Business Model Innovation Paths of Manufacturing Oriented towards Green Development in Digital Economy

Abstract

1. Introduction

2. Literature Review and Research Framework

2.1. Literature Review

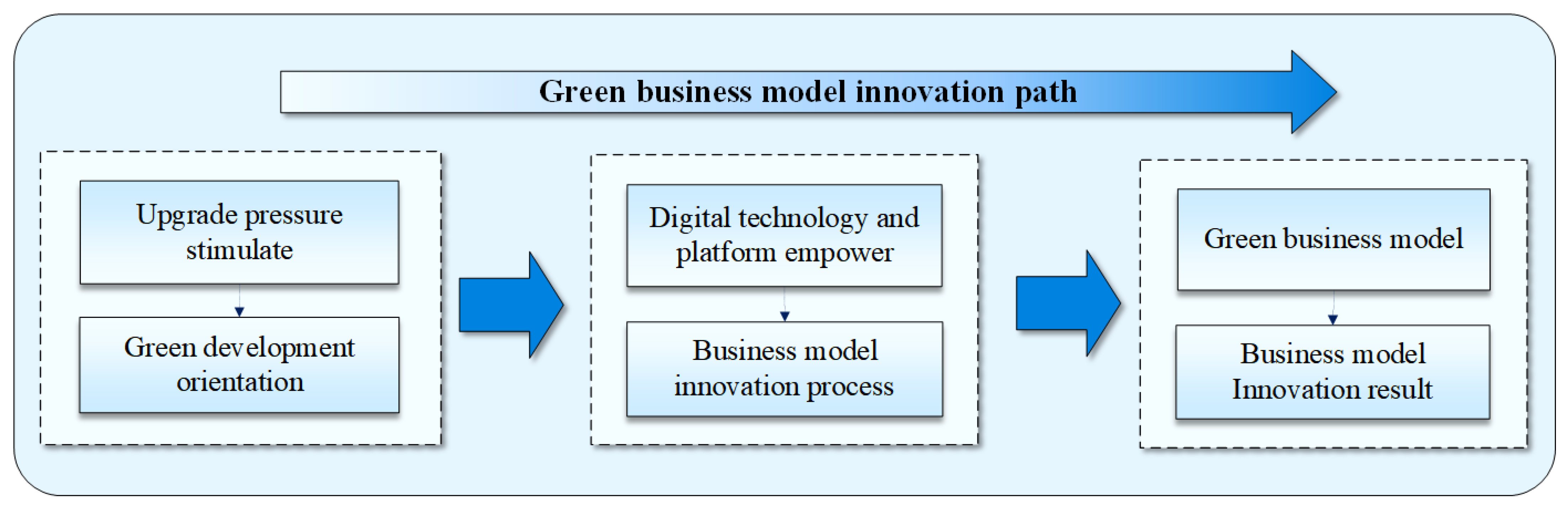

2.2. Research Framework

3. Research Design

3.1. Research Method

3.2. Research Case Selection

3.3. Data Collection

3.4. Data Coding

3.4.1. Open Coding

3.4.2. Axial Coding

3.4.3. Selective Coding

3.4.4. Theoretical Saturation Test

4. Case Analysis

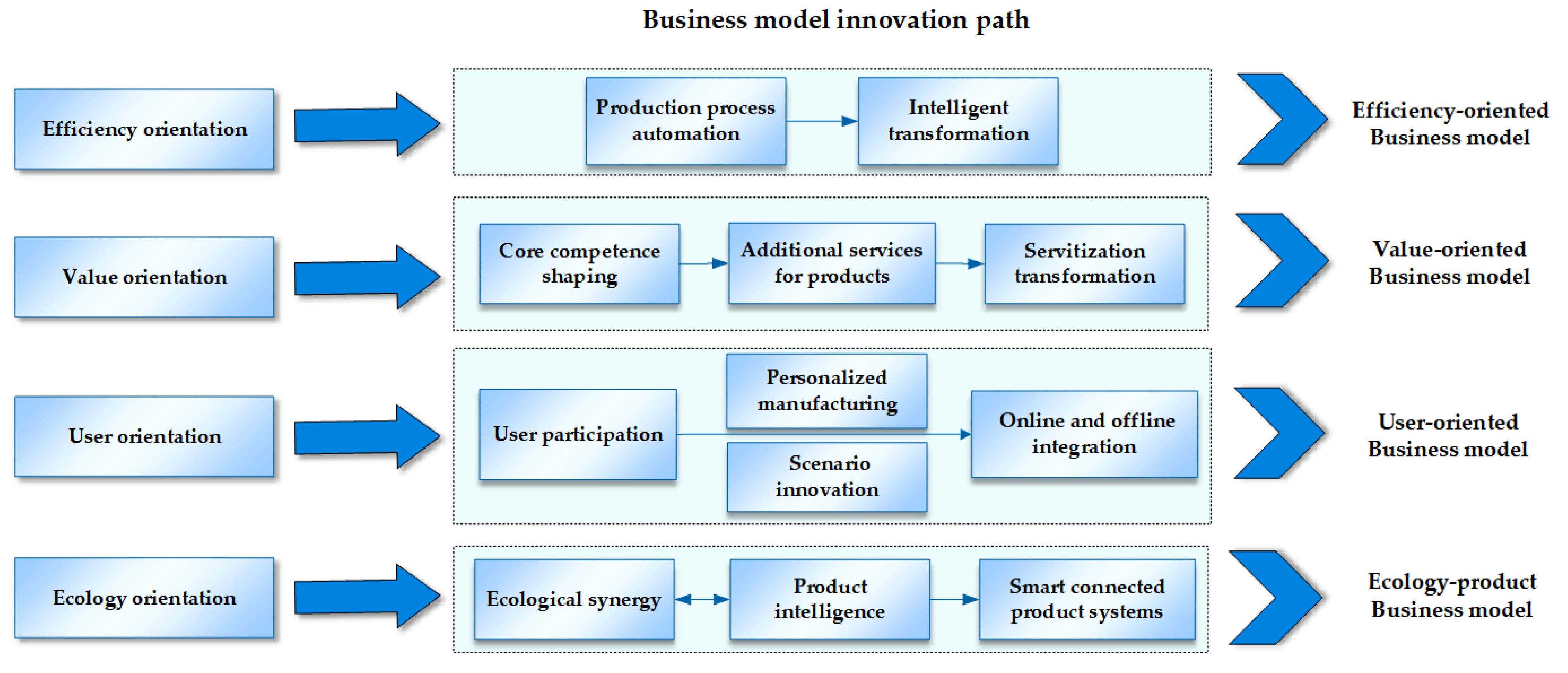

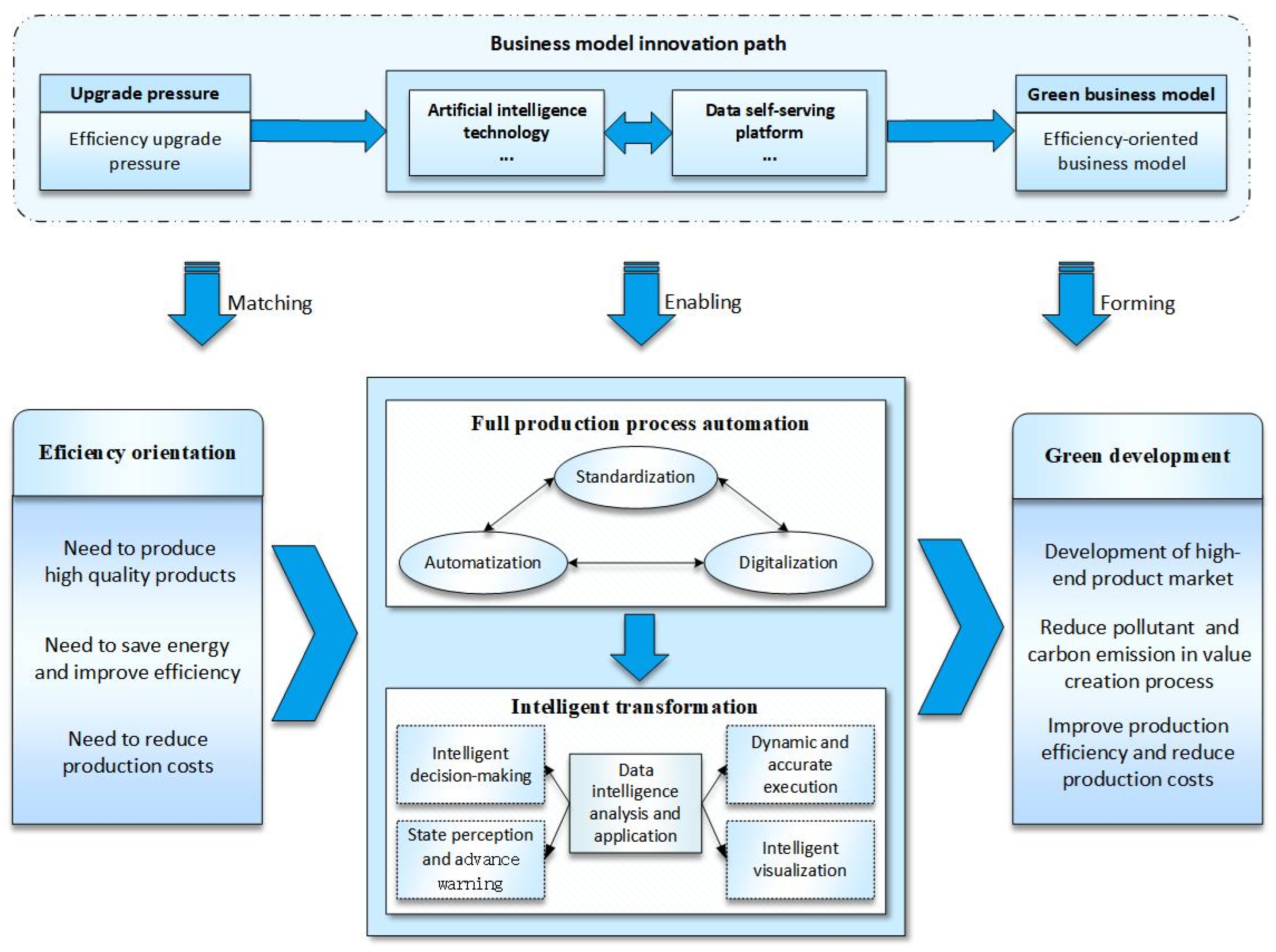

4.1. Efficiency-Oriented Path: From Production Process Automation to Intelligent Transformation

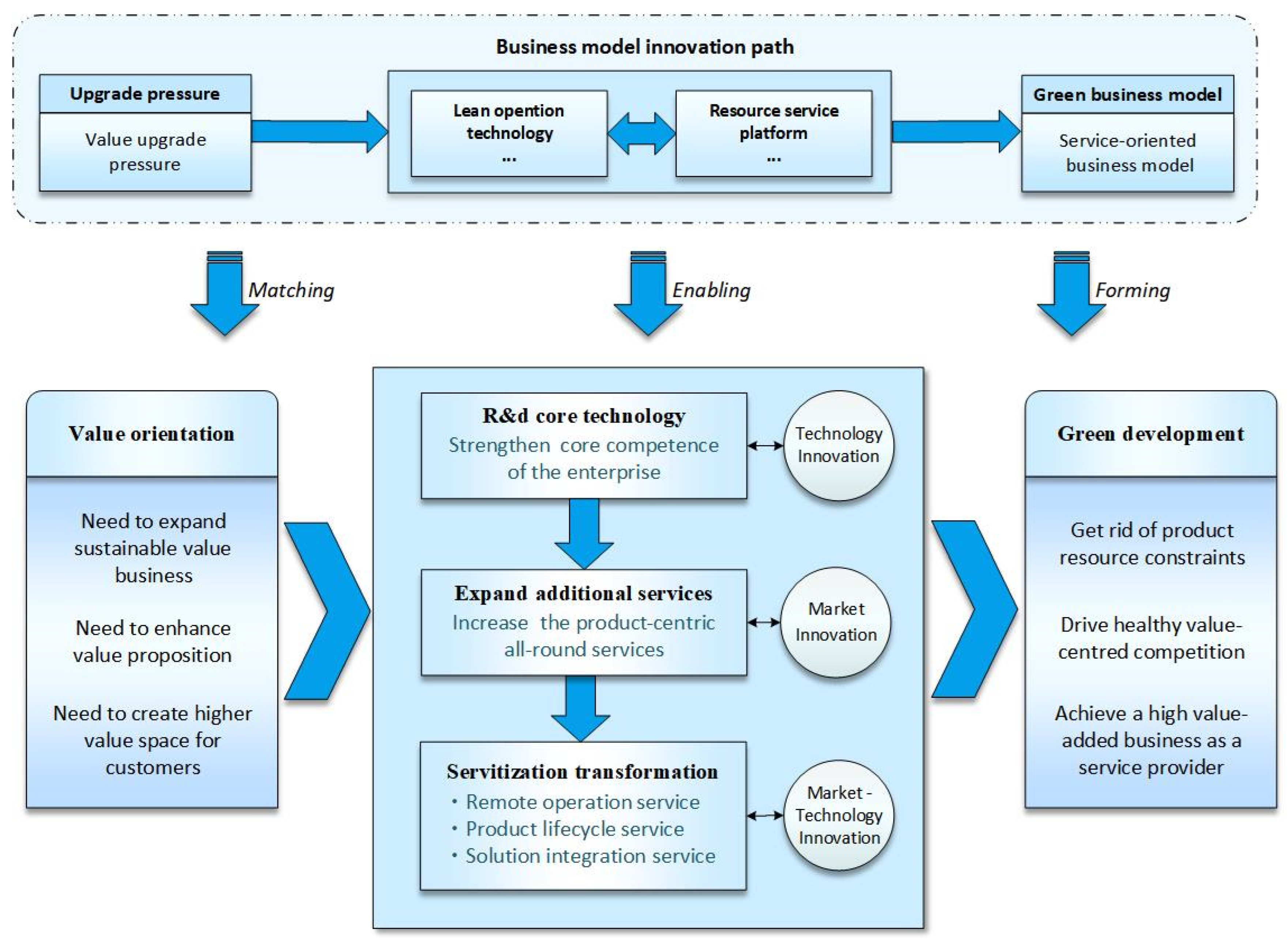

4.2. Value-Oriented Path: From Core Competence Shaping to Servitization Transformation

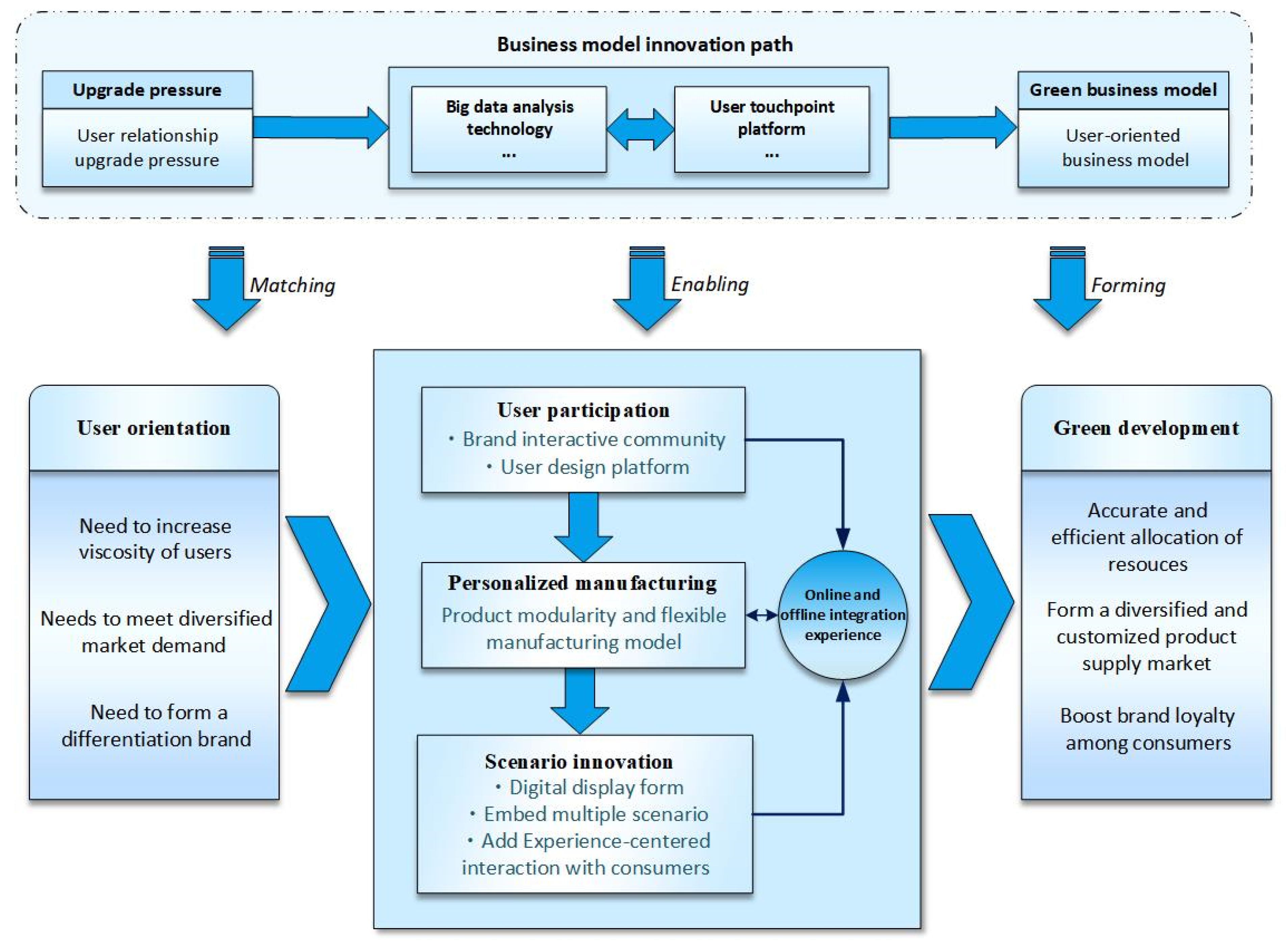

4.3. User-Oriented Path: From Personalized Customization to Scenario Innovation

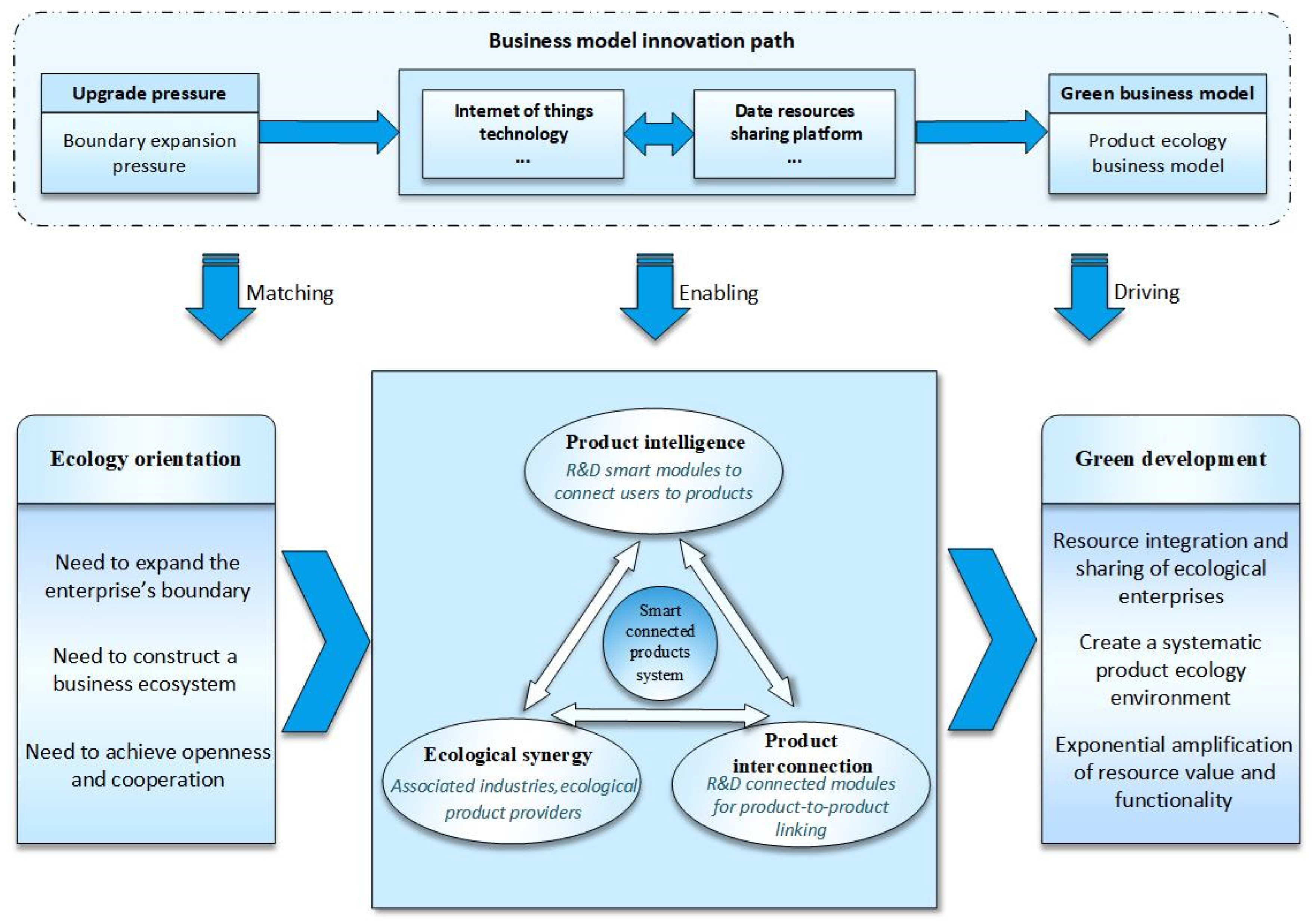

4.4. Ecology-Oriented Path: From Product Intelligence to Smart Connected Product Systems Construction

5. Comparison of Four Business Model Innovation Paths

6. Conclusions

7. Contributions of the Study

7.1. Theoretical Contributions

- (1)

- In this study, the multi-case study method has reinforced the universality of the research findings, which in turn has compensated for the inadequacy of the fact that most of the existing studies on the business model innovation path of manufacturing are single case studies. The four core categories of efficiency orientation, value orientation, user orientation, and ecological orientation are derived to illustrate the differentiated green development orientation of manufacturing under the background of the digital economy and green development. Furthermore, the four green business model innovation paths are presented and compared in this foundation, which extends the relevant theories on the types and choices of green business model innovation paths. Moreover, it compensates for the inadequacies of the current relevant research, such as a single perspective and vague definition of paths.

- (2)

- The relationship between the digital economy and green development has been deepened. This study combines the digital economy and green development and integrates their synergistic relationship into the business model, which is a further improvement of the relationship between the digital economy and green development discussed in the existing literature. Existing studies have shown that there is a two-way relationship between the digital economy and green development, but most of them are macro-oriented and lack consideration of the relationship between the two from the perspective of the business model. Through the case study, this paper finds that the business model innovation process under the guidance of green development of enterprises cannot be separated from digital technology, and the business model innovation under the digital economy can promote the sustainable development of the economy and reduce the related negative environmental externalities.

- (3)

