1. Introduction

The demand for a comfortable indoor environment in buildings in today’s society is always growing, and the challenge for the heating, ventilation and air conditioning (HVAC) industry is meeting this demand while also reducing the amount of energy required to provide a comfortable indoor environment [

1]. In countries that experience extreme desert climates such as Kuwait, centralized air conditioning systems are used to provide cooling from the beginning of April through to the end of October, and it accounts for up to 75% of the electricity consumption in Kuwait [

2]. The increased uptake of air conditioning systems in buildings has resulted in the overall energy consumption increasing, with the peak load demand also increasing. Air conditioners are the largest single contributor to the increase in the peak load demand, and the increased uptake of air conditioners has resulted in the demand for electricity during these periods of extreme heat in Kuwait growing at a faster rate [

3]. The current use of fossil fuels for the production of electricity is a significant contributor to greenhouse gas emissions and the associated climate change, which is the most significant challenge facing mankind today. One of the challenges for the air conditioning industry is maintaining good indoor air quality in buildings.

The introduction of energy conservation measures in buildings has raised concerns over the air quality in these buildings, which minimises ventilation with air from outside the building and has contributed to an increase in contaminants in the indoor environment of the building. This has resulted in a rapid increase in health hazards for occupants in buildings and a dissatisfaction with the indoor environment due to the poor air quality in these air-conditioned environments; its effects are extremely complex [

4]. Experiments conducted by the International Centre for Indoor Environment and Energy in Denmark showed that a warm indoor environment reduced the perceived air quality while also increasing eye, nose and throat irritation and headache intensity. Occupants who felt too warm were more likely to make errors, as the error rate increased by 56%, resulting in a reduction in productivity [

5]. These issues emphasize the need for a more sustainable air conditioning system [

6]. Thermally driven air conditioning systems utilise low-grade thermal energy such as solar thermal energy or waste heat to produce cooling. When solar heat is used to drive these systems, they are called solar thermal air conditioning systems. The advantages of these types of systems are the significant reduction in the amount of energy consumed, low global warming and ozone depletion potential and improved indoor air quality. The research work undertaken into solar thermal cooling systems has demonstrated that they can be adapted to a variety of climates and provide a feasible alternative to refrigerant HVAC systems [

7,

8,

9,

10]. One of the potential heat-driven air conditioning systems is a desiccant evaporative cooling system [

7,

8,

9,

10].

