Investigation of Unsafe Acts Influence Law Based on System Dynamics Simulation: Thoughts on Behavior Mechanism and Safety Control

Abstract

1. Introduction

2. Data Sources

2.1. Accident Causation Model

2.2. Unsafe Acts Causality Analysis in Coal and Gas Outburst Accidents

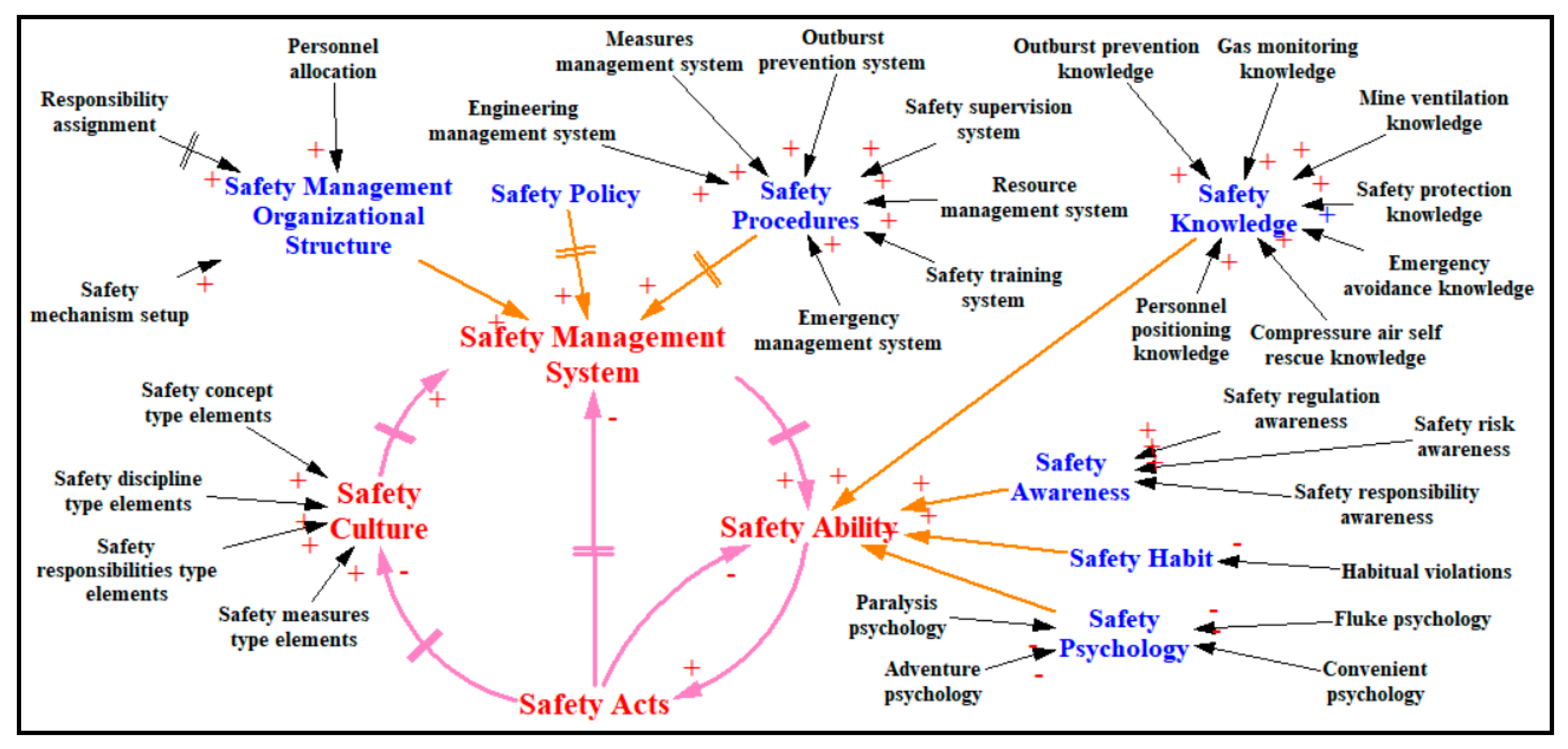

3. System Dynamics Model for Unsafe Acts

3.1. System Dynamics Model

3.2. System Dynamics Modeling

3.3. Construction of the Simulation Equation

- Initial time = 0, end time = 24, time step = 0.25, unit: month.

- 3.

- 4.

- 5.

- 6.

- 7.

- 8.

- 9.

- 10.

- 11.

- 12.

- 13.

- 14.

3.4. Initializing the Parameter Settings

- Parameter initial value setting

- The auxiliary Variable (AV) ranges from 0 to 100 and represents the ability of safety construction.

- The horizontal Variable (HV) ranges from 0% to 100% and represents the ratio of the safety value of the current factor to the maximum value.

- Weight coefficient setting

- Safety culture layer. a1:a2:a3:a4 = 2:6:7:7 = 0.09:0.27:0.32:0.32.

- Safety management system layer. b1:b2:b3 = 21:77:44 = 0.15:0.54:0.31; c1:c2:c3:c4:c5:c6:c7= 0.08:0.08:0.21:0.17:0.12:0.17:0.17; d1:d2:d3 = 0.2:0.5:0.3.

- Safety ability layer. h1:h2:h3:h4 = 0.5:0.1:0.2:0.2; e1:e2:e3:e4:e5:e6:e7 = 0.7896:0.0861:0.0615:0.0232:0.0137:0.0178:0.0082; f1:f2:f3 = 0.6066:0.2049:0.1885; g1:g2:g3:g4 = 0.4085:0.2022:0.2336:0.1557.

