Occupational Exposure to Ultrafine Particles in Metal Additive Manufacturing: A Qualitative and Quantitative Risk Assessment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Operation Conditions and Materials

2.2. Quantitative Assessment

- A condensation particle counter (CPC), TSI®® Model 3007, to measure particle number concentration, with a particle size range of 10 nm to >1 µm in 1 s time resolution;

- A thermo-hygrometer, TSI®® Model 9545, to measure air velocity, room temperature, and relative humidity;

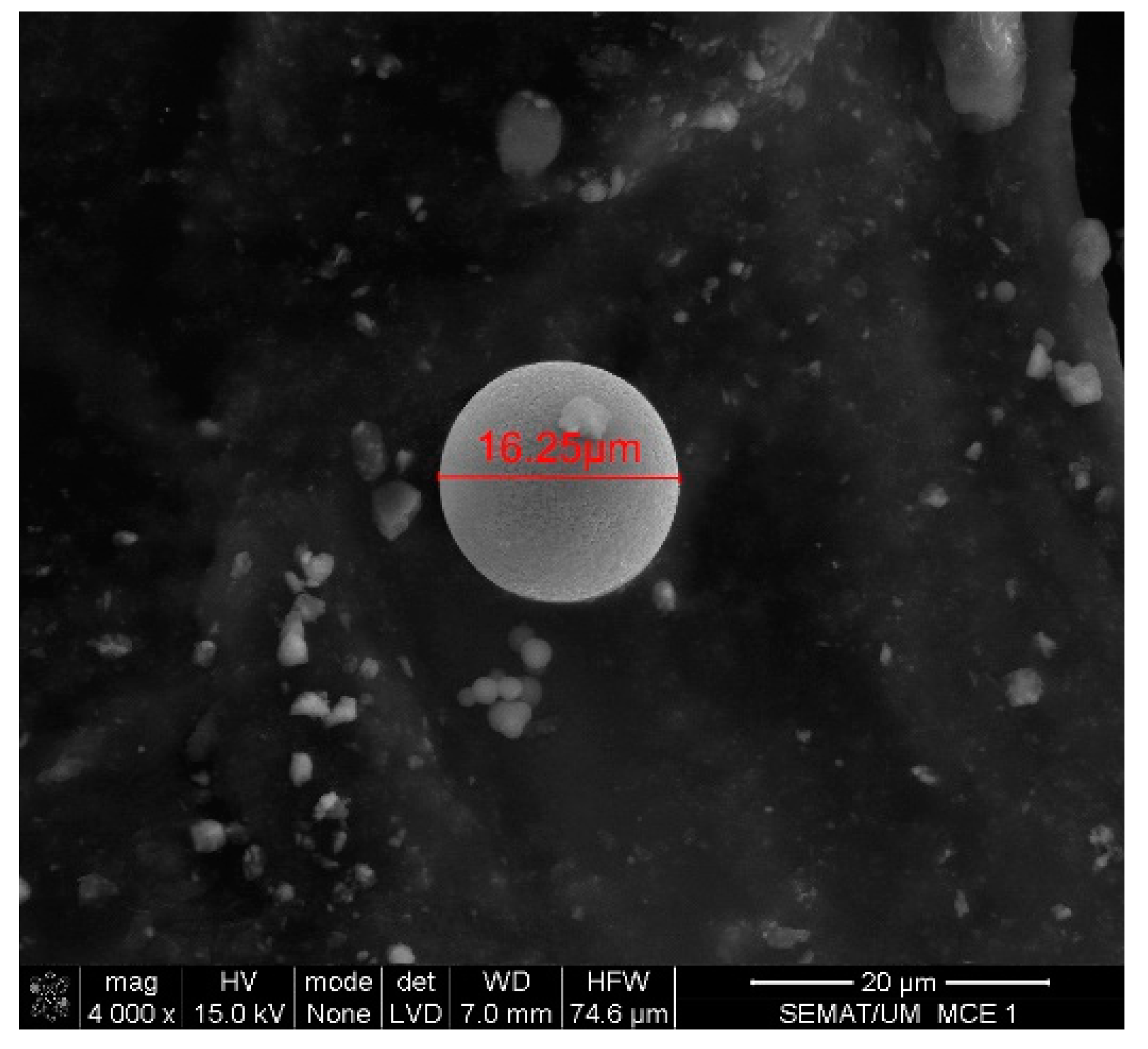

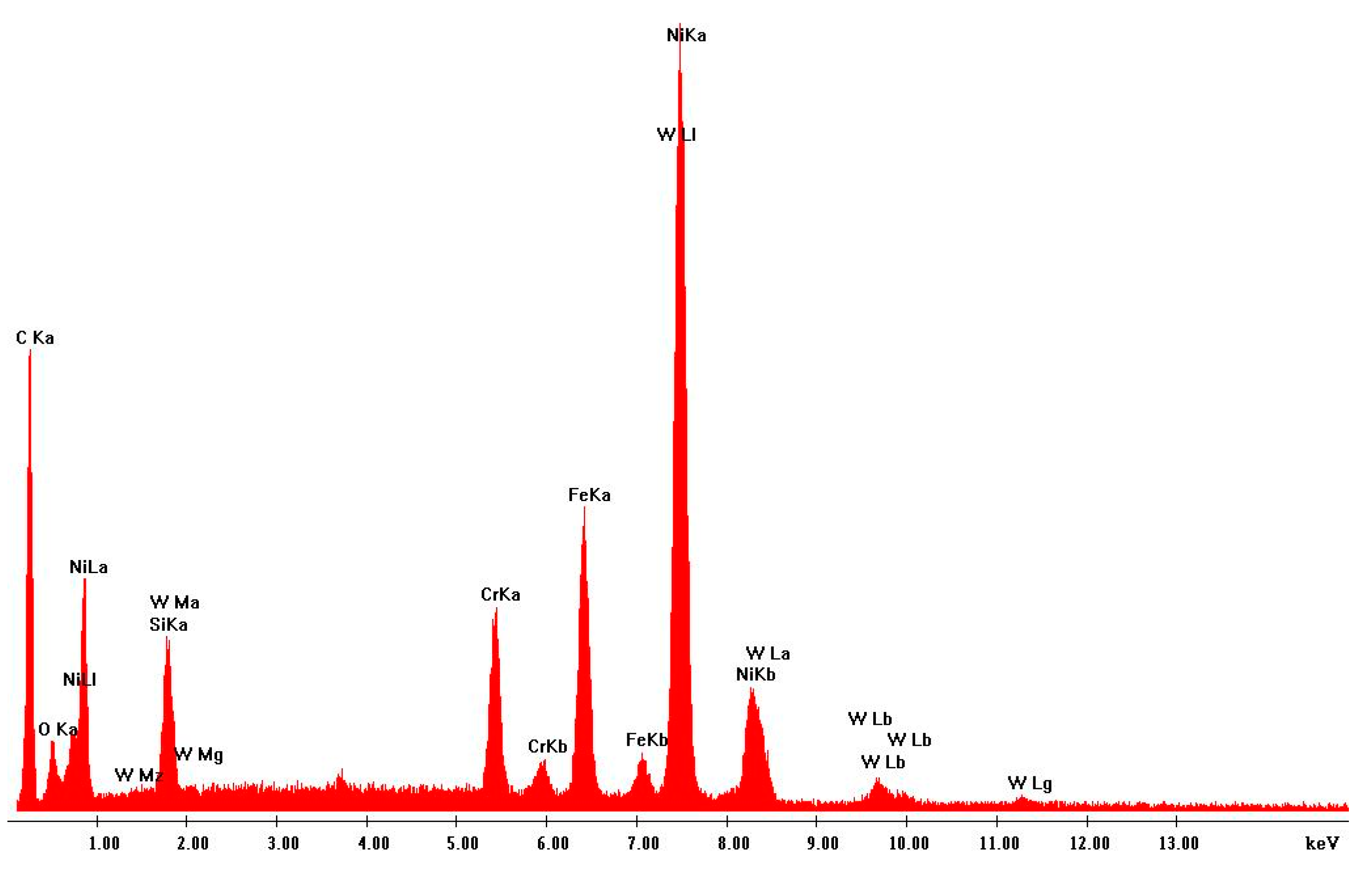

- A personal air sampling pump (SKC AirChek®® TOUCH) to collect samples for subsequent scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) analysis. The samples were collected using mixed cellulose ester (MCE) membrane filters (0.8 μm pore) that met NIOSH specifications for analysis of airborne metals. Additionally, these filters can collect particles with high efficiency, including particles much smaller than their nominal pore size [19].

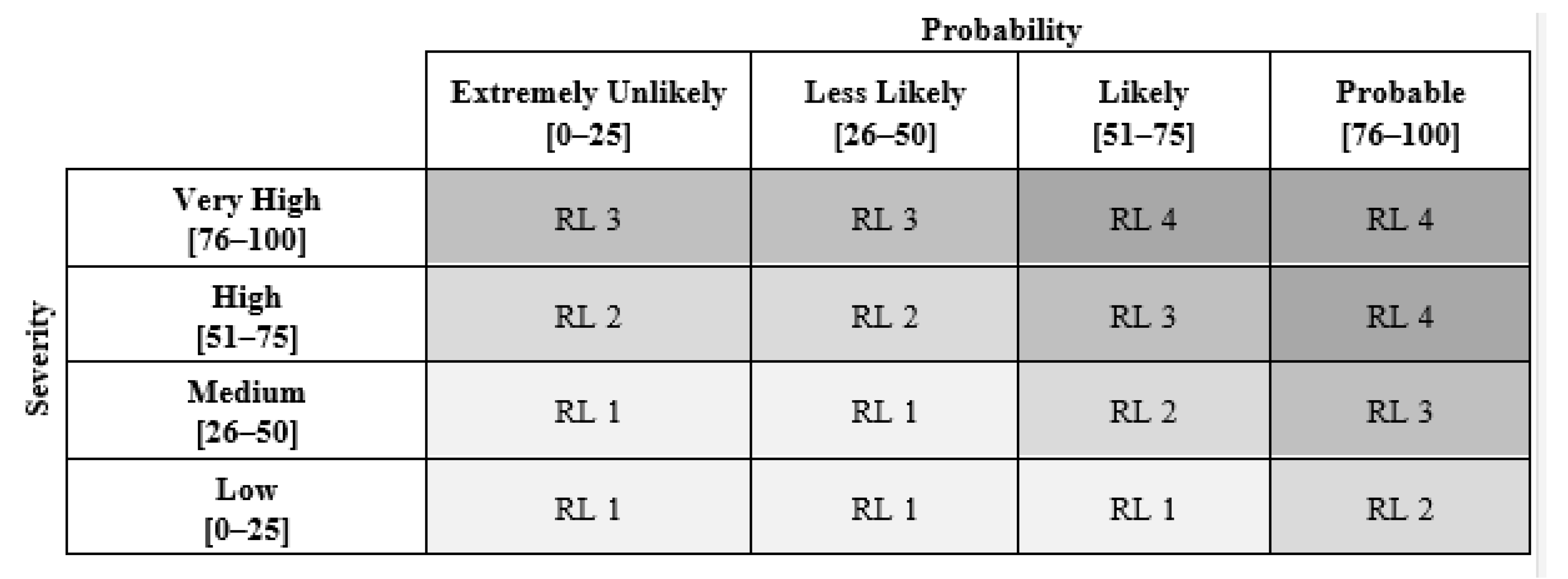

2.3. Qualitative Assessment

- surface chemistry (points: high = 10; medium = 5; low = 0; unknown = 7.5);

- particle shape (points: tubular/fibrous = 10; anisotropic = 5; compact/spherical = 0; unknown = 7.5);

- particle diameter (points: 1–10 nm = 10; 11–40 nm = 5; >40 nm = 0; unknown = 7.5);