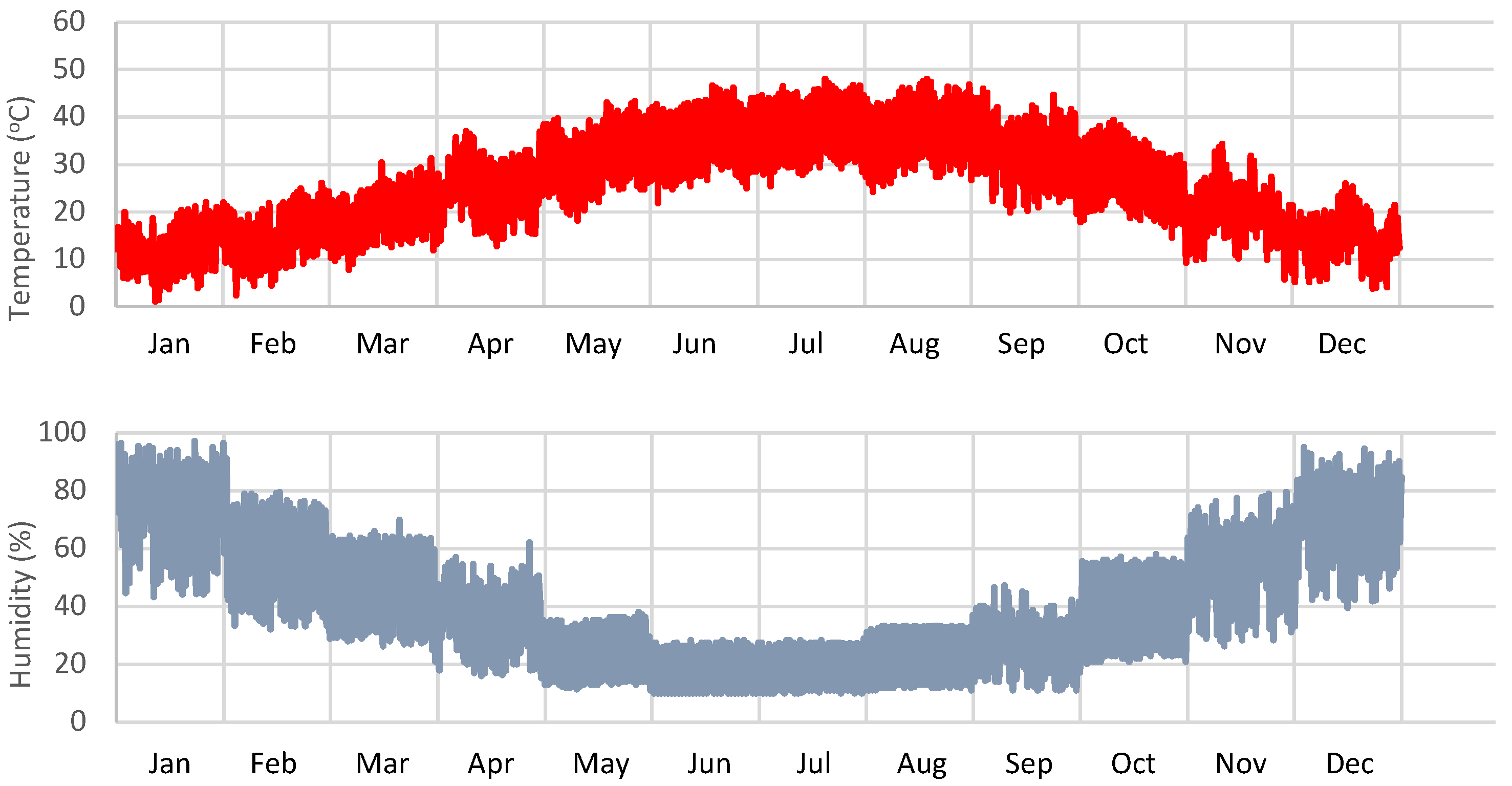

The climatic conditions of the region affect the performance and the amount of energy consumed by an air conditioner, and the design of the system is dependent on the temperature and relative humidity profile of the location where the air conditioning system is situated [

11]. According to the Kopppen–Geiger climate classification, Kuwait has a subtropical desert climate, with mild winters and very hot summers. The desert climate of Kuwait normally permits the sun to shine all year round. The temperature and relative humidity in Kuwait City over a one-year period are presented in

Figure 1. The hot season spans from April to November, and the demand for air conditioning during these months is high. The maximum temperature in Kuwait reaches 46 °C during July, with the average relative humidity being 60%. The relative humidity is the lowest during July and highest in December [

12].

To maintain a comfortable thermal environment for the occupants of the building, generally, the indoor air temperature in buildings is maintained between 18 and 26 °C, while the relative humidity fluctuates between 40 and 70% [

13]. Modern refrigerated air conditioning systems utilise the vapour compression refrigeration cycle to provide cool conditioned air for the occupants of the building. Air conditioners have a coefficient of performance (COP) of between three and seven units of cooling achieved, this means that, for every three to seven units of cooling that occurs, one unit of electricity is consumed. An alternate cooling method is evaporative cooling, which operates by humidifying hot dry air. Water is introduced into the evaporative cooling system, where it is vaporised, and during this vaporisation process, water absorbs heat from the air, thus cooling it. In hot, dry climates that experience elevated temperatures during the summer period, evaporative cooling systems have been able to achieve a COP above 20 [

7]. These types of systems are able to provide a continuous supply of fresh air for 100% of the time that it is operational. However, evaporative cooling systems are not as effective in humid climates due to the increased moisture content of the ambient air.

The evaporative cooling potential depends on the difference in the wet bulb and dry bulb temperatures of the air. The ability of the evaporative cooler to provide cool conditioned air decreases as the relative humidity of the air increases. The evaporative cooling systems are most effective in dry arid climates that have an average relative humidity of less than 30%. An increase in the humidity level of the air decreases the cooling capacity of the evaporative cooling system, as more water is vaporised when the relative humidity of the air is low. Low relative humidity will result in more heat being removed from the air. In more humid conditions, the cooling potential of the system that can be achieved will not be adequate. An evaporative cooling temperature reduction chart can be used to find the outlet temperature. For example, if the ambient air condition is at 40 °C and 60% relative humidity, as in the month of May in Kuwait, the evaporative cooler can bring down the temperature to 34.5 °C, which is completely outside the comfort region of 18–26 °C. Additionally, if the ambient air is at a temperature of 45 °C and a 40% relative humidity, as in the month of July, the temperature reduction achieved with an evaporative cooler will only go down to 35 °C, which, again, is outside of the comfort region, and occupants will feel thermally uncomfortable. When the relative humidity level is brought down by a dehumidifier to low levels (15–20%), thermally comfortable conditions can be achieved using an evaporative cooler. The desiccant evaporative cooling (DEC) system has a high potential in full-year air conditioning by using the desiccant wheel to dehumidify the fresh air entering the evaporative cooler [

4].

