Effect of Ridge Height, Row Grade, and Field Slope on Nutrient Losses in Runoff in Contour Ridge Systems under Seepage with Rainfall Condition

Abstract

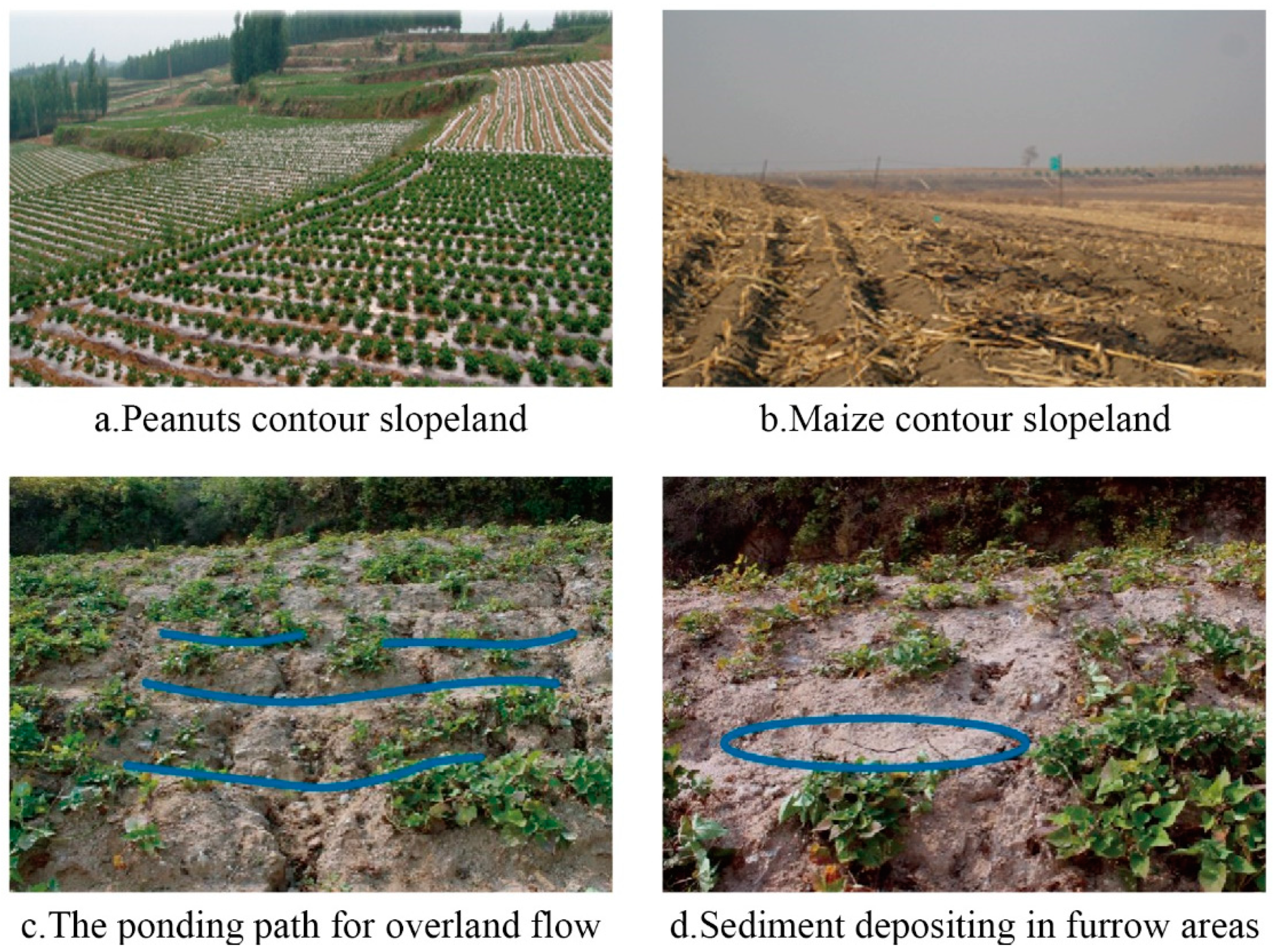

1. Introduction

2. Materials and Methods

2.1. Experimental Design

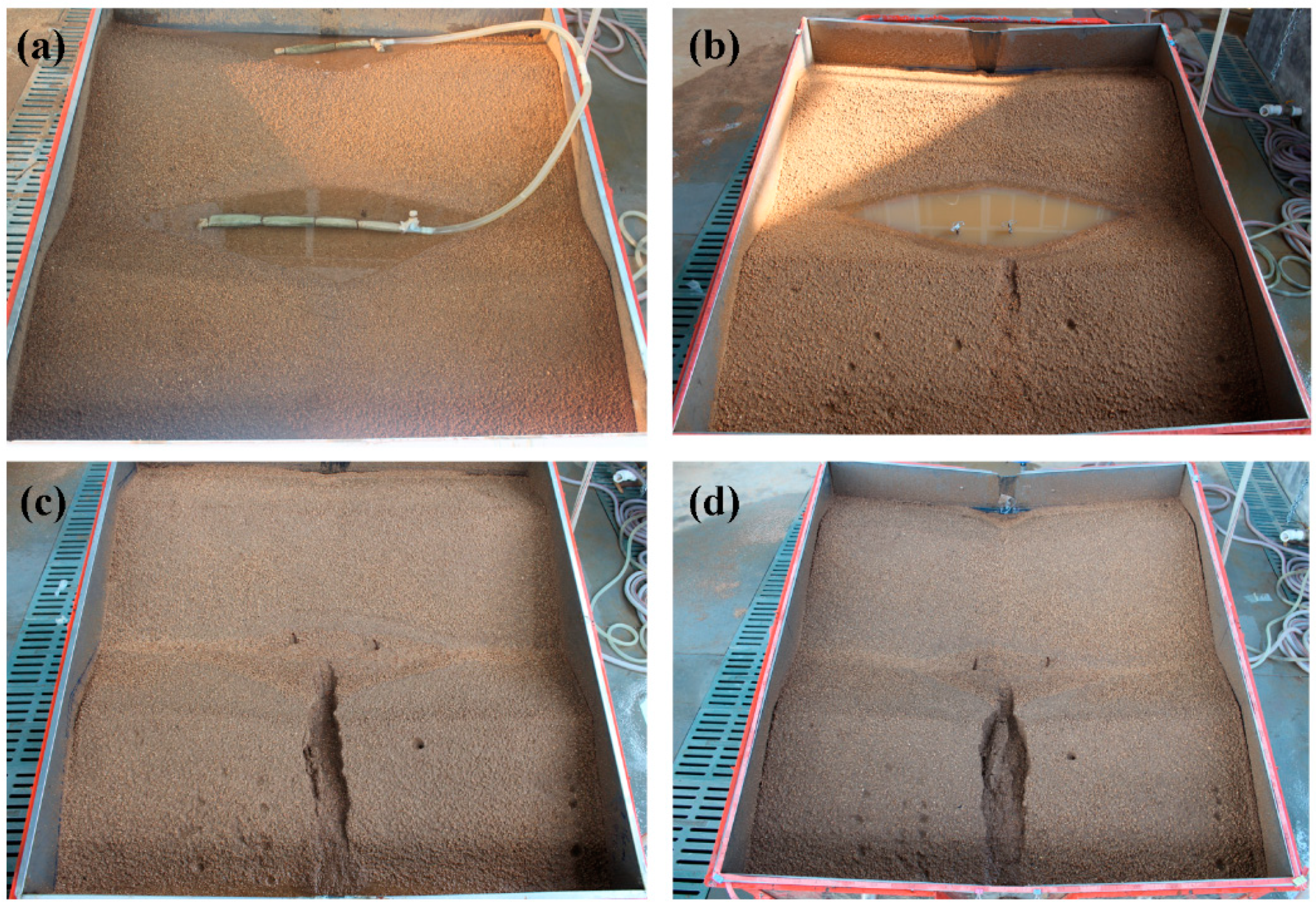

2.2. Experimental Setup

2.2.1. Rainfall Simulator System

2.2.2. Experimental Soil

2.2.3. Experimental Plots

2.3. Experimental Procedure

2.3.1. Experimental Seepage Process

2.3.2. Simulated Rainfall Process

2.4. Data Analysis

3. Results

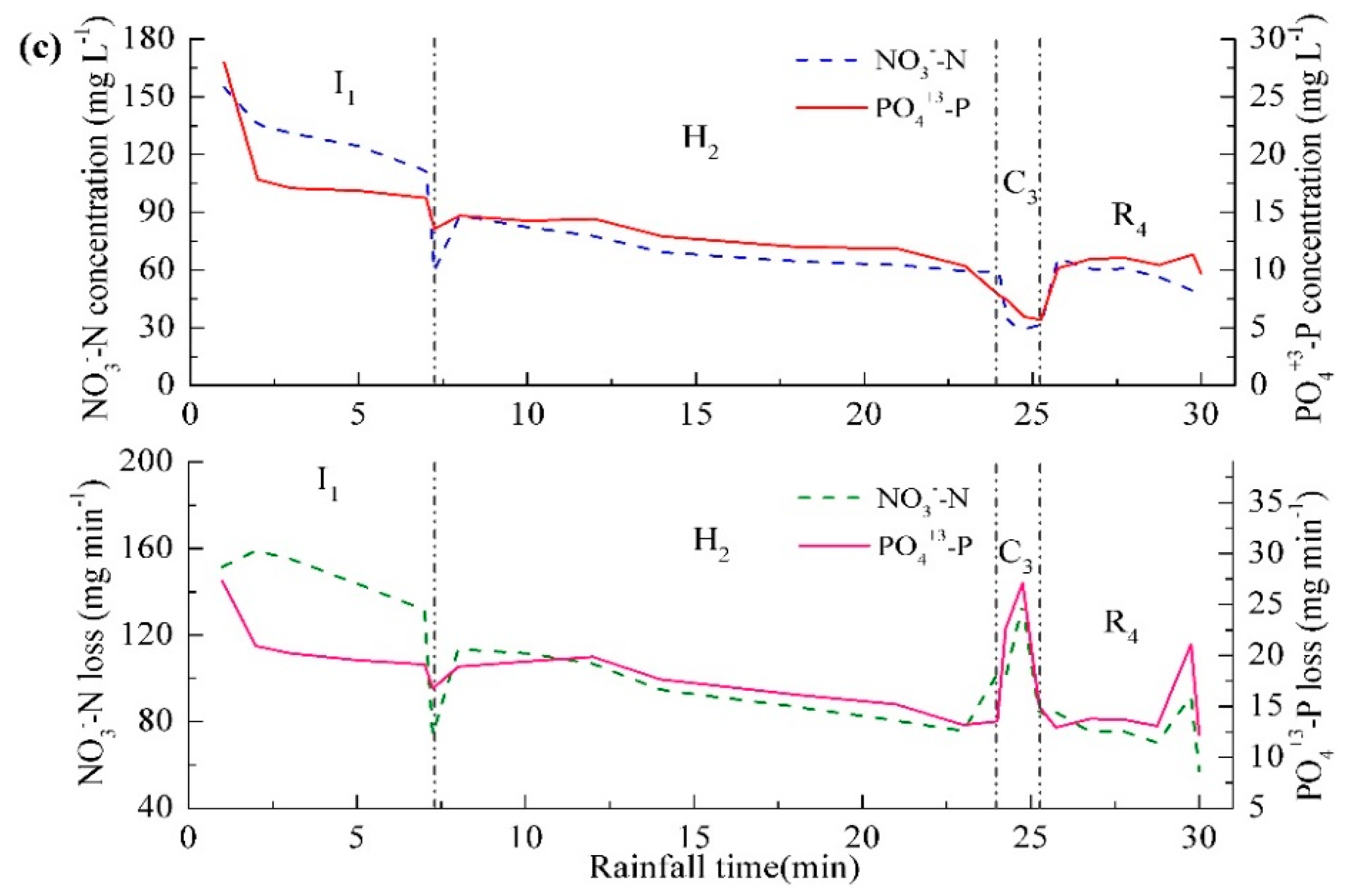

3.1. The Loss Characteristic of NO3−–N and PO4+3–P during Rainfall

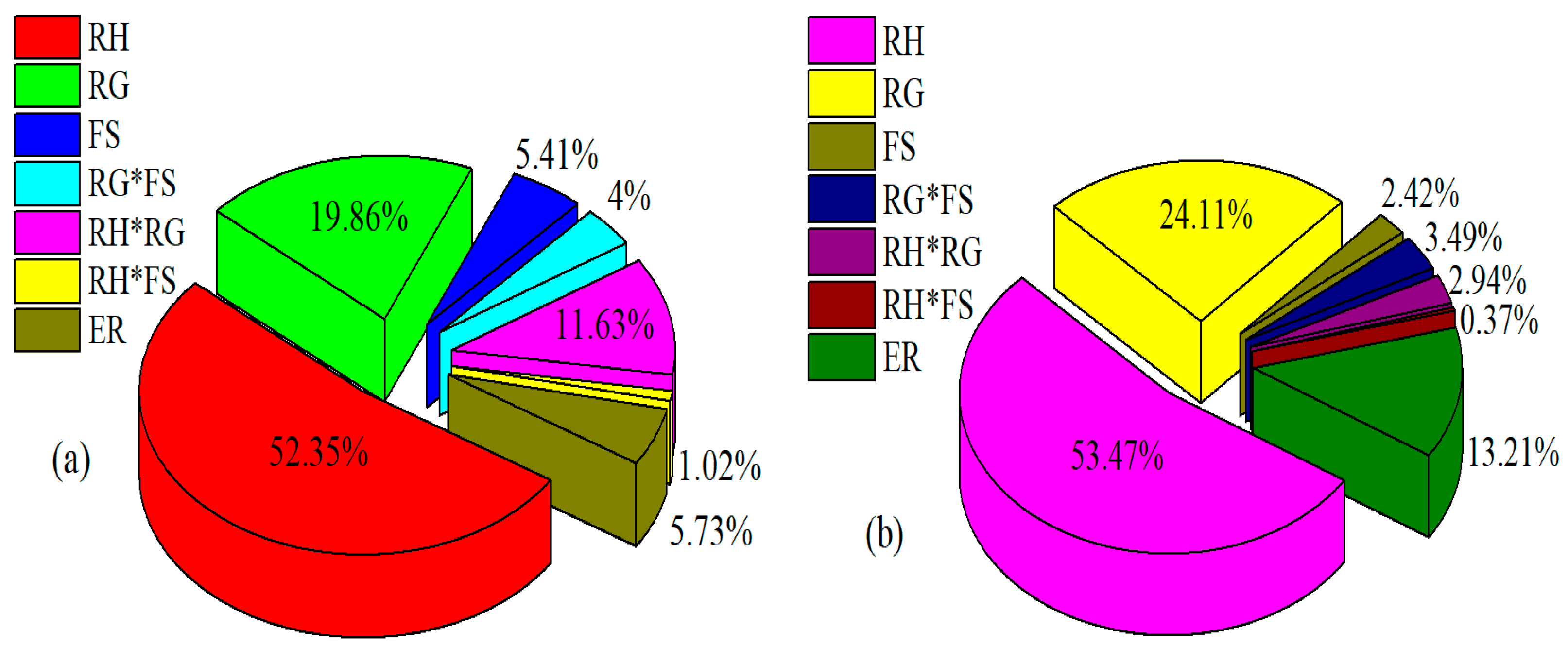

3.2. Effects and Interactions of the Influencing Factors on NO3−–N and PO4+3–PLosses

3.2.1. The Second-Order Polynomial Regression Models for NO3−–N and PO4+3–P Losses

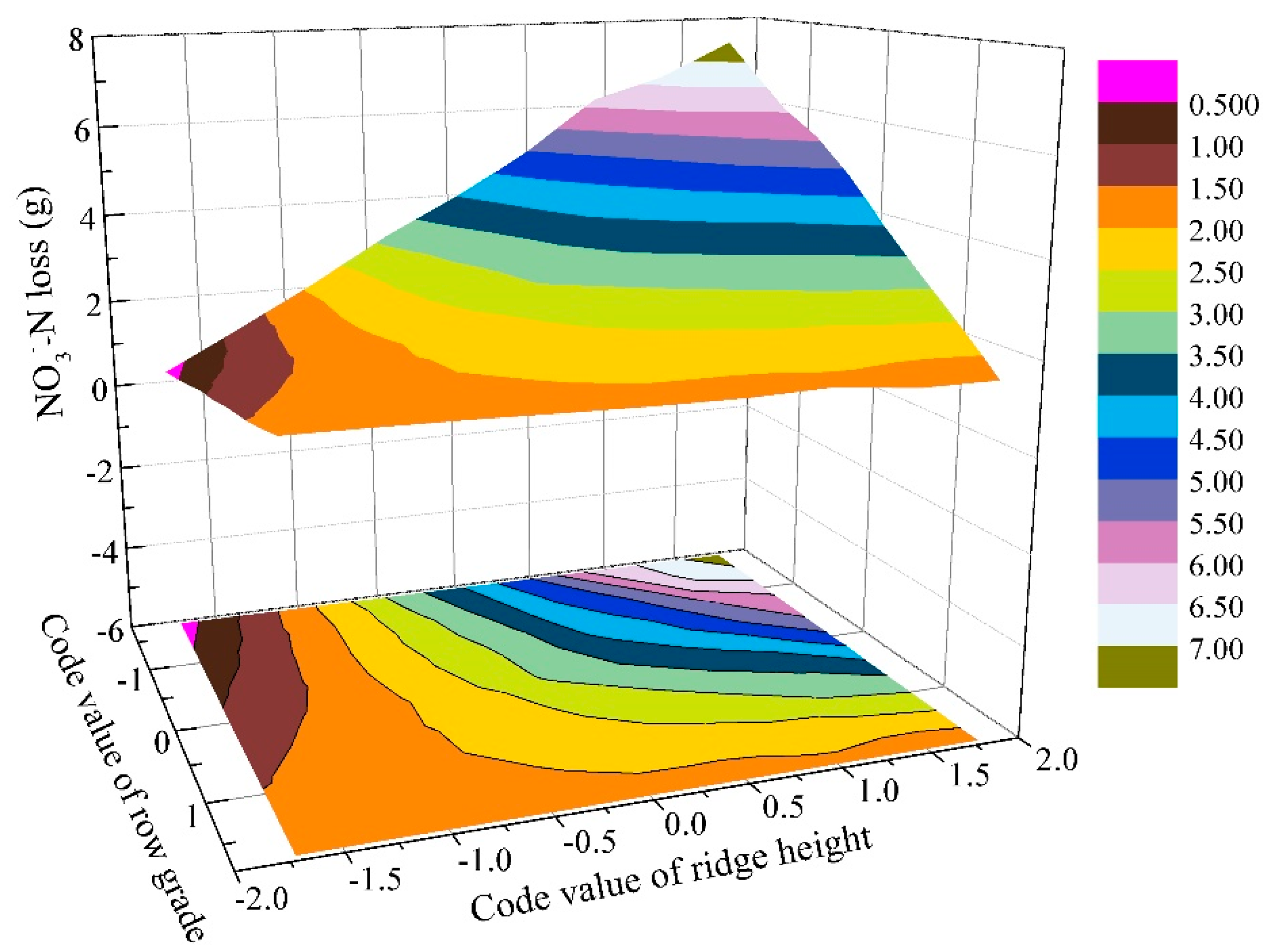

3.2.2. The Effects of Influential Factors on NO3−–N Loss

The Significant Effects and Contribution of Factors on NO3−–N Loss

The Main Factor for NO3−–N Loss Response

3.2.3. The Effects of Various Factors on PO4+3–P Loss

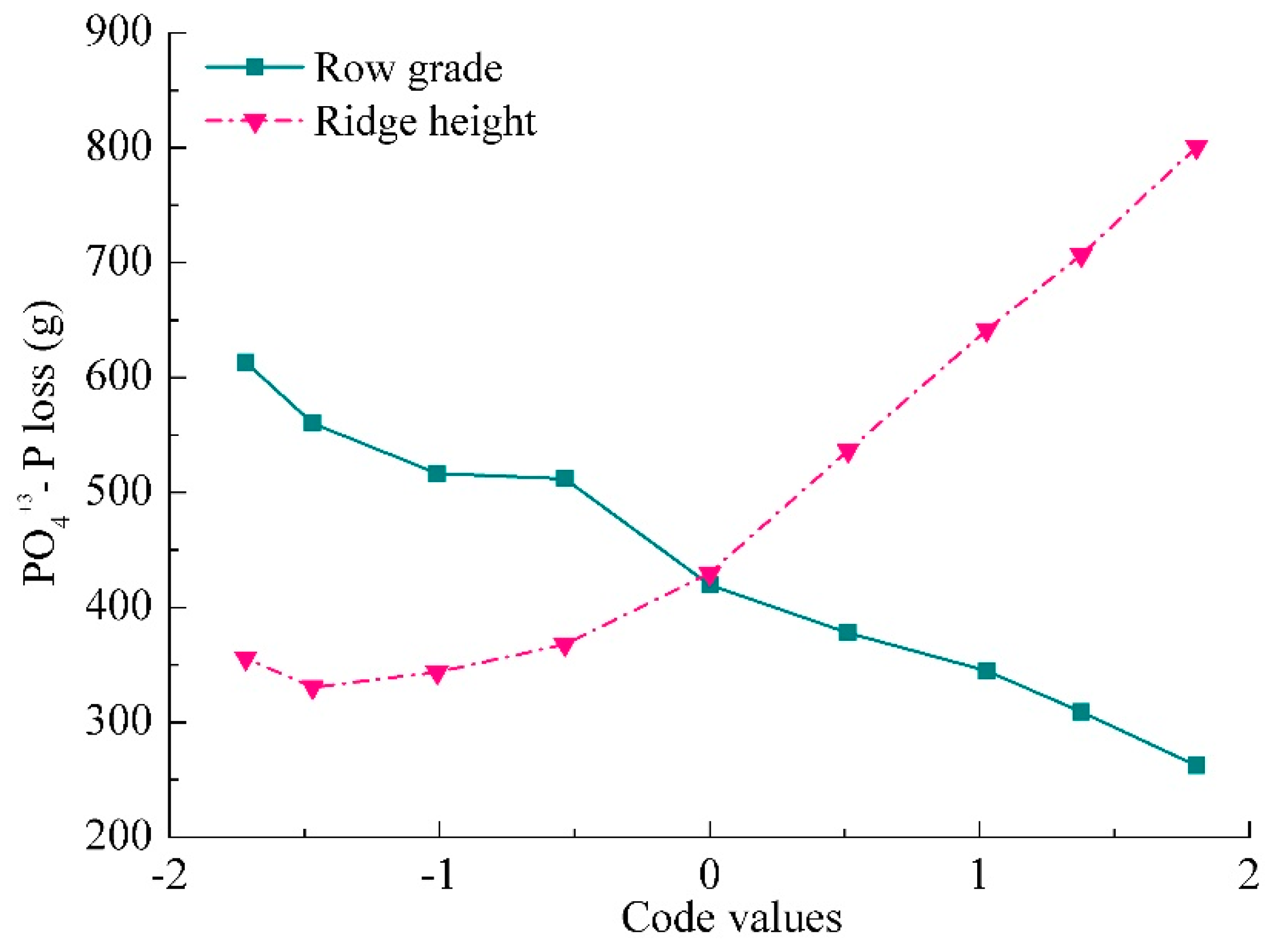

