Evaluation of Green Coffee-Roasting Biogas with Modeling Valorization of Possible Solutions

Abstract

1. Introduction

2. Materials and Methods

2.1. Substrate Origin

2.2. Substrate Characterization

2.3. Anaerobic Digestion Tests

2.4. Model Analysis of Batch and Fed-Batch Assay Results

2.5. Computation Model for Evaluation of Biomethane Solutions

- to obtain data concerning the productivity of biogas plants with the related possible gas flow rates;

- to know the energy consumption of the plant and the related remaining energy flows, which is useful for economic valorization (electrical- and/or thermal-produced energy, biomethane for transport use, and/or gas distribution grid);

- to take into account the total environmental impact of the system.

- Mass and energy balance of the system;

- The greenhouse gas balance of the system, referred to an equivalent traditional system with fossil fuels.

3. Results

3.1. Substrate Characterization

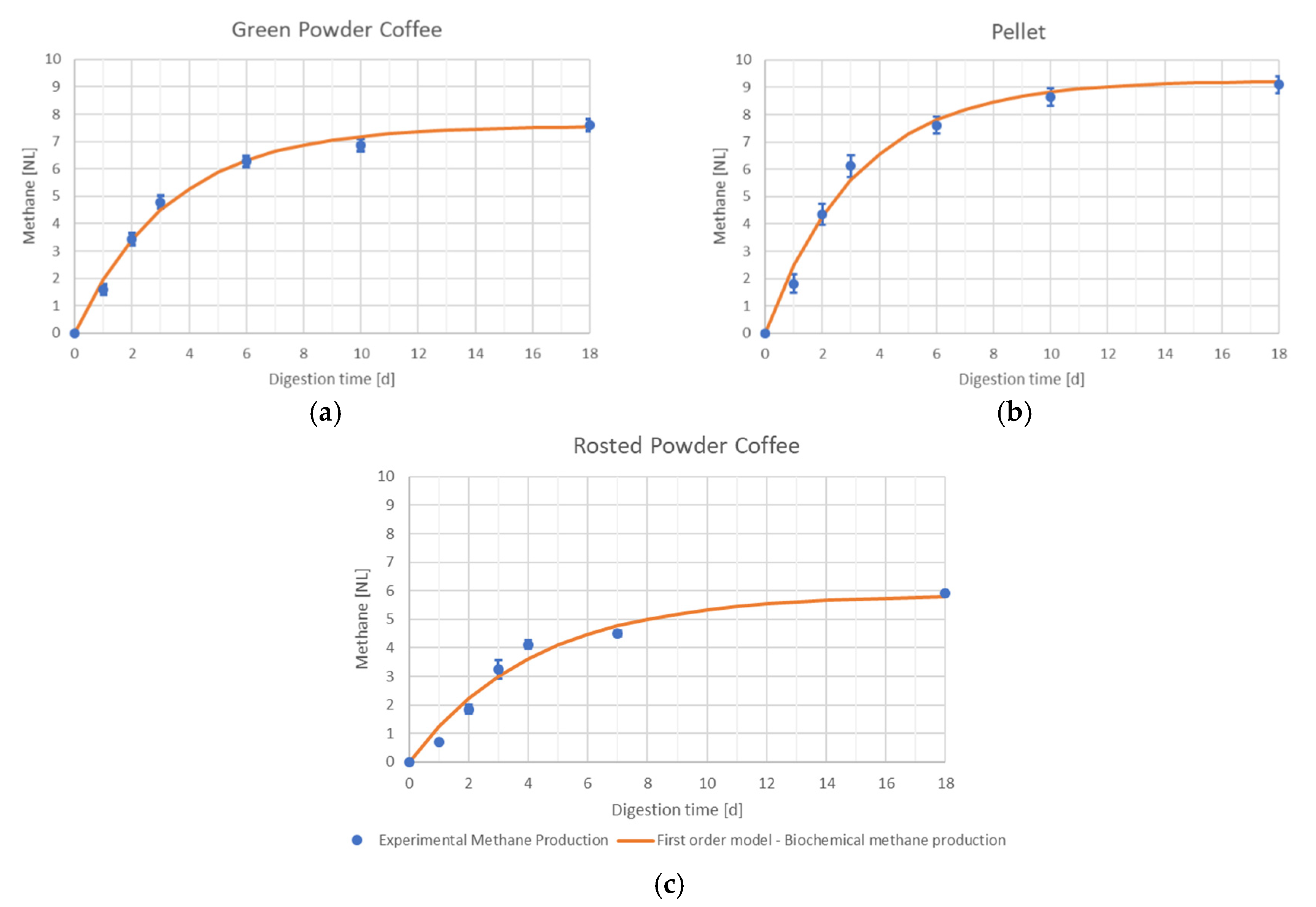

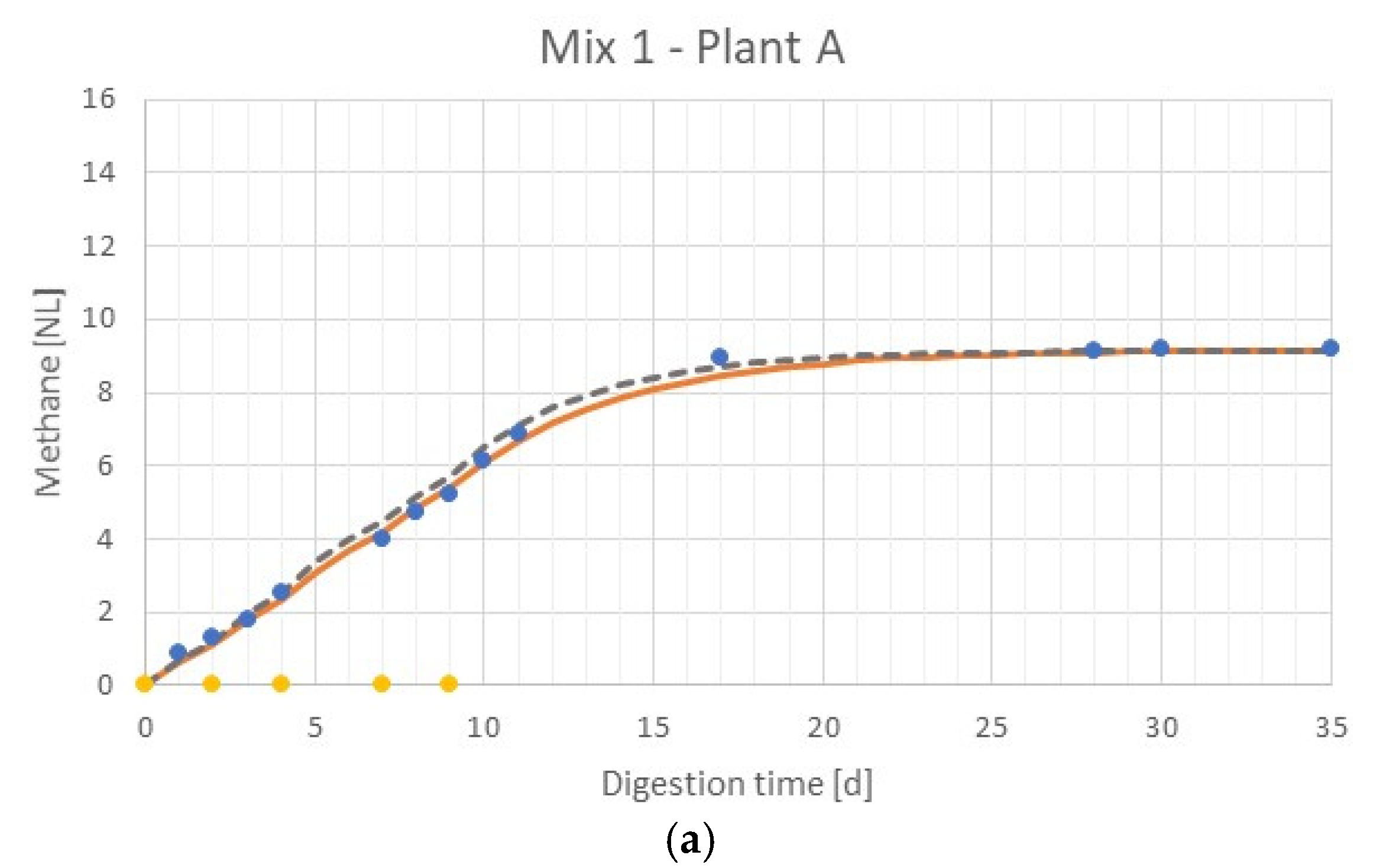

