Influence of Space Charge on Dielectric Property and Breakdown Strength of Polypropylene Dielectrics under Strong Electric Field

Abstract

:1. Introduction

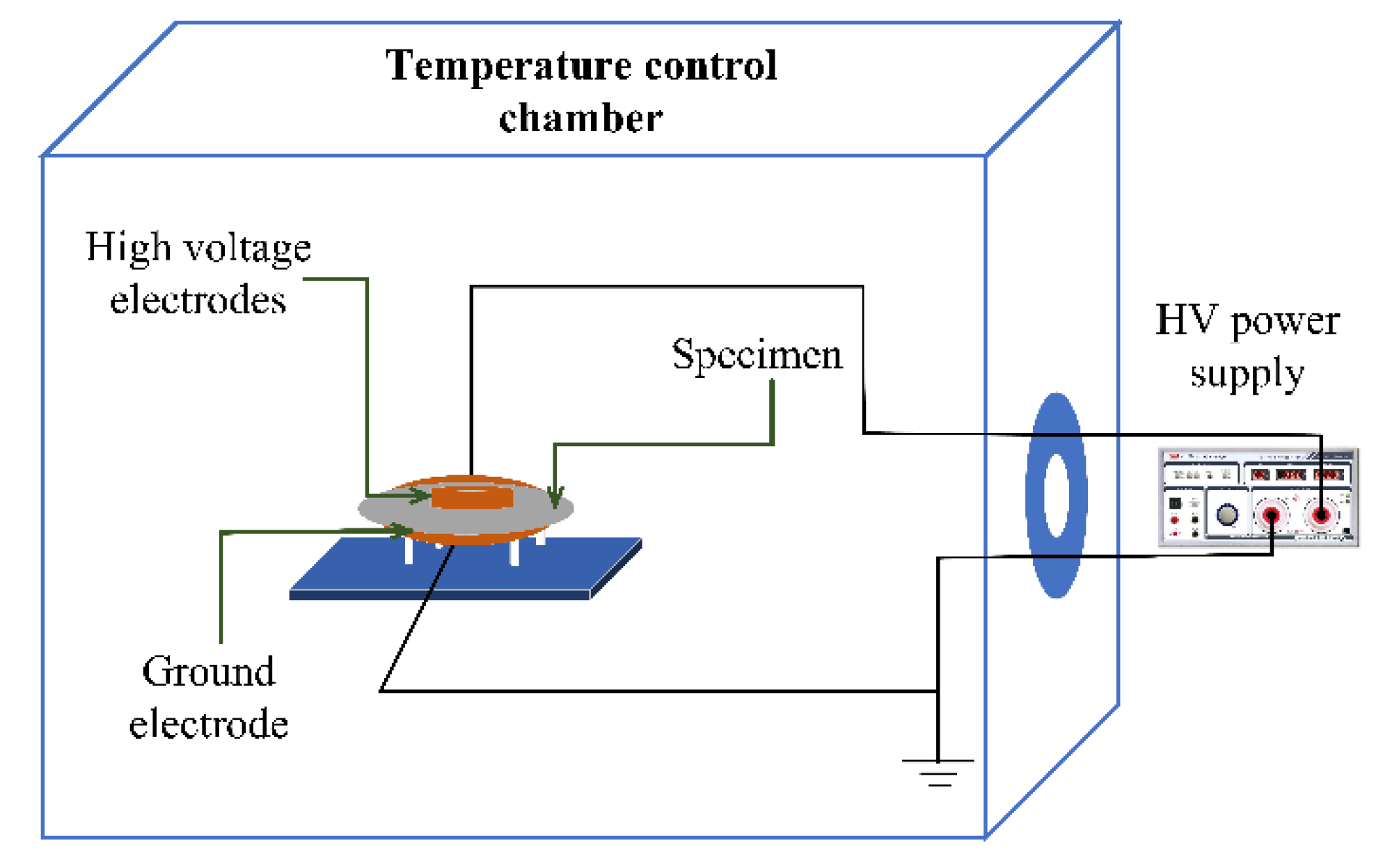

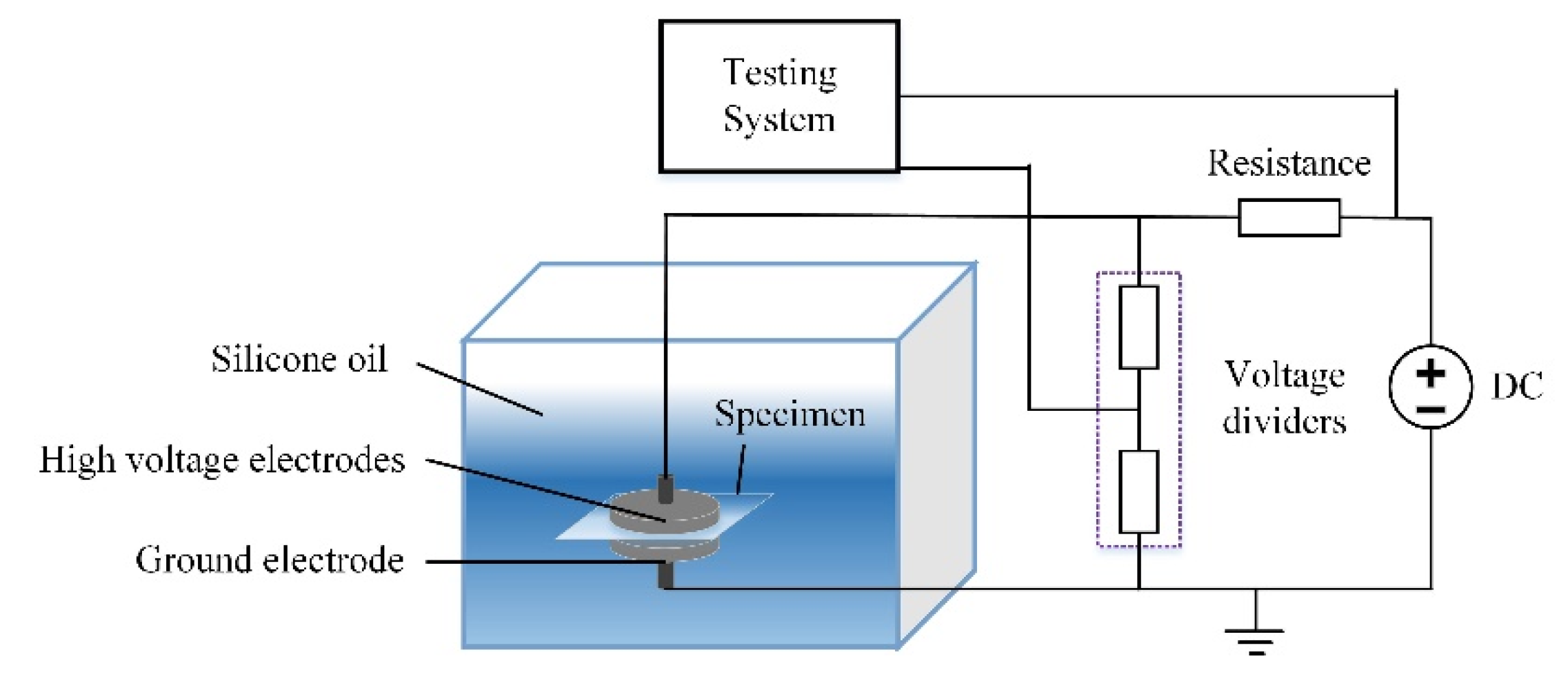

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

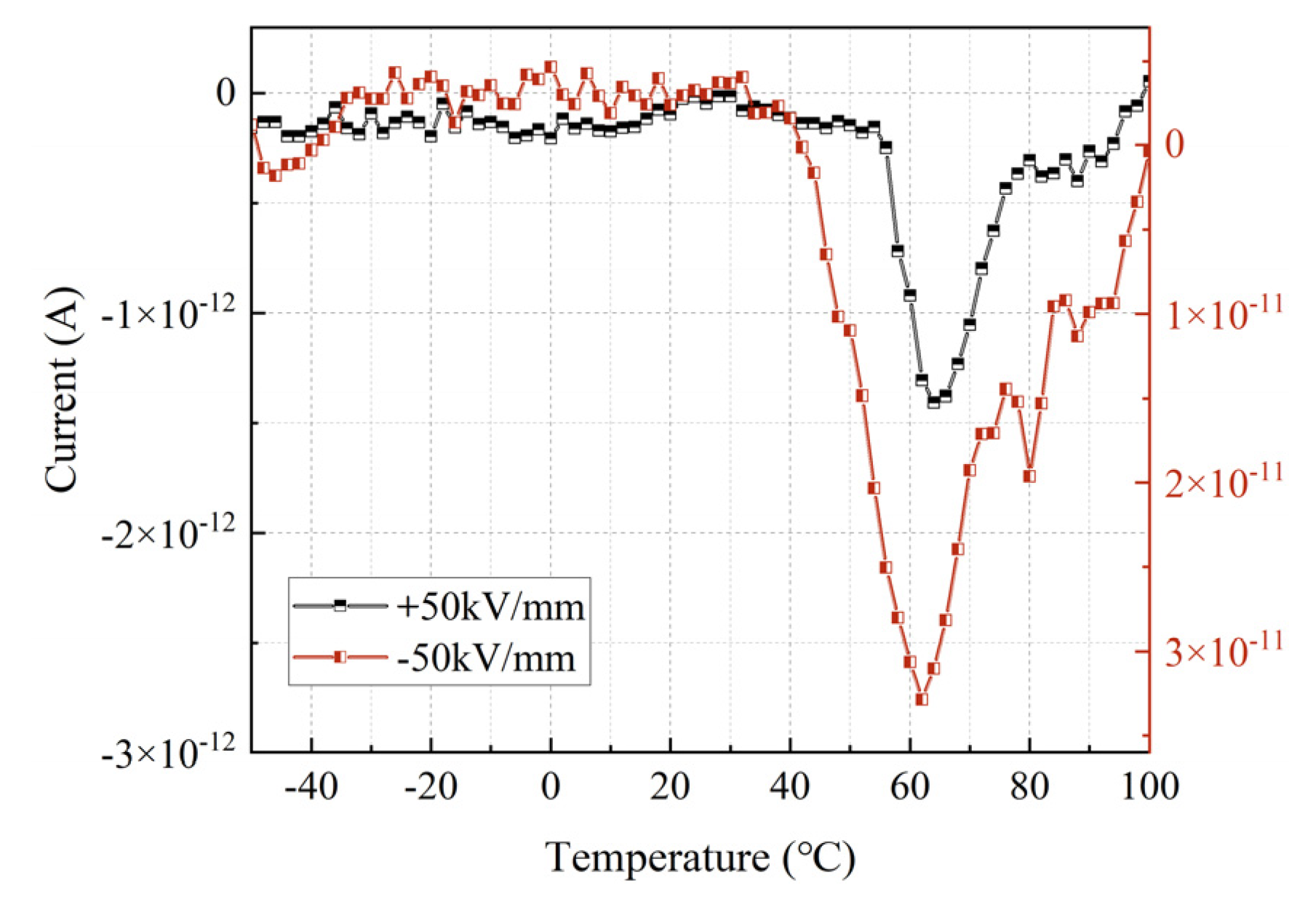