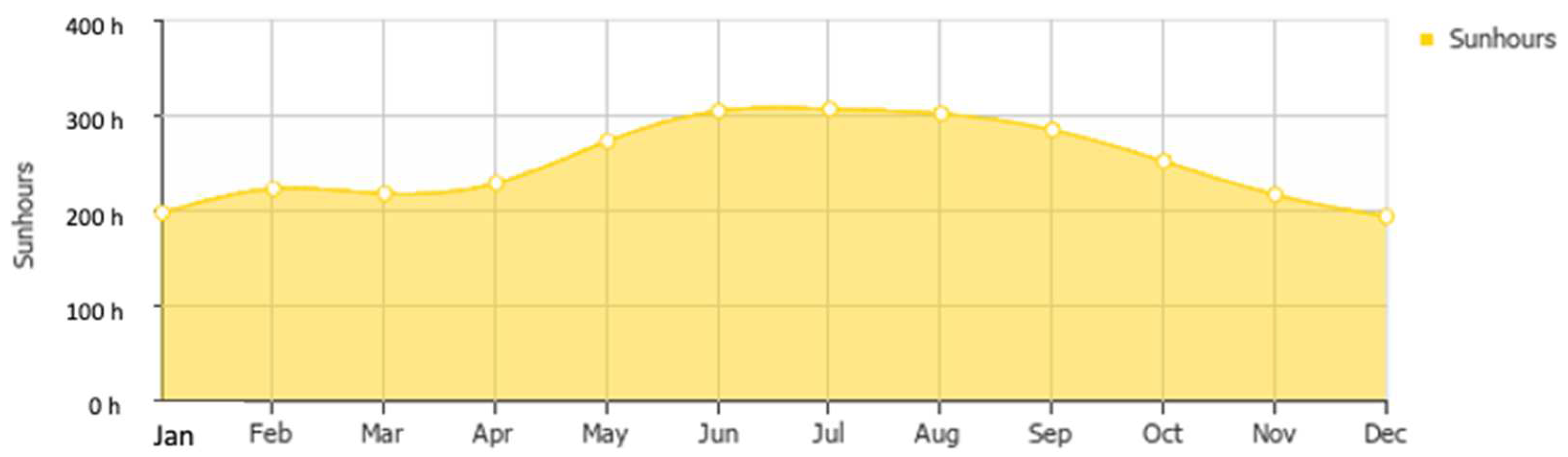

Kuwait receives a large amount of solar radiation and long sunshine hours per day, especially during the summer [

14,

15]. Kuwait receives an average annual sunshine rate of 3002 h, with maximum amount of approximately 300 h per month received from June through to August as shown on

Figure 2. Solar energy utilisation in these regions can potentially be cost-effective, particularly in the case of solar thermal technologies where high direct solar irradiance is required to improve their economic viability [

16]. It is an attractive proposition for a country like Kuwait, as the thermal energy collection subsystem has year-round utility uses for summer cooling, winter heating and hot water for services [

17].

A desiccant evaporative system consists of the following components, i.e., the desiccant wheel, a heat recovery wheel, evaporative coolers and a heater. The desiccant wheel dehumidifies the air to lower the humidity levels to enable effective cooling to occur in the evaporative coolers. A desiccant wheel has a matrix consisting of multiple channels that are coated with desiccant material. The wheel has two sections: the dehumidification section through which the supply air passes through to remove moisture from the and the regeneration section through which hot air passes through to reactivate the matrix and regenerate the desiccant wheel. The desiccant wheel continuously rotates through the two air streams. A solar thermal collector provides the thermal heating required to increase the temperature of the regeneration air. Since most of the demand for cooling occurs when solar gains are at their maximum, solar energy can be effectively used to improve the performance of the system. The electricity consumption of this type of system is very low, as it is used only to run the electric motor and fans.

The type of desiccant material used in the DDW will also have an effect on the amount of moisture removed from the air. A variety of materials are used as desiccant materials; these include silica gel, lithium chloride, calcium chloride, activated carbon, activated alumina, zeolite, calcium oxide and calcium sulphate [

18]. Manufacturers of desiccant dehumidification wheels (DDW) such as Novel Aire Technologies recommend that silica gel be used in their desiccant wheel where the relative humidity is greater than 60% and a molecular sieve desiccant where the relative humidity is less than 50% [

19].