- This paper expands the theory of business model innovation. On the one hand, it enriches the connotation of business model innovation theory. Most of the existing research on business model innovation focuses on economic influence. This paper takes into account the challenges brought by environmental change and resource scarcity, emphasizes the important position of green development orientation in the process of business model innovation, and seeks business model innovation paths that take into account both Economic benefit and environmental efficiency. On the other hand, it expands the application situation of business model innovation theory. Based on the “China story” under the background of the digital economy and green development, this study takes a number of Chinese local manufacturing enterprises as typical cases to reveal the common experience of manufacturing enterprises’ business model innovation and provides specific path suggestions for Chinese manufacturing enterprises in the critical period of transformation how to achieve business model innovation.

7.2. Management Implications

7.3. Policy Implications

- (1)

- Actively guide the manufacturing industry to implement innovative green business models. The government encourages enterprises to use market-based methods to achieve relevant green business model innovations, gives full play to the incentive role of fiscal policies, and reasonably amplifies the signaling role of government subsidies. For example, the government can provide substantial rewards and honorary support to enterprises that carry out green business model innovations, adjusts the ratio of ex-post to ex-ante subsidies, and explores diverse forms of subsidies and recognition.

- (2)

- Give full consideration to the heterogeneity of enterprises and implement differentiated support policies. The competent authorities should implement differentiated innovation support policies according to the technical level of the industry, the attributes of the industry’s production, the attributes of the industry’s market, and the product types of the enterprise. For example, the steel industry can promote its automation and intelligent development, the consumer goods manufacturing industry can promote its personalized customization, and the high-end equipment manufacturing industry can promote its service-oriented transformation. By conducting pilot evaluations in specific industries, local conditions can be adapted.

8. Limitations and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, J.H.; Wang, S.S. Evaluation and Influencing Factor Analysis of Sustainable Green Transformation Efficiency of Resource-Based Cities in Western China in the Post-COVID-19 Era. Front. Public Health 2022, 10, 832904. [Google Scholar] [CrossRef]

- Yao, S. Fuzzy-based Multi-criteria Decision Analysis of Environmental Regulation and Green Economic Efficiency in a Post-COVID-19 Scenario: The Case of China. Int. J. Environ. Res. Public Health 2021, 28, 30675–30701. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Chen, P.; Hao, Y.; Dagestani, A.A. Tax incentives and green innovation- The mediating role of financing constraints and the moderating role of subsidies. Front. Environ.Sci. 2022, 10, 1067534. [Google Scholar] [CrossRef]

- Jin, W.; Ding, W.; Yang, J. Impact of financial incentives on green manufacturing: Loan guarantee vs. interest subsidy. Eur. J. Oper. Res. 2022, 300, 1067–1080. [Google Scholar] [CrossRef]

- Sarkar, A.; Qian, L.; Peau, A.K. Overview of green business practices within the Bangladeshi RMG Industry: Competitiveness and Sustainable Development Perspective. Int. J. Environ. Res. Public Health 2020, 27, 22888–22901. [Google Scholar] [CrossRef]

- Hu, D.; Qiu, L.; She, M. Sustaining the sustainable development: How do firms turn government green subsidies into financial performance through green innovation? Bus. Strategy Environ. 2021, 30, 2271–2292. [Google Scholar] [CrossRef]