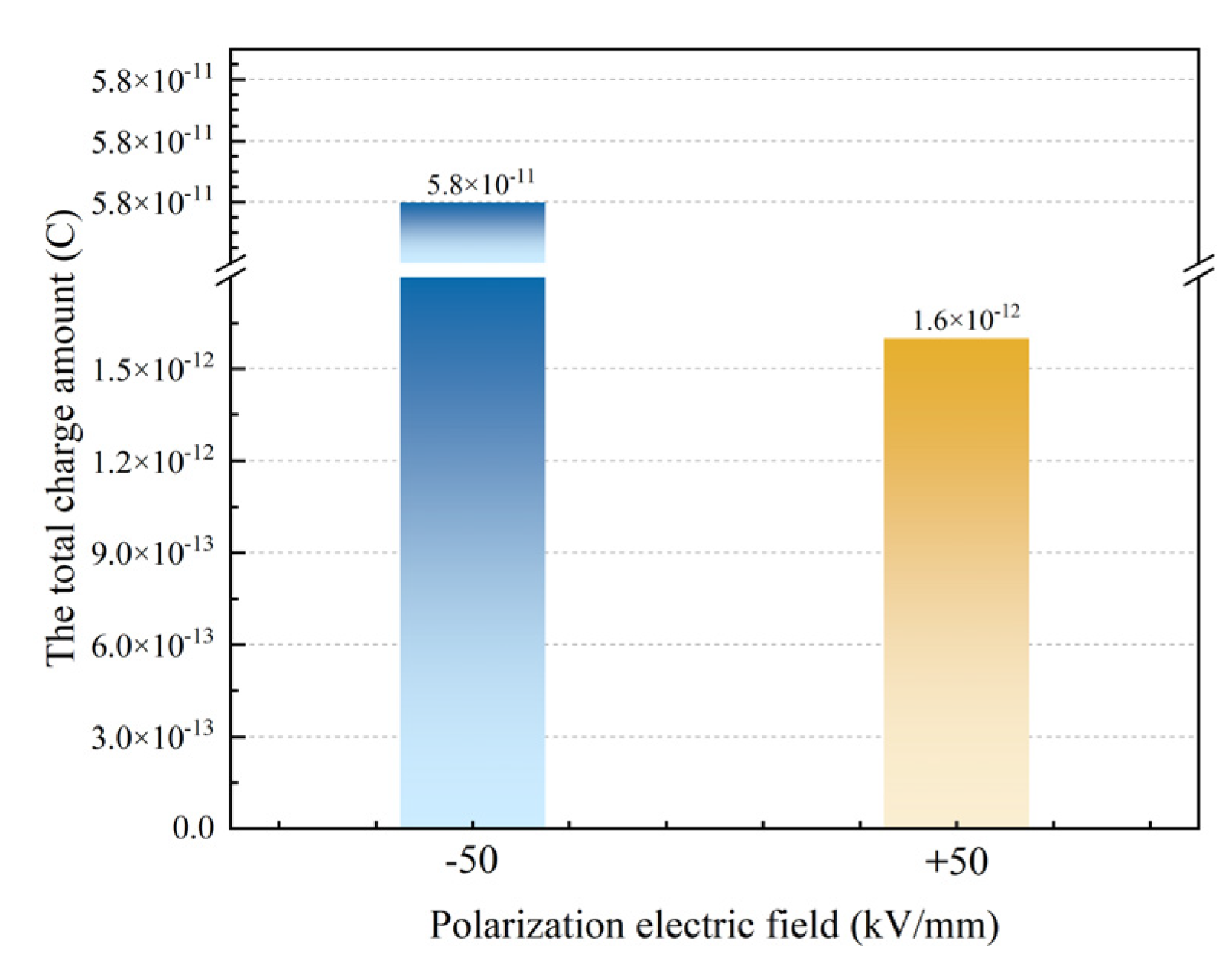

3.1. Quantitative Characterization of the Pre-Injected Space Charge

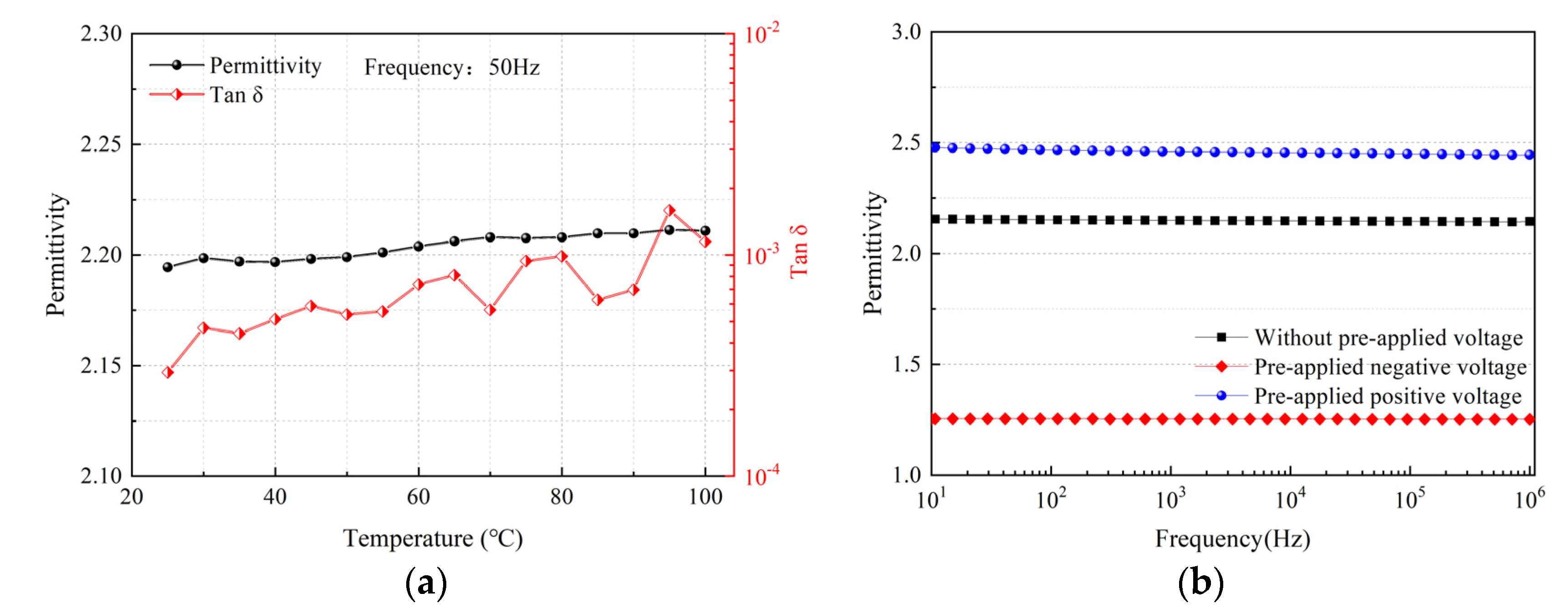

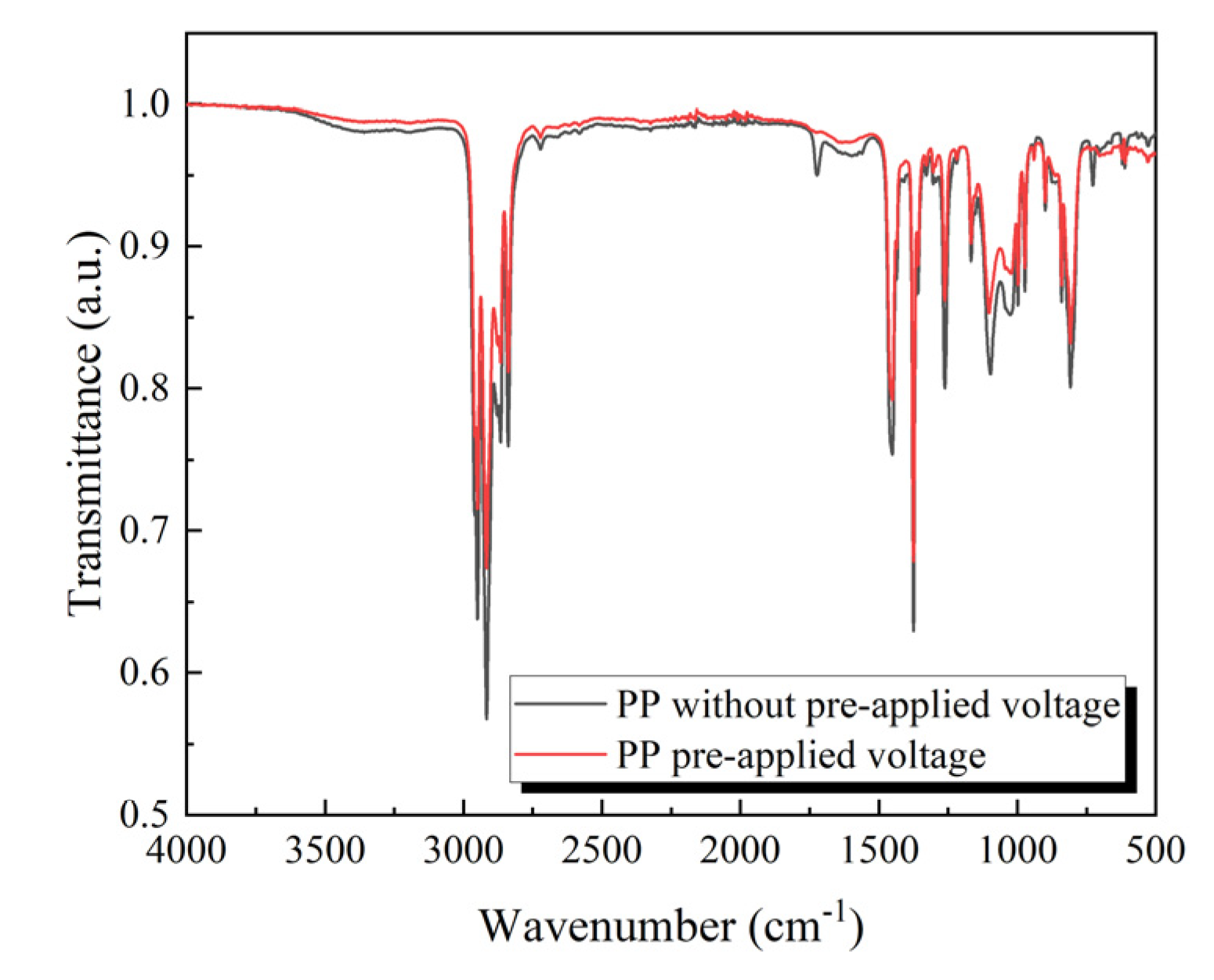

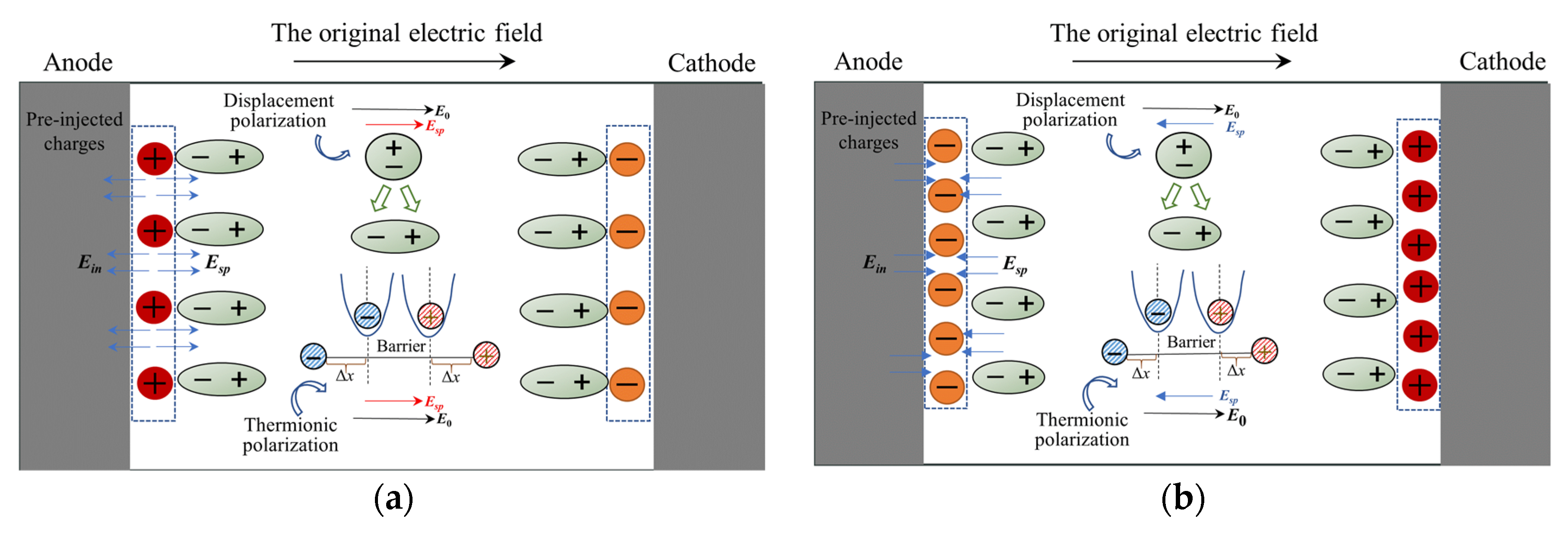

3.2. Effect of Space Charge on Dielectric Properties

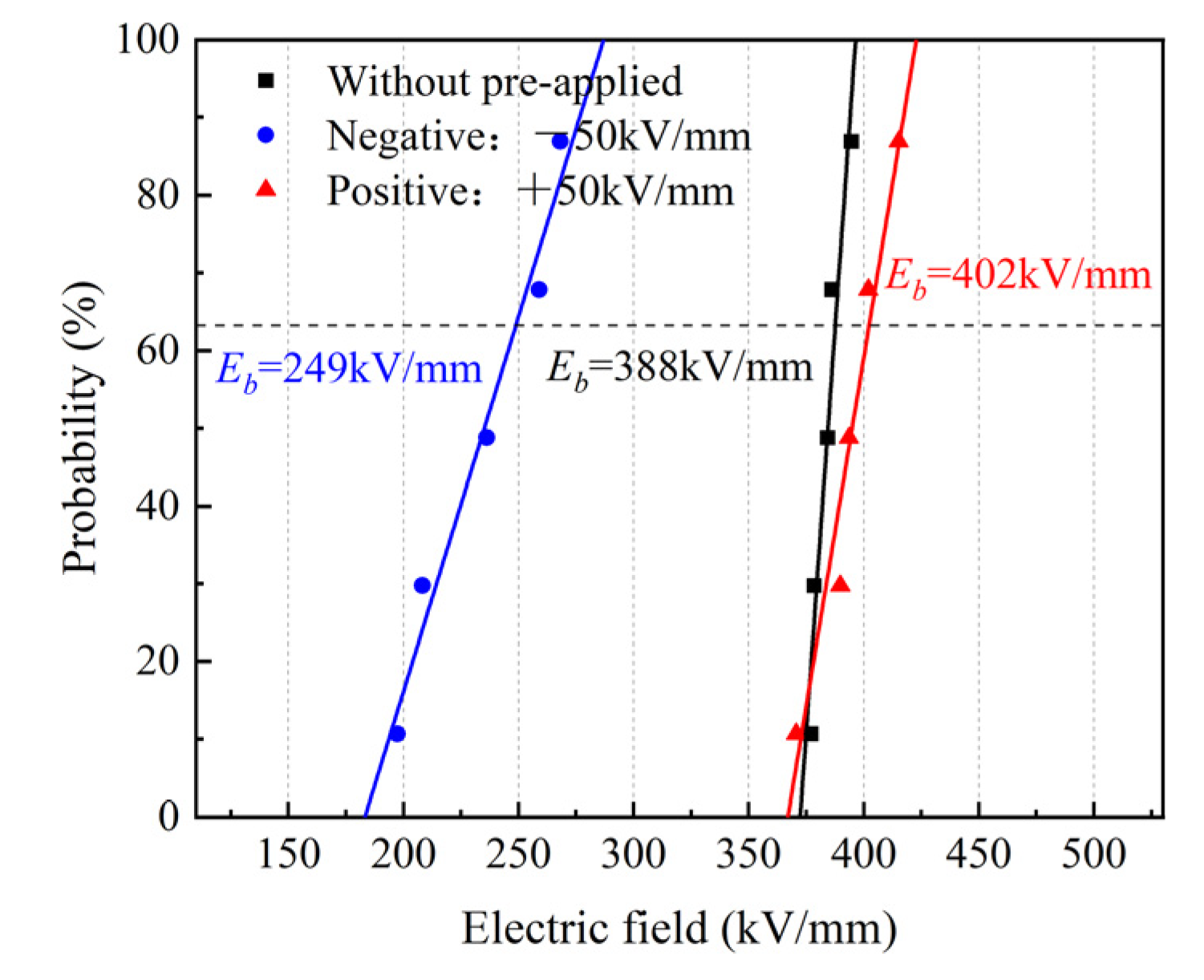

