Industrial Symbiosis for Sustainable Management of Meat Waste: The Case of Śmiłowo Eco-Industrial Park, Poland

Abstract

1. Introduction

2. Methods

- Economic effects are evaluated in terms of profitability resulting from higher revenues from realized CE enterprises and collaboration in terms of more productive utilization of material flow streams through companies. In addition, IS leads to a new collaboration and cross-value chain partnership, lower cost, and an improved cost system, with a balance among various scales of business. Innovative products with higher quality and enhanced utility should be the basic drivers of the versatility and elasticity of IS firms [42]. EIP companies should have decreased material and energy consumption, resulting in lower operating costs. This contains the recycling and reuse of materials and increased resource yields by circulating high-quality materials [3].

- Environmental effects refer to waste release quality, their amount, raw materials and energy use, reduction of waste toxicity, and management of by-products and waste. This resulted from the development of new methods of meat waste management and treatment, reuse of recycled products, and bioenergy recovery from waste, which allows for the decrease of operating costs because of using innovative technologies determined as the most accessible techniques that do not result in increased costs [33].

- Social benefits contain changes in consumption models through a socially acceptable use of goods. Higher quality wares resulted in an advantageous influence on human health. Participating and cooperating commerce practices make more economic, ecological, and social profits for consumers and stakeholders.

3. Results and Discussion

3.1. Case Study Presentation

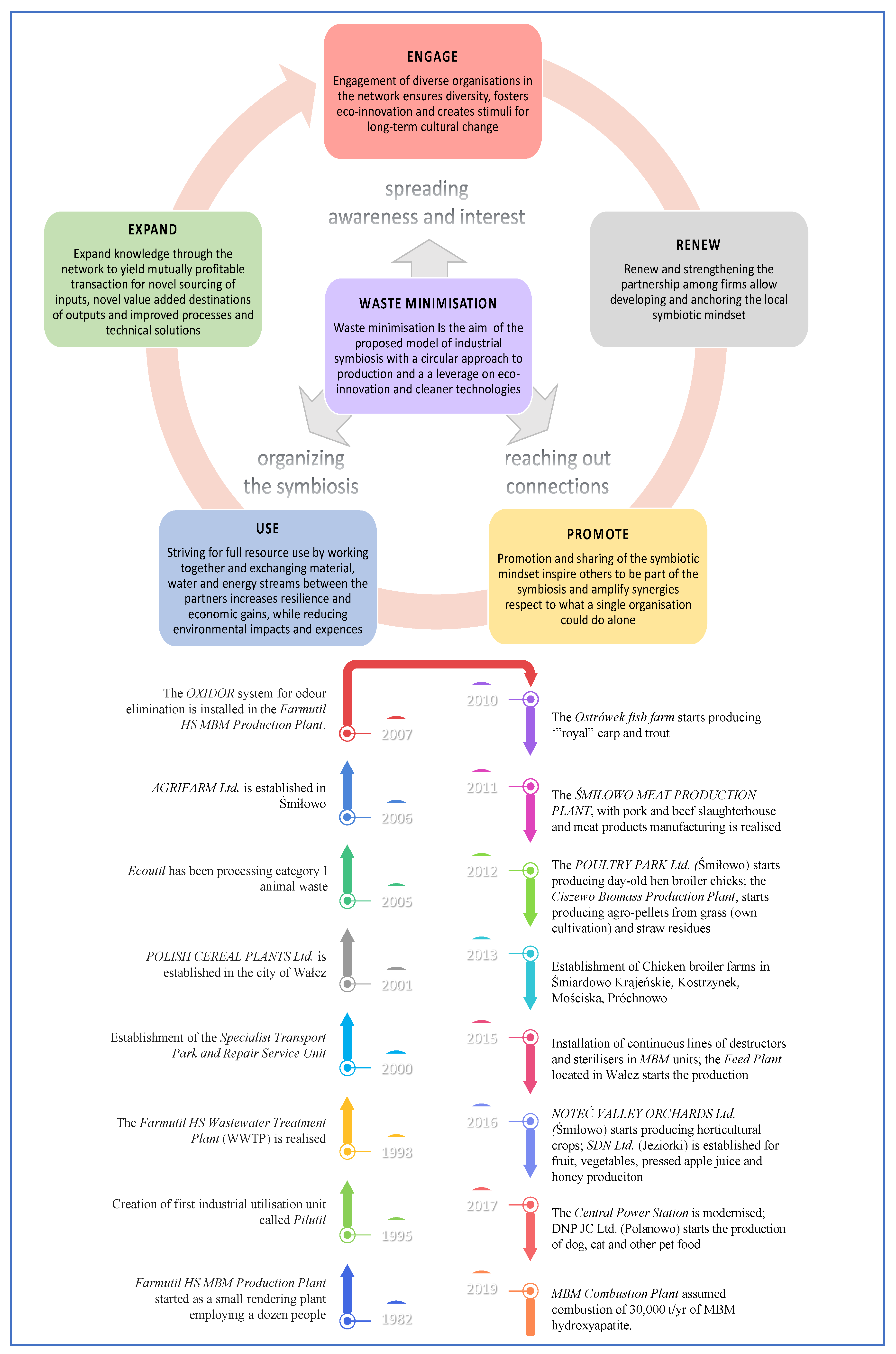

- Engagement of firms in the diverse perspectives and changes connected to IS creates an atmosphere of inclusion and growth. The various organizations collaborated in the network to ensure diversity and foster long-term eco-innovation. These changes require a joint effort from everyone, from leadership to the front lines of the employees.