- Quintás, M.A.; Martínez-Senra, A.I.; Sartal, A. The role of SMEs’ Green Business Models in the transition to a Low-carbon Economy: Differences in their Design and Degree of Adoption Stemming from Business Size. Sustainability 2018, 10, 2109. [Google Scholar] [CrossRef]

- Rajala, R.; Westerlund, M.; Lampikoski, T. Environmental Sustainability in Industrial Manufacturing: Re-examining the Greening of Interface’s Business model. J. Clean. Prod. 2016, 115, 52–61. [Google Scholar] [CrossRef]

- Ma, C.; Mao, J.Y.; An, X.P. The driving forces behind the phenomenal rise of the digital economy in China. Manag. Organ. Rev. 2022, 18, 803–815. [Google Scholar] [CrossRef]

- Gregori, P.; Holzmann, P. Digital Sustainable Entrepreneurship: A Business Model Perspective on Embedding Digital Technologies for Social and Environmental Value Creation. J. Clean. Prod. 2020, 272, 122817. [Google Scholar] [CrossRef]

- Feng, H.; Wang, F.; Song, G.; Liu, L. Digital Transformation on Enterprise Green Innovation: Effect and Transmission Mechanism. Int. J. Environ. Res. Public Health 2020, 19, 10614. [Google Scholar] [CrossRef]

- Fu, Q. How Does Digital Technology Affect Manufacturing Upgrading? Theory and Evidence from China. PLoS ONE 2020, 17, 0267299. [Google Scholar] [CrossRef] [PubMed]

- Xia, Q.H.; Fang, Q. Research on the path of manufacturing transformation and business model innovation -- Based on the double case analysis of Gree and Midea. Stud. Pract. 2017, 4, 31–41. [Google Scholar]

- Bashir, M.; Verma, R. Internal Factors & Consequences of Business Model Innovation. Manag. Decis. 2019, 57, 262–290. [Google Scholar]

- Bocken, N.M.P.; Geradts, T.H.J. Barriers and Drivers to Sustainable Business Model Innovation: Organization Design and Dynamic Capabilities. Long Range Plan. 2020, 53, 101950. [Google Scholar] [CrossRef]

- Ciampi, F.; Demi, S.; Magrini, A.; Marzi, G.; Papa, A. Exploring the Impact of Big Data Analytics Capabilities on Business Model Innovation: The Mediating Role of Entrepreneurial Orientation. J. Bus. Res. 2021, 123, 1–13. [Google Scholar] [CrossRef]

- Sorescu, A. Data-driven Business Model Innovation. J. Prod. Innov. Manag. 2017, 34, 691–696. [Google Scholar] [CrossRef]

- Yu, B.; Hao, S.; Wang, Y. Organizational Search and Business Model Innovation: The Moderating Role of Knowledge Inertia. J. Knowl. Manag. 2020, 24, 1705–1718. [Google Scholar] [CrossRef]

- Passlick, J.; Dreyer, S.; Olivotti, D. Predictive Maintenance as an Internet of Things Enabled Business Model: A Taxonomy. Electron. Mark. 2021, 31, 67–87. [Google Scholar] [CrossRef]

- Andreassen, T.W.; Lervik–Olsen, L.; Snyder, H. Business Model Innovation and Value-creation: The Triadic Way. J. Serv. Manag. 2018, 29, 883–906. [Google Scholar] [CrossRef]

- Möller, F.; Stachon, M.; Azkan, C. Designing Business Model Taxonomies–Synthesis and Guidance from Information Systems Research. Electron. Mark. 2022, 32, 701–726. [Google Scholar] [CrossRef]

- Lennart, S.A.; Peter, S. Disruption by Design? Classification Framework for the Archetypes of Disruptive Business Models. RD Manag. 2022, 52, 893–929. [Google Scholar] [CrossRef]

- Sun, K.; Wang, Z.F.; Yu, Z.H. Classification and Theoretical Model of Sharing Economy Business Model: Based on Three Typical Case Study. Manag. Rev. 2019, 31, 97–109. [Google Scholar] [CrossRef]

- Estelle, D.; Frederik, M.; Ilka, J.; Maleen, S.; Sükran, A.; Boris, O. Archetypes of Open-source Business Models. Electron. Mark. 2022, 32, 727–745. [Google Scholar] [CrossRef]

