1. Introduction

Back injuries account for more than a third of reported occupational musculoskeletal disorders (MSDs) in the U.S. labor force [

1]. Over 50 percent of workers who reported back injuries specified their low back [

2]. The overall economic impact of occupational low back pain (LBP) in the U.S. exceeds

$50 billion annually [

3,

4,

5,

6]. This value includes both direct costs (lost wages and medical treatment) and indirect costs (losses in productivity). During manual material handling (MMH) tasks, workers may be exposed to physical risk factors associated with LBP including awkward or non-neutral postures of the worker’s trunk, long periods of work activity involving the low back, excessive weight of loads moved, and high frequency of lifts or MMH tasks [

7,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19]. Manual materials handling tasks and their associated risks for LBP are common in many industries and small businesses including craft breweries [

20,

21,

22].

In the last decade, the number of craft breweries in the U.S. has grown 300% with over 7000 operations in 2020 [

23]. The definition of a craft brewery is a brewery that produces less than six million barrels per year [

24,

25]. Although individual craft breweries typically have small production scales, collectively, the U.S. craft brewing industry accounted for 13% of beer production and for 25% of all sales in the

$111.4 billion U.S. beer market [

23]. The success and subsequent expansion of the craft brewing industry has created a growing, yet understudied, working population.

Craft breweries typically begin as small businesses that lack the resources for initial investments in mechanized or robotic equipment. The Occupational Health and Safety Administration (OSHA) defines a small business as a company with fewer than 250 employees at a single facility and less than 500 employees overall [

26]. As a result, most work in craft breweries is performed through physical labor, even during periods of growth and increased production demands. The most strenuous physical labor in craft breweries involves MMH, which may increase the risk of occupational low back injuries [

11]. In contrast to craft breweries, large breweries are almost entirely automated and use robotics for keg handling.

Craft brewery workers frequently handle stainless steel kegs, which are used to store and transport beer. These durable, portable, reusable, pressurized containers have a single spear valve, which is the only opening used to clean, fill, and to drain liquid. Kegs are cleaned and sterilized before they are filled with beer. One of the most popular sizes of kegs used in craft breweries is the half-barrel keg. A half-barrel keg is 59.0 cm high, has a diameter of 41.0 cm, holds 58.7 L (15.5 U.S. gallons), and weighs between 13.5 kg (29.7 lbs.) empty and 72.8 kg (161.5 lbs.) full of beer. Craft brewery workers typically handle full, empty, and partially filled kegs throughout their shift. Given that kegs are relatively heavy objects that must be handled frequently within a craft brewery, it is likely that workers are exposed to physical risk factors associated with LBP and MSDs.

To date, aside from a National Institute for Occupational Safety and Health (NIOSH) Health Hazard Evaluation on brewery delivery workers [

20], there have been no published studies assessing occupational risk associated with keg handling. In the U.S., occupational injury data relevant to the brewing industry is categorized by the North American Industry Classification System (NAICS) as ‘breweries’ or the code 31,212 [

27]. While the basic process of brewing beer is constant, the size of production leads to different occupational exposures between workers at craft and large breweries. For example, workers at a large brewery that produces 10 million barrels with an automated kegging line will have different exposures to physical occupational risk factors for MSDs compared to workers at a craft (smaller) brewery that produces 10,000 barrels with a manual kegging line. The available occupational injury data associated with beer brewing does not include the size of the brewery. Thus, an analysis of NAICS injury data within the U.S. brewing industry is not specific to brewery size and may lead to ineffective intervention strategies aimed at reducing work-related injuries for large and craft breweries. In order to maximize the positive impact of interventions at craft breweries, it is critical that researchers understand the occupational exposure hazards within craft brewing operations.