Studies have demonstrated the potential of the desiccant evaporative cooling system when combined with solar thermal collectors as an alternative to conventional air conditioning systems. However, its dehumidification performance needs to be improved to make it a potential alternative. The research carried out by Narayanan et al. investigating the dehumidification process, design and development of an innovative design for a solid desiccant wheel showed that a significantly improved dehumidification performance and thereby far superior cooling for humid climates can be achieved [

20]. The research into the innovative concept of the main component of the system, the desiccant wheel called a ‘nonadiabatic desiccant wheel’, showed it could enhance the drying ability by around 45–53% with the same inlet conditions [

20].

Despite the immense potential for solar thermal cooling, research and development work in this area in Kuwait is mainly confined to the use of vapour absorption chillers fired by hot water at less than 100 °C using flat plate collectors [

14,

17]. Other research into solar cooling in the region includes a feasibility study conducted in Saudi Arabia on implementing solar-driven adsorption chillers with a domestic air conditioning system. This study suggested that solar adsorption cooling is able to provide a means for significantly reducing the amount of electricity required for air conditioning in Saudi Arabia. However, the adsorption chillers currently available will have been optimized to cope with the high ambient temperatures encountered in highly populated cities such as Riyadh [

21]. M. Ssembatya studied the performance of a solar cooling system in UAE using both experimental investigations and simulation. This solar cooling system is based on absorption chilling technology that uses hot water produced by an array of evacuated tube solar collectors to run it. This study concluded that this method of solar cooling for air conditioning applications in the UAE has great potential. However, further research is required to enhance the performances of the solar cooling systems and to assess the viable commercialisation of these types of systems [

22]. The literature research indicated that the potential of the desiccant evaporative cooling system incorporating high-temperature regeneration has not been investigated in relation to Kuwait’s climate, nor is there any research that focuses on the design optimisation of solar cooling systems for these climatic conditions. Therefore, this paper aims to carry out a comprehensive study on a solar desiccant-evaporative cooling system to enhance its performance for the climatic conditions of Kuwait by carrying out numerical investigations and optimising the operational and design parameters.

This paper targets a performance analysis of the design/operational parameters of a desiccant evaporative cooling system with different configurations/components. The thermal and humidification characteristics of the wheel are evaluated by developing a numerical model of the desiccant evaporative cooling system using TRNSYS software. The various components of this model are a desiccant wheel, solar collector, energy recovery wheel, evaporative cooler, building subsystem, climate data subsystem, storage system, control system and other standard utility components. An analysis of the characteristics of the involved subsystems of the model will allow the evaluation of the performance of the whole system and to carry out an analysis to achieve design characterisation under different operating conditions.

In this context, the contributions of our study are:

The performance evaluation of a solid desiccant air conditioning system in Kuwait’s climatic conditions. In this system, the air is first dehumidified using a desiccant wheel, and then, the air is cooled by an energy recovery wheel, followed by the indirect evaporative cooler.

A comparative study on the configurations of alternative solar heating options of a solar air heater and evacuated tube collector is carried out.

Comparison of the performances of the system when the alternative options for a regeneration stream such as ambient air and return air are conducted.

The evaluation of the thermal comfort that can be delivered by this system for the climatic conditions.

2. Model Development

To assess the performance and effectiveness of the proposed cooling system for use in buildings, a number of different configurations of the proposed system were developed using TRNSYS simulation software. The simulation models developed either used the ambient air to regenerate the desiccant wheel or return air from inside the building that has already undergone a dehumidification and cooling process. The models developed comprise a desiccant dehumidification wheel (DDW), an energy recovery wheel (ERW), an indirect evaporative cooler (IEC) and either one or two ventilations fans, depending on the configuration of the system to supply the air needed.

The parameters set for both TRNSYS models were identical (

Table 1), so as to enable an accurate comparison of the two systems. This allows for a better understanding of which system performs best in the climatic conditions in Kuwait and which system is more able to maintain a comfortable thermal environment for the occupants in the building. The parameters set for both TRNSYS models are as follows:

Two different types of solar collectors were selected for use in the simulation models to capture the thermal energy needed to heat the air for regenerating the DDW. These were either an evacuated tube solar collector or an unglazed air heating collector. The design of the proposed evaporative cooling systems for use in the building are shown in

Figure 3 and

Figure 4.

The surface area necessary for the solar thermal collector to heat the air required to regenerate the DDW differed significantly, as the evacuated tube solar collector required significantly less area than that of the unglazed air heating collector to provide the thermal energy necessary to heat the regenerative air for the DDW. The surface area required by the evacuated tube solar collector for the proposed system using conditioned air from the building to maintain the temperature within the building at 18–26 °C is only approximately 40 m2. The unglazed air heating collector requires a surface area of approximately 115 m2 to achieve room temperatures that are similar to those achieved using an evacuated tube solar collector.