- Zhang, X.; Meng, Q.; Le, Y. How Do New Ventures Implementing Green Innovation Strategy Achieve Performance Growth? Sustainability 2022, 14, 2299. [Google Scholar] [CrossRef]

- Li, L.; Msaad, H.; Sun, H.; Tan, M.X.; Lu, Y.; Lau, A. Green Innovation and Business Sustainability: New Evidence from Energy Intensive Industry in China. Int. J. Environ. Res. Public Health 2020, 17, 7826. [Google Scholar] [CrossRef]

- Palmié, M.; Miehé, L.; Oghazi, P. The Evolution of the Digital Service Ecosystem and Digital Business Model Innovation in Retail: The Emergence of Meta-ecosystems and the Value of Physical Interactions. Technol. Forecast. Soc. Chang. 2022, 177, 121496. [Google Scholar] [CrossRef]

- Ma, Y.; Yin, Q.; Pan, Y. Green product innovation and firm performance: Assessing the moderating effect of novelty-centered and efficiency-centered business model design. Sustainability 2018, 10, 1843. [Google Scholar] [CrossRef]

- Guo, H.; Guo, A.; Ma, H. Inside the black box: How Business Model Innovation Contributes to Digital Start-up Performance. J. Innov. Knowl. 2022, 7, 100188. [Google Scholar] [CrossRef]

- Bhatnagar, R.; Keskin, D.; Kirkels, A. Design principles for Sustainability Assessments in the Business Model Innovation Process. J. Clean. Prod. 2022, 377, 134313. [Google Scholar] [CrossRef]

- Chu, Y.; Chi, M.; Wang, W.; Luo, B. The Impact of Information Technology Capabilities of Manufacturing Enterprises on Innovation Performance: Evidences from SEM and fsQCA. Sustainability 2019, 11, 5946. [Google Scholar] [CrossRef]

- Kiel, D.; Arnold, C.; Voigt, K. The Influence of the Industrial Internet of Things on Business Models of Established Manufacturing Companies- A Business Level Perspective. Technovation 2017, 68, 4–19. [Google Scholar] [CrossRef]

- Matarazzo, M.; Penco, L.; Profumo, G.; Quaglia, R. Digital Transformation and Customer Value Creation in Made in Italy SMEs: A Dynamic Capabilities Perspective. J. Bus. Res. 2021, 123, 642–656. [Google Scholar] [CrossRef]

- Enkel, E.; Bogers, M.; Chesbrough, H. Exploring Open Innovation in the Digital Age: A Maturity Model and Future Research Directions. RD Manag. 2020, 50, 161–168. [Google Scholar] [CrossRef]

- Brenner, B. Transformative Sustainable Business Models in the Light of the Digital Imperative—A Global Business Economics Perspective. Sustainability 2018, 10, 4428. [Google Scholar] [CrossRef]

- Wen, L.; Hui, X.; Sihui, L.; Lei, M. Research on Business Model Innovation Path of Manufacturing Enterprises Based on Simulation—A Case study of Haier’s Servitization Transformation. Manag. Case Stud. Rev. 2021, 14, 622–639. [Google Scholar]

- Tian, Q.; Zhang, S.; Yu, H.; Cao, G. Exploring the Factors Influencing Business Model Innovation Using Grounded Theory: The Case of a Chinese High-End Equipment Manufacturer. Sustainability 2019, 11, 1455. [Google Scholar] [CrossRef]

- Chen, Y.H.; Zhang, Z.G.; Huang, L. Mechanism and Path of Digital Enabling Business Model Innovation of Manufacturing Enterprises. J. Manag. 2021, 18, 731–740. [Google Scholar] [CrossRef]

- Freudenreich, B.; Lüdeke-Freund, F.; Schaltegger, S. A Stakeholder Theory Perspective on Business Models: Value Creation for Sustainability. J. Bus. Ethics 2020, 166, 3–18. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K. The Role of Absorptive Capacity and Innovation Strategy in the Design of Industry 4.0 Business Models-A Comparison between SMEs and Large Enterprises. Eur. Manag. J. 2020, 39, 333–343. [Google Scholar] [CrossRef]

- Di Vaio, A.; Palladino, R.; Hassan, R. Artificial intelligence and business models in the sustainable development goals perspective: A systematic literature review. J. Bus. Res. 2020, 121, 283–314. [Google Scholar] [CrossRef]

- Teece, D.J. Business models and dynamic capabilities. Long Range Plan. 2018, 51, 40–49. [Google Scholar] [CrossRef]

- Foss, N.J.; Saebi, T. Business Models and Business Model Innovation: Between Wicked and Paradigmatic Problems. Long Range Plan. 2017, 51, 9–21. [Google Scholar] [CrossRef]

- Ghezzi, A.; Cavallo, A. Agile business model innovation in digital entrepreneurship: Lean startup approaches. J. Bus. Res. 2020, 110, 519–537. [Google Scholar] [CrossRef]

- Clauss, T. Measuring business model innovation: Conceptualization, scale development, and proof of performance. Rd Manag. 2017, 47, 385–403. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Song, L.; Wang, Y. Digital Economy Theoretical System and Research Prospects. Manag. World 2022, 38, 208–224. [Google Scholar]

- Caputo, A.; Pizzi, S.; Pellegrini, M.M. Digitalization and business models: Where are we going? A science map of the field. J. Bus. Res. 2021, 123, 489–501. [Google Scholar] [CrossRef]

- Ritter, T.; Pedersen, C.L. Digitization capability and the digitalization of business models in business-to-business firms: Past, present, and future. Ind. Mark. Manag. 2020, 86, 180–190. [Google Scholar] [CrossRef]

- Vaska, S.; Massaro, M.; Bagarotto, E.M. The digital transformation of business model innovation: A structured literature review. Front. Psychol. 2021, 35, 539363. [Google Scholar] [CrossRef]

- Niu, X.J.; Qin, S.F. Integrating Crowd-/Service-sourcing into Digital Twin for Advanced Manufacturing Service Innovation. Adv. Eng. Inform. 2021, 50, 101422. [Google Scholar] [CrossRef]

- Langley, D.J.; van Doorn, J. The Internet of Everything: Smart things and their impact on business models. J. Bus. Res. 2021, 122, 853–863. [Google Scholar] [CrossRef]

- Xie, X.M.; Han, Y.H.; Alistair, A.; Ribeiro-Navarrete, S. Digital Platforms and SMEs’ Business Model Innovation: Exploring the Mediating Mechanisms of Capability Reconfiguration. Int. J. Inform. Manag. 2022, 65, 102513. [Google Scholar] [CrossRef]

- De Reuver, M.; Sørensen, C.; Basole, R.C. The Digital Platform: A Research Agenda. J. Inf. Technol. 2018, 33, 124–135. [Google Scholar] [CrossRef]

- Lin, P.; Zhang, X.; Yan, S. Dynamic capabilities and business model innovation of platform enterprise: A case study of DiDi taxi. Sci. Program. 2020, 2020, 8841368. [Google Scholar] [CrossRef]

- Li, W. Research on the driving mechanism of business model innovation of Internet financial enterprises. Sci. Res. Manag. 2020, 41, 130–137. [Google Scholar] [CrossRef]

- Wang, B.C.; Zhang, Q. Research on the configuration of business model innovation of Internet Service Enterprises: Based on strategy and resource perspective. Manag. J. 2022, 35, 119–135. [Google Scholar] [CrossRef]

- Tian, H.; Li, Y.; Zhang, Y. Digital and intelligent empowerment: Can Big Data Capability Drive Green Process Innovation of Manufacturing Enterprises? J. Clean. Prod. 2022, 377, 134261. [Google Scholar] [CrossRef]

- Zhou, R.; Tang, D.; Da, D.; Chen, W.; Kong, L.; Boamah, V. Research on China’s Manufacturing Industry Moving towards the Middle and High-End of the GVC Driven by Digital Economy. Sustainability 2022, 14, 7717. [Google Scholar] [CrossRef]

- Huang, W.; Chau, K.Y.; Kit, I.Y.; Nureen, N.; Irfan, M.; Dilanchiev, A. Relating Sustainable Business Development Practices and Information Management in Promoting Digital Green Innovation: Evidence From China. Front. Psychol. 2020, 13, 930138. [Google Scholar] [CrossRef]

- Méndez–León, E.; Reyes–Carrillo, T.; Díaz–Pichardo, R. Towards a Holistic Framework for Sustainable Value Analysis in Business Models: A Tool for Sustainable Development. Bus. Strategy Environ. 2022, 31, 15–31. [Google Scholar] [CrossRef]

- Chen, W.Q.; Hauschild, M.Z.; Huang, B.J.; Kara, S. Life Cycle Engineering and Sustainable Manufacturing for Net-zero Targets and Environmental. Sustainability 2022, 186, 106480. [Google Scholar] [CrossRef]

- Wei, Z.; Sun, L. How to leverage manufacturing digitalization for green process innovation: An information processing perspective. Ind. Manag. Data Syst. 2021, 121, 1026–1044. [Google Scholar] [CrossRef]

- Roh, T.; Noh, J.; Oh, Y.; Park, K.S. Structural Relationships of a Firm’s Green Strategies for Environmental Performance: The Roles of Green Supply Chain Management and Green Marketing Innovation. J. Clean. Prod. 2022, 356, 131877. [Google Scholar] [CrossRef]

- Han, J.; Heshmati, A.; Rashidghalam, M. Circular Economy Business Models with a Focus on Servitization. Sustainability 2020, 12, 8799. [Google Scholar] [CrossRef]

- Zhu, X.; Liu, K.A. Systematic Review and Future Directions of the Sharing Economy: Business Models, Operational Insights and Environment-based Utilities. J. Clean. Prod. 2021, 290, 125209. [Google Scholar] [CrossRef]

- Laukkanen, M.; Tura, N. The potential of Sharing Economy Business Models for Sustainable Value Creation. J. Clean. Prod. 2020, 253, 120004. [Google Scholar] [CrossRef]

- Batlles–dela Fuente, A.; Belmonte–Ureña, L.J.; Plaza–Úbeda, J.A. Sustainable Business Model in the Product-Service System: Analysis of Global Research and Associated EU Legislation. Int. J. Environ. Res. Public Health 2021, 18, 10123. [Google Scholar] [CrossRef] [PubMed]