The focus of the present study was to perform a quantitative assessment of trunk postures exhibited by workers lifting kegs during operational hours at a craft brewery with a validated inertial measurement unit (IMU)-based kinematic measurement system. Researchers hypothesized that craft brewery workers operating the kegging line are exposed to awkward trunk postures, which have been associated with low back injury. Based on the results of the quantitative assessment, design recommendations to reduce the hazardous exposures were also identified.

3. Results

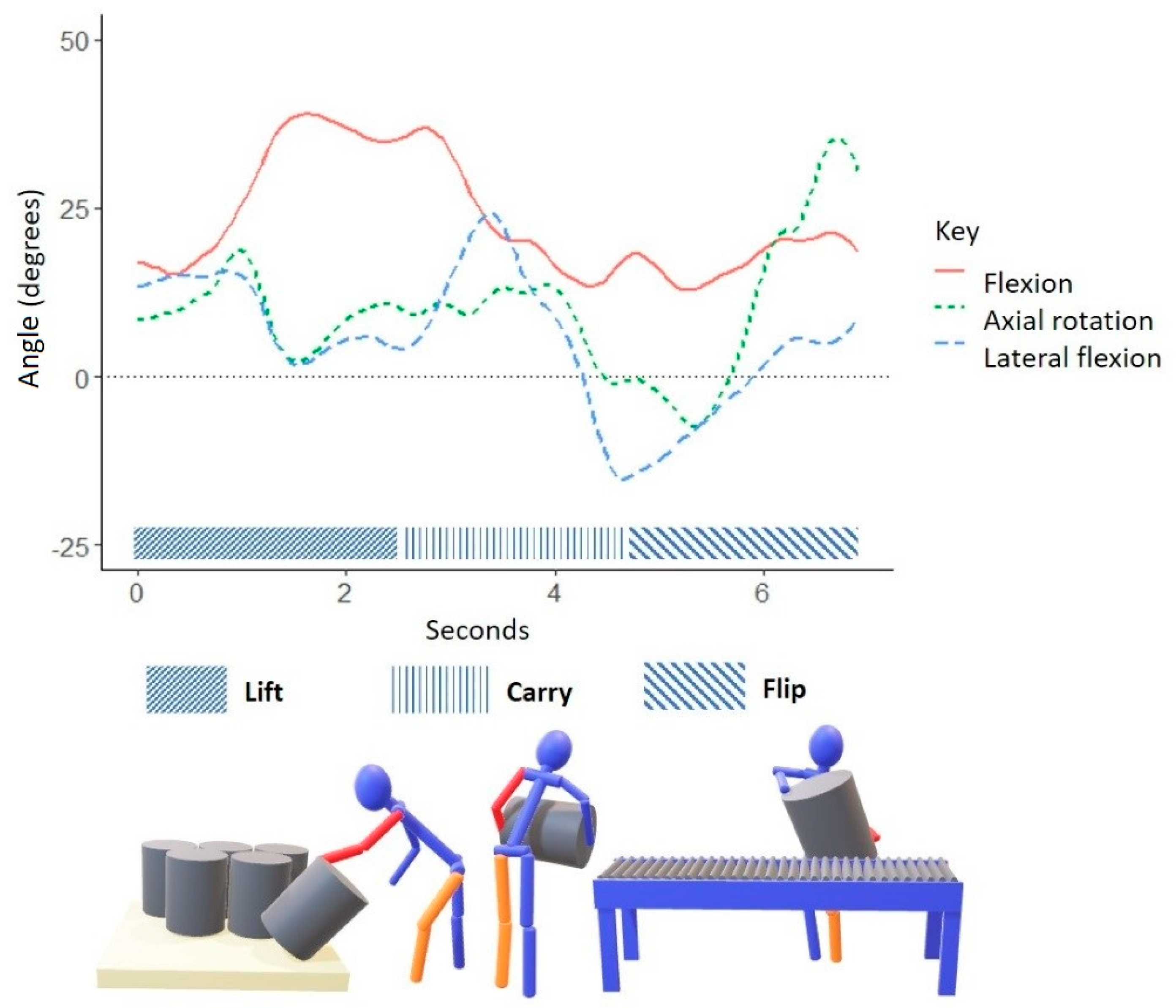

The proprietary sensor fusion algorithm for the IMU-based kinematic measurement system incorporated the participants’ anthropometric variables (shown in