The simulation models developed using TRNSYS were run over an eight-month period during the hottest period experienced in Kuwait, from April 1 (2160 h) to 30 November (8016 h); weather data from Kuwait was used to simulate atmospheric conditions that a building would experience. A commercial building design was used in the model (

Figure 5) that has all the internal and external walls, ceiling and roof thermally insulated. The building covers an area of approximately 300 m

2, and the proposed cooling system operates from 8 a.m. to 5 p.m. to better determine how the system performs in a commercial building during normal business hours when the building is occupied. The model is set up in such a way that the system switches on when the temperature is more than 26 °C.

The cooling load for the selected commercial building situated in Kuwait increases significantly from April through to July as the ambient air temperature increases during this period. The cooling load then decreases from August to November as the ambient air temperature decreases with the onset of Autumn, as highlighted in

Figure 6. As the evaporative cooling system for the building only operates from 8:00 a.m. to 5:00 p.m., the thermal energy absorbed by the building during the period that it is not operational results in a significantly greater thermal load accumulating in the building. The modelling shows that the cooling load for the building increases by a factor of approximately three from April to July, highlighting the increase in the thermal energy absorbed by the building.

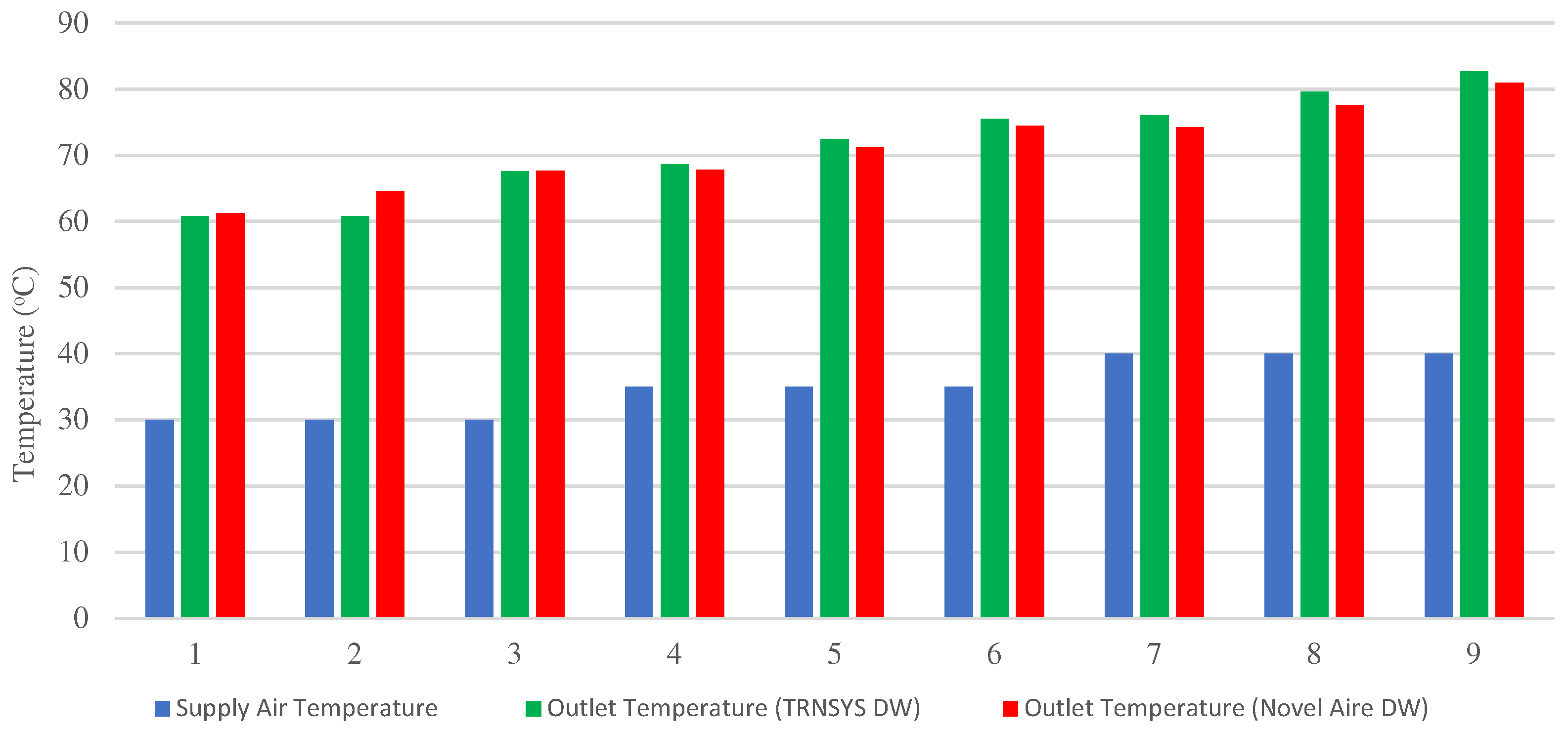

To validate the accuracy of the data from the DDW component used in the TRNSYS models, online desiccant wheel simulation software from Novel Aire Technologies, a manufacturer and supplier of desiccant wheels, was used. A comparison of different temperatures with variations in the humidity ratio (

Table 2) was performed to determine the accuracy of the TRNSYS DDW component. The regeneration air temperature was set at 90 °C for all simulations, with the humidity ratio of the regeneration air remaining constant at 10.6 g/kg. The differences in the temperature of the process air exiting the DDW in the TRNSYS component or Novel Aire simulation software varied by no more than 2 °C for the majority of the simulation, with only one simulation having a temperature difference of approximately 3.8, as illustrated in

Figure 7.

The differences in the humidity ratio between the TRNSYS models and Novel Aire simulation software were also not significant; the data show that the difference in the humidity ratio is minimal on the process air side of the DDW, with the differences between the TRNSYS models and the Novel Aire simulation software varying between 0.5 and 1.7 g/kg (

Figure 8). The differences in the process air outlet temperature and humidity ratio of the TRNSYS DDW component and the Novel Aire simulation software can possibly be attributed to the differences in the materials used in the desiccant wheel that each of the software is based on, as manufacturers of desiccant wheels will each have their own unique formulations in the material compositions of their desiccant wheels.

3. Results and Discussion