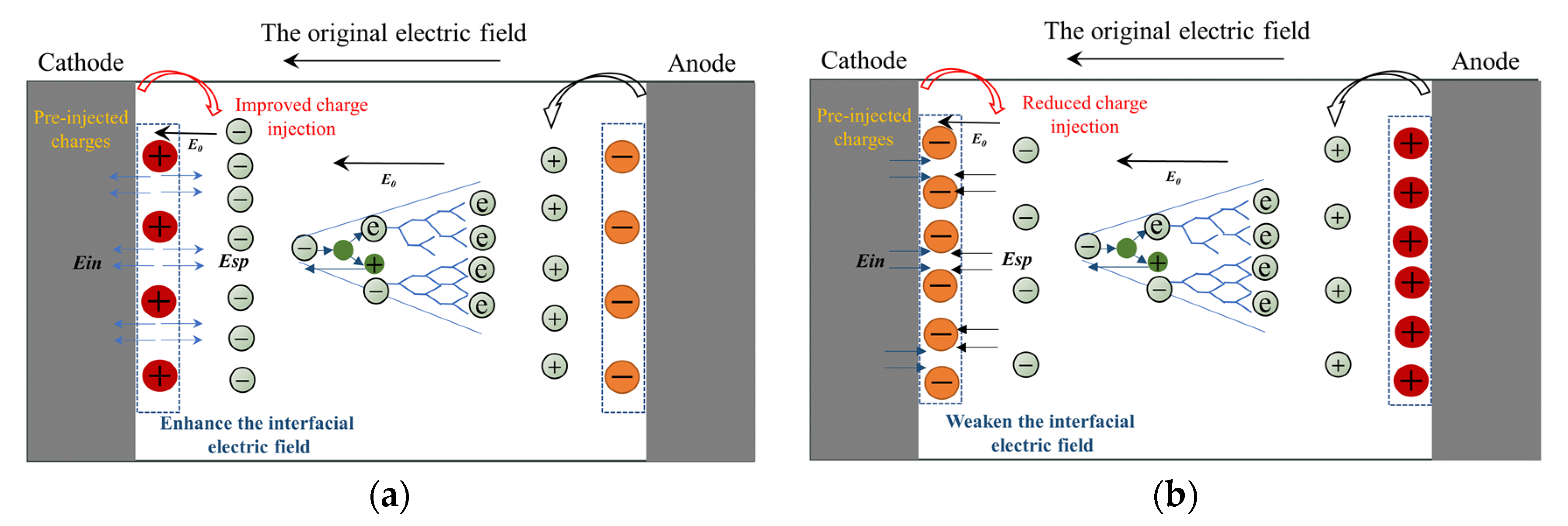

3.3. Effect of Space Charge on Breakdown Strength

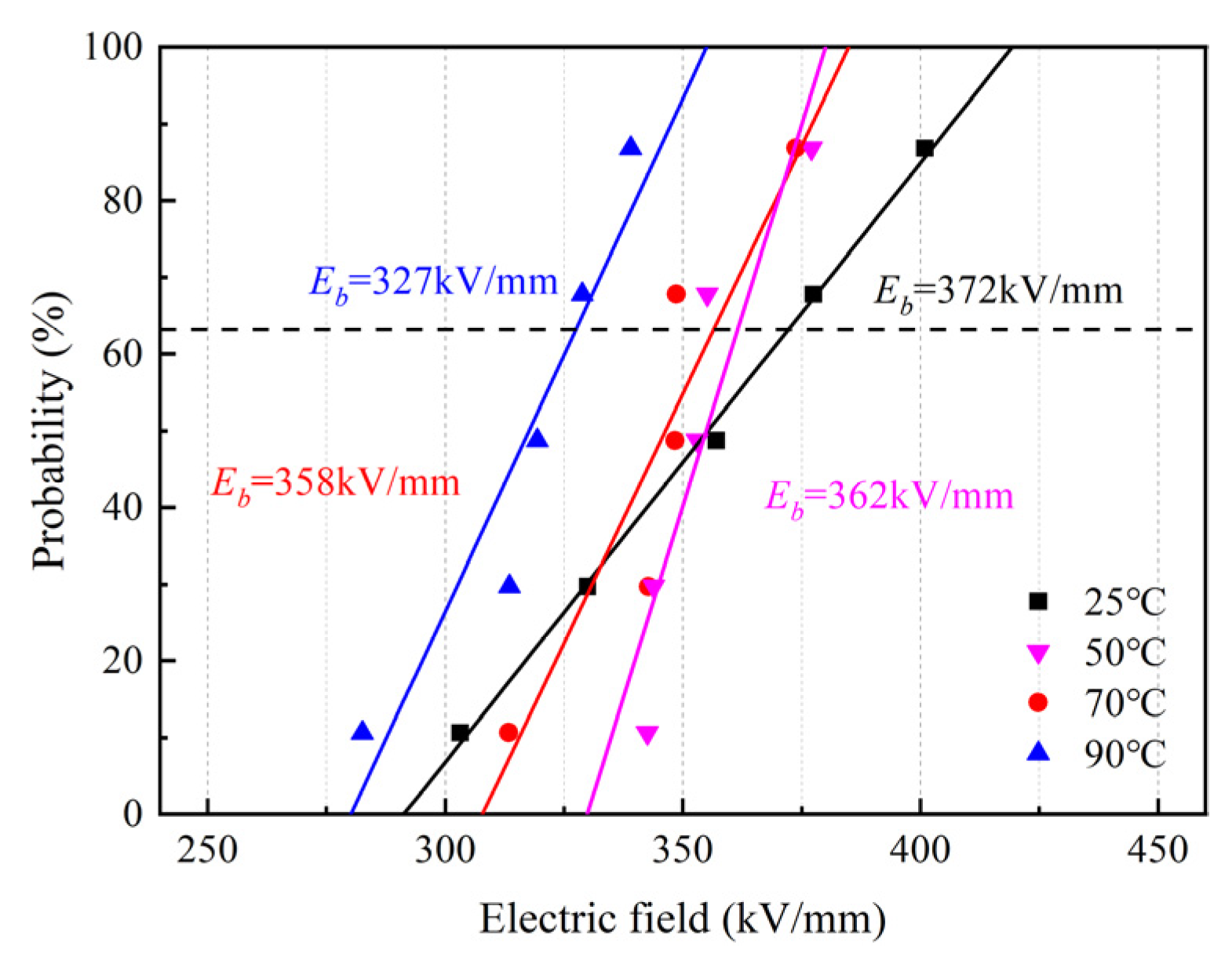

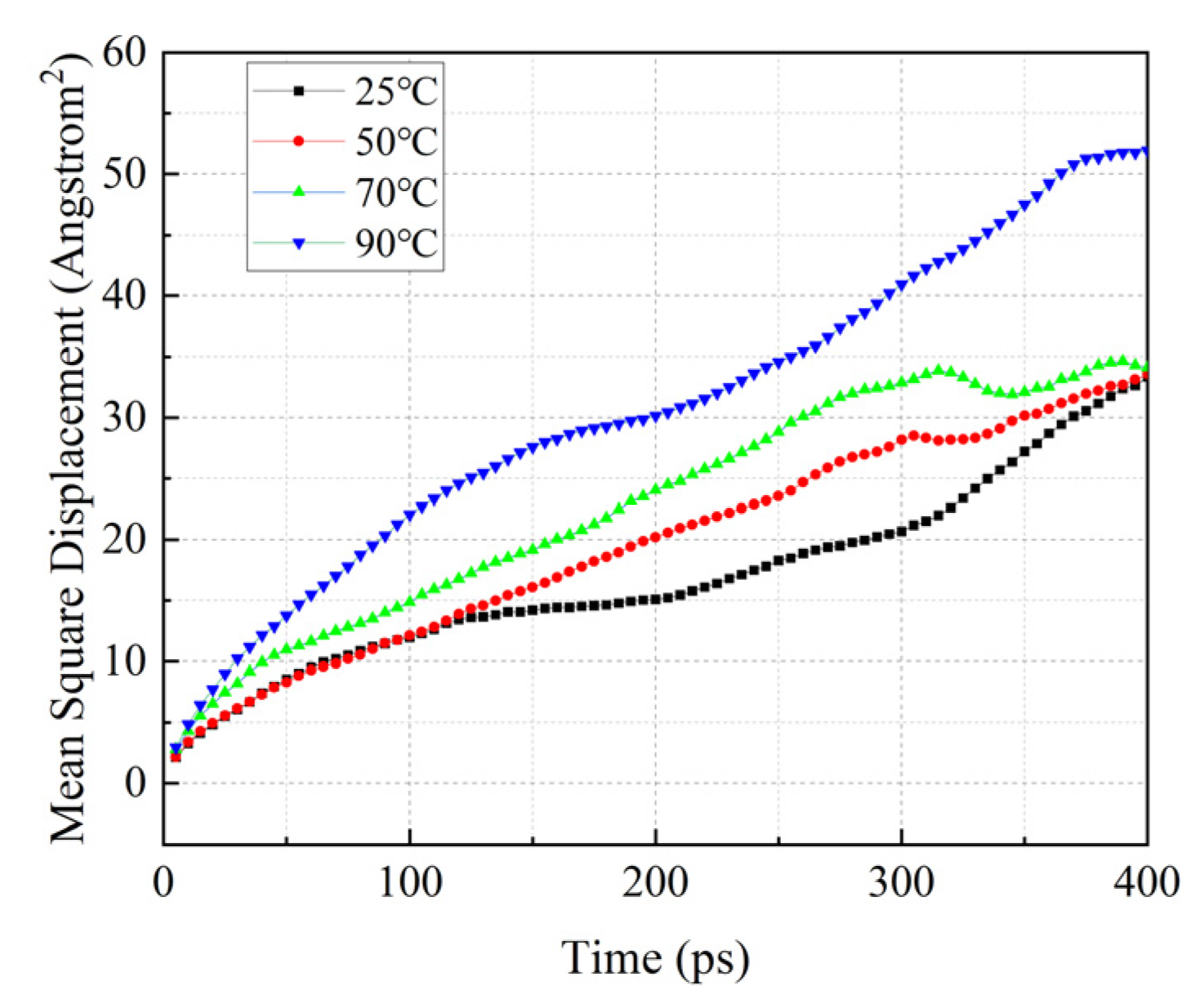

3.4. Effect of Temperature on Breakdown Strength

4. Conclusions

- (1)

- The injected charges in PP under the negative polarity voltage was significantly larger than that in the positive polarity case. The total charges are 5.8 × 10−11 C and 1.6 × 10−12 C under conditions of −50 kV/mm and +50 kV/mm, respectively. This is because the charges are more easily injected across the interfacial potential barrier to the bulk of the material under the negative polarity voltage;

- (2)

- Space charge in PP affect its dielectric properties, and the effect of negative polarity pre-voltage on the dielectric constant is much greater than that of positive polarity. The dielectric constant of PP under hetero-polar pre-voltage conditions decreases from 2.2 to 1.3, decreasing by approximately 41%. In comparison, it slightly increases under homo-polarity pre-voltage. This is mainly related to the polarity and amount of pre-injected space charges in PP. It is necessary to pay more attention to the effect of space charge accumulation on the dielectric constant of energy storage material in long-term operation;

- (3)

