Developing Key Safety Management Factors for Construction Projects in China: A Resilience Perspective

Abstract

:1. Introduction

2. Literature Review

2.1. The Concept of Resilience

2.2. Application of Resilience in Construction Projects Safety Management

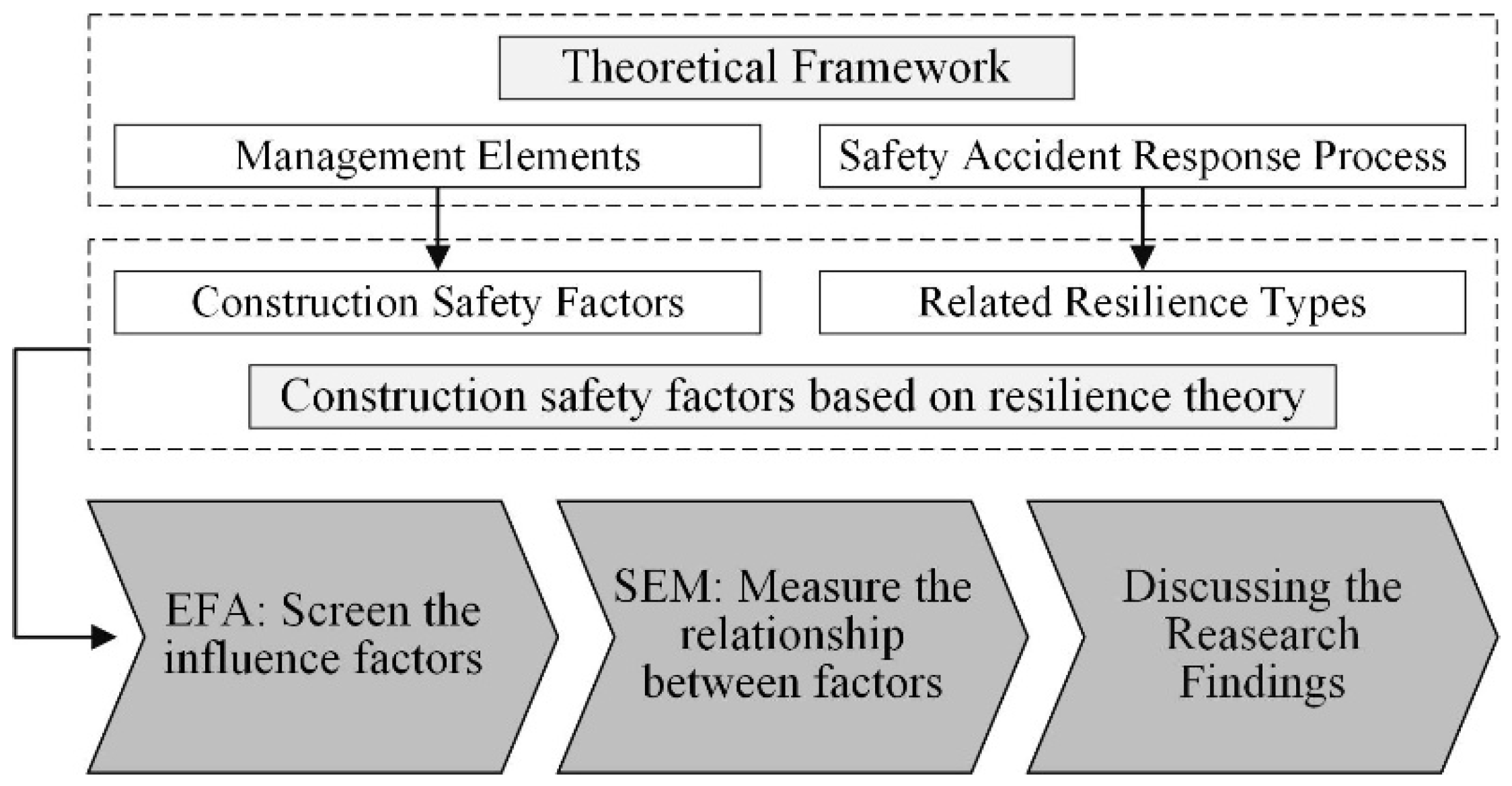

2.3. Theoretical Framework and Hypotheses

3. Research Method

3.1. Exploratory Factor Analysis (EFA) and Structural Equation Modeling (SEM)

3.2. Data Collection

4. Data Analysis

4.1. Demographic Characteristics

4.2. Exploratory Factor Analysis

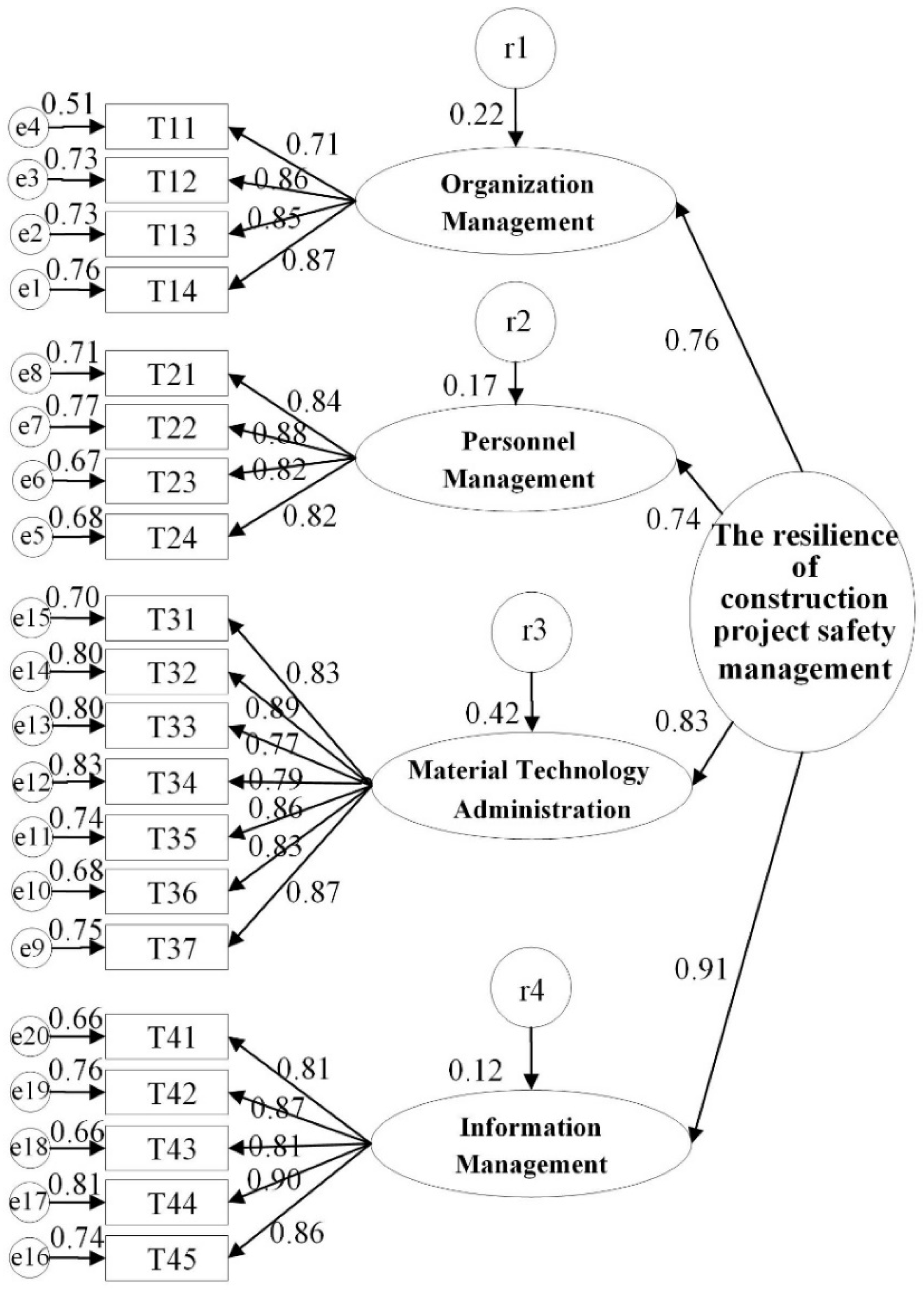

4.3. Confirmatory Factor Analysis

5. Discussion

5.1. Improving the Resilience of Information Flow to Strengthen the Element Interaction of the System

5.2. The Key Safety Management Factors

5.3. Practical Implications and Recommendations

6. Conclusions

- (1)

- The safety resilience of the project is determined by both the accident defense resilience and the recovery resilience. The defense capability of the project should be optimized before the accident, and the recovery capability of the project should be enhanced when the accident occurs and after the accident, so as to realize the goal of the safety resilience of the project by the optimal means.

- (2)