- Renewing and strengthening the partnership among firms allows for the development of the local symbiotic mindset. Renew also implies how important it is to still recognize and join new participants to develop new chains.

- Inspiration and participation in the way of symbiotic thinking stimulate other firms to be a member of the symbiosis. Partnerships thrive and create synergies when partners see that they can do more together than they could do separately. Achieving this takes a careful understanding not just of how partners work together but also of the unique strengths, risks, and needs of each partner.

- Striving for full resource use through an inter-firm collaboration based on materials and energy exchanges allows high resilience and economic growth, as well as the reduction of environmental impacts, using European Circular Economy Stakeholder Platform ECESP according to different IS models [47].

- Knowledge to expand the business using the value chain to yield many beneficial transactions for a new finding of inputs, value-added final solutions, and enhanced technology and business methods. Business action demands using a wide range of knowledge and experience. The system of business data collection using its own knowledge could be the most important element for effective development.

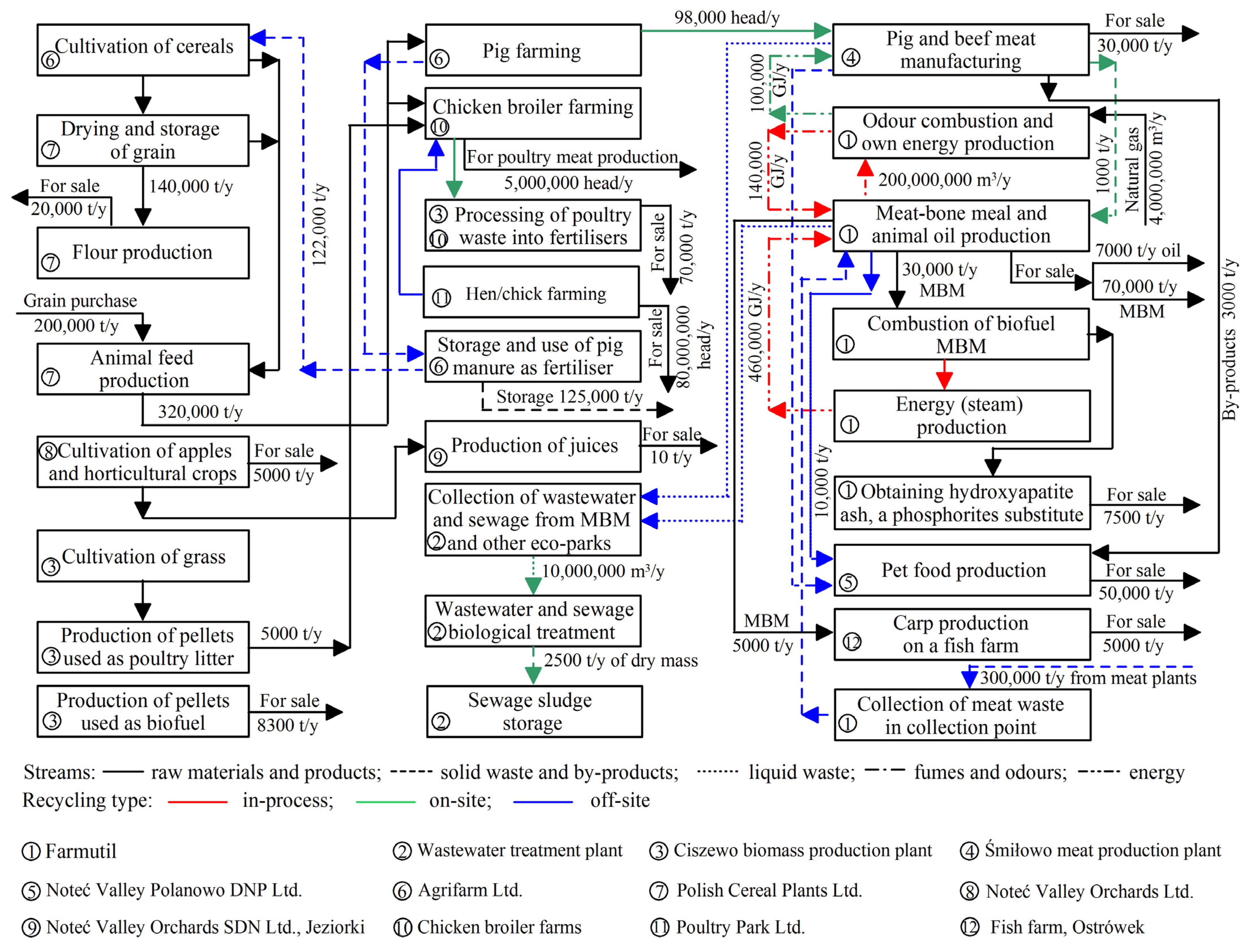

3.2. Quantification and Mapping of the Main IS Exchanges

3.3. Evaluation of the Activities in Terms of SD, CP, and CE

3.4. Analysis of Drivers and Barriers in Śmiłowo EIP Implementation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chertow, M.R. Industrial symbiosis: Literature and taxonomy. Annu. Rev. Energ. Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef]