4. Simulation Results and Analysis

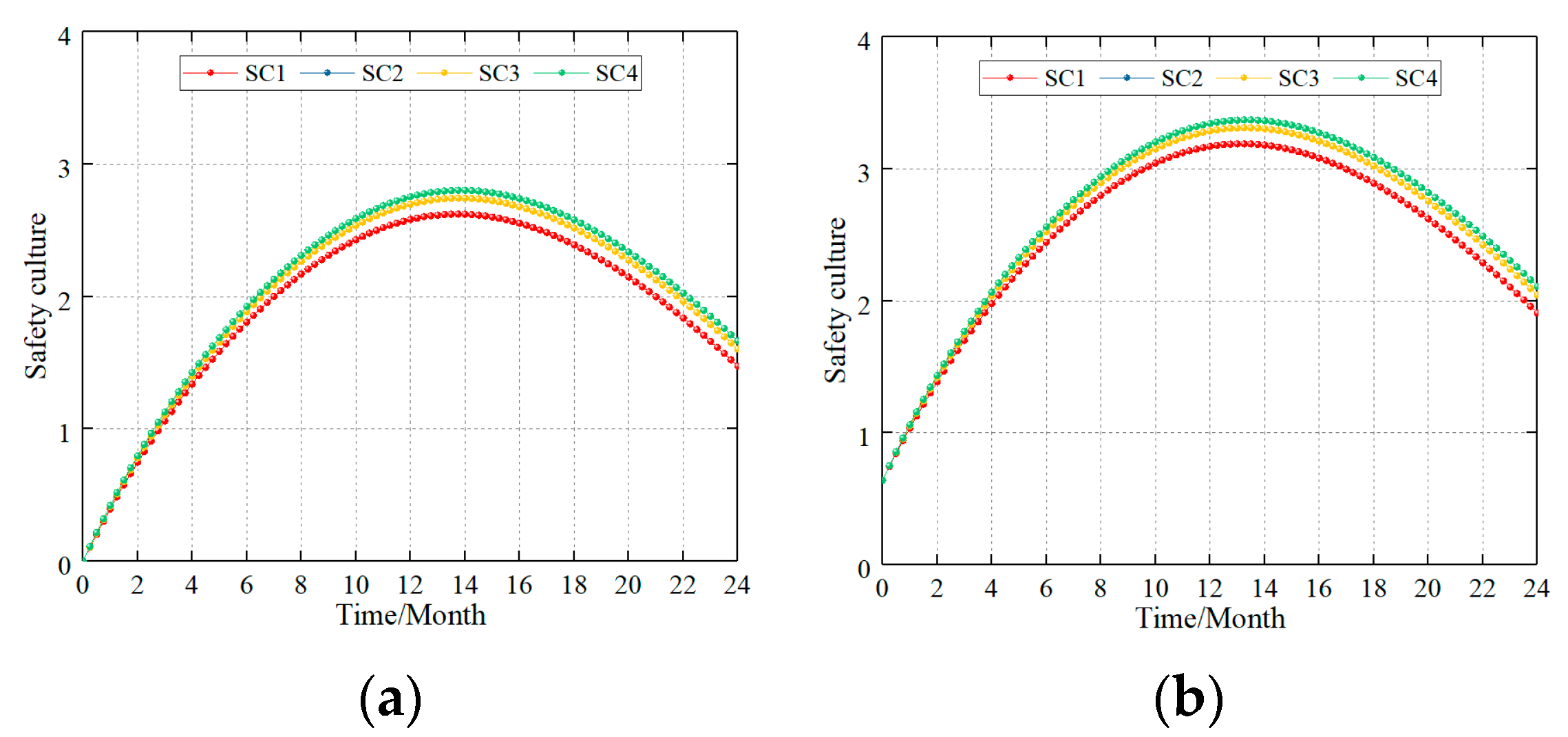

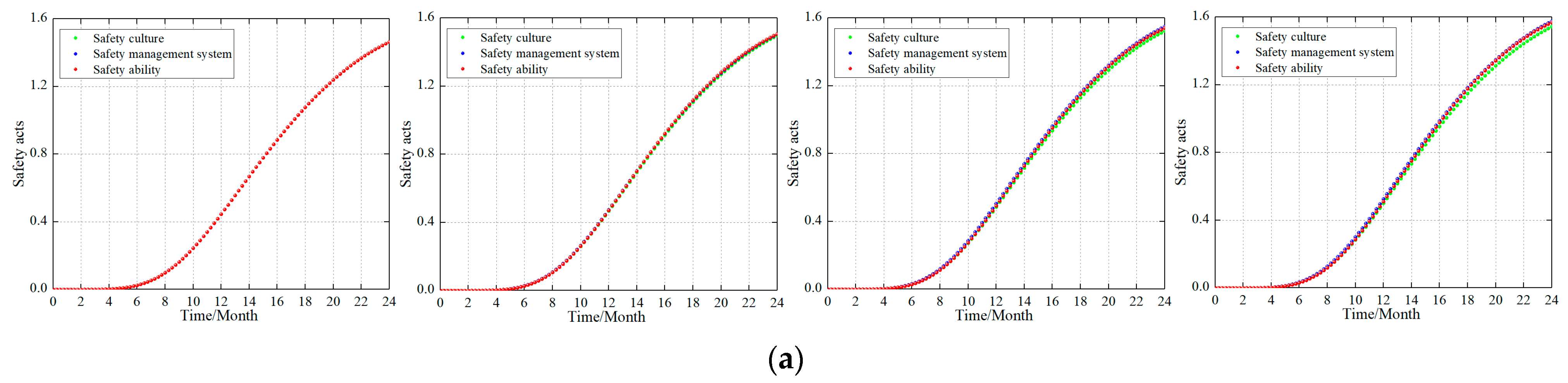

4.1. Simulation Results for the New Coalmine

4.2. Simulation Results for the Production Coalmine

4.2.1. Simulation Laws for Different Safety Factors

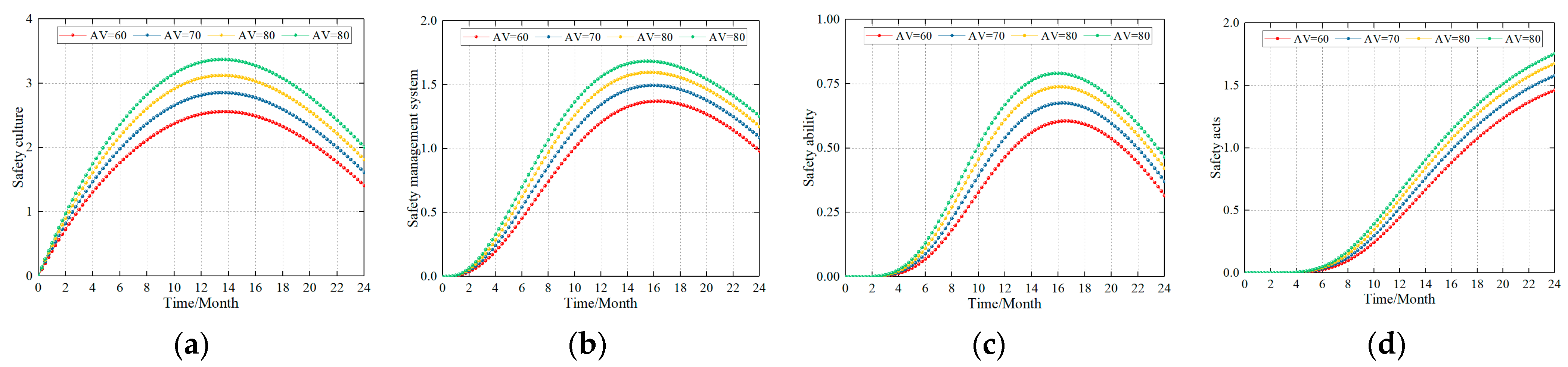

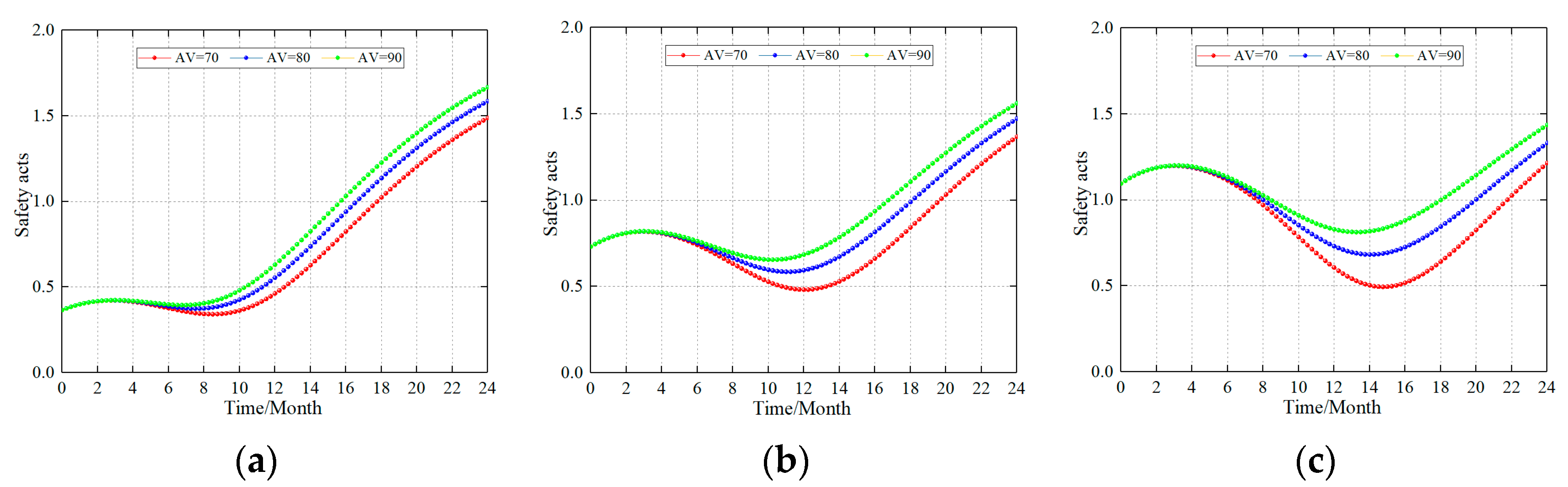

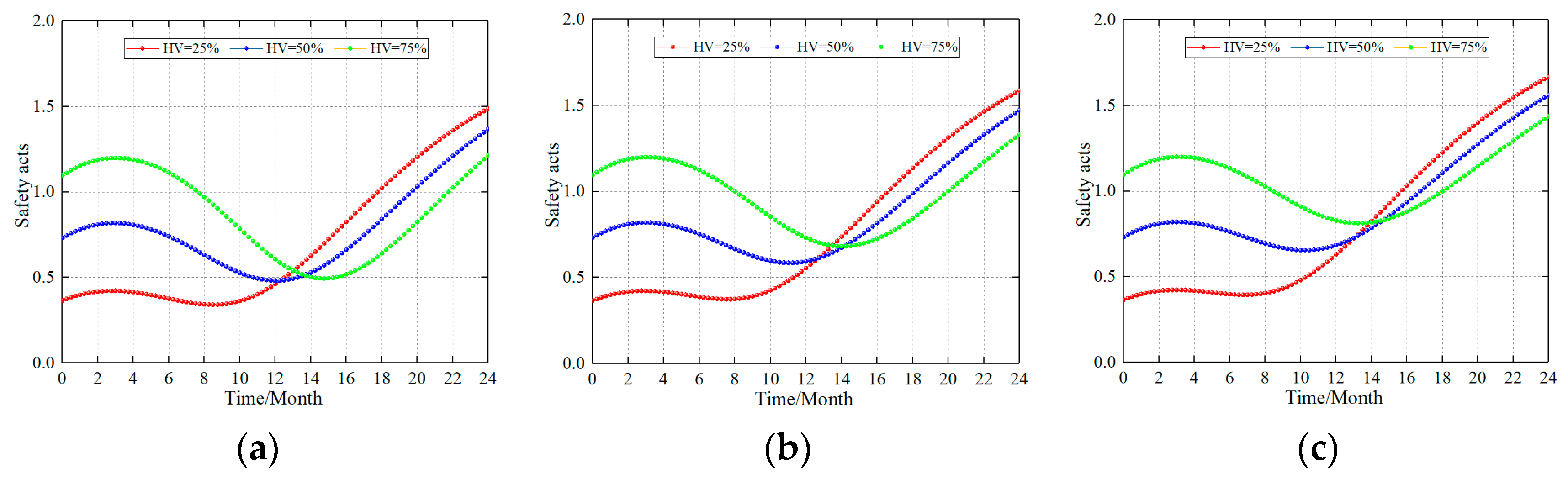

4.2.2. Impact on the Safety Acts with Different Safety Building Ability at the Same Safety Level

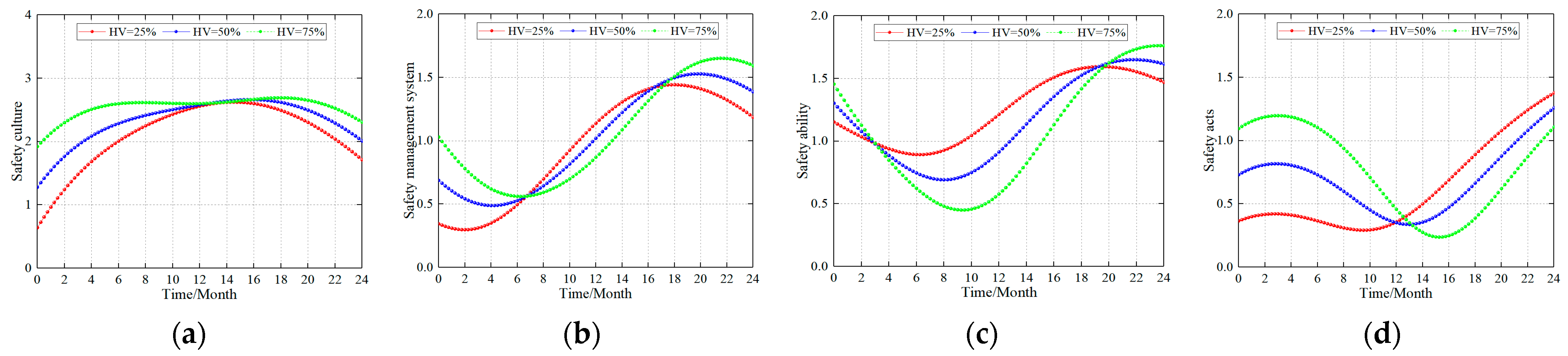

4.2.3. Impact on the Safety Acts of Different Safety Levels and the Same Safety Building Ability

4.3. Simulation Results at the Single Accident Cause Level

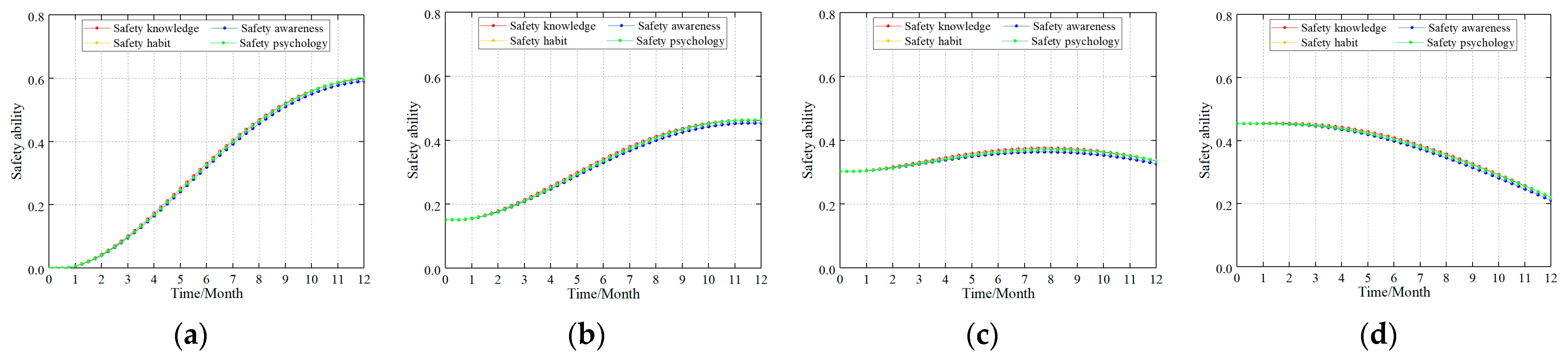