3.2. Anaerobic Digestion Tests

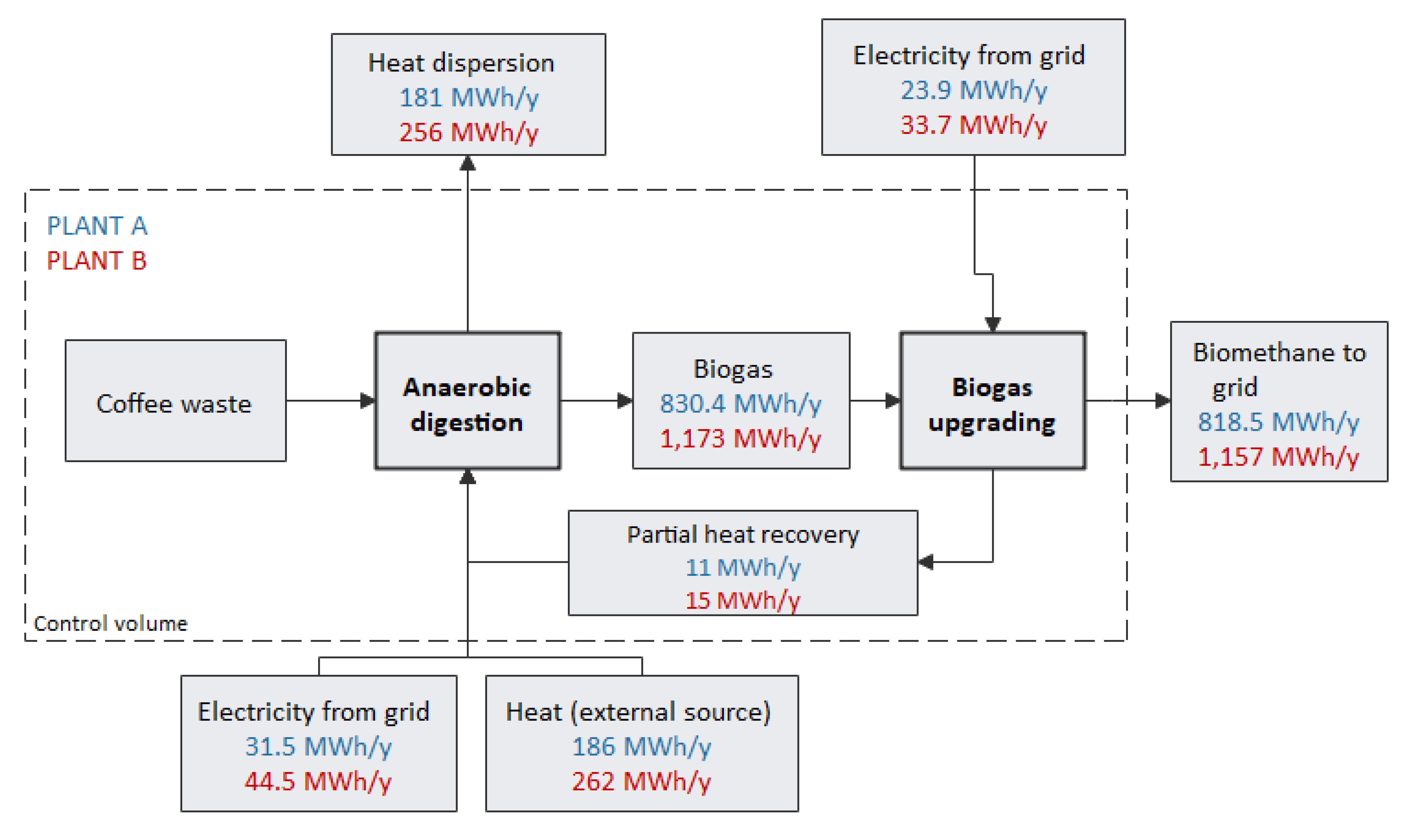

3.3. Full-Scale Simulation Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AD | anaerobic digestion |

| Bth | theoretical biochemical methane potential |

| B0 | biochemical methane potential |

| CHNS | carbon hydrogen nitrogen sulfur |

| CHP | combined heat and power |

| COD | chemical oxygen demand |

| CO2eq | equivalent carbon dioxide |

| CRY | cryogenic separation |

| HHV | higher heating value |

| GHG | greenhouse gases |

| k | first-order hydrolysis rate constant |

| MEA | chemical absorption with amine solutions |

| MB | membrane permeation |

| PSA | pressure swing absorption |

| PWS | pressurized water scrubbing |

| SBPex | experimental biogas production |

| TS | total solids |

| VS | volatile solids |

| Y | absolute biodegradability |

References

- Ruffino, B.; Zanetti, M.C. Present and future solutions of waste management in a candied fruit—jam factory: Optimized anaerobic digestion for on site energy production. J. Clean. Prod. 2017, 159, 26–37. [Google Scholar] [CrossRef]