- Frosch, R.A.; Gallopoulos, N.E. Strategies for manufacturing. Sci. Am. 1989, 261, 144–152. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A comprehensive review of industrial symbiosis. J. Clean. Prod. 2020, 247, 119113. [Google Scholar] [CrossRef]

- Friant, M.C.; Vermeulen, W.J.V.; Salomone, R. A typology of circular economy discourses: Navigating the diverse visions of a contested paradigm. Resour. Conserv. Recycl. 2020, 161, 104917. [Google Scholar] [CrossRef]

- Cecchin, A.; Salomone, R.; Deutz, P.; Raggi, A.; Cutaia, L. Relating industrial symbiosis and circular economy to the sustainable development debate. In Industrial Symbiosis for the Circular Economy. Strategies for Sustainability, 2nd ed.; Salomone, R., Cecchin, A., Deutz, P., Raggi, A., Cutaia, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–25. [Google Scholar] [CrossRef]

- Cecchin, A.; Salomone, R.; Deutz, P.; Raggi, A.; Cutaia, L. What is in a name? The rising star of the circular economy as a resource-related concept for sustainable development. Circ. Econ. Sust. 2021, 1, 83–97. [Google Scholar] [CrossRef]

- Aggeri, F. Industrial eco-parks as drivers of the circular economy. Field Actions Sci. Rep. 2021, 23, 60–61. Available online: http://journals.openedition.org/factsreports/6642 (accessed on 27 February 2023).

- Martin, M. Evaluating the environmental performance of producing soil and surfaces through industrial symbiosis. J. Ind. Ecol. 2020, 24, 626–638. [Google Scholar] [CrossRef]

- Salomone, R.; Cecchin, A.; Deutz, P.; Raggi, A.; Cutaia, L. Industrial Symbiosis for the Circular Economy: Operational Experiences, Best Practices and Obstacles to a Collaborative Business Approach, 2nd ed.; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Shi, L. Industrial symbiosis: Context and relevance to the sustainable development goals (SDGs). Responsible Consumption and Production. In Responsible Consumption and Production; Encyclopedia of the UN Sustainable Development Goals; Leal Filho, W., Azul, A., Brandli, L., Özuyar, P., Wall, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 381–391. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). Changing Production Patterns: Learning from the Experience of National Cleaner Production Centers; United Nations Publication: Paris, France, 2002; Available online: https://www.unep.org/resources/report/changing-production-patterns-learning-experience-national-cleaner-production (accessed on 5 May 2022).

- Clift, R. Clean technology and industrial ecology. In Pollution: Causes, Effects and Control, 4th ed.; Harrison, R.M., Ed.; The Royal Society of Chemistry: Cambridge, UK, 2001; pp. 411–444. [Google Scholar] [CrossRef]

- Oldenburg, K.U.; Geiser, K. Pollution prevention and … or industrial ecology? J. Clean. Prod. 1997, 5, 103–108. [Google Scholar] [CrossRef]

- Liu, C.; Côté, R.P.; Zhang, K. Implementing a three-level approach in industrial symbiosis. J. Clean. Prod. 2015, 87, 318–327. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef]

- Henriques, J.; Azevedo, J.; Estrela, M.; Dias, R. Relating industrial symbiosis and sustainable development goals. Mater. Proc. 2022, 5, 111. [Google Scholar] [CrossRef]

- Fraccascia, L.; Giannoccaro, I. What, where, and how measuring industrial symbiosis: A reasoned taxonomy of relevant indicators. Resour. Conserv. Recycl. 2020, 157, 104799. [Google Scholar] [CrossRef]

- Jacobsen, N.B. Industrial symbiosis in Kalundborg, Denmark: A quantitative assessment of economic and environmental aspects. J. Ind. Ecol. 2006, 10, 239–255. [Google Scholar] [CrossRef]

- Kosmol, L.; Maiwald, M.; Pieper, C.; Plötz, J.; Schmidt, T. An indicator-based method supporting assessment and decision-making of potential by-product exchanges in industrial symbiosis. J. Clean. Prod. 2021, 289, 125593. [Google Scholar] [CrossRef]

- Taddeo, R. Local industrial systems towards the eco-industrial parks: The model of the ecologically equipped industrial areas. J. Clean. Prod. 2016, 131, 189–197. [Google Scholar] [CrossRef]

- Fraccascia, L.; Magno, M.; Albino, V. Business models for industrial symbiosis: A guide for firms. Procedia Environ. Sci. Eng. Manag. 2016, 3, 83–93. [Google Scholar]