4.3.1. Influence of the Safety Culture on the Safety Acts

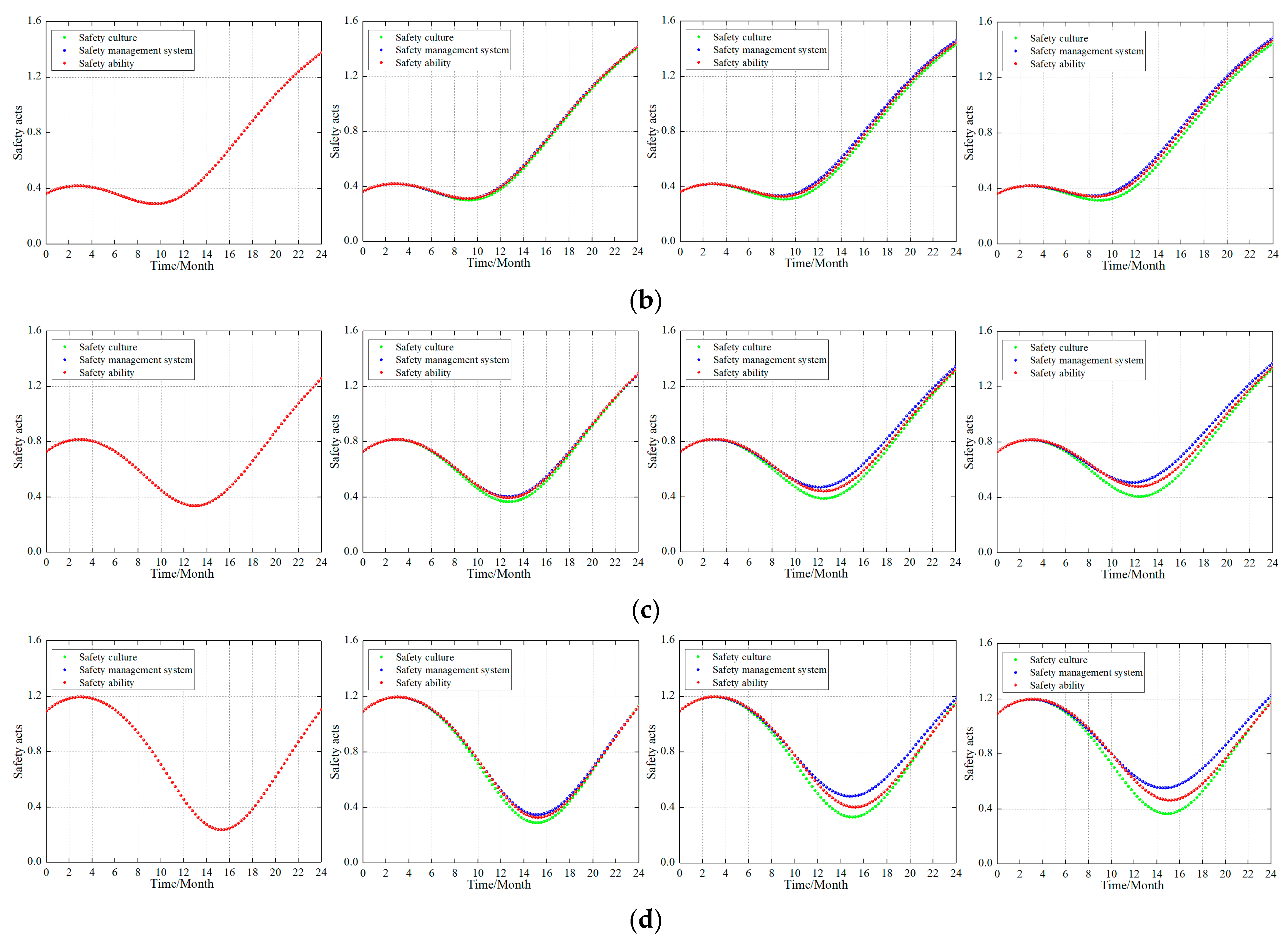

4.3.2. Influence of the Safety Management System on the Safety Acts

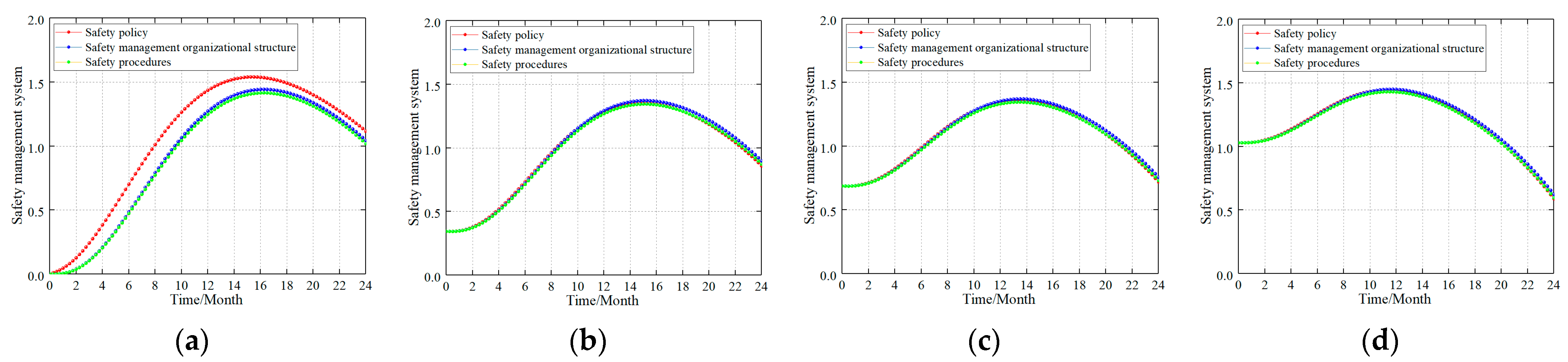

4.3.3. Influence of the Safety Ability on the Safety Acts

4.4. Simulation Results for Different Accident Cause Levels

4.5. Simulation Results for the Influence of Different Factors within the Accident Cause Hierarchy

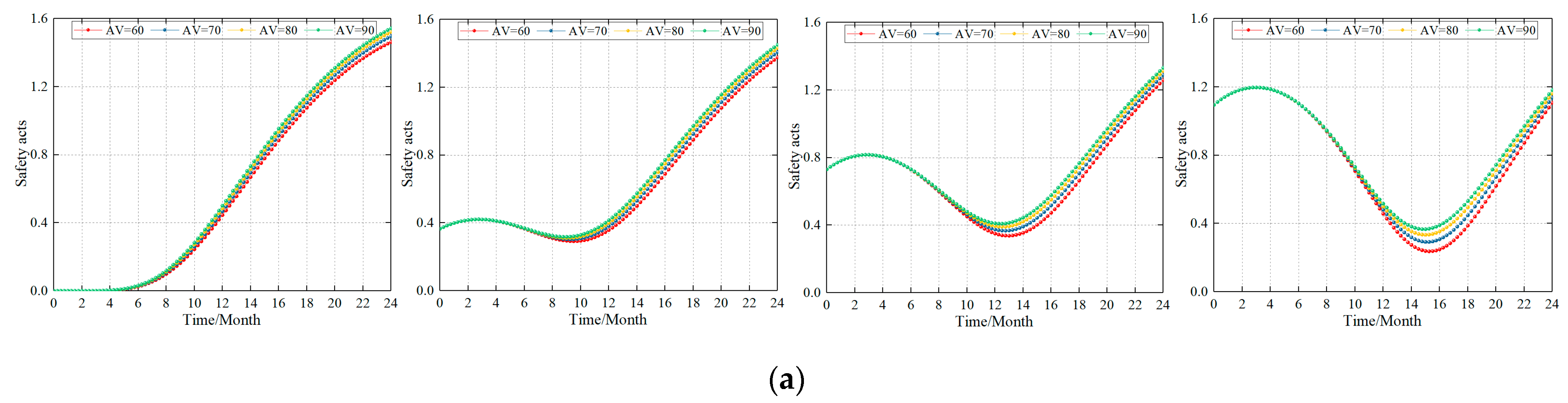

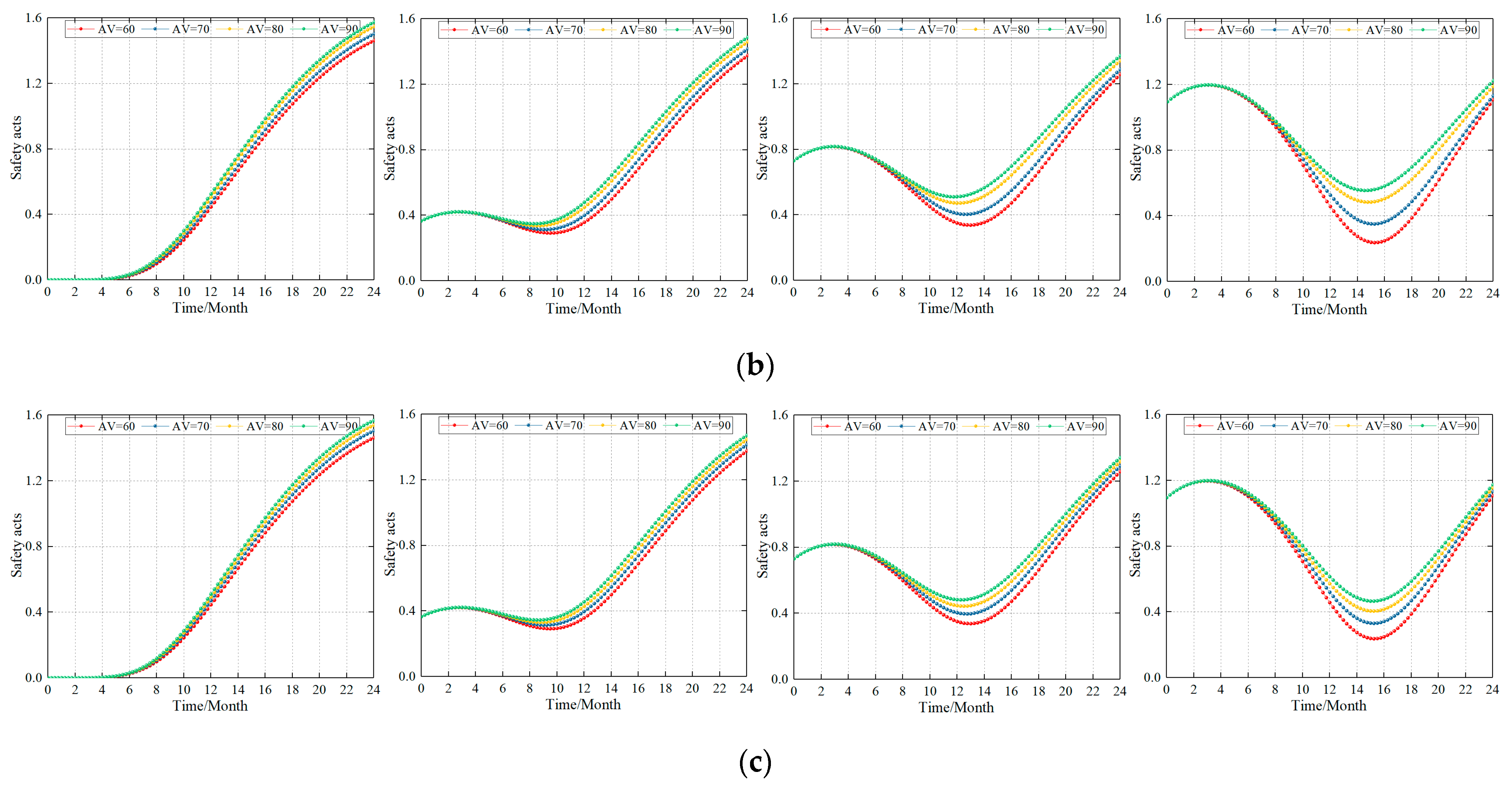

4.5.1. Safety Culture Layer

- (1)

- When HV = 0% (new coalmine), the safety construction ability of four types of elements was adjusted from AV = 60 to AV = 80, where the simulation results for the safety culture level are shown in Figure 9a.

