The Opportunities and Challenges Associated with the Implementation of Fourth Industrial Revolution Technologies to Manage Health and Safety

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Results from Secondary Data

3.1.1. H&S Regulations Compliance Challenges

3.1.2. The 4iR in Construction

3.1.3. Available 4iR Technologies in the Construction Industry

3.1.4. Current Opportunities to Manage H&S Using 4iR Technologies

3.1.5. Challenges of 4iR Technologies Implementation

Construction Firms’ Level of Interest and Views

The Size of Projects and Availability of Resources

3.1.6. Implementation Strategies

3.2. Empirical Findings

3.2.1. Opportunities for 4iR Implementation in H&S Management

Descriptive Results on the Opportunities

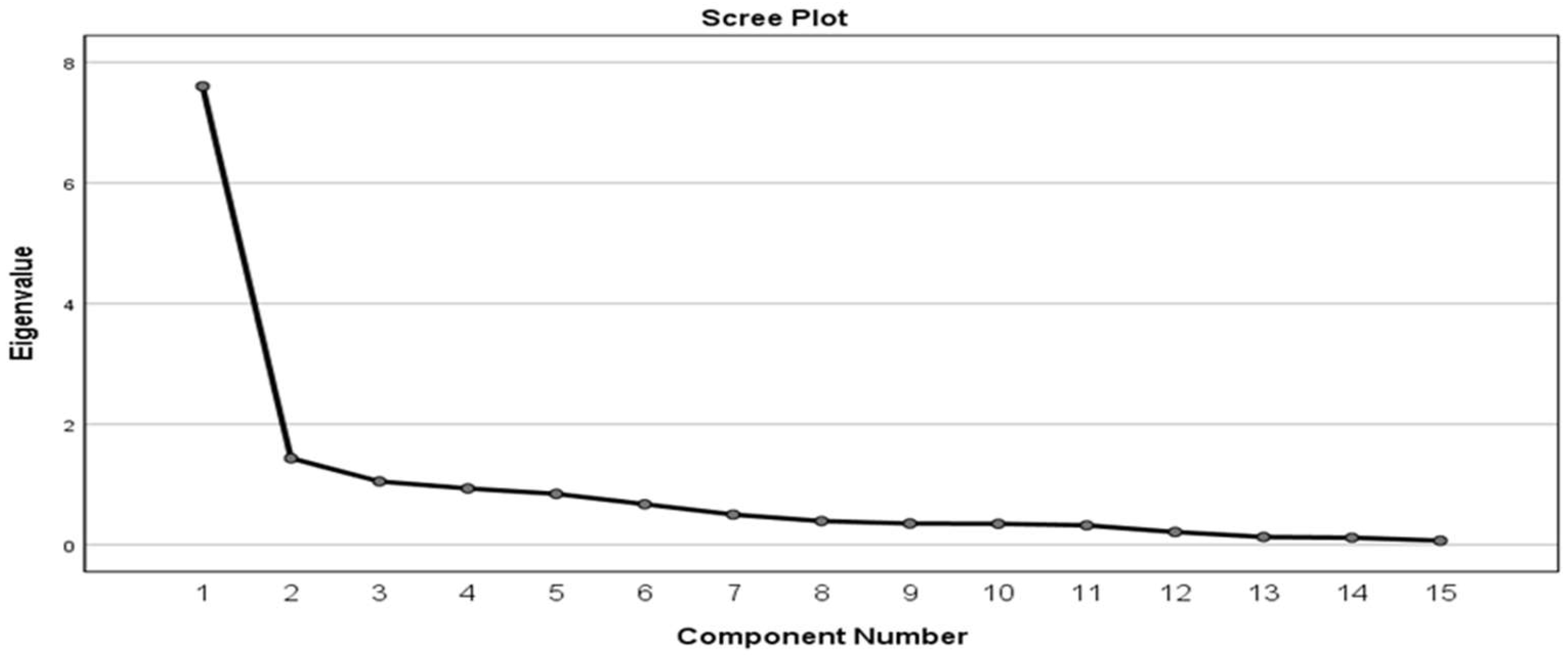

Inferential Analysis Results (Factor Analysis) on Existing Opportunities

3.2.2. Challenges in Implementing 4iR Technologies

Descriptive Results on the Implementation Challenges

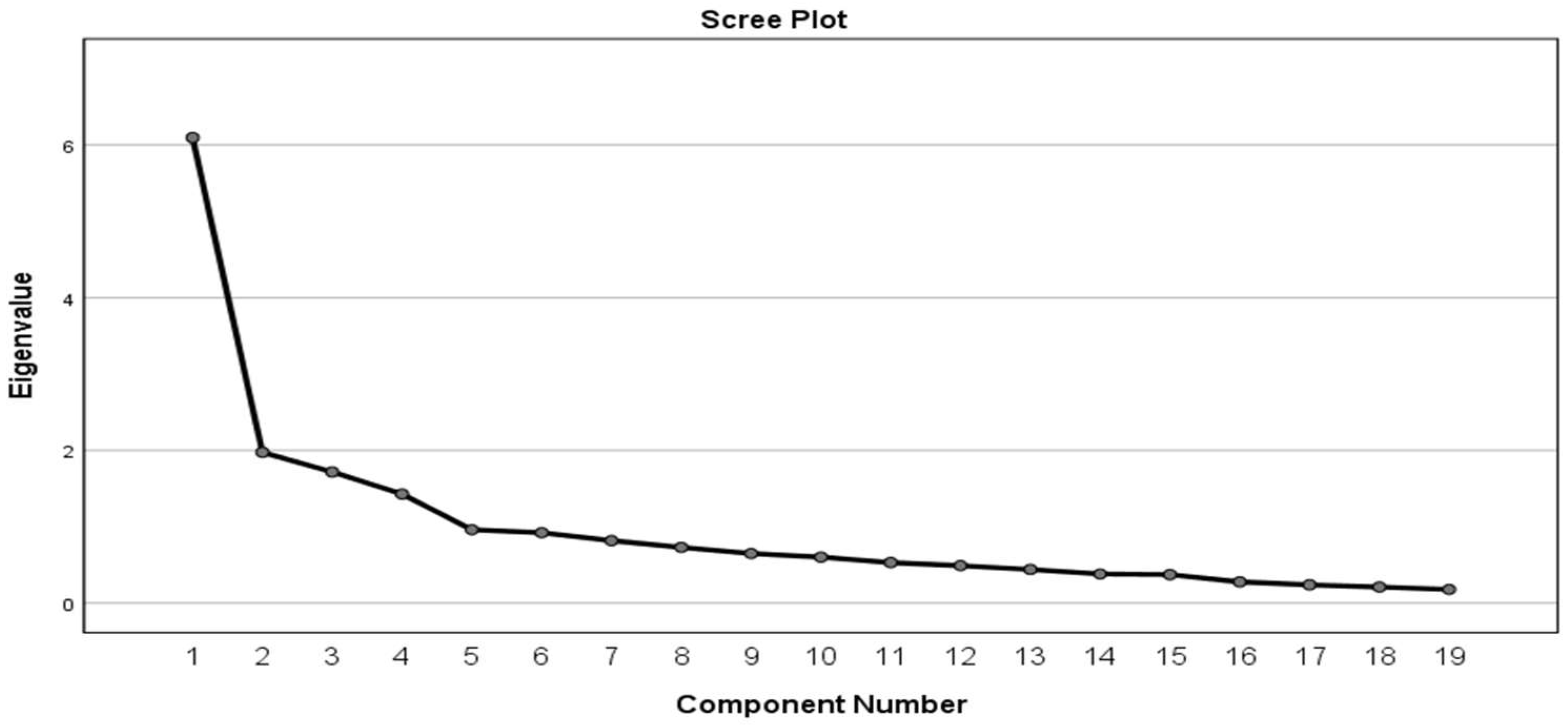

Inferential Analysis Results (Factor Analysis) on Implementation Challenges

4. Discussion

4.1. Opportunities for 4iR Technologies to Manage H&S

4.1.1. Component Two: Company-Specific Benefits

4.1.2. Component Three: Project-Specific Benefits

4.2. Challenges in Implementing 4iR Technologies

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lopes, M.; Haupt, T.C.; Fester, F.C. The Influence of Clients on Construction Health and Safety in South Africa. Occupational Health Southern Africa. 2012. Available online: https://www.occhealth.co.za/?/download/articles_205_1217/The+influence+of+clients+on+%C2%ADconstruction+health+and+safety+conditions+in+South+Africa.pdf (accessed on 5 April 2020).