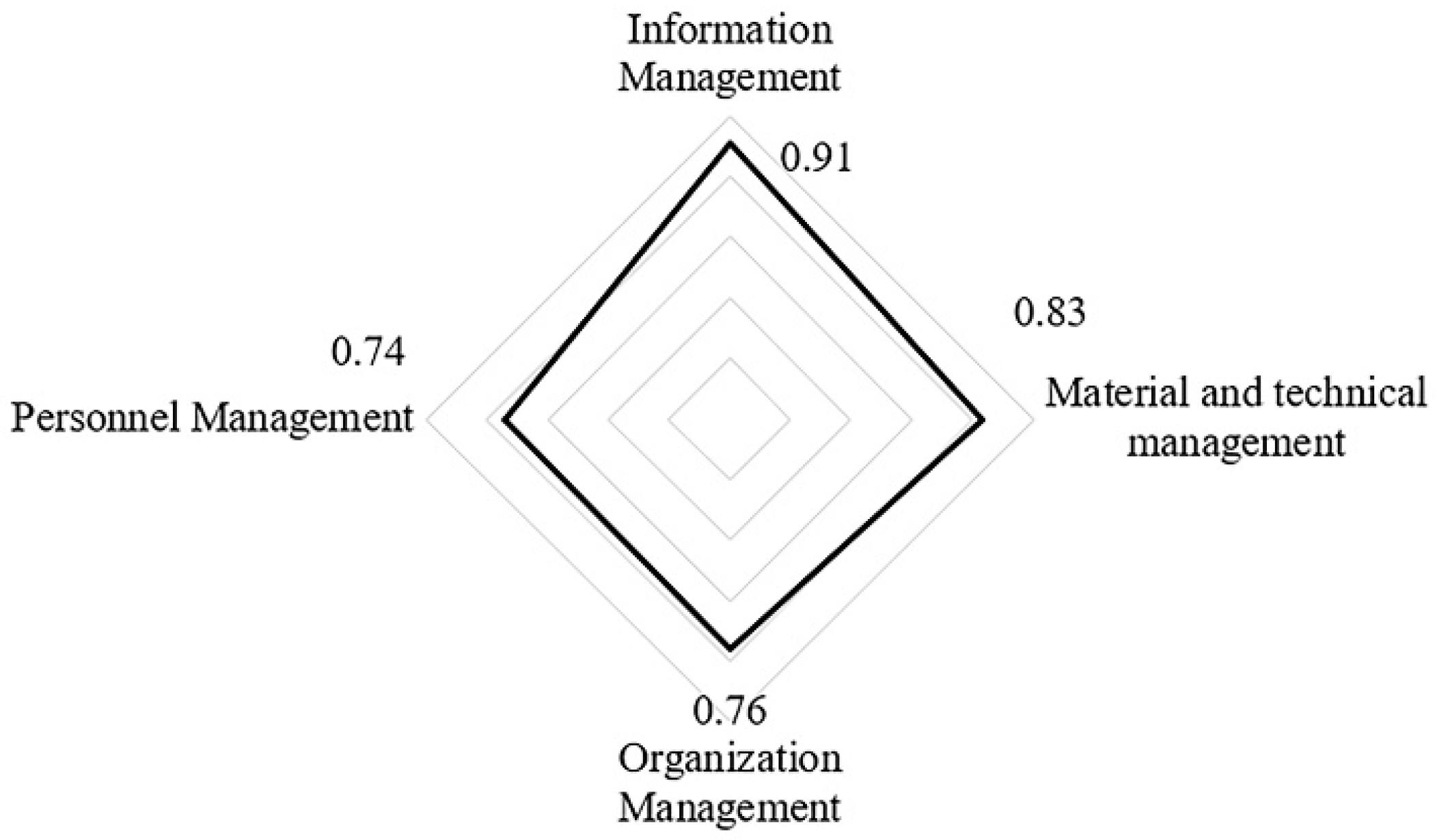

- In the life cycle of accident development, through information management, material and technology management, organization management and personnel management, the safety and resilience of the project will be comprehensively improved. According to the results of SEM, although the four dimensions differ in priority, they have little difference in importance (in order is 0.91, 0.83, 0.76 and 0.74), so they should all be paid great attention to in the construction safety management.

- (3)

- Comparatively speaking, the information management has the greatest influence on the safety and resilience of the construction project. This factor is an intermediary to enhance the interaction of various elements in the management system and to thoroughly promote system resilience. Therefore, the level of information management in construction projects should be consistently improved by means of information technology in the future.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kang, L.; Wu, C.; Liao, X.; Wang, B. Safety performance and technology heterogeneity in China’s provincial construction industry. Saf. Sci. 2020, 121, 83–92. [Google Scholar] [CrossRef]

- Ding, L.; Yu, H.; Li, H.; Zhou, C.; Wu, X.; Yu, M. Safety risk identification system for metro construction on the basis of construction drawings. Autom. Constr. 2012, 27, 120–137. [Google Scholar] [CrossRef]

- Gunduz, M.; Ahsan, B. Construction safety factors assessment through Frequency Adjusted Importance Index. Int. J. Ind. Ergon. 2018, 64, 155–162. [Google Scholar] [CrossRef]

- Zheng, X.; Zhou, J.; Wang, F.; Chen, Y. Routes to failure and prevention recommendations in work systems of hydropower construction. J. Civ. Eng. Manag. 2018, 24, 206–222. [Google Scholar] [CrossRef]

- Zhou, Z.; Goh, Y.M.; Li, Q. Overview and analysis of safety management studies in the construction industry. Saf. Sci. 2015, 72, 337–350. [Google Scholar] [CrossRef]

- Leu, S.-S.; Chang, C.-M. Bayesian-network-based safety risk assessment for steel construction projects. Accid. Anal. Prev. 2013, 54, 122–133. [Google Scholar] [CrossRef]

- Shao, B.; Hu, Z.; Liu, Q.; Chen, S.; He, W. Fatal accident patterns of building construction activities in China. Saf. Sci. 2018, 111, 253–263. [Google Scholar] [CrossRef]

- Nahangi, M.; Chen, Y.; McCabe, B. Safety-based efficiency evaluation of construction sites using data envelopment analysis (DEA). Saf. Sci. 2019, 113, 382–388. [Google Scholar] [CrossRef]

- Alkaissy, M.; Arashpour, M.; Ashuri, B.; Bai, Y.; Hosseini, M.R. Safety management in construction: 20 years of risk modeling. Saf. Sci. 2020, 129, 104805. [Google Scholar] [CrossRef]

- Pi, Z.; Gao, X.; Chen, L.; Liu, J. The New Path to Improve Construction Safety Performance in China: An Evolutionary Game Theoretic Approach. Int. J. Environ. Res. Public Health 2019, 16, 2443. [Google Scholar] [CrossRef] [Green Version]

- Zaira, M.M.; Hadikusumo, B.H. Structural equation model of integrated safety intervention practices affecting the safety behaviour of workers in the construction industry. Saf. Sci. 2017, 98, 124–135. [Google Scholar] [CrossRef]

