually exceeds 8 kg/m³. Thus, it seems necessary to evaluate the risk of damage due to ASR in UHPFRC. Due to the very low permeability of UHPFRC, the external sulphate attack is not expected, however, it needs to be confirmed. Sulphate attack is rarely the only phenomenon responsible for concrete deterioration [51]; it often co-occurs when reactive aggregates are used and are typically observed in structures or elements exposed to sulphate-rich solutions, such as rivers, seawater, and groundwaters [52]. Considering the rehabilitation or strengthening of sea structures has been an exciting application field for UHPFRC, durability against expansive reactions must be evaluated. However, it is still missing from the literature survey.

In CONSTRUCT-LABEST, research projects have been conducted to make UHPFRC a more practical, cost-effective, eco-efficient, and widely accepted material/solution. One of the aims was to develop a UHPFRC using locally available raw materials, incorporating local non-value-added by-products or waste materials and simple manufacturing and curing methods [53,54,55]. Those features can reduce the cost and ecological footprint of UHPFRC and contribute to a circular economy. The current work evaluated the durability of the non-property and greener UHPC (with no fibres) against expansive reactions, namely, alkali-silica reactions and expansion due to external sulphates, by macro and micro-scale integrative analysis. At the macro level, linear expansion tests were performed according to ASTM C 1260 and LNEC E−364 to access the mitigation effect of UHPC against ASR and external sulphates, respectively. After ASR and sulphate tests, SEM observations and EDX analysis were carried out. In addition, porosity and microstructure analyses on sound UHPC samples were performed.

2. Materials and Methods

2.1. Raw Materials and Mix Design

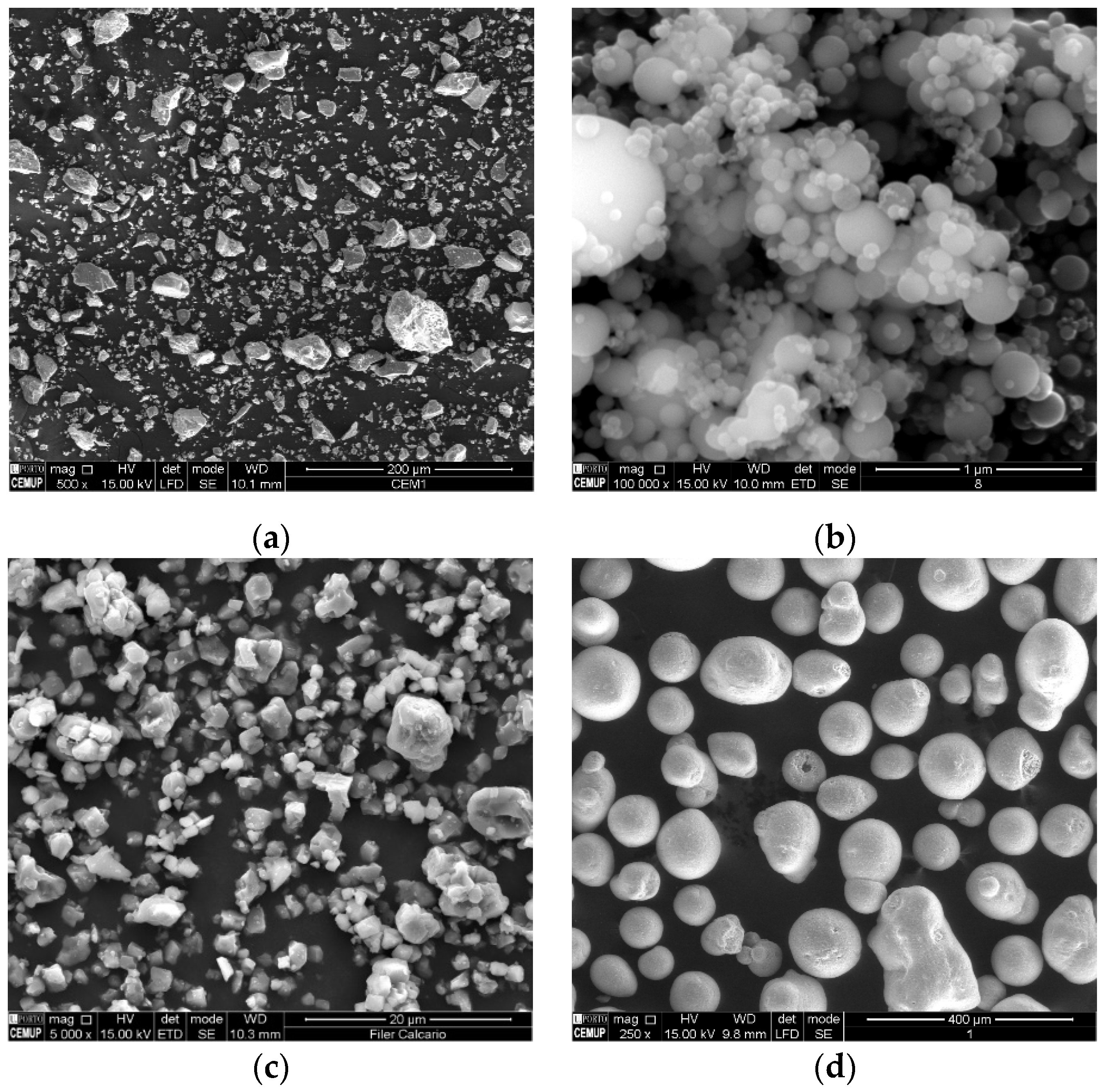

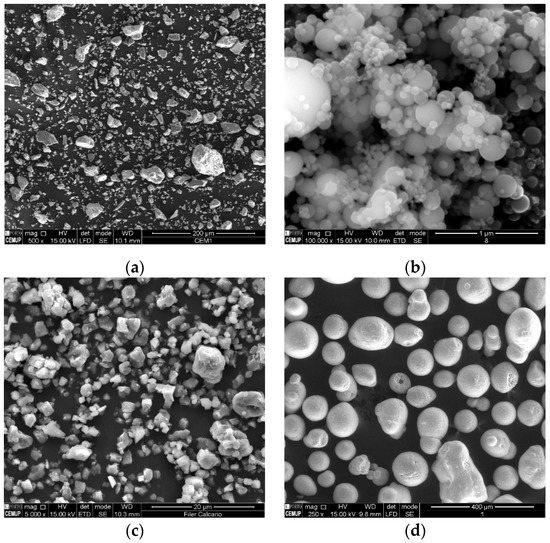

The author developed the UHPFRC [53,54,55] using locally available materials in Portugal/Europe. The mixture design included a local waste material, the spent equilibrium catalyst (ECat) from the fluid catalytic cracking unit of Sines Refinery in Portugal. A breakthrough of the work was using ECat, for the first time, as an internal curing agent proving engineering benefits with additional cost and eco-efficiency outputs. More information can be found elsewhere [53,54,55]. It follows a brief description of constituent raw materials and mixture proportions. The binder fraction is constituted by a ternary blend of Portland cement CEM I 42.5 R, dry fume silica fume, and limestone filler, whose main oxide composition and physical properties are shown in Table 1. The aggregate fraction corresponds to (in volume): 85% fine sand with a maximum diameter of 1 mm, density of 2580 kg/m3, and water absorption of 0.02%, and 15% of ECat with a density of 2660 kg/m3 and absorption of 30%. A superplasticiser based on modified carboxylates with a density of 1080 kg/m3 and a solid content of 40% was employed to ensure self-compactability and adequate cementitious particle dispersion. Figure 1 presents the secondary electron mode SEM images of particle morphology of cement, silica fume, limestone filler, and ECat. Steel fibres 0.2 mm in diameter and 13 mm in length (lf/df = 65) were incorporated to produce UHPFRC mixtures (UHPC with 3% fibre reinforced in volume), with tensile strength and modulus of elasticity 2750 MPa and 200 GPa, respectively.

Table 1.

Main oxide composition, LOI, and physical properties of cementitious materials.

Figure 1.

SEM images of (a) cement, (b) silica fume, (c) limestone filler, and (d) ECat.