- solubility (points: insoluble = 10; soluble = 5; unknown = 7.5);

- carcinogenicity (points: yes = 6; no = 0; unknown = 4.5);

- reproductive toxicity (points: yes = 6; no = 0; unknown = 4.5);

- mutagenicity (points: yes = 6; no = 0; unknown = 4.5);

- dermal toxicity (points: yes = 6; no = 0; unknown = 4.5);

- asthmagen (points: yes = 6; no = 0; unknown = 4.5).

- occupational exposure limits (OELs) (points: <10 µg/m3 = 10; 10–100 µg/m3 = 5; 101–1000 µg/m3 = 2.5; unknown = 7.5; >1000 µg/m3 = 0);

- carcinogenicity (points: yes = 4; no = 0; unknown = 3);

- reproductive toxicity (points: yes = 4; no = 0; unknown = 3);

- mutagenicity (points: yes = 4; no = 0; unknown = 3);

- dermal toxicity (points: yes = 4; no = 0; unknown = 3);

- asthmagen (points: yes = 4; no = 0; unknown = 3).

- estimated amount of material used (points: >100 mg = 25; 11–100 mg = 12.5; 0–10 mg = 6.25; unknown = 18.75);

- dustiness/mistiness (points: high = 30; medium = 15; low = 7.5; unknown = 22.5);

- number of employees with similar exposure (points: >15 = 15; 11–15 = 10; 6–10 = 5; 1–5 = 0; unknown = 11.25);

- frequency of operation (points: daily = 15; weekly = 10; monthly = 5; >monthly = 0; unknown =11.25);

- duration of operation (points: >4 h = 15; 1–4 h = 10; 30–60 min = 5; <30 min = 0; unknown = 11.25).