- Qian, Q.; Lin, P. Safety risk management of underground engineering in China: Progress, challenges and strategies. J. Rock Mech. Geotech. Eng. 2016, 8, 423–442. [Google Scholar] [CrossRef] [Green Version]

- Holling, C.S. Resilience and Stability of Ecological Systems. Annu. Rev. Ecol. Syst. 1973, 4, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Hosseini, S.; Barker, K.; Ramirez-Marquez, J.E. A review of definitions and measures of system resilience. Reliab. Eng. Syst. Saf. 2016, 145, 47–61. [Google Scholar] [CrossRef]

- Du Plessis, E.M.; Vandeskog, B. Other stories of resilient safety management in the Norwegian offshore sector: Resilience engineering, bullshit and the de-politicization of danger. Scand. J. Manag. 2020, 36, 101096. [Google Scholar] [CrossRef]

- Bergström, J.; Van Winsen, R.; Henriqson, E. On the rationale of resilience in the domain of safety: A literature review. Reliab. Eng. Syst. Saf. 2015, 141, 131–141. [Google Scholar] [CrossRef] [Green Version]

- Ranasinghe, U.; Jefferies, M.; Davis, P.; Pillay, M. Resilience Engineering Indicators and Safety Management: A Systematic Review. Saf. Health Work 2020, 11, 127–135. [Google Scholar] [CrossRef] [PubMed]

- Haimes, Y.Y. On the Definition of Resilience in Systems. Risk Anal. 2009, 29, 498–501. [Google Scholar] [CrossRef]

- Pariès, J.; Macchi, L.; Valot, C.; Deharvengt, S. Comparing HROs and RE in the light of safety management systems. Saf. Sci. 2019, 117, 501–511. [Google Scholar] [CrossRef]

- Peñaloza, G.A.; Saurin, T.A.; Formoso, C.T. Monitoring complexity and resilience in construction projects: The contribution of safety performance measurement systems. Appl. Ergon. 2020, 82, 102978. [Google Scholar] [CrossRef]

- Li, Y.; Guldenmund, F.W. Safety management systems: A broad overview of the literature. Saf. Sci. 2018, 103, 94–123. [Google Scholar] [CrossRef]

- Winge, S.; Albrechtsen, E.; Arnesen, J. A comparative analysis of safety management and safety performance in twelve construction projects. J. Saf. Res. 2019, 71, 139–152. [Google Scholar] [CrossRef]

- Wehbe, F.; Al Hattab, M.; Hamzeh, F. Exploring associations between resilience and construction safety performance in safety networks. Saf. Sci. 2016, 82, 338–351. [Google Scholar] [CrossRef]

- Provan, D.J.; Woods, D.D.; Dekker, S.; Rae, A.J. Safety II professionals: How resilience engineering can transform safety practice. Reliab. Eng. Syst. Saf. 2020, 195, 106740. [Google Scholar] [CrossRef]

- Patriarca, R.; Bergström, J.; Di Gravio, G.; Costantino, F. Resilience engineering: Current status of the research and future challenges. Saf. Sci. 2018, 102, 79–100. [Google Scholar] [CrossRef]

- Righi, A.W.; Saurin, T.A.; Wachs, P. A systematic literature review of resilience engineering: Research areas and a research agenda proposal. Reliab. Eng. Syst. Saf. 2015, 141, 142–152. [Google Scholar] [CrossRef]

- Pei, J.; Liu, W.; Han, L. Research on Evaluation Index System of Chinese City Safety Resilience Based on Delphi Method and Cloud Model. Int. J. Environ. Res. Public Health 2019, 16, 3802. [Google Scholar] [CrossRef] [Green Version]

- Sawacha, E.; Naoum, S.; Fong, D. Factors affecting safety performance on construction sites. Int. J. Proj. Manag. 1999, 17, 309–315. [Google Scholar] [CrossRef]

- Bavafa, A.; Mahdiyar, A.; Marsono, A.K. Identifying and assessing the critical factors for effective implementation of safety programs in construction projects. Saf. Sci. 2018, 106, 47–56. [Google Scholar] [CrossRef]

- Teo, E.A.L.; Ling, F.Y.Y. Developing a model to measure the effectiveness of safety management systems of construction sites. Build. Environ. 2006, 41, 1584–1592. [Google Scholar]

- Shakioye, S.O.; Haight, J.M. Modeling using dynamic variables—An approach for the design of loss prevention programs. Saf. Sci. 2010, 48, 46–53. [Google Scholar] [CrossRef]

- Guo, Q.; Amin, S.R.; Hao, Q.; Haas, O. Resilience assessment of safety system at subway construction sites applying analytic network process and extension cloud models. Reliab. Eng. Syst. Saf. 2020, 201, 106956. [Google Scholar] [CrossRef]

- Aminbakhsh, S.; Gunduz, M.; Sonmez, R. Safety risk assessment using analytic hierarchy process (AHP) during planning and budgeting of construction projects. J. Saf. Res. 2013, 46, 99–105. [Google Scholar] [CrossRef] [PubMed]

- Behm, M. Safe Design Suggestions for Vegetated Roofs. J. Constr. Eng. Manag. 2012, 138, 999–1003. [Google Scholar] [CrossRef] [Green Version]