- Magaril, E.R.; Magaril, R.; Panepinto, D.; Genon, G.; Ravina, M.; Trushkova, L.; Zanetti, M.C. Production and utilization of energy and climate adaptation: Global tasks and local routes. Int. J. Sustain. Dev. Plan. 2017, 12, 1326–1337. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Martins, S.; Teixeira, J.A. Production, Comosition and Application of Coffee and Its Industrial Residues. Food Bioprocess Technol. 2011, 4, 661–672. [Google Scholar] [CrossRef]

- Franca, A.S.; Oliveira, L.S. Coffee Processing Solid Wastes: Current Uses and Future Prospectives. Agric. Wastes 2009, 9, 155–189. [Google Scholar]

- Panepinto, D.; Riggio, V.A.; Campo, G.; Cerutti, A.; Zanetti, M.C. Analysis of two treatment technologies for coffee roasting matrixes: Combustion and anaerobic digestion. Clean Technol. Environ. Policy 2019, 21, 685–694. [Google Scholar] [CrossRef]

- IIT: Dagli Scarti alla Bioplastica, la Sostenibilità è Energia. 2018. Available online: http://www.askanews.it/video/2018/03/30/iit-dagli-scarti-alla-bioplastica-la-sostenibilit%c3%a0-%c3%a8-tecnologia-20180330_video_12543414/ (accessed on 22 September 2020).

- Kovalcik, A.; Kucera, D.; Matouskova, P.; Pernicova, I.; Obruca, S.; Kalina, M.; Enev, V.; Marova, I. Influence of removal of microbial inhibitors on PHA production from spent coffee grounds employing Halomonas halophila. J. Environ. Chem. Eng. 2018, 6, 3495–3502. [Google Scholar] [CrossRef]

- Obruca, S.; Benesova, P.; Petrik, S.; Oborna, J.; Prikryl, R.; Marova, I. Production of polyhydroxyalkanoates using hydrolysate of spent coffee grounds. Process Biochem. 2014, 49, 1409–1414. [Google Scholar] [CrossRef]

- Battista, F.; Barampouti, E.M.; Mai, S.; Moustakas, D.B.D.M.K.; Loizidou, M. Added-value molecules recovery and biofuels production from spent coffee grounds. Renew. Sustain. Energy Rev. 2020, 131, 110007. [Google Scholar] [CrossRef]

- Petroff, A. London Buses are Being Powered by a New Fuel: Coffee. 2017. Available online: https://money.cnn.com/2017/11/20/technology/coffee-fuel-bus-london-bio-bean/index.html (accessed on 22 September 2020).