An analysis of the data shows that using the conditioned air that has been circulated through the building to regenerate the DDW improves the overall performance of the evaporative cooling system compared to using the ambient air from the surrounding environment. The modelling shows that the evacuated tube and unglazed air heating collectors used in the TRNSYS models of the evaporative cooling system should be able to increase the temperature of the air used to regenerate the DDW to 90 °C and 85 °C, respectively, during the hottest part of the day. This allows the evaporative cooler to maintain the temperature in the building within the 18–26 °C temperature range for some of the period that the system is operating, as shown in

Figure 9. The evaporative cooler commences providing cool conditioned air to the building from approximately April 6 to November 15, when the ambient air temperature in Kuwait is consistently above 26 °C. During regular business hours from 8 a.m. to 5 p.m., when the desiccant evaporative cooling system is operational, the temperature in the building narrowly exceeded 26 °C for approximately 846 h annually, when the evacuated tube solar collector is used, with the temperature in the building reaching a maximum of 30 °C, whereas, when the unglazed air heating collector is used, the temperature in the building exceeded 26 °C for approximately 911 h annually, with the temperature in the building also reaching a maximum temperature of 30 °C, highlighting the evacuated tube solar collector’s superior performance compared to the unglazed air heating collector.

When ambient air from the surrounding environment is used to regenerate the DDW, the modelling shows that the temperature in the building would exceed 26 °C for significantly longer periods during regular business hours. The temperature would exceed 26 °C in the building for approximately 1615 h annually when an evacuated tube solar collector is used, whereas, when the air heating collector is used in the system, the temperature in the building would exceed 26 °C for approximately 1618 h annually. Both the evacuated tube and air heater solar collector would be able to heat the regenerative air entering the DDW to a temperature of 94 °C and 86 °C, respectively, when the cooling system is operational.

The modelling indicates that the relative humidity of the air in the building is higher for the majority of the time that the cooling system is operating when conditioned air from the building is recycled back through the DDW to regenerate it compared to using the ambient air. A drop of up to approximately 20% in the relative humidity of the air in the building is possible just by using the ambient air to regenerate the DDW, as highlighted in

Figure 10. The decrease in the relative humidity may be partly due to the higher temperature of the air in the building when the ambient air is used to regenerate the desiccant. The higher temperature of the air exiting the solar collector when the ambient air is used may also contribute to more moisture being removed from the DDW when undergoing the regeneration process than when conditioned air from the building is used. This allows the DDW to absorb more moisture from the supply air that is to undergo the cooling process in the IEC before it enters the building.