- Pęciłło, M. The resilience engineering concept in enterprises with and without occupational safety and health management systems. Saf. Sci. 2016, 82, 190–198. [Google Scholar] [CrossRef]

- Demirkesen, S.; Arditi, D. Construction safety personnel’s perceptions of safety training practices. Int. J. Proj. Manag. 2015, 33, 1160–1169. [Google Scholar] [CrossRef]

- Jitwasinkul, B.; Hadikusumo, B.H.; Memon, A.Q. A Bayesian Belief Network model of organizational factors for improving safe work behaviors in Thai construction industry. Saf. Sci. 2016, 82, 264–273. [Google Scholar] [CrossRef]

- Saurin, T.A.; Formoso, C.T.; Cambraia, F.B. An analysis of construction safety best practices from a cognitive systems engineering perspective. Saf. Sci. 2008, 46, 1169–1183. [Google Scholar] [CrossRef]

- Shen, Y.; Tuuli, M.M.; Xia, B.; Koh, T.Y.; Rowlinson, S. Toward a model for forming psychological safety climate in construction project management. Int. J. Proj. Manag. 2015, 33, 223–235. [Google Scholar] [CrossRef] [Green Version]

- Xie, X.; Guo, D. Human factors risk assessment and management: Process safety in engineering. Process. Saf. Environ. Prot. 2018, 113, 467–482. [Google Scholar] [CrossRef]

- Wu, C.; Li, N.; Fang, D. Leadership improvement and its impact on workplace safety in construction projects: A conceptual model and action research. Int. J. Proj. Manag. 2017, 35, 1495–1511. [Google Scholar] [CrossRef]

- Baek, J.; Choi, Y. Smart Glasses-Based Personnel Proximity Warning System for Improving Pedestrian Safety in Construction and Mining Sites. Int. J. Environ. Res. Public Health 2020, 17, 1422. [Google Scholar] [CrossRef] [Green Version]

- Kang, Y.; Siddiqui, S.; Suk, S.J.; Chi, S.; Kim, C. Trends of Fall Accidents in the U.S. Construction Industry. J. Constr. Eng. Manag. 2017, 143, 04017043. [Google Scholar] [CrossRef]

- Choi, S.D.; Carlson, K. Occupational Safety Issues in Residential Construction Surveyed in Wisconsin, United States. Ind. Health 2014, 52, 541–547. [Google Scholar] [CrossRef] [PubMed]

- Norris, M.; Lecavalier, L. Evaluating the Use of Exploratory Factor Analysis in Developmental Disability Psychological Research. J. Autism Dev. Disord. 2009, 40, 8–20. [Google Scholar] [CrossRef]

- Xue, X.; Zhang, R.; Zhang, X.; Yang, R.; Li, H. Environmental and social challenges for urban subway construction: An empirical study in China. Int. J. Proj. Manag. 2015, 33, 576–588. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, T.; Zhou, W.; Tang, J. Safety risk factors of metro tunnel construction in China: An integrated study with EFA and SEM. Saf. Sci. 2018, 105, 98–113. [Google Scholar] [CrossRef]

- Kline, R.B. Principles and Practice of Structural Equation Modeling; Guilford Publications: New York, NY, USA, 2015. [Google Scholar]

- Worthington, R.L.; Whittaker, T.A. Scale Development Research. Couns. Psychol. 2006, 34, 806–838. [Google Scholar] [CrossRef]

- Preedy, V.R.; Watson, R.R. Handbook of Disease Burdens and Quality of Life Measures; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Atanda, O.J. Developing a social sustainability assessment framework. Sustain. Cities Soc. 2019, 44, 237–252. [Google Scholar] [CrossRef]

- Ismail, Z.; Doostdar, S.; Harun, Z. Factors influencing the implementation of a safety management system for construction sites. Saf. Sci. 2012, 50, 418–423. [Google Scholar] [CrossRef]

- Yu, Q.; Ding, L.; Zhou, C.; Luo, H. Analysis of factors influencing safety management for metro construction in China. Accid. Anal. Prev. 2014, 68, 131–138. [Google Scholar] [CrossRef] [PubMed]

- Woods, D.D. Resilience Engineering: Redefining the Culture of Safety and Risk Management. HFES Bulletin 2006, 49, 6. [Google Scholar]

- Sun, Y.; Fang, D.; Wang, S.; Dai, M.; Lv, X. Safety Risk Identification and Assessment for Beijing Olympic Venues Construction. J. Manag. Eng. 2008, 24, 40–47. [Google Scholar] [CrossRef]

- Abudayyeh, O.; Fredericks, T.K.; Butt, S.E.; Shaar, A. An investigation of management’s commitment to construction safety. Int. J. Proj. Manag. 2006, 24, 167–174. [Google Scholar] [CrossRef]

- Nielsen, K. Improving safety culture through the health and safety organization: A case study. J. Saf. Res. 2014, 48, 7–17. [Google Scholar] [CrossRef] [Green Version]

- Perlman, A.; Sacks, R.; Barak, R. Hazard recognition and risk perception in construction. Saf. Sci. 2014, 64, 22–31. [Google Scholar] [CrossRef]

- Sacks, R.; Rozenfeld, O.; Rosenfeld, Y. Spatial and Temporal Exposure to Safety Hazards in Construction. J. Constr. Eng. Manag. 2009, 135, 726–736. [Google Scholar] [CrossRef]