The Significant Effects and Contribution of Various Factors on PO4+3–P Loss

The PO4+3–P Loss Response to the Key Factors

3.3. The Optimal Design of Factors for the Control of NO3−–N and PO4+3–P Losses

3.3.1. The Optimal Design for NO3−–N Loss Control

3.3.2. The Optimal Design for PO4+3–P Loss Control

4. Discussion

4.1. The Effects of the Primary Factors on NO3−–N and PO4+3–P Losses

4.2. The Optimal Design of Contour Ridge System for Controlling Nutrient Loss

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Keesstra, S.; Mol, G.; de Leeuw, J.; Okx, J.; de Cleen, M.; Visser, S. Soil-related sustainable development goals: Four concepts to make land degradation neutrality and restoration work. Land 2018, 7, 133. [Google Scholar] [CrossRef]

- Visser, S.; Keesstra, S.; Maas, G.; De Cleen, M. Soil as a basis to create enabling conditions for transitions towards sustainable land management as a key to achieve the SDGs by 2030. Sustainability 2019, 11, 6792. [Google Scholar] [CrossRef]

- Chen, M.; Chen, J.; Sun, F. Agricultural phosphorus flow and its environmental impacts in China. Sci. Total Environ. 2008, 405, 140–152. [Google Scholar] [CrossRef] [PubMed]