Table 1) when determining trunk kinematics. During a typical low keg lift, the worker’s trunk posture began in forward flexion and gradually returned to an upright position while simultaneously moving from right to left lateral flexion and trunk axial rotation to the left before placing the keg on the roller conveyor (

Figure 3). When lifting high kegs, the worker began with right axial trunk rotation and left lateral trunk flexion, then gradually transitioned to left axial rotation with right lateral trunk flexion and slight trunk extension as they placed the keg on the roller conveyor (

Figure 4).

Table 2 displays the magnitudes of the workers’ trunk postures and direction while they operated the kegging line. Results of the fixed effect ANOVA are shown in

Table 3. For the lift height condition main effect, there was sufficient evidence of a relationship among several variables (

p > 0.05). There was sufficient evidence to suggest an interaction between subject and lift height condition among several variables. Overall, during low keg lifts, workers exhibited larger magnitudes of the following trunk postures: right, left, and mean lateral trunk flexion; right axial rotation, mean flexion, maximum flexion, and maximum extension. During high keg lifts, workers exhibited greater magnitudes of mean and left axial rotation.

Trunk posture was assessed for each lift repetition among the two keg lift heights for all five worker participants. The height of the lift was the main effect of interest. Looking strictly at the ANOVA of the main effect, the researchers had sufficient evidence of a relationship between trunk posture and lift height for the following trunk posture variables: right and left lateral flexion, right and mean axial rotation, and trunk flexion (p < 0.05). The interaction effect of height and subject was statistically significant for all trunk posture variables except mean axial rotation, right axial rotation, and minimum flexion (p < 0.05). Results of the fixed effects ANOVA suggested that while there was evidence of a relationship between lift height and a worker’s trunk posture, individual differences among workers also contributed to the observed values. For both lift heights, workers exhibited greater magnitudes of left axial rotation (compared to right) and greater magnitudes of right lateral flexion (compared to left). Overall, workers would rotate to the left and lean to the right when handling empty kegs.

Researchers applied the LiFFT cumulative damage measure to estimate the risk of a worker developing a low back disorder from operating the kegging line. The risk model required the maximum horizontal distance between the lifted load and the workers’ center of mass, weight of the load, and the number of repetitions during an eight-hour shift [

38]. Craft brewery workers often carried the empty keg close to their body (seen in

Figure 2,

Figure 3 and

Figure 4), but extended their reach when reaching for the keg as well as flipping and placing the keg onto the conveyor roller. The worker’s posture of forward flexion plus reaching or pushing the keg represented the greatest peak horizontal distances during keg handling. Researchers applied the mean peak horizontal distance (63.2 cm, 24.9 in) and assumed kegs were empty (13.5 kg, 29.7 lbs.) to calculate a peak moment arm 81.3 Nm (60 ft lbs.). As described earlier, kegging demands varied from 100 to 600 kegs per eight-hour shift. The present study observed 64 lifts, which equated to 324 lifts per shift. Thus, researchers applied LiFFT to all three lifting frequency scenarios. Risk estimate was calculated assuming kegs were empty for all three lifting scenarios.

Table 4 provides the LiFFT assessment of risk associated with keg handling task characteristics. In terms of cumulative damage and percent risk, handling empty kegs under three common frequency scenarios equated to a medium risk or 30–50% of total damage. For example, according to LiFFT, a worker who lifts an empty keg 100 times with a peak moment of 81.3 Nm (60 ft lbs.) will accrue a cumulative damage daily dose of 0.0033, a figure associated with an estimated risk of 30.6% of experiencing a low back disorder (i.e., medium risk).