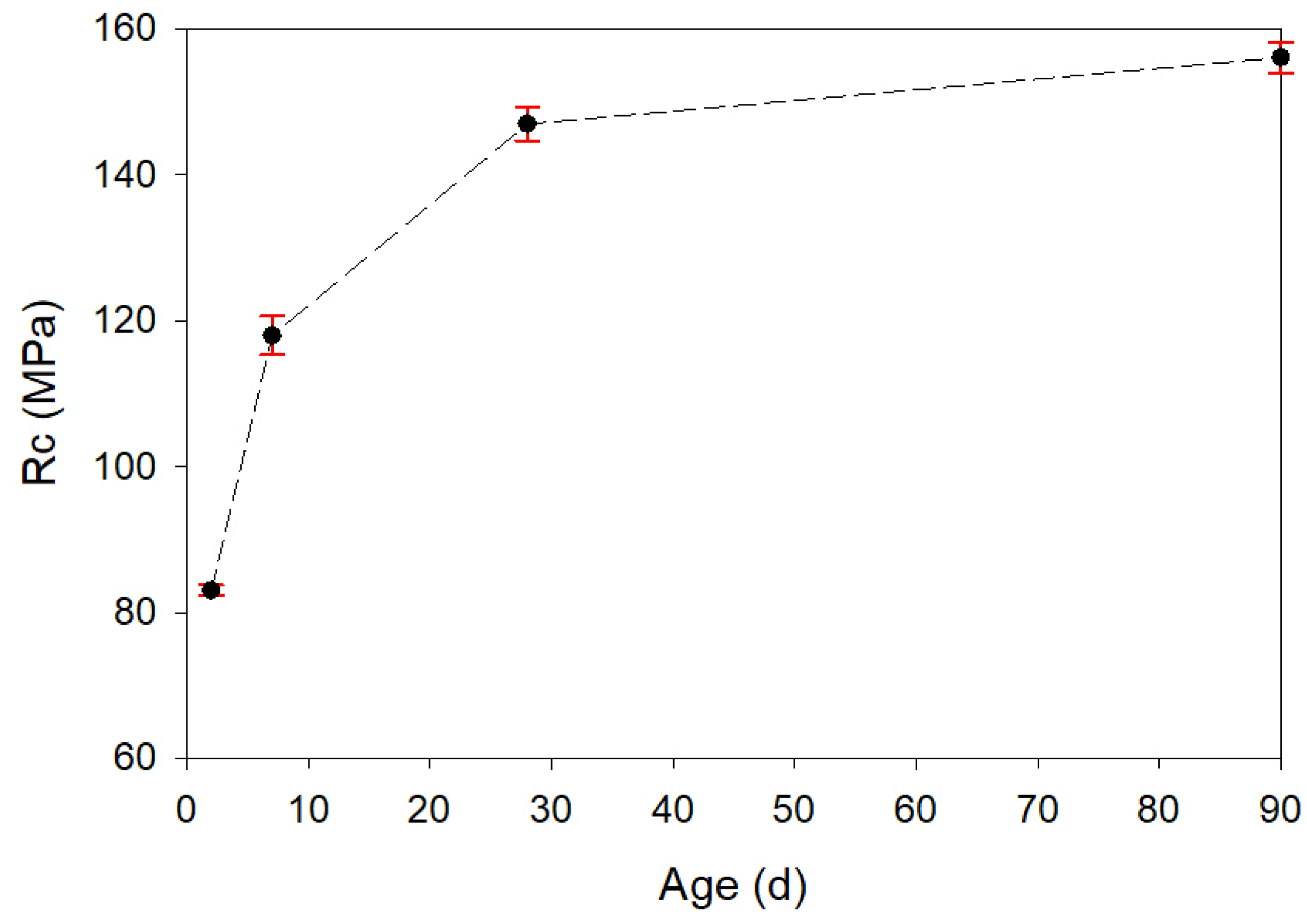

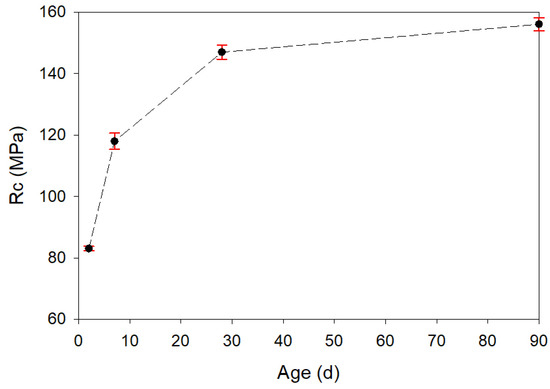

Even though the UHPFRC developed presents lower cement and silica fume dosage than the commercially available blends (see Appendix A), it presents a compressive strength in the range expected for this cement-based materials family, see Figure 2. Moreover, no special curing treatments were applied, and UHPC specimens remained under standard water curing at 20 ± 2 °C.

Figure 2.

Compressive strength and standard deviation bars of UHPFRC between 2 and 90 days.

The current durability study was performed in UHPC (with no fibres), and the mixture proportions are presented in Table 2.

Table 2.

The UHPC mixture proportions.

2.2. Experimental Tests Procedures

The current work aimed to characterise the UHPC at (i) micro-scale level through mercury intrusion porosimetry (MIP) on sound UHPC specimens and SEM observations on sound and damaged UHPC samples after ASR and sulphate tests; (ii) macro level by linear length change measurements due to expansive reactions (ASR and external sulphates). The experimental program summary is presented in Table 3, including the property or indicator, test procedure, curing regime, testing age, and specimen information. The following Section 2.2.1, Section 2.2.2, Section 2.2.3 and Section 2.2.4 describe the test methods in more detail.

Table 3.

Experimental program summary.

2.2.1. Porosity

After 28 days of water curing, UHPC samples were dried until constant mass and tested. MIP, using a Poremaster−60 equipment, which can measure pore sizes from 200 to 0.0035 μm. During the MIP testing, the applied pressures varied between 0.14 and 412 MPa, and the surface tension was 480 mN/m with a contact angle of 140°.

2.2.2. Resistance to ASR

The potential of ASR mitigation of UHPC was evaluated by the accelerated mortar bar test ASTM C 1260 [56]. ASTM 1260 specifies mixture proportions and aggregate grading; however, the UHPC mix proportions and ingredients described previously (see Table 2) were used in the current study. Three UHPC bar specimens were cast. After 24 h, the UHPC specimens were demolded. Then, the bar specimens were placed in an 80 °C water bath for the following 24 h and finally immersed in the 80 °C 1N NaOH solution bath and only taken off to perform the linear length measurements on pre-defined days. The lengths of the bar specimens after immersion in hot water were considered the initial readings (). In the current work, the linear length measurements were performed for half a year, and the length of each sample was measured using a digital indicator with an accuracy of 0.001 mm.

2.2.3. Resistance to External Sulphates

UHPC resistance to external sulphate attack was evaluated according to the Portuguese specification E−462 [57], which aims to assess the cement susceptibility of external sulphates. Even though Portuguese specification E−462 suggested a mixture proportion, the UHPC mix proportions described previously (see Table 2) were used. Thus, six-bar specimens (1, 2, 3, 4, 5, and 6) with dimensions of 16 × 16 × 160 mm3 were cast. All of the UHPC bar specimens remained in the mold for 24h and then were immersed in saturated calcium hydroxide solution for 28 days in a controlled environment (T = 20 ± 2 °C). At 28 days, linear length measurements along the four side faces of each specimen were performed and taken as the initial length (). The UHPC bar specimens 2, 4, and 6 were then transferred to a sodium sulphate solution (16g/L SO42−), and the others (1, 3, and 5) were kept in calcium hydroxide saturated solution. The length change measurements of all UHPC bars were taken every two weeks for 26 weeks. At each length measurement, the sulphate solution was renewed. The expansion of each specimen in day was calculated as:

where is the expansion of specimens kept in saturated calcium hydroxide solution (specimens 1, 3 and 5) at day

where is the expansion of specimens kept in sodium sulphate solution (specimens 2, 4, and 6) at day .

Thus, the expansion due to external sulphate is:

The length of each sample was measured using a digital indicator with an accuracy of 0.0001 mm.

2.2.4. SEM

Scanning electron microscopy (SEM) instantaneous microanalysis using energy-dispersive X-ray spectroscopy analysis (EDX) has been employed to explain the complex internal structure of cement-based materials [58]. In the current work, the SEM potential was used to observe the microstructure of the UHPC samples. In addition, after expansive test completion (ASR and sulphate tests), samples were taken from the UHPC bar specimens exposed to ASR and the sodium sulphate solution. The microstructures of those samples were also investigated using SEM analysis with EDX spectrums.