- Japheth, C.; Kiprotich, K. An Investigation on Building Information Modelling in Project Management: Challenges, Strategies and Prospects in the Gauteng. 92. 2014. Available online: https://wiredspace.wits.ac.za/bitstream/handle/10539/15492/Charles%20Kiprotich_FINAL%20REPORT_February%202014.pdf?sequence=2 (accessed on 22 June 2020).

- Ibem, E.O.; Laryea, S. E-Procurement use in the South African construction industry. J. Inf. Technol. Constr. 2015, 20, 364–384. Available online: https://www.researchgate.net/publication/281901594_EProcurement_use_in_the_South_African_construction_Industry (accessed on 27 July 2020).

- Department of Labour. Amended Health and Safety Act. 2010. Available online: http://www.labour.gov.za/DOL/legislation/acts/occupational-health-and-safety/read-online/amended-occupational-health-and-safety-act-7 (accessed on 12 January 2020).

- Musonda, I. Construction Health and Safety (H&S) Performance Improvement- A Client. Doctoral Thesis, University of Johannesburg, Johannesburg, South Africa, 2012. in press. [Google Scholar]

- Mitchell, D. What Is Health and Safety and What does It Mean for Me?|Envico®. Envico Ltd. 2018. Available online: https://www.healthandsafetycourse.co.uk/articles/what-is-health-and-safety-and-what-does-it-mean-for-me/ (accessed on 19 March 2020).