3. Results

3.1. Quantitative Assessment Results

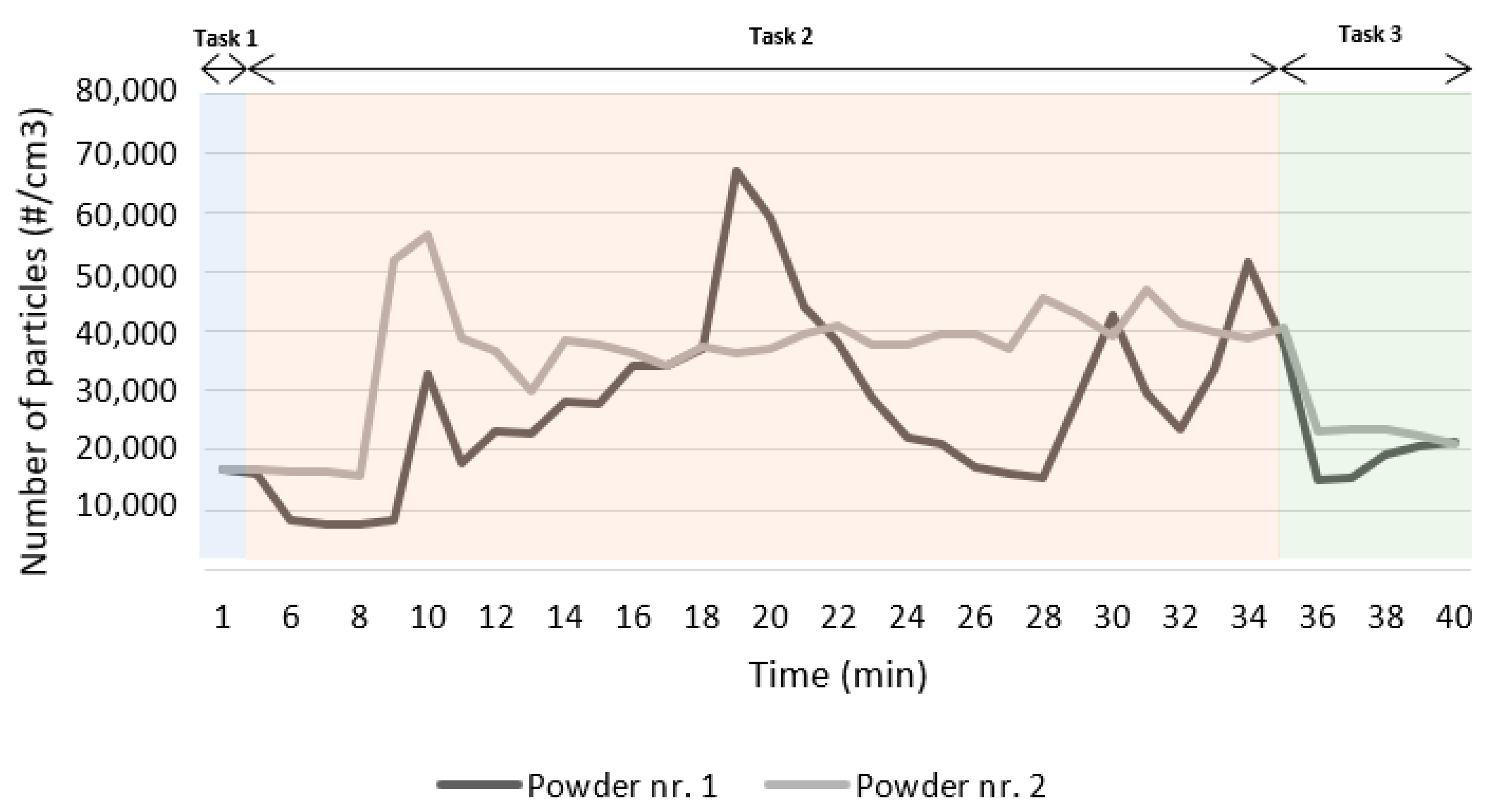

3.1.1. On-Site Measurements Results

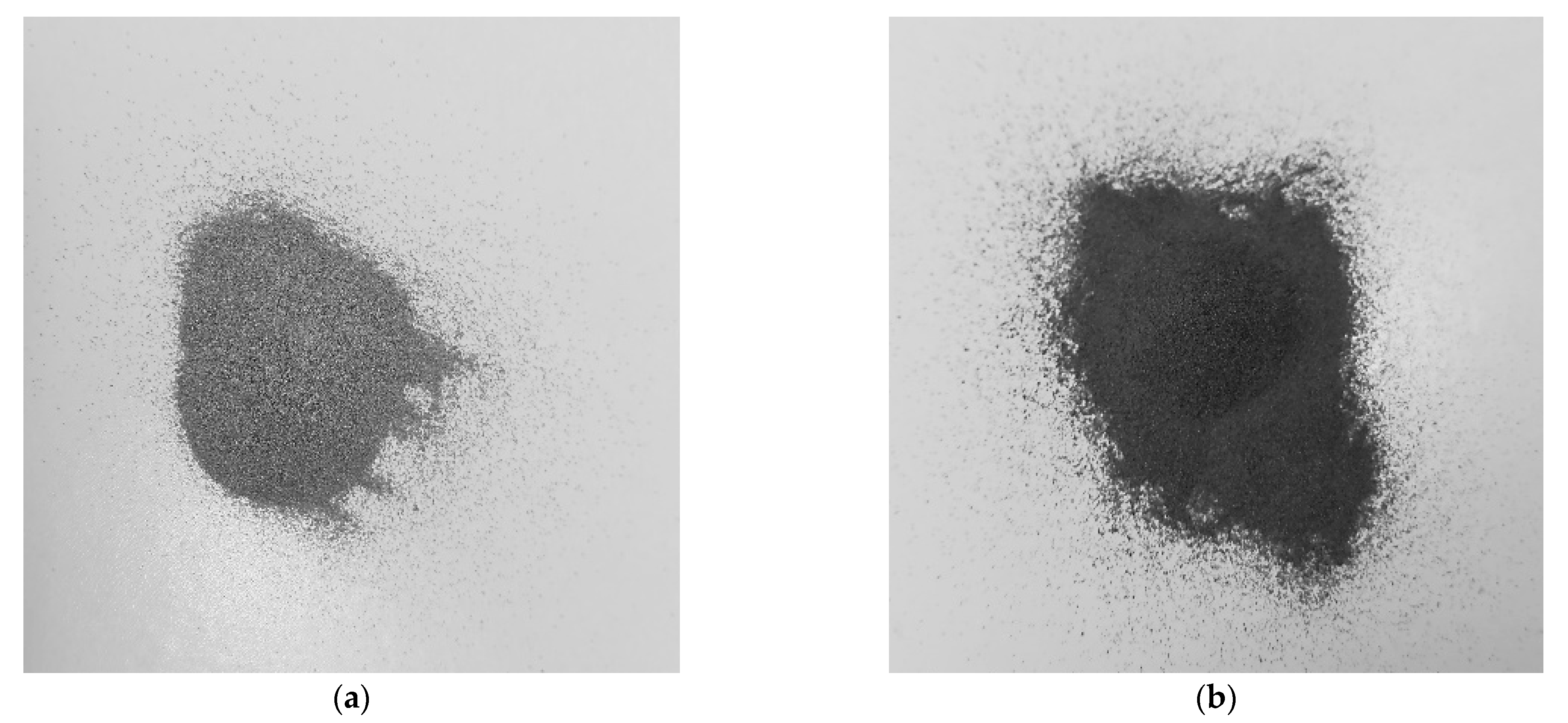

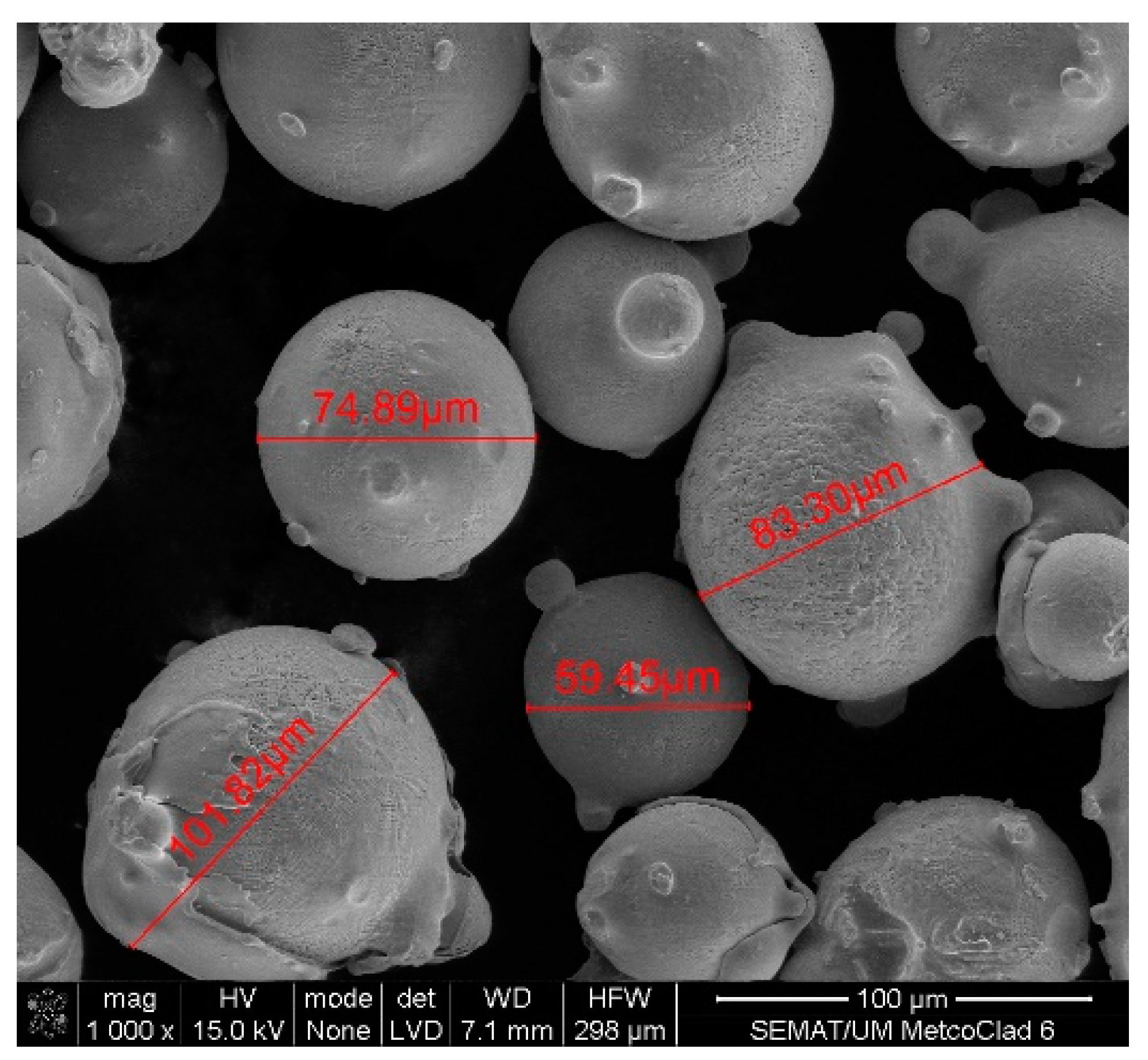