- (2)

- When HV = 25% (production coalmine), the safety construction ability of the four types of elements was respectively adjusted from AV = 60 to AV = 80. The simulation results for the safety culture level are shown in Figure 9b.

4.5.2. Safety Management System Layer

4.5.3. Safety Ability Layer

5. Thoughts on Behavior Mechanism and Safety Control

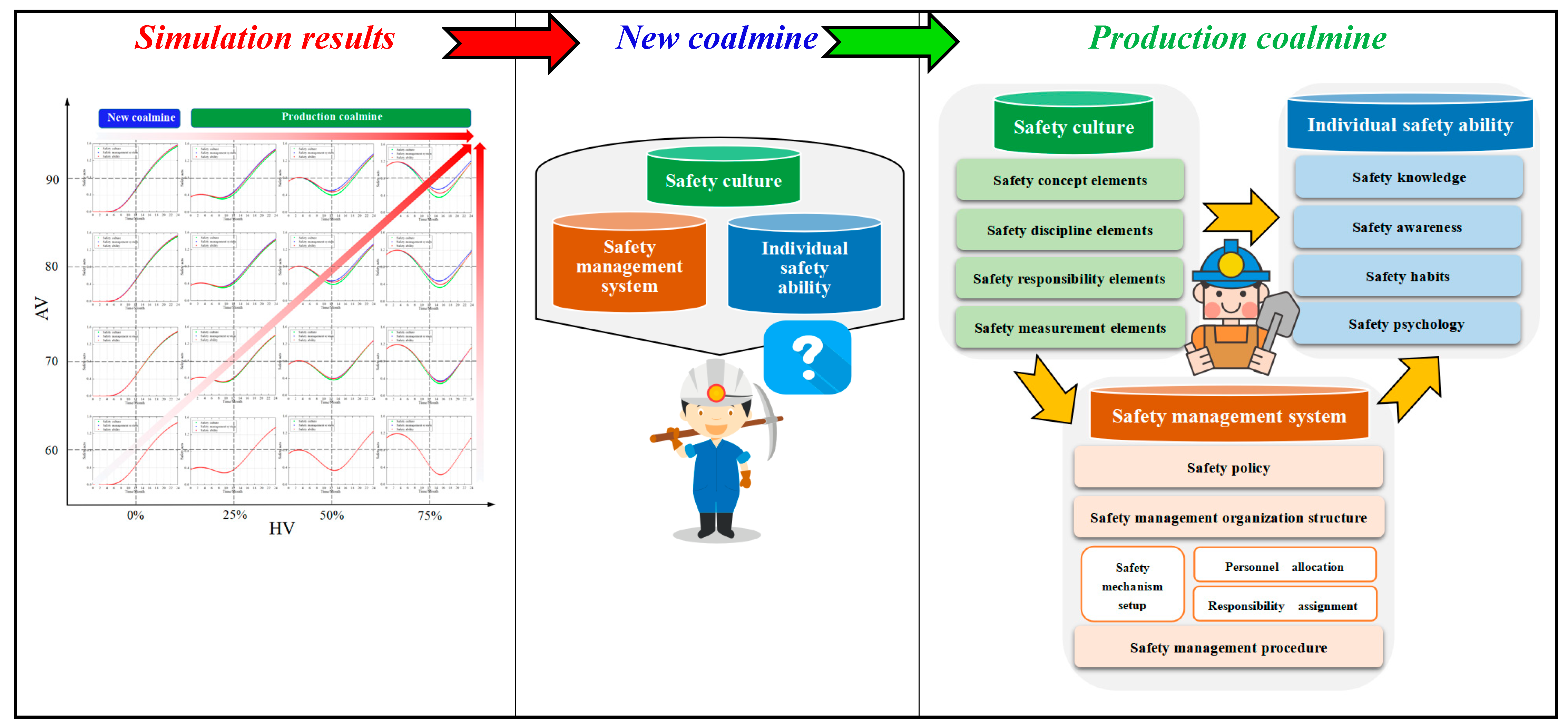

5.1. Enterprise Safety System

5.1.1. Current Enterprise Safety System

- New coalmine. The impact of safety culture, safety management system, and individual safety ability all have a consistent impact on unsafe acts.

- Production coalmine. The order of influence on unsafe acts is safety management system > safety ability > safety culture. The greater the level of coalmine safety or safety construction ability, the more obvious this shortcoming.

5.1.2. Unsafe Acts Occurrence Mechanism in Enterprise Safety System

- New coalmine. The enterprise safety construction has just begun, and a mature and stable safety system has not yet been formed. At this time, the corporate safety culture has not been formed. In the safety management system, responsibility assignments are unclear, personnel allocation is uneven, and safety management procedures are missing. These reasons result in insufficient individual safety knowledge, weak safety awareness, failure to develop safety habits, and failure to form safety psychology. On the whole, in the new coalmine safety system, the content of the safety culture and safety management system is only a form of a signal transmitted to employees, so there is no difference in their impact on unsafe acts. At this time, the unsound safety system causes the individual’s safety ability to be weak, resulting in the individual failing to form stable safety acts.

- Production coalmine. In modern enterprise safety management, a healthy enterprise pays attention to a sound safety management system and a programmed safety management process. At the same time, the operation of the safety management system directly affects the formation of individual safety abilities. Therefore, the control effect of the mandatory and binding force of the safety management system on unsafe acts will be very obvious. At the same time, employees already have certain safety abilities and are familiar with the operation of the safety management system. The level of individual safety ability will directly affect the occurrence of unsafe acts. As a safety concept, safety culture does not have the coercive and binding force of safety management, and the control over unsafe acts will become very weak at this time.

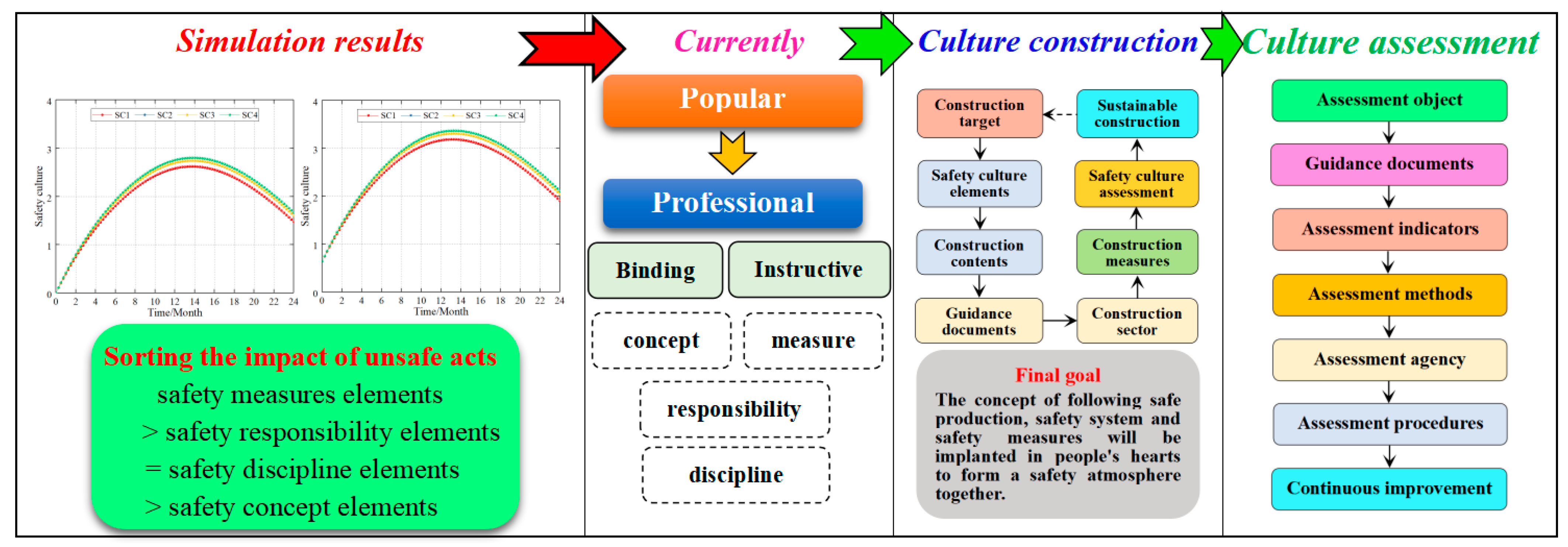

5.2. Safety Culture

5.2.1. Current Safety Culture

- The constraining force of safety culture. Based on the simulation data, the ranking of the influence of safety culture elements on unsafe acts is as follows: safety measures elements > safety responsibility elements = safety discipline elements > safety concept elements. This shows that elements such as safety measures, safety responsibilities, safety disciplines, etc., are more binding for unsafe acts. This paper suggests that in the construction of safety culture, on the basis of the propaganda of safety concepts, the elements of safety culture should be diversified and specific, and the construction of elements of safety measures, safety responsibilities, and safety discipline should be strengthened. In this way, the safety culture is combined with the construction of the safety management system, which increases the binding force of the safety culture.

- Safety culture guidance. Currently, China’s construction of safety culture is a popular science culture and lacks professional guidance. This paper suggests that in the construction of safety culture, in addition to distinguishing safety culture into safety concept elements, safety discipline elements, safety responsibility elements, and safety measure elements, it should also be differentiated and refined according to different departments, workshops, and positions. The enterprise-level safety culture focuses on the publicity of safety concepts, the department-level safety culture should emphasize responsibility and discipline, and the post-level safety culture should emphasize safety measures and safety responsibilities. The combination of safety culture with job responsibilities makes the control of unsafe acts more informative and constraining.

5.2.2. Safety Culture Construction

5.2.3. Safety Culture Assessment

- Lacking guiding documents for safety culture assessment. China’s safety culture assessment refers to the “Assessment standards of enterprise safety culture developing” (AQ/T 9005-2008), but it has not been perfected for 15 years and lacks practicality. At present, there is no general guidance document for safety culture assessment in the world.

- Lacking guiding assessment indicators. The scope of safety culture assessment is relatively wide and involves many industries. However, there is still no unified guiding safety culture assessment index in the world. Each assessment agency sets its own assessment indicators and weights, so the assessment results lack uniformity and accuracy.

- This paper believes that safety culture assessment can be divided into two categories: safety culture software assessment and safety culture hardware assessment.

- Safety culture software assessment, which is mainly an assessment of employees’ understanding and recognition of safety culture construction contents, that is, whether employees can put the safety culture construction contents into their minds, which can be achieved by answering questions and systematic questionnaires. In this regard, Fu Gui designed a safety culture assessment question bank based on the safety culture element table (cf. Table 1) and developed a safety culture analysis program [43], which can be referred to for safety culture assessment.