- Vivekananthan, K.; Macrae, M.L.; Lobb, D.A.; Ali, G.A. Contribution of overland and tile flow to runoff and nutrient losses from vertisols in manitoba, Canada. J. Environ. Qual. 2019, 48, 959–965. [Google Scholar]

- Ongley, E.D.; Zhang, X.L.; Yu, T. Current status of agricultural and rural non-point source pollution assessment in China. Environ. Pollut. 2010, 158, 1159–1168. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Tan, Y.; Yang, G. Environmental impact assessments of the three gorges project in China: Issues and interventions. Earth Rev. 2013, 124, 115–125. [Google Scholar] [CrossRef]

- Zheng, F.L.; Huang, C.; Norton, L.D. Effects of near-surface hydraulic gradients on nitrate and phosphorus losses in surface runoff. J. Environ. Qual. 2004, 33, 2174–2182. [Google Scholar] [CrossRef]

- Silva, R.G.; Holub, S.M.; Jorgensen, E.E.; Ashanuzzaman, A.N.M. Indicators of nitrate leaching loss under different land use of clayey and sandy soils in southeastern Oklahoma. Agr. Ecosyst. Environ. 2005, 109, 346–359. [Google Scholar] [CrossRef]

- Jia, H.Y.; Lei, A.L.; Lei, J.S.; Ye, M.; Zhao, J.Z. Effects of hydrological processes on nitrogen loss in purple soil. Agr. Water Manag. 2007, 89, 89–97. [Google Scholar] [CrossRef]