- Choi, M.; Ahn, S.; Seo, J. VR-Based investigation of forklift operator situation awareness for preventing collision accidents. Accid. Anal. Prev. 2020, 136, 105404. [Google Scholar] [CrossRef] [PubMed]

- Nnaji, C.; Gambatese, J.; Lee, H.W.; Zhang, F. Improving construction work zone safety using technology: A systematic review of applicable technologies. J. Traffic Transp. Eng. 2020, 7, 61–75. [Google Scholar] [CrossRef]

- Nnaji, C.; Karakhan, A.A. Technologies for safety and health management in construction: Current use, implementation benefits and limitations, and adoption barriers. J. Build. Eng. 2020, 29, 101212. [Google Scholar] [CrossRef]

- Shamsudin, N.M.; Mahmood, N.H.N.; Rahim, A.R.A.; Mohamad, S.F.; Masrom, M. Virtual Reality Training Approach for Occupational Safety and Health: A Pilot Study. Adv. Sci. Lett. 2018, 24, 2447–2450. [Google Scholar] [CrossRef]

- Raphaelson, H. Top 7 Innovations That Aim to Improve Construction Site Safety. 2019. Available online: https://www.manufacturing.net/article/2018/10/top-7-innovations-aim-improve-construction-site-safety (accessed on 16 April 2020).

- Ramage, M. 9 Ways Technology Is Lowering Risk on the Jobsite. 2019. Available online: https://www.constructionbusinessowner.com/safety/9-ways-technology-lowering-risk-jobsite (accessed on 18 June 2020).

- Ikuabe, M.; Aigbavboa, C.; Oke, A. Cyber-Physical Systems: Matching Up its Application in the Construction industry and other Selected Industries. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Dubai, United Arab Emirates, 10–12 March 2020; pp. 1543–1552. [Google Scholar]

- Osunsanmi, T.O.; Oke, A.E.; Aigbavboa, C.O. Barriers for the Adoption of Incorporating RFID with Mobile Technology for Improved Safety of Construction Professionals. In The Construction Industry in the Fourth Industrial Revolution; Springer: Cham, Switzerland, 2019; pp. 297–304. [Google Scholar]

- van Rensburg, R.J. Home/Trades/Construction and the 4iR (4iR) Construction and the 4iR (4iR). 2020. Available online: https://gildes.solidariteit.co.za/en/construction-and-the-fourth-industrial-revolution-4iR/ (accessed on 23 July 2020).

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Kennedy, I.B. Industrial Revolution 4.0 in the construction industry: Challenges and opportunities for stakeholders. Ain Shams Eng. J. 2020, 11, 225–230. [Google Scholar] [CrossRef]

- Lau, S.E.N.; Aminudin, E.; Zakaria, R.; Saar, C.C.; Abidin, N.I.; Roslan, A.F.; Shaharuddin, A.B. Revolutionizing the Future of the Construction Industry: Strategizing and Redefining Challenges. Building Information Modelling (BIM) in Design, Construction and Operations III. 1. 2019, pp. 105–115. Available online: https://doi.org/10.2495/bim190101 (accessed on 22 September 2020).

- Osunsanmi, T.O.; Aigbavboa, C.O.; Oke, A.E.; Liphadzi, M. Appraisal of stakeholders’ willingness to adopt construction 4.0 technologies for construction projects. Built Environ. Proj. Asset Manag. 2020, 10, 547–565. [Google Scholar] [CrossRef]

- Gaspar, M.; Julião, J.; Cruz, M. Organizational Strategies Induced by the Fourth Industrial Revolution: Workforce Awareness and Realignment. In Proceedings of the International Conference on Innovation, Engineering and Entrepreneurship, Guimaraes, Portugal, 27–29 June 2018; Volume 505, pp. 330–336. [Google Scholar] [CrossRef]

- Chimhundu, S. A Study on the Bim Adoption Readiness and Possible. Wits Institutional Repository: DSPACE. 2015. Available online: https://core.ac.uk/download/pdf/188774452.pdf (accessed on 22 July 2020).

- Qi, B.; Razkenari, M.; Costin, A.; Kibert, C.; Fu, M. A systematic review of emerging technologies in industrialized construction. J. Build. Eng. 2021, 39, 102265. [Google Scholar] [CrossRef]

- Akram, R.; Thaheem, M.J.; Nasir, A.R.; Ali, T.H.; Khan, S. Exploring the role of building information modeling in construction safety through science mapping. Saf. Sci. 2019, 120, 456–470. [Google Scholar] [CrossRef]

- Manda, M.I.; Ben Dhaou, S. Responding to the challenges and opportunities in the 4th industrial revolution in developing countries. In ACM International Conference Proceeding Series; F1481; Association for Computing Machinery: Melbourne, VIC, Australia, 2019; pp. 244–253. Available online: https://doi.org/10.1145/3326365.3326398 (accessed on 14 April 2021).

- Claydon, L.S. Rigour in quantitative research. Nurs. Stand. 2015, 29, 43–48. Available online: https://doi.org/10.7748/ns.29.47.43.e8820 (accessed on 16 April 2021). [CrossRef]

- Okoro, C.S. Nutritional Quality and Health and Safety Performance in the South African Construction. Master’s Dissertation, University of Johannesburg, Johannesburg, South Africa, 2015. in press. Available online: http://hdl.handle.net/10210/56185 (accessed on 16 May 2020).

- Hamid, A.R.A.; Singh, B.; Mohd, A.S. Cost of Compliance with Health and Safety Management System among Contractor in Construction Industry. In Proceedings of the National Seminar on Civil Engineering Research, Universiti Teknologi Malaysia, Johor Bahru, Malaysia, 14–15 April 2014. [Google Scholar]

- Farrell, S. Open-Ended vs. Closed-Ended Questions in User Research. 2016. Available online: https://www.nngroup.com/articles/open-ended-questions/ (accessed on 17 August 2020).