- Safety culture hardware assessment, which mainly evaluates whether the organizational structure of safety culture construction is complete, whether the construction measures are appropriate, and whether the safety culture carrier is effective. This evaluation is more complicated.

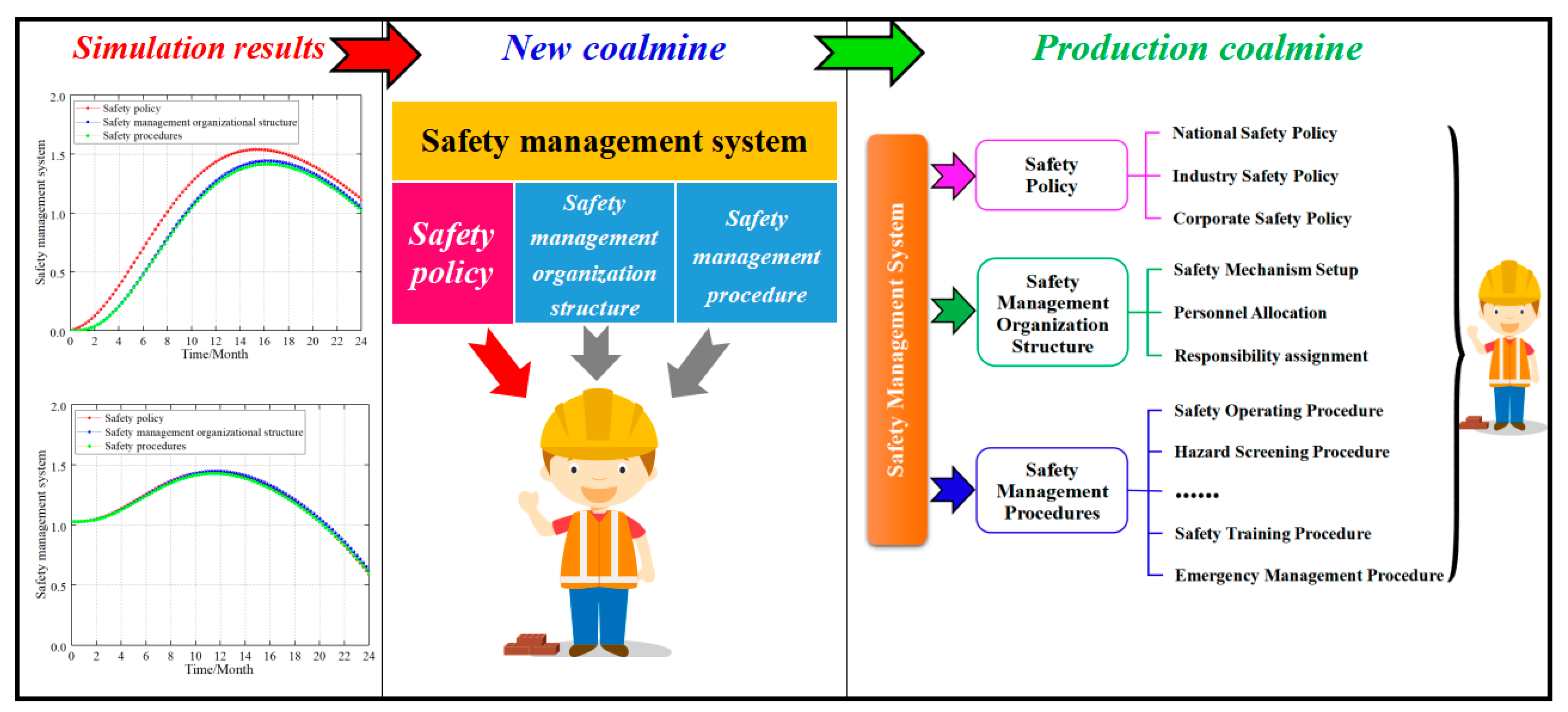

5.3. Safety Management System

- Some companies do not follow the national and corporate safety policy, which is illegal production.

- In the organizational structure of safety management, the mechanism setup is not perfect, the responsibility assignment is not clear, and the personnel allocation is insufficient (especially technical personnel and department heads).

- The enterprise safety management program is missing or not running smoothly.