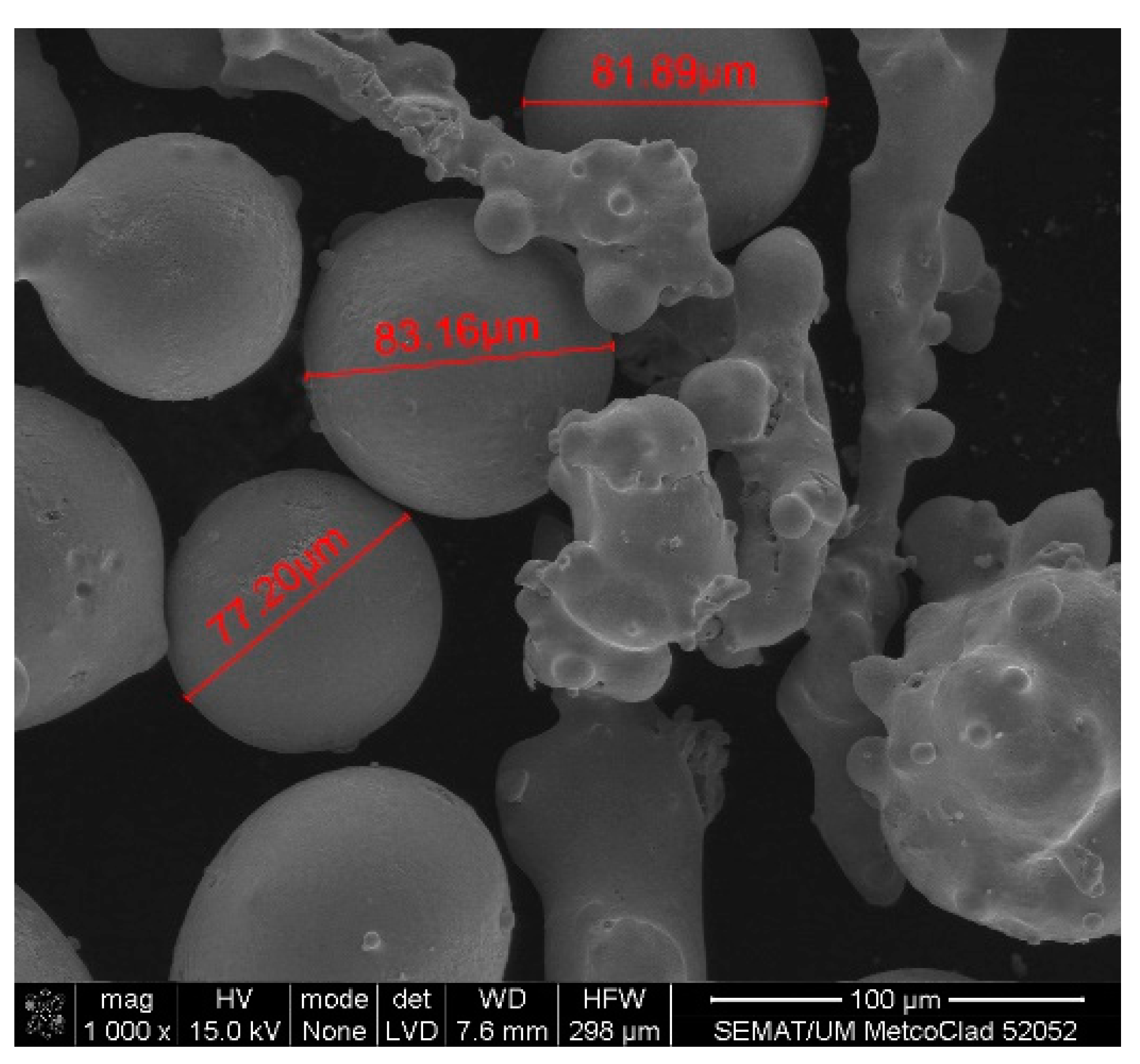

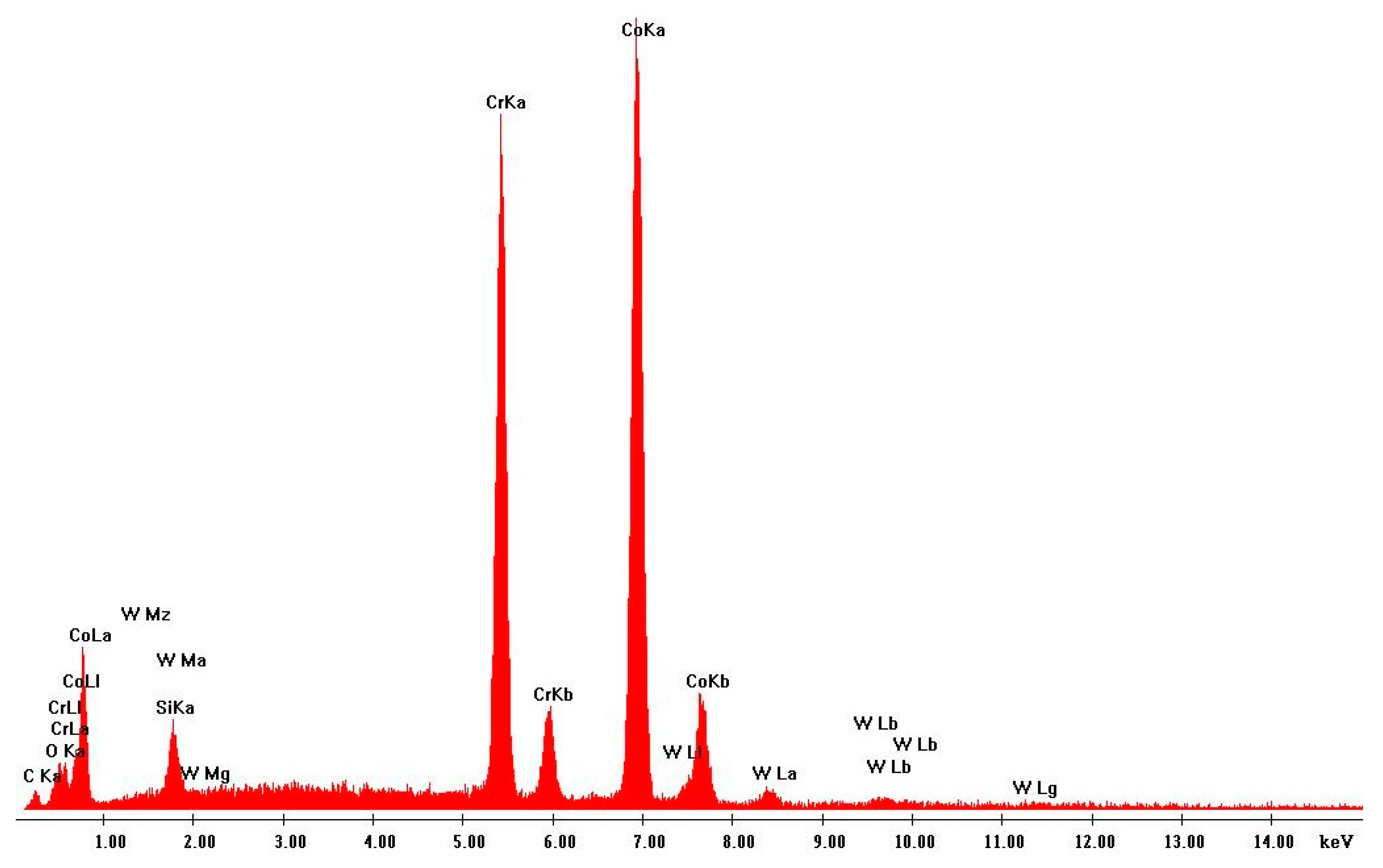

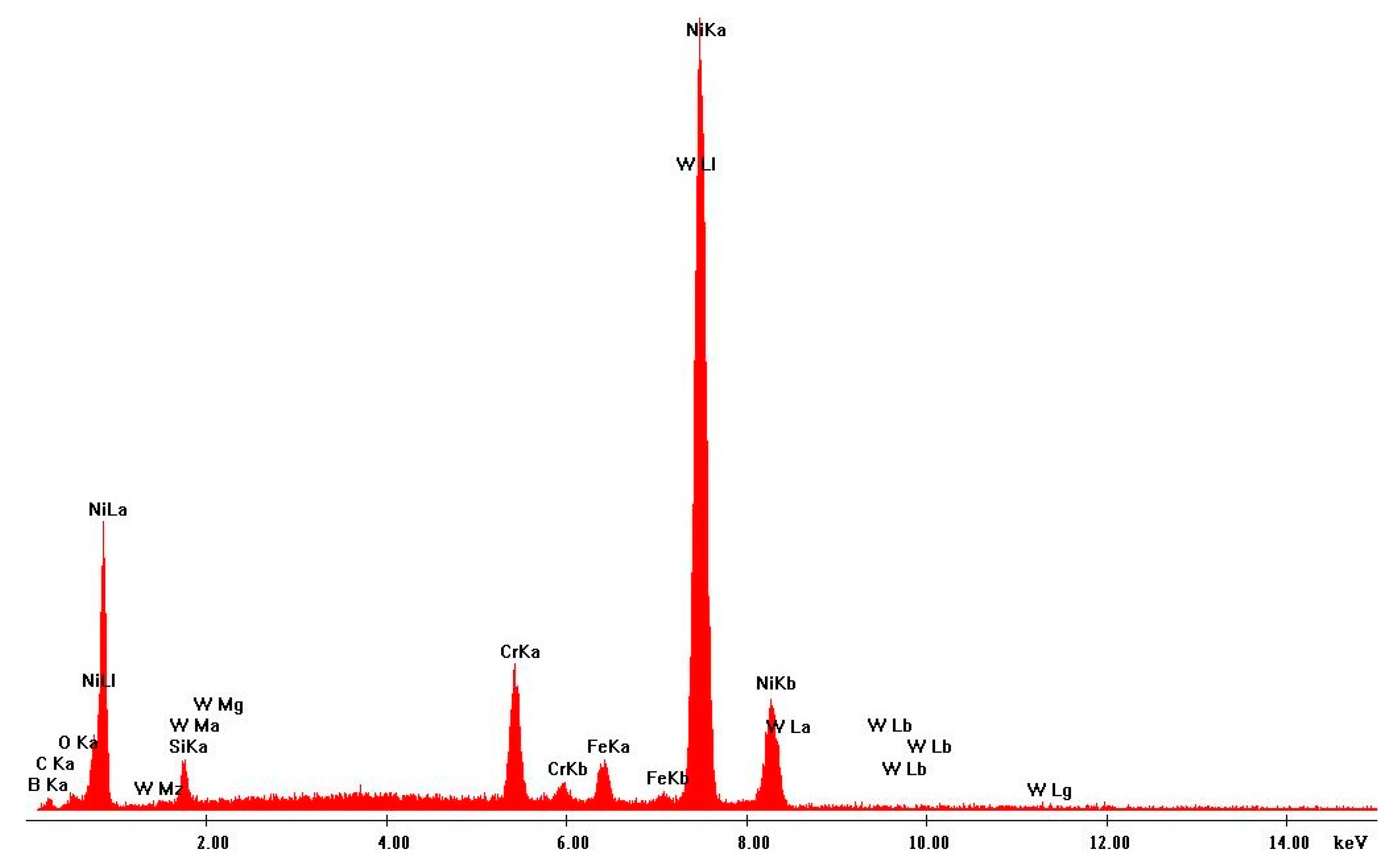

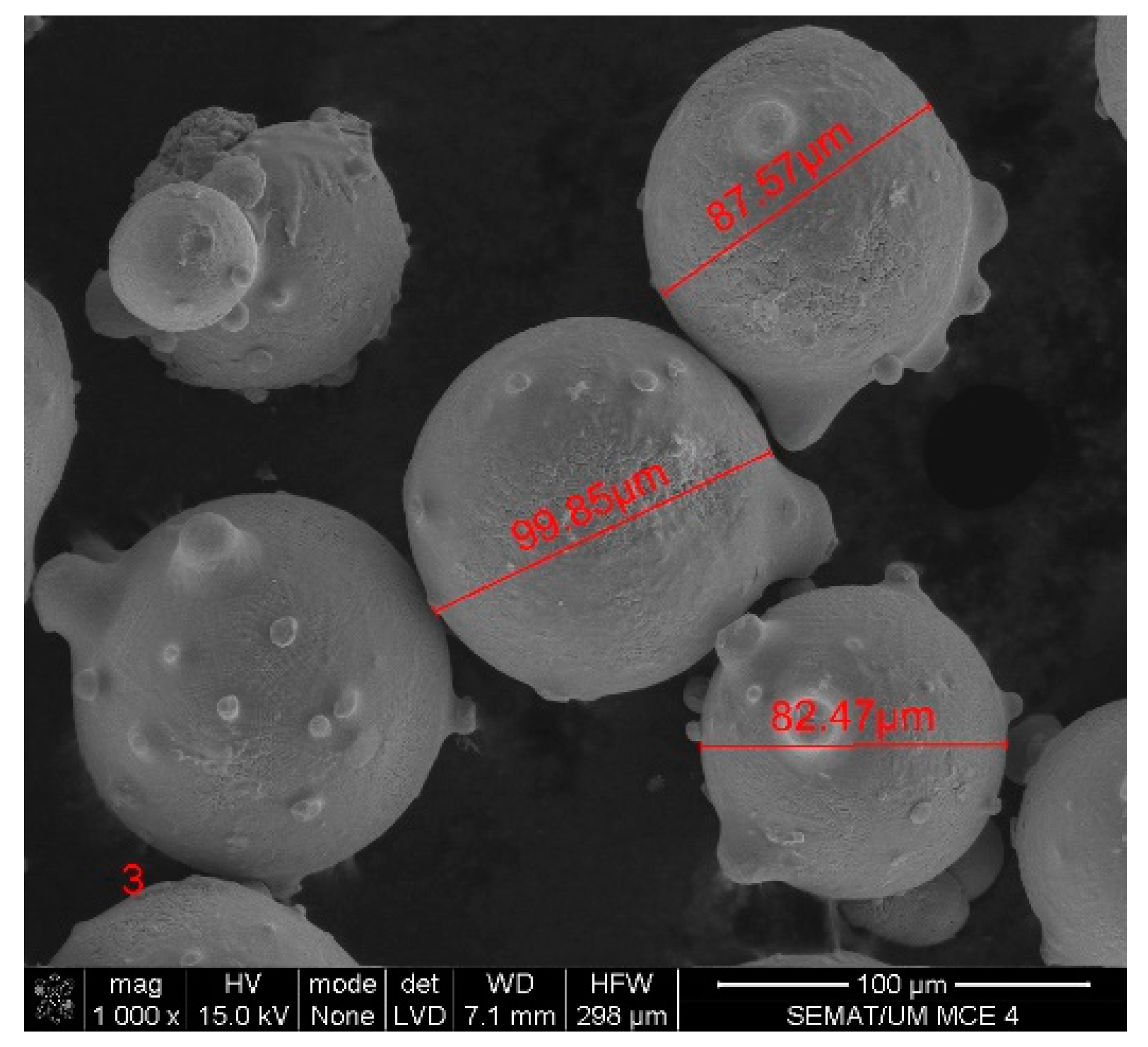

3.1.2. SEM and EDS Results

3.2. Qualitative Assessment Results

4. Discussion

4.1. Quantitative Assessment

4.2. Qualitative Assessment

4.3. Comparision between Qualitative and Quantitative Assessments

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Vaneker, T.; Bernard, A.; Moroni, G.; Gibson, I.; Zhang, Y. Design for additive manufacturing: Framework and methodology. CIRP Ann. 2020, 69, 578–599. [Google Scholar] [CrossRef]