- Churchill, E.F., Jr.; McLaughin, J.W. Qualitative Research on Japanese Learners and Contexts. Temple Univ. Jpn. Work. Pap. Appl. Linguist. 2001, 19, 188–206. [Google Scholar]

- Agumba, J.N. A Construction Health and Safety Performance Improvement Model for South African Small and Medium Enterprises Justus Ngala Agumba; University of Johannesburg (South Africa); ProQuest Dissertations Publishing: Johannesburg, South Africa, 2013; p. 28376999. [Google Scholar]

- Habib, A. Gauteng Poised to Lead in South Africa’s 4th Industrial Revolution. 2019. Available online: https://www.3cubeproperty.co.za/news/gauteng-poised-to-lead-in-south-africas-4th-industrial-revolution/ (accessed on 22 September 2020).

- Smallwood, J.; Emuze, F. Towards Zero Fatalities, Injuries, and Disease in Construction. Creat. Constr. Conf. 2016, 164, 453–460. Available online: https://www.researchgate.net/publication/311362110_Towards_Zero_Fatalities_Injuries_and_Disease_in_Construction (accessed on 18 November 2020). [CrossRef]

- Fairfield University. Survey Response Rates, Validity, and Survey Fatigue. 2020. Available online: https://192.160.243.43:8443/download/attachments/27722315/Survey%20Response%20Rates%20and%20Validity.pdf?api=v2 (accessed on 16 April 2021).

- Frost, J. Guidelines for Removing and Handling Outliers in Data. 2021. Available online: https://statisticsbyjim.com/basics/remove-outliers/ (accessed on 13 June 2021).

- Ponnam, A.; Sahoo, D.; Sarkar, A.; Mohapatra, S.N. An exploratory study of factors affecting credit card brand and category selection in India. J. Financ. Serv. Mark. 2014, 19, 221–233. Available online: https://doi.org/10.1057/fsm.2014.17 (accessed on 26 September 2020).

- Tabachnick, B.G.; Fidell, L.S. Using Multivariate Statistics; Allyn and Bacon: Boston, MA, USA, 2001; Available online: https://faculty.chass.ncsu.edu/garson/PA765/tabachnick.htm (accessed on 26 May 2021).

- Meno, T. An Assessment of Risk Associated with Digitalisation in the South African Construction Industry. Magister Technologiae (Quantity Surveying). University of Johannesburg: ProQuest. 2017. Available online: https://www.proquest.com/openview/362e4668bf72b79aa0b67d72ba0df104/1?pq-origsite=gscholar&cbl=18750&diss=y (accessed on 22 March 2021).

- Bartlett, M.S. A Note on the Multiplying Factors for Various χ2 Approximations. J. R. Stat. Soc. Ser. B 1954, 16, 296–298. [Google Scholar] [CrossRef]

- Kaiser, H.F. A Second-Generation Little Jiffy Henry F. Kamer. Psychometrika. 1970, 35, 401–415. Available online: https://www.deepdyve.com/lp/springer-journals/a-second-generation-little-jiffy-O7I0OVk4EC (accessed on 23 March 2021). [CrossRef]

- Kaiser, H.F. An index of factorial simplicity. Psychometrika 1974, 39, 31–36. [Google Scholar] [CrossRef]

- Deng, H.; Ou, Z.; Deng, Y. Multi-Angle Fusion-Based Safety Status Analysis of Construction Workers. Int. J. Environ. Res. Public Health 2021, 18, 11815. [Google Scholar] [CrossRef]

- Al-Bayati, A.J. Firm Size Influence on Construction Safety Culture and Construction Safety Climate. Pr. Period. Struct. Des. Constr. 2021, 26, 04021028. [Google Scholar] [CrossRef]

- Windapo, A.; Oladapo, A.A. Determinants of Construction Firms ‘compliance with Health and Safety Regulations in South Africa. In Proceedings of the 28th Annual ARCOM Conference, Edinburgh, UK, 3–5 September 2012; Volume 2, pp. 433–444, Association of Researchers in Construction Management (ARCOM). Available online: http://www.scopus.com/inward/record.url?eid=2-s2.0-84912090708&partnerID=MN8TOARS (accessed on 22 July 2020).

- Cunningham, T.; Jacklitsch, B.; Richards, R. Intermediary Perspectives on Total Worker Health in Small Businesses. Int. J. Environ. Res. Public Health 2021, 18, 10398. [Google Scholar] [CrossRef]

- Hon, C.K.; Hinze, J.; Chan, A.P. Safety climate and injury occurrence of repair, maintenance, minor alteration and addition works. Facilities 2014, 32, 188–207. [Google Scholar] [CrossRef]

- Windapo, A. Relationship between degree of risk, cost and level of compliance to occupational health and safety regulations in construction. Constr. Econ. Build. 2013, 13, 67–82. [Google Scholar] [CrossRef] [Green Version]

- Schwab, K. Four Leadership Principles for the Fourth Industrial Revolution. 2016. Available online: https://www.weforum.org/agenda/2016/10/four-leadership-principles-for-the-fourth-industrial-revolution/ (accessed on 21 March 2020).

- Malinga, S. Fourth Industrial Revolution can Propel SA’s Economic Growth. 2019. Available online: https://www.itweb.co.za/content/dgp45vaGwbYMX9l8 (accessed on 7 September 2020).