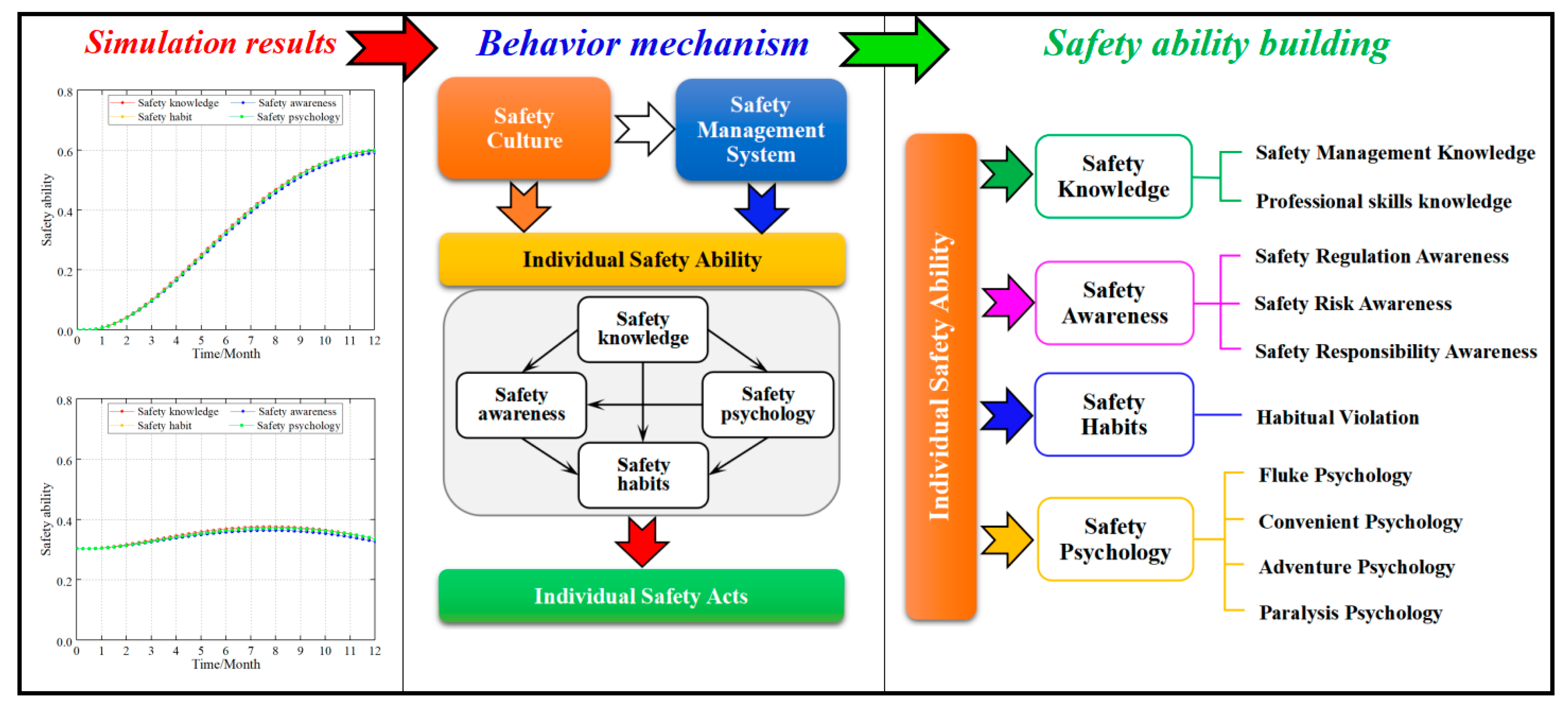

5.4. Individual Safety Ability

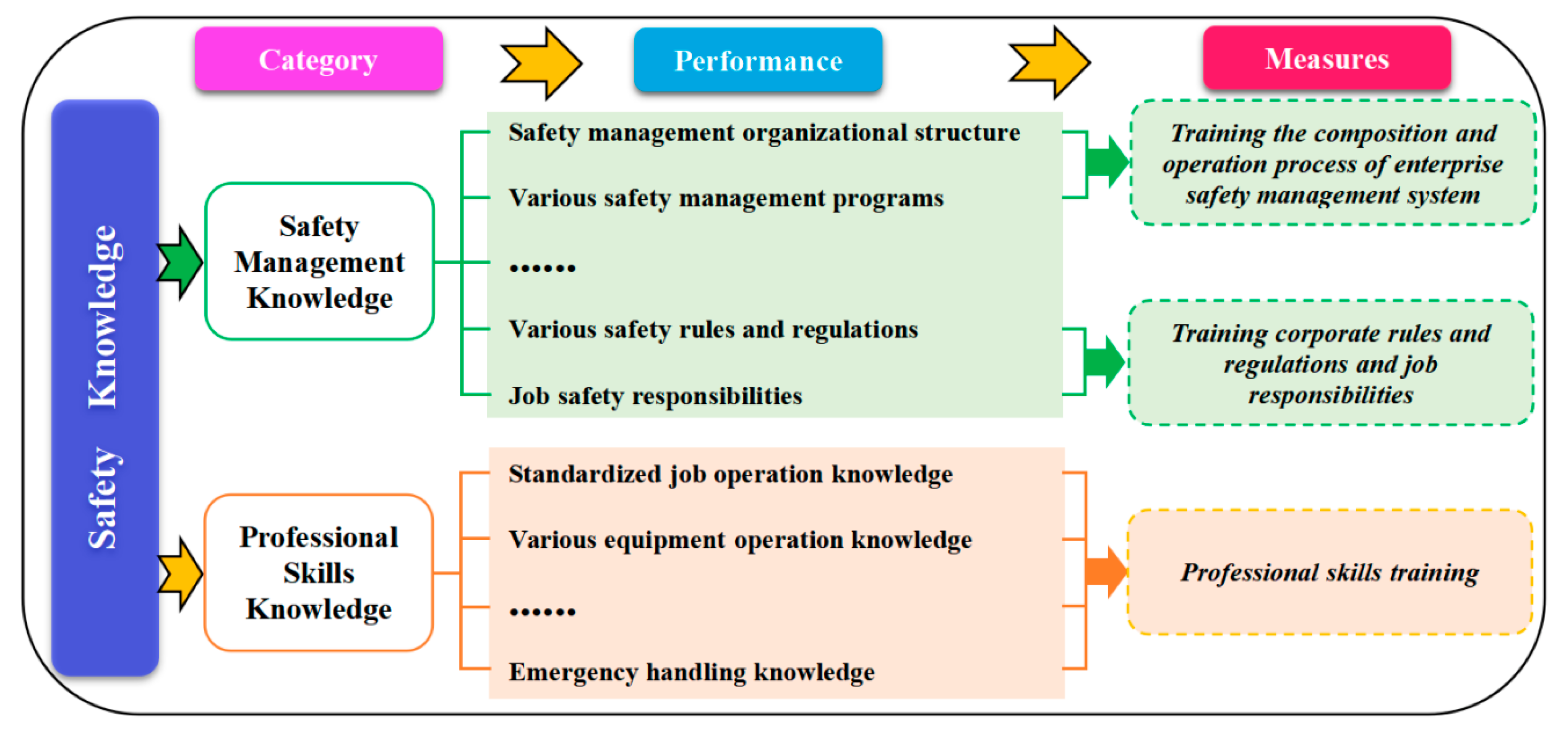

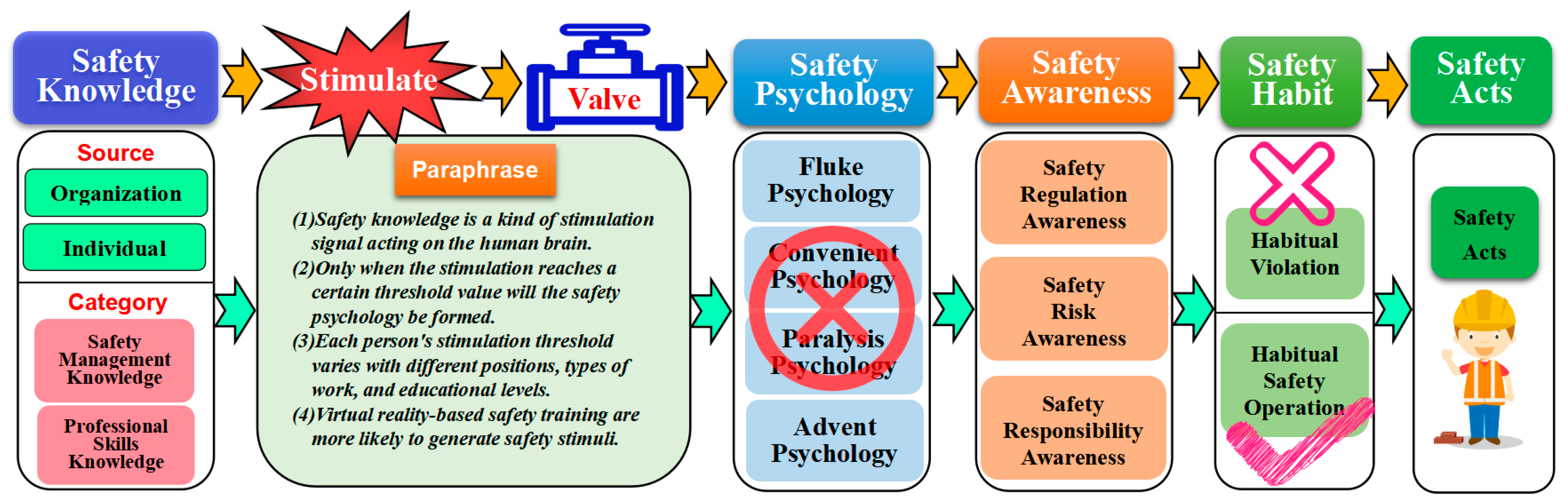

5.4.1. Safety Knowledge

- Safety management knowledge is mainly the knowledge of enterprise safety systems, including safety culture knowledge, safety management organizational structure knowledge, safety procedures knowledge, safety management responsibility system knowledge, etc.

- Professional skills knowledge is mainly the knowledge of professional skills in safety operations, including standardized job operation knowledge, professional equipment operation knowledge, emergency response knowledge, etc.

- Safety knowledge should be comprehensive. The enterprise’s safety department should systematically sort out the reasons for accidents and compile an accident reasons database. At the same time, it is necessary to combine knowledge of safety procedures and policies. This allows employees to gain comprehensive knowledge of safety management and professional skills.

- For safety management knowledge training, it is encouraged to adopt logical and clear methods such as flowcharts, which can make it easier for employees to understand the operating mode of the company’s safety management system.

- For professional skills knowledge training, it is necessary to clarify specific terms, operation methods, operation procedures, etc., so as to accurately master professional skills.

- This paper proposes that in safety knowledge training, different categories of employees should conduct safety training based on their work priorities. Senior leadership should focus on training national and industrial safety policies, safety management decisions, and so on. Middle management should focus on cultivating industry standards, norms and actions, etc. Frontline staff should focus on cultivating standardized post-operations skills, equipment operations skills, and emergency response skills.

- Conventional methods of safety training (such as lectures) rely primarily on rapid knowledge transfer. It has a relatively boring and monotonous classroom format and lacks flexibility and activity. Consequently, the adoption of new modes of instruction such as video instruction, VR experience instruction, and on-site instruction will be closer to reality, and the safety training effect will be better.

- Paying attention to assessing the effect of employee education. Employees will find it easier to accept a more visual, modular, and convenient assessment model than traditional assessment methods.

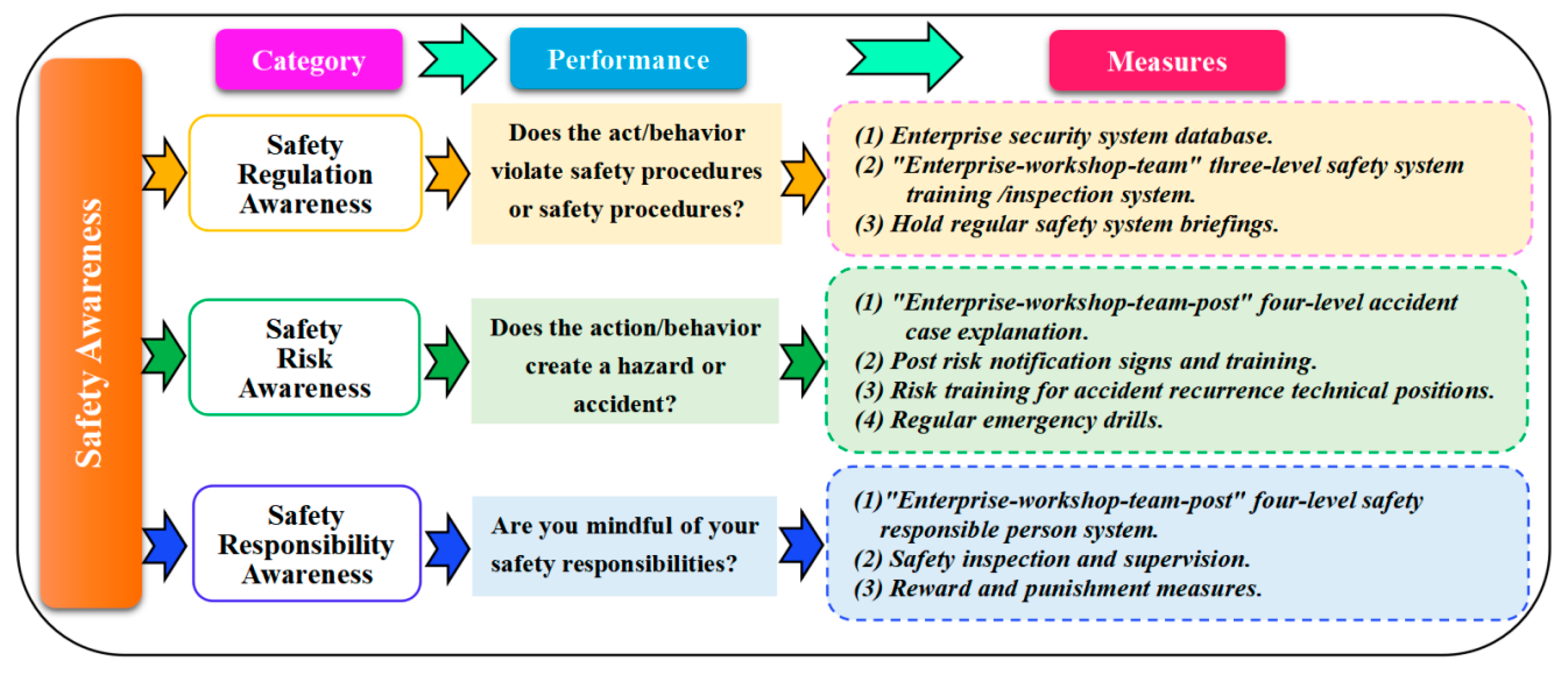

5.4.2. Safety Awareness

- Safety regulation awareness: whether employees are aware of whether their behavior violates safety standards, safety regulations, safety procedures, etc.

- Safety risk awareness: whether employees are aware that their acts will lead to risks or accidents.

- Safety responsibility awareness: whether employees are aware that their behavior violates their job responsibilities, that is, whether they have implemented a safety responsibility system.