- Ardito, L.; Dangelico, R.M. Firm Environmental Performance Under Scrutiny: The Role of Strategic and Organizational Orientations. Corp. Soc. Responsib. Environ. Manag. 2018, 25, 426–440. [Google Scholar] [CrossRef]

- Qiu, L.; Hu, D.; Wang, Y. How do Firms Achieve Sustainability Through Green Innovation under External Pressures of Environmental Regulation and Market Turbulence? Bus. Strategy Environ. 2020, 29, 2695–2714. [Google Scholar] [CrossRef]

- Petri, Y. Case study research in the social sciences. Stud. Hist. Philos. Sci. 2019, 10, 30–35. [Google Scholar]

- Tasci, A.D.; Wei, W.; Milman, A. Uses and misuses of the case study method. Ann. Tour. Res. 2020, 82, 102815. [Google Scholar] [CrossRef]

- Amjad, M.S.; Rafique, M.Z.; Khan, M.A. Leveraging Optimized and Cleaner Production Through Industry 4.0. Sustain. Prod. Consum. 2021, 26, 859–871. [Google Scholar] [CrossRef]

- Fernando, Y.; Jabbour, C.J.C.; Wah, W.X. Pursuing Green Growth in Technology Firms Through the Connections Between Environmental Innovation and Sustainable Business Performance: Does Service Capability Matter? Resour. Conserv. Recycl. 2019, 141, 8–20. [Google Scholar] [CrossRef]

- Viciunaite, V.; Alfnes, F. Informing Sustainable Business Models with a Consumer Preference Perspective. J. Clean. Prod. 2020, 242, 118417. [Google Scholar] [CrossRef]

- Baldassarre, B.; Calabretta, G.; Bocken, N.M.P. Bridging Sustainable Business Model Innovation and User-oriented Innovation: A Process for Sustainable Value Proposition Design. J. Clean. Prod. 2017, 147, 175–186. [Google Scholar] [CrossRef]

- Zheng, P.; Lin, T.J.; Chen, C.H. A Systematic Design Approach for Service Innovation of Smart Product-service Systems. J. Clean. Prod. 2018, 201, 657–667. [Google Scholar] [CrossRef]

| Name | Address | Segmented Industry | Leading Products | Founding Time |

|---|---|---|---|---|

| Goldwind Science & Technology Co., Ltd. | Xinjiang, China | Wind turbine industry | Wind turbine manufacturing | 1998 |

| Baoshan Iron & Steel Group Co., Ltd. | Shanghai, China | Steel industry | Steel manufacturing | 1992 |

| Xiaomi Co., Ltd. | Beijing, China | Electronics industry | Electronics manufacturing | 2010 |

| QuMei Home Furnishings Group Co., Ltd | Beijing, China | Furniture industry | Furniture manufacturing | 1987 |

| Material Sources | Source Examples | Source Marker |

|---|---|---|

| Public interviews, transcripts of speeches endorsed by executives | Senior executives are interviewed by leading magazines and speak on special occasions or at major events, such as anniversary celebrations. | Goldwind-I-GW Xiaomi-I-XM QuMei-I-QM Baosteel-I-BS |

| Authority obtained by official channels Information | Official website information, internal enterprise journals, financial report disclosure, and annual report of listed companies. | Goldwind-C-GW Xiaomi-C-XM QuMei-C-QM Baosteel-C-BS |

| Documentation | Literature downloaded from CNKI, Web of Science, etc. | Goldwind-D-GW Xiaomi-D-XM QuMei-D-QM Baosteel-D-BS |

| Research report | Research reports of brokerage institutions downloaded from databases, such as Wind and CSMAR. | Goldwind-R-GW Xiaomi-R-XM QuMei-R-QM Baosteel-R-BS |

| Publishing books | “Xiaomi philosophy Lei Jun ‘s business ecological operation logic ”; “Goldwind Science & Technology Innovation Road.” | Goldwind-B-GW Xiaomi-B-XM QuMei-B-QM Baosteel-B-BS |

| Other Internet channels | Materials obtained through news media and social platforms | Goldwind-E-GW Xiaomi-E-XM QuMei-E-QM Baosteel-E-BS |

| Subcategories | Conceptualization | Typical Source Material Examples |

|---|---|---|

| Need to reduce production costs (dd1) (d1,d2,d3) | Raw material cost increases d1 | “The prices of raw materials such as iron ore, coal, alloy, and scrap steel have increased significantly, eroding the profits of the steel industry, which further tests our cost control ability.” (I-BS) |

| Labor cost increases d2 | “With the gradual disappearance of the demographic dividend in China and the improvement of the national social security policy, the labor cost keeps rising, which brings us new pressures and challenges” (I-BS) | |

| Steel prices decline d3 | “Affected by repeated domestic epidemics, the domestic economy is weak, the pace of consumption recovery is not as good as expected, the demand of steel is declining, and the steel market is generally showing a weak demand and low expectations, and steel prices are low” (I-BS) | |

| Need to produce high-quality products (dd2) (d5,d6) | Faced with overcapacity d5 | “China’s steel industry is generally faced with the problem of” low-end surplus and high-end shortage ”of structural excess capacity” (R-BS) |

| A big gap in the high-end product market d6 | “There is still a big gap in the market of high-end products with higher added value, and we have shown insufficient adaptability and flexibility in dealing with high-quality product manufacturing and multi-variety production organization before.” (I-BS) | |

| Need to save energy and reduce emissions (dd3) (d7) | Make energy saving and emission reduction target d7 | “For the steel industry with high energy consumption, there is a long way to go to save energy and reduce emissions. We should have the technological capability to reduce carbon by 30% in 2025, strive to reduce carbon by 30% in 2035, and achieve the goal of "carbon neutrality" in 2050.” (I-BS) |

| Introduction of automated equipment (dd4) (d8,d9) | Accelerate the application of industrial robots d8 | “Accelerate the application and promotion of industrial robots, double the number of robots in 2021, and keep the number of robots ahead of the industry.” (I-BS) |

| Building an intelligent infrastructure d9 | “We build a complete intelligent manufacturing infrastructure with intelligent equipment as the port” (I-BS) | |

| Standardization of operational processes (dd5) (d10,d11) | Process management and optimization d10 | “Process and system optimization is a work that is constantly updated. Therefore, a system support and operation team is set up within the sharing center, which is mainly responsible for sorting out which processes need to be optimized and organizing the establishment of optimization projects” (I-BS) |

| Standardized process d11 | “Because of the long process characteristics of Baosteel’s internal management, the importance of process management and optimization was fully emphasized at the beginning of the establishment of the sharing center, and the process was straightened out and standardized, which laid the foundation for subsequent stability.” (I-BS) | |

| Basic data collection (dd6) (d12) | Real-time data collection and integration d12 | “The real-time data of thousands of monitoring devices installed in Baosteel’s production site, including various instruments, thermocouples and other monitoring devices, are collected into the process control computer system through the field bus.” (I-BS) |

| Data integration (dd7) (d13,d14,d15) | Unified data standard d13 | “We improve system flexibility by adopting unified data standards” (I-BS) |

| Achieve unit collaboration d14 | “By adopting different deployment methods, the information systems of the group management and control and the main iron and steel business management layer can quickly cover new units, strengthening the group management and control, and strengthening the collaboration between new units and other units.” (I-BS) | |

| Connect data node d15 | “Cut through the steel manufacturing application scenario, connect all edge data nodes, and realize more comprehensive intelligent management and control of steel mill processes and production lines” (I-BS) | |

| Production automation (dd8) (d16,d17,d18) | Unmanned production d16 | “Through the application of new technologies such as automation, information technology and artificial intelligence, unmanned driving is realized, and unmanned logistics operations such as reservoir management and steel coil lightering are realized; Dirty and dangerous positions such as unit entrance baling, zinc pot slag fishing, export sampling, baling and labeling are unmanned.” (C-BS) |

| Automation of equipment and process control d17 | “By promoting the unmanned scene, accelerating the application of new technologies such as industrial robots, unmanned driving, artificial intelligence, and building a steel product production line, the automation of process equipment and process control has been completed. Shanghai base is the first in the world to realize one-button steelmaking and tapping.” (I-BS) | |

| Construction of fully automated production line d18 | “Under the company’s “four unifications ”intelligent manufacturing plan, the hot rolling mill has started a new round of “1+N” full-automatic production line construction featuring automation, intensification and digitalization, and the transportation chain, rough rolling and coiling areas have been fully automatic.” (C-BS) | |

| State perception (dd9) (d19,d20) | Real-time monitoring of equipment status d19 | “Preliminary completion of three-dimensional construction simulation of key equipment maintenance projects, real-time monitoring of equipment status, intelligent diagnosis of equipment faults, and practical improvement of work efficiency and quality of equipment maintenance and fault diagnosis.” (I-BS) |

| Product quality inspection d20 | “We apply the steel surface defect detector, based on machine vision and image processing technology, to detect all kinds of surface quality defects of steel online in real-time.” (I-BS) | |

| Intelligent decision-making (dd10) (d21) | Establish an intelligent grading decision system d21 | “Apply artificial intelligence machine learning and deep learning model to improve the defect detection and classification accuracy of strip surface defect detector, establish an intelligent grading decision system for strip surface defects, replace manual quality inspection, and realize automatic grading and intelligent management of strip surface quality” (C-BS) |

| Advance warning (dd11) (d22) | Anticipate business risks and give an early warning d22 | “Steel is a large-scale commodity, with a large transaction amount and high risk. We comprehensively analyze and evaluate the credit level and debt-paying ability of our customers by using the internal and external market, operation and legal data, so as to predict the business risk of the enterprise as early as possible and issue an early warning of trading behavior risk” (I-BS) |

| Intelligent visualization (dd12) (d23) | Visual Digital Twin Application Scene d23 | “Through the data interaction of 3D model, simulation model, and equipment condition monitoring model, we complete digital mapping of virtual space and realize the integration of static data of engineering construction and real-time dynamic data of production and operation to form a visual digital twin application scene ” (I-BS) |

| Dynamic and accurate execution (dd13) (d24,d25) | The intelligent temper mill control model d24 | “Establish an intelligent temper mill control model to achieve automatic optimal matching control of elongation, rolling force, surface quality and shape.” (I-BS) |