- Baumers, M.; Duflou, J.; Flanagan, W.; Gutowski, T.G.; Kellens, K.; Lifset, R. Charting the Environmental Dimensions of Additive Manufacturing and 3D Printing. J. Ind. Ecol. 2017, 21, S9–S14. [Google Scholar] [CrossRef] [Green Version]

- de Sousa, M.M.; Arezes, P.; Silva, F. Nanomaterials exposure as an occupational risk in metal additive manufacturing. J. Phys. Conf. Ser. 2019, 1323, 1323. [Google Scholar] [CrossRef]

- Viitanen, A.-K.; Uuksulainen, S.; Koivisto, A.J.; Hämeri, K.; Kauppinen, T. Workplace Measurements of Ultrafine Particles—A Literature Review. Ann. Work Expo. Health 2017, 61, 749–758. [Google Scholar] [CrossRef] [PubMed]

- Schulte, P.A.; Salamanca-Buentello, F. Ethical and Scientific Issues of Nanotechnology in the Workplace. Environ. Health Perspect. 2007, 115, 5–12. [Google Scholar] [CrossRef] [Green Version]

- Schulte, P.A.; Leso, V.; Niang, M.; Iavicoli, I. Current state of knowledge on the health effects of engineered nanomaterials in workers: A systematic review of human studies and epidemiological investigations. Scand. J. Work Environ. Health 2019, 45, 217–238. [Google Scholar] [CrossRef] [PubMed]

- Graff, P.; Ståhlbom, B.; Nordenberg, E.; Graichen, A.; Johansson, P.; Karlsson, H. Evaluating Measuring Techniques for Oc-cupational Exposure during Additive Manufacturing of Metals: A Pilot Study. J. Ind. Ecol. 2017, 21, 120–129. [Google Scholar] [CrossRef] [Green Version]

- Jensen, A.C.Ø.; Harboe, H.; Brostrøm, A.; Jensen, K.A.; Fonseca, A.S. Nanoparticle Exposure and Workplace Measurements During Processes Related to 3D Printing of a Metal Object. Front. Public Health 2020, 8, 1–11. [Google Scholar] [CrossRef]

- Ljunggren, S.A.; Karlsson, H.; Ståhlbom, B.; Krapi, B.; Fornander, L.; Karlsson, L.E.; Bergström, B.; Nordenberg, E.; Ervik, T.K.; Graff, P. Biomonitoring of Metal Exposure During Additive Manufacturing (3D Printing). Saf. Health Work 2019, 10, 518–526. [Google Scholar] [CrossRef] [PubMed]

- Schrand, A.M.; Rahman, M.F.; Hussain, S.M.; Schlager, J.J.; Smith, D.A.; Syed, A.F. Metal-based nanoparticles and their toxicity assessment. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2010, 2, 544–568. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bau, S.; Payet, R.; Toussaint, A.; Witschger, O.; Todea, A.M.; Monz, C.; Asbach, C.; Payet, R.; Toussaint, A.; Witschger, O.; et al. Combining NSAM and CPC concentrations to determine airborne nanoparticle count median diameter: Application to various laboratory and workplace aerosols. J. Occup. Environ. Hyg. 2018, 15, 492–501. [Google Scholar] [CrossRef] [PubMed]

- Kim, E.; Lee, J.H.; Kim, J.K.; Lee, G.H.; Ahn, K.; Park, J.D.; Yu, I.J. Case Study on Risk Evaluation of Silver Nanoparticle Exposure from Antibacterial Sprays Containing Silver Nanoparticles. J. Nanomater. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Miller, A.; Drake, P.L.; Hintz, P.; Habjan, M. Characterizing Exposures to Airborne Metals and Nanoparticle Emissions in a Refinery. Ann. Occup. Hyg. 2010, 54, 504–513. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pavlovska, I.; Martinsone, Z.; Vanadziņš, I.; Martinsone, I.; Seile, A.; Sudmalis, P. Occupational exposure parameters for characterization of nanoparticulate matter toxicity: Metal versus wood processing. Process. Saf. Environ. Prot. 2016, 102, 230–237. [Google Scholar] [CrossRef]

- Pietroiusti, A.; Stockmann-Juvala, H.; Lucaroni, F.; Savolainen, K. Nanomaterial exposure, toxicity, and impact on human health. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2018, 10, 10. [Google Scholar] [CrossRef] [PubMed]

- Shepard, M.N.; Brenner, S. An Occupational Exposure Assessment for Engineered Nanoparticles Used in Semiconductor Fabrication. Ann. Occup. Hyg. 2014, 58, 251–265. [Google Scholar]

- Mihalache, R.; Verbeek, J.; Graczyk, H.; Murashov, V.; van Broekhuizen, P. Occupational exposure limits for manufactured nanomaterials, a systematic review. Nanotoxicology 2017, 11, 7–19. [Google Scholar] [CrossRef]

- Aschberger, K.; Micheletti, C.; Sokull-klüttgen, B.; Christensen, F.M. Analysis of currently available data for characterising the risk of engineered nanomaterials to the environment and human health-Lessons learned from four case studies. Environ. Int. 2011, 37, 1143–1156. [Google Scholar] [CrossRef]

- Soo, J.-C.; Monaghan, K.; Lee, T.; Kashon, M.; Harper, M. Air sampling filtration media: Collection efficiency for respirable size-selective sampling. Aerosol Sci. Technol. 2015, 50, 76–87. [Google Scholar] [CrossRef] [Green Version]

- Erbis, S.; Ok, Z.; Isaacs, J.; Benneyan, J.C.; Kamarthi, S. Review of Research Trends and Methods in Nano Environmental, Health, and Safety Risk Analysis. Risk Anal. 2016, 36, 1644–1665. [Google Scholar] [CrossRef]

- Sousa, M.; Arezes, P.; Silva, F. Occupational exposure to incidental nanoparticles: A review on control banding. J. Phys. Conf. Ser. 2021, 1953, 012008. [Google Scholar] [CrossRef]