3. Results and Discussion

3.1. Porosity and Microstructure

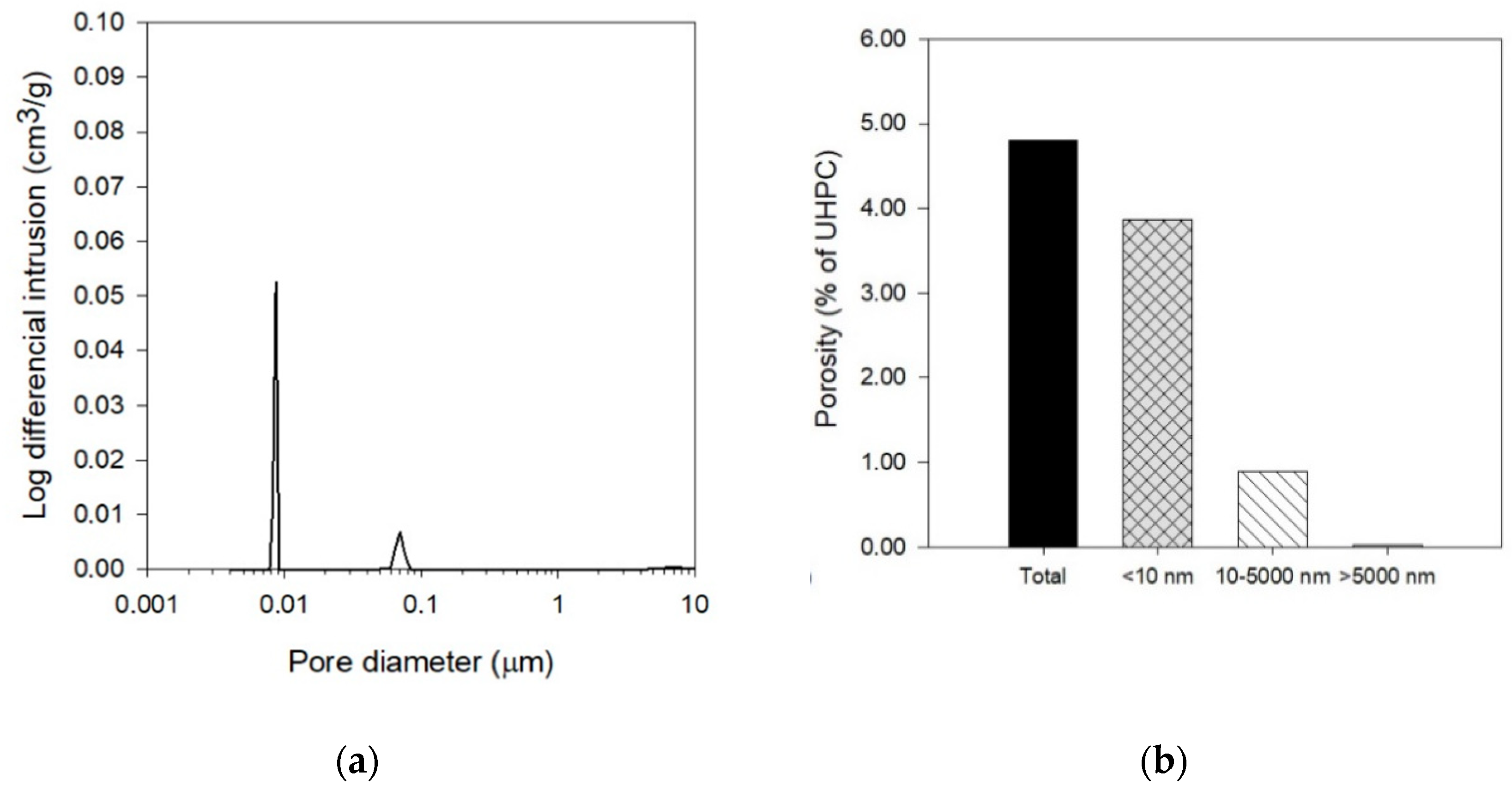

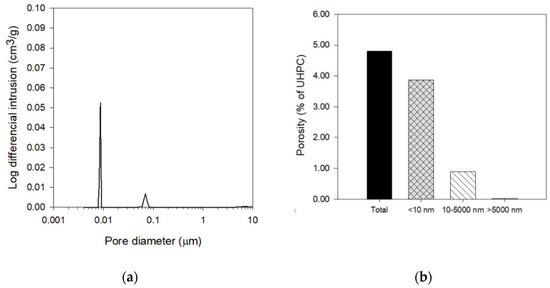

The pore size distribution of UHPC obtained from the MIP test is depicted in Figure 3a. From 3.5 nm (lower limit of MIP), the UHPC pore size distribution is bimodal, with a higher pore peak around 8 nm, followed by a sharp decrease in pore diameter size. Then, a smaller peak occurred at 70 nm, and no pores larger than 100 nm were found. The average pore diameter corresponds to 8.8 nm, and the total porosity is 4.8%, which seems to agree with previous studies [29]. In Figure 3b, the measured pore distribution is divided into three size ranges: gel or micropores (<10 nm), capillary pores (10–5000 nm), and macro pores (>5000 nm), according to [59]. However, it must be stressed that an official or standard pore size classification for cement-based materials still does not exist, so different pore size classifications may be found in the literature [60]. Still, the consensus is that gel pores correspond to interconnected spaces between the gel particles, usually presented by needle-plate or foil-shaped [61,62]. On the other hand, capillary pores may be defined as the empty spaces not filled by cementitious materials or hydration products [61,62]. Since the hydration products occupy more than two times the volume of the original solid phase, the volume of the capillary system is reduced as the hydration progresses. Thus, capillary pores strongly depend on the w/c ratio and the degree of hydration [60].

Figure 3.

Porosity distribution of an UHPC in the reference dry state after 28 curing age days: (a) Differencial pore size distribution; (b) Pores size distribution in terms of pore size classification according [60].

Previous research suggested that pores lower than 100 nm slightly impact the strength and durability of cement-based materials [33,63,64]. Figure 3b indicates that the main porosity of UHPC came from gel (<10 nm), and only 1% of total pores are capillary pores (10–5000 nm). The very low volume of pores and the absence of capillary pores are the main reasons for the expected high durability against harmful gas and water agents. In addition, it is generally accepted that the pozzolanic additions, in this case, silica fume and ECat, improve the pore structure by its filler effect, filling the void between cement grains and between cement grains and aggregates particles; and the chemical effect, i.e., the pozzolanic reaction, in which SCM reacts with calcium hydroxide from cement hydration producing additional CSH, thus contributing to porosity reduction.

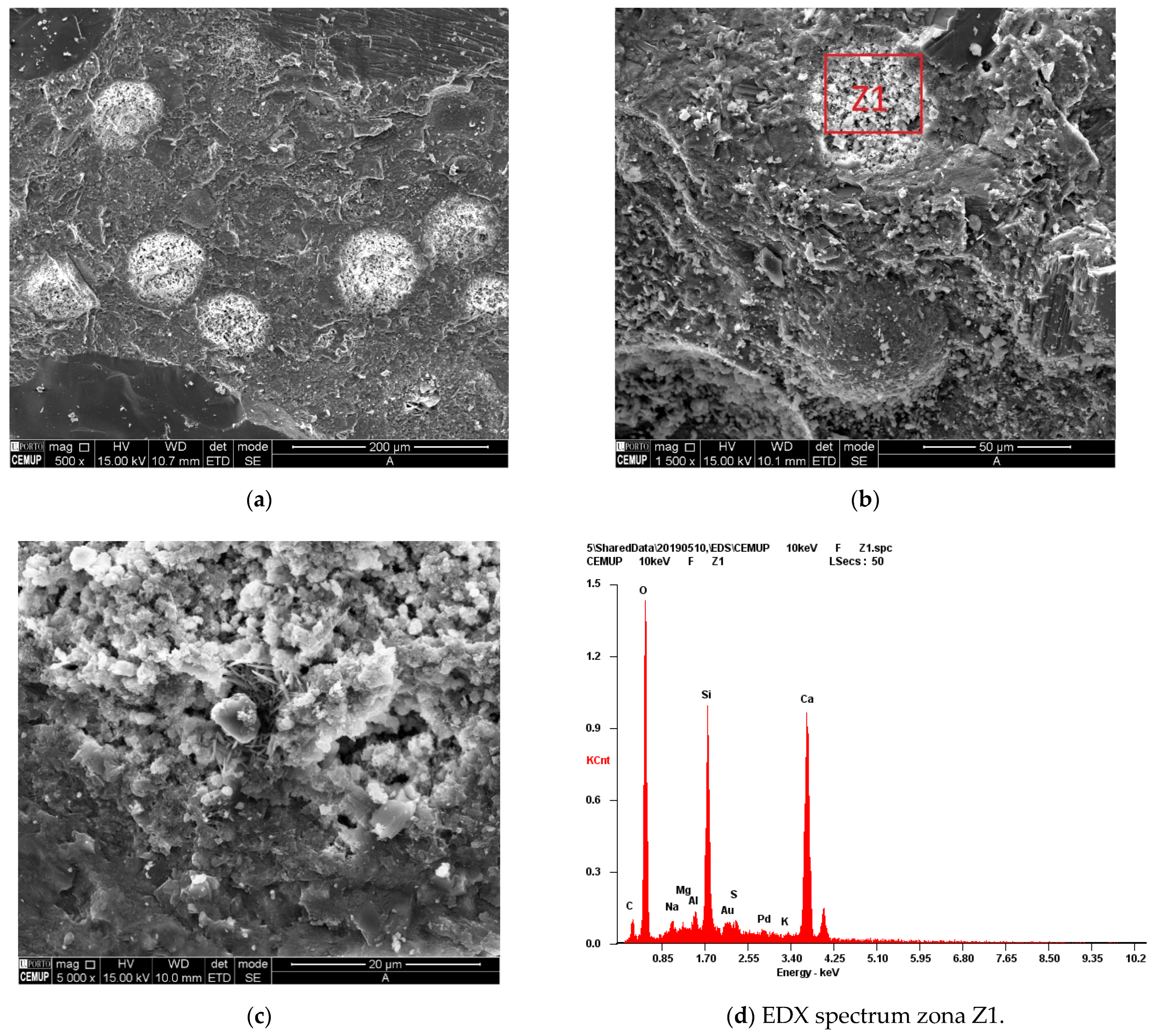

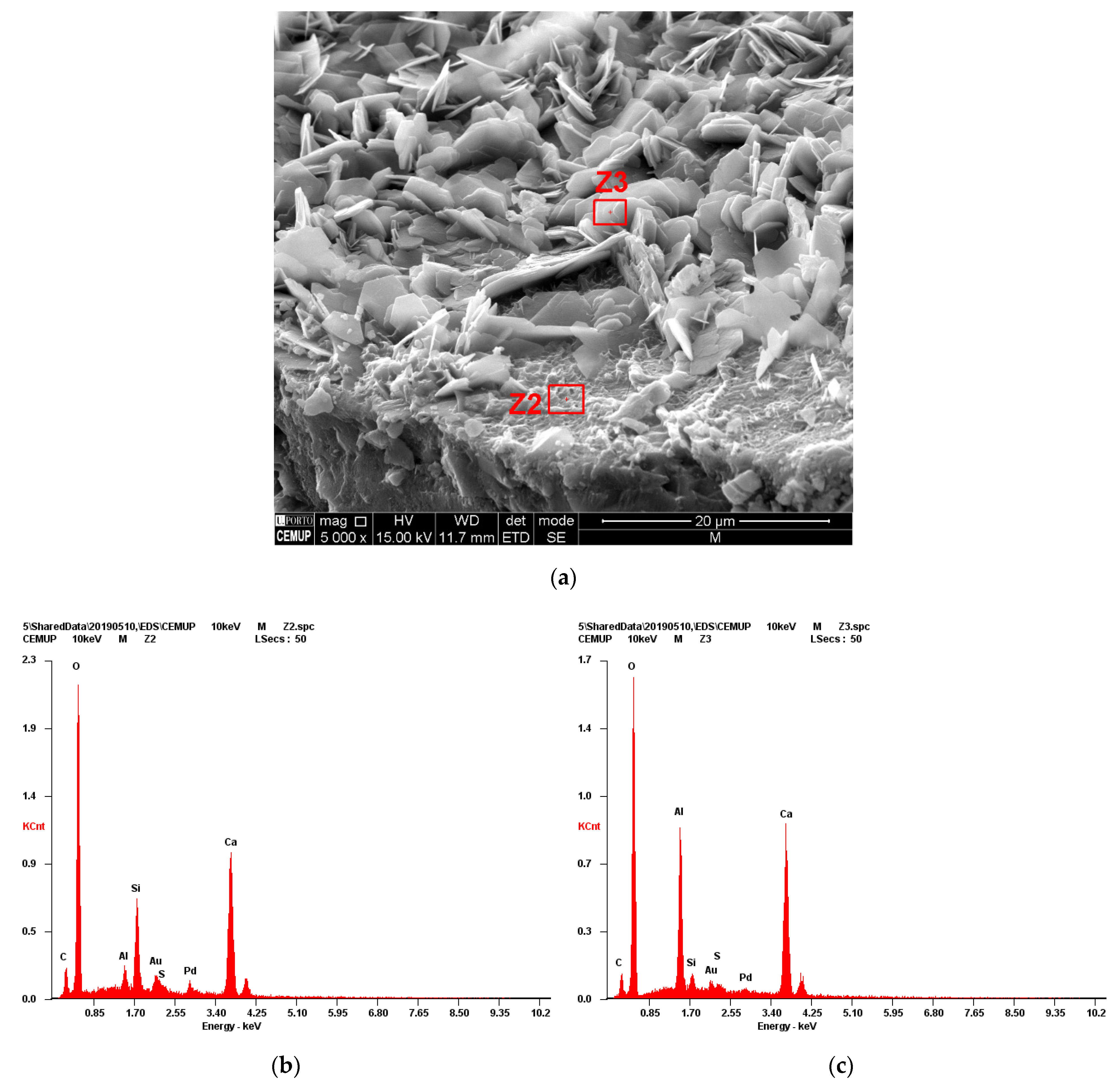

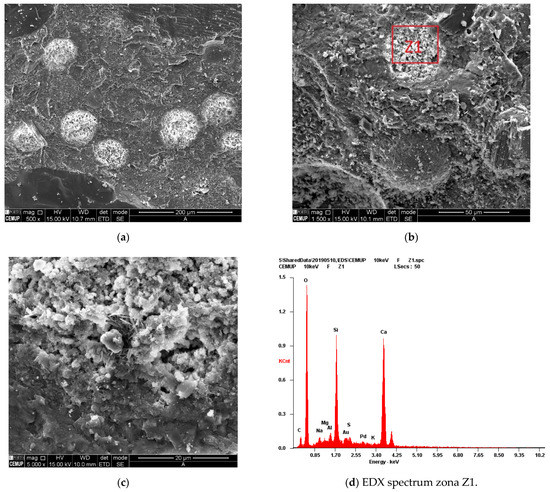

Microstructure photos of UHPC samples are presented in Figure 4 and Figure 5. The lighter zones in the matrix (Figure 4a) correspond to the ECat particles completely surrounded by hydration products and well bonded to the matrix. As can be perceived, the microstructure seems very dense and compact. Moreover, hydration products were found, namely, calcium hydroxide, but with aluminates, as shown in Figure 5.