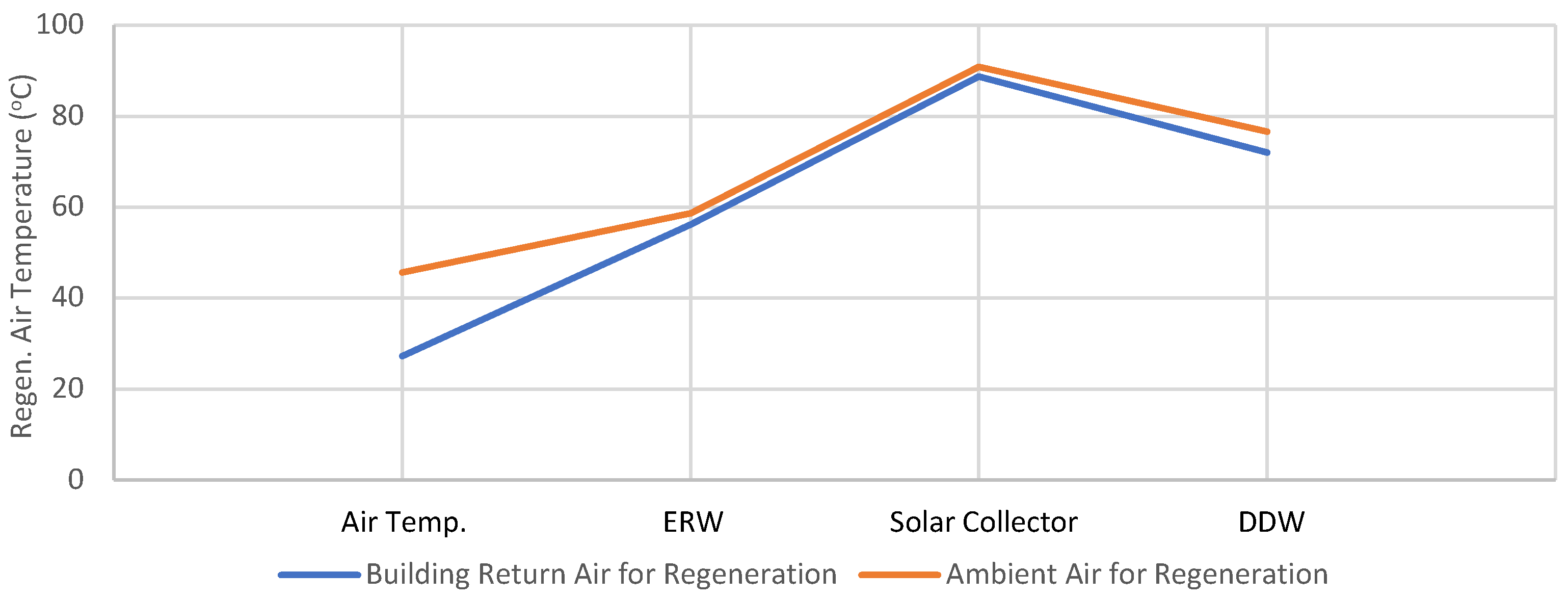

To illustrate the difference in performance between using conditioned air from the building and ambient air to regenerate the DDW, the data taken from the TRNSYS model that used an evacuated tube solar collector on 29 July at 1300 h are presented in

Figure 11 and

Figure 12, which show the differences in the temperature of the air as it passes through each component on both the supply and regenerative sides. It shows that recycling the conditioned air from the building through the regenerative side of the system to regenerate the DDW is a more effective method of reducing the temperature of the conditioned air entering the building than using ambient air. The analysis of the data shows that, when conditioned air is used, the temperature of the supply air passing through the ERW is reduced by approximately 32 °C, and the regeneration air temperature is increased by approximately 29 °C.

When ambient air is used, the supply air passing through the ERW is only reduced by approximately 14 °C, while the regeneration air temperature is only increased by approximately 13 °C. The differences in the performance levels of the ERW in both systems are due to the 18 °C difference in the temperature of regeneration air passing through the ERW. Additionally, as the conditioned air exiting the building has already been dehumidified and is significantly cooler than the ambient air, the conditioned air used for regenerating the DDW is able to absorb more thermal energy in the form of sensible heat and not latent heat. This allows for more thermal energy to be transferred from the supply side to the regeneration side of the system, resulting in a greater variation in the temperature of the supply and regeneration air as it travels through the ERW during the hottest period of the day compared to using ambient air.