| Accurately control the temperature d25 | “Through artificial intelligence virtual measurement technology, the temperature of strip steel in zinc pot can be accurately controlled, and the surface quality of strip steel can be significantly improved.” (I-BS) | |

| Data center platform (dd14) (d26) | Building a Big Data Center d26 | “We started the construction of a smart manufacturing big data center, which is intended to plan the evolution of a new generation of information architecture. Based on the cloud data nodes, a business middle station that controls the whole process of steel manufacturing services and a middle data station that provides intelligent decision-making ”(I-BS) will be formed. |

| Data analysis and application (dd15) (d27) | A digital ecosystem of application interconnection d27 | “The big data center with the new architecture will completely break the “information island,” realize data co-acquisition, data sharing, system co-construction and function sharing, create a digital ecosystem of application interconnection, and further penetrate the whole process of real-time data collection, analysis and decision-making.” (I-BS) |

| Need to expand sustainable value business (dd16) (d28,d29,d30) | Change of profit point of wind power industry value chain d28 | “The strategic control points and profit points of the wind power industry value chain have changed with the expansion and change of market space. The manufacturing and sales of wind turbines, which once had high profits, have resulted in overcapacity, profit compression, or even disappearance due to the swarming of competitors, resulting in low-price competition in the market.” (I-GW) |

| Expand energy environmental protection business d29 | “We stick to the business development route that is beneficial to the society and the environment while consolidating the wind power manufacturing business, we actively expand the energy conservation and environmental protection business for our customers and contribute to the sustainable development of the environment and society.” (I-GW) | |

| Providing solution business d30 | “Solving problems and providing solution business to make the clean energy industry cleaner is not only the requirement of national green development, but also a major development trend and new growth opportunity of the industry.” (I-GW) | |

| Need to enhance the value proposition (dd17) (d31,d32) | Remodeling Enterprise Value Positioning d31 | “Goldwind Technology has established the strategic positioning of the overall wind power solution provider. Strive to change from a single product manufacturer to a system solution provider and system service provider in the field of energy conversion, from product management to brand management and capital operation.” (I-GW) |

| Help more enterprises reduce carbon emissions d32 | “While continuing to carry out scientific and technological innovation, we will further explore zero-carbon products and solutions with innovation as the engine. In the future, we will help more enterprises reduce carbon emissions and energy use costs by deploying green energy.” (I-GW) | |

| Need to create higher value space for customers (dd18) (d33) | Create more value for customers d33 | “We pursue high quality, high reliability and high power generation efficiency instead of being big. We constantly optimize the overall solution and strive to create more valuable space for customers in every link of wind power development and operation. Strive to create more value for customers by improving the quality of products and services ”(I-GW) |

| Core technology R&D capability (dd19) (d34,d35) | Continuous scientific and technological innovation d34 Independent research and development d35 | “Our continuous investment in scientific research and innovation has solved the green development problem of the company. In the end, we have obtained independent intellectual property rights, which has established the company’s leading position in the world.” (I-GW)-d34 “Our self-developed direct-drive permanent magnet technology has laid a commanding lead for long-term sustainable development, and Goldwind’s wind turbine technology products can be said to have been in the leading position in the world.” (I-GW)-d35 |

| Data collection and analysis capabilities (dd20) (d36) | Abundant data d36 | “Since its establishment, we have attached great importance to the collection and collation of basic data. Since the establishment of the company, we have established basic databases such as business database and financial database, and mastered abundant basic data.” (I-GW) |

| Specialized service capability (dd21) (d37,d38) | Accumulate management and technical experience d37 Stable customer relationship d38 | “The company has accumulated rich experience in the development of high-quality wind resources and the operation and management of wind farms(d37). At the same time, it has the leading technology in the wind power industry. Through years of mature wind turbine sales, our capital chain customer relationship network has matured(d38)” (I-GW) |

| Additional Services for Products (dd22) (d39,d40,d41,d42) | Product maintenance d39 Product upgrades d40 Product logistics management d41 Product development and design d42 | “Goldwind Technology continues to provide warranty service at an additional charge; Wind farm operation and maintenance business, that is, Goldwind Technology helps users manage wind farm assets; Other separately paid services, including customer customization, sales of spare parts, technical consultation and technical services, technical transformation and upgrading of wind farms, maintenance of wind turbines, logistics management” (C-GW) |

| Engineering-procurement-construction (dd23) (d43) | Signing EPC general contract d43 | “We signed the EPC general contract with Shanghai Institute in a consortium way, and jointly undertook all the work from the preliminary design of the project to the overall completion acceptance, and built the Dafeng H8-2 project into a new model of an offshore wind farm.” (I-GW) |

| Solution services (dd24) (d44) | Provide smart energy solutions d44 | “Taking the successful practice of Beijing Yizhuang Carbon Neutral Park as a starting point, we provide smart energy solutions for many large-scale conferences, scientific research centers, industrial parks, and ports, increase the proportion of green power use, and explore the creation of a new path of “zero carbon” development.” (I-GW) |

| Remote operation and maintenance services (dd25) (d45) | Provide remote operation and maintenance service d45 | “In Australia and North America, where our international expansion is relatively mature, different business models bring opportunities to the operation and maintenance business. We cooperated with our tax investors Citibank and Berkshire Hathaway Energy Company on the Rattlesnake wind farm project in Texas. Besides supplying wind turbines, we also contracted all the remote operation and maintenance services of wind farms on an annual basis.” (I-GW) |

| Industrial financial services (dd26) (d46,d47) | Providing financial solutions and asset management d46 Financial Services in the Whole Industry Chain d47 | “In the new era of wind power, we provide financial services in the whole industry chain, such as financial solutions and asset management, to realize the full ecological asset operation and value-added of wind power products. Goldwind Technology’s whole industry chain financial solution takes credit transmission and risk control as the core to improve the financial ecology of the industry.” (I-GW) |

| Cloud service platform (dd27) (d48,d49) | Operation platform d48 | “We embedded wind power big data, intelligent operation and maintenance into wind power equipment manufacturing and overall wind power solutions and proposed a wind power intelligent operation 2.0 platform solution. The platform integrates SES and SM, and relies on the global monitoring service center set up in Beijing to provide more than 20,000 units with system integration operation and maintenance solutions” (I-GW) |

| Digital Energy and Carbon Management Platform d49 | “The “three carbon reductions plus one platform” created by Goldwind Technology, through the digital energy and carbon management platform, reduces carbon on the energy consumption side, the energy supply side and the transaction side, realizes the energy management and carbon emission management throughout the whole process, and provides the best economic path for enterprises to build carbon emission reduction.” (I-GW) | |

| Need to increase the viscosity of users (dd28) (d50) | Maintain consumer brand loyalty d50 | “For the home furnishing industry, where product sales have always been low frequency, low repurchase and high unit price, after-sales service and word-of-mouth maintenance have become the top priority. We always adhere to the principle of honesty first and formulate systematic and scientific marketing communication strategies, putting the real product quality and service level at the core, and with excellent product quality and service, creating the brand image of a good home for the people.” (I-QM) |

| Need to meet diversified market demands (dd29) (d51,d52,d53) | Catering to personalized consumption demand d51 Analysis of Ideal Lifestyle d52 Observe the details of life d53 | “When the 80s and 90s are the main consumers, as brands, we should not only cater to the consumption needs of youth, individuality and fashion, but also be the “intimate friends” of consumers, not only knowing their decoration preferences, but also analyzing their lifestyle and understanding the true psychology of young people. We should know their ideal life better than consumers, observe the details of life, and provide meticulous and thoughtful service.” (I-QM) |

| Need to form a differentiation brand (dd30) (d54) | Trying to solve the problem of sales terminal differentiation d54 | “In recent years, the furniture industry has entered the “homogenization” competition, and the products, prices, brand-building behaviors, store decoration, and display are increasingly consistent. We form the terminal “marketing potential energy”, raise the threshold of market competition, try to solve the problem of sales terminal differentiation, establish the added value of products, turn products into works, let consumers know Qumei in an environment, and create the market barriers of Qumei sales terminal.” (I-QM) |

| Big data analysis (dd31) (d55) | Big data analysis to accurately grasp consumer preferences d55 | “We have reached in-depth cooperation with JD.COM, and with the help of JD.COM’s intelligent big data analysis capabilities, we have designed and laid out products around young consumers’ preferences.” (I-QM) |

| Personalized customization (dd32) (d56) | All products are open and customized d56 | “All our product lines are open and customized, which can fully meet the individual needs of consumers.” (I-QM) |

| Flexible manufacturing model (dd33) (d57) | Flexible production chain and intelligent production workshop d57 | “At present, Qumei Home, with its flexible production chain and intelligent production workshop, uses an ERP system to break the information island within the enterprise and realize intelligent collaboration, thus realizing the industry-leading mass customization mode.” (C-QM) |

| Create the brand characteristic scenario (dd34) (d58) | Convey the brand idea of the store d58 | “We hired a well-known domestic design agency to open the 4th generation independent store in the Asian Games Village, Datun Road, Chaoyang District, Beijing, upgrading from a furniture brand to a fashion home brand. The independent store with the brand-new image of “Wan Ziwen” conveys Qumei’s aesthetic concept of “simplicity, elegance and refinement”, which has become the store image of Qumei that continues to this day.” (I-QM) |

| Experiential life scenario (dd35) (d59) | Establish an experiential life scene d59 | “We break the one-dimensional relationship between products and consumers through the scene display design of stores, establish an experiential life scene, and complete the deep connection with consumers. In Qumei, consumers can not only see the unique home model rooms but also sit down to have coffee, read books, chat and have a deep experience of life scenes.” (I-QM) |

| Setting VR virtual interaction scenarios (dd36) (d60) | VR Experience Zone d60 | “We have VR experience areas with different themes and styles in the comprehensive life experience store, so that consumers can feel the ideal home space.” (I-QM) |

| Online and offline consumption channels (dd37) (d61) | Online and offline mode d61 | “Qumei’s home market network is extensive, and stores have been opened in more than 200 cities across the country. The “cement+mouse” marketing model pioneered by the industry perfectly integrates online shopping malls and physical storefronts and achieves a double leap in brand marketing power and market share. Qumei Home’s innovative channel model has created a new 24 h online shopping experience and a creative e-color space for consumers.” (C-QM) |