- Ke, L.; Takahashi, A. Strength reduction of cohesion less soil due to internal erosion induced by one-dimensional upward seepage flow. Soils Found. 2012, 52, 698–711. [Google Scholar] [CrossRef]

- An, J.; Liu, Q.J.; Wu, Y.Z. Optimization of the contour ridge system for controlling nitrogen and phosphorus losses under seepage condition. Soil Use Manag. 2015, 31, 89–97. [Google Scholar]

- Wilson, G.V.; Periketi, R.K.; Fox, G.A.; Dabney, S.M.; Shields, F.D.; Cullum, R.F. Soil properties controlling seepage erosion contributions to streambank failure. Earth Surf. Proc. Land 2007, 32, 447–459. [Google Scholar] [CrossRef]

- Midgley, T.L.; Fox, G.A.; Wilson, G.V.; Heeren, D.M.; Langendoen, E.J. Seepage induced streambank erosion and instability in situ constant—Head experiments. J. Hydrol. Eng. 2013, 18, 1200–1210. [Google Scholar] [CrossRef]

- Chu-Agor, M.L.; Fox, G.A.; Cancienne, R.M.; Wilson, G.V. Seepage caused tension failures and erosion undercutting of hillslopes. J. Hydrol. 2008, 359, 247–259. [Google Scholar] [CrossRef]