- Olojede, O.A.; Agbola, S.B.; Samuel, K.J. Technological innovations and acceptance in public housing and service delivery in South Africa: Implications for the Fourth Industrial Revolution. J. Public Adm. 2019, 54, 162–183. [Google Scholar]

- Wu, G.; Yang, R.; Li, L.; Bi, X.; Liu, B.; Li, S.; Zhou, S. Factors influencing the application of prefabricated construction in China: From perspectives of technology promotion and cleaner production. J. Clean. Prod. 2019, 219, 753–762. [Google Scholar] [CrossRef]

- Lee, Y.-C.; Shariatfar, M.; Rashidi, A.; Lee, H.W. Evidence-driven sound detection for prenotification and identification of construction safety hazards and accidents. Autom. Constr. 2020, 113, 103127. [Google Scholar] [CrossRef]

- Haupt, T.C.; Akinlolu, M.; Raliile, M.T. Emerging Technologies in Construction Safety and Health Management. International Conference on Innovation, Technology, Enterprise, and Entrepreneurship (ICITEE). 2019, pp. 413–420. Available online: https://www.researchgate.net/publication/338990941_Emerging_Technologies_in_Construction_Safety_and_Health_Management (accessed on 2 October 2020).

- Smallwood, J.J.; Emuze, F.; Allen, C. Building Information and Modelling: South African Architects’ and Contractors Perceptions and Practices. In Proceedings of the 1st UK Academic Conference on Building Information Modelling (BIM), Newcastle upon Tyne, UK, 5–9 September 2012; pp. 1–10. Available online: https://www.researchgate.net/publication/273445892_BUILDING_INFORMATION_AND_MODELLING_SOUTH_AFRICAN_ARCHITECTS'_AND_CONTRACTORS'_PERCEPTIONS_AND_PRACTICES (accessed on 2 October 2020).

- Getuli, V.; Ventura, S.M.; Capone, P.; Ciribini, A.L. BIM-based Code Checking for Construction Health and Safety. Procedia Eng. 2017, 196, 454–461. [Google Scholar] [CrossRef]

- Niu, Y.; Lu, W.; Xue, F.; Liu, D.; Chen, K.; Fang, D.; Anumba, C. Towards the “third wave”: An SCO-enabled occupational health and safety management system for construction. Saf. Sci. 2018, 111, 213–223. [Google Scholar] [CrossRef]

- Gheisari, M.; Esmaeili, B. Unmanned Aerial Systems (UAS) for Construction Safety Applications. Construction Research Congress 2016: Old and New Construction Technologies Converge in Historic San Juan. In Proceedings of the 2016 Construction Research Congress, CRC 2016, San Juan, PR, USA, 31 May–2 June 2016; pp. 2642–2650. [Google Scholar] [CrossRef]

- Alhumayani, H.; Gomaa, M.; Soebarto, V.; Jabi, W. Environmental assessment of large-scale 3D printing in construction: A comparative study between cob and concrete. J. Clean. Prod. 2020, 270, 122463. [Google Scholar] [CrossRef]

- Llale, J.; Setati, M.; Mavunda, S.; Ndlovu, T.; Root, D.; Wembe, P. A Review of the Advantages and Disadvantages of the Use of Automation and Robotics in the Construction Industry. In Proceedings of the Construction Industry Development Board Post Graduate Research Conference, Johannesburg, South Africa, 28–30 July 2019; Springer: Cham, Switzerland, 2020; pp. 197–204. [Google Scholar]

- Aghimien, D.; Aigbavboa, C.; Oke, A.; Thwala, W. Mapping out research focus for robotics and automation research in construction-related studies: A bibliometric approach. J. Eng. Des. Technol. 2019, 18, 1063–1079. [Google Scholar] [CrossRef]

- Hanus, M.J.; Harris, A.T. Nanotechnology innovations for the construction industry. Prog. Mater. Sci. 2013, 58, 1056–1102. [Google Scholar] [CrossRef]

- Zhou, W.; Whyte, J.; Sacks, R. Construction safety and digital design: A review. Autom. Constr. 2012, 22, 102–111. [Google Scholar] [CrossRef] [Green Version]

- Jiang, S.; Skibniewski, M.J.; Yuan, Y.; Sun, C.; Lu, Y. Ultra-wide band applications in industry: A critical review. J. Civ. Eng. Manag. 2011, 17, 437–444. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Fenais, A.; Ariaratnam, S.T.; Ayer, S.K.; Smilovsky, N. Integrating Geographic Information Systems and Augmented Reality for Mapping Underground Utilities. Infrastructures 2019, 4, 60. [Google Scholar] [CrossRef] [Green Version]

- Tatum, M.C.; Liu, J. Unmanned Aircraft System Applications in Construction. Procedia Eng. 2017, 196, 167–175. [Google Scholar] [CrossRef]

- Howard, J.; Murashov, V.; Branche, C.M. Unmanned aerial vehicles in construction and worker safety. Am. J. Ind. Med. 2017, 61, 3–10. [Google Scholar] [CrossRef]

- Zhang, S.; Sulankivi, K.; Kiviniemi, M.; Romo, I.; Eastman, C.M.; Teizer, J. BIM-based fall hazard identification and prevention in construction safety planning. Saf. Sci. 2015, 72, 31–45. [Google Scholar] [CrossRef]