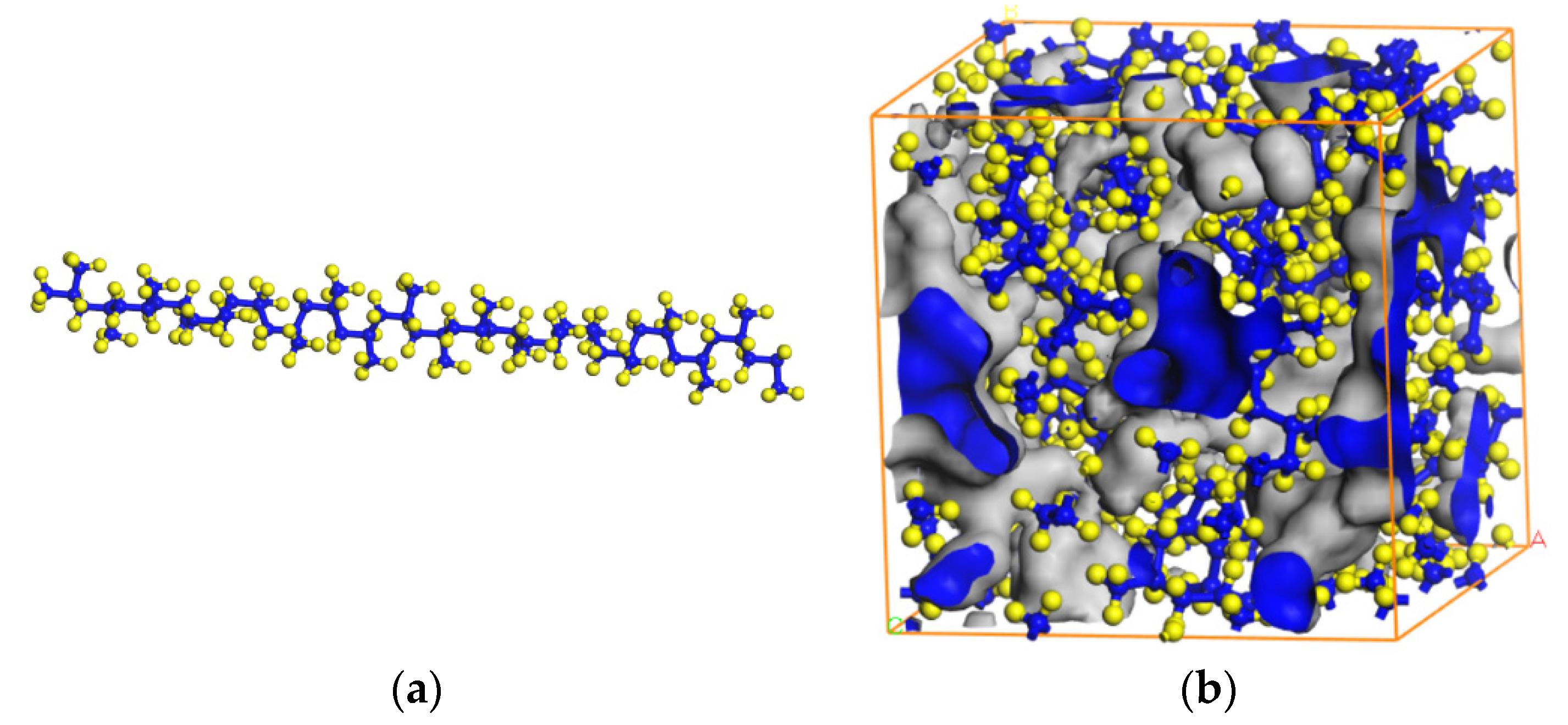

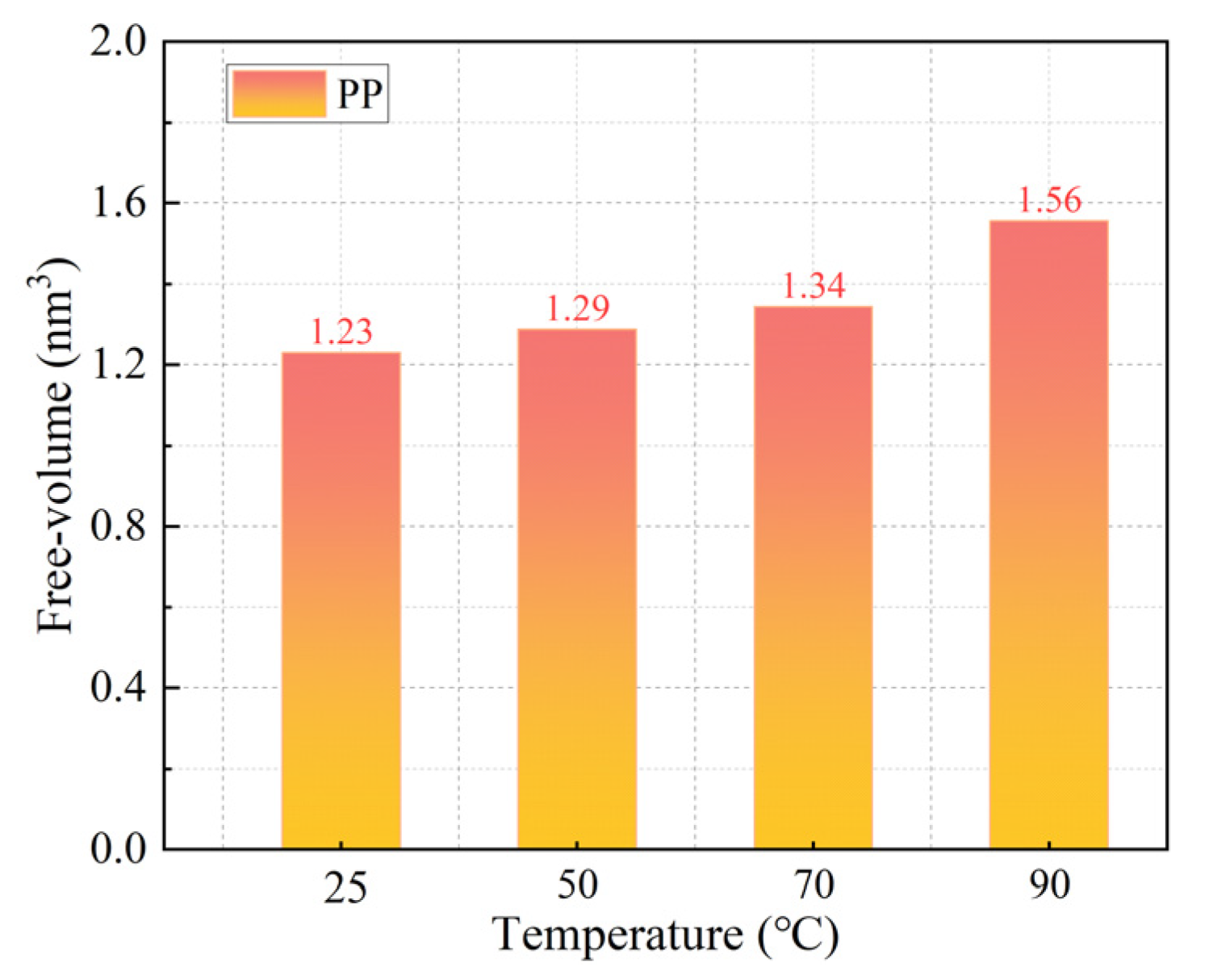

- The breakdown strength of PP has a slight increase after homo-polarity pre-voltage, and the breakdown strength of hetero-polarity decreases by approximately 36% than that of PP without pre-voltage. This is mainly related to the change in the interfacial electric field caused by the space charge near the electrode. In addition, the breakdown strength decreases with the increasing temperature, which is related to the carrier migration and free volume change caused by the temperature. Compared with the room temperature and 90 °C, the free volume increases by 26.8% and the increase in electron free travel is beneficial to the development of electron collision ionization and electron collapse.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rabuffi, M.; Picci, G. Status quo and future prospects for metallized polypropylene energy storage capacitors. IEEE Trans. Plasma Sci. 2002, 30, 1939–1942. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, X.; Chen, Q. Recent development of high energy density polymers for dielectric capacitors. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1036–1042. [Google Scholar] [CrossRef]

- Zhang, S.; Zou, C.; Kushner, I. Semicrystalline polymers with high dielectric constant, melting temperature, and charge-discharge efficiency. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1158–1166. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, H.J.; Kwon, I.S. Evaluation of Electrical Performance and Life Estimation of PPs for HVDC Power Cable. Energies 2021, 14, 5673. [Google Scholar] [CrossRef]

- Green, C.; Vaughan, A.; Stevens, G. Thermoplastic cable insulation comprising a blend of isotactic polypropylene and a propylene-ethylene copolymer. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 639–648. [Google Scholar] [CrossRef] [Green Version]

- Du, B.; Li, Z.; Yang, Z. Application and research progress of HVDC XLPE cables. High Volt. Eng. 2017, 43, 344–354. [Google Scholar]

- Hao, J.; Zou, R.; Liao, R. New Method for Shallow and Deep Trap Distribution Analysis in Oil Impregnated Insulation Paper Based on the Space Charge Detrapping. Energies 2018, 11, 271. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Wu, Y.; Fu, C. Effects of Pre-Crosslinking on Space Charge and Breakdown Characteristics of XLPE Cable Insulation. Energies 2022, 15, 2360. [Google Scholar] [CrossRef]