4. Discussion

4.1. Trunk Postures

Craft brewery workers experienced less trunk flexion during high keg lifts compared to low keg lifts. Given that empty kegs typically arrived stacked, the vertical distance a worker had to lift a low keg from the pallet to conveyor roller was 70.4% greater than the distance the worker had to lift a high keg. This task configuration likely contributed to differences in measured trunk flexion among workers in the present study.

While there was sufficient evidence of a relationship between maximum trunk flexion and lift height (with workers experiencing greater trunk flexion during low lifts), the interaction between lift height and worker was also significant (p < 0.05). Individual worker lift strategies likely contributed to differences between trunk flexion and lift characteristic. During data collection, workers were observed reaching across pallets to grasp the high keg top rim compared to walking around the pallet to access low kegs. This difference in keg grasping by different workers may have contributed to observed increases in worker trunk flexion. The limited sample size could have allowed the workers’ unique lifting styles to have a greater influence on the results.

Workers exhibited greater lateral trunk flexion during low keg lifts compared to high keg lifts. Workers leaned, or laterally flexed, 34% farther to the right during low keg lifts. Comparing lateral trunk flexion direction, workers exhibited over 80% greater magnitudes of lateral trunk flexion during low lifts compared to high lifts (88% greater lateral flexion to the right during high lifts and 78% greater lateral flexion to the left during low lifts). The workers’ trunk axial rotations did not vary significantly between high and low keg lifts. Workers exhibited 120% greater trunk axial rotation to the left compared to the right during keg handling (given that the mean trunk rotation was five degrees for low lifts and 20 degrees for high lifts).

Overall, workers exhibited greater trunk flexion and greater lateral trunk flexion when lifting low kegs compared to high kegs. Regardless of keg lift height, workers exhibited greater lateral trunk flexion to the right and greater axial trunk rotation to the left. The current kegging line design was such that incoming empty kegs arrived alongside the roller conveyor. If a worker stood between the roller conveyor and pallet of empty kegs, they could lean to the right, grasp the keg’s top rim, lift, rotate, and place the inverted keg on the roller conveyor located to their left (as shown in

Figure 1 and

Figure 2).

4.2. Estimates of Cumulative Damage Derived from LiFFT Risk Assessment Tool

Under empty keg assumptions across multiple task repetition scenarios, researchers estimated workers to be at a ‘medium risk’ for developing a low back disorder. However, kegs may be returned to the craft brewery with residual amounts of beer. Kegs are opaque; thus, workers do not know the true weight of the keg until they initiate the lift. Researchers also applied the LiFFT model to estimate the risk of developing a low back disorder if a craft brewery worker encountered an entire kegging shift of kegs with a quarter of residual beer in each (28.58 kg, 63 lbs.) using the same postures for assumed empty kegs. If a worker lifted 100 non-empty kegs, using LiFFT, it was estimated that the craft brewery worker could experience a peak moment of 171 Nm (126 ft. lbs.) and accrue a cumulative damage daily dose of 0.0962, a figure associated with an estimated risk of 66.4% of experiencing a low back disorder (i.e., high risk).

While it is unlikely that workers would experience an entire shift of partially full kegs as they operated the kegging line, workers described finding (and researchers observed) sporadic non-empty kegs during kegging operations. When workers encounter non-empty kegs, they must manually decant the kegs because the kegging line is not designed to drain kegs before cleaning. Not only does the presence of non-empty kegs disrupt workflow, non-empty kegs also increase the workers’ estimated risk of a low back disorder.

Table 5 presents a hypothetical scenario where, on a slow kegging shift (100 kegs), a worker handles a combination of empty and partially full kegs. According to LiFFT analysis, that kegging task exposes the worker to a high risk of developing a low back disorder, with a total cumulative damage of 0.1633 and an estimated probability of a high risk job of 71.4%.