- Li, C.T.; Cheng, J.C.; Chen, K. Top 10 technologies for indoor positioning on construction sites. Autom. Constr. 2020, 118, 103309. [Google Scholar] [CrossRef]

- Woodhead, R.; Stephenson, P.; Morrey, D. Digital construction: From point solutions to IoT ecosystem. Autom. Constr. 2018, 93, 35–46. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Liu, C. Applications of multirotor drone technologies in construction management. Int. J. Constr. Manag. 2018, 19, 401–412. [Google Scholar] [CrossRef]

- Zhang, M.; Cao, T.; Zhao, X. Applying Sensor-Based Technology to Improve Construction Safety Management. Sensors 2017, 17, 1841. [Google Scholar] [CrossRef] [Green Version]

- Olaitan, O.O.; Issah, M.; Wayi, N. A framework to test South Africa’s readiness for the fourth industrial revolution. SA J. Inf. Manag. 2021, 23, 10. [Google Scholar]

- Mahachi, J. Challenges in Implementing Innovative Building Technologies: Housing Case Studies in South Africa. University of Johannesburg. 2020. Available online: https://ujcontent.uj.ac.za/vital/access/services/Download/uj:34033/SOURCE1 (accessed on 4 October 2020).

- Bayode, A.; van der Poll, J.; Ramphal, R. 4th Industrial Revolution: Challenges and Opportunities in the South African Context. In Proceedings of the 17th Johannesburg International Conference on Science, Engineering, Technology & Waste Management, Johannesburg, South Africa, 18–19 November 2019; pp. 341–347. Available online: https://doi.org/10.17758/EARES8.EAP1119285 (accessed on 22 July 2020).

- Akinboade, O.A. Drivers of housing technology adoption in South Africa. J. Geogr. Reg. Plan. 2012, 5, 328–338. [Google Scholar] [CrossRef]

- Alade, K.; Windapo, A. 4IR leadership effectiveness and practical implications for construction business organisations. In Proceedings of the Construction Industry Development Board Postgraduate Research Conference, Johannesburg, South Africa, 28–30 July 2019; Springer: Cham, Switzerland, 2019; pp. 62–70. [Google Scholar]

- Birkel, H.S.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.-I. Development of a Risk Framework for Industry 4.0 in the Context of Sustainability for Established Manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef] [Green Version]

- Kariem, A. Draft Digital Futures South Africas Digital Readiness for the 4iR. The National Planning Commission. 2020. Available online: https://researchictafrica.net/publication/digital-futures-south-africas-readiness-for-the-4ir/ (accessed on 2 December 2019).

- Moloi, D.; Zibani, S.; Makhubela, R. Fourth Industrial Revolution and the Future of Government. Natl. Treas. 2018, 11, 1–34. [Google Scholar]

- Osunsanmi, T.O.; Aigbavboa, C.; Oke, A. Construction 4.0: The Future of the Construction Industry in South Africa. Int. J. Civ. Environ. Eng. 2018, 12, 206–212. Available online: https://publications.waset.org/10008621/construction-40-the-future-of-the-construction-industry-in-south-africa (accessed on 24 March 2020).

- Aghimien, D.; Aigbavboa, C.; Aghimien, L.; Thwala, W.D.; Ndlovu, L. Making a case for 3D printing for housing delivery in South Africa. Int. J. Hous. Mark. Anal. 2020, 13, 565–581. [Google Scholar] [CrossRef]

- Oke, A.; Fernandes, F.A.P. Innovations in Teaching and Learning: Exploring the Perceptions of the Education Sector on the 4th Industrial Revolution (4IR). J. Open Innov. Technol. Mark. Complex. 2020, 6, 31. [Google Scholar] [CrossRef]

- Keogh, M.; Smallwood, J.J. The role of the 4th Industrial Revolution (4IR) in enhancing performance within the construction industry. IOP Conf. Ser. Earth Environ. Sci. 2021, 654, 012021. Available online: https://iopscience.iop.org/article/10.1088/1755-1315/654/1/012021/pdf (accessed on 22 September 2020). [CrossRef]

- Samuels, P. Advice on Exploratory Factor Analysis. 2017. Available online: 10.13140/RG.2.1.5013.9766 (accessed on 13 December 2021).

- Odubiyi, T.B. An Evaluation of Information and Communication Technology Application in South African Construction Industry. University of Johannesburg: ProQuest. 2019. Available online: https://www.proquest.com/openview/1299b9de89e40f3e2331c63977506595/1?pq-origsite=gscholar&cbl=2026366&diss=y (accessed on 27 June 2020).