- Chung, T.M. Functionalization of Polypropylene with High Dielectric Properties: Applications in Electric Energy Storage. Green Sustain. Chem. 2012, 2, 29–37. [Google Scholar] [CrossRef] [Green Version]

- Yuan, X.; Matsuyama, Y.; Chung, T.C. Synthesis of Functionalized Isotactic Polypropylene Dielectrics for Electric Energy Storage Applications. Macromolecules 2010, 43, 4011–4015. [Google Scholar] [CrossRef]

- Zhou, Y.; Han, S.T.; Xu, Z.X.; Yang, X.B. Functional High-k Nanocomposite Dielectrics for Flexible Transistors and Inverters with Excellent Mechanical Proper-ties. Mater. Chem. 2012, 22, 14246–14253. [Google Scholar] [CrossRef]

- Habazaki, H.; Koyama, S.; Aoki, Y. Enhanced Capacitance of Composite Anodic ZrO2 Films ComprisingHigh Permittivity Oxide Nanocrystals and Highly Resistive Amor-phous Oxide Matrix. ACS Appl. Mater. Interfaces 2011, 3, 2665–2670. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chung, T.C.; Petchsuk, A. Synthesis and Properties of Ferroelectric Fluoroterpolymers with Curie Transition at Ambient Temperature. Macromolecules 2002, 35, 7678–7684. [Google Scholar] [CrossRef]

- Wang, J.L.; Yuan, S.Z.; Tian, L. Transition from relaxor to ferroelectric-like phase in poly(vinylideneflouride-trifluoroethylene-chloroflouroethylene) terpolymer ultrathin films. Appl. Phys. Lett. 2011, 98, 1115. [Google Scholar] [CrossRef]

- Yang, L.; Kong, X.; Li, F. Perovskite lead-free dielectrics for energy storage applications. Prog. Mater. Sci. 2019, 102, 72–108. [Google Scholar] [CrossRef]

- Takala, M.; Karttunen, M.; Salovaara, P. Dielectric properties of nanostructured polypropylene-polyhedral oligomeric silsesquioxane compounds. Dielectr. Electr. Insul. IEEE Trans. 2008, 15, 40–51. [Google Scholar] [CrossRef]

- Cho, S.; Kim, M.; Lee, J.S. Polypropylene/Polyaniline Nanofiber/Reduced Graphene Oxide Nanocomposite with Enhanced Electrical, Dielectric, and Ferroelectric Properties for a High Energy Density Capacitor. ACS Appl. Mater. Interfaces 2015, 7, 22301–22314. [Google Scholar] [CrossRef]

- Prashanth, H.; Jaymani, E.; Soon, K.H. Interfacial Polarization Effects on Dielectric Properties in Flax Reinforced Polypropylene/Strontium Titanate Composites. Mater. Chem. Phys. 2021, 265, 124489. [Google Scholar]

- Wang, Q.; Xie, S.Q.; Hua, Z. Influence of isotactic polypropylene grafted with styryl-group on the polymer crystallization behavior. Polym. Test. 2022, 108, 107508. [Google Scholar] [CrossRef]

- Zhou, Y.; Yuan, C.; Wang, S. Interface-modulated nanocomposites based on polypropylene for high-temperature energy storage. Energy Storage Mater. 2020, 282, 55–263. [Google Scholar] [CrossRef]

- Li, Z.; Du, B. Application and Research Status of High Voltage Direct Current Cross-linked Polyethylene Cable. Insul. Mater. 2016, 49, 9–14. [Google Scholar]

- Hanley, T.L.; Burford, R.P.; Fleming, R.J. A general review of polymeric insulation for use in HVDC cables. IEEE Electr. Insul. Mag. 2003, 19, 13–24. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.; Li, Z. Polarization characteristics of metallized polypropylene film capacitors at different temperatures. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 682–688. [Google Scholar] [CrossRef]

- Wei, Y.H.; Han, W.; Li, G.C. Aging Characteristics of Transformer Oil-Impregnated Insulation Paper Based on Trap Parameters. Polymers 2021, 13, 1364. [Google Scholar] [CrossRef]

- Zhou, Y.X.; Zhou, Y.X.; Zhang, L. Space charge evolution and its effects on electrical tree degradation in silicone rubber at varied temperature under polarity reversal voltage. J. Electrost. 2022, 115, 103668. [Google Scholar]

- Park, J.J.; Lee, J.Y. Effects of SiC nanoparticles on space charge behaviors of LSR/nano-SiO2/nano-SiC composites for insulating material of HVDC cable joints. Mater. Chem. Phys. 2021, 270, 124868. [Google Scholar] [CrossRef]

- Li, S.; Xie, D.; Min, D. Simulation of DC breakdown characteristics and charge transport of polypropylene/Al2O3 nanocomposite media. Chin. J. Electr. Eng. 2019, 39, 9. [Google Scholar]

- Zhou, X.G.; Yang, J.J.; Gu, Z.L. Effect of Boron Nitride Concentration and Morphology on Dielectric and Breakdown Properties of XLPE/BN Nanocomposites. Adv. Eng. Mater. 2021, 23, 2100008. [Google Scholar] [CrossRef]

| Scale Parameter α (kV/mm) | Shape Parameter β | |

|---|---|---|

| Without pre-applied | 388 | 70 |

| Negative: −50 kV/mm | 249 | 9 |

| Positive: +50 kV/mm | 402 | 29 |

| Scale Parameter α (kV/mm) | Shape Parameter β | |

|---|---|---|

| 25 °C | 372 | 11 |

| 50 °C | 362 | 20 |

| 70 °C | 358 | 17 |

| 90 °C | 327 | 33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, Z.; Gu, Z.; Zhang, C.; Guo, S.; Cui, H.; Lei, Q.; Li, G. Influence of Space Charge on Dielectric Property and Breakdown Strength of Polypropylene Dielectrics under Strong Electric Field. Energies 2022, 15, 4412. https://doi.org/10.3390/en15124412

Xing Z, Gu Z, Zhang C, Guo S, Cui H, Lei Q, Li G. Influence of Space Charge on Dielectric Property and Breakdown Strength of Polypropylene Dielectrics under Strong Electric Field. Energies. 2022; 15(12):4412. https://doi.org/10.3390/en15124412

Chicago/Turabian StyleXing, Zhaoliang, Zhenlu Gu, Chong Zhang, Shaowei Guo, Huize Cui, Qingquan Lei, and Guochang Li. 2022. "Influence of Space Charge on Dielectric Property and Breakdown Strength of Polypropylene Dielectrics under Strong Electric Field" Energies 15, no. 12: 4412. https://doi.org/10.3390/en15124412

APA StyleXing, Z., Gu, Z., Zhang, C., Guo, S., Cui, H., Lei, Q., & Li, G. (2022). Influence of Space Charge on Dielectric Property and Breakdown Strength of Polypropylene Dielectrics under Strong Electric Field. Energies, 15(12), 4412. https://doi.org/10.3390/en15124412