4.3. Comparisons to Other Occupational Groups

Although there are no other published studies to date that quantify craft brewery worker trunk posture during keg handling, previous studies have characterized occupational physical exposures associated with MMH tasks in other industries. Previous studies used wearable motion capture devices to investigate physical risk exposures associated with LBP among reforestation workers, grocery stockers, nurses, and distribution workers conducting MMH tasks [

40,

41,

42,

43]. Common occupational exposures to physical risk factors for LBP between craft brewery workers and the comparison occupational groups included awkward and non-neutral postures while handling heavy loads.

The maximum trunk flexion measured among craft brewery workers was less than that reported for distribution workers [

42], reforestation workers [

41], and nurses [

40]. However, maximum trunk flexion measured among craft brewery workers during high lifts was greater than that reported for grocery workers [

43]. The maximum lateral trunk flexion measured among craft brewery workers during high lifts was below that reported for warehouse distribution workers [

42]. However, maximum lateral trunk flexion measured among craft brewery workers was greater than that reported for reforestation workers [

41]. Craft brewery workers operating the kegging line exhibited greater trunk axial rotation than grocery workers unloading carts [

43]. The comparisons between the present craft brewery study and other occupational groups are outlined in

Table 6.

Differences in the work environment and task nature likely contributed to the postural differences between workers in craft breweries and other industries. Studies quantifying posture among distribution workers [

42] and nurses [

40] measured workers throughout their entire shift whereas craft brewery workers, grocery workers [

43], and reforestation workers [

41] were measured during specific tasks within a single shift. Tree saplings, as an example of task differences, are typically shorter than half-barrel kegs (stacked or single). The difference in lifted item height (saplings vs. kegs) requires reforestation workers to exhibit greater magnitudes of trunk flexion as they complete planting tasks compared to craft brewery workers handling kegs [

41]. Marras et al. (2010) assessed worker posture throughout the work shift (from forklift driving to building and breaking down pallets) among workers in grocery, automotive, merchandise, and clothing distribution facilities. Nurses studied by Schall et al. (2016) handled patients, charts, and monitored equipment. Grocery workers handled beverage cases (bottles and cans), among other stock, from a cart [

43]. Craft brewery workers also often handled packaged beer in cases of cans and bottles; however, the present study focused on keg handling tasks.

Demographics of the workforce might contribute to postural differences between occupational groups. Craft brewery workers were older than reforestation workers [

41], younger than distribution workers [

42], and similar in age to grocery workers [

43] and nurses [

40]. A worker’s age may increase their risk of developing LBP, especially during manual materials’ handling tasks [

44]. The present study only measured trunk postures exhibited by male craft brewery workers. Likewise, workers studied in reforestation [

41], grocery [

43], and distribution [

42] industries were predominately, if not entirely, male (see

Table 6 for comparisons). By studying trunk kinematics of only male workers, the present study has limited generalizability as it excludes female workers. As the craft brewing industry continues to expand, the population of craft brewery workers will grow in size and diversity. To ensure a safe and healthy craft brewing workforce, it is critical that researchers and practitioners understand task demands associated with MMH in this understudied yet growing industry.

Other researchers, from the studies cited above, characterized worker posture and movement using various wearable motion capture devices. The lumbar motion monitor (LMM), a wearable exoskeleton device, measured postures exhibited among distribution center workers [

42] and grocery workers [

43]. Inertial measurement unit sensors measured postures exhibited among reforestation workers [

41], nurses [

40], and craft brewery workers. The researchers of the present study applied an IMU system with 17 sensors to quantify worker posture compared to other studies that used four sensors [

41] and three sensors [

40] placed on key body regions. Systems with fewer IMU sensors may be less expensive with a quicker setup, but may also generate simplified posture data. For example, the three-sensor system used by Schall et al. (2016) only reported trunk sagittal flexion. Wearable motion capture devices are tools to quantify human trunk posture, and the scope of the research question should drive technology tool selection.