- Södergren, K.; Palm, J. The role of local governments in overcoming barriers to industrial symbiosis. Clean. Environ. Syst. 2021, 2, 100014. [Google Scholar] [CrossRef]

- Poponi, S.; Arcese, G.; Pacchera, F.; Martucci, O. Evaluating the transition to the circular economy in the agri-food sector: Selection of indicators. Resour. Conserv. Recycl. 2022, 176, 105916. [Google Scholar] [CrossRef]

- Dueñas, M.; García-Estévez, I. Agricultural and food waste: Analysis, characterization and extraction of bioactive compounds and their possible utilization. Foods 2020, 9, 817. [Google Scholar] [CrossRef]

- Amicarelli, V.; Fiore, M.; Bux, C. Hidden flows assessment in the agri-food sector: Evidence from the Italian beef system. Br. Food J. 2021, 123, 384–403. [Google Scholar] [CrossRef]

- Wu, J.; Guo, Y.; Li, C.; Qi, H. The redundancy of an industrial symbiosis network: A case study of a hazardous waste symbiosis network. J. Clean. Prod. 2017, 149, 49–59. [Google Scholar] [CrossRef]

- Yedla, S.; Park, H.S. Eco-industrial networking for sustainable development: Review of issues and development strategies. Clean Technol. Environ. Policy 2017, 19, 391–402. [Google Scholar] [CrossRef]

- Domenech, T.; Bleischwitz, R.; Doranova, A.; Panayotopoulos, D.; Roman, L. Mapping Industrial Symbiosis Development in Europe-typologies of networks, characteristics, performance and contribution to the Circular Economy. Resour. Conserv. Recycl. 2019, 141, 76–98. [Google Scholar] [CrossRef]

- Taddeo, R.; Simboli, A.; Morgante, A.; Erkman, S. The development of industrial symbiosis in existing contexts. Experiences from three Italian clusters. Ecol. Econ. 2017, 139, 55–67. [Google Scholar] [CrossRef]

- Kowalski, Z.; Krupa-Żuczek, K. A model of the meat waste management. Pol. J. Chem. Technol. 2007, 9, 91–97. [Google Scholar] [CrossRef]

- Kowalski, Z.; Makara, A. The circular economy model used in the Polish agro-food consortium: A case study. J. Clean. Prod. 2021, 284, 124751. [Google Scholar] [CrossRef]

- Stokłosa, H.; Kowalski, Z.; Makara, A. The use of the circular economy model and cleaner technologies on in the example of the Polish agro-food company Farmutil. Przem. Chem. 2019, 98, 709–714. [Google Scholar]

- Yin, R.K. Applications of Case Study Research, 3rd ed.; Sage Publications, Inc.: London, UK, 2011. [Google Scholar]

- Kristensen, H.S.; Mosgaard, M.A. A review of micro level indicators for a circular economy—Moving away from the three dimensions of sustainability? J. Clean. Prod. 2020, 243, 118531. [Google Scholar] [CrossRef]

- Boons, F.; Chertow, M.; Park, J.; Spekkink, W.; Shi, H. Industrial symbiosis dynamics and the problem of equivalence: Proposal for a comparative framework. J. Ind. Ecol. 2017, 21, 938–952. [Google Scholar] [CrossRef]

- Walker, A.M.; Vermeulen, W.J.V.; Simboli, A.; Raggi, A. Sustainability assessment in circular inter-firm networks: An integrated framework of industrial ecology and circular supply chain management approaches. J. Clean. Prod. 2021, 286, 125457. [Google Scholar] [CrossRef]

- Bicket, M.; Guilcher, S.; Hestin, M.; Hudson, C.; Razzini, P.; Tan, A.; Watkins, E. Scoping Study to Identify Potential Circular Economy Actions, Priority Sectors, Material Flows and Value Chains; Publications Office of the European Union: Luxembourg, 2014. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef]

- Garrido Azevedo, S.; Godina, R.; de Oliveira Matias, J.C. Proposal of a sustainable circular index for manufacturing companies. Resources 2017, 6, 63. [Google Scholar] [CrossRef]

- Lehtoranta, S.; Nissinen, A.; Mattila, T.; Melanen, M. Industrial symbiosis and the policy instruments of sustainable consumption and production. J. Clean. Prod. 2011, 19, 1865–1875. [Google Scholar] [CrossRef]

- Pacurariu, R.L.; Vatca, S.D.; Lakatos, E.S.; Bacali, L.; Vlad, M. A critical review of EU key indicators for the transition to the circular economy. Int. J. Environ. Res. Public Health 2021, 18, 8840. [Google Scholar] [CrossRef]

- Henriques, J.; Ferrão, P.; Castro, R.; Azevedo, J. Industrial symbiosis: A sectoral analysis on enablers and barriers. Sustainability 2021, 13, 1723. [Google Scholar] [CrossRef]

- Madsen, J.K.; Boisen, N.; Nielsen, L.U.; Tackmann, L.H. Industrial Symbiosis Exchanges: Developing a Guideline to Companies. Waste Biomass Valorization 2015, 6, 855–864. [Google Scholar] [CrossRef]