- Guo, B.H.W.; Yiu, T.W.; Guo, B.H.W.; Yiu, T.W. Developing Leading Indicators to Monitor the Safety Conditions of Construction Projects. J. Manag. Eng. 2016, 32, 04015016. [Google Scholar] [CrossRef]

- Hallowell, M.R.; Hinze, J.W.; Baud, K.; Wehle, A. Proactive Construction Safety Control: Measuring, Monitoring, and Responding to Safety Leading Indicators. J. Constr. Eng. Manag. 2013, 139, 04013010. [Google Scholar] [CrossRef]

- Shen, Y.; Ju, C.; Koh, T.Y.; Rowlinson, S.; Bridge, A. The Impact of Transformational Leadership on Safety Climate and Individual Safety Behavior on Construction Sites. Int. J. Environ. Res. Public Health 2017, 14, 45. [Google Scholar] [CrossRef] [Green Version]

- Zohar, D.; Luria, G. The use of supervisory practices as leverage to improve safety behavior: A cross-level intervention model. J. Saf. Res. 2003, 34, 567–577. [Google Scholar] [CrossRef] [PubMed]

- Abdelhamid, T.; Everett, J.G. Identifying Root Causes of Construction Accidents. J. Constr. Eng. Manag. 2000, 126, 52–60. [Google Scholar] [CrossRef]

- Mitropoulos, P.; Abdelhamid, T.S.; Howell, G. Systems Model of Construction Accident Causation. J. Constr. Eng. Manag. 2005, 131, 816–825. [Google Scholar] [CrossRef]

- Menches, C.L.; Chen, J. Using ecological momentary assessment to understand a construction worker’s daily disruptions and decisions. Constr. Manag. Econ. 2013, 31, 180–194. [Google Scholar] [CrossRef]

- Hinze, J.; Gambatese, J. Factors That Influence Safety Performance of Specialty Contractors. J. Constr. Eng. Manag. 2003, 129, 159–164. [Google Scholar] [CrossRef] [Green Version]

- Meng, X.; Zhai, H.; Chan, A.H. Development of Scales to Measure and Analyse the Relationship of Safety Consciousness and Safety Citizenship Behaviour of Construction Workers: An Empirical Study in China. Int. J. Environ. Res. Public Health 2019, 16, 1411. [Google Scholar] [CrossRef] [Green Version]

- Tam, C.M.; Zeng, S.; Deng, Z. Identifying elements of poor construction safety management in China. Saf. Sci. 2004, 42, 569–586. [Google Scholar] [CrossRef]

- Hadjimanolis, A.; Boustras, G. Health and safety policies and work attitudes in Cypriot companies. Saf. Sci. 2013, 52, 50–56. [Google Scholar] [CrossRef]

- Awwad, R.; El Souki, O.; Jabbour, M. Construction safety practices and challenges in a Middle Eastern developing country. Saf. Sci. 2016, 83, 1–11. [Google Scholar] [CrossRef]

- Vinodkumar, M.; Bhasi, M. Safety management practices and safety behaviour: Assessing the mediating role of safety knowledge and motivation. Accid. Anal. Prev. 2010, 42, 2082–2093. [Google Scholar] [CrossRef]

- Zhou, Z.; Irizarry, J.; Li, Q. Applying advanced technology to improve safety management in the construction industry: A literature review. Constr. Manag. Econ. 2013, 31, 606–622. [Google Scholar] [CrossRef]

- Park, C.-S.; Kim, H.-J. A framework for construction safety management and visualization system. Autom. Constr. 2013, 33, 95–103. [Google Scholar] [CrossRef]

- Al Haadir, S.; Panuwatwanich, K. Critical Success Factors for Safety Program Implementation among Construction Companies in Saudi Arabia. Procedia Eng. 2011, 14, 148–155. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; McCabe, B.; Hyatt, D. Impact of individual resilience and safety climate on safety performance and psychological stress of construction workers: A case study of the Ontario construction industry. J. Saf. Res. 2017, 61, 167–176. [Google Scholar] [CrossRef]

| Dimension | Source | Influence Factors | Related Types of Resilience |

|---|---|---|---|

| Organization Management | [12,16,20,25,30,35,37] | Rationality of organizational model | Defense resilience Recovery resilience |

| Completeness of organizational structure | Defense resilience Recovery resilience | ||

| Safety supervision system | Defense resilience | ||

| Risk management system | Defense resilience | ||

| Accident Emergency Response System | Recovery resilience | ||

| Post-disaster recovery system | Recovery resilience | ||

| Personnel Management | [16,20,23,24,30,35,36,40] | Safety accomplishment of managers | Defense resilience |

| Organizational competencies of managers | Defense resilience Recovery resilience | ||

| Emergency response capability of managers | Recovery resilience | ||

| Workers’ safety attitude | Defense resilience | ||

| Workers receive safety training | Defense resilience | ||

| Experience and skills of workers | Defense resilience | ||

| Education level of workers | Defense resilience | ||

| Material and Technology Administration | [24,26,30,31,36,38] | Technical disclosure | Defense resilience |

| Civilized construction | Defense resilience | ||

| Emergency drills | Recovery resilience | ||

| Risk control | Defense resilience | ||

| Handling of safety accidents | Recovery resilience | ||

| Investment in safety production expenses | Defense resilience Recovery resilience | ||