- Fox, A.; Heeren, M.; Wilson, G.V.; Langendoen, E.J.; Fox, A.K.; Chu-Agor, M.L. Numerically predicting seepage gradient forces and erosion: Sensitivity to soil hydraulic properties. J. Hydrol. 2010, 389, 354–362. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Q.J.; Yu, X.X. The influences of row grade, ridge height and field slope on the seepage hydraulics of row sideslopes in contour ridge systems. Catena 2016, 147, 686–694. [Google Scholar] [CrossRef]

- Huang, C.; Laflen, J.M. Seepage and soil erosion for a clay loam soil. Soil Sci. Soc. Am. J. 1996, 60, 408–416. [Google Scholar] [CrossRef]

- Nouwakpo, S.K.; Huang, C.; Bowling, L.; Owens, P. Impact of vertical hydraulic gradient on rill erodibility and critical shear stress. Soil Sci. Soc. Am. J. 2010, 74, 1914–1921. [Google Scholar] [CrossRef]

- Gabbard, D.; Huang, C.; Norton, L.; Steinhardt, G. Landscape position, surface hydraulic gradients and erosion processes. Earth Surf. Proc. Land 1998, 23, 83–93. [Google Scholar] [CrossRef]

- Zheng, F.L.; Huang, C.H.; Norton, L.D. Vertical hydraulic gradient and run-on water and sediment effects on erosion processes and sediment regimes. Soil Sci. Soc. Am. J. 2000, 64, 4–11. [Google Scholar] [CrossRef]