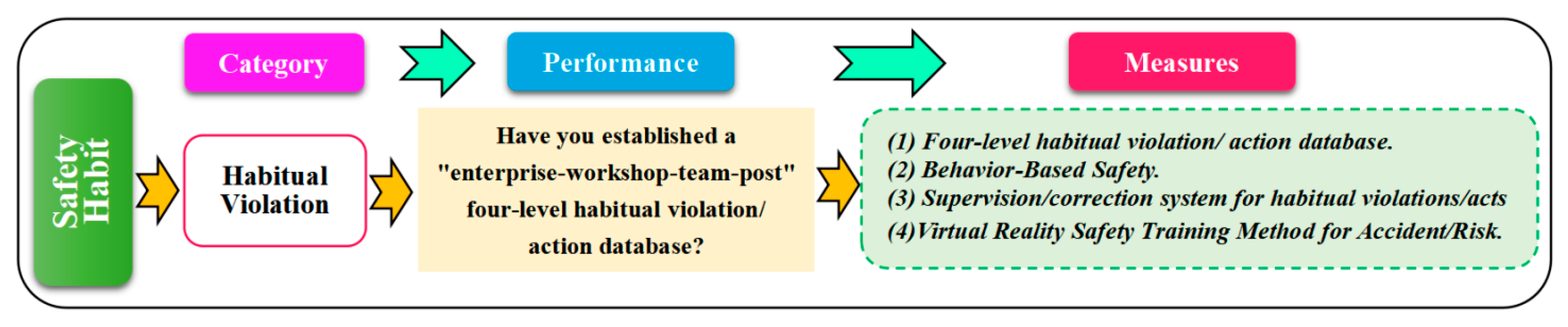

5.4.3. Safety Habit

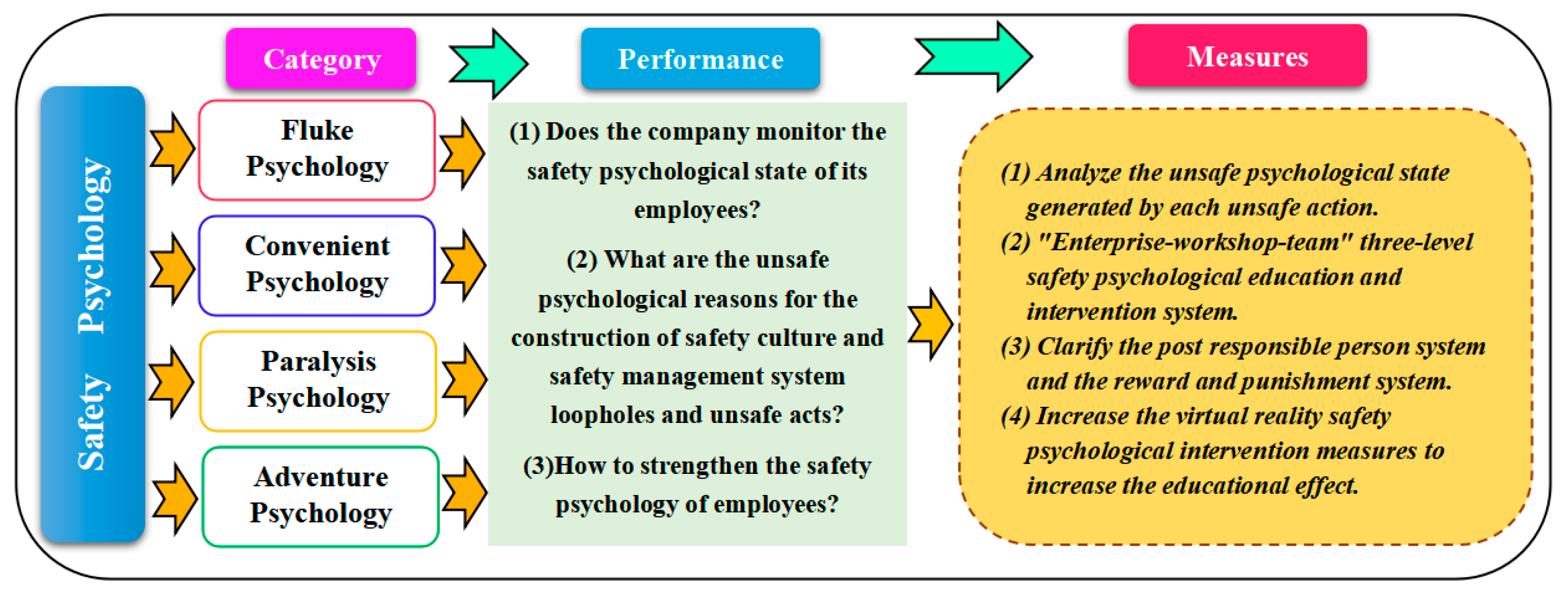

5.4.4. Safety Psychology

5.4.5. Influence Mechanism of Individual Safety Ability on Unsafe Acts

6. Conclusions

- For new coalmines and low safety level production coalmines, this study proposes building an enterprise safety culture, safety management system, and individual safety ability according to the maximum safety ability of the enterprise. For an enterprise with a high level of safety, this study proposes certain optimizations and adjustments of the safety construction measures to be performed. However, it is not recommended to perform large-scale safety construction to avoid disrupting the high-quality safety management methods that employees are accustomed to, which reduces the safety level.

- In new coalmines, the influence of the safety culture, safety management system, and safety ability on the safety acts was similar. In production coalmines, the order of influence on the safety acts was as follows: safety management system > safety ability > safety culture. The difference is most evident in months ten to eighteen. The greater the level of safety and the safety construction standard of the enterprise, the greater the difference.

- In the construction of safety culture, the order of influence was as follows: safety measure elements > safety responsibility elements = safety discipline elements > safety concept elements. From the sixth month, it shows the difference in influence and reaches the maximum value from the twelfth to the fourteenth month. In the construction of the safety management system, the degree of influence in new coalmines was as follows: safety policy > safety management organization structure > safety management procedures. Among them, especially in the first 18 months, the impact of the safety policy is most apparent. However, in the production mine, the degree of influence was as follows: safety management organization structure > safety management procedures > safety policy, but the difference is very weak. In the construction of safety ability, the degree of influence was as follows: safety knowledge > safety psychology = safety habits > safety awareness, but the difference in the impact was small.

- Based on the simulation results and the actual safety management, this paper analyzes the occurrence mechanism of unsafe acts. At the same time, this paper simultaneously sets out the measures and methods of safety culture construction and evaluation, safety management system construction, and safety ability construction so as to control the occurrence of unsafe acts. Based on the mechanism of unsafe acts, the control of unsafe acts should be implemented jointly from the safety culture, safety management system, and safety ability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fu, G.; Xie, X.; Jia, Q.; Li, Z.; Chen, P.; Ge, Y. The development history of accident causation models in the past 100 years: 24Model, a more modern accident causation model. Process Saf. Environ. Prot. 2022, 134, 47–82. [Google Scholar] [CrossRef]

- Ge, J.; Zhang, Y.; Xu, K.; Li, J.; Yao, X.; Wu, C.; Li, S.; Yan, F.; Zhang, J.; Xu, Q. A new accident causation theory based on systems thinking and its systemic accident analysis method of work systems. Process Saf. Environ. Prot. 2022, 158, 644–660. [Google Scholar] [CrossRef]

- Fu, G.; Xie, X.; Jia, Q.; Tong, W.; Ge, Y. Accidents analysis and prevention of coal and gas outburst: Understanding human errors in accidents. Process Saf. Environ. Prot. 2020, 134, 1–23. [Google Scholar] [CrossRef]

- Wrobel, K. Searching for the origins of the myth: 80% human error impact on maritime safety. Reliab. Eng. Syst. Saf. 2021, 216, 107942. [Google Scholar] [CrossRef]

- Xu, R.; Luo, F. Research on simulation of risk control strategy for air traffic controllers’ unsafe acts. Saf. Sci. 2022, 151, 105728. [Google Scholar] [CrossRef]

- Shen, Y.; Ju, C.; Koh, T.Y.; Rowlinson, S.; Bridge, A.J. The Impact of Transformational Leadership on Safety Climate and Individual Safety Behavior on Construction Sites. Int. J. Environ. Res. Public Health 2017, 14, 45. [Google Scholar] [CrossRef]

- Xie, X.; Shen, S.; Fu, G.; Shu, X.; Hu, J.; Jia, Q.; Shi, Z. Accident case data-accident cause model hybrid-driven coal and gas outburst accident analysis: Evidence from 84 accidents in China during 2008–2018. Process Saf. Environ. Prot. 2022, 164, 67–90. [Google Scholar]

- Baldissone, G.; Comberti, L.; Bosca, S.; Murè, S. The analysis and management of unsafe acts and unsafe conditions. Data Collect. Analysis. Saf. Sci. 2019, 119, 240–251. [Google Scholar]

- Choi, S.Y.; Park, J.; Kim, Y.; Kim, S.; Jung, W. A study for unsafe acts classification under crew interact during procedure-driven operation. Ann. Nucl. Energy 2016, 96, 187–196. [Google Scholar] [CrossRef]

- Niu, Y.; Li, Z.; Fan, Y. Analysis of truck drivers’ unsafe driving behaviours using four machine learning methods. Int. J. Ind. Ergon. 2021, 86, 103192. [Google Scholar] [CrossRef]

- Wang, J.; Yan, M. Application of an Improved Model for Accident Analysis: A Case Study. Int. J. Environ. Res. Public Health 2019, 16, 2756. [Google Scholar] [CrossRef]

- Xuecai, X.; Xueming, S.; Gui, F.; Shifei, S.; Qingsong, J.; Jun, H.; Zhirong, W. Accident causes data-driven coal and gas outburst accidents prevention: Application of data mining and machine learning in accident path mining and accident case-based deduction. Process Saf. Environ. Prot. 2022, 162, 891–913. [Google Scholar] [CrossRef]

- Tong, R.; Wang, X.; Wang, L.; Hu, X. A dual perspective on work stress and its effect on unsafe behaviors: The mediating role of fatigue and the moderating role of safety climate. Process Saf. Environ. Prot. 2022, 165, 929–940. [Google Scholar] [CrossRef]

- Tong, R.; Yang, X.; Parker, T.; Zhang, B.; Wang, Q. Exploration of relationships between safety performance and unsafe behavior in the Chinese oil industry. J. Loss Prev. Process Ind. 2020, 66, 104167. [Google Scholar] [CrossRef]

- Shakerian, M.; Jahangiri, M.; Alimohammadlou, M. Individual cognitive factors affecting unsafe acts among Iranian industrial workers: An integrative meta-synthesis interpretive structural modeling (ISM) approach. Saf. Sci. 2019, 120, 89–98. [Google Scholar] [CrossRef]

- Xie, X.; Guo, D. Human factors risk assessment and management: Process safety in engineering. Process Saf. Environ. Prot. 2018, 113, 467–482. [Google Scholar] [CrossRef]

- Ouache, R.; Bakhtavar, E.; Hu, G. Evidential reasoning and machine learning-based framework for assessment and prediction of human error factors-induced fire incidents. J. Build. Eng. 2022, 49, 104000. [Google Scholar] [CrossRef]

- Tong, R.; Li, H.; Zhang, B.; Yang, X.; Ma, X. Modeling of unsafe behavior risk assessment: A case study of Chinese furniture manufacturers. Saf. Sci. 2021, 136, 105157. [Google Scholar] [CrossRef]

- Comu, S.; Kazar, G.; Marwa, Z. Evaluating the attitudes of different trainee groups towards eye tracking enhanced safety training methods. Adv. Eng. Inform. 2022, 49, 101353. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C.; Kang, L.; Reniers, G.; Huang, L. Work safety in China’s Thirteenth Five-Year plan period (2016–2020): Current status, new challenges and future tasks. Saf. Sci. 2018, 104, 164–178. [Google Scholar] [CrossRef]

- Fang, W.; Love, P.E.; Luo, H.; Ding, L. Computer vision for behaviour-based safety in construction: A review and future directions. Adv. Eng. Inform. 2020, 43, 100980. [Google Scholar] [CrossRef]

- Bjelland, H.; Njå, O. A Nordic approach to fire safety engineering—Will standardization of probabilistic methods to verify fire safety designs of novel buildings improve engineering practices? Saf. Sci. 2022, 148, 105651. [Google Scholar] [CrossRef]

- Parsi, S.S.; Lal, K.M.; Kosbab, B.D.; Ingersoll, E.D.; Shirvan, K.; Whittaker, A.S. Seismic isolation: A pathway to standardized advanced nuclear reactors. Nucl. Eng. Des. 2022, 387, 111445. [Google Scholar] [CrossRef]

- Fu, G.; Zhao, Z.; Hao, C.; Wu, Q. The Accident Path of coalmine Gas Explosion Based on 24 Model: A Case Study of the Ruizhiyuan Gas Explosion Accident. Processes 2019, 7, 73. [Google Scholar] [CrossRef]

- Zareharofteh, F.; Hidarnia, A.; Morowatisharifabad, M.A. Unsafe behaviours in Iranian adult pedestrians. J. Transp. Health 2021, 21, 101058. [Google Scholar] [CrossRef]

- Cao, Q.; Yu, K.; Zhou, L.; Wang, L.; Li, C. In-depth research on qualitative simulation of coalminers’ group safety behaviors. Saf. Sci. 2019, 113, 210–232. [Google Scholar] [CrossRef]

- Thakur, S.; Ranjitkar, P.; Rashidi, S. Investigating evacuation behaviour under an imminent threat of volcanic eruption using a logistic regression-based approach. Saf. Sci. 2022, 149, 105688. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Y. Big data in safety management: An overview. Saf. Sci. 2021, 143, 105414. [Google Scholar] [CrossRef]

- Johnson, B. Metacognition for artificial intelligence system safety—An approach to safe and desired behavior. Saf. Sci. 2022, 151, 105743. [Google Scholar] [CrossRef]