| Online and offline data integration (dd38) (d62) | Online and offline data fusion d62 | “Our knowledge of offline users is limited to the “physical level”, such as how big a room they live in, how many people they have, while online users’ insights outline richer and more three-dimensional “portraits”, learn about consumers’ shopping categories and habits about home in JD.COM Mall, and directly guide the combination of goods on this basis.” (I-QM) |

| Establish a we-media system (dd39) (d63,d64,d65) | Social platform d63 Digital marketing d64 live streaming d65 | “In order to quickly build the private domain traffic pool of the brand and broaden the marketing channels, we have continuously developed social platforms where young people such as WeChat official account, Weibo, Toutiaohao, Tik Tok, Auto Quicker and Xiaohongshu gather, and built Qumei self-media system with “fashion, richness, and value” as the keyword; Promote the normalization of online sales and live streaming sales with goods, and will continue to focus on online drainage and offline empowerment. Through more than 1000 stores in more than 400 cities across China, we will continue to lead people to visit stores, understand products and provide services by live broadcast.” (I-QM) |

| Digital stores (dd40) (d66,d67) | Digital store d66 Unbounded retail d67 | “Before digitalization, offline stores had a limited understanding of “field”. Basically, they had to contact consumers and generate sales in the fastest way in a tangible and limited space. In the process of internet plus, intelligent, technological and experiential transformation, with the blessing of the camera, Wi-Fi probe and other store technologies, the “field” becomes more unbounded, the value chain becomes longer and longer, and it is easier for consumers to immerse themselves in “one-stop experience consumption”.” (I-QM) |

| Cross-border fusion scenario (dd41) (d68) | Cross-border fusion d68 | “With Qumei Furniture as the logical center, different goods such as furniture, home and life are integrated. The close consumption relationship of categories in the home scene makes the consumption structure more and more diversified.” (I-QM) |

| Develop a brand-interactive community (dd42) (d69) | Launching the Wanzhong Design Platform d69 | “We have launched the Wanzhong Design Platform, which provides users with an interactive platform to print pictures and communicate, and at the same time allows users to participate in home space design.” (I-QM) |

| Launch a user design platform (dd43) (d70) | Develop a 3D customized ecommerce platform d70 | “We have developed a 3D customized e-commerce platform, with customization as the core concept. Customers can build their own floor plan on the 3D stereo software, place all kinds of furniture virtually according to their own wishes, and simulate their own reality to the greatest extent through parameter setting, so as to realize the free customization of the color and size of their own furniture.” (I-QM) |

| Need to achieve openness and cooperation (dd44) (d71) | Broad alliance d71 | “The most important thing for our company is to form a broad alliance and cooperate with an open mind. The more friends, the better.” (I-XM) |

| Need to construct a business ecosystem (dd45) (d72) | Make the Xiaomi Ecosphere Goal d72 | “We have set the goal of investing in 100 eco-chain enterprises within five years, forming a “Xiaomi Ecosphere” with Xiaomi Company as the core.” (I-XM) |

| Need to expand the enterprise boundary (dd46) (d73) | Not satisfied to only make the mobile phone d73. | “Xiaomi’s mobile phone brand has gradually become a climate and has a certain right to speak in the industrial chain. However, a millet that only makes mobile phones will not have a real future, and its effect will soon be suppressed. We need to get rid of the excessive dependence on mobile phone categories ”(I-XM) |

| Human–machine intelligent interaction (dd47) (d74,d75,d76) | Voice interaction d74 | “The interactive mode has been upgraded from traditional buttons and touch screens to sounds, actions and other ways that are closer to human interaction.” (I-XM) |

| Action interaction d75 | “We also provide intelligent voice assistant Xiaoai students for Mijia products, and Xiaoai students provide services to users in various scenes in a more human-friendly way.” (I-XM) | |

| Intelligent voice assistant d76 | “As an important terminal, the car’s interaction mode is very important. We cooperate with Li ONE Automobile to create a voice interaction environment in the car through Xiaoai classmates.” (I-XM) | |

| Intelligent environment detection (dd48) (d77) | Monitoring environmental value d77 | “We have introduced an intelligent maintenance product-Flower Monitor, which is the first product to “establish communication” between plants and people. It can help flower lovers to better raise flowers and enhance the maintenance pleasure by monitoring the values of temperature, moisture, fertility and light of green plants.” (I-XM) |

| R&D intelligent modules (dd49) (d78) | R&D intelligent modules d78 | “We invest in Green Rice, specializing in the research and development of intelligent modules for smart homes. By embedding this module, home appliances become intelligent, and through sensors, we can find out whether users are home or not, thus providing related services, which attracts users to use Xiaomi products.” (I-XM) |

| Intelligent analysis function (dd50) (d79) | Provide exercise plan through intelligent analysis d79 | The acceleration sensor in mi band measures the change of direction and acceleration to count the steps, and processes the data with intelligent computing ability to match the user’s exercise type, and then monitors the user’s walking number and calorie consumption, providing data support for the user to make a more scientific exercise plan. (C-XM) |

| Ecological-chain pattern (dd51) (d80,d81) | Set up ecological chain department d80 Extended product d81 | “We set up an eco-chain department, which extends to mobile phone peripherals, intelligent hardware and daily consumables products through the mode of ‘investment+incubation’ eco-chain enterprises. ”(I-XM) |

| Collaborative research and development (dd52) (d82) | Cooperation in research and development d82 | Xiaomi also cooperated with all seasons hotels, cars, homes and love spaces, committed to research and development innovation in the field of AloT, and launched the developer incentive plan-Xiaomi AIoT Developer Fund at the conference, with an initial investment of 100 million yuan. (C-XM) |

| Cross-border integration (dd53) (d83) | Cross-border integration d83 | “We have reached cross-border integration with IKEA, a home furnishing company, and all intelligent lighting products of IKEA will be connected to Xiaomi IoT platform … Xiaomi and IKEA have a high degree of agreement, and this cooperation will accelerate the intelligentization of the global home furnishing industry” (I-XM) |

| Resource sharing (dd54) (d84) | Share common resource d84 | “The purpose of Xiaomi’s ecological chain is to share common resources and invest in innovative enterprises to deepen the segmentation. We focus on the main framework, such as design and quality, which is specifically produced by eco-chain companies” (I-XM) |

| Ecological platform construction (dd55) (d85) | Platform strategy d85 | “The strategy of the Internet of Things is not to be hardware, but to be a platform. Apply standards to existing hardware vendors through the platform portal” (I-XM) |

| Online ecological cloud platform d86 | “We launched the eco-cloud platform, so that enterprises can not only store data in the cloud, but also make products share the data in the cloud, breaking product boundaries and further improving product functions” (I-XM) | |

| Data standardization (dd56) (d87) | Unified chip d87 | “In the process of expanding intelligent hardware, we found that some product intelligent modules are not unified, and data cannot be integrated. We rely on Songguo Electronics to develop a unified IoT smart chip, and promote products to generate standardized data and realize interactive linkage.” (I-XM) |

| Unified product style (dd57) (d88) | Harmonized product style d88 | “In the Internet of Things era, many products serve the same user, and the user consistency experience is crucial. Xiaomi has hundreds of products, which are unified and coordinated, with a wide variety but not messy. This is due to Xiaomi’s minimalist design principle, which not only reduces the difficulty of the production line, but also ensures that all product styles are coordinated and unified.” (I-XM) |

| Scenario linkage (dd58) (d89) | Connect between scenes d89 | “It’s very simple. As long as we master the data entry and application, we can apply user and product data to various fields simultaneously, and promote the connection between scenes. For example, embedding Xiaoai classmates into IKEA lighting system to expand To B fields such as hotels, travel and real estate, which will bring immeasurable value.” (I-XM) |

| Providing life scenario system solutions (dd59) (d90) | A life scene system solution d90 | “We provide systematic solutions for users. For example, Xiaomi Eco-chain enterprises embed chips in bracelets and lamps respectively, and jointly launch a “quality sleep solution”, that is, the lamps will automatically adjust the brightness according to the user’s sleep state detected by mi band.” (I-XM) |

| Product function interaction (dd60) (d91) | Interaction between products d91 | “For example, Dr. Xiaomi Eco-Chain Baby’s toothbrush, toothbrush and small love speaker can interact with each other, and the story will be automatically played when children brush their teeth, which can guarantee the user’s brushing time and provide a value-added experience for the product.” (I-XM) |

| R&D connected modules (dd61) (d92) | Release connected modules d92 | “We released the Wi-Fi module, which was only priced at 9.9 yuan, which greatly reduced the cost of the Internet of Everything. We will open the platform for third-party brands, and products can access the loT platform as long as they are embedded in this module, which expands Xiaomi loT Scope.” (I-XM) |

| Main Category | Subcategories | Numbering |

|---|---|---|

| Efficiency Orientation | Need to produce high-quality products; need to save energy and reduce emissions; need to reduce production costs | D1 |

| Value Orientation | Need to expand sustainable value business; need to enhance the value proposition; need to create higher value space for consumers | D2 |

| User Orientation | Need to increase the viscosity of users; need to meet diversified market demands; need to form a differentiation brand | D3 |

| Ecology Orientation | Need to achieve openness and cooperation; need to construct a business ecosystem; need to expand the enterprise boundary | D4 |

| Production Process Automation | Introduction of automated equipment; standardization of operational processes; basic data collection; data integration; production automation | D5 |

| Core Competence Shaping | Core technology R&D capability; data collection and analysis capabilities; specialized service capability | D6 |

| Product Intelligence | R&D intelligent modules; human–machine intelligent interaction; intelligent environment detection; intelligent analysis function | D7 |

| Intelligent Transformation | Data center platform; state perception; intelligent decision-making; advance warning; intelligent visualization; dynamic and accurate execution; intelligent data analysis and application | D8 |

| Servitization Transformation | Engineering-procurement-construction; solution services; remote operation and maintenance services; industrial financial services; cloud service platform | D9 |

| Ecological Synergy | Ecological-chain pattern; ecological platform construction; cross-border integration; collaborative research and development; resource sharing | D10 |

| Smart Connected Product Systems | R&D connected modules; data standardization; product function interaction; unified product style; providing life scenario system solutions; scenario linkage | D12 |

| Personalized Manufacturing | Big data analysis; personalized customization; flexible manufacturing model | D13 |

| Scenario Innovation | Create the brand characteristic scenario; setting VR virtual interaction scenarios; digital stores; experiential life scenario; cross-border fusion scenario | D14 |