- Mortensen, L.; Kørnøv, L. Critical factors for industrial symbiosis emergence process. J. Clean. Prod. 2019, 212, 56–69. [Google Scholar] [CrossRef]

- Makara, A.; Kowalski, Z.; Lelek, Ł.; Kulczycka, J. Comparative analyses of pig farming management systems using the Life Cycle Assessment method. J. Clean. Prod. 2019, 241, 118305. [Google Scholar] [CrossRef]

- European Circular Economy Stakeholder Platform (ECESP), Kalundborg Symbiosis: Six Decades of a Circular Approach to Production. European Union. 2019. Available online: https://circulareconomy.europa.eu/platform/en/good-practices/kalundborg-symbiosis-six-decades-circular-approach-production (accessed on 5 May 2022).

- European Commission, Regulation (EC) No 1774/2002 of the European Parliament and of the Council of 3 October 2002—Laying down Health Rules Concerning Animal by-Products not Intended for Human Consumption. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32002R1774&from=EN (accessed on 5 May 2022).

- European Commission, Regulation (EC) No 1069/2009 of the European Parliament and of the Council of 21 October 2009—Laying down health Rules as Regards Animal by-Products and Derived Products not Intended for Human Consumption and Repealing Regulation (EC) No. 1774/2002. Available online: https:eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32009R1069&from=EN (accessed on 5 May 2022).

- Kowalski, Z.; Kulczycka, J.; Makara, A.; Harazin, P. Quantification of material recovery from meat waste incineration–An approach to an updated food waste hierarchy. J. Hazard. Mater. 2021, 416, 126021. [Google Scholar] [CrossRef]

- Makara, A.; Kowalski, Z. Selection of pig manure management strategies: Case study of Polish farms. J. Clean. Prod. 2018, 172, 187–195. [Google Scholar] [CrossRef]

- Tudor, T.; Adam, E.; Bates, M. Drivers and limitations for the successful development and functioning of EIPs (eco-industrial parks): A literature review. Ecol. Econ. 2007, 61, 199–207. [Google Scholar] [CrossRef]

| Material/Utility | Stream Flows * [t/y] | |||||

|---|---|---|---|---|---|---|

| Total | Own Use | For Sale | Disposal | |||

| Amount | Use/Off Process Recycling for | Amount | Income ** [EUR M/y] | |||

| Pig manure | 247,000 | 122,000 | Fertilization | 125,000 | ||

| Hazardous meat waste | 300,000 | MBM production | ||||

| Sewage sludge | 12,000 | 12,000 | Fertilization | |||

| Meat bone meal | 110,000 | 10,000 | Pet food production | 70,000 | 32.11 | |

| Meat bone meal Energy [GJ] produced from meat bone meal | 460,000 | 30,000 460,000 | MBM incineration and Energy production for EIP companies | |||

| Animal oil | 7000 | 7000 | 5.78 | |||

| Meat by-product | 3000 | Pet food production | ||||

| Dried grain | 20,000 | Flour production | ||||

| Flour | 20,000 | 20,000 | 16.0 | |||

| Dried grain | 120,000 | Animal feed production | ||||

| Purchased grain | 200,000 | Animal feed production | ||||

| Animal feed | 320,000 | 320,000 | Pig and poultry farming | |||

| Pigs | 98,000 | 98,000 | Pig meat manufacturing | |||

| Pig and beef meat products | 30,000 | 185.57 | ||||

| Pete foods | 50,000 | 123.73 | ||||

| Hydroxyapatite ash | 7500 | 0.87 | ||||

| Royal carp | 5000 | 41.14 | ||||

| Day-old hen broiler chicks [pcs] | 90 million | 55.67 | ||||

| Chicken broilers | 5,000,000 | 6.5 | ||||

| Chicken manure fertilizer | 70,000 | 50.51 | ||||

| Apples | 5000 | 0.41 | ||||

| Grass pellets | 13,300 | 5000 | Poultry litter | 8300 | 3.3 | |

| Energy (steam) [GJ] | 240,000 | 700,000 | MBM production and all EIP companies | |||

| Sewage and wastewater [m3] | 10,000,000 | 10,000,000 | Biological treatment | |||

| Food-grade water [m3] | 600,000 | 600,000 | All EIP companies | |||

| Odor [m3] | 200,000,000 | 200,000,000 | Elimination by thermal treatment | |||

| CO2 | Elimination of emission | |||||

| Total income | 521.59 | |||||

| EIP Units | Service Description |

|---|---|

| Central Power Station | Electricity supply for the EIP companies |

| Specialist Transport Park | Meat products and waste transport |

| Repair Service Unit | Repair and maintenance of transport and production equipment |

| Investa Investment Service Centre Ltd. | Design and realization of investment with supervision |

| Investbud Ltd. | Investment realization; design and building of objects, production units, and other investments |

| Auto Building Ltd. | Container manufacturing |

| Warehouse for Occupational Health and Safety (OHS) goods | Wholesale and storage of OHS devices |