- Zhu, C.; Qi, M.; Jiang, J. Quantifying human error probability in independent protection layers for a batch reactor system using dynamic simulations. Process Saf. Environ. Prot. 2020, 133, 243–258. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, L.; Hu, J. An integrated method of human error likelihood assessment for shale-gas fracturing operations based on SPA and UAHP. Process Saf. Environ. Prot. 2019, 123, 105–115. [Google Scholar] [CrossRef]

- Zarei, E.; Khan, F.; Abbassi, R. Importance of human reliability in process operation: A critical analysis. Reliab. Eng. Syst. Saf. 2021, 211, 107607. [Google Scholar] [CrossRef]

- Islam, R.; Khan, F.; Abbassi, R.; Garaniya, V. Human error assessment during maintenance operations of marine systems—What are the effective environmental factors? Saf. Sci. 2018, 107, 85–98. [Google Scholar] [CrossRef]

- Golestani, N.; Abbassi, R.; Garaniya, V.; Asadnia, M.; Khan, F. Human reliability assessment for complex physical operations in harsh operating conditions. Process Saf. Environ. Prot. 2020, 140, 1–13. [Google Scholar] [CrossRef]

- McLeod, R.W. Human factors in barrier management: Hard truths and challenges. Process Saf. Environ. Prot. 2017, 110, 31–42. [Google Scholar] [CrossRef]

- Stanton, N.A.; Harvey, C.; Allison, C.K. Systems Theoretic Accident Model and Process (STAMP) applied to a Royal Navy Hawk jet missile simulation exercise. Saf. Sci. 2019, 113, 461–471. [Google Scholar] [CrossRef]

- Yousefi, A.; Rodriguez Hernandez, M.; Lopez Peña, V. Systemic Accident Analysis Models: A Comparison Study between AcciMap, FRAM, and STAMP. Process Saf. Prog. 2018, 38, e12002. [Google Scholar] [CrossRef]

- Huang, W.; Shuai, B.; Zuo, B.; Xu, Y.; Antwi, E. A systematic railway dangerous goods transportation system risk analysis approach: The 24 Model. J. Loss Prev. Process Ind. 2019, 61, 94–103. [Google Scholar] [CrossRef]

- Leveson, N.; Daouk, M.; Dulac, N.; Marais, K. Applying Stamp in Accident Analysis; Massachusetts Institute of Technology, Engineering Systems Division: Cambridge, MA, USA, 2003. [Google Scholar]

- Xu, R.; Luo, F.; Chen, G.; Zhou, F.; Abdulahi, E.W. Application of HFACS and grounded theory for identifying risk factors of air traffic controllers’ unsafe acts. Int. J. Ind. Ergon. 2021, 86, 103228. [Google Scholar] [CrossRef]

- Grant, E.; Salmon, P.M.; Stevens, N.J.; Goode, N.; Read, G.J. Back to the future: What do accident causation models tell us about accident prediction? Saf. Sci. 2018, 104, 99–109. [Google Scholar] [CrossRef]

- Man, S.S.; Chan, A.H.; Alabdulkarim, S.; Zhang, T. The effect of personal and organizational factors on the risk-taking behavior of Hong Kong construction workers. Saf. Sci. 2021, 136, 105155. [Google Scholar] [CrossRef]

- Jiang, W.; Fu, G.; Liang, C.Y.; Han, W. Study on quantitative measurement result of safety culture. Saf. Sci. 2020, 128, 104751. [Google Scholar] [CrossRef]

- Pilanawithana, N.M.; Feng, Y.; London, K.; Zhang, P. Developing resilience for safety management systems in building repair and maintenance: A conceptual model. Saf. Sci. 2022, 152, 105768. [Google Scholar] [CrossRef]

- Adami, P.; Rodrigues, P.B.; Woods, P.J.; Becerik-Gerber, B.; Soibelman, L.; Copur-Gencturk, Y.; Lucas, G. Effectiveness of VR-based training on improving construction workers’ knowledge, skills, and safety behavior in robotic teleoperation. Adv. Eng. Inform. 2021, 50, 101431. [Google Scholar] [CrossRef]

- Forrester, J.W. The model versus a modeling process. Syst. Dyn. Rev. 1985, 1, 133–134. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Safety Culture in Pre-Operational Phases of Nuclear Power Plant Projects. Safety Reports Series No.74. 2012. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.303.5813&rep=rep1&type=pdf (accessed on 5 March 2023).

- Zanin, L.M.; Stedefeldt, E.; Luning, P.A. The evolvement of food safety culture assessment: A mixed-methods systematic review. Trends Food Sci. Technol. 2021, 118, 125–142. [Google Scholar] [CrossRef]

- Zwetsloot, G.; van Kampen, J.; Steijn, W.; Post, S. Ranking of process safety cultures for risk-based inspections using indicative safety culture assessments. J. Loss Prev. Process Ind. 2020, 64, 104065. [Google Scholar] [CrossRef]

- Andersson, M.; Moen, O.; Brett, P.O. The organizational climate for psychological safety: Associations with SMEs’ innovation capabilities and innovation performance. J. Eng. Technol. Manag. 2020, 55, 101554. [Google Scholar] [CrossRef]

- Parker, H.; du Plooy, E. Team-based games: Catalysts for developing psychological safety, learning and performance. J. Bus. Res. 2021, 125, 45–51. [Google Scholar] [CrossRef]

- Dodoo, J.E.; Surienty, L.; Zahidah, S. Safety citizenship behaviour of miners in Ghana: The effect of hardiness personality disposition and psychological safety. Saf. Sci. 2021, 143, 105404. [Google Scholar]

- Choi, B.; Lee, S. The psychological mechanism of construction workers’ safety participation: The social identity theory perspective. J. Saf. Res. 2022, 82, 194–206. [Google Scholar] [CrossRef]

- Hu, J.; Xie, X.; Shu, X.; Shen, S.; Ni, X.; Zhang, L. Fire Risk Assessments of Informal Settlements Based on Fire Risk Index and Bayesian Network. Int. J. Environ. Res. Public Health 2022, 19, 15689. [Google Scholar] [CrossRef]

- Mohammadi, A.; Tavakolan, M. Identifying safety archetypes of construction workers using system dynamics and content analysis. Saf. Sci. 2020, 129, 104831. [Google Scholar] [CrossRef]

- Xie, X.; Fu, G.; Xue, Y.; Zhao, Z.; Chen, P.; Lu, B.; Jiang, S. Risk prediction and factors risk analysis based on IFOA-GRNN and apriori algorithms: Application of artificial intelligence in accident prevention. Process Saf. Environ. Prot. 2019, 122, 169–184. [Google Scholar] [CrossRef]

| No. | Safety Culture Element Name | No. | Safety Culture Element Name |

|---|---|---|---|

| SCE1 | Safety Importance | SCE17 | Safety Meeting |

| SCE2 | Beliefs of Zero Accidents | SCE18 | Formation of Safety Rules |

| SCE3 | Trade-off between Safety and Profit | SCE19 | Enforcement of Safety Rules |

| SCE4 | Safety and Management Integration | SCE20 | Injury and Incident Investigation |

| SCE5 | Safety Awareness | SCE21 | Workplace Audits, Inspections |

| SCE6 | Primary Responsibility for Workplace Safety | SCE22 | Modified Duty and Return-to-Work Systems |

| SCE7 | Safety Investment | SCE23 | Off-the-Job Safety |

| SCE8 | Safety Regulations | SCE24 | Recognition for Safety Performance |

| SCE9 | Safety Values | SCE25 | Facility Satisfaction |

| SCE10 | Safety Responsibility of Mangers | SCE26 | Measuring and Bench marking Safety Performance |

| SCE11 | Role of Safety Department | SCE27 | Hiring for Safety Attitude |

| SCE12 | Individual Involvement in Safety | SCE28 | Safety of Contractors and Subsidiaries |

| SCE13 | Demand of Safety Training | SCE29 | Safety Organization |

| SCE14 | Responsibilities for Safety in Every Department | SCE30 | Safety Department |

| SCE15 | Involvement in Community Safety | SCE31 | Overall Expectation for Safety |

| SCE16 | Role of Safety Management System | SCE32 | Emergency Capability |

| SCE1–SCE3: Safety concept elements | SCE9–SCE16: Safety responsibility elements | ||

| SCE4–SCE8: Safety discipline elements | SCE17–SCE32: Safety measurement elements |

| No | Year | Publisher | Directives | Main Contribution |

|---|---|---|---|---|

| 1 | 1991 | IAEA | Safety Culture (No.75-INSAG-4) |

|

| 2 | 1994 | IAEA | TECDOC 743: ASCOT Guidelines―Guidelines for Organizational Self-Assessment of Safety Culture and for Reviews by the Assessment of Safety Culture in Organizations Team |

|

| 3 | 1997 | IAEA | Safety Reports Series No.1: Examples of Safety Culture Practices |

|

| 4 | 1998 | IAEA | Safety Reports Series No.11: Developing Safety Culture in Nuclear Activities—Practical Suggestions to Assist Progress |

|

| 5 | 2002 | IAEA | Key Practical Issues in Strengthening Safety Culture (INSAG 15) |

|

| 6 | 2002 | IAEA |

|

|

| 7 | 2003 | ILO | 91st International Labour Conference |

|

| 8 | 2006 | ILO |

| |

| 9 | 2008 | MEMPRC | Directives for developing enterprise safety culture (AQ/T 9004-2008) |

|

| 10 | 2012 | IAEA | Safety Reports Series No.74: Safety Culture in Pre-operational Phases of Nuclear Power Plant Projects |

|

| 11 | 2016 | IAEA | Safety Reports Series No.83: Performing Safety Culture Self-Assessments |

|

| (1) International Atomic Energy Agency = IAEA, (2) International Labour Organization = ILO, (3) Ministry of Emergency Management of the People’s Republic of China = MEMPRC | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, X.; Hu, J.; Fu, G.; Shu, X.; Wu, Y.; Huang, L.; Shen, S. Investigation of Unsafe Acts Influence Law Based on System Dynamics Simulation: Thoughts on Behavior Mechanism and Safety Control. Int. J. Environ. Res. Public Health 2023, 20, 4733. https://doi.org/10.3390/ijerph20064733

Xie X, Hu J, Fu G, Shu X, Wu Y, Huang L, Shen S. Investigation of Unsafe Acts Influence Law Based on System Dynamics Simulation: Thoughts on Behavior Mechanism and Safety Control. International Journal of Environmental Research and Public Health. 2023; 20(6):4733. https://doi.org/10.3390/ijerph20064733

Chicago/Turabian StyleXie, Xuecai, Jun Hu, Gui Fu, Xueming Shu, Yali Wu, Lida Huang, and Shifei Shen. 2023. "Investigation of Unsafe Acts Influence Law Based on System Dynamics Simulation: Thoughts on Behavior Mechanism and Safety Control" International Journal of Environmental Research and Public Health 20, no. 6: 4733. https://doi.org/10.3390/ijerph20064733

APA StyleXie, X., Hu, J., Fu, G., Shu, X., Wu, Y., Huang, L., & Shen, S. (2023). Investigation of Unsafe Acts Influence Law Based on System Dynamics Simulation: Thoughts on Behavior Mechanism and Safety Control. International Journal of Environmental Research and Public Health, 20(6), 4733. https://doi.org/10.3390/ijerph20064733