- Huang, C.; Gascuel-Odoux, C.; Cros-Cayot, S. Hill slope topographic and hydrologic effects on overland flow and erosion. Catena 2001, 46, 177–188. [Google Scholar] [CrossRef]

- Al-Madhhachi, A.T.; Fox, G.A.; Hanson, G.J.; Tyagi, A.K.; Bulut, R. Mechanistic detachment rate model to predict soil erodibility due to fluvial and seepage forces. J. Hydraul. Eng. 2014, 140, 1–12. [Google Scholar] [CrossRef]

- An, J.; Zheng, F.L.; Romkens, J.M.; Li, G.F.; Yang, Q.S.; Wen, L.L.; Wang, B. The role of soil surface water regimes and raindrop impact on hillslope soil erosion and nutrient losses. Nat. Hazards 2013, 67, 411–430. [Google Scholar] [CrossRef]

- Barton, A.P.; Fullen, M.A.; Mitchell, D.J.; Hocking, T.J.; Liu, L.; Wu, B.Z.; Zheng, Y.; Xia, Z.Y. Effects of soil conservation measures on erosion rates and crop productivity on subtropical Ultisols in Yunnan Province, China. Agric. Ecosyst. Environ. 2004, 104, 343–357. [Google Scholar] [CrossRef]

- Patil, S.L.; Sheelavantar, M.N. Effect of cultural practices on soil properties, moisture conservation and grain yield of winter sorghum (Sorghum bicolor L. Moench) in semi-arid tropics of India. Agr. Water Manag. 2004, 64, 49–67. [Google Scholar] [CrossRef]

- Stevens, C.J.; Quinton, J.N.; Bailey, A.P.; Deasy, C.; Silgram, M.; Jackson, D.R. The effects of minimal tillage, contour cultivation and in-field vegetative barriers on soil erosion and phosphorus loss. Soil Till. Res. 2009, 106, 145–151. [Google Scholar] [CrossRef]

- Liu, Q.J.; Zhang, H.Y.; An, J.; Wu, Y.Z. Soil erosion processes on row sideslopes within contour ridging systems. Catena 2014, 115, 11–18. [Google Scholar] [CrossRef]

- Dai, C.T.; Liu, Y.J.; Wang, T.W.; Li, Z.X.; Zhou, Y.W. Exploring optimal measures to reduce soil erosion and nutrient losses in southern China. Agr. Water Manag. 2018, 210, 41–48. [Google Scholar] [CrossRef]

- Fang, H.; Gu, X.B.; Jiang, T.C.; Yang, J.Y.; Li, Y.N.; Huang, P.; Chen, P.P.; Yang, J. An optimized model for simulating grain-filling of maize and regulating nitrogen application rates under different film mulching and nitrogen fertilizer regimes on the Loess Plateau, China. Soil Till. Res. 2020, 199, 104546. [Google Scholar] [CrossRef]

- Liu, M.X.; Wang, J.A.; Yan, P.; Liu, L.Y.; Ge, Y.Q.; Li, X.Y.; Hu, X.; Song, Y.; Wang, L. Wind tunnel simulation of ridge-tillage effects on soil erosion from cropland. Soil Till. Res. 2006, 90, 242–249. [Google Scholar] [CrossRef]

- Griffith, D.R.; Parsons, S.D.; Mannering, J.V. Mechanics and adaptability of ridge planting for corn and soya bean. Soil Till. Res. 1990, 18, 113–126. [Google Scholar] [CrossRef]

- Keesstra, S.; Nunes, J.P.; Saco, P.; Parsons, T.; Poeppl, R.; Masselink, R.; Cerdà, A. The way forward: Can connectivity be useful to design better measuring and modelling schemes for water and sediment dynamics? Sci. Total Environ. 2018, 644, 1557–1572. [Google Scholar] [CrossRef] [PubMed]

- Jesús, R.C.; Saskia, D.; Keesstra, A.C. Connectivity assessment in Mediterranean vineyards using improved stock unearthing method, LiDAR and soil erosion field surveys. Earth Surf. Process. Landf. 2018, 43, 2193–2206. [Google Scholar]

- He, X.L.; Zheng, Z.C.; Li, T.X. Effects of tillage practices on soil erosion and phosphorus loss in sloping cropland of purple soil. Sci. Agric. Sin. 2013, 46, 2492–2500, (In Chinese with English abstract). [Google Scholar]

- Zhao, L.S.; Hou, R.; Wu, F.; Keesstra, S. Effect of soil surface roughness on infiltration water, ponding and runoff on tilled soils under rainfall simulation experiments. Soil Till. Res. 2018, 179, 47–53. [Google Scholar] [CrossRef]

- USDA-ARS. Draft Science Documentation, Revised Universal Soil Loss Equation Version 2. Available online: http://www.ars.usda.gov/sp2UserFiles/Place/64080510/RUSLE/RUSLE2_Science_Doc.pdf (accessed on 1 March 2008).

- Renard, K.G.; Foster, G.R.; Weesies, G.A.; McCool, D.K.; Yoder, D.C. Predicting Soil Erosion by Water. A Guide to Conservation Planning with the Revised Universal Soil Loss Equation (RUSLE). Agriculture Handbook 703; USDA: Washington, DC, USA, 1997.

- Hessel, R.; Messing, I.; Chen, L.D.; Ritsema, C.; Stolte, J. Soil erosion simulations of land use scenarios for a small loess plateau catchment. Catena 2003, 54, 289–302. [Google Scholar] [CrossRef]

- Wischmeier, W.H.; Smith, D.D. Predicting Rainfall Erosion Losses—A Guide to Conservation Planning. Agriculture Handbook 537; USDA: Washington, DC, USA, 1978.

- Flanagan, D.; Livingston, S. Water Erosion Prediction Project (WEPP) User Summary—NSERL; Report No. 11; USDA-ARS National Soil Erosion Research Laboratory: West Lafayette, IN, USA, 1995.