| Investa Aero Service | Helicopter and aircraft airport and transport |

| Biochemik | Research, chemical, and microbiological analyses using certified methods |

| Weekly News | Information about the EIP and its promotion |

| Scheme | Description Based on SD, CP, and CE Models | Company; Belonging Plants/Farms | Production/Service Type |

|---|---|---|---|

| Production for sale and own use | Biomass production. Production of high-quality feed for own pig and poultry farming. High-tech production development using locations in the Nature 2000 area. Development of own poultry and pig farms using modern breeding technology. Development of feed and flour production. Continuous development of farmland area for profitable production of own crops and high-quality feeds. Production of fruit and vegetables, natural juices, and honey. Making the water flow chain shorter with fewer stations. | Meat production plant Śmiłowo. | Pork and beef slaughterhouse and manufacturing plant, producing 100 t/day of meat products. Meat products are produced according to well-proven and very high-quality recipes developed 40 years ago. |

| Farmutil Inc., Śmiłowo, Poland; MBM plants: Pilutil and Ekoutil, Śmiłowo. | The biggest EIP company that processes meat waste to produce 100,000 t/y MBM in the most innovative European plants. In addition to the MBM, 20,000 t/y of animal fat is produced as a by-product. | ||

| Biomass production plant, Ciszewo | Production of 8300 t/y agri-pellets from 18,000 t/y of grass (obtained in 5000 ha of cultivated area) and straw residues. The agri-pellet biofuel (12 GJ/t calorific value) substitutes natural energy resources. Additionally, pellets are used as bedding in poultry farming. | ||

| Noteć Valley Polanowo DNP Ltd., Polanowo, Poland | Manufacturing of pet foods, based on inedible meat residues and by-products. DNP uses also category III MBM (off-site recycling). The DNP contributes to job opportunities in an area of high unemployment. | ||

| Agrifarm Ltd., Śmiłowo; Agricultural Plants: a/Śmiłowo, b/Zelgniewo, c/Mościska, d/Zacharzyn, e/Miłostowo, f/Komorzewo, g/Przytoczna | Grain cultivation on 4208 ha. Pig manure is applied to fertilize 4100 ha of land with a standard dose of 44 t/ha, using tankers equipped with splash plates for broad-spreading. This is the cheapest method of applying manure used in Europe. Quantity of pig breeding (heads); Miłostowo (32,000), Komorzewo (16,000), Śmiłowo (1600 sows), and Przytoczna (4000). | ||

| Polish Cereal Plants Ltd., Wałcz, Poland; | Production of feedstuff for livestock, capacity 500,000 t/y. Production of feed (320,000 t/y) totally meets Farmutil’s needs for feedstuffs to use in poultry and pig farming. The innovative unit used modern technology and equipment, characterized by short transport distances and a cascading system of materials flows. Products meet the highest quality and safety standards. The feeds are prepared on the basis of the most up-to-date nutritional knowledge. Their own farms allow the testing of nutritional solutions before introducing them to the market. | ||

| Chicken Broiler Farms: a/Śmiardowo Krajeńskie, b/Kostrzynek, c/Mościska Agricultural Plants: a/Próchnowo, b/Brzeżno | Rapeseed, wheat, and triticale have been cultivated in Brzeźno on 2057 ha and in Próchnowo on 1500 ha. The farms are involved in the breeding of 5 million broiler chickens per year. Broiler chickens are typically white and are specifically farmed to produce meat for consumers. They are fed with top-quality fodder. | ||

| Fisheries Farm, Ostrówek | Breeding of highest quality carps and trout in 14 ponds (area of 424 ha), producing 450 t/y of fish using MBM as fish feed. Localization in ecological park Natura 2000, provided clean water and air and enabled the production of the highest quality products. | ||

| Noteć Valley Orchards Ltd., Śmiłowo, Poland | Cultivation of apples, cherries, pears, and plums on 150 ha and a bee apiary (400 hives of bees). The modern production of fresh, tasty, and healthy high-quality fruits in full correlation with European Union EU environmental regulations. | ||

| SDN Ltd., Jeziorki, Poland | Processing, storage, and sale of fruits, vegetables, apple juice, and honey from Noteć Valley Orchards. | ||

| Poultry Park Ltd., Śmiłowo, Poland | Production of 90 million/y one-day-old broiler chicks from the highest quality feedstuffs. Leading Polish producer using global-level technology. | ||

| Bio-energy production and recovery | Bio-energy use and recovery Substitution of coal with biofuel. | Farmutil Inc., Śmiłowo; MBM Combustion Plant, Śmiłowo. | Incineration 30,000 t/y MBM. Production of steam from bioenergy. Energy recovery and in-process heat recycling (for MBM production). |

| Waste management and processing | Recycling and reuse of processed meat waste. Development of innovative meat waste utilization technologies. Network of collection units. | Take-back waste plants: a/Prusice, b/Węgry, c/Miszewo Wielkie, d/Śmiłowo | High-quality recycling/upcycling collection points with a capacity of 600,000 t/y. Optimum logistic collection of animal and food waste, used for meat bone meal production. |