| Technologies | Description/Function | Source |

|---|---|---|

| Radio Frequency Identification (RFID) | This comprises tags and readers system used to detect, alarm and transfer data using a wireless. This technology is used on humans and equipment on site to ensure that they are working in a safe environment | Osunsanmi, Oke and Aigbavboa [14]; Haupt, Akinlolu and Raliile [51] |

| Building Information Modelling (BIM) | Optimizes the integration of design, procurement, construction, end of use of building and structures. The technology is used during the pre-planning of site safety management to identify possible hazards which may arise during construction, and suggest solutions. During construction, BIM works as a semi-automatic technology that helps check multiple safety regulation and safety plan, detecting any clashes to ensure good safety performance is managed. | Smallwood, Emuze and Allen [52]; Getuli, Ventura, Capone, and Ciribini [53] |

| Artificial Intelligence (AI) | A technology that can replace humans, operating through computer techniques monitoring and controlling the safety of the workers, equipment, and the structure. The technology works faster than humans, and monitors and manages site H&S with urgency. | Niu et al., [54]; Gheisari and Esmaeili [55] |

| Third Dimensional (3D) Printing | A technology that automates the building of structures while creating a less hazardous environment. | Alhumayani, Gomaa, Soebarto and Jabi [56] |

| Robotics | Automates construction works, creates less hazardous zones and greater visibility of the site and performs tasks that are even difficult to humans. Robotics help in mitigating human injuries and decreasing accidents on-site. | Llale, Setati, Mavunda, Ndlovu, Root and Wembe [57]; Aghimien, Aigbavboa, Oke and Thwala [58] |

| Sensors | Analyzes measurements of health monitoring through centralized real-time information reporting. Sensing reduces construction safety fatalities by alarming workers of risks within their zones. | Hanus and Harris [59]; Zhou, Whyte and Sacks [60] |

| Ultra-Wide Band (UWB) | Uses three or more receivers positioned at the area to be monitored to detect anything that could cause safety issues at the workplace. | Jiang, Skibniewski, Yuan, Sun and Lu [61] |

| The Internet of Things (IOT) | Helps with the H&S management processes from the initial stage and during construction by providing automated H&S training and monitoring of humans and site vehicles and plants. | Tang, Shelden, Eastman, Pishdad-Bozorgi and Gao [62] |

| Smart Devices | Are tools attached on humans and plants, detecting possible hazards, monitoring their movements, computing the data and sounding alarms when nearing dangerous zones or objects. | Niu et al., [54] |

| Geographical Information System (GIS) | Collects the geographic distribution of onsite works using spatial relations, creating a protocol that results in ease of H&S management. | Fenais, Ariaratnam, Ayer and Smilovsky [63] |

| Drones | Captures through video big data from lower ground level to the highest heights of a construction site providing real-time movement of the works, detecting possible safety risks and providing feedback via audio communication. Further, this technology is used for the inspection of safety and wellbeing of humans and plants at the workplace. | Gheisari and Esmaeili [55]; Tatum and Liu [64]; Howard, Murashov and Branche [65] |

| Virtual Reality (VR) | Is applied as an automated H&S training providing visualization of real-time detection of hazards, and enhancing knowledge on safety management. | Zhou, Whyte and Sacks [60] |

| Four-Dimensional Computer Aided Design (4D CAD) | The information about the project activities is inserted in this technology. The information is then analysed, detect any possible risks and generate a safety management plan at the design stage. | Zhou, Whyte and Sacks [60]; Zhang, Sulankivi, Kiviniemi, Romo, Eastman Teizer [66] |

| Global Navigation Satellite System (GNSS) | Provides real-time monitoring of data of a large population from geosynchronous satellites, ensuring easy control and management of workplace safety. | Fenais, Ariaratnam, Ayer and Smilovsky [63] |

| Global positing system (GPS) | A positioning tool that uses wireless to track works and detect collision. It works as a security safeguard machinery in a robotic construction. | Li, Cheng and Chen [67] |

| The 4ir Technologies Opportunities Existing in the Construction Industry to Manage H&S | σX | R | |