Figure 4.

SEM images and XRD diffraction analysis of UHPC microstructure: (a) site of ECat particles; (b) location of zone Z1; (c) ECat particle connection to cementitious matrix; and (d) XRD diffraction analysis of material in zone Z1.

Figure 5.

SEM images and XRD diffraction analysis: (a) site of calcium hydroxide and location of zones Z2 and Z3; (b) XRD diffraction analysis of material in zone Z2; and (c) XRD diffraction analysis of material in zone Z3.

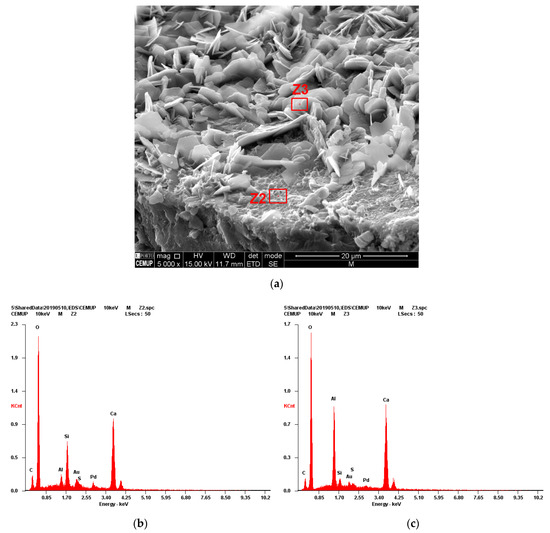

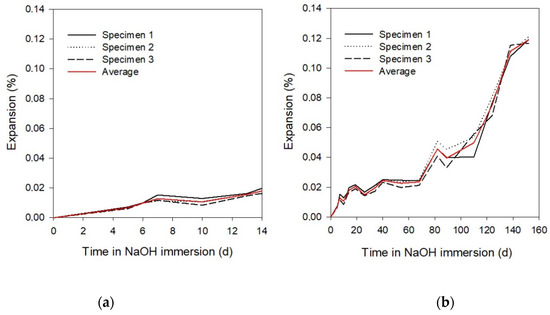

3.2. ASR

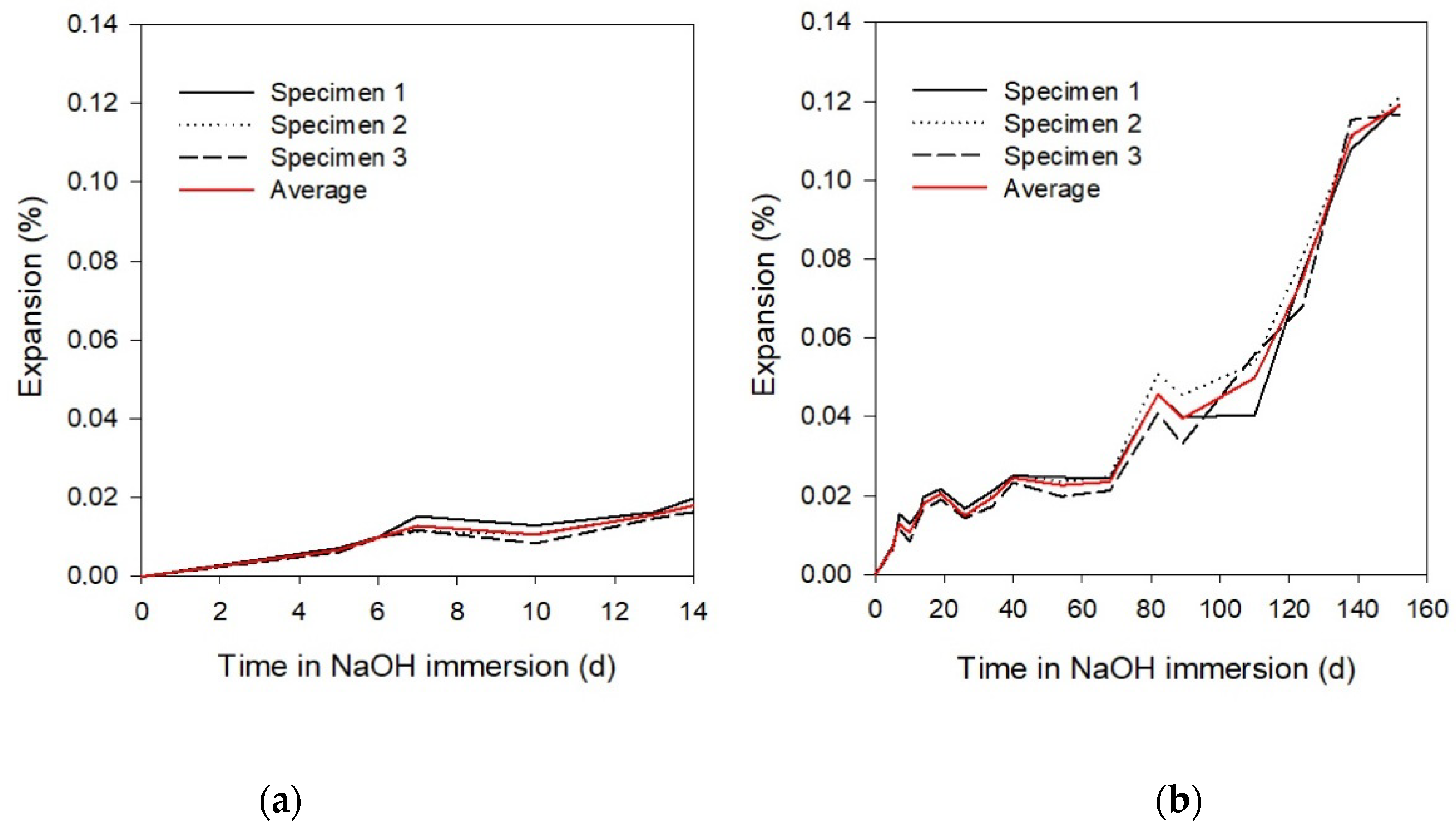

Figure 6a presents ASR expansion evolution up to 14 days (the standard test time). This indicates that the average expansion of three UHPC bar specimens was far above 0.10% after 14 days of testing (0.0180 ± 0.002%). In the present study, the test was performed up to specimens achieve 0.1% expansion, which took about half a year, as depicted in Figure 6b. It was also noticed from Figure 6b that after a certain period of exposure, the ASR-induced expansion started to increase more significantly (84 days). This phenomenon was also observed by Li et al. [65]. Photos of the bar specimens after the ASR test, i.e., after the long period of immersion in alkaline solution, are shown in Figure 7, and no damage was observed.

Figure 6.

Linear length change due to ASR up to (a) 14 days (standard test days) and (b) half a year (extended test in the current study).

Figure 7.

UHPC specimens after ASR test (extended up to 180 days).

Moser and Pfeifer [31] argue that even in UHPC, ASR may occur but not causing damage. Moreover, the authors denoted that besides no damages due to ASR occurred, they found locally concentrated ASR gel by SEM observations. Graybeal and Tanesi [32] stated that accelerated curing provoked by the ASTM C 1260 procedure, i.e., 24 h in hot water, may veil ASR occurrence in UHPC. It is recognised that ASR phenomena take place when a combination of conditions are verified, namely, (i) aggregates with a certain amount of reactive siliceous minerals, (ii) rich concrete pore solution, (iii) high moisture, and iv) calcium ions available [45]. Considering the very low permeability of UHPC, as discussed in Section 3.1, ASR may not manifest even considering long-term UHPC durability.

On the other hand, it is of utmost importance to use pozzolanic SCM as a mitigation/prevention measure against ASR. Pozzolanic SCM reacts with Ca(OH)2, ensuring no more calcium ions are available for ASR. Silica fume is particularly effective against ASR since it preferentially reacts with the alkalis. Moreover, the inclusion of ECat was already found to mitigate the ASR when used as partial replacement of cement [66] or fine aggregate [67].