4.4. Design Recommendations

As part of the present study, the researchers presented the findings on trunk postures exhibited by workers as they handled kegs to the packaging department at the craft brewery where the research was conducted. Researchers discussed the findings with the packaging department and collaborated on developing design modifications to reduce workers’ exposure to risk factors for LBP and MSDs. Specifically, the recommendations targeted the initial lift, carry, and flip stages of keg handling.

4.4.1. Recommendation 1: Empty Kegs at One Level

In the current kegging line, kegs arrived at two levels (high and low heights). As a result, workers exhibited different trunk postures as they handled high or low kegs. Postures exhibited during both keg height conditions were considered to be awkward or non-neutral. Craft brewery workers were at an increased risk of developing LBP during both height conditions. The researchers recommend modifying the workstation so that empty kegs are delivered at a single optimal height. Incoming empty kegs could be loaded at one height, then a sloped roller conveyor gradually delivers the kegs to the cleaning and filling machinery. If kegs arrive at the optimal height (ideally the same height as the destination), the worker would simply need to rotate the keg. This approach would require kegs to be delivered as single pallets, or onto a sloped conveyor so that kegs eventually reached this optimal height before being flipped.

4.4.2. Recommendation 2: Redesign Workstation Layout

Forklift operators were often rushed and hastily placed pallets at irregular locations in the work area which required workers on the kegging line to carry empty kegs various distances to the roller conveyor. If workers carried kegs a consistent and short distance, they could have more time to focus on managing the line or additional brewing tasks. The researchers recommend three possible solutions to improve the carry phrase of keg handling: floor markings, a safety mirror, and/or a platform with casters to move pallets of kegs to their optimal location. The addition of floor markings could standardize where forklift operators place incoming pallets. During busy shifts, if a forklift driver has to deposit pallets outside the floor markings, the pallets could be on casters so that the worker could easily reposition the pallet before handling the kegs. Installing a safety mirror could help forklift drivers visually identify where to place pallets of kegs. Forklift operators could also use the safety mirror to see the worker operating the kegging line, even when they are blocked behind existing stacks of kegs. If a forklift operator does not see (or know that) a kegging line worker is behind stacks of existing kegs, there is a risk that the forklift operator could push pallets of new kegs into the worker. Upon completion of the present study, the craft brewery installed a safety mirror above the kegging line.

4.4.3. Recommendation 3: Mechanical Keg Handling and Robotics

The kegging line requires kegs to be placed upside down, but empty kegs typically arrive upright. While an upright position allows the consumer to access the keg’s spear valve, kegs need to be upside down to be cleaned and filled with fresh beer. Therefore, under current task configurations, workers flip the kegs as they place them on the roller conveyor.

Craft breweries with resources to invest in mechanized equipment or alternative practices (often larger establishments) could automate kegging operations so that any combination of the lift, carry, and flip stages of keg handling may be eliminated.

Specialized vacuum lift-assist devices, often used by craft brewery workers to place full kegs on pallets, could be applied to empty keg handling. To use a vacuum lift-assist device, the worker simply activates the pump, guides the lifted item from the origin to the destination, and releases the vacuum. Some vacuum lift-assist devices have rotational capabilities, which may be used to reorient empty kegs. Vacuum lift-assist devices eliminate the weight of the load, but still require a worker to maneuver the object.

A robotic keg de-palletizer could eliminate all manual keg handling among workers. The craft brewery that participated in the present study currently handles full kegs robotically. After empty kegs are cleaned and filled with beer, a robotic palletizer arranges the full kegs on a pallet. Forklift operators then transport these pallets across the craft brewery. The manual handling of empty kegs could be eliminated by applying a similar robotic keg-handling technology. However, automation is not always economically feasible for many small developing craft breweries that lack resources to invest in sophisticated materials handling equipment.