| Wastewater biological treatment plant WWTP, Śmiłowo | A modern WWTP with a high technical level. Obtained sewage sludge is entirely used as fertilizer. Treatment of 10,000,000 m3/y of wastewater from MBM and EIP units. | ||

| Service and auxiliary activities | Development of own central modern laboratory and research service. Centralized distribution, sales, and transport services. Logistics/infrastructure facilities. Technical service for all EIP companies. Centralized electricity supply and service. Upgrading, maintenance, and repair of equipment and products. Centralized design, investment realization, supervision, and consultancy. Production of disinfecting agents and their application. Maintenance and services of airport, aircraft, and air transport services. Storage and sale of OHS equipment. EIP information and promotion. | Farmutil, Śmiłowo Specialist transport park | Transport services across the EIP: over 2000 trucks and modern vehicles with self-loading and material cooling systems. The transport of the EIP materials is facilitated by the optimal location of the meat collection points and proper distribution of products to the chain of 350 meat stores. |

| Polish Cereal Plants Ltd., Wałcz, Poland; Grain Elevator: a/Piła, b/Wałcz, c/Strzelce Krajeńskie d/Drying and storage complex Śmiłowo. | Drying, transportation, purchase, and storage of cereals and rapeseed. | ||

| Noteć Valley Orchards SDN Ltd., Jeziorki, Poland Food-quality water intake and production plant | Provides EIP with drinking water (2000 m3/day) treated by the filtration method. The use of food quality and cheap water resulted in the highest quality and lower operating costs. The water is used in the manufacture of poultry and meat products, as well as in obtaining natural juices. | ||

| Service and Research Laboratory Biochemik Ltd., Śmiłowo, Poland | Studies and tests in terms of chemistry, microbiology, sampling, environment, and calibration. | ||

| Auto Building Ltd., Wałcz, Poland | Manufactures containers, trailers, and semi-trailers, as well as other steel structures. | ||

| Investa Investment Service Centre Ltd., Piła; a/Investa Chem Production Plant, Łowicz Wałecki; b/Warehouse for OHS, Śmiłowo, Poland Investa Aero Service LTD., Śmiłowo, Poland | Investment realization, supervision, consultancy, and construction reviews. Production of disinfectants and washing-disinfecting agents. Warehouse of OHS devices. Airport and maintenance services of 5 helicopters and 3 aircraft. | ||

| Investbud Ltd., Piła, Poland. | Investment projects and the realization of industrial units and other buildings. | ||

| Weekly News, Ltd., Piła, Poland | Promotion/information on the Śmiłowo EIP and its companies. |

| Activities | Triple Button-Line Sustainability Benefits | ||

|---|---|---|---|

| Economic | Environmental | Social | |

| Production for sale and own use | Ensure a strong position in the market. Develop pet food production. Modularity design products with newer features/functionalities. Longer product lifetime. Supply chains become shorter with improved traceability of products and related transactions. Higher materials efficiency. Reduced MBM production costs. Sale of hydroxyapatite ash. Pellets are used as high-quality bedding. System for effective insemination of sows Lower feed/flour production costs due to use of own crops. Decrease pig/poultry farming costs due to the use of their own feeds. Net fertilizer effects due to the use of pig manure. Production of own food-quality water. Higher effectiveness of crop storage and purchasing. More effective cooperation and exchange. | Decrease environmental impact due to reduced release of waste, odor, and GHG emissions. High-quality technologies for recycling/reuse of processed wastes. Manufacturing of bioenergy resulting in decreased consumption of non-renewable fuel resources Recycling of meat waste and non-food meat waste. Take-back structure and collection points guarantee the continuous flow of waste for processing. Own production of disinfection agents results in more effective package recycling and reuse. Proper location of new installations reduces the environmental impacts due to shorter transport routes and complemented use of existing logistics and infrastructure facilities. | Job proposals, especially for qualified workers. Improve relationship with the public due to odor elimination. Certificate for good quality products. Reduce damage to human health. Creation of consumption models for consumers to decrease the use of goods. Better traceability of products. |

| Energy production and recovery | Profitable production of bioenergy. Low energy cost. Higher efficiency of energy recovery. Reduce costs for heat sharing between companies. Reuse of processed hay/straw as biofuel. | Bioenergy production. Removal of coal use in energy manufacture. Waste-free energy production. Energy in-/off-process recycling and recovery. | Creation of consumption of products using low energy. |

| Waste management and treatment | Lower wastewater treatment costs. Effective take-back meat waste scheme. Reuse of processed waste. | Recycling and reuse of animal waste and by-products. Wastewater take-back collection systems. Waste-less technologies. | Improve companies’ image in society. Reduce damage to human health. |

| Service and auxiliary activities | Lower costs of laboratory services. Lower transport costs. Shorter electricity supply chain. Lower electricity costs. Lower investment, repair, and maintenance costs. Lower promotion costs. | Reduce environmental impacts of meat transport and waste collection. Reduce material use. | Creation of new business services (e.g., parts/component regeneration). Offer specialized knowledge. Creation of new product usage patterns. |