- Liu, Q.J.; An, J.; Wang, L.Z.; Wu, Y.Z.; Zhang, H.Y. Influence of ridge height, row grade, and field slope on soil erosion in contour ridging systems under seepage conditions. Soil Till. Res. 2015, 147, 50–59. [Google Scholar] [CrossRef]

- Ferreira, S.L.C.; Bruns, R.E.; da Silva, E.G.P.; dos Santosc, W.N.L.; Quintella, C.M.; David, J.M.; Andrade, J.B.d.A.; Breitkreitz, M.C.; Jardim, I.C.S.F.J.; Neto, B.B. Statistical designs and response surface techniques for the optimization of chromatographic systems. J. Chromatogr. A 2007, 1158, 2–14. [Google Scholar] [CrossRef]

- Oughlis-Hammache, F.; Hamaidi-Maouche, N.; Aissani-Benissad, F.; Bourouina-Bacha, S. Central composite design for the modeling of the phenol adsorption process in a fixed-bed reactor. J. Chem. Eng. Data 2010, 55, 2489–2494. [Google Scholar] [CrossRef]

- Jiang, N.; Zhang, A.Z.; Yang, R.Q.; Zhang, Y.C. An experimental approach to optimize several processing conditions when extruding soybeans. Anim. Feed Sci. Tech. 2011, 170, 277–283. [Google Scholar] [CrossRef]

- Zhang, G.H.; Liu, B.Y.; Li, P.K. Principles and properties of artificial trough rainfall simulator. Bull. Soil Water Conserv. 2007, 27, 56–60, (In Chinese with English abstract). [Google Scholar]

- Tang, Q.Y.; Feng, M.G. Data Analysis System—Experimental Design, Statistical Analysis and Model Optimization; China Scientific Press: Beijing, China, 2006. [Google Scholar]

- Guo, S.F.; Zhai, L.M.; Liu, J.; Liu, H.B.; Chen, A.Q.; Wang, H.Y.; Wu, S.X.; Lei, Q.L. Cross-ridge tillage decreases nitrogen and phosphorus losses from sloping farmlands in southern hilly regions of China. Soil Till. Res. 2019, 191, 48–56. [Google Scholar] [CrossRef]

- Kouwenhoven, J.K.; Perdok, U.D.; Jonkheer, E.C.; Sikkema, P.K.; Wieringa, A. Soil ridge geometry for green control in French fry potato production on loamy clay soils in The Netherlands. Soil Till. Res. 2003, 74, 125–141. [Google Scholar] [CrossRef]

- Robert, D.H.; Smith, D.R.; Haney, R.L.; Allen, P.M. Comparison of nutrient loss pathways: Run-off and seepage flow in vertisols. Hydrol. Process. 2019, 33, 2384–2393. [Google Scholar]

- Liu, G.; Zheng, F.L.; Lu, J.; Jia, Y.F.; Zhang, X.C.; Hu, F.N.; Zhang, J.Q. Interactive effects of raindrop impact and groundwater seepage on soil erosion. J. Hydrol. 2019, 1578, 124066. [Google Scholar] [CrossRef]

- Liu, Q.J.; Ma, L.; Zhang, H.Y. Applying seepage modeling to improve sediment yield predictions in contour ridge systems. J. Arid Land 2020, 12, 676–689. [Google Scholar] [CrossRef]

- Liu, Q.J.; Shi, Z.H.; Yu, X.X.; Zhang, H.Y. Influence of microtopography, ridge geometry and rainfall intensity on soil erosion induced by contouring failure. Catena 2014, 136, 1–8. [Google Scholar] [CrossRef]

- Liu, Q.J.; An, J.; Zhang, G.H.; Wu, X.Y. The effect of row grade and length on soil erosion from concentrated flow in furrows of contouring ridge systems. Soil Till. Res. 2016, 160, 92–100. [Google Scholar] [CrossRef]

- Ding, W.F.; Zhang, P.C. Characteristic of nutrient transportation of subsurface flow of purple soil slope. J. Soil Water Conserv. 2009, 23, 15–17, (In Chinese with English abstract). [Google Scholar]

- Jia, L.Z.; Zhao, W.W.; Zhai, R.J.; Liu, Y.; Kang, M.M.; Zhang, X. Regional differences in the soil and water conservation efficiency of conservation tillage in China. Catena 2019, 175, 18–26. [Google Scholar] [CrossRef]

- Gammoh, I.A. Double furrow with raised bed-A new improved mechanized water-harvesting technique for large-scale rehabilitation of arid rain-fed areas. Soil Till. Res. 2011, 113, 61–69. [Google Scholar] [CrossRef]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Rodrigo-Comino, J.; Terol, E.; Mora, G.; Giménez-Morera, A.; Cerdà, A. Vicia sativa roth. can reduce soil and water losses in recently planted vineyards (Vitis vinifera L.). Earth Syst. Environ. 2020, 4, 827–842. [Google Scholar] [CrossRef]

- Araya, A.; Stroosnijder, L. Effects of tied ridges and mulch on barley (Hordeum vulgare) rainwater use efficiency and production in Northern Ethiopia. Agric. Water Manag. 2010, 97, 841–847. [Google Scholar] [CrossRef]