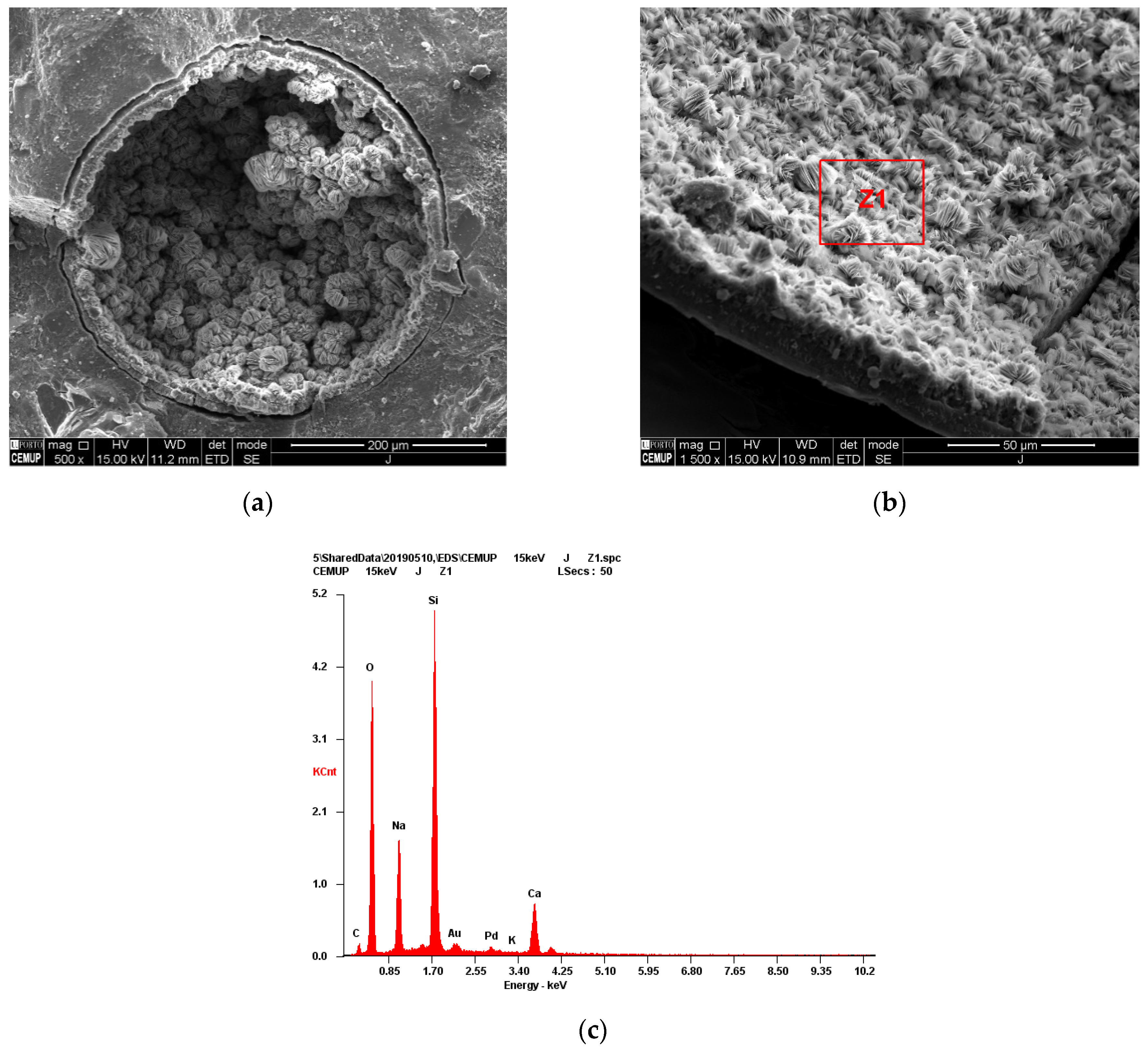

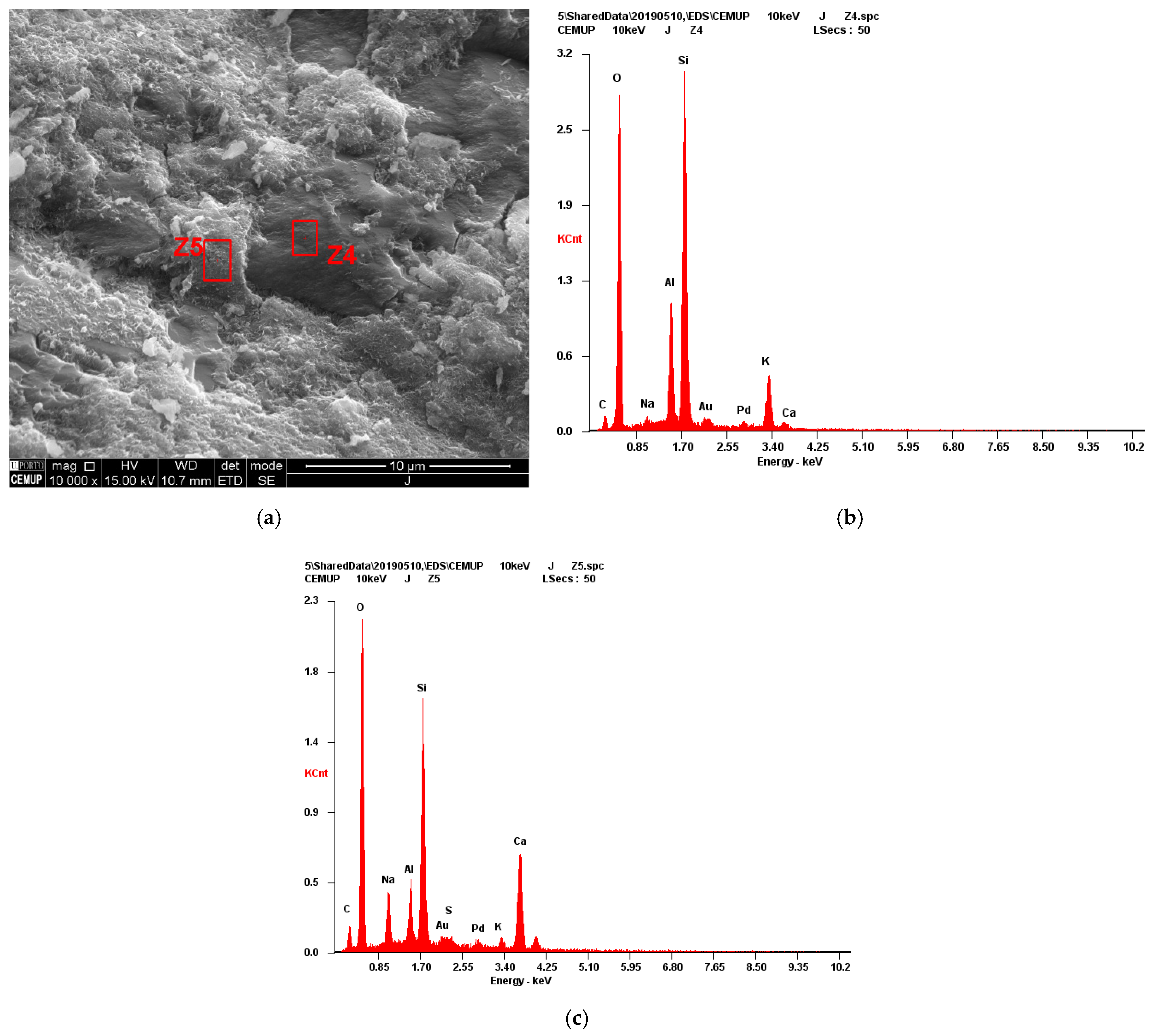

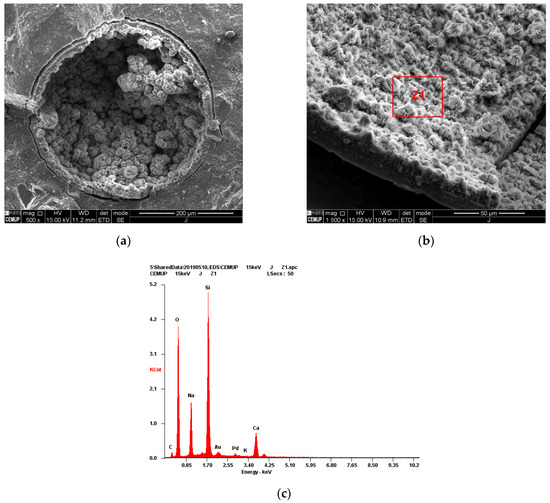

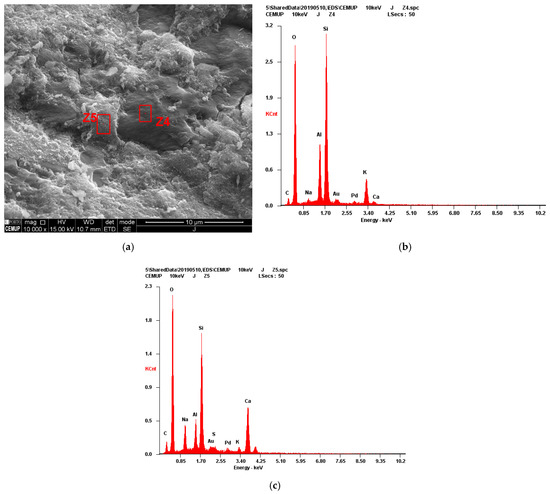

After half a year in NaOH immersion, samples from UHPC bars were examined using SEM. Since the specimens have no visual damage (see Figure 7), the author’s analysed samples are taken from the specimen’s surface and the inside. It must be noted that no signals of ASR products were found in samples taken from the interior of the UHPC specimens after half a year in the aggressive alkali environment. The typical gel formed in ASR was found in a few pores on surface samples, as shown in Figure 8. Moreover, traces of silico-alkali gel were found on the surface of the aggregate, as dipicted in Figure 9.

Figure 8.

SEM images and XRD diffraction analysis: (a) site of ASR gel formation over a pore; (b) location of zones Z1 (gel); and (c) XRD diffraction analysis of material in zone Z1.

Figure 9.

SEM images and XRD diffraction analysis: (a) site of ASR gel formation on aggregate surface and location of zones Z4 (aggregate) and Z5 (gel); (b) XRD diffraction analysis of material in zone Z4; and (c) XRD diffraction analysis of material in zone Z5.