|---|---|---|---|

| Better Information management | 4.21 | 1.00 | 1 |

| Improved workflow | 4.20 | 0.98 | 2 |

| Improved safety inspections | 4.16 | 1.00 | 3 |

| Better accountability | 4.14 | 0.91 | 4 |

| Preventing accident | 4.13 | 0.97 | 5 |

| Better reporting | 4.10 | 1.05 | 6 |

| Improve in controlling and monitoring | 4.09 | 1.02 | 7 |

| Create greater visibility | 4.09 | 0.85 | 7 |

| Better collection of data platform | 4.09 | 1.07 | 7 |

| Decreasing fatalities | 4.08 | 1.11 | 8 |

| Better communication | 4.06 | 1.09 | 9 |

| Reduce injuries | 4.02 | 1.03 | 10 |

| More time to solve more difficult issues | 3.98 | 0.93 | 11 |

| Construction gains sustainability | 3.90 | 1.04 | 12 |

| Saves on cost | 3.47 | 1.30 | 13 |

| Measures of Sampling Adequacy | ||

|---|---|---|

| Kaiser-Meyer-Olkin | 0.82 | |

| Bartlett’s Test of Sphericity | Approx. Chi-Square | 879,900 |

| df | 105 | |

| Sig. | 0.000 |

| Component | Initial Eigenvalues | Extraction Sums of Squared Loadings | ||||

|---|---|---|---|---|---|---|

| Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | |

| 1 | 7.60 | 50.69 | 32.082 | 6.096 | 50.69 | 50.69 |

| 2 | 1.47 | 9.57 | 42.471 | 1.974 | 9.57 | 60.26 |

| 3 | 1.05 | 7.01 | 51.504 | 1.716 | 7.01 | 67.27 |

| 5 | 0.935 | 6.23 | 64.069 | |||

| 6 | 0.845 | 5.64 | 68.913 | |||

| Component | |||

|---|---|---|---|

| 1 | 2 | 3 | |

| Construction gains sustainability | 0.91 | ||

| Decreases fatalities | 0.793 | ||

| Reduce injuries | 0.705 | ||

| Improve workflow | 0.701 | ||

| Better collection of data platform | 0.685 | ||

| Improved safety inspections | 0,.657 | ||

| Better Information management | 0.632 | ||

| Better accountability | 0.581 | ||

| Saves on cost | 0.441 | ||

| Create greater visibility | 0.741 | ||

| More time to solve more difficult issues | 0.661 | ||

| Preventing accident | 0.562 | ||

| Better reporting | 0.979 | ||

| Better communication | 0.845 | ||

| Improve in controlling and monitoring | 0.540 | ||

| Challenges Associated with the Implementation of 4iR Technologies | σX | R | |

|---|---|---|---|

| Technologies are too expensive | 3.95 | 1.203 | 1 |

| Fear of job losses | 3.92 | 1.147 | 2 |

| Lack of adequate skills | 3.72 | 1.184 | 3 |

| Lack of cost to adopt | 3.58 | 1.210 | 4 |

| Unavailability of training capabilities | 3.57 | 1.335 | 5 |

| Prefer traditional method | 3.56 | 1.303 | 6 |

| Unavailability of funds from client | 3.55 | 1.372 | 7 |

| Fear of change | 3.55 | 1.330 | 7 |

| Unavailability of financial resources | 3.49 | 1.330 | 8 |

| Unskilled technical support | 3.49 | 1.268 | 8 |

| Lack of innovation | 3.44 | 1.353 | 9 |

| Lacks client insistence | 3.43 | 1.258 | 10 |

| Unalignment of labour supply | 3.38 | 1.187 | 11 |

| Size of project | 3.35 | 1.269 | 12 |

| Unavailability of specialist | 3.35 | 1.269 | 12 |

| Lack of education | 3.26 | 1.280 | 13 |

| Lack of access to the wireless broadband | 3.16 | 1.268 | 14 |

| Lacks interest | 3.07 | 1.302 | 15 |

| Insufficient electricity | 2.84 | 1.485 | 16 |

| Measures of Sampling Adequacy | ||

|---|---|---|

| Kaiser-Meyer-Olkin | 0.80 | |

| Bartlett’s Test of Sphericity | Approx. Chi-Square | 649,148 |

| df | 171 | |

| Sig. | 0.000 |

| Component | Initial Eigenvalues | Extraction Sums of Squared Loadings | ||||

|---|---|---|---|---|---|---|

| Total | % of Variance | Cumulative % | Total | % of Variance | Cumulative % | |

| 1 | 6.096 | 32.082 | 32.082 | 6.096 | 32.082 | 32.082 |

| 2 | 1.974 | 10.388 | 42.471 | 1.974 | 10.388 | 42.471 |

| 3 | 1.716 | 9.033 | 51.504 | 1.716 | 9.033 | 51.504 |

| 4 | 1.427 | 7.512 | 59.016 | 1.427 | 7.512 | 59.016 |

| 5 | 0.960 | 5.054 | 64.069 | |||

| 6 | 0.920 | 4.844 | 68.913 | |||

| Component | ||||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| Unskilled technical support | 0.832 | |||

| Unavailability of specialist | 0.829 | |||

| Unavailability of training capabilities | 0.650 | |||

| Lack of adequate skills | 0.624 | |||

| Lack of client insistence | 0.599 | |||

| Lack of interest | 0.540 | |||

| Prefer traditional method | 0.403 | |||

| Technologies are too expensive | 0.746 | |||

| Fear of change | 0.644 | |||

| Lack of innovation | 0.522 | |||

| Insufficient electricity | 0.452 | |||

| Unavailability of financial resources | 0.807 | |||

| Unavailability of funds from client | 0.703 | |||

| Lack of cost to adopt | 0.601 | |||

| Size of project | 0.600 | |||

| Lack of education | 0.795 | |||

| Unalignment of labour supply | 0.731 | |||

| Fear of job losses | 0.656 | |||

| Lack of access to the wireless broadband | 0.612 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malomane, R.; Musonda, I.; Okoro, C.S. The Opportunities and Challenges Associated with the Implementation of Fourth Industrial Revolution Technologies to Manage Health and Safety. Int. J. Environ. Res. Public Health 2022, 19, 846. https://doi.org/10.3390/ijerph19020846

Malomane R, Musonda I, Okoro CS. The Opportunities and Challenges Associated with the Implementation of Fourth Industrial Revolution Technologies to Manage Health and Safety. International Journal of Environmental Research and Public Health. 2022; 19(2):846. https://doi.org/10.3390/ijerph19020846

Chicago/Turabian StyleMalomane, Reneiloe, Innocent Musonda, and Chioma Sylvia Okoro. 2022. "The Opportunities and Challenges Associated with the Implementation of Fourth Industrial Revolution Technologies to Manage Health and Safety" International Journal of Environmental Research and Public Health 19, no. 2: 846. https://doi.org/10.3390/ijerph19020846

APA StyleMalomane, R., Musonda, I., & Okoro, C. S. (2022). The Opportunities and Challenges Associated with the Implementation of Fourth Industrial Revolution Technologies to Manage Health and Safety. International Journal of Environmental Research and Public Health, 19(2), 846. https://doi.org/10.3390/ijerph19020846