| User Participation | Establish a we-media system; launch a user design platform; develop a brand interactive community | D15 |

| Additional Services for Products | Product maintenance; product upgrades; product logistics management; product development and design | D16 |

| Online and Offline Integration | Online and offline consumption channels; online and offline data integration | D17 |

| Path | Category |

|---|---|

| Efficiency-oriented path | Efficiency orientation; production process automation; intelligent transformation |

| Value-oriented Path | Value orientation; core competence shaping; additional services for products; servitization transformation |

| User-oriented path | User orientation; user participation; personalized manufacturing; scenario innovation; online and offline integration |

| Ecology-oriented path | Ecology orientation; ecological synergy; product intelligence; smart connected product systems |

| Category | Case Company | Examples of Typical Data |

|---|---|---|

| Efficiency orientation; production process automation; intelligent transformation;user orientation; user participation; personalized manufacturing; | China Chang’an Automobile Group Co., Ltd., Beijing, China. | “We focus on how to achieve high-quality product output, reduce inventory turnover and reduce the cost of complete vehicle manufacturing.”-efficiency orientation “We introduced industrial robots, improved our technology level, set up our own automated production lines and improved economies of scale.”-production process automation “We use simulations to verify vehicle safety and system stability. Later, the IT system architecture on Ali Cloud greatly reduced the deployment time and cost. Through external integration ability and structural flexibility, digital technology is applied to the whole process of product production and sales, and finally realize the intelligent process.”-intelligent transformation “Changan Automobile adheres to the product orientation of “customer first”, and through big data analysis of customer behavior patterns and basic information, excavates customers’ explicit and potential demands, and continuously creates value for customers.”-user orientation “We let users participate in the whole process from product research and development to the final product sales and pricing. We emphasize user feelings and attach importance to the expression of the emotional value of products and services, forming a set of design standards and manufacturing standards for customer needs.”-user participation “Our R&D brain platform can automatically match and recommend modular product integration according to user-set parameters”-personalized manufacturing … |

| Value orientation; core competence shaping; additional services for products; servitization transformation | Shenyang Machine Tool Co., Ltd., Shenyang, China. | “The era of low profit in China’s machine tool industry has arrived. The machine tool market continues to be depressed, and the market competition is more fierce. It is necessary to expand high value-added business”-value orientation “By reforming the system, reorganizing the departments, reforming the process and strengthening the management, we have effectively realized the reform of the enterprise management mode, promoted the enterprise’s learning and absorption of external knowledge, and completed the learning and absorption of the introduced technology, so as to improve our technical level.”-core competence shaping “We provide services based on customer demand characteristics such as quality, service, delivery time and price. At this stage, our focus is still on manufacturing, and passive services such as basic auxiliary installation and after-sales maintenance are only set as part of additional product attributes to improve product sales.”-additional services for products “Through innovation and systematic adjustment, the company has realized the transformation of profit model, realized the magnificent turn from machine tool manufacturer to the industrial service provider, and carried out the strategic transformation from industrial manufacturer to intelligent manufacturing comprehensive solution provider.”-servitization transformation … |

| User orientation; user participation; personalized manufacturing; online and offline integration | Qingdao Red Collar Group Co., Ltd., Qingdao, Shandong, China | “Outstanding personalized needs are increasingly being paid attention to by merchants. In the garment manufacturing industry, consumers pay more attention to personalized needs, which provides fertile soil for Red Collar’s business model. Red Collar Group is driven by consumer demand.”-user orientation “In order to better interact with users, we build a virtual and real interaction platform for users through the Internet”-user participation “The original “three-point-one-line” volumetric method collects 24 data from 19 parts of the body and inputs them into the Red collar personalized customization platform. The system will conduct data modeling and quickly form a data version exclusive to the customer.”-personalized manufacturing “This is the integration of online and offline, offline to complete the experience, see the appearance of the garment, measure the figure, introduce the category and collocation of clothes, and then enter the online customization. Also through online activities a large number of diversion, offline conversion, further reducing marketing costs.”-online and offline integration … |

| Ecology orientation; ecological synergy; product intelligence; smart connected product systems | Haier Group Co., Ltd., Qingdao, Shandong, China | “Constantly introduce new products, new models and new business forms, constantly break out new ecosystems, and realize the global layout of multi-brand collaboration”-ecology orientation “Haier COSMO platform has gathered more than 300 million users and more than 3.8 million global ecological resources, realizing cross-industry and cross-field expansion and service.”-ecological synergy “We enable products to hear, speak and think, to achieve the natural interaction between hardware products and users, and to achieve the best experience for users”-product intelligence “We realize the real-time interaction of platform hardware and software devices, use artificial intelligence to realize the interconnection between people and things, and finally use the ecosystem to provide users with intelligent interconnected products, and quickly show off their talents in the Internet of Things smart home appliances.”-smart connected product systems … |

| Value orientation; core competence shaping; additional services for products; servitization transformation | Xi’an Shaangu Power Co., Ltd., Xi’an, China. | “With the increasingly fierce market competition, the exploration of high value-added areas of the industrial chain is related to the survival of enterprises and the fundamental interests of employees.”-value orientation “We get out of the single domain of turbine machinery thinking and continue to process Reengineering, resource integration, optimization of support system and other measures, from the operation, equipment, Service and other dimensions to comprehensively improve our technical level”-core competence shaping “Provide maintenance, remote monitoring, zero inventory of spare parts, equipment upgrading and other supporting basic support services for the safety and efficiency problems existing in the operation of energy conversion equipment”-additional services for products “Based on customers’ functional requirements for energy conversion equipment, provide integrated operation services of the integrated park and operation and maintenance services for taking over customers’ operation activities such as electricity, gas and solid waste treatment”-servitization transformation … |

| Path Type | Efficiency-Oriented Path | Value-Oriented Path | User-Oriented Path | Ecology-Oriented Path | |

|---|---|---|---|---|---|

| Contents | |||||

| Starting point | Start on production process automation | Start on developing core technologies | Start on user social platform design | Start on the transformation in product intelligence | |

| Direction and focus | Follow the direction of improving production efficiency. Achieve intelligent manufacturing, improve the efficiency of resource utilization, and drive enterprises to upgrade to high-end products. | Follow the direction of enhancing the value by servitization. Shape the advantages with core capability, achieve the service-oriented extension, and provide high-value and unique services. | Follow the direction of improving user relationships. Implement personalized manufacturing, scenario innovation, and online and offline integration to improve the consumer experience. | Follow the direction of expanding the enterprise boundary. Build smart connected product systems through the “Internet of Everything” to achieve resource sharing across organizational boundaries. | |

| Process | Digitalization of the production process ←→ automation of the production process → intelligent transformation | Core competence shaping → additional services for products → servitization transformation | User participation ←→ flexible manufacturing → personalized manufacturing ←→ scenario innovation → online and offline integration | Product intelligence → product interconnection → smart connected product systems based on the ecological platform | |

| Environmental efficiency | Production automation and intelligence can increase the efficiency of resources and energy, achieve energy saving and emission reduction in the production process, and get rid of overcapacity dilemma. | Service is an important intangible resource, and the enhancement of service alleviates the consumption of product resources and provides sustainable value for industry development. | Precise, personalized manufacturing overcomes product homogeneity and prevents resource mismatch and waste. Scene innovation pursues the comparison of user experience and avoids the vicious competition of resources. | Intelligent products have stronger performance and higher utilization. Through the business ecosystem, we can share resources, knowledge, wealth, and value creation, improve the value of resource allocation and realize the value of resource combination. | |

| Economic benefit | Production automation and intelligence can not only improve output but also reduce production costs and achieve economies of scale. It also helps to improve product quality and open up the high-end market. | Servitization in manufacturing is the main value-added point. Unique digital services create a core competitive advantage and expand profit channels, stimulating service consumption to foster new economic growth points. | Personalized customization brings product premium and forms differentiated products to increase the viscosity of users. Scene innovation can shape a unique brand concept to encourage users to consume. | The intelligent connected product system expands the industry boundaries and product categories, improves the added value and function of products, and drives the supporting consumption of ecological products. | |

| Innovation risk | The innovation process is prone to a shortage of human resources, resulting in the introduction of a large number of automatic equipment and technologies but not their efficient application. | The development of servitization is a long-term process with a high risk of domain expansion and requires core technology and service capabilities as support. | Personalized manufacturing may lose mass-production economies of scale and requires sustainable production methods. Scenario innovation necessitates continuous renewal. | The expansion of the ecosystem may bring about data silos, collaboration difficulties, and product connectivity problems, which prevent further value-added data and result in ecological disintegration. | |

| Applicable condition | The industry has a certain degree of technological absorption and large-scale automation capability, and the market is relatively mature and stable. | Possess core technology research and development capabilities and original innovation capabilities. Presence of high technical barriers and long value chains | The products are close to the daily lives of the public. Enterprises have their brands and many marketing and sales channels. | The core products have been successfully built. Products have the basis for embedded smart modules. Enterprises are able to share resources with suitable partners. | |

| Applicable enterprise | Steel, chemical, and other process manufacturing. Discrete manufacturing with a high degree of modularization | Producing highly technical and complex products and facing enterprise-level consumers, such as equipment manufacturing, new energy enterprises | Products have low technical barriers and are aimed at mass consumers, such as furniture, food, and clothing. | High-technology industries in consumer goods manufacturing, such as automotive, home appliances, and electronic equipment. | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Zhang, J. Business Model Innovation Paths of Manufacturing Oriented towards Green Development in Digital Economy. Int. J. Environ. Res. Public Health 2022, 19, 16454. https://doi.org/10.3390/ijerph192416454

Han X, Zhang J. Business Model Innovation Paths of Manufacturing Oriented towards Green Development in Digital Economy. International Journal of Environmental Research and Public Health. 2022; 19(24):16454. https://doi.org/10.3390/ijerph192416454

Chicago/Turabian StyleHan, Xiao, and Jiayun Zhang. 2022. "Business Model Innovation Paths of Manufacturing Oriented towards Green Development in Digital Economy" International Journal of Environmental Research and Public Health 19, no. 24: 16454. https://doi.org/10.3390/ijerph192416454

APA StyleHan, X., & Zhang, J. (2022). Business Model Innovation Paths of Manufacturing Oriented towards Green Development in Digital Economy. International Journal of Environmental Research and Public Health, 19(24), 16454. https://doi.org/10.3390/ijerph192416454