3.3. External Sulphates Attack

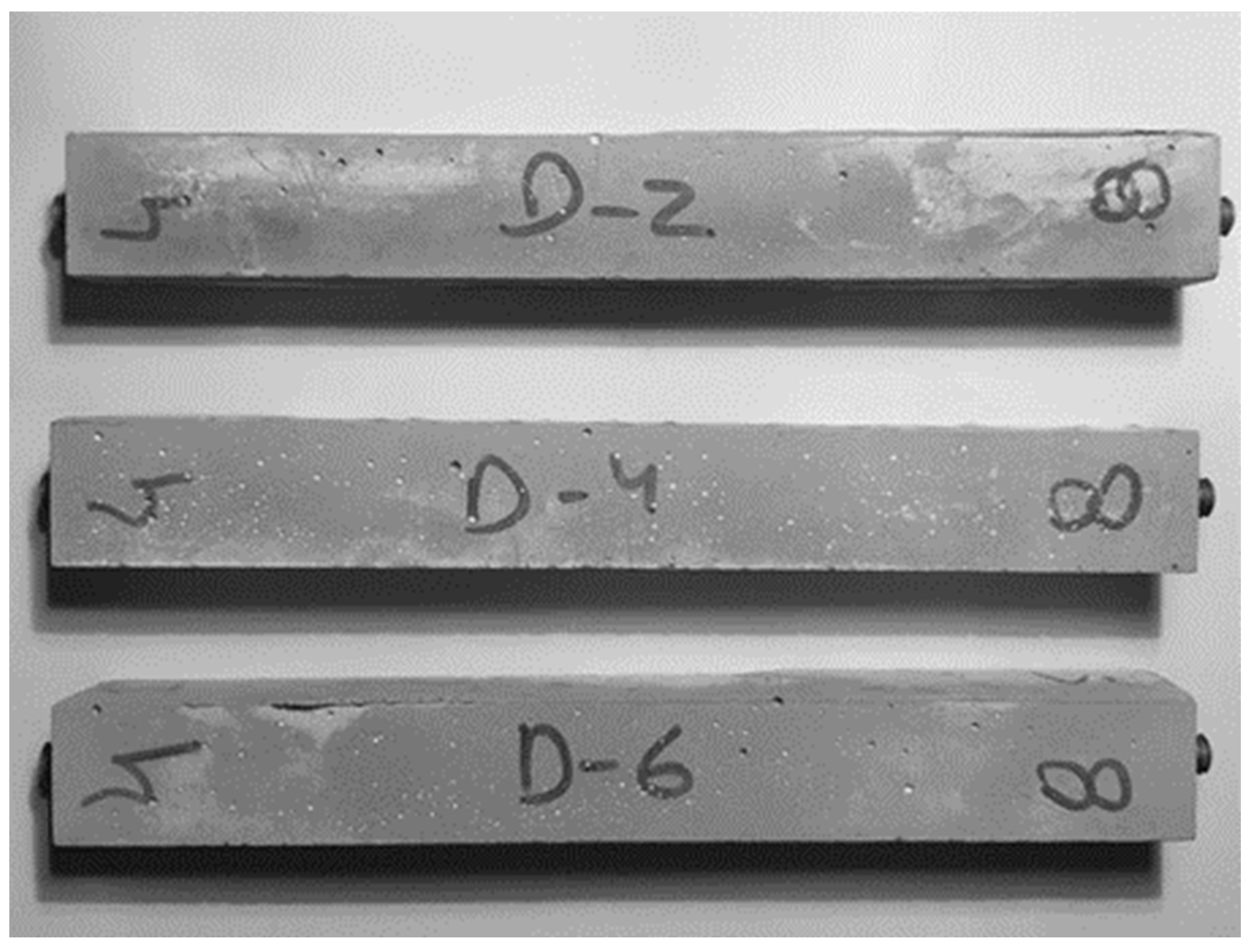

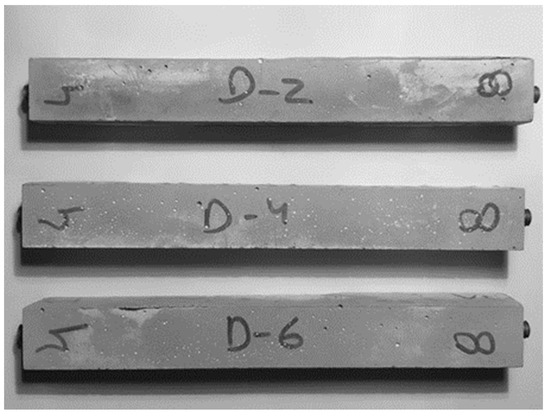

UHPC showed outstanding performance in the sulphate-rich environment. As can be seen in Table 4, no expansion occurs. According to LNEC E−462, the cement is resistant to sulphates if the expansion after 26 weeks of immersion is lower than 0.1%. The visual examination of UHPC specimens exposed to sodium sulphate solution, depicted in Figure 10, reveals no damage.

Table 4.

Sulphate expansion results (according to Equations (1)–(3), Section 2.2.3).

Figure 10.

UHPC specimens after external sulphate test (specimens series exposed to Na2SO4).

Susceptibility to sulfate attack depends on both physical and chemical factors. Magnesium sulfate and sodium sulfate are particularly active salts [61]. Sodium sulphate reacts with the free calcium hydroxide and forms calcium sulphate (gypsum), which then reacts with tri-calcium aluminate to form calcium sulpho-aluminates (Ettringite) [61]. The rate of attack by sulphate solutions depends on the solution’s concentration and the cement composition [61]. The permeability of the cementitious-based matrix is a major factor affecting the attack rate [68]. The low w/b ratio and the ultra-dense matrix of UHPC avoided the sulphate entrance. In addition, the pozzolanic activity of ECat and the SF, translated into the consumption of calcium hydroxide from cement hydration and thus was no longer available for reaction with external sulphates, mitigating the formation of gypsum. Moreover, the pozzolanic reaction also decreases the cementitious matrix porosity and strengthens the cementitious paste–aggregate interface.

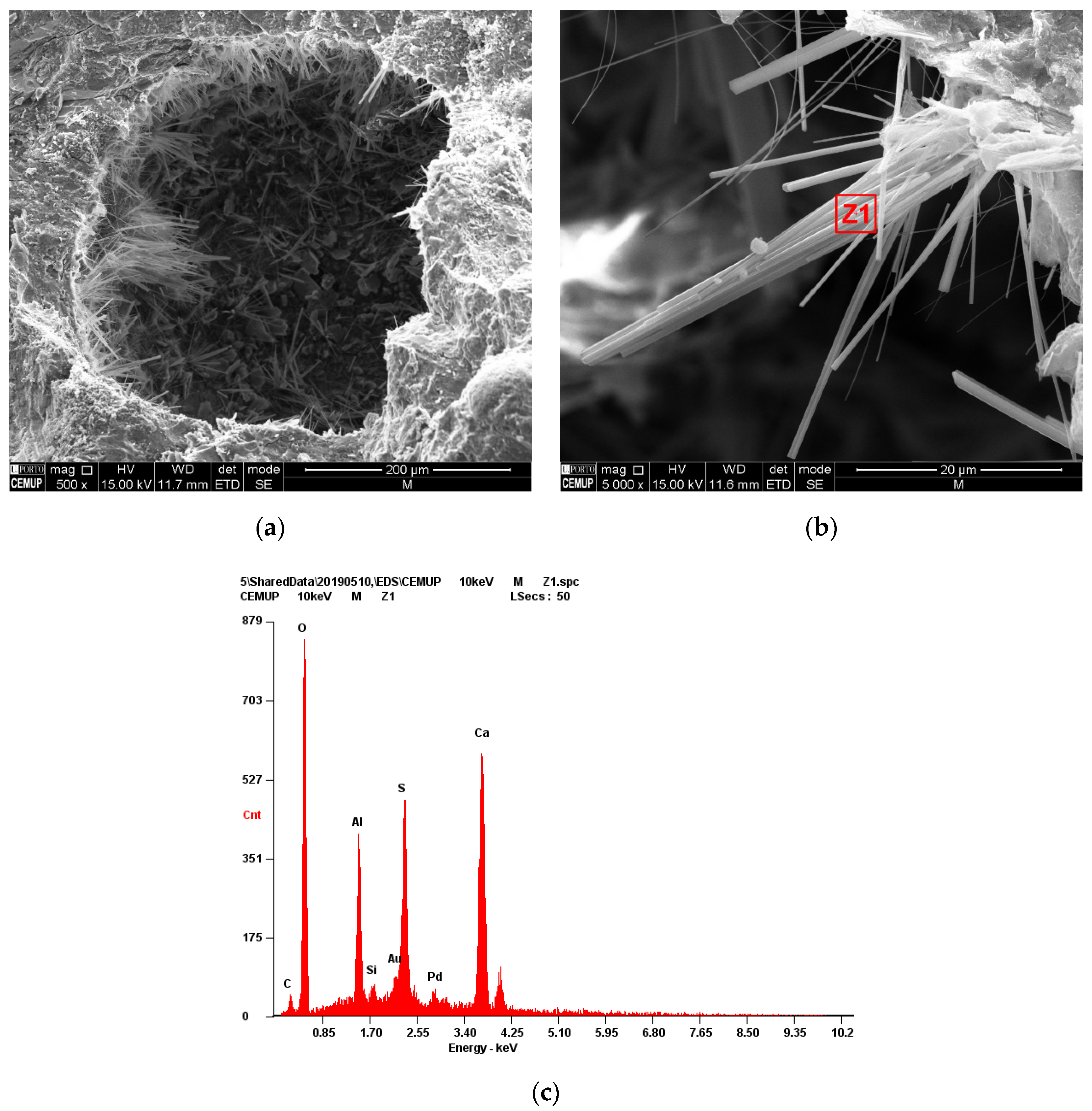

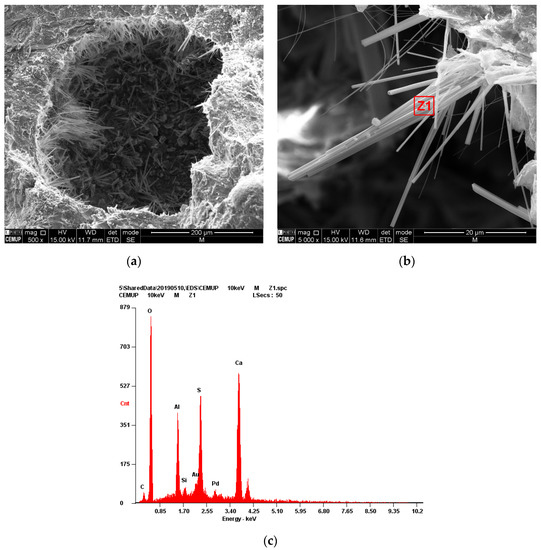

After sulphate solution exposure, samples were taken from bar specimens and examined by SEM. Even though there was no expansion and no visual damage (see Figure 10), a few products from sulphate reaction were found on UHPC samples after exposure to sulphate solution, namely, ettringite (calcium sulfoaluminate) needles, as can be observed in Figure 11.

Figure 11.

SEM images and XRD diffraction analysis: (a) site of ettringite formation over a pore; (b) location of zones Z1 (ettringite); and (c) XRD diffraction analysis of material in zone Z1.