- Paik, S.Y.; Zalk, D.M.; Swuste, P. Application of a pilot control banding tool for risk level assessment and control of nanoparticle exposures. Ann. Occup. Hyg. 2008, 52, 419–428. [Google Scholar] [PubMed] [Green Version]

- Zalk, D.M.; Paik, S.Y.; Swuste, P. Evaluating the Control Banding Nanotool: A qualitative risk assessment method for controlling nanoparticle exposures. J. Nanopart. Res. 2009, 11, 1685–1704. [Google Scholar] [CrossRef]

- Zalk, D.M.; Paik, S.Y.; Chase, W.D. A Quantitative Validation of the Control Banding Nanotool. Ann. Work Expo. Health 2019, 63, 898–917. [Google Scholar] [CrossRef]

- Huang, H.; Li, H.; Li, X. Physicochemical Characteristics of Dust Particles in HVOF Spraying and Occupational Hazards: Case Study in a Chinese Company. J. Therm. Spray Technol. 2016, 25, 971–981. [Google Scholar] [CrossRef]

- CT042. Standard NP 1796:2014—Occupational Health and Safety: Occupational Exposure Limits and Biological Exposure Indices to Chemical Agents; Portuguese Institute of Quality: Lisbon, Portugal, 2014.

| Task 1 | Manual handling of the powder to fill the machine container with raw powder |

| Task 2 | Removing and cleaning the final part from the machine after the coating process is completed (inside the machine operating area) |

| Task 3 | Removing the remains of the powder and cleaning the powder container |

| Assessed Parameters | Background (Before Coating Operations) | Near the Machine Powder Tank | Inside the Chamber (Machine) |

|---|---|---|---|

| Temperature [°C] | 22.5 | 23.1 | 22.6 |

| Relative Humidity [%] | 44.7 | 45.2 | 45.0 |

| Air Velocity [m/s] | <0.01 | <0.01 | <0.01 |

| Task 1 | Task 2 | Task 3 | Background | |

|---|---|---|---|---|

| Trial 1—Mean Particle number concentration [particles/cm3] | 16,421.69 | 28,895.80 | 18,279.44 | 13,358.94 |

| Trial 2—Mean Particle number concentration [particles/cm3] | 16,716.12 | 37,568.52 | 22,708.98 |

| CB Factors | Task 1 | Task 2 | Task 3 |

| PM OEL | 20 µg/m3 1 | 20 µg/m3 1 | 20 µg/m3 1 |

| PM Carcinogenicity | No | No | No |

| PM Reproductive | Yes 2 | Yes 2 | Yes 2 |

| PM Mutagenicity | No | No | No |

| PM Dermal Toxicity | Yes 3 | Yes 3 | Yes 3 |

| PM Asthmagen | Yes 4 | Yes 4 | Yes 4 |

| NM Surface Chemistry | unknown | unknown | unknown |

| NM Particle Shape | unknown | unknown | unknown |

| NM Particle Diameter | unknown | unknown | unknown |

| NM Solubility | unknown | unknown | unknown |

| NM Carcinogenicity | unknown | unknown | unknown |

| NM Reproductive Toxicity | unknown | unknown | unknown |

| NM Mutagenicity | unknown | unknown | unknown |

| NM Dermal Toxicity | unknown | unknown | unknown |

| NM Asthmagen | unknown | unknown | unknown |

| Severity Score|Band | 72|High | 72|High | 72|High |

| Estimated amount of material used | >100 mg | >100 mg | >100 mg |

| Dustiness/mistiness | High | High | High |

| Number of employees with similar exposure | 1–5 | 1–5 | 1–5 |

| Frequency of operation | Daily | Daily | Daily |

| Duration of operation | <30 min | 1–4 h | 30–60 min |

| Probability Score|Band | 70|Likely | 80|Probable | 75|Likely |

| Overall Risk Level Without Controls | RL 3—Containment | RL 4—Seek Specialist Advice | RL 3—Containment |

| CB Factors | Task 1 | Task 2 | Task 3 |

| PM OEL | 200 µg/m3 1 | 200 µg/m3 1 | 200 µg/m3 1 |

| PM Carcinogenicity | Yes 2 | Yes 2 | Yes 2 |

| PM Reproductive | No | No | No |

| PM Mutagenicity | No | No | No |

| PM Dermal Toxicity | Yes 3 | Yes 3 | Yes 3 |

| PM Asthmagen | No | No | No |

| NM Surface Chemistry | unknown | unknown | unknown |

| NM Particle Shape | unknown | unknown | unknown |

| NM Particle Diameter | unknown | unknown | unknown |

| NM Solubility | unknown | unknown | unknown |

| NM Carcinogenicity | unknown | unknown | unknown |

| NM Reproductive Toxicity | unknown | unknown | unknown |

| NM Mutagenicity | unknown | unknown | unknown |

| NM Dermal Toxicity | unknown | unknown | unknown |

| NM Asthmagen | unknown | unknown | unknown |

| Severity Score|Band | 63|High | 63|High | 63|High |

| Estimated amount of material used | >100 mg | >100 mg | >100 mg |

| Dustiness/mistiness | High | High | High |

| Number of employees with similar exposure | 1–5 | 1–5 | 1–5 |

| Frequency of operation | Daily | Daily | Daily |

| Duration of operation | <30 min | 1–4 h | 30–60 min |

| Probability Score|Band | 70|Likely | 80|Probable | 75|Likely |

| Overall Risk Level Without Controls | RL 3—Containment | RL 4—Seek Specialist Advice | RL 3—Containment |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sousa, M.; Arezes, P.; Silva, F. Occupational Exposure to Ultrafine Particles in Metal Additive Manufacturing: A Qualitative and Quantitative Risk Assessment. Int. J. Environ. Res. Public Health 2021, 18, 9788. https://doi.org/10.3390/ijerph18189788

Sousa M, Arezes P, Silva F. Occupational Exposure to Ultrafine Particles in Metal Additive Manufacturing: A Qualitative and Quantitative Risk Assessment. International Journal of Environmental Research and Public Health. 2021; 18(18):9788. https://doi.org/10.3390/ijerph18189788

Chicago/Turabian StyleSousa, Marta, Pedro Arezes, and Francisco Silva. 2021. "Occupational Exposure to Ultrafine Particles in Metal Additive Manufacturing: A Qualitative and Quantitative Risk Assessment" International Journal of Environmental Research and Public Health 18, no. 18: 9788. https://doi.org/10.3390/ijerph18189788

APA StyleSousa, M., Arezes, P., & Silva, F. (2021). Occupational Exposure to Ultrafine Particles in Metal Additive Manufacturing: A Qualitative and Quantitative Risk Assessment. International Journal of Environmental Research and Public Health, 18(18), 9788. https://doi.org/10.3390/ijerph18189788