The simulation results show that the proposed desiccant evaporative cooling system is capable of maintaining the temperature in the building within the desired temperature range for a certain period of time throughout the period that the system is operational. The temperature in the building does exceed the maximum comfort range of 26 °C for both proposed systems. The main issue for either of the proposed systems developed using TRNSYS is the inability to expand the size of the IEC component. The IEC component only has five dry and four wet bulb channels, resulting in approximately 55% of the air on the supply side passing through the dry channels and entering the building, while the remaining 45% passes through the wet channels before being vented out into the surrounding environment. Increasing the size and number of channels would improve the IEC’s ability to cool the volume of air entering the system.

Research into the effectiveness of indirect evaporative coolers in providing a cool thermal environment for occupants of a building has shown them to be able to provide the cool air required to maintain a thermally comfortable environment. Research conducted by Bruno [

23] into a type of IEC known as a dew point evaporative cooler and its effectiveness in providing a comfortable thermal environment in a building was conducted in the regional town of Roxby Downs located 511 km northwest of Adelaide. The research showed that an IEC can provide the thermal comfort required for the occupant of the building. The building used had a floor area of 140 m

2, and the IEC was able to cool the ambient air from a temperature in excess of 40 °C down to 15 °C before it entered the building. When the IEC was operating between 9:00 a.m. and 7:30 p.m., the daily average temperature fluctuated between 27.5 °C and 40.4 °C. The daily average relative humidity of the ambient air fluctuated between 12.8% and 32.2%. When the IEC system was operational, the air exiting the dew point evaporative cooler averaged 14.9 °C. The research highlights the effectiveness of indirect evaporative systems in providing cool, conditioned air for buildings in hot climates. Still, the system needs to be designed to meet the climatic conditions in which the building is situated.

4. Conclusions and Recommendations

One of the main benefits of evaporative cooling systems compared to conventional air conditioning systems used in buildings is the significant savings in energy consumption that can be achieved. It is estimated that energy savings of 60–80% can be achieved with evaporative coolers compared to conventional air conditioners. The efficiency of evaporative coolers is dependent on the ambient air temperature and the relative humidity level of the air. The rate of evaporation in evaporative coolers is dependent on the type of material used in the precooling pads, the thickness of the pads and the configuration of them [

24].

The transient simulation model of the desiccant evaporative cooling system in a commercial building operating for the entire cooling period was developed, incorporating the climate data of Kuwait. The various configurations analysed include the alternative air streams and heating options for the regeneration of the DDW. The results show that the recycling of the return air from the building back through the DDW to regenerate it improves the overall performance of the evaporative cooling system. The modelling also shows that this configuration is more effective at maintaining the temperature in the building between 18 and 26 °C than using ambient air to regenerate the DDW. The analysis of the data shows that both configurations are able to lower the temperature of the ambient air entering the building down to a temperature that would provide a comfortable thermal environment for the occupants of the building for certain periods of time over the 8-month period when the cooling system is operating from 8 a.m. to 5 p.m. The data shows that the temperature in the building does exceed the maximum thermal comfort temperature of 26 °C with both configurations of the proposed system, which is quite common even in the refrigerated air conditioning system. The simulation shows that, when an evacuated tube solar collector is used in conjunction with using conditioned air from the building to regenerate the DDW, the temperature in the building exceeds 26 °C for approximately 846 h annually compared to 1615 h when the ambient air is used. This can possibly be rectified by using a larger IEC with more wet and dry channels to provide more surface area for the evaporation process to occur in the IEC.

The results show that the evacuated tube solar collector is more efficient than the unglazed air heating collector in increasing the temperature of the air used to regenerate the DDW. It only requires an area of 40 m2 to raise the temperature of the regenerative air for the DDW to a maximum of approximately 94 °C during the hottest period of the day when the system is operational. At the same time, the unglazed air heater collector requires an area of 115 m2 to achieve a maximum temperature of 85 °C for the regenerative air during the same period. One important factor that needs to be considered with this type of system is the amount of available space on top of a building. The ability of the solar collector to heat the air used to regenerate the DDW while using the least amount of the surface area will influence the size of the evaporative cooling system. If the solar collector is unable to heat the regenerative air adequately for the desiccant wheel to undergo the regenerative process, this will have an effect on the dehumidification process on the supply side. This will result in less moisture being removed from the supply air, which will then also affect the rate of evaporation occurring in the IEC and result in a warmer air temperature in the building.

It is recommended that an evacuated tube solar collector be used in conjunction with conditioned air from the building to regenerate the DDW. The modelling shows that this configuration with the inclusion of an ERW and an appropriately sized IEC will enable the evaporative cooling system to provide conditioned air within the required temperature range of 18–26 °C, allowing a comfortable thermal environment to be maintained for the occupants of the commercial buildings in climates such as in Kuwait.