| Workers’ safety protection equipment and living conditions guarantee | Defense resilience | ||

| Safety guarantee materials on construction site | Defense resilience | ||

| Large-scale machinery management | Defense resilience | ||

| Dangerous material management | Defense resilience | ||

| Temporary facilities management | Defense resilience | ||

| Emergency equipment management | Recovery resilience | ||

| Information Management | [12,20,25,30,35,36,37] | Hazard source monitoring | Defense resilience |

| Identification and analysis of risks | Defense resilience | ||

| Sharing and learning of safety knowledge | Defense resilience Recovery resilience | ||

| Efficiency of security information transmission | Defense resilience Recovery resilience | ||

| Accuracy of safety information transmission | Defense resilience Recovery resilience |

| Part | Questionnaire Content |

|---|---|

| 1 | The background information of respondents, including 4 questions of ages, level of education, working years and position. |

| 2 | Evaluating the importance of each factor that may affect the safety and resilience of the construction project. The Likert’s 7-level scale is used to indicate the attendees’ view on the listed question in the part 2, 1 = very unimportant, and 7 = very important. |

| Attribute | n | Percentage | |

|---|---|---|---|

| Age | 20–30 | 71 | 44.1% |

| 31–40 | 66 | 41.0% | |

| 41–50 | 17 | 10.6% | |

| More than 50 | 7 | 4.3% | |

| Level of education | Postgraduate or above | 47 | 29.2% |

| Undergraduate | 49 | 30.4% | |

| Junior college | 18 | 11.2% | |

| High school, technical secondary school or vocational high school | 26 | 16.1% | |

| Other | 21 | 13.0% | |

| Working years | More than 10 years | 42 | 26.1% |

| 6–10 years | 40 | 24.8% | |

| 1–5 years | 44 | 27.3% | |

| Less than 1 year | 35 | 21.7% | |

| Position | Company management personnel | 21 | 13.0% |

| Project management personnel | 38 | 23.6% | |

| Ordinary employees | 63 | 39.1% | |

| Construction personnel | 14 | 8.7% | |

| University researchers | 25 | 15.5% | |

| Inspection Items | Inspection Value | |

|---|---|---|

| KMO | 0.935 | |

| Bartlett spherical test | Approximate chi-square | 4561.016 |

| df | 496 | |

| sig. | 0.000 | |

| Influence Factors | Dimension | Composition | Default Dimension | |||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| Risk control | Material and technical management | 0.985 | Material and technical management | |||

| Education level of workers | 0.965 | Personnel Management | ||||

| Handling of safety accidents | 0.815 | Material and technical management | ||||

| Emergency equipment management | 0.803 | Material and technical management | ||||

| Safety guarantee materials on construction site | 0.659 | Material and technical management | ||||

| Civilized construction | 0.640 | Material and technical management | ||||

| Technical disclosure | 0.636 | Material and technical management | ||||

| Emergency drills | 0.604 | Material and technical management | ||||

| Experience and skills of workers | 0.603 | Personnel Management | ||||

| Workers receive safety training | 0.598 | Personnel Management | ||||

| Dangerous material management | 0.528 | Material and technical management | ||||

| Workers’ safety protection equipment and living conditions guarantee | 0.474 | Material and technical management | ||||

| Efficiency of Security Information Transmission | Information Management | 0.944 | Information Management | |||

| Identification and analysis of risks | 0.927 | Information Management | ||||

| Hazard source monitoring | 0.782 | Information Management | ||||

| Sharing and learning of safety knowledge | 0.748 | Information Management | ||||

| Accuracy of safety information transmission | 0.744 | Information Management | ||||

| Investment in safety production expenses | 0.435 | Material and technical management | ||||

| Emergency response capability of managers | Personnel Management | 0.899 | Personnel Management | |||

| Safety accomplishment of managers | 0.844 | Personnel Management | ||||

| Accident emergency response system | 0.694 | Organization Management | ||||

| Organizational competencies of managers | 0.663 | Personnel Management | ||||

| Post-disaster recovery system | 0.635 | Organization Management | ||||

| Workers’ safety attitude | 0.517 | Personnel Management | ||||

| Rationality of organizational model | Organization Management | 0.764 | Organization Management | |||

| Completeness of organizational structure | 0.742 | Organization Management | ||||

| Safety supervision system | 0.505 | Organization Management | ||||

| Risk management system | 0.367 | Organization Management | ||||

| Dimension | EFA Factor | Related Types of Resilience | ||

|---|---|---|---|---|

| T1 | Organization Administration | T11 | Rationality of Organizational Model | Defense resilience, recovery resilience |

| T12 | Completeness of organizational structure | Defense resilience, recovery resilience | ||

| T13 | Safety supervision system | Defense resilience | ||

| T14 | Risk management system | Defense resilience | ||

| T2 | Personnel Administration | T21 | Safety Accomplishment of Managers | Defense resilience, recovery resilience |

| T22 | Organizational competencies of managers | Defense resilience, recovery resilience | ||

| T23 | Emergency response capability of managers | Recovery resilience | ||

| T24 | Workers’ Safety Attitude | Defense resilience | ||

| T3 | Material Technology Management | T31 | Risk Control | Defense resilience |