- He, B.H.; Liang, Y.L.; Huang, H. Characteristic of soil micro-aggregates loss on slopes with different surface water drainage patterns. Trans. China Soc. Agric. Eng. 2017, 33, 151–158, (In Chinese with English abstract). [Google Scholar]

| Factors | Code Gradients | ||||

|---|---|---|---|---|---|

| 1.682 | 1 | 0 | −1 | −1.682 | |

| Ridge height (cm) | 16 | 14.4 | 12 | 9.6 | 8 |

| Row grade (°) | 10 | 8.4 | 6 | 3.6 | 2 |

| Field slope (°) | 15 | 13 | 10 | 7 | 5 |

| No | Code Gradients | Seepage Discharge * (L min−1) | Nutrient Loss (g) | Erosion Type # | |||

|---|---|---|---|---|---|---|---|

| Ridge Height (X3) | Row Grade (X1) | Field Slope (X2) | NO3−–N | PO4+3–P | |||

| 1 | 1 | 1 | 1 | 0.96 | 3.25 | 0.40 | I-H-C-R |

| 2 | −1 | 1 | 1 | 0.78 | 2.04 | 0.28 | I-H |

| 3 | 1 | 1 | −1 | 0.87 | 2.85 | 0.36 | I-H |

| 4 | −1 | 1 | −1 | 0.63 | 2.52 | 0.21 | I-H |

| 5 | 1 | −1 | 1 | 1.04 | 6.53 | 0.55 | I-H |

| 6 | −1 | −1 | 1 | 0.69 | 2.69 | 0.27 | I-H |

| 7 | 1 | −1 | −1 | 0.80 | 4.19 | 0.78 | I-H |

| 8 | −1 | −1 | −1 | 0.47 | 1.66 | 0.36 | I-H |

| 9 | 0 | −1.682 | 0 | 0.93 | 3.26 | 0.58 | I-H-C |

| 10 | 0 | 1.682 | 0 | 0.90 | 1.26 | 0.20 | I-H |

| 11 | 0 | 0 | −1.682 | 0.66 | 3.06 | 0.40 | I-H |

| 12 | 0 | 0 | 1.682 | 0.49 | 3.24 | 0.33 | I-H |

| 13 | −1.682 | 0 | 0 | 0.25 | 0.91 | 0.30 | I-H |

| 14 | 1.682 | 0 | 0 | 1.27 | 4.24 | 0.87 | I-H |

| 15 | 0 | 0 | 0 | 0.52 | 2.05 | 0.51 | I-H-C-R |

| 16 | 0 | 0 | 0 | 0.62 | 2.92 | 0.25 | I-H-C |

| 17 | 0 | 0 | 0 | 0.35 | 2.95 | 0.29 | I-H-C |

| 18 | 0 | 0 | 0 | 0.82 | 3.06 | 0.47 | I-H |

| 19 | 0 | 0 | 0 | 0.59 | 2.71 | 0.41 | I-H-C-R |

| 20 | 0 | 0 | 0 | 0.62 | 2.68 | 0.51 | I-H-C-R |

| 21 | 0 | 0 | 0 | 0.79 | 3.09 | 0.51 | I-H-C-R |

| 22 | 0 | 0 | 0 | 0.61 | 3.05 | 0.39 | I-H |

| 23 | 0 | 0 | 0 | 0.42 | 2.29 | 0.38 | I-H-C-R |

| Source * | NO3−–N Loss (g) | PO4+3–P Loss (mg) | ||||

|---|---|---|---|---|---|---|

| Regression Coefficient | F-Value # | p-Value | Regression Coefficient | F-Value | p-Value | |

| X1 | 1.01 | 76.14 | 0.00 | 137.22 | 36.20 | 0.00 |

| X2 | −0.62 | 27.23 | 0.00 | −97.15 | 19.05 | 0.00 |

| X3 | 0.25 | 4.32 | 0.06 | −25.474 | 1.25 | 0.29 |

| X12 | 0.05 | 0.19 | 0.73 | 53.00 | 6.60 | 0.03 |

| X22 | −0.03 | 0.09 | 0.80 | −21.13 | 1.03 | 0.35 |

| X32 | 0.25 | 5.09 | 0.04 | −33.04 | 2.56 | 0.16 |

| X1*X2 | −0.65 | 18.01 | 0.00 | −53.30 | 3.36 | 0.11 |

| X1*X3 | 0.24 | 2.42 | 0.16 | −24.09 | 0.70 | 0.47 |

| X2*X3 | −0.40 | 6.61 | 0.03 | 55.15 | 3.68 | 0.10 |

| Regression | - | 14.81 | 0.00 | - | 7.91 | 0.00 |

| Lack of Fit | - | 1.89 | 0.21 | - | 0.45 | 0.82 |

| Nutrient | Code Value | Natural Value | ||||

|---|---|---|---|---|---|---|

| Ridge Height | Row Grade | Field Slope | Ridge Height (cm) | Row Grade (°) | Field Slope (°) | |

| NO3−–N | 0.592–1.032 | −0.768–0.197 | −0.484–0.213 | 13.42–14.48 | 4.16–5.53 | 8.55–10.64 |

| PO4+3–P | 0.412–0.893 | −0.698–0.179 | −0.382–0.167 | 12.99–15.14 | 4.32–6.43 | 8.85–10.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, J.; Geng, J.; Yang, H.; Song, H.; Wang, B. Effect of Ridge Height, Row Grade, and Field Slope on Nutrient Losses in Runoff in Contour Ridge Systems under Seepage with Rainfall Condition. Int. J. Environ. Res. Public Health 2021, 18, 2022. https://doi.org/10.3390/ijerph18042022

An J, Geng J, Yang H, Song H, Wang B. Effect of Ridge Height, Row Grade, and Field Slope on Nutrient Losses in Runoff in Contour Ridge Systems under Seepage with Rainfall Condition. International Journal of Environmental Research and Public Health. 2021; 18(4):2022. https://doi.org/10.3390/ijerph18042022

Chicago/Turabian StyleAn, Juan, Jibiao Geng, Huiling Yang, Hongli Song, and Bin Wang. 2021. "Effect of Ridge Height, Row Grade, and Field Slope on Nutrient Losses in Runoff in Contour Ridge Systems under Seepage with Rainfall Condition" International Journal of Environmental Research and Public Health 18, no. 4: 2022. https://doi.org/10.3390/ijerph18042022

APA StyleAn, J., Geng, J., Yang, H., Song, H., & Wang, B. (2021). Effect of Ridge Height, Row Grade, and Field Slope on Nutrient Losses in Runoff in Contour Ridge Systems under Seepage with Rainfall Condition. International Journal of Environmental Research and Public Health, 18(4), 2022. https://doi.org/10.3390/ijerph18042022