4. Conclusions and Final Remarks

A greener UHPC was developed using locally available materials and a local industrial waste material from the oil refinery. The new UHPC evidenced ultra-high compressive strength even though lower cement and silica fume dosages were employed. The current work evaluated the susceptibility of new UHPC against expansive reactions, ASR and external sulphate attack, from micro to macro scale. The following conclusions can be drawn:

- UHPC presented very low porosity (4.8%), with no capillary pores, and the average pore size diameter was 8.8 nm;

- The ASR test revealed the extraordinary resistance of UHPC (no expansion) against very harsh rich alkalis conditions during 14 days of the standard ASTM 1260 test;

- The ASR test was extended until the UHPC specimens reached 0.1%, which took half a year;

- After half a year of immersion in harsh rich alkalis conditions, the specimens did not present visual damage; however, the ASR gel was found by SEM observations;

- The external sulphates also seemed not to be a concern in UHPC since after 26 weeks of immersion in sodium sulphate solution, specimens did not present expansion or damage;

- Even though UHPC specimens did not expand or present visual damage, ettringite was found by SEM observations.

Further validation of UHPC performance against expansive reaction requires structural level research and considering “in service” conditions, i.e., in cracking conditions.

Funding

This work was financially supported by: Base Funding—UIDB/04708/2020 and Programmatic Funding—UIDP/04708/2020 of the CONSTRUCT—Instituto de I&D em Estruturas e Construções—funded by national funds through the FCT/MCTES (PIDDAC); by the project POCI-01-0145-FEDER-031777—“UHPGRADE—Next generation of ultra-high performance fibre-reinforced cement-based composites for rehabilitation and strengthening of the existing infrastructure” funded by FEDER funds through COMPETE2020—Programa Operacional Competitividade e Internacionalização (POCI) and by national funds (PIDDAC) through FCT/MCTES; and by FCT—Fundação para a Ciência e a Tecnologia through the Scientific Employment Stimulus 2021.01765.CEECIND (individual call).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The materials supply and collaboration of Sines Refinery/Galp Energia, Secil, Omya, Sika, and EUROMODAL is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| ASR | Alkali silica reaction |

| Ca(OH)2 | Calcium hydroxide |

| CSH | Calcium silicate hydrate |

| ECat | Spent equilibrium catalyst |

| HPC | High-performance concretes |

| LF | Limestone filler |

| MIP | Mercury intrusion porosimetry |

| Na2Oeq | Equivalent alkali content (%) |

| NaOH | Sodium Hydroxide |

| OC | Ordinary concrete |

| PC | Portland cement |

| RH | Relative humidity (%) |

| SCM | Supplementary cementitious materials |

| SF | Silica fume |

| Sp | Superplasticizer |

| t | Time (day) |

| T | Temperature (°C) |

| UHPC | Ultra-high-performance cement-based composites |

| UHPFRC | Ultra-high-performance fiber-reinforced cement-based composites |

| w/c | Water to cement weight ratio |

| w/b | Water to binder weight ratio |

Appendix A

Table A1.

Mixture proportion and main properties of commercially available blended UHPFRC.

Table A1.

Mixture proportion and main properties of commercially available blended UHPFRC.

| Ductal® | BSI/Ceracem® | CRC® | Cor Tuf® | CEMTECmultiscale® | CARDIF® | BCV® | DUCAN® | DURA® | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Country | France | France | Denmark | USa | France | Wales | France | Germany | Malasya | |||||||

| Year | 1990’s | 1990’s | 1995 | 2001 | 2004 | 1998 | 2004 | 2006 | ||||||||

| Constituent kg/m3 | Type | Type | Type | Type | Type | Type | Type | |||||||||

| Cement | Portland | 746 | 1114 | Binder | 930 | CEM I 52.5 | 1050 | 885 | 2115 premix | |||||||

| Silica fume | 242 | 169 | Binder 1555 | 275 | ||||||||||||

| Quartz flour | 224 | 885 | ||||||||||||||

| Sand (mm) | 0.1−0.6 | 1066 | 0−6 | 1072 | 0−5 | 1325 | 1300 | <0.5 | 730 | 0.009–0.6 | 940 | |||||

| Water | w/c | 0.19 | w/c | 0.19 | w/b | 0.16 | w/b 0.16 | w/c | 0.18 | w/c | 0.22 | w/c | 0.25 | |||

| Admixture | Chryso | 9 | SIKA | 10 | Chryso | 35 | 21.5 | |||||||||

| Fiber (l/d) | 13/0.2 | 161 | 20/0.3 | 234 | 12/0.4 | 150–300 | 150–300 | 10/0.2 | 470 | 468 | 156 | Vol% | 3–7% | |||

| Slump flow (mm) | 700 | 640 | 750 | |||||||||||||

| fct, 28 (MPa) | 8 | 8.8 | 90 °C | 30 | 8–10 | 8–20 | 6–10 | |||||||||

| fcm, 7 (MPa) | 20 °C | 101 | 20 °C | 165 | 20 °C | 98 | ||||||||||

| fcm, 28 (MPa) | 20 °C/90 °C | 124/198 | 20 °C | 199 | 20 °C/90 °C | 150/400 | 20 °C | 168 | 90 °C | 207 | 20 °C/90 °C | 130/200 | 90–200 | 130–170 | ||

References

- Hewlett, P. Lea’s Chemistry of Cement and Concrete, 4th ed.; Elsevier Science & Technology Books: Amsterdam, The Netherlands, 2004. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Fehling, E.; Schmidt, M.; Walraven, J.; Leutbecher, T.; Frohlich, S. Ultra-High Performance Concrete UHPC: Fundamentals, Design, Examples; Ernst & Sohn, Wiley: Berlin, Germany, 2014. [Google Scholar] [CrossRef]

- Graybeal, B.; Brühwiler, E.; Kim, B.-S.; Toutlemonde, F.; Voo, Y.L.; Zaghi, A. International Perspective on UHPC in Bridge Engineering. J. Bridge Eng. 2020, 25, 04020094. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Bakar, B.H.A.; Johari, M.A.M.; Voo, Y.L. Evaluation of Bond Strength between Normal Concrete Substrate and Ultra High Performance Fiber Concrete as a Repair Material. Procedia Eng. 2013, 54, 554–563. [Google Scholar] [CrossRef] [Green Version]

- Nematollahi, B.; Raizal Saifulnaz, M.R.; Voo, Y.L. Sustainability assessment of precast ultra-high performance fiber reinforced concrete (UHPFRC) cantilever retaining walls. Res. J. Appl. Sci. Eng. Technol. 2014, 7, 3971–3977. Available online: http://www.scopus.com/inward/record.url?eid=2-s2.0-84901989877&partnerID=tZOtx3y1 (accessed on 23 May 2022). [CrossRef]

- Tayeh, B.A.; Bakar, B.H.A.; Johari, M.A.M.; Voo, Y.L. Utilisation of Ultra-high Performance Fibre Concrete (UHPFC) for Rehabilitation—A Review. Procedia Eng. 2013, 54, 525–538. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C. Complete characterisation of tensile properties of Ductal® UHPFRC according to the French recommendations. In Proceedings of the International Workshop High Performance Fiber Reinforced Cement Composites, Ann Arbor, MI, USA, 16–18 June 2003; Volume 1, pp. 21–34. [Google Scholar]

- Wille, K.; Kim, D.J.; Naaman, A.E. Strain-hardening UHP-FRC with low fiber contents. Mater. Struct./Mater. Constr. 2011, 44, 583–598. [Google Scholar] [CrossRef]

- Graybeal, B.A.; Russel, H.G. Ultra-High Performance Concrete: A State-of-the-Art Report for the Bridge Community; Publication No. FHWA-HRT-13-060; Federal Highway Administration: Washington, DC, USA, 2013. [Google Scholar]

- McDonagh, M.D.; Foden, A.J.; Brinckerhoff Andrew Foden, P.J.; Brinckerhoff, P. Benefits of Ultra-High Performance Concrete for the Rehabilitation of the Pulaski Skyway. In Proceedings of the First International Interactive Symposium on UHPC, Des Moines, IA, USA, 18–20 July 2016. [Google Scholar]

- Zmetra, K.; Zaghi, A.E.; Wille, K. Rehabilitation of Steel Bridge Girders with Corroded Ends Using Ultra-High Performance Concrete. In Proceedings of the 2015 Structures Congress, Portland, Oregon, 23–25 April 2015; pp. 1411–1422. [Google Scholar] [CrossRef]

- Graybeal, B. Construction of Field-Cast Ultra-High Performance Concrete Connections, April 2012—FHWA-HRT-12-038. 2012. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/structures/bridge/12038/index.cfm (accessed on 17 May 2022).

- Competitive and Sustainable Growth (GROWTH) Programme. SAMARIS Sustainable and Advanced MAterials for Road InfraStructure WP 14: HPFRCC (High Performance Fibre Reinforced Cementitious Composites) for Rehabilitation Deliverable D25b Guidelines for the Use of UHPFRC for Rehabilitation of Concrete Highway Structures; Competitive and Sustainable Growth (GROWTH) Programme: Delft, The Netherlands, 2006. [Google Scholar]

- Brühwiler, E.; Denarié, E. Rehabilitation of concrete structures using Ultra-High Performance Fibre Reinforced Concrete. In Proceedings of the UHPC-2008: The Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 1–8. [Google Scholar]

- Bruhwiler, E.; Denarie, E. Rehabilitation and Strengthening of Concrete Structures Using Ultra-High Performance Fibre Reinforced Concrete. Struct. Eng. Int. 2013, 23, 450–457. [Google Scholar] [CrossRef]

- Denarié, E.; Brühwiler, E. Cast-on site UHPFRC for improvement of existing structures—Achievements over the last 10 years in practice and research. In Proceedings of the HPFRCC7: 7th Workshop on High Performance Fiber Reinforced Cement Composites, Stuttgart, Germany, 1–3 June 2015. [Google Scholar]

- Denarié, E.; Brühwiler, E. Structural Rehabilitations with Ultra-High Performance Fibre Reinforced Concretes (UHPFRC)/Strukturelle Instandsetzung von Betonbrücken mit Ultra-hochleistungsfähigem Faserfeinkornbeton (UHFB). Restor. Build. Monum. 2006, 12, 93–108. [Google Scholar] [CrossRef]

- Nabaei, S.; Nendaz, S. Rehabilitation of transportation infrastructures: The potential of new materials. In Proceedings of the IABSE Conference: Structural Engineering: Providing Solutions to Global Challenges, Geneva, Switzerland, 23–25 September 2015. [Google Scholar]