- Fiore, S.; Ruffino, B.; Campo, G.; Roati, C.; Zanetti, M.C. Scale-up evaluation of the anaerobic digestion of food-processing industrial wastes. Renew. Energy 2016, 96, 949–959. [Google Scholar] [CrossRef]

- Figueroa, G.A.; Homann, T.; Rawel, H.M. Coffee Production Wastes: Potentials and Perspectives. Food Sci. 2016, 1, 1014. [Google Scholar]

- Somnuk, K.; Eawlex, P.; Prateepchaikul, G. Optimization of coffee oil extraction from spent coffee grounds using four solvents and prototype-scale extraction using circulation process. Agric. Nat. Resour. 2017, 51, 181–189. [Google Scholar] [CrossRef]

- Bessada, S.; Alves, R.C.; Oliveira, M.B.P. Coffee Silverskin: A Review on Potential Cosmetic Applications. Cosmetics 2018, 5, 5. [Google Scholar] [CrossRef]

- Wang, H.; Chiang, P.C.; Cai, Y.; Li, C.H.; Wang, X.; Chen, T.L.; Wei, S.; Huang, Q. Application of Wall and Insulation Materials on Green Building: A Review. Sustainability 2018, 10, 3331. [Google Scholar] [CrossRef]

- Cecchini, C. Bioplastics made from upcycled food waste. Prospects for their use in the field of design. Des. J. 2017, 20, S1596–S1610. [Google Scholar] [CrossRef]

- Panepinto, D.; Genon, G. Analysis of the extrusion as a pretreatment for the anaerobic digestion process. Ind. Crop. Prod. 2016, 83, 206–212. [Google Scholar] [CrossRef]

- American Public Health Association (APHA); American Water Works Association (AWWA); Water Environment Federation (WEF). Standard Methods for the Examination of Water and Wastewater, 21st ed.; APHA; AWWA; WEF: Washington, DC, USA, 2005; ISBN 978-0875530475. [Google Scholar]

- Tchobanoglous, G.; Theisen, H.; Vigil, S.A. Integrated Solid Waste Management; McGraw-Hill International Editions; McGraw-Hill: New York, NY, USA, 1993; pp. 681–682. [Google Scholar]

- Ruffino, B.; Cerutti, A.; Campo, G.; Scibilia, G.; Lorenzi, E.; Zanetti, M. Thermophilic vs. mesophilic anaerobic digestion of waste activated sludge: Modelling and energy balance for its applicability at a full scale WWTP. Renew. Energy 2020, 156, 235–248. [Google Scholar] [CrossRef]

- VDI Standard: VDI 4630 Fermentation of Organic Materials. Characterization of the Substrate, Sampling, Collection of Material Data, Fermentation Tests. 2006, p. 92. Available online: http://www.vdi.eu/guidelines (accessed on 1 October 2017).

- Ruffino, B.; Cerutti, A.; Campo, G.; Scibilia, G.; Lorenzi, E.; Zanetti, M. Improvement of energy recovery from the digestion of waste activated sludge (WAS) through intermediate treatments: The effect of the hydraulic retention time (HRT) of the first-stage digestion. Appl. Energy 2019, 240, 191–204. [Google Scholar] [CrossRef]

- Van Lier, J.B.; Mahmaud, N.; Zeeman, G. Chapter 16: Anaerobic Wastewater Treatment. In Biological Wastewater Treatment: Processes, Modelling and Design; IWA Publishing: London, UK, 2008. [Google Scholar]

- Zhen, G.; Lu, X.; Kato, H.; Youcai, Z.; Cheng, J. Overview of pretreatment strategies for enhancing sewage sludge disintegration and subsequent anaerobic digestion: Current advances, full-scale application and future perspectives. Renew. Sustain. Energy Rev. 2017, 69, 559–577. [Google Scholar] [CrossRef]

- Batstone, D.J.; Pind, P.F.; Angelidaki, I. Kinetics of thermophilic, anaerobic oxidation of straight and branched chain butyrate and valerate. Biotechnol. Bioeng. 2003, 84, 195–204. [Google Scholar] [CrossRef]

- Wei, W.; Zhou, X.; Wangab, D.; Sun, J.; Wang, Q. Free ammonia pre-treatment of secondary sludge significantly increases anaerobic methane production. Water Res. 2017, 118, 12–19. [Google Scholar] [CrossRef]

- Ravina, M.; Castellana, C.; Panepinto, D.; Zanetti, M.C. MCBioCH4: A computational model for biogas and biomethane evaluation. J. Clean. Prod. 2019, 227, 739–747. [Google Scholar] [CrossRef]

- Ravina, M.; Genon, G. Global and local emissions of a biogas plant considering the production of biomethane as an alternative end-use solution. J. Clean. Prod. 2015, 102, 115–126. [Google Scholar] [CrossRef]