| Drivers/ Barriers | Level of Occurrence | Type | ||||

|---|---|---|---|---|---|---|

| Physical/Technical | Regulatory | Resources | Collaboration | Motivation | ||

| Drivers realizing IS exchanges | Intra-organizational | The diverse range of EIP production companies and service activities. SD of transport in IS. Possibilities of the realization of technical challenges in terms of quantity and quality of industrial by-products. | Incentives. Partnership and collaboration with community and local authorities. Promoting the local symbiotic mindset. | Self-organized within Farmutil consortium and bottom-up approach resulting from its strategic goals. Provision of financing for SD projects. Easier direct interaction among Farmutil firms. | Experience of managers from the meat industry sector. Social challenges arise from trusting companies belonging to consortiums to fulfill quantity needs and standards. Flexible production cooperation model based on a supply chain using IS elements. | Expected savings and income. New business opportunities. Competitive advantages. Brand improvement. Farmutil SD strategy. Cost factor influences firms. Increase innovative outreach. Expanding the focus on product and by-product streams. |

| Drivers relevant to company level | Company | Increasing material interchanges. Take-back systems. Firms cooperate to decrease waste amounts, increase value, and achieve economies in their activity. | Initiative promotion. Use of easily applicable mode for funds. Funds aid the research. | Facilities schemes. Business workshop. Networks with SD data on technical research. The data set of IS methods and procedures. Care for by-products. Models of funds petition. | Knowledge of neighbor firms. Industry organization with good knowledge and sharing. Trust for firms’ collaboration. Integrity by the sustainable use of waste and bio-processes. An easier collaboration promotes a symbiotic mindset. | New business ideas. Good experience leading to more CP activity. Fulfilling company strategy. Clear economic benefits. Industry demand for CE. Possible competitive advantage. Public interest in CE. |

| Employee | High-quality employees. | Network expands knowledge. | Professional pride. | |||

| Barriers to realizing IS exchanges | Intra-organizational | Delivery and needs correlation. Infrastructural use. Some problems with specific information needs of industrial users concerning waste (classification, distribution, and others). | Uncertainty of local legal regulations and consistency of regional. development policy No enforcement of IS development and appropriate legal requirements. | Unknown profits factor. Various investment processes. Negotiation experience. No skills and resources. Going outside the traditional supply chain requires support. Lack of time and money. | Sharing of companies in costs and profits. Relationship and trust of firms. Needs to improve market and other information flow between companies. Conflict of education and experience results in not seeing IS as a priority. | Limited public awareness of IS. No SD works priority. Scarcity of innovation incentives. No business incentive from the market or regulators. Estimation of financing mechanism viability and lack of business case studies and steering mechanisms. |

| Barriers relevant to companies | Company | Harder to find buyers than suppliers. Amounts adjustment. Ambient physical area. | Not enough contacts of companies with authorities and municipalities. Decreased explanation of IS. No clear SD tips. | Unknown benefits. Lower raw material cost. Priority of benefits. Problem with employee acquisition. Keeping key competencies. Scarcity of expertise and IS and CE education. | Scale differences. Priority of collaboration. Scarcity of trust. Participation of companies in costs and benefits. Differences in company manner. | Various goals and reasoning. No priority of SD work. IS has low priority due to not being treated as a basic phase of production. Lack of knowledge in the community on SD and CE. |

| Employee | No knowledge and perception of the IS principles. | Lack of promoters in companies. | No priority for IS. No employee education. | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalski, Z.; Kulczycka, J.; Makara, A.; Mondello, G.; Salomone, R. Industrial Symbiosis for Sustainable Management of Meat Waste: The Case of Śmiłowo Eco-Industrial Park, Poland. Int. J. Environ. Res. Public Health 2023, 20, 5162. https://doi.org/10.3390/ijerph20065162

Kowalski Z, Kulczycka J, Makara A, Mondello G, Salomone R. Industrial Symbiosis for Sustainable Management of Meat Waste: The Case of Śmiłowo Eco-Industrial Park, Poland. International Journal of Environmental Research and Public Health. 2023; 20(6):5162. https://doi.org/10.3390/ijerph20065162

Chicago/Turabian StyleKowalski, Zygmunt, Joanna Kulczycka, Agnieszka Makara, Giovanni Mondello, and Roberta Salomone. 2023. "Industrial Symbiosis for Sustainable Management of Meat Waste: The Case of Śmiłowo Eco-Industrial Park, Poland" International Journal of Environmental Research and Public Health 20, no. 6: 5162. https://doi.org/10.3390/ijerph20065162

APA StyleKowalski, Z., Kulczycka, J., Makara, A., Mondello, G., & Salomone, R. (2023). Industrial Symbiosis for Sustainable Management of Meat Waste: The Case of Śmiłowo Eco-Industrial Park, Poland. International Journal of Environmental Research and Public Health, 20(6), 5162. https://doi.org/10.3390/ijerph20065162