- Brühwiler, E.; Bastien Masse, M. Strengthening the Chillon viaducts deck slabs with reinforced UHPFRC. In Proceedings of the IABSE Conference Geneva 2015—Structural Engineering: Providing Solutions to Global Challenges, Geneva, Switzerland, 23–25 September 2015. [Google Scholar]

- Nazar, S.; Ismaiel, M.A.; Ahmed, M. Possibility to Improve Strength and Structural Stability of Bridge Deck Slabs by Using Ultra High Performance Fiber Reinforced Concrete. IOSR J. Mech. Civ. Eng. 2014, 11, 79–87. [Google Scholar]

- Wang, W.; Liu, J.; Agostini, F.; Davy, C.A.; Skoczylas, F.; Corvez, D. Durability of an Ultra High Performance Fiber Reinforced Concrete (UHPFRC) under progressive aging. Cem. Concr. Res. 2014, 55, 1–13. [Google Scholar] [CrossRef]

- Heinz, D.; Dehn, F.; Urbonas, L. Fire Resistance of Ultra High Perfoemance Concrete (UHPC)—Testing of Laboratory Samples and Column under Load. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004. [Google Scholar]

- Herold, G.; Müller, H.S. Measurement of porosity of ultra high strength fiber reinforced concrete. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 685–694. [Google Scholar]

- Roux, N.; Andrade, C.; Sanjuan, M.A. Experimental Study of Durability of Reactive Powder Concretes. J. Mater. Civ. Eng. 1996, 8, 1–6. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Shi, C.; Yuan, Q.; Zhang, Z. Durability of ultra-high performance concrete—A review. Constr. Build. Mater. 2020, 255, 119296. [Google Scholar] [CrossRef]

- Cheyrezy, M.; Maret, V.; Frouin, L.; Bouygues, D.S.; Quentin, S. Microstructural analysis of RPC (Reactive Powder Concrete). Cem. Concr. Res. 1995, 25, 1491–1500. [Google Scholar] [CrossRef]

- Matos, A.M.; Nunes, S.; Costa, C.; Aguiar, J.L.B. Durability of an UHPC containing spent equilibrium catalyst. Constr. Build. Mater. 2021, 305, 124681. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; El-Tawil, S.; Parra-Montesinos, G.J. Ultra-high performance concrete and fiber reinforced concrete: Achieving strength and ductility without heat curing. Mater. Struct. 2012, 45, 309–324. [Google Scholar] [CrossRef]

- Moser, B.; Pfeifer, C. Microstructure and Durability of Ultra-High Performance Concrete. In Proceedings of the UHPC-2008: The Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008. [Google Scholar]

- Graybeal, B.; Tanesi, J. Durability of an Ultrahigh-Performance Concrete. J. Mater. Civ. Eng. 2007, 19, 848–854. [Google Scholar] [CrossRef]

- Odler, I.; Rößler, M. Investigations on the relationship between porosity, structure and strength of hydrated Portland cement pastes. II. Effect of pore structure and of degree of hydration. Cem. Concr. Res. 1985, 15, 401–410. [Google Scholar] [CrossRef]

- Yazici, H.; Yardımcı, M.Y.; Aydin, S.; Karabulut, A.S. Mechanical properties of reactive powder concrete containing mineral admixtures under different curing regimes. Constr. Build. Mater. 2009, 23, 1223–1231. [Google Scholar] [CrossRef]

- Yazıcı, H.; Yardımcı, M.Y.; Yigiter, H.; Aydın, S.; Turkel, S. Mechanical properties of reactive powder concrete containing high volumes of ground granulated blast furnace slag. Cem. Concr. Compos. 2010, 32, 639–648. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of cement substitution by limestone on the hydration and microstructural development of ultra-high performance concrete (UHPC). Cem. Concr. Compos. 2017, 77, 86–101. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef] [Green Version]

- Pyo, S.; Kim, H.K. Fresh and hardened properties of ultra-high performance concrete incorporating coal bottom ash and slag powder. Constr. Build. Mater. 2017, 131, 459–466. [Google Scholar] [CrossRef]

- Rajasekar, A.; Arunachalam, K.; Kottaisamy, M.; Saraswathy, V. Durability characteristics of Ultra High Strength Concrete with treated sugarcane bagasse ash. Constr. Build. Mater. 2018, 171, 350–356. [Google Scholar] [CrossRef]

- Vaitkevičius, V.; Šerelis, E.; Hilbig, H. The effect of glass powder on the microstructure of ultra high performance concrete. Constr. Build. Mater. 2014, 68, 102–109. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Partial substitution of silica fume with fine glass powder in UHPC: Filling the micro gap. Constr. Build. Mater. 2017, 139, 374–383. [Google Scholar] [CrossRef]

- Van Tuan, N.; Ye, G.; Van Breugel, K.; Fraaij, A.L.A.; Bui, D.D. The study of using rice husk ash to produce ultra high performance concrete. Constr. Build. Mater. 2011, 25, 2030–2035. [Google Scholar] [CrossRef]

- Van, V.T.A.; Rößler, C.C.; Bui, D.D.; Ludwig, H.M. Rice husk ash as both pozzolanic admixture and internal curing agent in ultra-high performance concrete. Cem. Concr. Compos. 2014, 53, 270–278. [Google Scholar] [CrossRef]

- Latifee, E. Miniature Concrete Prism Test—A New Test Method For Evaluating the ASR Potential of Aggregates, the Effectiveness of ASR Mitigation and the Job Mixture. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2013. [Google Scholar]

- Sims, I.; Poole, A.B. (Eds.) Alkali-Aggregate Reaction in Concrete: A World Review; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Mohammadi, A.; Ghiasvand, E.; Nili, M. Relation between mechanical properties of concrete and alkali-silica reaction (ASR)—A review. Constr. Build. Mater. 2020, 258, 119567. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Fournier, B.; Folliard, K.J. Alkali-Aggregate Reactivity (AAR) Facts Book; US Department of Transportation: Washington, DC, USA, 2013. [Google Scholar]

- Fanijo, E.O.; Kolawole, J.T.; Almakrab, A. Alkali-silica reaction (ASR) in concrete structures: Mechanisms, effects and evaluation test methods adopted in the United States. Case Stud. Constr. Mater. 2021, 15, e00563. [Google Scholar] [CrossRef]

- Cao, J.; Gowripalan, N.; Sirivivatnanon, V.; South, W. Accelerated test for assessing the potential risk of alkali-silica reaction in concrete using an autoclave. Constr. Build. Mater. 2021, 271, 121871. [Google Scholar] [CrossRef]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Alkali Release from Aggregates in Long-Service Concrete Structures: Laboratory Test Evaluation and ASR Prediction. Materials 2018, 11, 1393. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Metha, P.K. Concrete in the Marine Environment; Taylor & Francis e-Library: Essex, UK, 2003. [Google Scholar]

- Matos, A.M.; Sousa-Coutinho, J. ASR and sulphate performance of mortar containing industrial waste. Struct. Concr. 2016, 17, 84–95. [Google Scholar] [CrossRef]

- Matos, A.M. Design of Eco-Efficient Ultra-High Performance Fibre Reinforced Cement-Based Composite for Rehabilitation/Strengthening Applications. Ph.D. Thesis, University of Porto, Porto, Portugal, 2020. Available online: https://sigarra.up.pt/reitoria/en/pub_geral.pub_view?pi_pub_base_id=381627 (accessed on 29 May 2021).

- Matos, A.M.; Nunes, S.; Costa, C.; Barroso-Aguiar, J.L. Characterisation of Non-proprietary UHPC for Use in Rehabilitation/Strengthening Applications. In Rheology and Processing of Construction Materials; Springer: Cham, Switzerland, 2020; Volume 23. [Google Scholar] [CrossRef]

- Matos, A.M.; Nunes, S.; Costa, C.; Barroso-Aguiar, J.L. Spent equilibrium catalyst as internal curing agent in UHPFRC. Cem. Concr. Compos. 2019, 104, 103362. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. ASTM C 1260-07. Standard Test Method for Potential Alkali Reactivity of Cement-Aggregate Combinations (Mortar-Bar Method). In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2007; pp. 1–5. [Google Scholar] [CrossRef]

- Laboratório Nacional de Engenharia Civil (LNEC). E-462. Resistência dos Cimentos ao Ataque por Sulfatos; LNEC: Lisbon, Portugal, 2004; p. 4. [Google Scholar]

- Matos, A.M.; Sousa Coutinho, J. Waste glass powder in cement: Macro and micro scale study. Adv. Cem. Res. 2016, 28, 423–432. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Multi-scale investigation of microstructure, fiber pullout behavior, and mechanical properties of ultra-high performance concrete with nano-CaCO3 particles. Cem. Concr. Compos. 2018, 86, 255–265. [Google Scholar] [CrossRef]

- Canut, M.M.C. Pore Structure in Blended Cement Pastes. Ph.D. Thesis, Technical University of Denmark, Copenhagen, Denmark, 2011. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Longman Group Limited: London, UK, 2011. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Zhang, J.; Bian, F.; Zhang, Y.; Fang, Z.; Fu, C.; Guo, J. Effect of pore structures on gas permeability and chloride diffusivity of concrete. Constr. Build. Mater. 2018, 163, 402–413. [Google Scholar] [CrossRef]

- He, Z.; Du, S.; Chen, D. Microstructure of ultra high performance concrete containing lithium slag. J. Hazard. Mater. 2018, 353, 35–43. [Google Scholar] [CrossRef]

- Li, Z.; Afshinnia, K.; Rangaraju, P.R. Effect of alkali content of cement on properties of high performance cementitious mortar. Constr. Build. Mater. 2016, 102, 631–639. [Google Scholar] [CrossRef]

- Costa, C.; Ribeiro, M.S.; Brito, N. Effect of Waste Oil-Cracking Catalyst Incorporation on Durability of Mortars. Mater. Sci. Appl. 2014, 5, 905–914. [Google Scholar] [CrossRef] [Green Version]

- Sota, J.D.; Traversa, L.P.; Dimaio, A.A.; Zega, C. Reciclado y Fijacion de RCD y RP en Una Matriz de Hormigon de Cemento Portland. In Proceedings of the VI Congreso Internacional de Patología Dual, Córdoba, Argentina, 19–22 June 2019. [Google Scholar]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford: London, UK, 1997. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).