| T32 | Handling of security incidents | Recovery resilience | ||

| T33 | Emergency equipment management | Recovery resilience | ||

| T34 | Construction site safety guarantee substance | Defense resilience | ||

| T35 | Safe and civilized construction | Defense resilience | ||

| T36 | Technical know-how | Defense resilience | ||

| T37 | Emergency drills | Recovery resilience | ||

| T4 | Information Management | T41 | Hazard Source Monitoring | Defense resilience |

| T42 | Identification and analysis of risks | Defense resilience | ||

| T43 | Sharing and learning of safety knowledge | Defense resilience, recovery resilience | ||

| T44 | Efficiency of safety information transmission | Defense resilience, recovery resilience | ||

| T45 | Accuracy of safety information transfer | Defense resilience, recovery resilience | ||

| Index Name | Results | Evaluation |

|---|---|---|

| CMIN/df | 1.732 | Well |

| RMSEA | 0.073 | Well |

| CFI | 0.929 | Well |

| TLI | 0.920 | Well |

| Path | Estimate | S.E. (Standard Error) | C.R. (Critical Ratio) | p |

|---|---|---|---|---|

| Organization Management<—The resilience of construction project safety management | 0.76 | 0.620 | 2.340 | 0.019 |

| Personnel Management<—The resilience of construction project safety management | 0.74 | 0.558 | 2.197 | 0.028 |

| Material Technology Administration<—The resilience of construction project safety management | 0.83 | 0.913 | 2.563 | 0.010 |

| Information Management<---The resilience of construction project safety management | 0.91 | |||

| T14<—Organization Management | 0.87 | |||

| T13<—Organization Management | 0.85 | 0.068 | 13.722 | *** |

| T12<—Organization Management | 0.86 | 0.064 | 13.747 | *** |

| T11<—Organization Management | 0.71 | 0.077 | 10.060 | *** |

| T24<—Personnel Management | 0.82 | |||

| T23<—Personnel Management | 0.82 | 0.066 | 12.396 | *** |

| T22<—Personnel Management | 0.88 | 0.078 | 14.036 | *** |

| T21<—Personnel Management | 0.84 | 0.075 | 13.039 | *** |

| T37<—Material Technology Administration | 0.87 | |||

| T36<—Material Technology Administration | 0.83 | 0.060 | 12.972 | *** |

| T35<—Material Technology Administration | 0.86 | 0.070 | 14.018 | *** |

| T34<—Material Technology Administration | 0.79 | 0.052 | 12.049 | *** |

| T33<—Material Technology Administration | 0.77 | 0.056 | 11.534 | *** |

| T32<—Material Technology Administration | 0.89 | 0.061 | 15.151 | *** |

| T31<—Material Technology Administration | 0.83 | 0.066 | 13.184 | *** |

| T45<—Information Management | 0.86 | |||

| T44<—Information Management | 0.90 | 0.055 | 16.278 | *** |

| T43<—Information Management | 0.81 | 0.063 | 12.986 | *** |

| T42<—Information Management | 0.87 | 0.053 | 15.226 | *** |

| T41<—Information Management | 0.81 | 0.056 | 12.977 | *** |

| Dimension | Affecting Defense Resilience (before Event) | Affecting Recovery Resilience (When/after Event) |

|---|---|---|

| Information Administration | Improve the Effectiveness and Efficiency of Risk Identification and Analysis | Improve the Effectiveness and Efficiency of Safety Information Transmission |

| Improving the Effectiveness and Efficiency of Safety Information Transmission | Strengthen the Accuracy of Safety Information Transmission | |

| Strengthen the Accuracy of Safety Information Transmission | / | |

| Material and Technical Management | Improve the Efficiency of Risk Control | Improve the Efficiency of Handling Safety Accidents |

| Promoting Safe and Civilized Construction | Strengthen emergency drills | |

| Organization Administration | Formulate a sound risk management system | Establish a complete organizational structure |

| Formulate safety supervision system | / | |

| Establish a complete organizational structure | / | |

| Personnel Administration | Improve the organizational ability of managers | Improve the organizational ability of managers |

| Raise workers’ safety attitude | Improve the emergency response capability of managers |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Yuan, J.; Shao, Q.; Zhang, L.; Wang, G.; Li, X. Developing Key Safety Management Factors for Construction Projects in China: A Resilience Perspective. Int. J. Environ. Res. Public Health 2020, 17, 6167. https://doi.org/10.3390/ijerph17176167

Zhu Z, Yuan J, Shao Q, Zhang L, Wang G, Li X. Developing Key Safety Management Factors for Construction Projects in China: A Resilience Perspective. International Journal of Environmental Research and Public Health. 2020; 17(17):6167. https://doi.org/10.3390/ijerph17176167

Chicago/Turabian StyleZhu, Zheng, Jingfeng Yuan, Qiuhu Shao, Lei Zhang, Guangqi Wang, and Xuewei Li. 2020. "Developing Key Safety Management Factors for Construction Projects in China: A Resilience Perspective" International Journal of Environmental Research and Public Health 17, no. 17: 6167. https://doi.org/10.3390/ijerph17176167

APA StyleZhu, Z., Yuan, J., Shao, Q., Zhang, L., Wang, G., & Li, X. (2020). Developing Key Safety Management Factors for Construction Projects in China: A Resilience Perspective. International Journal of Environmental Research and Public Health, 17(17), 6167. https://doi.org/10.3390/ijerph17176167