- Kiselev, A.; Magaril, E.R.; Magaril, R.; Panepinto, D.; Ravina, M.; Zanetti, M.C. Towards Circular Economy: Evaluation of Sewage Sludge Biogas Solutions. Resources 2019, 8, 91. [Google Scholar] [CrossRef]

- Borzooei, S.; Campo, G.; Cerutti, A.; Meucci, L.; Panepinto, D.; Ravina, M.; Riggio, V.; Ruffino, B.; Scibilia, G.; Zanetti, M.C. Feasibility analysis for reduction of carbon footprint in a wastewater treatment plant. J. Clean. Prod. 2020, 271, 122526. [Google Scholar] [CrossRef]

- Malave, A.C.; Bernardi, M.; Fino, D.; Ruggeri, B. Multistep anaerobic digestion (MAD) as a tool to increase energy production via H2 þ CH4. Int. J. Hydrogen Energy 2015, 40, 5050–5061. [Google Scholar] [CrossRef]

- Institute for Environmental Protection and Research. Greenhouse Gas Emission Factors in the National Electricity Sector and in Major European Countries. Available online: http://www.isprambiente.gov.it/files2019/pubblicazioni/rapporti/R_303_19_gas_serra (accessed on 22 September 2020).

- Baêta, B.E.L.; de Miranda Cordeiro, P.H.; Passos, F.; Gurgel, L.V.A.; de Aquino, S.F.; Fdz-Polanco, F. Steam explosion pretreatment improved the biomethanization of coffee husks. Bioresour. Technol. 2017, 245, 66–72. [Google Scholar] [CrossRef]

- Battista, F.; Fino, D.; Mancini, G. Optimization of biogas production from coffee production waste. Bioresour. Technol. 2016, 200, 884–890. [Google Scholar] [CrossRef]

- Paolini, V.; Petracchini, F.; Segreto, M.; Tomassetti, L.; Naja, N.; Cecinato, A. Environmental impact of biogas: A short review of current knowledge. J. Environ. Sci. Heal. Part A 2018, 53, 899–906. [Google Scholar] [CrossRef] [PubMed]

- Ministero dello Sviluppo Economico. Incentivazione dell’Energia Elettrica Prodotta da Fonti Rinnovabili Diverse dal Fotovoltaico; GU n.150 of 29-6-2016; Ministero dello Sviluppo Economico: Rome, Italy, 2016.

| Utilization Methods | Coffee Husks, Pulp | Green Coffee Powder | Pellets | Roasted Coffee Powder | Coffee Grounds |

|---|---|---|---|---|---|

| Combustion | [4] | [12] | [12] | [9,12] | [12] |

| Anaerobic digestion | [12] | [12] | [12] | [9,12] | [12] |

| Substrate for the growth of edible mushrooms | [4] | - | - | - | [3] |

| Feed for livestock as a supplement for the diet of pigs, cattle, fish, sheep, and poultry | [4] | - | - | - | - |

| Fertilizers | [4] | - | - | - | [12] |

| Preparation of activated carbon | [4] | - | - | - | - |

| Biodiesel | - | - | - | - | [3,13] |

| Pharmaceutical industries | - | - | [3] | - | - |

| Cosmetic industries | - | - | [14] | - | - |

| Bioethanol | - | - | - | - | [3] |

| Production of a steak drink | - | - | - | - | [3] |

| Insulation material for buildings | - | - | - | - | [12,15] |

| Bioplastic | - | - | - | - | [14] |

| PLANTS | Pellets (ton) | Green Coffee Powder (ton) | Roasted Coffee Powder (ton) |

|---|---|---|---|

| Plant A | 780 | 70 | 280 |

| Plant B | 766 | 155 | 627 |

| Input Parameter/Value | Plant A | Plant B |

|---|---|---|

| CH4 loss from digestion and conversion processes (%) | 1.6 | |

| Energy autoconsumption for thermal process sustainment (MWh/y) | 181 | 845 |

| Electricity autoconsumption, biogas section (MWh/y) | 30.2 | 114 |

| Upgrading system efficiency (%) | 98.6 | |

| Electricity autoconsumption, upgrading system (MWh/y) | 22.9 | 109.32 |

| Emission factor for natural gas consumption/substitution (gCO2e/kWh) | 206 | 206 |