4.4.4. Recommendation 4: Outsourcing and Collaborating with Contract Breweries

Craft breweries may outsource empty keg handling by contracting with a third party to reposition empty kegs with the spear valve pointed downwards. A forklift operator would then load the pallet of correctly positioned kegs onto the kegging line. While this technique eliminates manual keg handling among craft brewery workers, the MMH requirements have simply been shifted to a separate workforce.

Instead of modifying their own brewing facilities, craft breweries could hire contract breweries to reduce exposures to physical risk factors associated with keg handling. Contract breweries are brewing facilities whose primary purpose is to provide an environment for small craft breweries to brew beer [

24]. In contrast to typical craft breweries, contract breweries do not have to rationalize equipment costs with investments toward personal branding, tap room management, and other related business demands. Historically, controversy has surrounded contract breweries as the operation itself depersonalizes the brewing process by ‘producing local beer somewhere else.’ However, the benefits of accessing large scale production equipment may outweigh the controversy surrounding contract breweries. Some craft breweries utilize contract breweries as an intermediate step to continue their growth as they gather resources to expand their own facility, while others integrate contract brewing into their permanent production strategies. Today, both single craft breweries and collections of multiple craft breweries regularly utilize contract brewing as a means of producing more beer than what is feasible at their own facilities.

4.5. Limitations and Suggestions for Further Research

In the present study, trunk postures exhibited by workers applied directly to the kegging line operation in a single craft brewery were observed. While the sample size was small (five participants), it successfully captured all of the workers conducting that task at the craft brewery. This craft brewery is the second largest in the county and the largest operation that handles empty kegs using both manual (for empty kegs) and automatic (for filling and handling full kegs) techniques for keg handling. Keg handling procedures, and subsequent workers’ postures, may vary across craft breweries throughout Colorado.

The tool utilized to measure worker motions recorded comprehensive information about the entire body and velocity, acceleration in addition to position and angular displacement. While the focus of the present study was strictly angular displacement of the trunk, future analysis could investigate other body parts such as the shoulder and knee.

This study only investigated awkward or non-neutral postures and heavy loads (assumed to be empty half-barrel kegs) as occupational physical risk factors affecting craft brewery workers. While researchers focused on individual component rotations, future studies could combine rotations about multiple anatomical axes to represent more complex multiplanar postures and movements. In addition to postures, other occupational physical risk factors associated with MMH and LBP include long periods of work activity, excessive weight of loads moved, and high frequency of lifts [

7,

8,

12,

13,

14,

15]. Workers operating the kegging line were also responsible for additional jobs throughout the brewery, thus assessing posture during one task may not represent their entire work-demands. Workers exhibited non-neutral trunk postures as they lifted pallets from the floor, crouched under pipes, handled large bags of ingredients, and conducted other common brewing tasks. The present study investigated keg handling characteristics within a single craft brewery, but operations vary among craft breweries depending on the production scale and business scope. The researchers recommend that future studies investigate worker motions throughout multiple craft brewing tasks and across different craft brewing facilities.

5. Conclusions

Craft brewery workers are exposed to awkward postures and heavy loads as they handle kegs, and are at an increased risk for developing MSDs and LBP. Researchers estimated that workers were at a ‘medium risk’ of developing a low back disorder if they only handled truly empty kegs. If workers handled partially filled kegs, the risk increased to ‘high risk’. Researchers outlined design recommendations to reduce the awkward postures and heavy lifting associated with operating the kegging line.

The U.S. craft brewing industry is rapidly growing with workers who are exposed to physical risk factors associated with MSDs. Despite this industry growth, little is understood about work-demands among craft brewery workers. Thus, it is worthwhile for researchers to continue research among craft brewery workers to characterize and assess work-demands beyond keg handling. As researchers and practitioners better understand exposures to physical risk factors during craft brewing work, they can apply that knowledge to developing effective interventions to reduce the risk of MSDs and to improve the quality of work life among craft brewery workers.