| Emission factor for electricity substitution (Italian grid) (gCO2e/kWh) | 337 | 337 |

| Matrix | N (%) | C (%) | H (%) | S (%) | O (%) | Bth (Nm3/kgVS) | HHV (MJ/kg) | TS (%) | VS (%) |

|---|---|---|---|---|---|---|---|---|---|

| Pellets | 3.2 | 50.6 | 6.5 | 0.1 | 39.6 | 0.50 | 13.9 | 93.9 | 86.1 |

| Roasted coffee powder | 3.1 | 54.2 | 6.9 | 0.0 | 35.9 | 0.55 | 12.8 | 97.4 | 92.8 |

| Green coffee powder | 2.6 | 50.3 | 6.4 | 0.0 | 40.8 | 0.49 | 19.9 | 90.7 | 84.4 |

| Matrix | B0 (Nm3/kgVS) | k (1/d) | Y (-) |

|---|---|---|---|

| Pellets | 0.22 (±0.01) | 0.31 | 0.44 |

| Roasted coffee powder | 0.33 (±0.01) | 0.24 | 0.60 |

| Green coffee powder | 0.18 (±0.01) | 0.30 | 0.37 |

| Plants A (mixed matrix) | 0.24 (±0.01) | 0.26 | 0.45 |

| Plants B (mixed matrix) | 0.27 (±0.02) | 0.28 | 0.50 |

| Plants | Methane (Nm3/y) | Electrical Energy (kWh/y) | Electrical Power of Biogas Engine (kW) |

|---|---|---|---|

| Mix from Plant A | 150,000 | 600,000 | 75 |

| Mix from Plant B | 226,000 | 900,000 | 113 |

| Input Parameter/Value | Plant A | Plant B |

|---|---|---|

| Gross biogas energy content (MWh/y) | 830.4 | 1173.6 |

| Net useful energy in biomethane (MWh/y) | 818.5 | 1157.0 |

| Thermal energy autoconsumption covered by external source (%) | 100 | 100 |

| Electricity autoconsumption covered by external source (%) | 100 | 100 |

| GHG emission produced substrates handling and fugitive CH4 loss (t CO2e/y) | 30.7 | 43.4 |

| GHG emission produced—electricity autoconsumption (t CO2e/y) | 18.7 | 26.4 |

| GHG emission produced—natural gas for thermal autoconsumption (t CO2e/y) | 38.2 | 54.0 |

| Total GHG emissions produced | 87.6 | 123.8 |

| Total GHG emissions avoided for natural gas replacement (t CO2e/y) | −168.7 | −238.4 |

| GHG emission balance (t CO2e/y) | −81.0 | −114.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Campo, G.; Cerutti, A.; Ravina, M.; Panepinto, D.; Riggio, V.A.; Zanetti, M. Evaluation of Green Coffee-Roasting Biogas with Modeling Valorization of Possible Solutions. Int. J. Environ. Res. Public Health 2020, 17, 6947. https://doi.org/10.3390/ijerph17196947

Campo G, Cerutti A, Ravina M, Panepinto D, Riggio VA, Zanetti M. Evaluation of Green Coffee-Roasting Biogas with Modeling Valorization of Possible Solutions. International Journal of Environmental Research and Public Health. 2020; 17(19):6947. https://doi.org/10.3390/ijerph17196947

Chicago/Turabian StyleCampo, Giuseppe, Alberto Cerutti, Marco Ravina, Deborah Panepinto, Vincenzo A. Riggio, and Mariachiara Zanetti. 2020. "Evaluation of Green Coffee-Roasting Biogas with Modeling Valorization of Possible Solutions" International Journal of Environmental Research and Public Health 17, no. 19: 6947. https://doi.org/10.3390/ijerph17196947

APA StyleCampo, G., Cerutti, A., Ravina, M., Panepinto, D., Riggio, V. A., & Zanetti, M. (2020). Evaluation of Green Coffee-Roasting Biogas with Modeling Valorization of Possible Solutions. International Journal of Environmental Research and Public Health, 17(19), 6947. https://doi.org/10.3390/ijerph17196947